Nickel-zinc soft ferrite for wireless charging and preparation method and application thereof

A soft ferrite, wireless charging technology, applied in the direction of magnetic objects, inorganic material magnetism, circuits, etc., can solve the problems of no further elaboration of magnetic properties, low loss, low material properties, etc., to eliminate abnormally fast response, excellent Comprehensive magnetic properties, smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

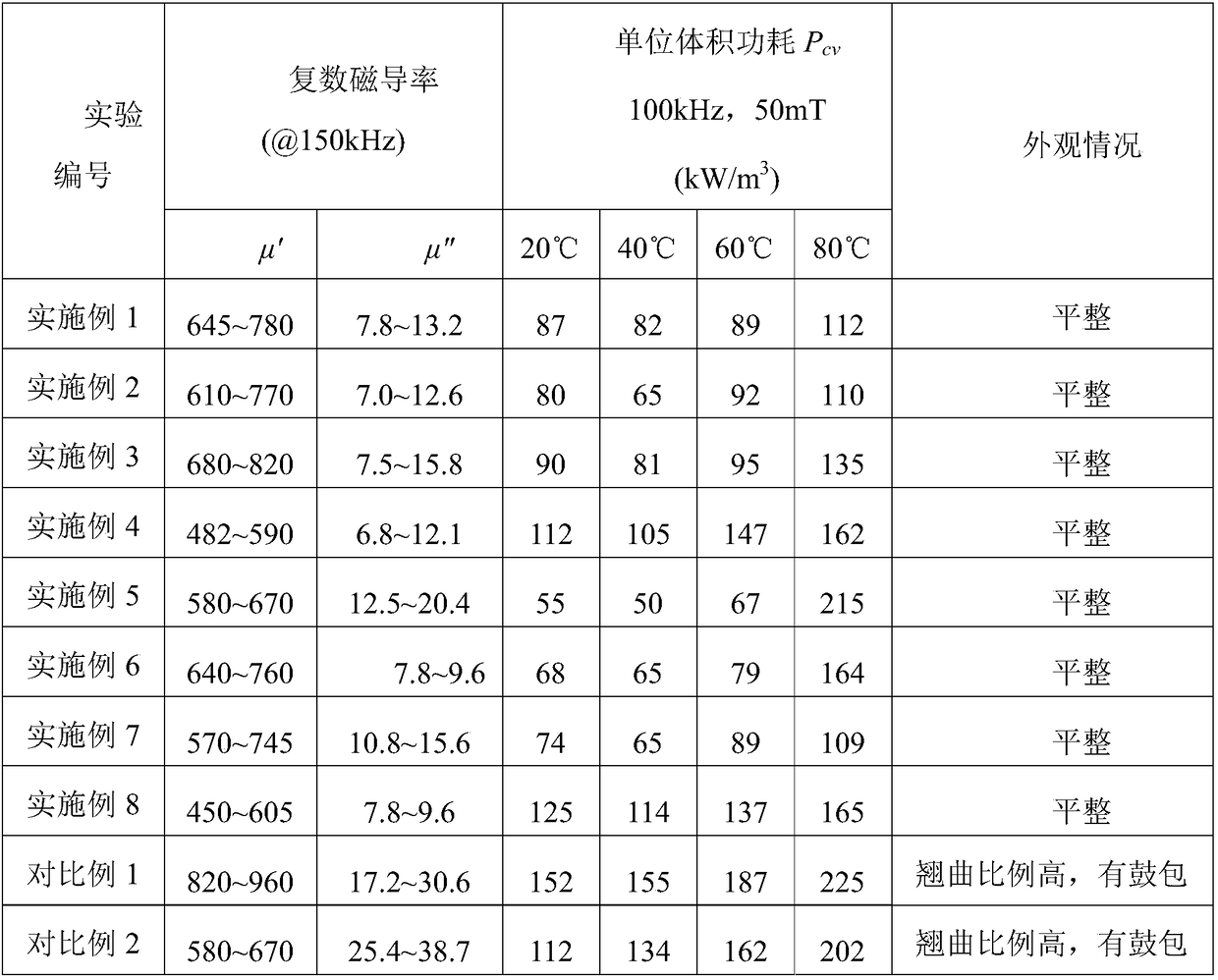

Examples

preparation example Construction

[0039] The method for preparing a nickel-zinc soft ferrite for wireless charging of the present invention specifically includes the following steps:

[0040] (1) Weigh the raw materials in the above-mentioned main components and doped components, and mix them evenly by ball milling / sanding. The grinding medium used is iron balls or zirconia balls. After ball milling, the raw materials are mixed. Laser particle size D50≤1μm, after ball milling The powder is dried, sieved, and calcined. The calcining temperature is 850~900℃, the calcining time is 2~5h, and the air atmosphere is calcined; after calcining, the powder is subjected to secondary ball milling / sand milling, and the grinding medium used is also iron Ball or zirconia ball, the mixed raw material after the second ball milling, the laser particle size D50≤2μm, the powder after the second ball milling / sanding is dried and sieved to obtain the required ferrite powder;

[0041] (2) Based on the weight of ferrite powder, add 30-60w...

Embodiment 1

[0045] In the ferrite thin magnetic sheet for wireless charging of electronic products of the first embodiment, the nickel-zinc soft ferrite used in it is made of the following raw materials: main component: Fe 2 O 3 65.3kg, NiO is 5.6kg, ZnO is 22.5kg and CuO is 6.6kg, doped composition: Dy 2 O 3 It is 0.1kg; its preparation method includes the following steps:

[0046] (1) Weigh the above-mentioned metal oxide raw materials according to the above-mentioned ratio, mix and wet ball mill at a speed of 400r / min for 4 hours at a time, dry, and then pre-fire in an air atmosphere at a pre-fire temperature of 910℃ / 4h; The powder is once again subjected to wet ball milling, ball milled at a speed of 600r / min for 6 hours, and dried to obtain ferrite powder;

[0047] (3) To prepare the casting slurry, the solvent used is a mixture of methyl ethyl ketone and toluene system with a mass ratio of 1:1, and the added amount is 44wt% based on the weight of the ferrite powder; the binder is polyviny...

Embodiment 2

[0051] In the second embodiment of the ferrite thin magnetic sheet for wireless charging of electronic products, the nickel-zinc soft ferrite used in it is made of the following raw materials: main component: Fe 2 O 3 65.3kg, NiO is 5.6kg, ZnO is 22.5kg and CuO is 6.6kg, doped composition: Dy 2 O 3 0.05kg, Y 2 O 3 0.05kg and Tb 2 O 3 Is 0.05kg;

[0052] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com