Patents

Literature

193results about How to "Reduce after-sales maintenance costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

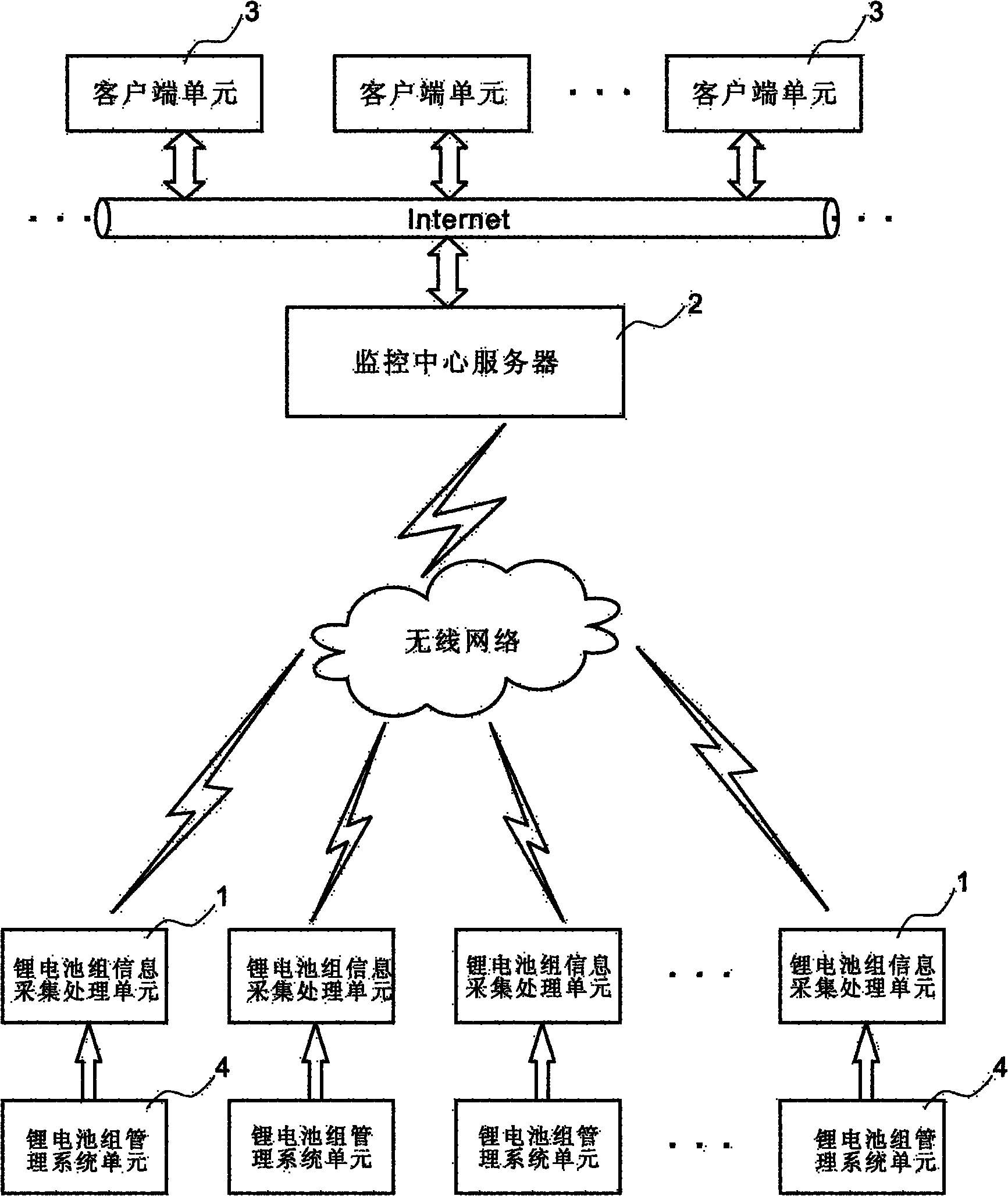

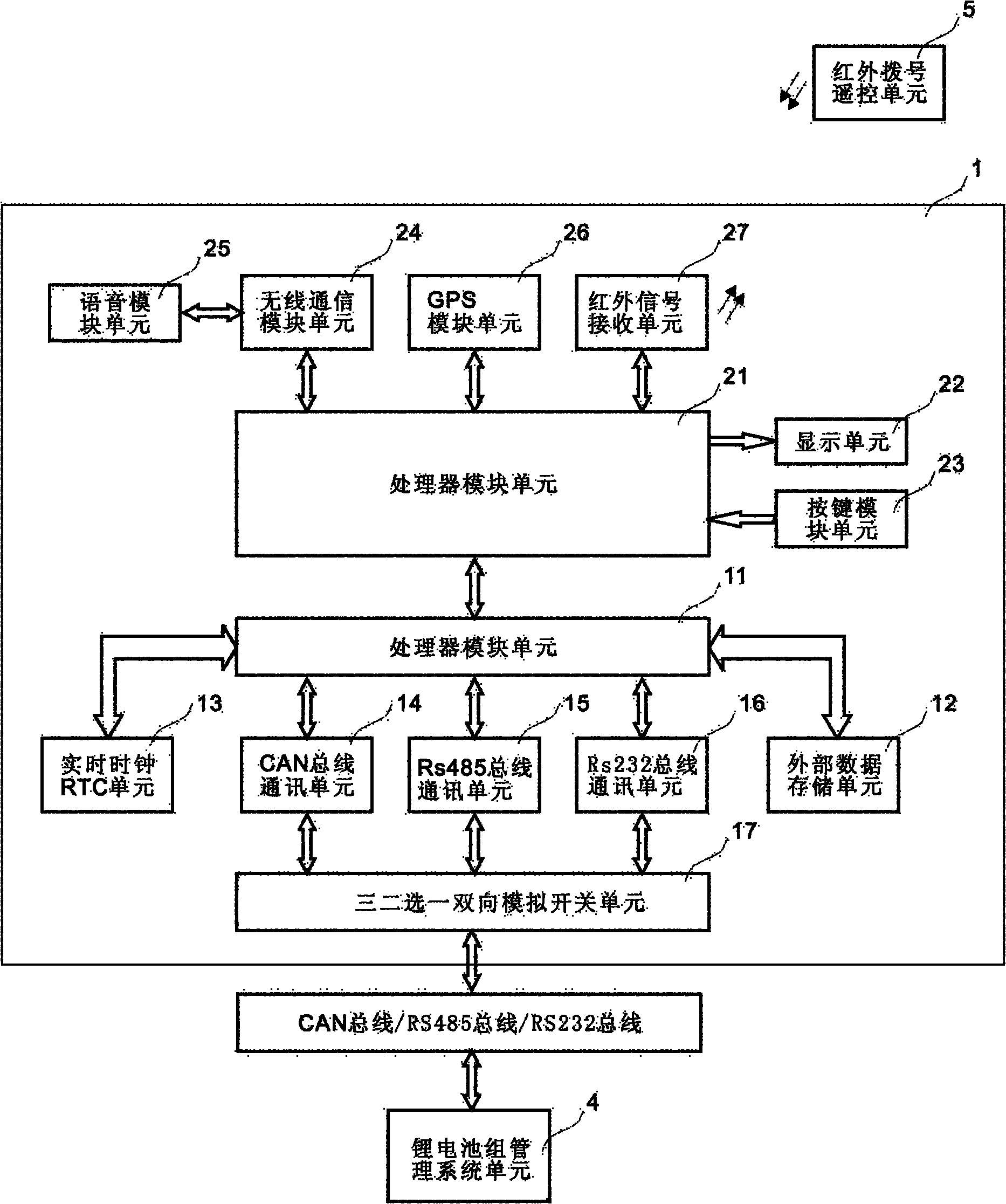

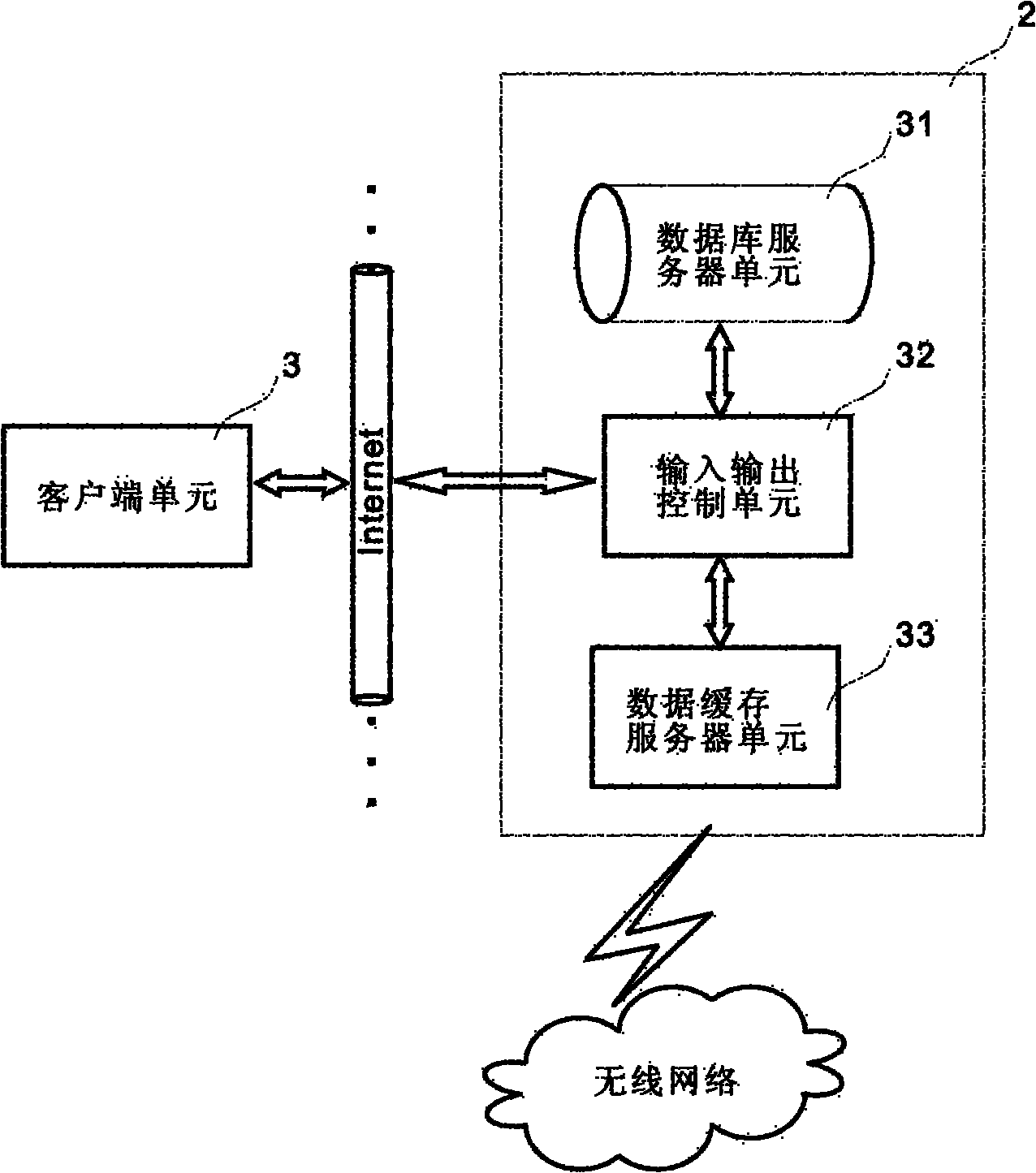

Remote monitoring system for lithium battery pack

InactiveCN102142186AReliable dataAvoid Unrecoverable FailuresTransmission systemsElectrical testingData acquisitionState of charge

The invention discloses a remote monitoring system for a lithium battery pack. The remote monitoring system comprises a lithium battery pack management system unit, a lithium battery pack information collecting and processing unit, a monitoring center server unit and a client unit, wherein, voltage, current, temperature, state of charge and fault information of the lithium battery pack is monitored and collected by the lithium battery pack management system unit in real time and then is transferred into the lithium battery pack information collecting and processing unit for data processing; then the processed data is transmitted to the monitoring center server unit through a wireless network so as to be stored; and the client unit is connected with the monitoring center server unit through Internet. The remote monitoring system can be used for solving the problems of the lithium battery pack such as low data collection efficiency, poor fault early-warning real-time property and shortage of failure analysis data in the prior art.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

