Building combined template

A technology of combining formwork and construction, applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of insufficient size stability, insufficient strength, easy deformation, etc., to achieve convenient organization and construction, smooth and smooth appearance. , Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

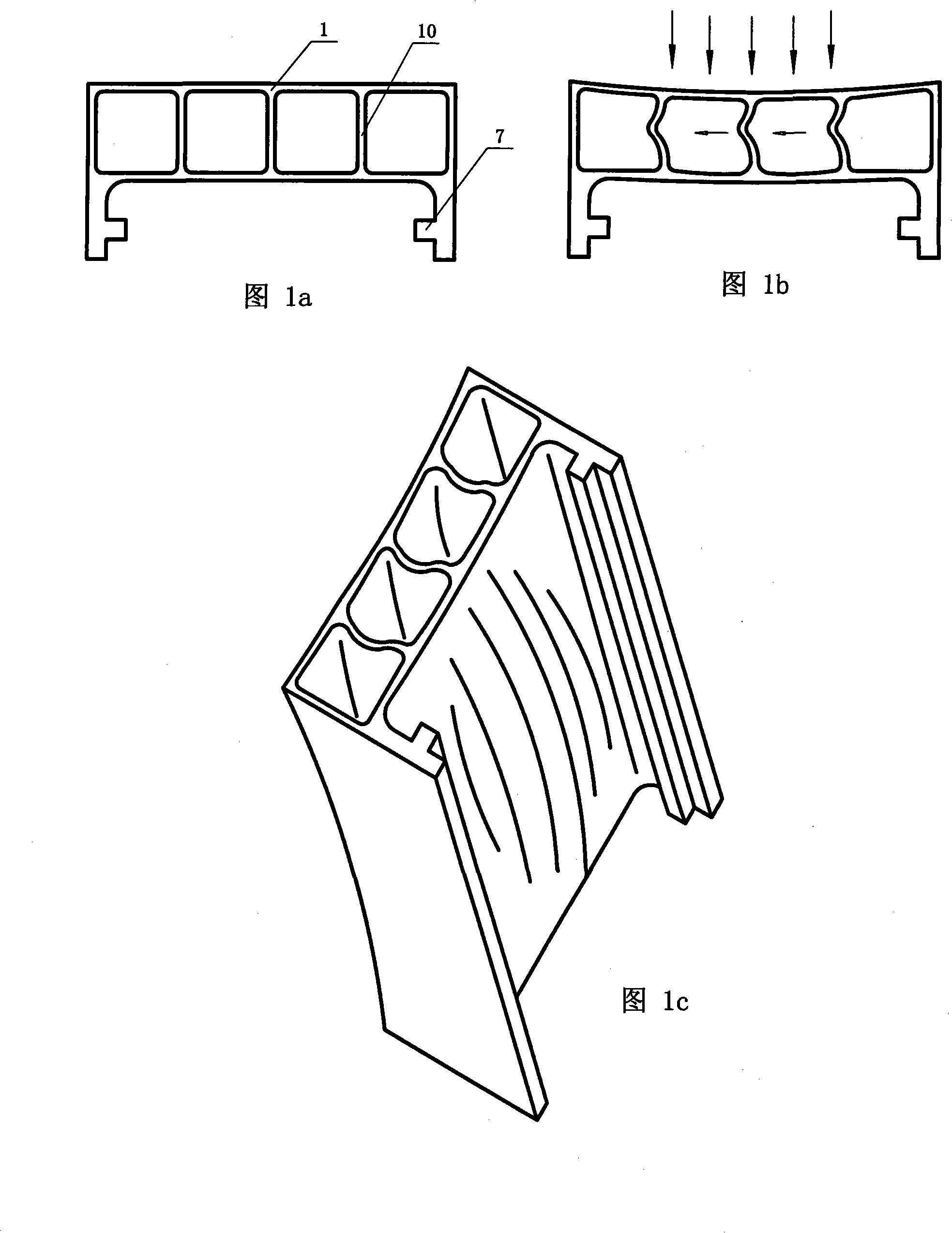

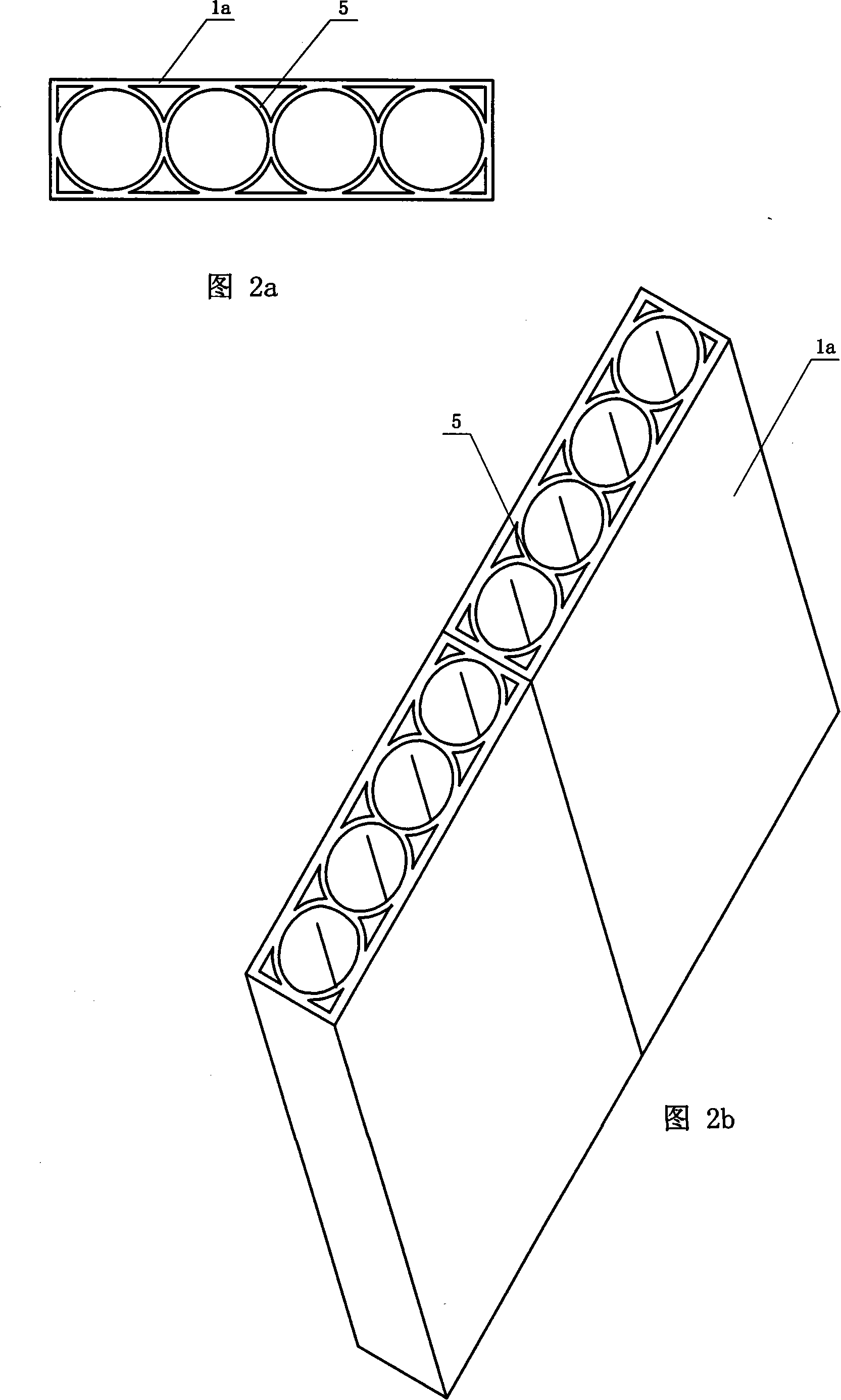

[0071] Embodiment 1: Refer to Fig. 2a, Fig. 2b, Fig. 6a, Fig. 6b, Fig. 6c, Fig. 7a, Fig. 7b, Fig. 7c, Fig. 14, Fig. 15, Fig. 18, a kind of building composite template, which contains a hollow surrounded by four sides The box-type end plate, in the hollow box-type end plate, is fixed with a ring connected support structure 5, and the cross section of the hollow box-type end plate is a rectangular structure 1a (as shown in Figure 2a, Figure 2b), or two The rectangular structure is perpendicular to the L-shaped structure 1e (as shown in FIG. 14 ). The above two structures (1a, 1e) are assembled into a beam-and-mold combined structure, a column-and-moulded combined structure, a cast-in-place roof combined structure, and a corner beam or column combined structure required by the building. At the same time, the two ends of the hollow box-type end plates 1a, 1e without end faces can be matched and installed with a head 12, on one face of the head 12 (as shown in Figure 6a or Figure 7...

