Water-based baking coating for anti-theft door as well as preparation method and application thereof

A anti-theft door and coating technology, which is applied in the coating field in the chemical industry, can solve the problems of long drying time, unrealistic effect, poor adhesion, etc., and achieve the effect of smooth appearance and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

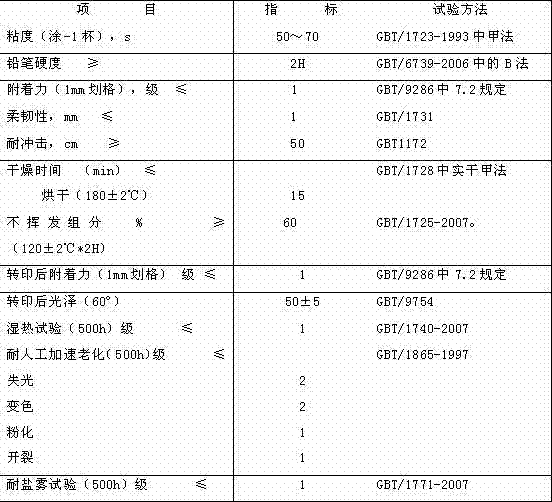

Examples

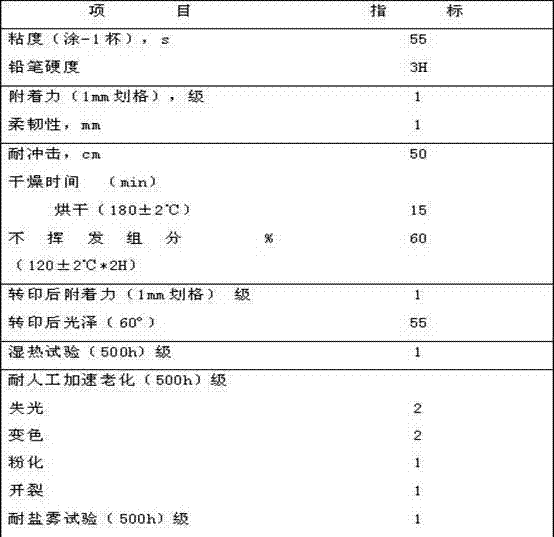

Embodiment 1

[0036] Add 124 grams of modified water-soluble polyester resin and 60 grams of special water-soluble acrylic resin into the paint mixing tank, and stir evenly; Polymerized at low temperature, molecular weight 5000-5500; the special water-soluble acrylic resin is polymerized by heating acrylic acid, methyl acrylate and hydroxypropyl acrylate at 140°C, molecular weight is 8000-8500, and 5wt% of resin solids Modified bisphenol A epoxy resin; add 2 grams of dimethylethanolamine, 4 grams of ammonia to adjust the pH value to 8.2, add 3 grams of isopropanol, 40 grams of ethylene glycol butyl ether, 6 grams of ethylene glycol butyl Ether acetate and 2 grams of KC additive solution, 4 grams of BYK-345, 5 grams of BYK-333, after stirring evenly, add 50 grams of 072 amino resin to obtain a baking coating solution, and sample it on the surface of the metal sample for 180 Bake at ℃ for 10 minutes and quickly dry to form a film. After passing the performance test (parameters see Table 2), f...

Embodiment 2

[0040] 159 grams of modified water-soluble polyester resin and 40 grams of special water-soluble acrylic resin are added to the paint mixing tank and stirred evenly; the modified water-soluble polyester resin is composed of pentaerythritol, neopentyl glycol and isophthalic acid. It is polymerized at 160-240°C, with a molecular weight of 5300-5700; the special water-soluble acrylic resin is polymerized by heating acrylic acid, ethyl acrylate, and hydroxypropyl acrylate at 140°C, with a molecular weight of 8500-9000, and the resin The bisphenol A epoxy resin of 8wt% of solid amount is modified; Add 4 gram dimethylethanolamine agents and pH value is adjusted to 8, add 3 gram isopropanols, 20 gram ethylene glycol butyl ethers, 6 gram ethylene glycol Alcohol butyl ether acetate, 2 grams of ethylene glycol phenyl ether, 2 grams of BYK-345, 2 grams of BYK-333, 2 grams of 8991 matting powder, stir well, add 30 grams of 072 amino resin, 30 grams of CYMEL 303LF amino resin, and get Bake...

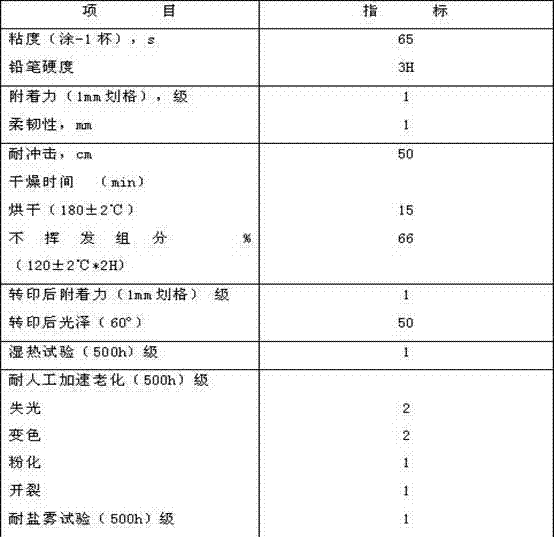

Embodiment 3

[0043] Example 3 90 grams of modified modified water-soluble polyester resin and 70 grams of special water-soluble acrylic resin are added to the paint mixing tank and stirred evenly; the modified water-soluble polyester resin is composed of pentaerythritol, neopentyl glycol and oxalic acid, Equimolar isophthalic acid is polymerized at 160-240°C, with a molecular weight of 5500-6000; the special water-soluble acrylic resin is made of acrylic acid, methyl acrylate, ethyl acrylate, and hydroxypropyl acrylate heated at 140°C Polymerization, the molecular weight is 8500-9000, and the bisphenol A epoxy resin of 10wt% of resin solids is used for improvement; add 5 grams of dimethylethanolamine, 3 grams of ammonia water to adjust the pH value to 8.5, and add 4 grams of isopropanol , 25 grams of ethylene glycol butyl ether, 3 grams of ethylene glycol butyl ether acetate, 5 grams of ethylene glycol phenyl ether and 3 grams of KC additive solution, 4 grams of BYK-345, 4 grams of BY...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com