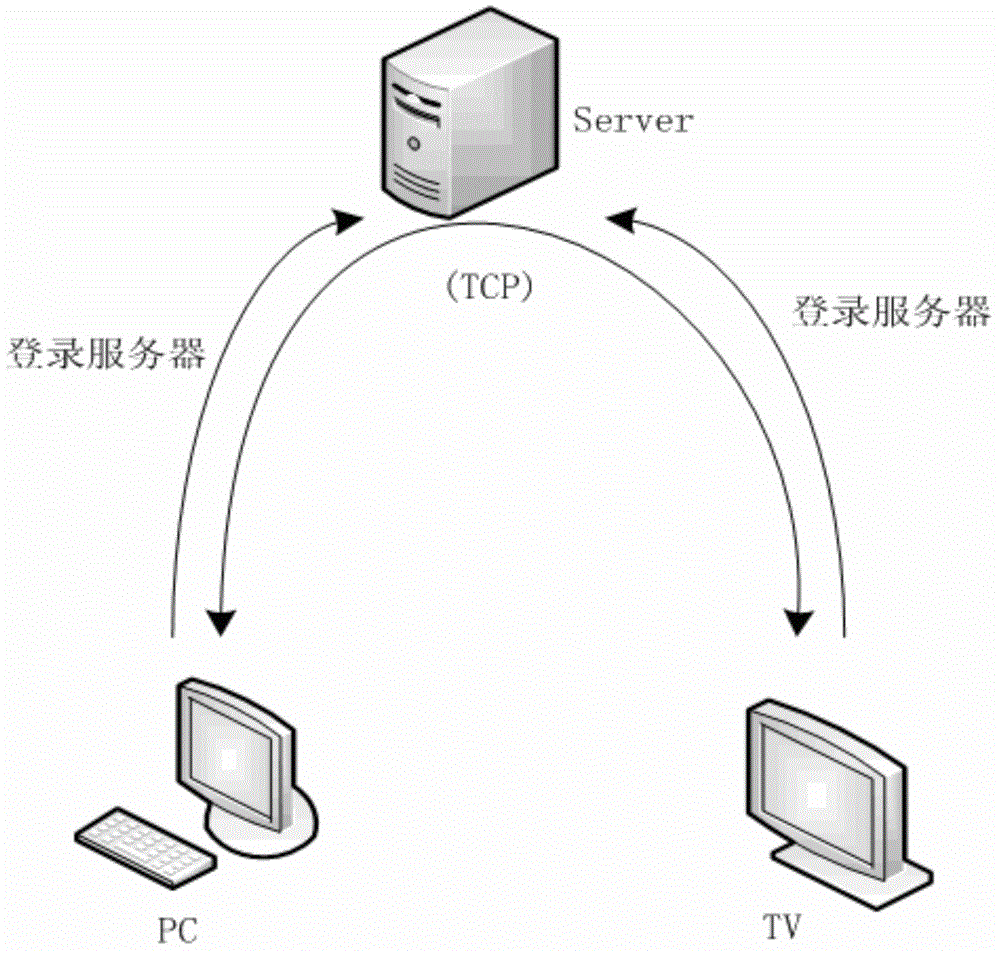

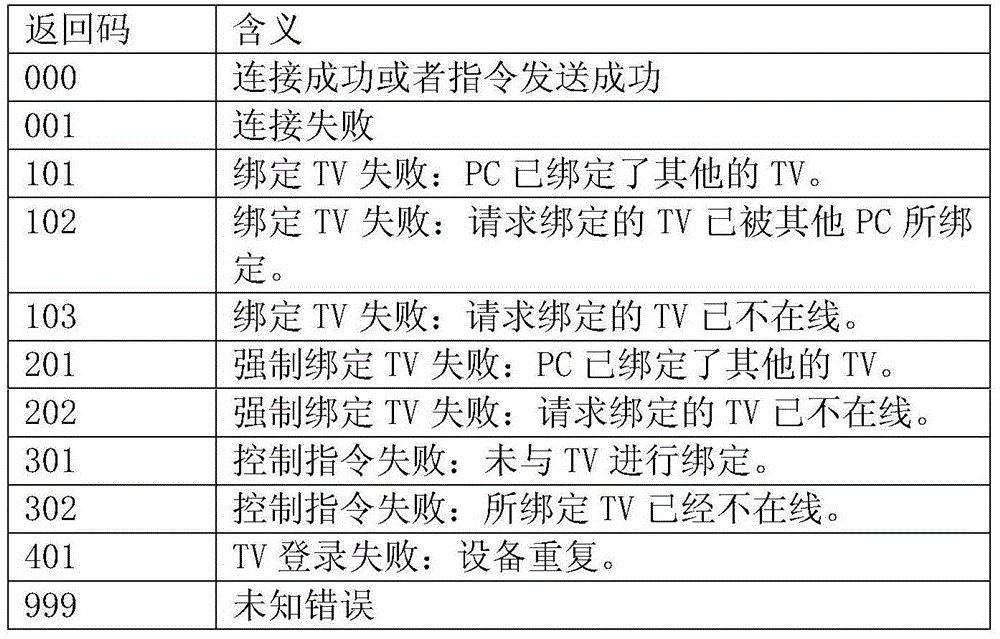

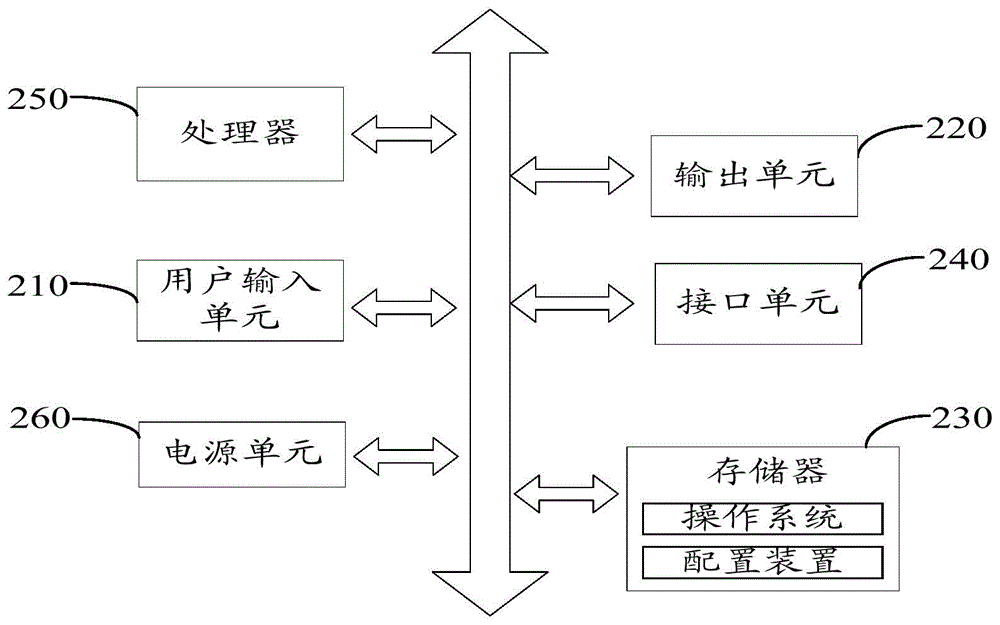

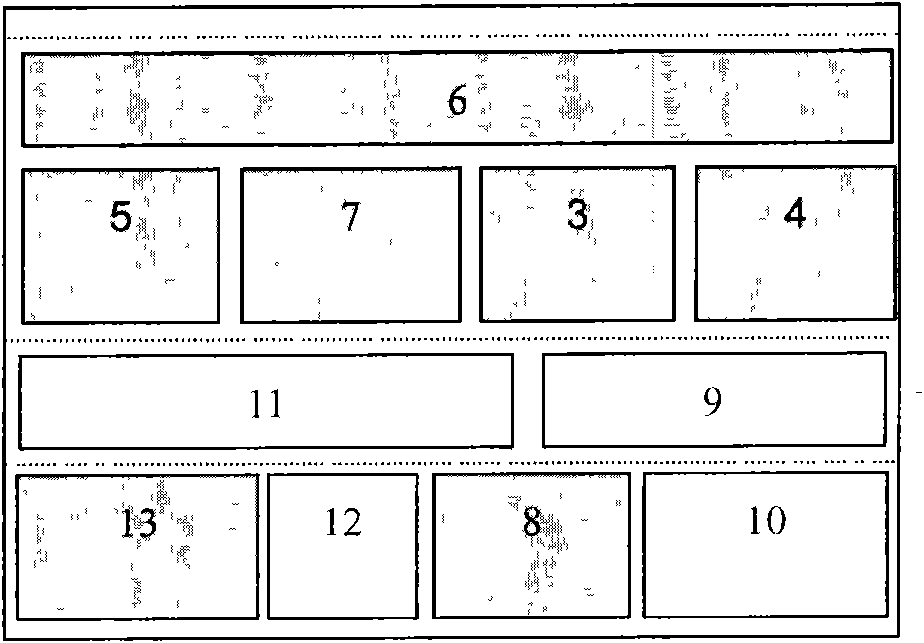

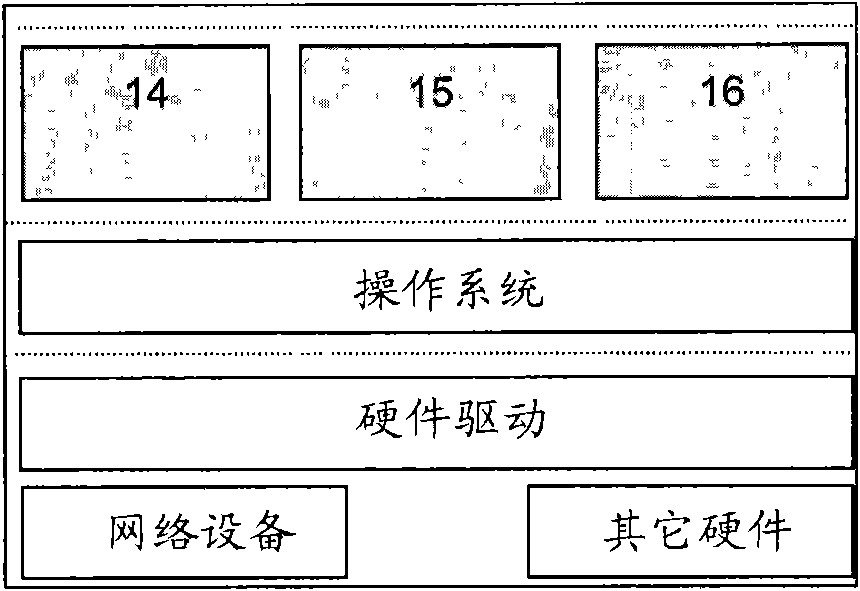

Intelligent television remote debugging system and method

InactiveCN104093080AEasy to analyzeReduce after-sales maintenance costsSelective content distributionComputer hardwareService personnel

The invention relates to the technique of intelligent television maintenance, and discloses an intelligent television remote debugging system. According to the intelligent television remote debugging system and method, when an intelligent television breaks down, a remote debugging controlled end program can be started, a server is connected and logged in, the intelligent television is added to an online equipment list through the server, after-sale service personnel can log in the server through a control terminal, the online equipment list is obtained, the corresponding intelligent television which breaks down can be selected from the online equipment list and bound, then the after-sale service personnel can communicate with the intelligent television which breaks down by means of the data forwarding function of the server, and accordingly remote debugging and control of the intelligent television which breaks down can be achieved. Besides, the invention further discloses a corresponding remote debugging method suitable for remote debugging of the intelligent television which breaks down.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

