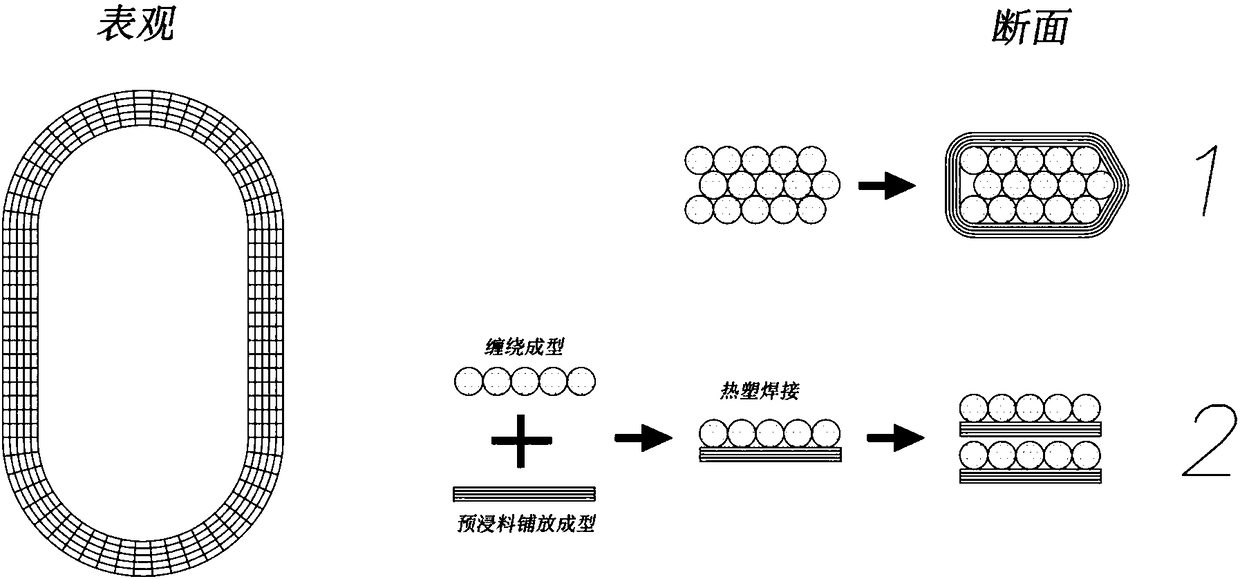

Winding-pressing forming process and device of fiber-reinforced composite material

A composite material and fiber reinforced technology, applied in the field of fiber reinforced composite material wrapping molding process and device, can solve the problems of weak interlayer connection performance, poor mechanical performance, long manufacturing cycle, etc., and achieve good mechanical performance and short manufacturing cycle. , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A thermosetting fiber-reinforced composite material winding and pressing molding process includes the following steps:

[0050] 1. Feeding and spreading yarn: the fiber yarn shaft is fixedly placed on the creel, and the yarn is spread through the creel;

[0051] 2. Preheating, dipping, and spreading: preheat the fiber spreading yarn and enter the dipping device to fully dipping, put the thermoplastic resin pellets into the feed port of the extruder, and melt in the extruder before entering the dipping The device impregnates the die head and impregnates the fibers in the die head. The prepreg wire is formed through the outlet of the die head of the dipping device, and then the prepreg wire with smooth surface is formed by the setting device; the prepreg after setting is passed through the spreading roller Spread the yarn.

[0052] 3. Traction and winding: The prepreg wire or prepreg tape is drawn through the traction winding device, and the molten prepreg wire or prepreg tape ...

Embodiment 2

[0057] A thermoplastic fiber-reinforced composite material wrapping and molding process includes the following steps:

[0058] 1. Feeding and spreading yarn: the fiber yarn shaft is fixedly placed on the creel, and the yarn is spread through the creel;

[0059] 2. Preheating, dipping, and spreading: preheat the fiber spreading yarn and enter the dipping device to fully dipping, put the thermoplastic resin pellets into the feed port of the extruder, and melt in the extruder before entering the dipping The device impregnates the die head and impregnates the fibers in the die head. The prepreg wire is formed through the outlet of the die head of the dipping device, and then the prepreg wire with smooth surface is formed by the setting device; the prepreg after setting is passed through the spreading roller Spread the yarn.

[0060] 3. Traction and winding: The prepreg wire or prepreg tape is drawn through the traction winding device, and the molten prepreg wire or prepreg tape is passe...

