Pipeline hot melting wire arrangement method

A wiring method and hot-melt technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of difficult recycling and separation of metal wires, few engineering applications, troublesome production of joints, etc., and achieve simple operation , low cost and short welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

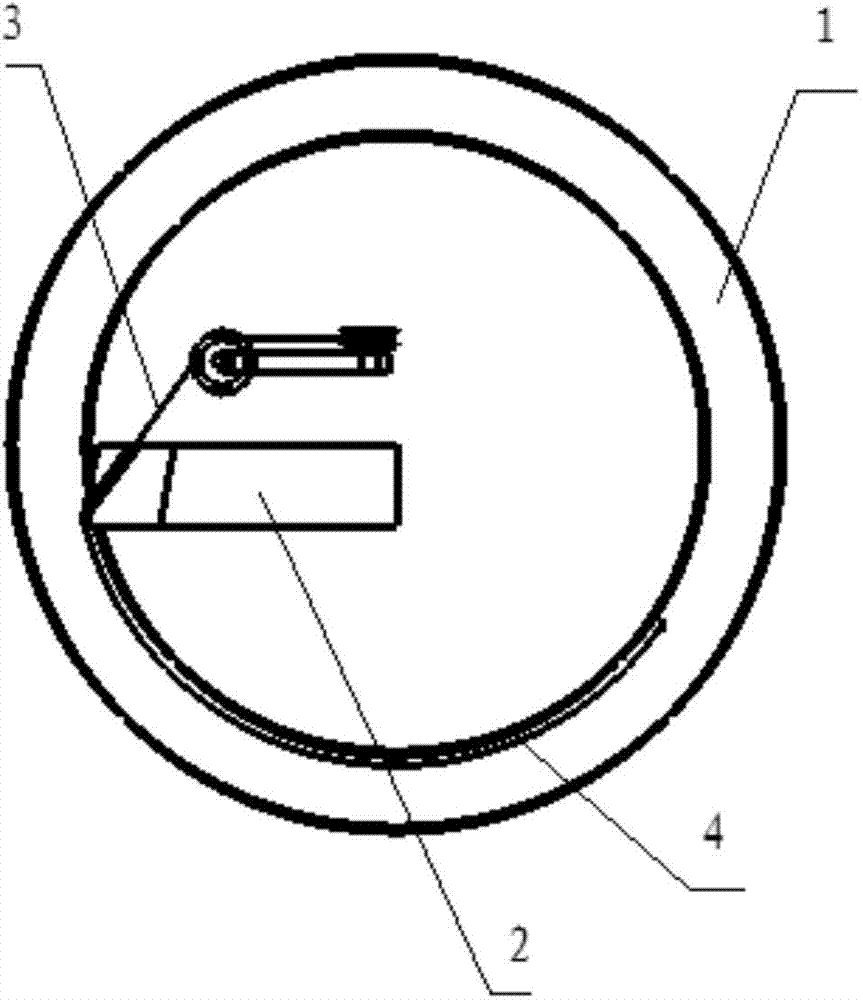

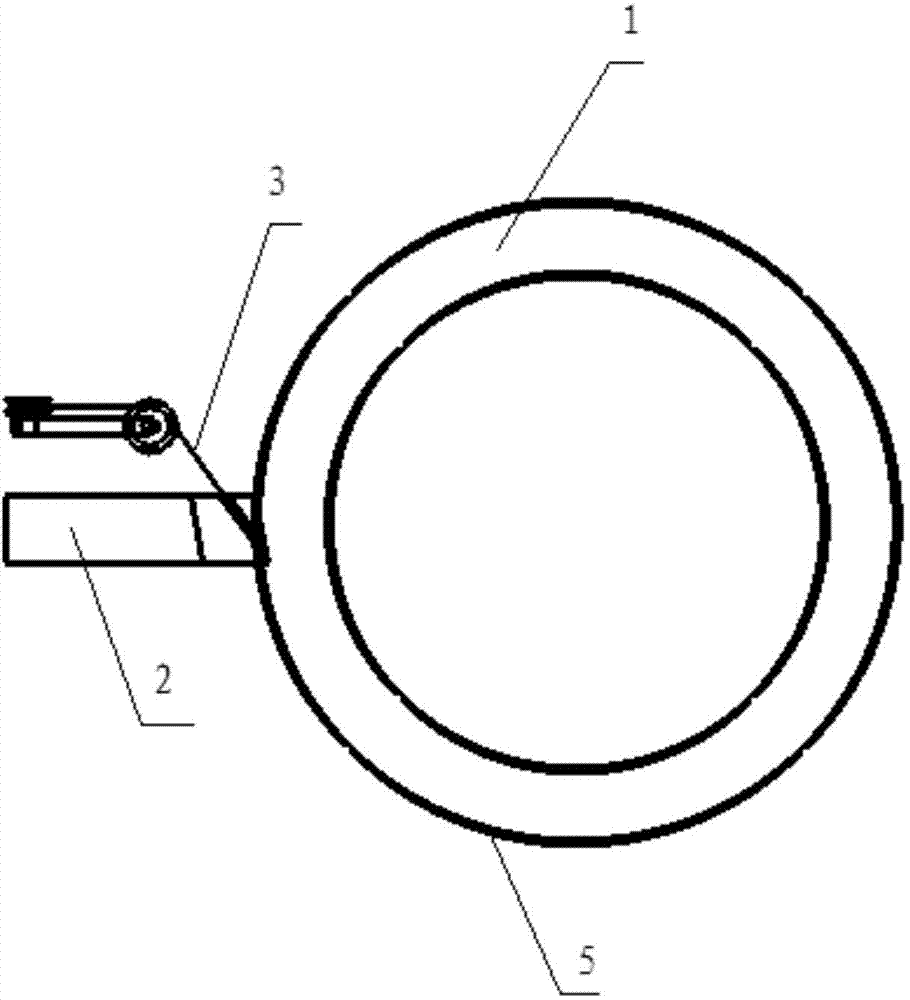

[0013] see Figure 1~2 Shown, a kind of pipe hot-melt wiring method, comprises the following steps:

[0014] In the area to be welded of the plastic pipe 1, use a wiring knife 2 to inlay the metal wire 3 under the plastic surface of the outer diameter 5 or the inner diameter 4 at both ends of the plastic pipe 2 according to the corresponding wiring pitch, and cover the area to be welded. A section of the two ends of the metal wire is reserved to be exposed outside the plastic surface layer. After the metal wire is laid out, it is welded. After the welding is completed, the metal wire ends exposed outside the plastic surface layer of the plastic pipe are cut off.

[0015] Further, the metal wire is embedded 2-4mm below the plastic surface of the plastic tube.

[0016] The metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com