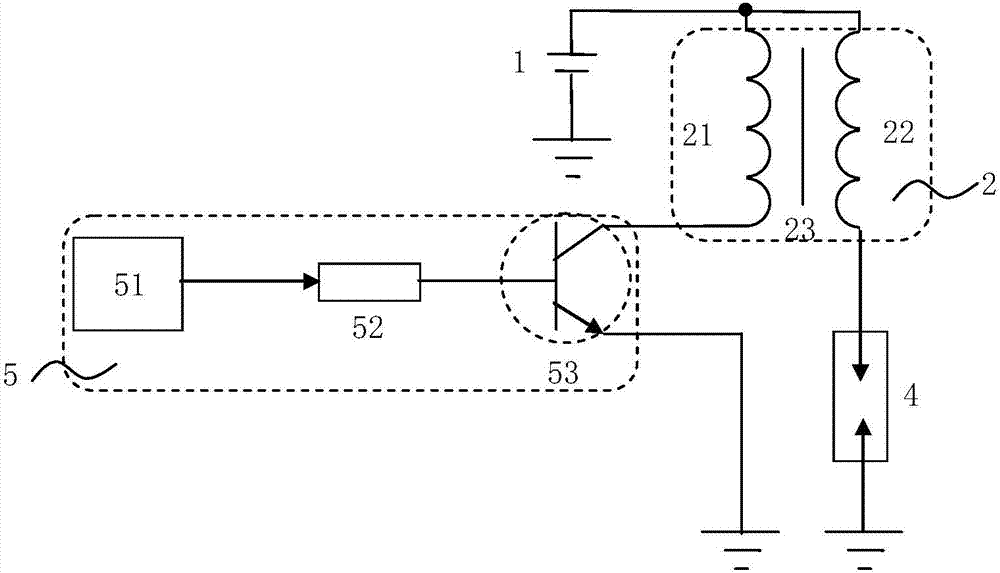

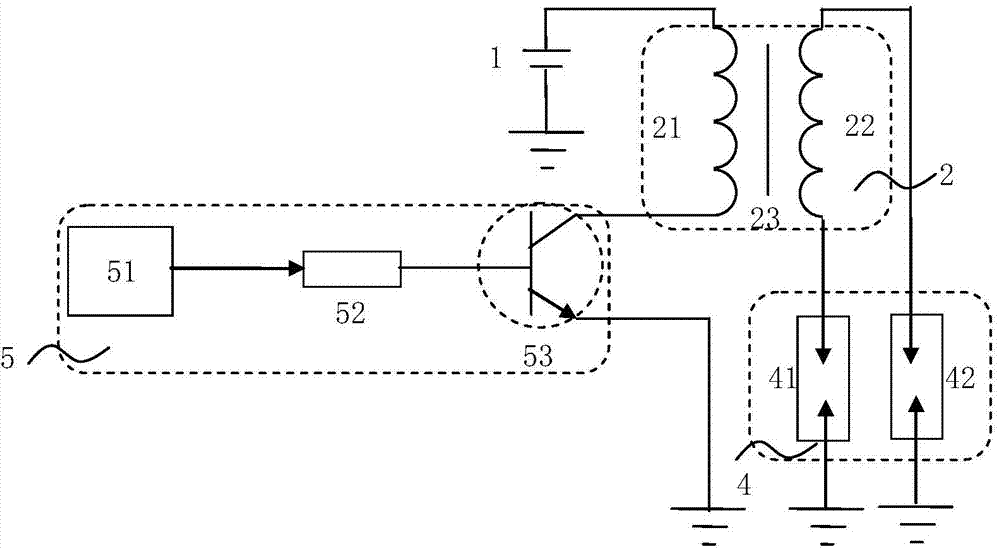

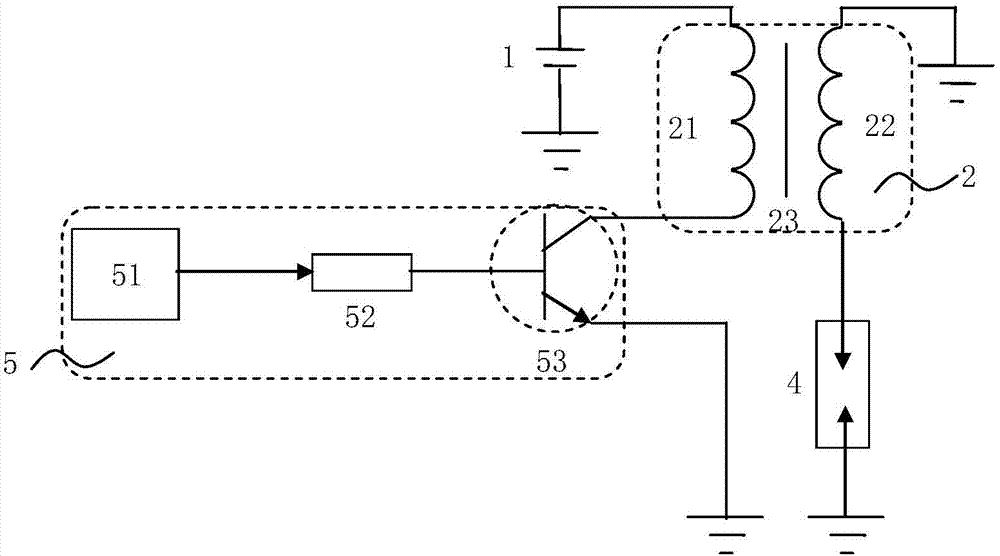

Fault diagnosis circuit and method of internal-drive electrically-controlled ignition system

ActiveCN103941720AImplement ignition diagnosticsAchieve protectionElectric testing/monitoringElectrical resistance and conductanceMicrocontroller

The invention discloses a fault diagnosis circuit of an internal-drive electrically-controlled ignition system. The internal-drive electrically-controlled ignition system is structurally characterized in that a microcontroller, a first resistor and a switching element are arranged in an ECU of a vehicle, an output end of the microcontroller is connected with the grid of the switching element through the first resistor, and the drain or collector of the switching element is connected with one end of a primary coil. The fault diagnosis circuit is structurally characterized in that a sampling resistor, a comparator, series resistors and a feedback resistor are arranged in the ECU, the source or emitter of the switching device is connected with the ground through the sampling resistor and is connected with a first input end of the comparator through one series resistor, a second input end of the comparator is connected with the ground through the other series resistor, the feedback resistor is connected with a first input end of the comparator and the output end of the comparator, and the output end of the comparator is connected with an input end of the microcontroller. By means of the fault diagnosis circuit, ignition diagnosis of the internal-drive electrically-controlled ignition system can be achieved, ignition drive chips and the ECU are protected, after-sales maintenance cost is reduced, and economical and technical dual-benefits are acquired.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

