Method for manufacturing iron core and iron core product

A manufacturing method and iron core technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of poor powder fluidity, low compaction density, complex manufacturing process, etc., and achieve high precision in size flexible design, Comprehensive performance improvement, smooth appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

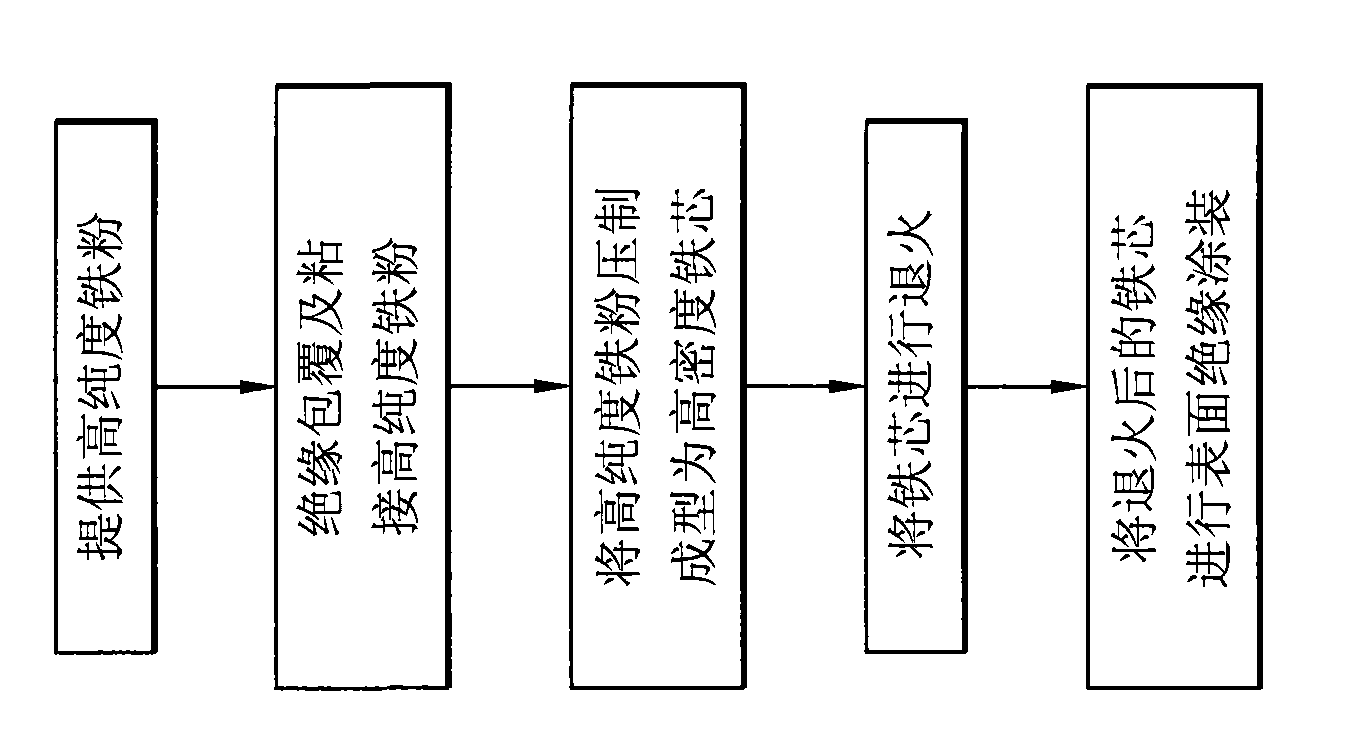

[0027] see figure 1 and Figure 2A to Figure 2F , the present invention provides a method for manufacturing an iron core, especially a method for manufacturing a motor stator (or rotor) iron core, comprising the following steps:

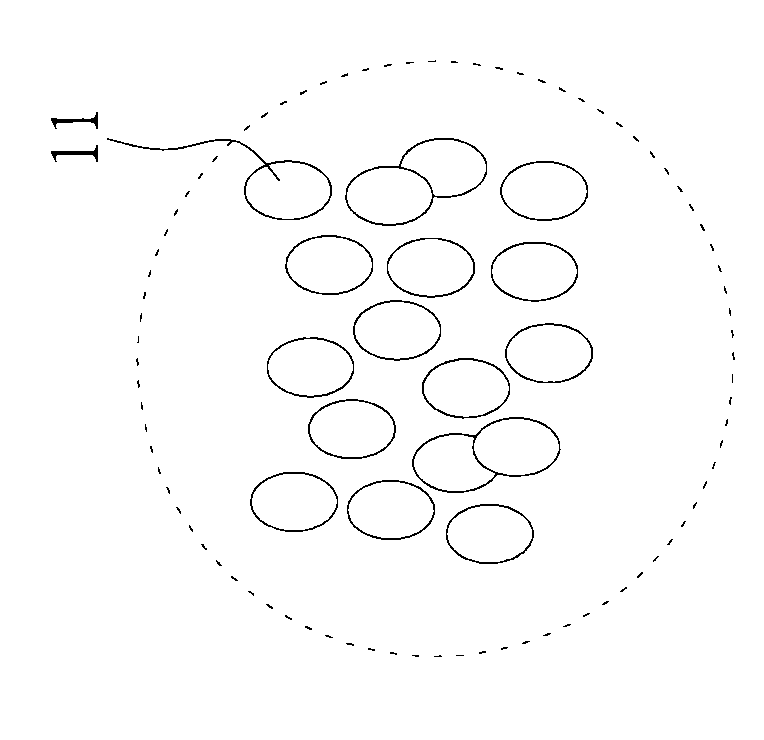

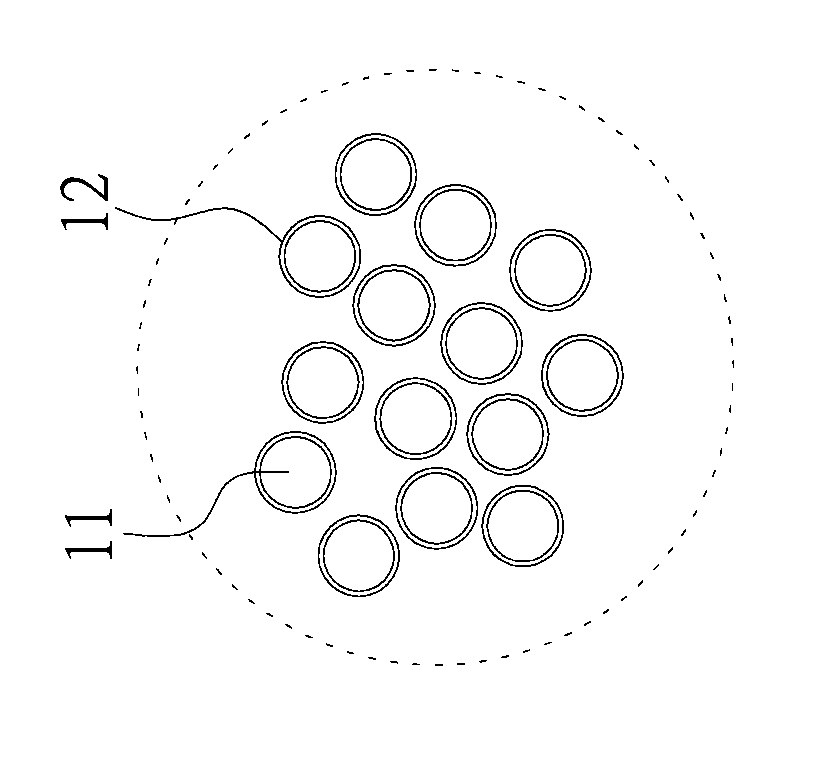

[0028] (1) First, provide an appropriate amount of high-purity iron powder 11 (such as Figure 2A shown); in the present embodiment, the high-purity iron powder 11 is iron powder with high magnetic properties, and the granular shape of the iron powder is irregular, and the hammer-type disintegration method is used to ensure that the granular shape is not destroyed and prevent the surface from being damaged. Oxidation, the required particle size is controlled by multi-stage sieving, the average particle size is 1-150 μm, and the average particle size is 100 μm is the best.

[0029] The high-purity iron powder produced by the above process has excellent properties of high bulk density, good fluidity and high compressibility:

[0030] projec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com