Embodiment 2

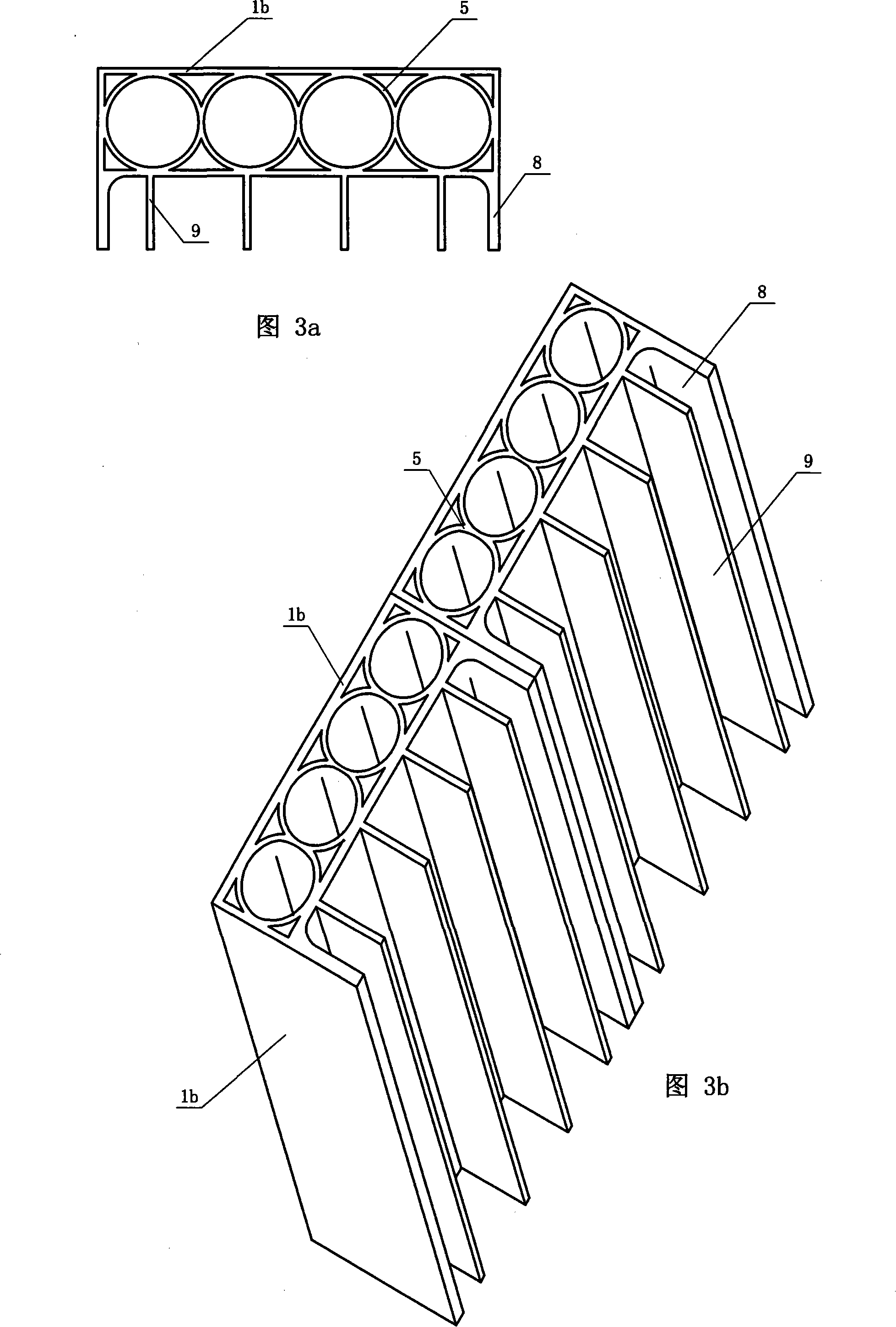

[0072] Embodiment 2: Refer to Figure 3a, Figure 3b, Figure 6a, Figure 6b, Figure 6c, Figure 7a, Figure 7b, Figure 7c, Figure 10, Figure 11, Figure 15, Figure 19, Figure 20, a building combination formwork, It contains a hollow box-type end plate surrounded by four sides. In the hollow box-type end plate, a ring-connected support structure 5 is fixed, and a longitudinal reinforcement plate or longitudinal rib is fixed on one side of the hollow box-type end plate. The reinforcing plate is approximately vertically fixed to the end face of the hollow box-type end plate. The cross-section of the hollow box-type end plate is a rectangular structure 1b (as shown in Figure 3a, Figure 3b), or an L-shaped structure 1f (as shown in Figure 10) and 1g (as shown in Figure 11) where two rectangular structures are perpendicular to each other. . The above-mentioned various structures (1b, 1f, 1g) are assembled into a beam-and-mold combined structure, a column-and-moulded combined structure, a...

Embodiment 5

[0078] Embodiment five, embodiment six, embodiment seven, embodiment eight: refer to Fig. 23a, Fig. 23b, Fig. 23c, Fig. 23d respectively, the numbering is the same or consistent with Embodiment 1, 2, 3, 4, the content is the same, the same It will not be repeated here, the difference is that at least one transverse reinforcing plate or transverse reinforcing rib is added to the ring-connected supporting structure 5 fixed in the hollow box-type end plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com