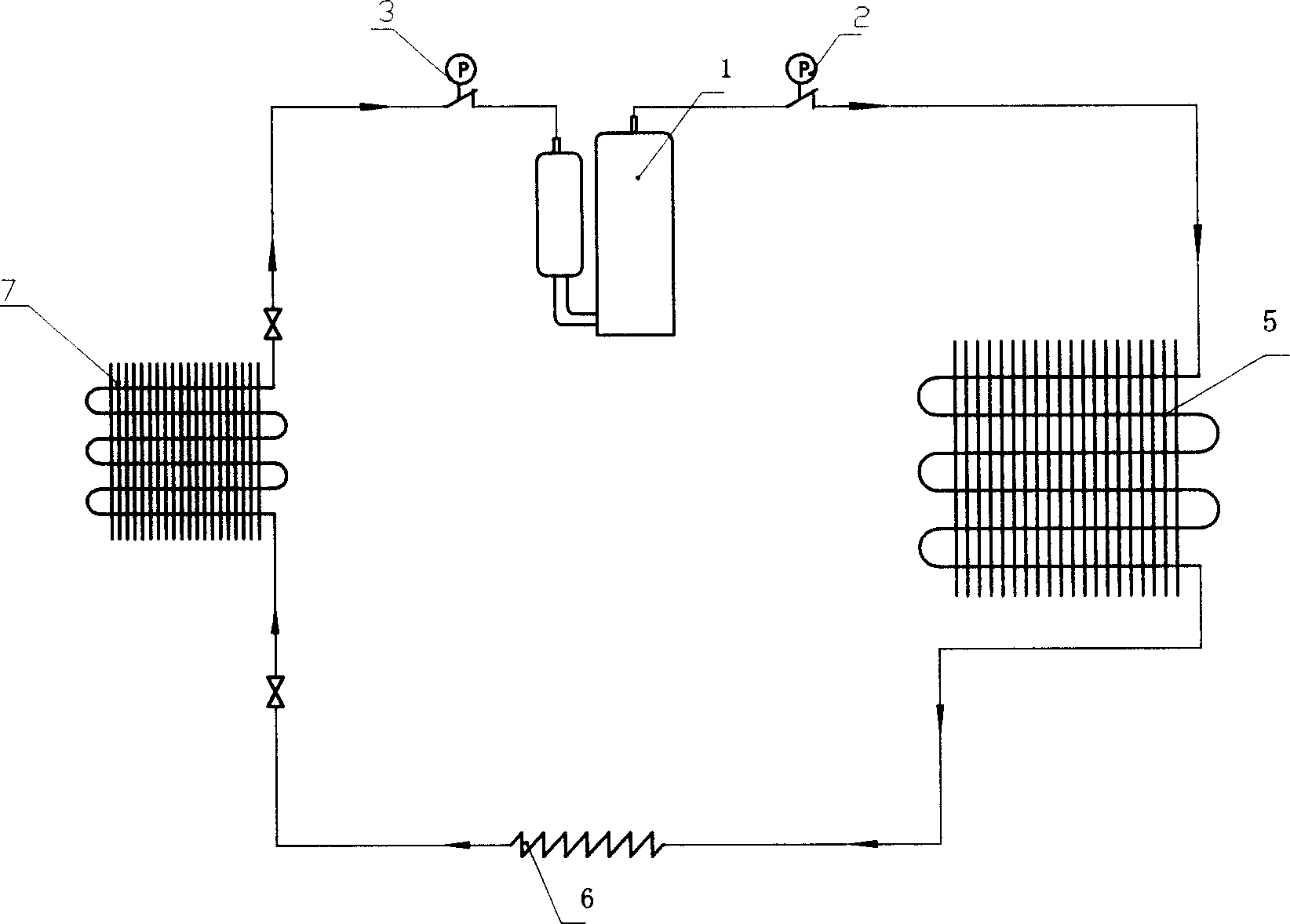

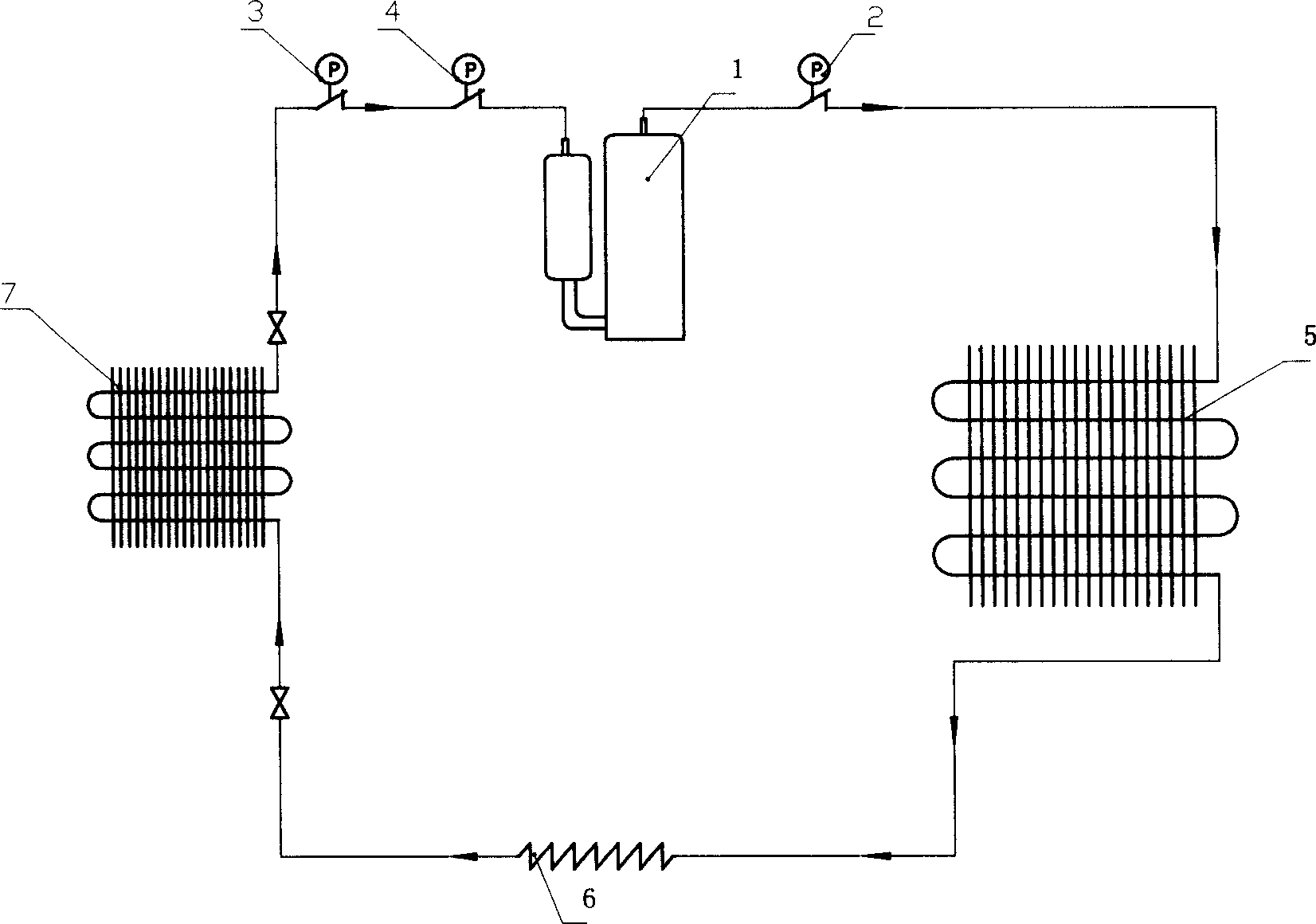

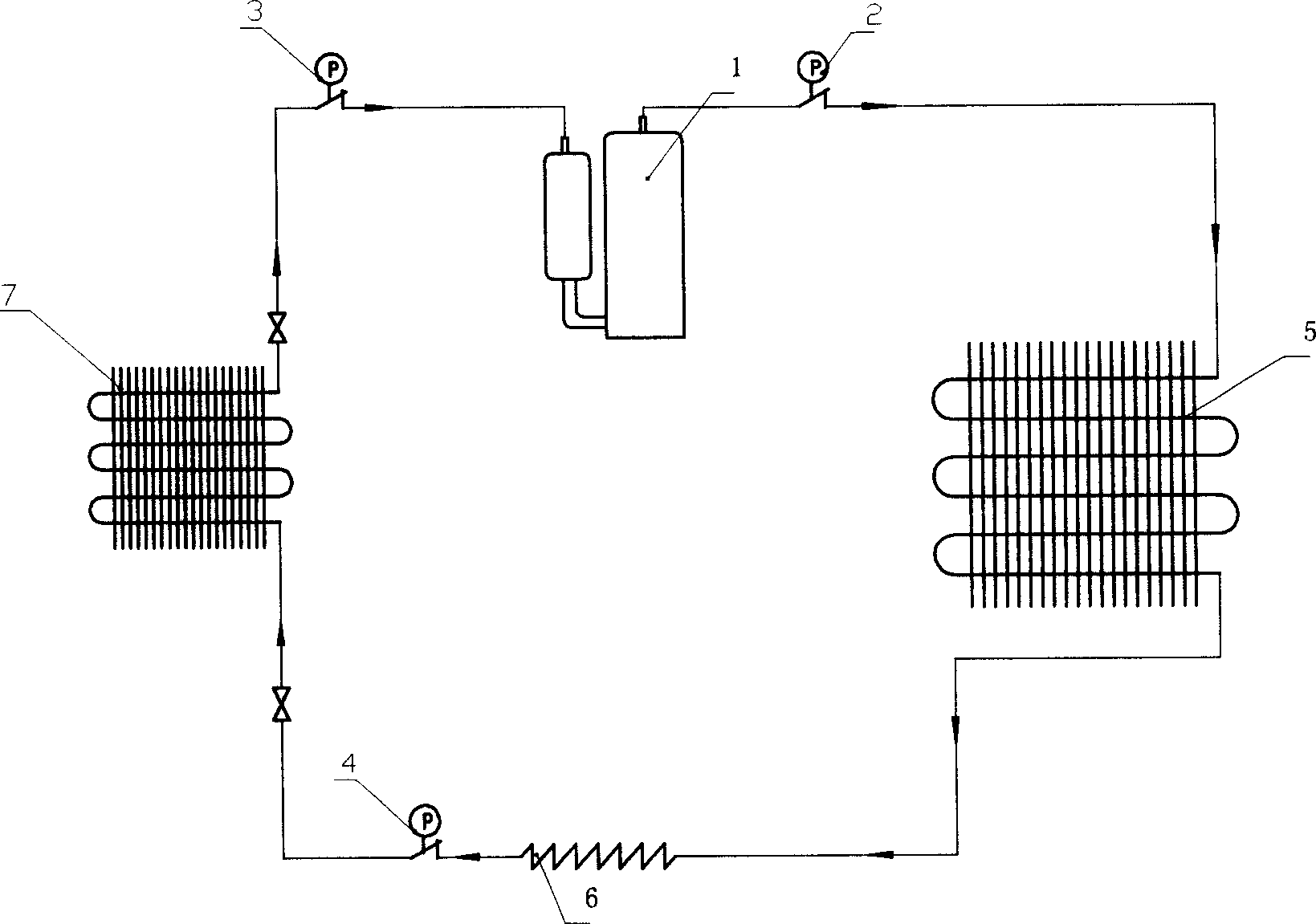

Safety prealarming device of refrigerating system

InactiveCN1710359AAvoid normal operationExtended use timeRefrigeration safety arrangementElectricityControl system

A safety pre-alarm device on refrigerating system consists of pre-alarm low pressure valve and control circuit for transmitting electric signal, the input end of control circuit is electrically - connected to pre-alarm low pressure valve. It can remind or request the operator to stop air conditioner and to carry out relative detection when refrigerant leakage is occurred on refrigerating loop to cause loop return air pressure drop to meet pre-alarm pressure value of pre-alarm low pressure valve.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

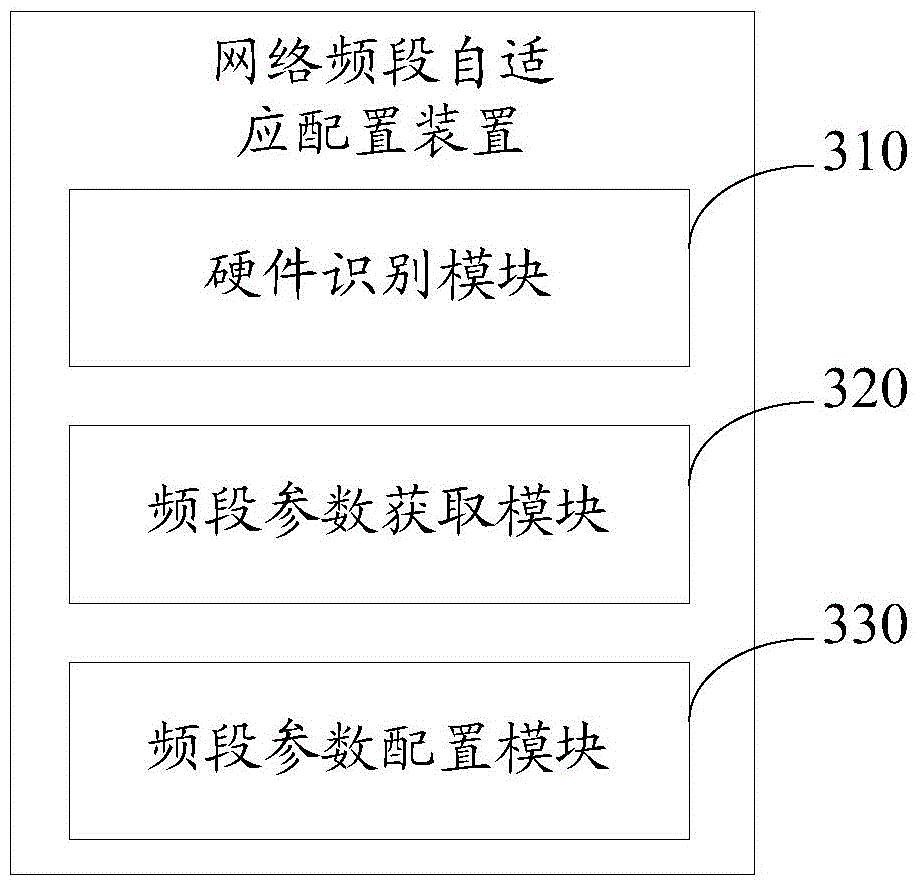

Adaptive configuration method and device for network frequency band of mobile terminal

ActiveCN105101479AReduce development costsReduce after-sales maintenance costsWireless communicationSoftware developmentComputer terminal

The invention discloses an adaptive configuration method for a network frequency band of a mobile terminal. The adaptive configuration method comprises the steps: obtaining a hardware identification tag of the mobile terminal; obtaining a frequency band configuration tag corresponding to the hardware identification tag, and obtaining frequency band parameters corresponding to the frequency band configuration tag from a preset frequency band configuration file; writing the obtained frequency band parameters into corresponding parameter items of the mobile terminal. The invention further discloses an adaptive configuration device for the network frequency band of the mobile terminal. Software development and after-sales maintenance costs are effectively reduced.