Embodiment 3

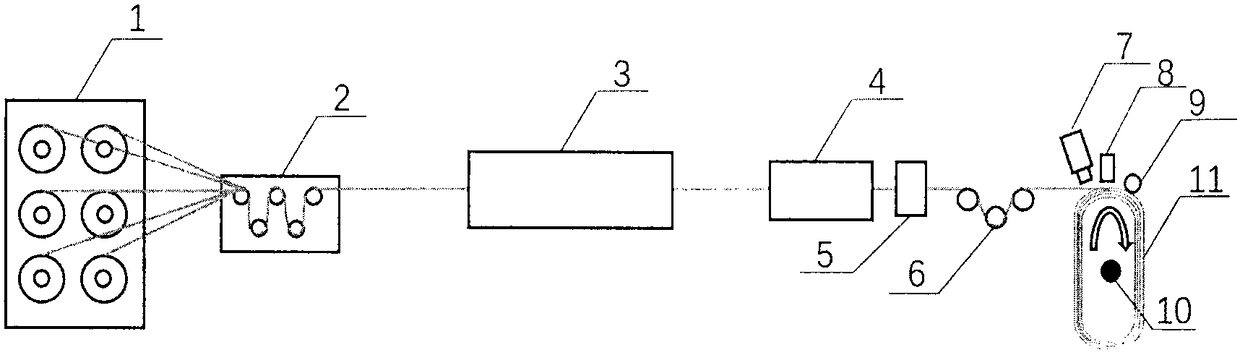

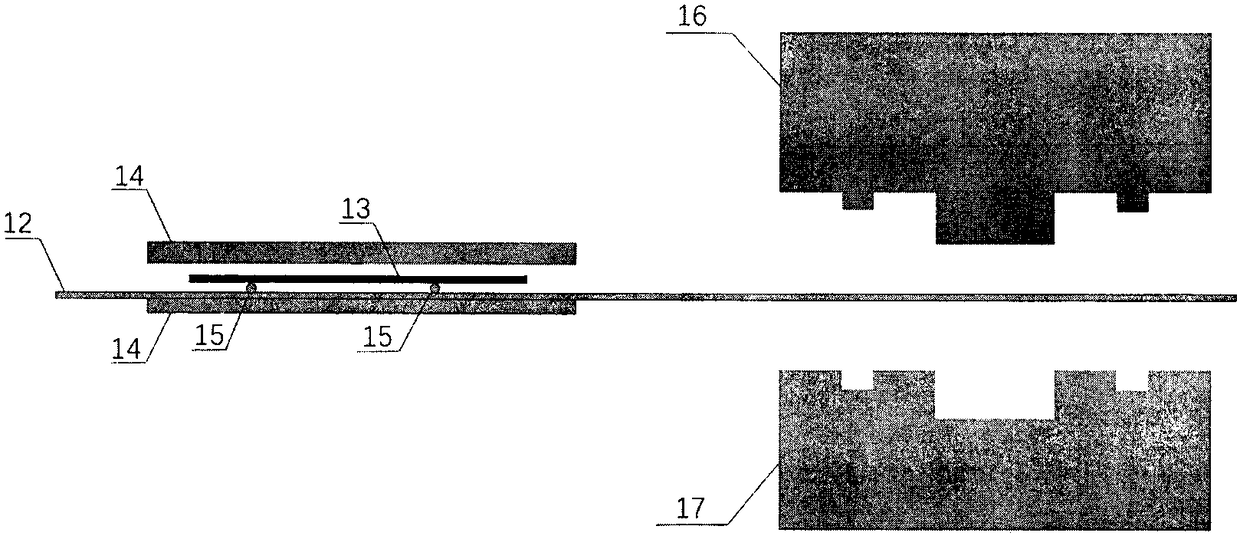

[0067] A one-step fiber-reinforced thermoplastic composite material wrapping and forming device, such as figure 1 with figure 2 As shown, it includes: wire feeding machine 1, yarn spreading frame 2, preheating device 3, impregnating device 4, setting device 5, yarn spreading roller 6, winding traction device and molding device; the wire feeding machine 1 is placed at the forefront, and After that, the yarn spreading rack 2, the preheating device 3, the dipping device 4, the setting device 5, the yarn spreading roller 6, the winding traction device and the molding device are arranged in sequence. The dipping device 4 is composed of a single screw extruder and a die dipping die The dipping tank and dipping roller are arranged in the dipping die of the machine head, and the dipping roller is installed in the dipping tank. The winding traction device is composed of a hot air gun 7, an infrared thermometer 8, a pressure roller 9, a transmission shaft 10, a servo motor (not shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com