Wood-plastic formwork for construction engineering

A wood-plastic formwork and construction engineering technology, applied in the field of building materials, can solve the problems of low bending strength, impact strength, toughness, mechanical properties, ineffective stress transmission, and unsuitable building formwork, and achieve dimensional stability and compressive strength. Improve hardness, eliminate glass fiber exposure, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

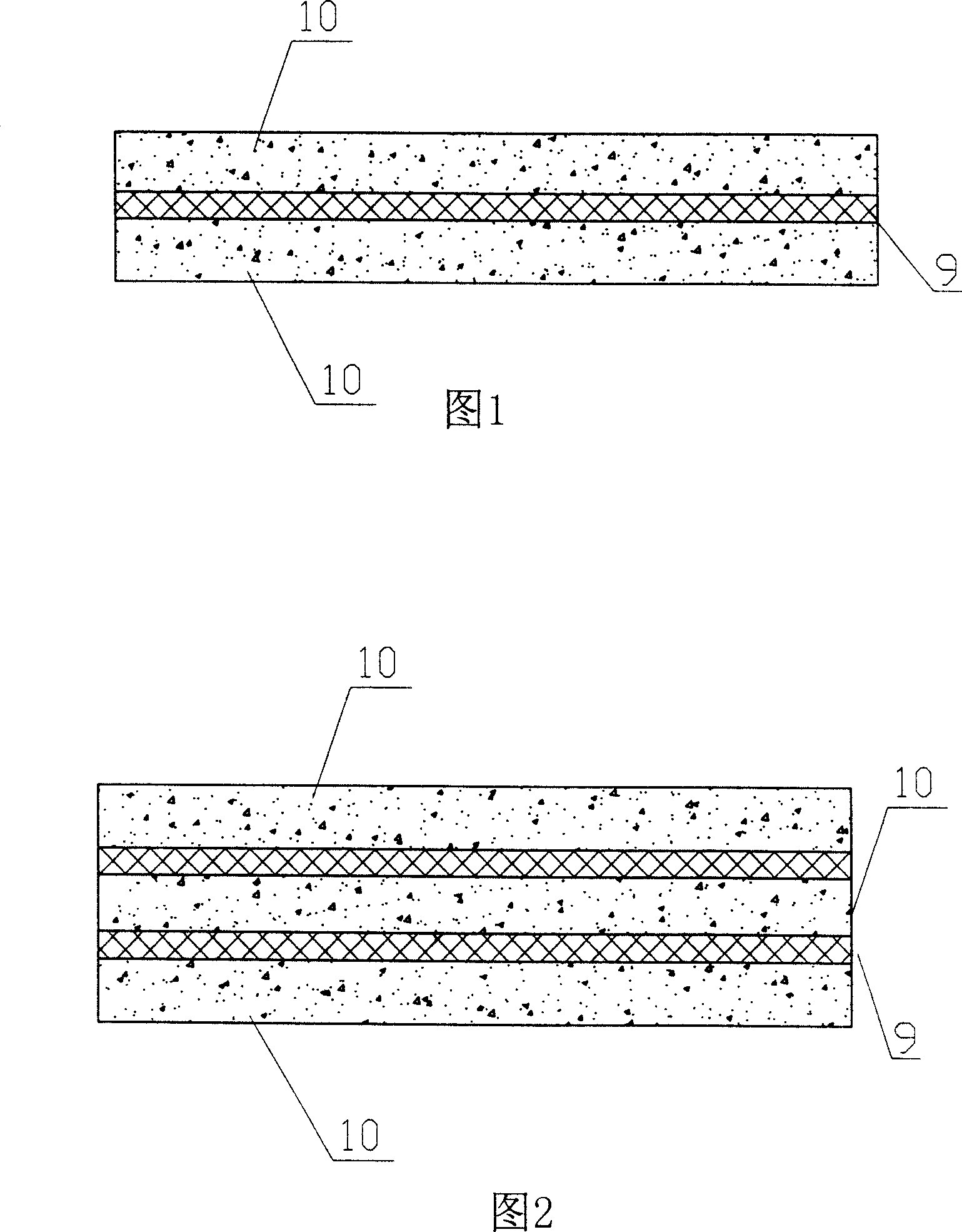

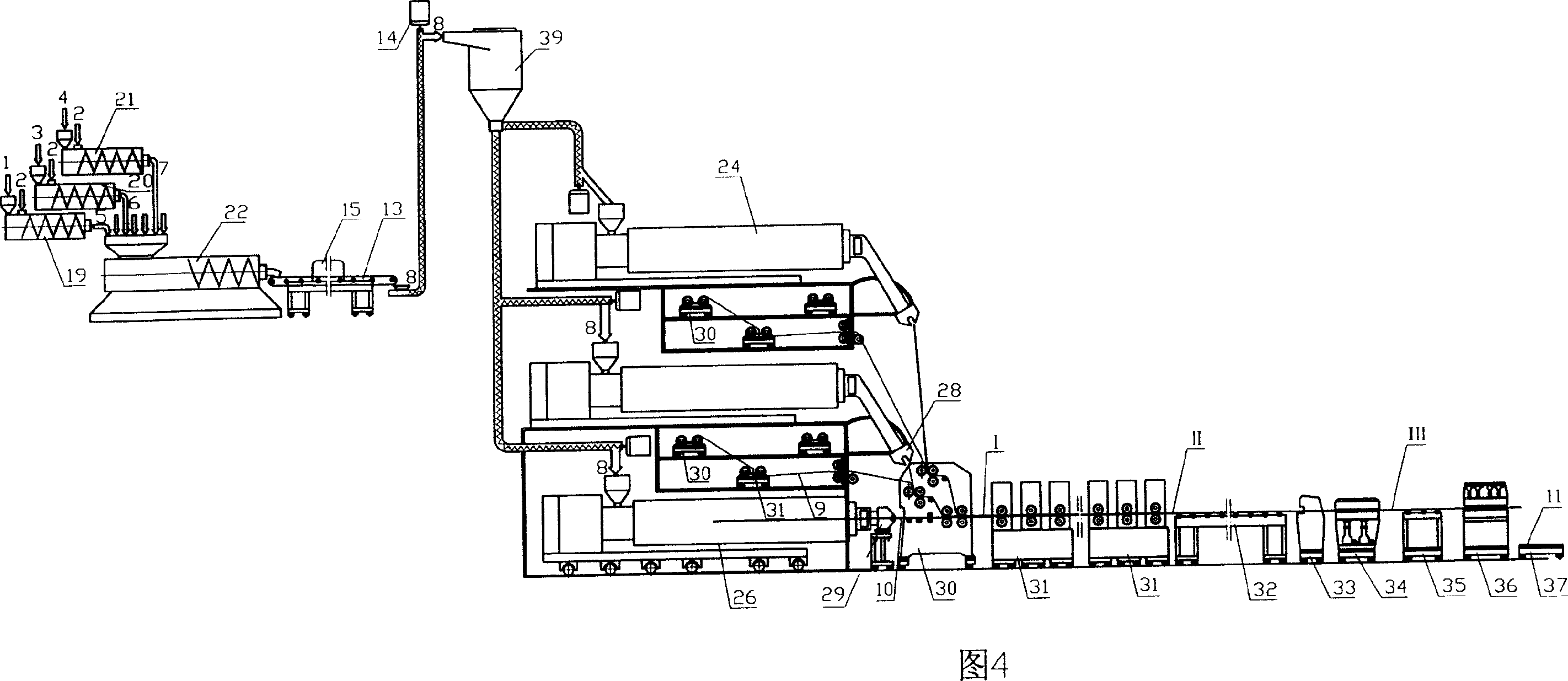

[0049] In this embodiment, the construction engineering wood-plastic formwork 11 shown in FIG. 1 is taken as an example to illustrate its components and manufacturing process steps. Please refer to FIG. 3 .

[0050] Firstly, the ceramic hollow microspheres and the maleic anhydride grafting agent are weighed in a ratio of 3:1, and the two are fully mixed to obtain a mechanical performance modifier.

[0051] Then press the following weight percentages:

[0053] Glass fiber 25%;

[0054] Polyvinyl chloride (PVC) recycled pellets 20%;

[0056] Mechanical performance modifier 7%;

[0057] Silane coupling agent 3.5%;

[0058] PE wax 2.5%.

[0059] To weigh the above raw materials. Then weigh three parts of mechanical property modifiers respectively according to 2% of bagasse fiber weight, 5% of glass fiber weight, and 4% of polyvinyl chloride (PVC) regenerated pellet weight.