Owner:NUBIA TECHNOLOGY CO LTD

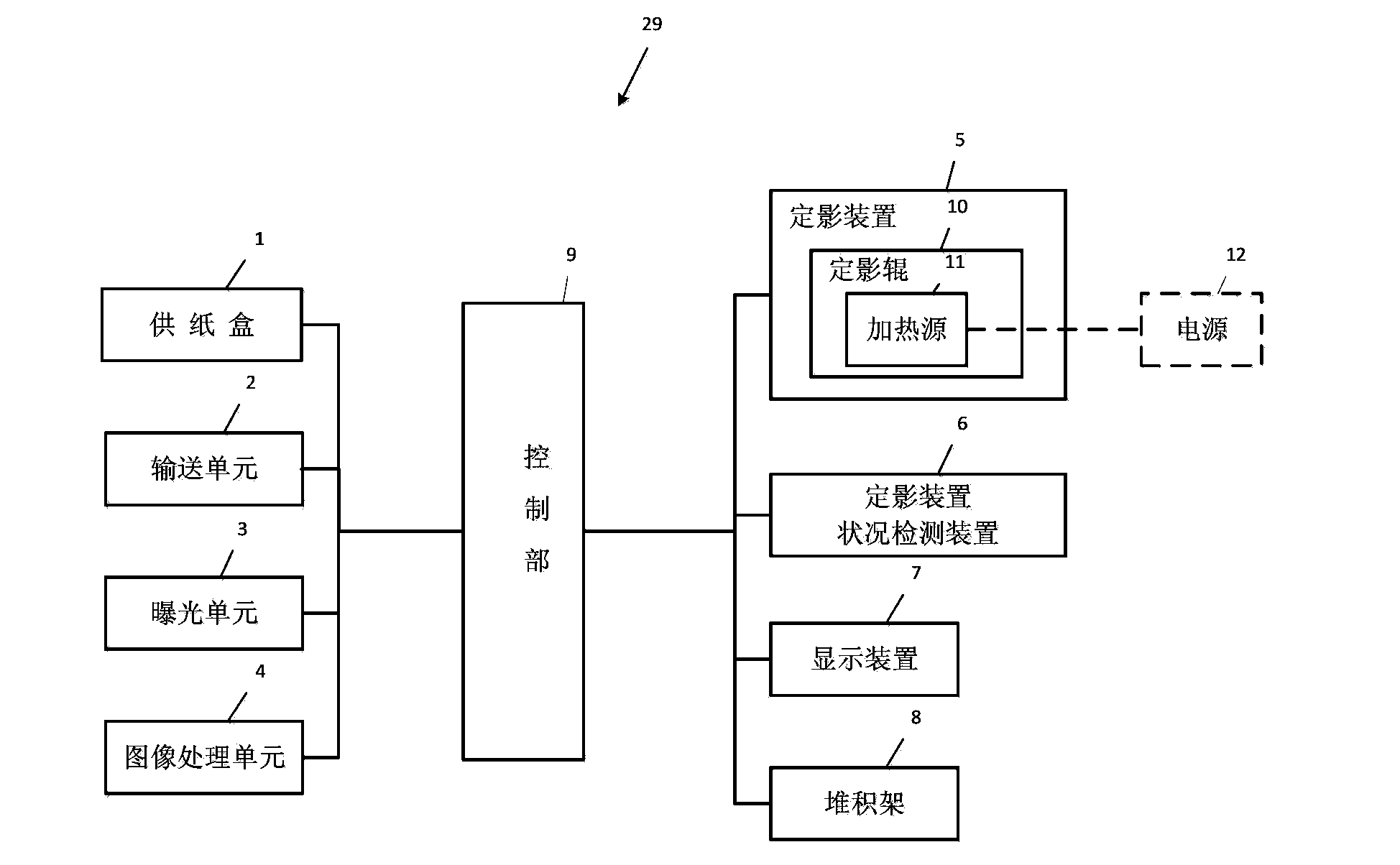

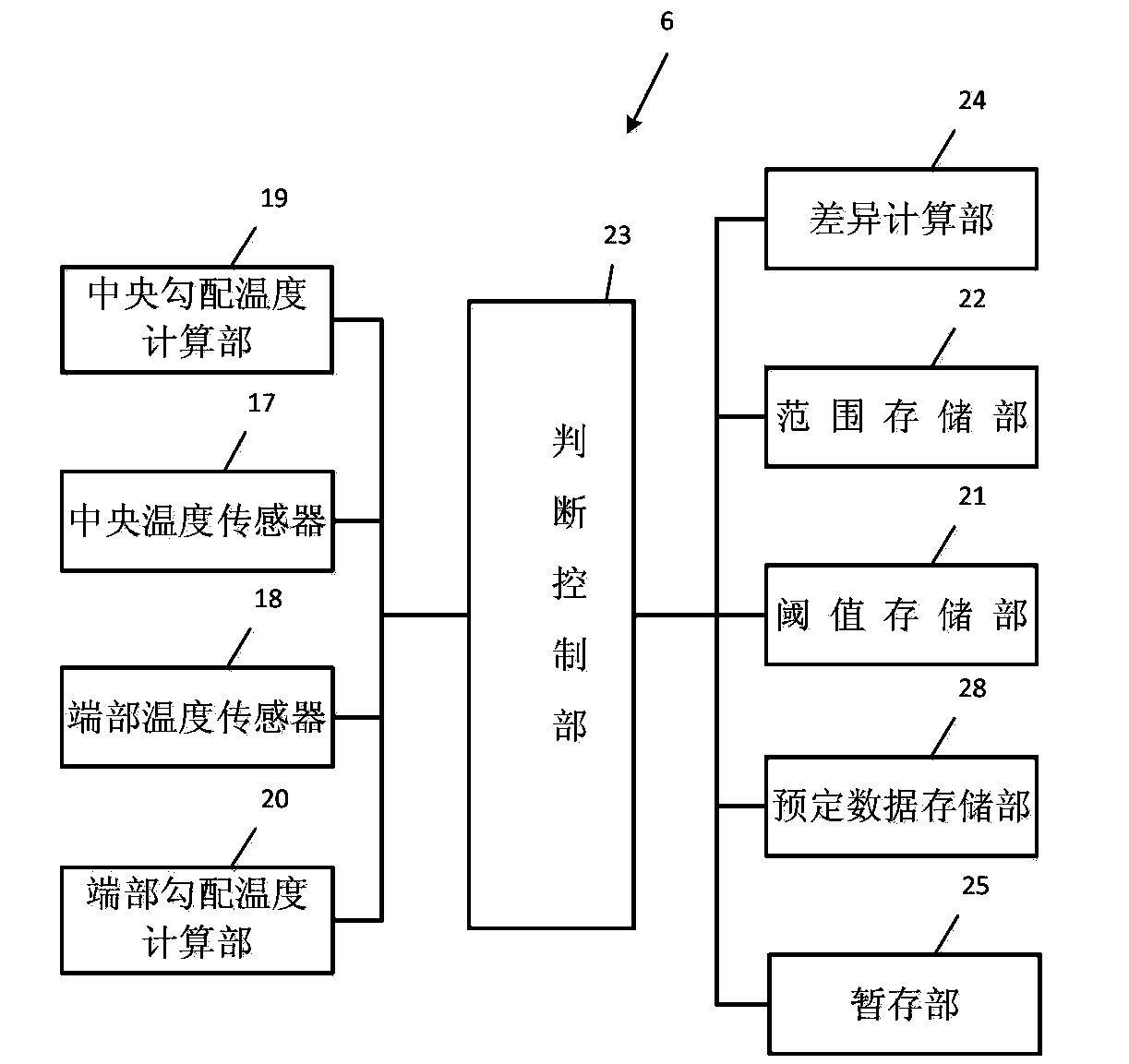

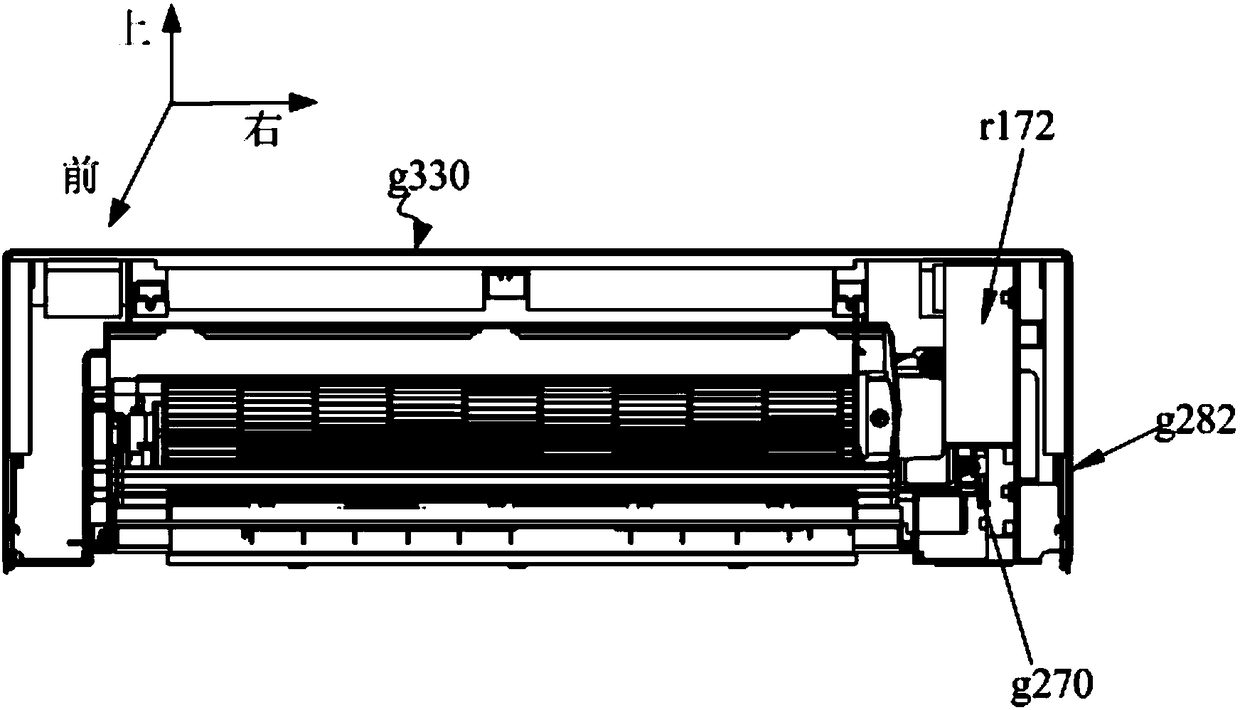

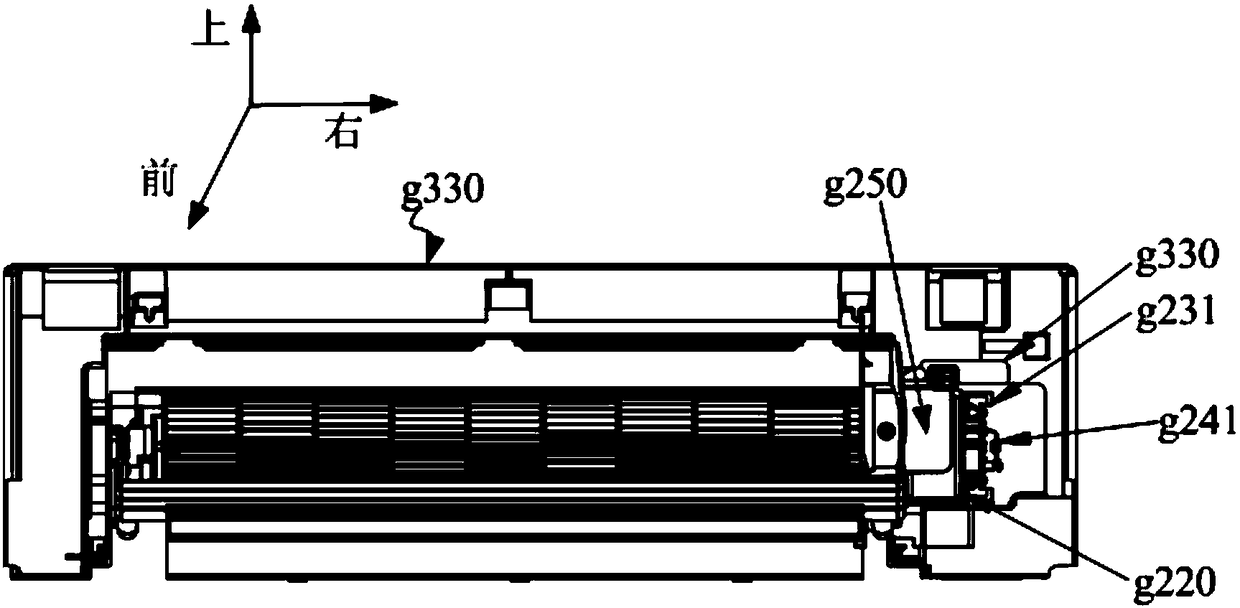

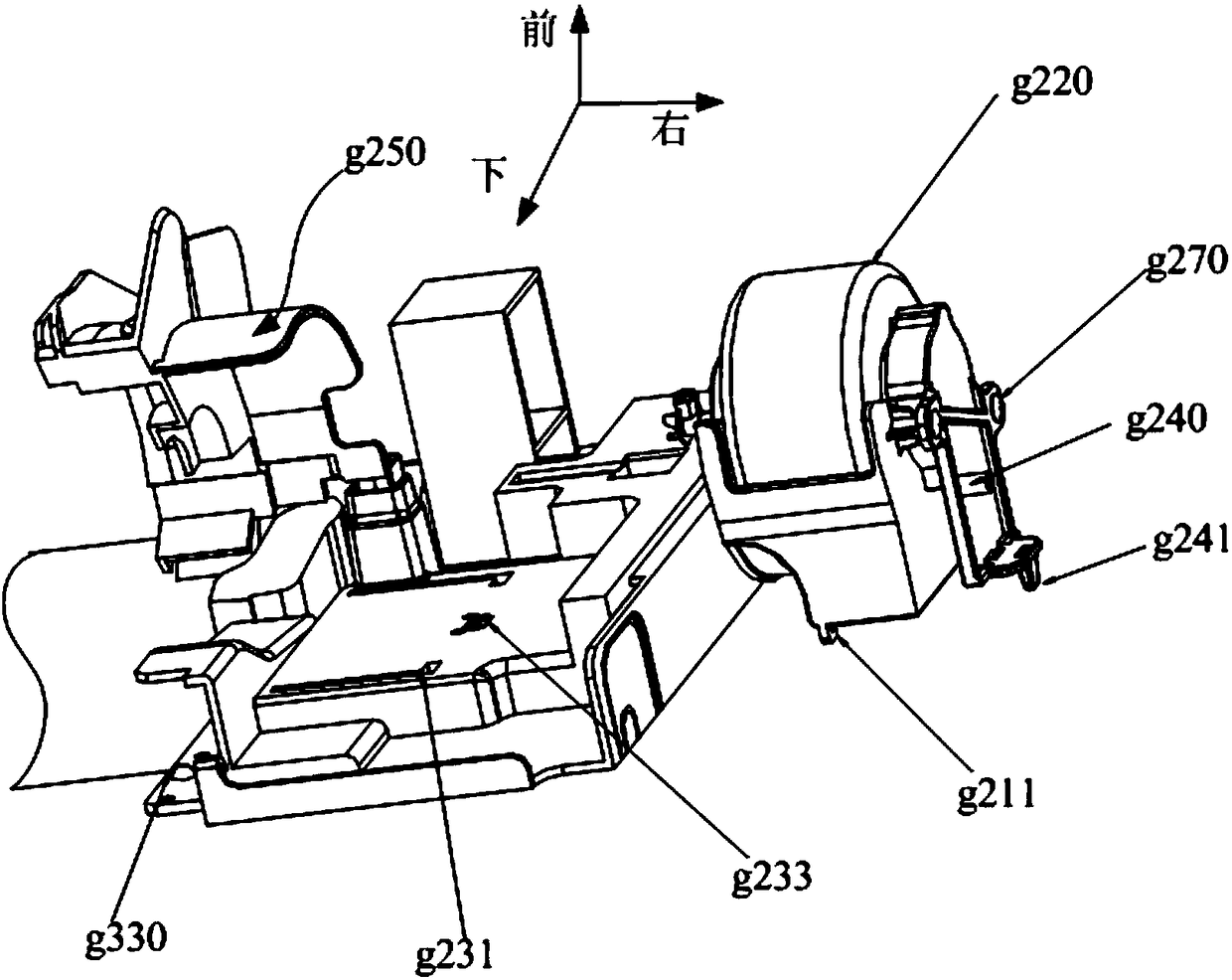

Detection device for fixing apparatus state and image formation device

ActiveCN103885311ASave time and costReduce after-sales maintenance costsElectrographic process apparatusLower limitImage formation

The invention relates to a detection device for fixing apparatus state and an image formation device with the detection device. A central temperature sensor and an end part temperature sensor are respectively disposed at the central area and an end part area of a fixing roller of an image formation device; the detection device calculates a central blending temperature, an end part blending temperature and a blending temperature difference according to the central temperature and the end part temperature detected by the central temperature sensor and the end part temperature sensor, and performs blending temperature difference determination and continuous determination of a central blending temperature threshold, so the fixing apparatus can work normally in a certain range below the lower limit of the specified power supply voltage, which prevents the problem that current image formation devices are easy to misreport fixing apparatus failure when an actual power supply voltage is lower than the lower limit of the specified power supply voltage, and facilitates user time saving and reduction of manufacturer after-sales maintenance cost.

Owner:RICOH KK

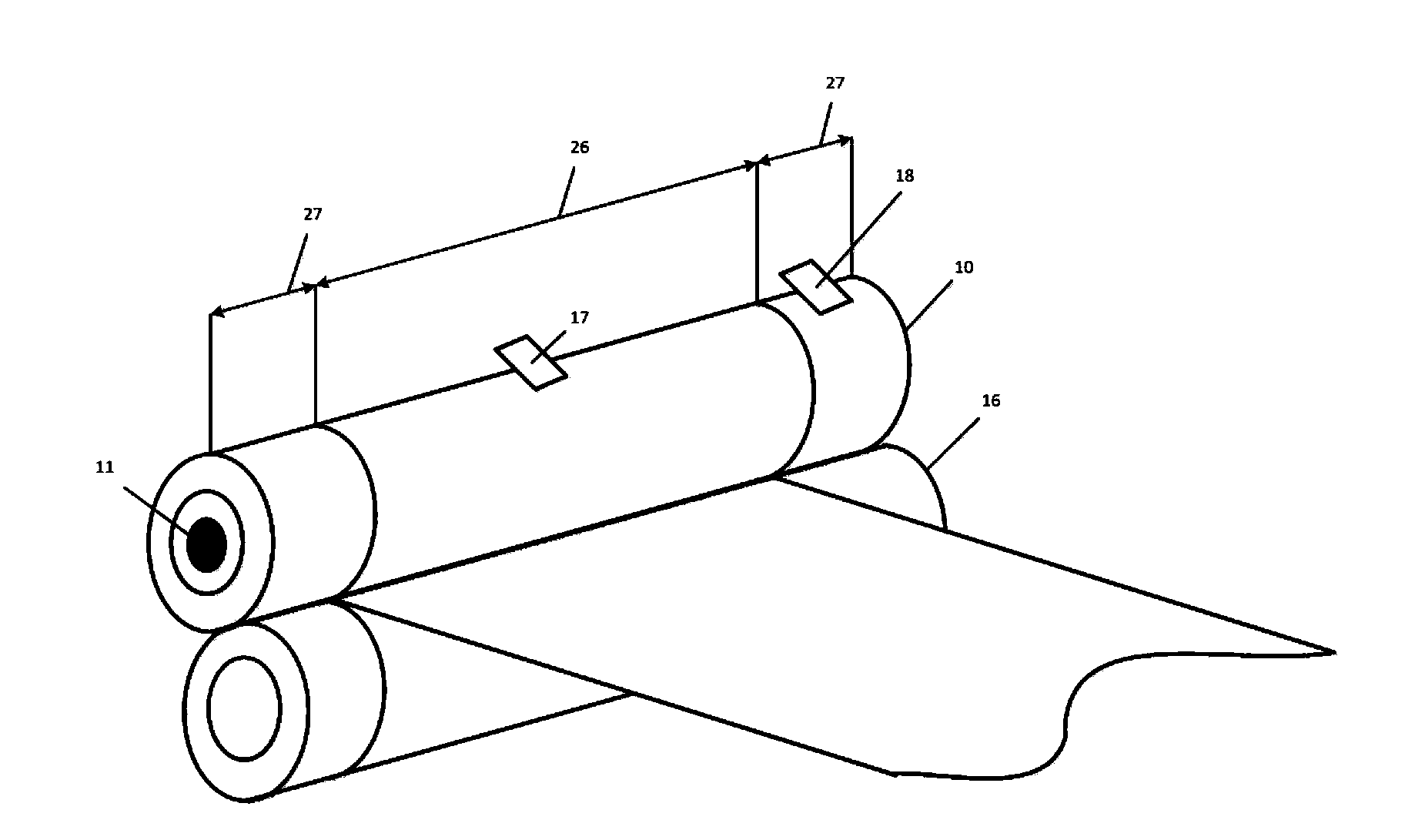

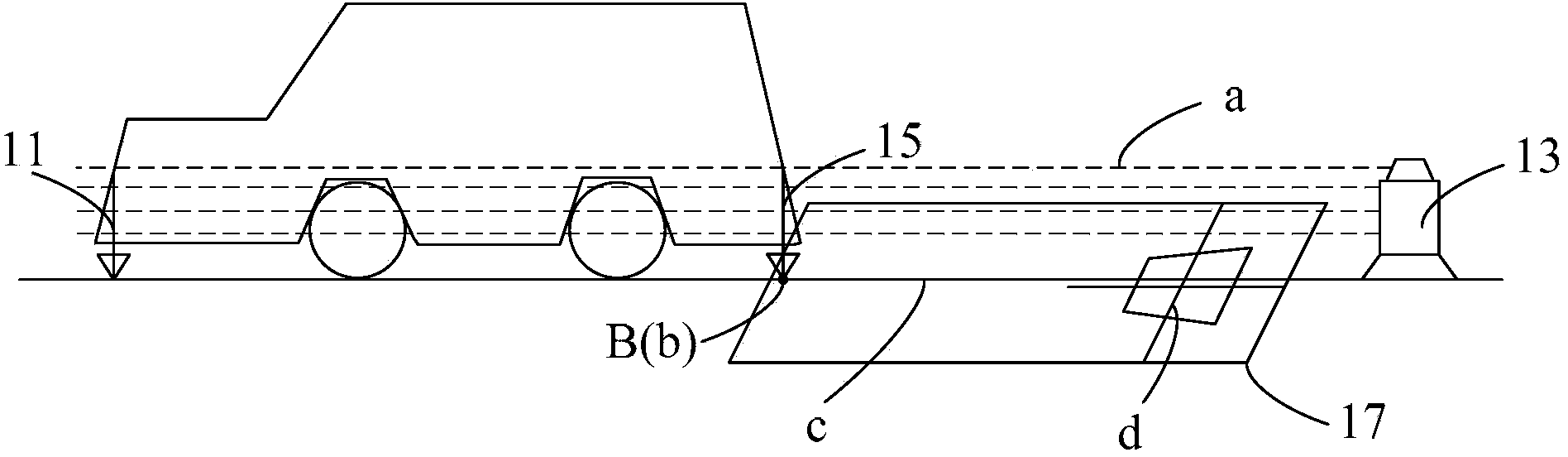

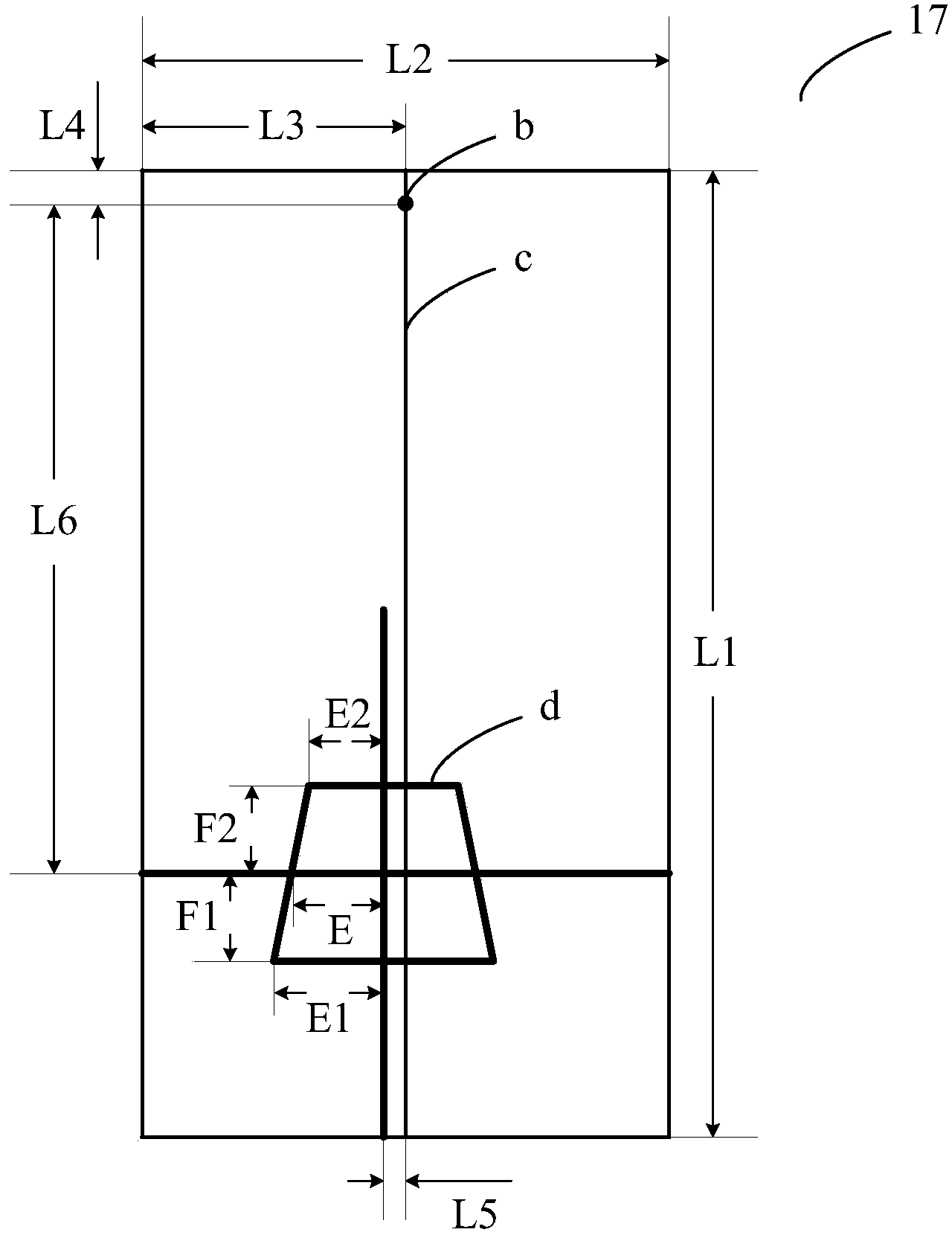

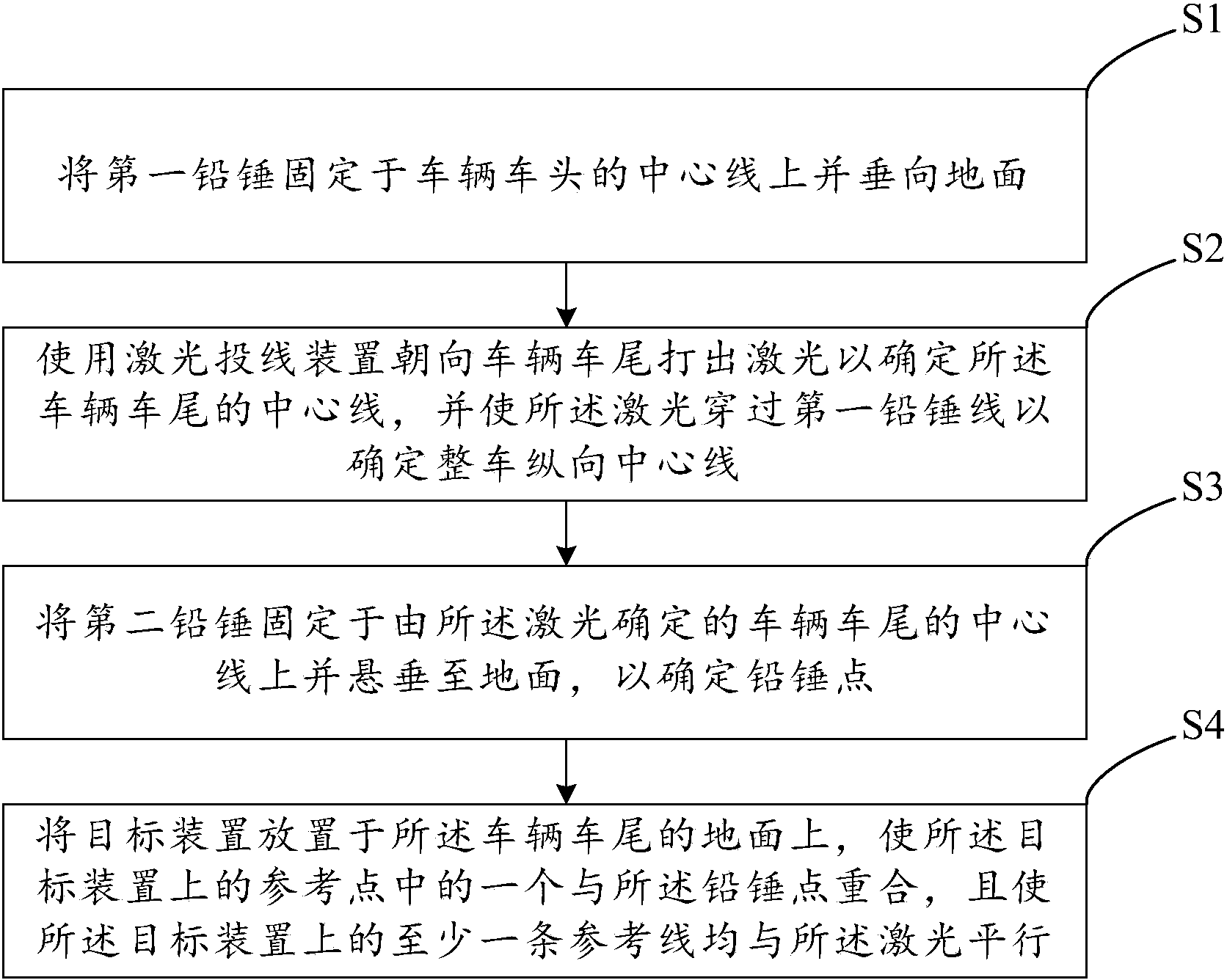

Device and method for demarcating rearview camera

The invention discloses a device and a method for demarcating a rearview camera, relates to the technical field of automobiles and aims at realizing simplicity in structure and easiness in operation and lowering cost. The device comprises a first plumb, a laser casting device, a second plumb and a target device, the first plumb is fixed on a central line of the head of an automobile and is perpendicular to the ground, the laser casting device casts laser to the tail of the automobile to determine a central line of the tail of the automobile, the laser penetrates a first plumb line to determine a central line of the whole automobile, the second plumb is fixed on the central line, of the tail of the automobile, determined by the laser and overhung to the ground to determine a plumb point, at least one reference point, at least one reference line penetrating each reference point and demarcating patterns are arranged on the target device which is placed on the ground at the tail of the automobile, one of the reference point is coincident with the plumb point, and all of the reference lines are parallel to the laser. The device and the method are suitable for being used in the demarcating process of the rearview camera of the automobile.