Embodiment 2

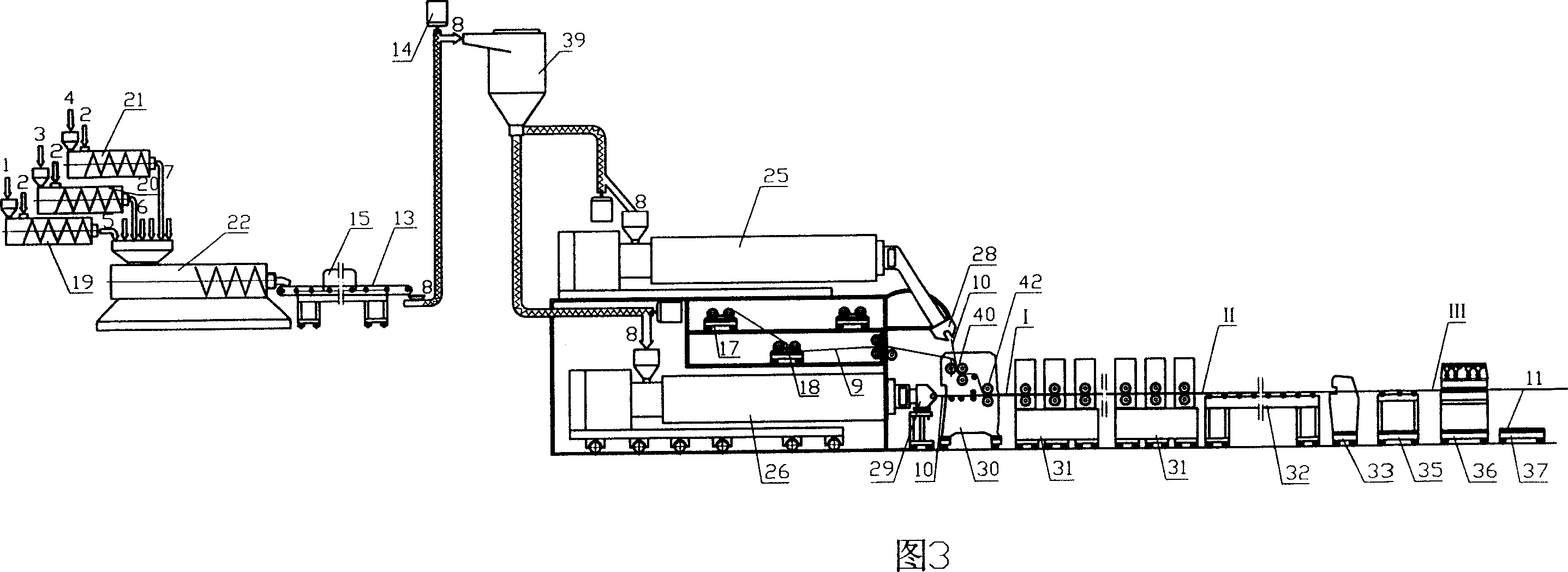

[0068] This embodiment takes the production of the wood-plastic construction template 11 shown in FIG. 2 as an example to illustrate its components and manufacturing process steps, please refer to FIG. 4 .

[0069] Firstly, the ceramic hollow microspheres and the maleic anhydride grafting agent are weighed in a ratio of 4:1, and the two are fully mixed to obtain a mechanical performance modifier.

[0070] Then press the following weight percentages:

[0071] Wood flour fiber 60%;

[0072] Glass fiber 10%;

[0073] Polyethylene (PE) new pellets 20%;

[0075] Mechanical performance modifier 4%;

[0076] Titanate coupling agent 1%;

[0077] Silicone masterbatch 4%.

[0078] To weigh the above-mentioned raw materials. Then weigh three parts of mechanical performance modifiers respectively by 3% of wood flour fiber weight, 4% of glass fiber weight, and 5% of polyethylene (PE) new pellet weight.

Embodiment 3

[0082] This embodiment takes the production of the wood-plastic building engineering formwork 11 shown in FIG. 1 as an example to illustrate its components and manufacturing process steps, please refer to FIG. 3 .

[0083] Firstly, the ceramic hollow microspheres and the maleic anhydride grafting agent are weighed according to the ratio of 5:1, and the two are fully mixed to prepare the mechanical performance modifier.

[0084] Then press the following weight percentages:

[0085] Sorghum straw fiber 48%;

[0086] Glass fiber 10%;

[0087] Polypropylene (PP) recycled pellets 32%;

[0089] Mechanical performance modifier 2%;

[0090] Silane coupling agent 3.5%;

[0091] Silicone oil 0.5%.

[0092] To weigh the above raw materials. Three parts of mechanical property modifier 4 were weighed according to 4.5% by weight of sorghum straw fiber, 3.5% by weight of glass fiber, and 3% by weight of plastic 3 .

[0093] Send the weighed plant fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com