Owner:GREAT WALL MOTOR CO LTD

Automatic dual-system guide method of embedded device

ActiveCN102214106AImprove stabilityQuality improvementProgram loading/initiatingTransmissionEmbedded systemEnvironment variable

The invention provides an automatic dual-system guide method of an embedded device. The method comprises the following steps: reading an environment variable; determining whether to guide from the current sub-area based on the read environment variable; if yes, guiding the embedded device from the current sub-area; if no, determining whether to switch to another sub-area; if yes, guiding the embedded device from the switched sub-area; and if no, starting a remote network to guide the embedded device.

Owner:SAMSUNG ELECTRONICS CHINA R&D CENT +1

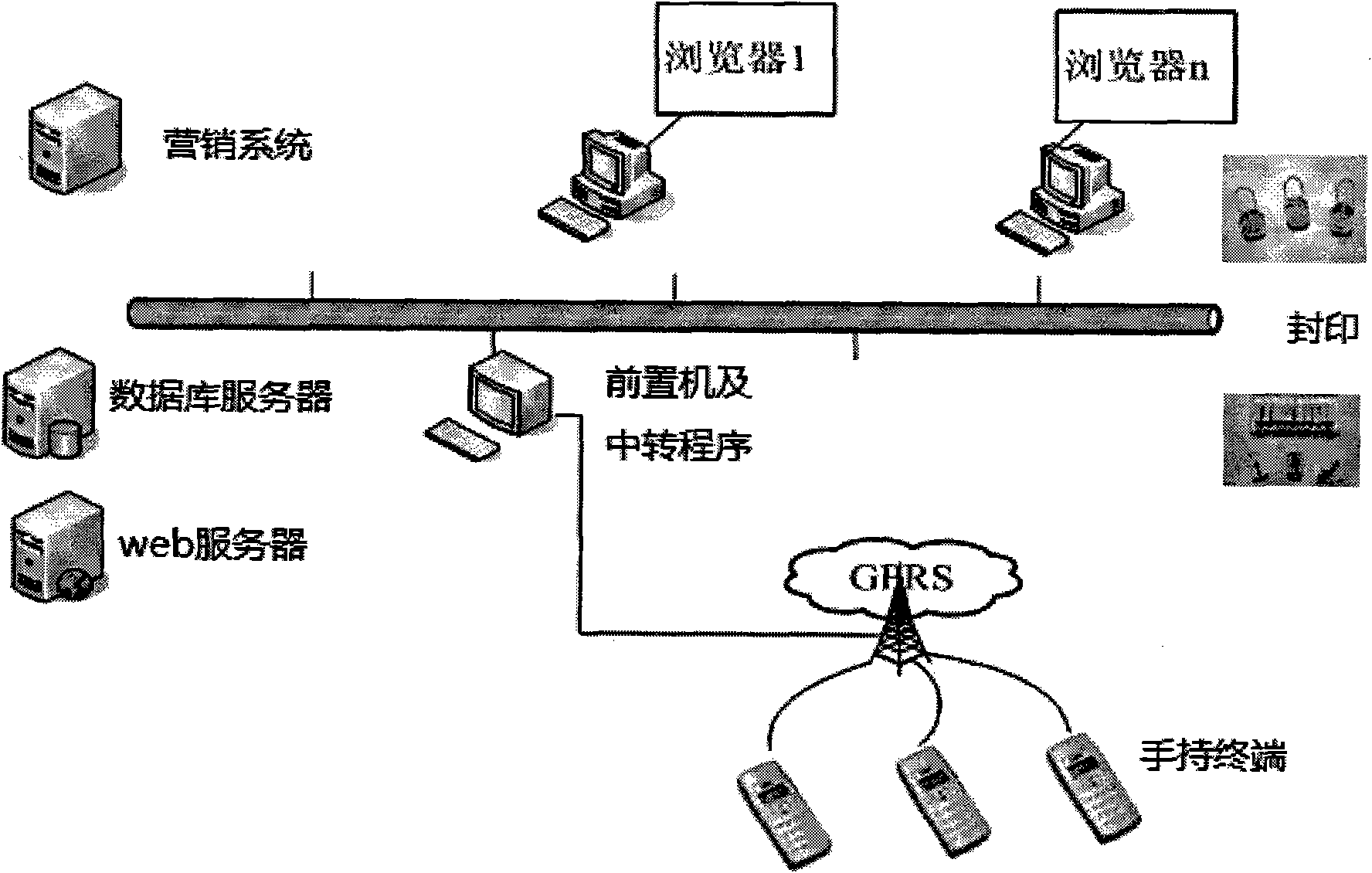

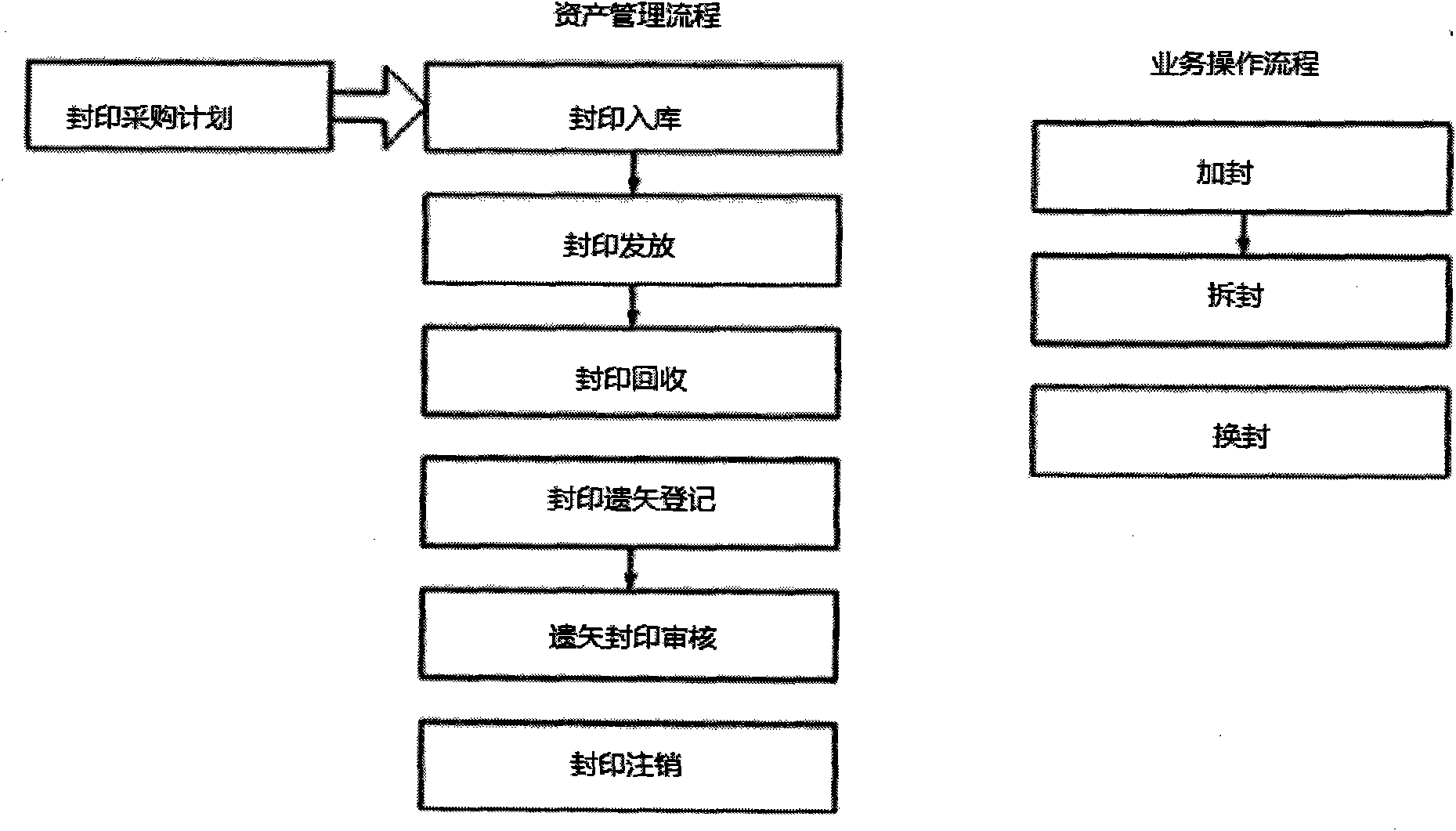

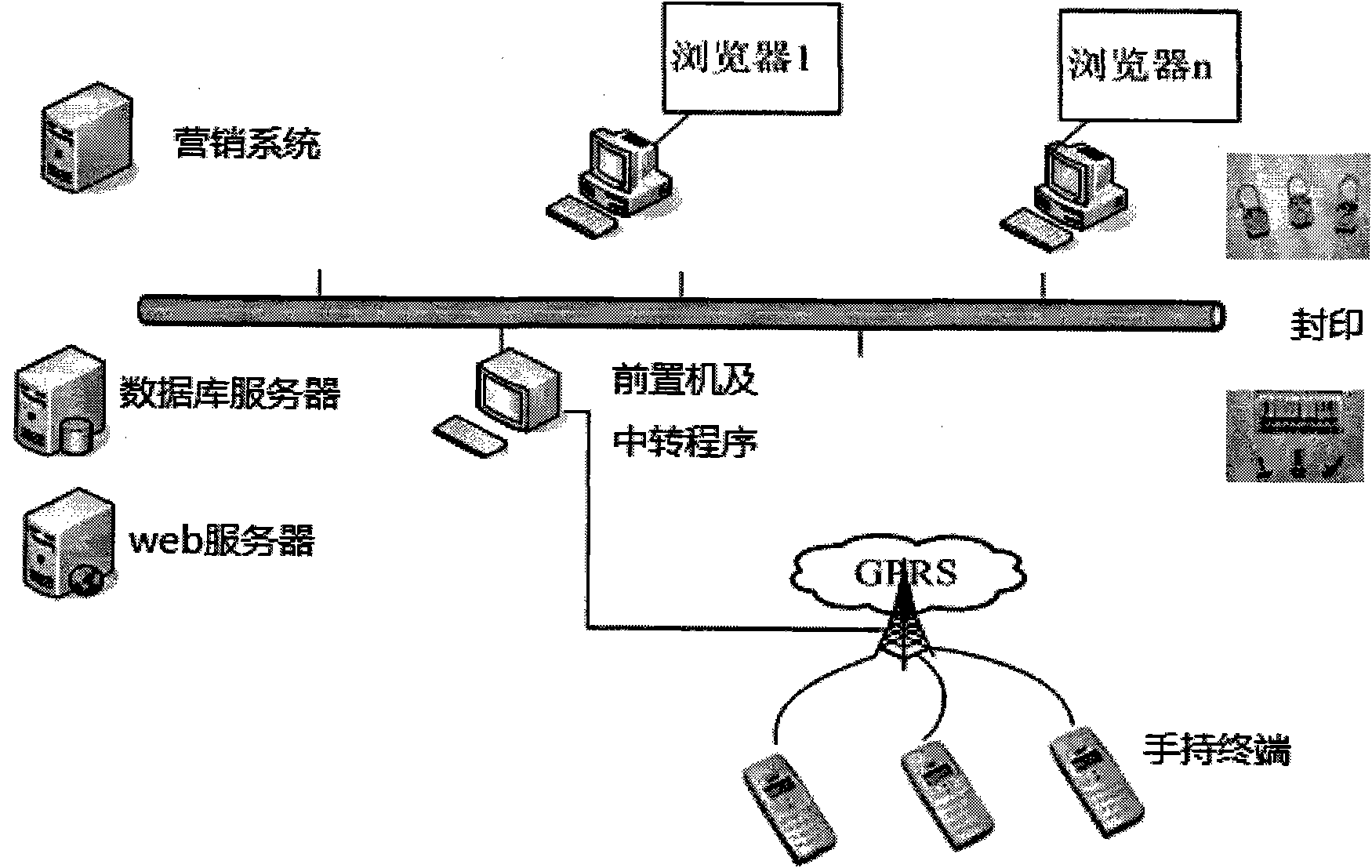

Web-based system and method for managing electric meter seal

InactiveCN101957947AReduce installation service volumeReduce maintenance and after-sales costsTransmissionTime integral measurementWeb applicationDatabase server

The invention discloses a web-based system and a web-based method for managing an electric meter seal. A personnel computer (PC) database server is in communication link with a front-end processor; a PC web application server is in communication link with the front-end processor; a handheld terminal is in wired or wireless communication link with the front-end processor; a bar code scanning module for reading seal information is arranged in the handheld terminal; the PC database server sets up a database service needed by an application program of a web management electric meter seal system; and the PC web application server sets up services needed by the application program of the web management electric meter seal system, the running environment of the application program and a web release configuration. The system has the advantages of simple on-site implementation, only need of deploying a server end, convenient maintenance and capability of greatly reducing the future service volume and the after-sale maintenance cost for enterprises.

Owner:SHENZHEN CLOU ELECTRONICS

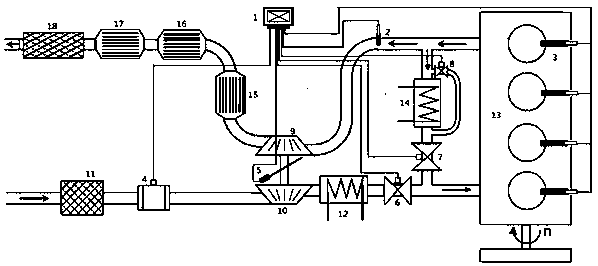

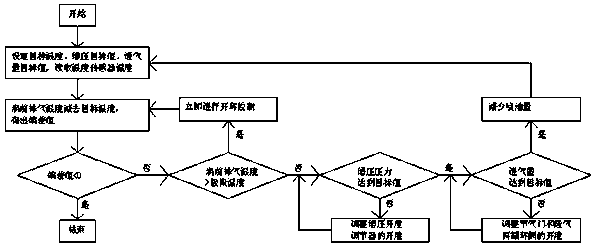

Turbine front exhaust temperature closed-loop control device and method adopting temperature sensor

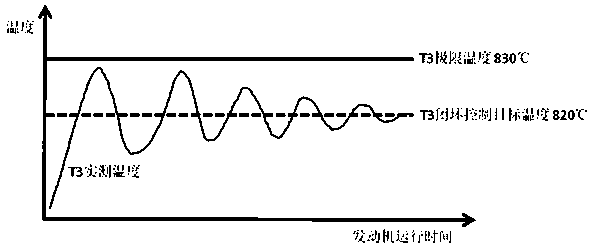

ActiveCN108730056AReduced safety marginHigh energyElectrical controlInternal combustion piston enginesLoop controlClosed loop

The invention discloses a turbine front exhaust temperature closed-loop control device and method adopting a temperature sensor. The temperature sensor (2) is arranged between an oil atomizer (3) anda waste gas turbine (9) and connected with an engine control unit (1). The closed-loop control target temperature value of T3 is set, the engine control unit reads the actual measurement temperature of T3, and if T3 is smaller than the closed-loop control target temperature, control is not conducted; if T3 is larger than or equal to the closed-loop control target temperature and smaller than the extreme temperature, closed-loop control is conducted; if the deviation value is larger than 0, whether the supercharge pressure reaches the target value or not is judged, if the supercharge pressure does not reach the target value, the aperture of a supercharge aperture adjuster (5) is adjusted, and if the supercharge pressure reaches the target value, whether the air inlet volume reaches the target value or not is judged; if the air inlet volume does not reach the target value, the aperture of a waste gas recirculation valve (7) and the aperture of a throttle valve (6) are adjusted; and if T3is larger than or equal to the extreme temperature and the maintaining time is larger than 3 s, open-loop control is immediately conducted, in other words, the oil injection amount is reduced to thepreset value till the T3 is smaller than the closed-loop control target temperature, and the maintaining time is larger than 3 s.

Owner:SAIC MOTOR

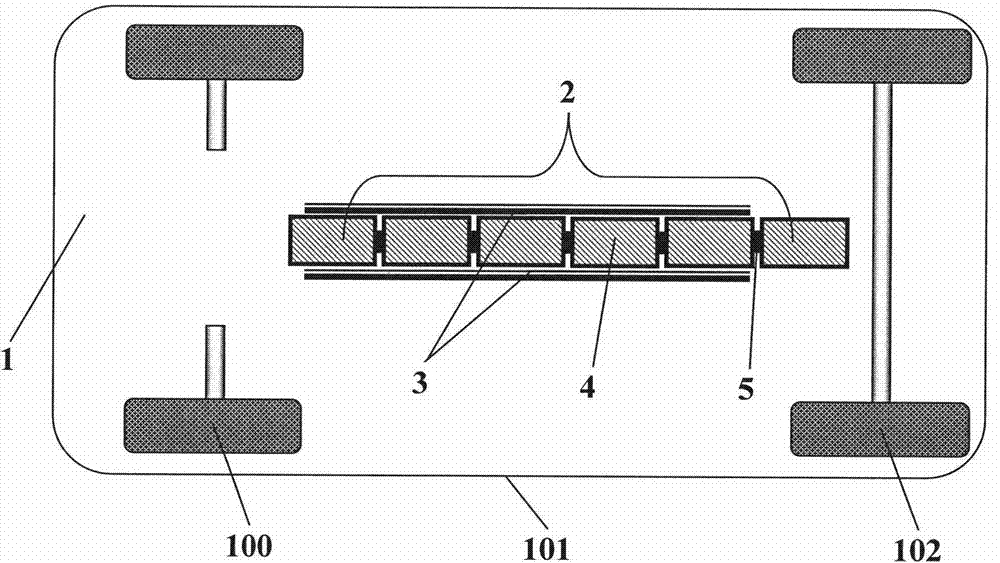

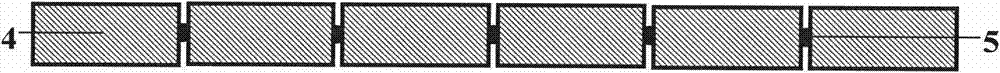

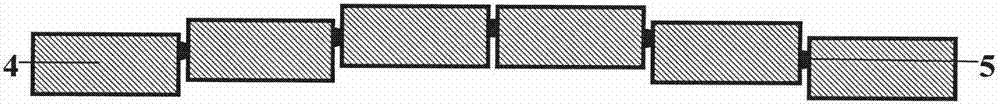

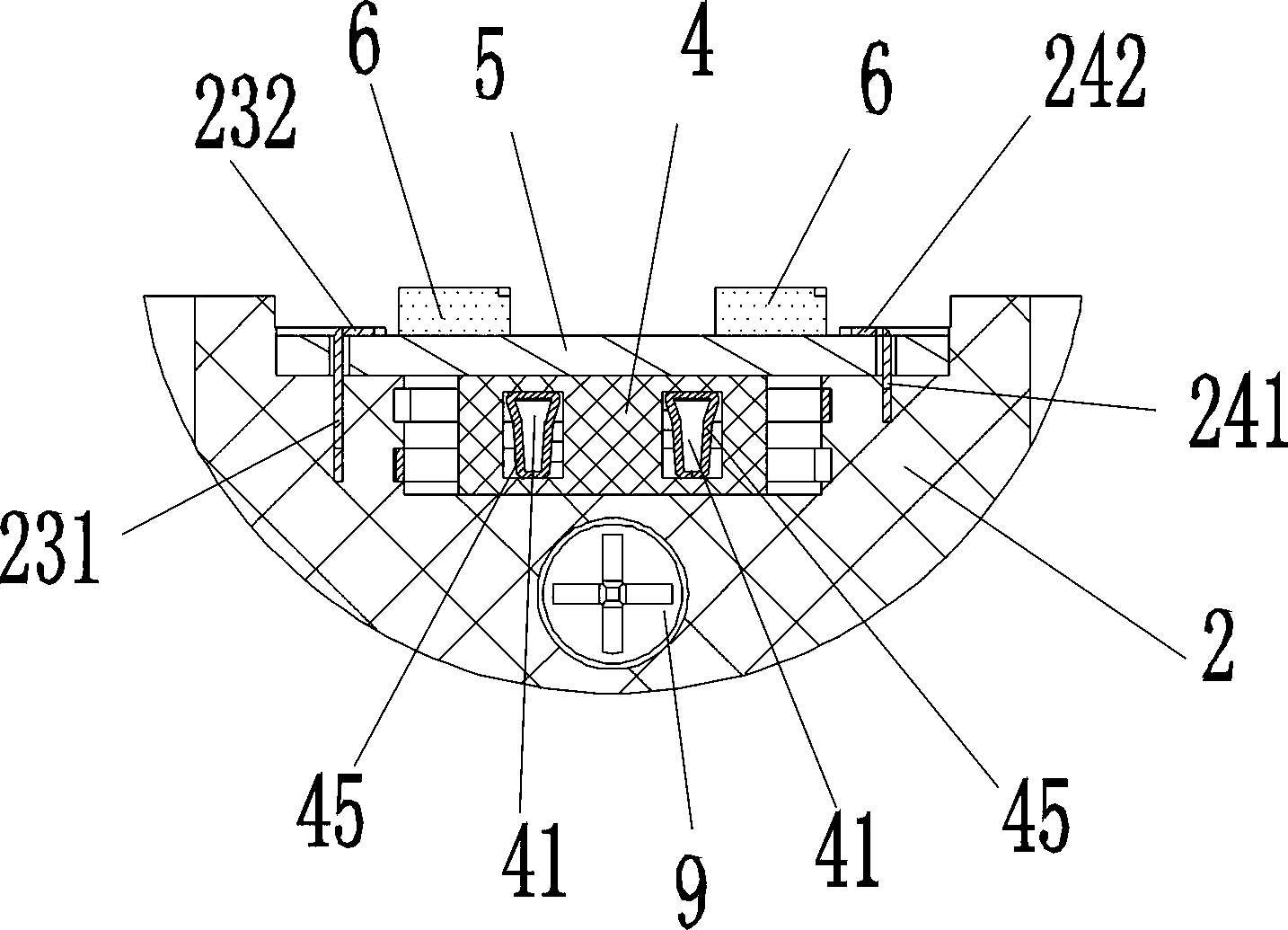

Electric vehicle arranging structure

InactiveCN103895484AReduce loadLight steeringElectric propulsion mountingVehicle sub-unit featuresDisplay deviceRoad surface

The invention belongs to the field of electric vehicle arranging, and provides an electric vehicle arranging structure which ingeniously solves the problems that battery arranging is hard, temperature is not even, the battery can easily catch a fire when being collided, the whole vehicle is not reasonable in arrangement, and cost is high. A battery pack (2) is arranged in a center channel (3) in the front-back longitudinal direction of a whole vehicle (1), movable joints (5) are arranged between battery pack bodies (4), and a gear switch (6), a hand brake (7), an emergency stop switch (8) and a balancing, temperature-controlling and liquid level display device of the battery pack (2) are arranged on the center channel (3). The two ends of the battery pack (2) are respectively provided with an electric control part (19), a direct-current convertor (20) and a mechanical buffer (21). The electric vehicle arranging structure is used for electric sightseeing vehicle, scooters, cars and the like, the whole vehicle is compact in arrangement, and a large space is saved; the axle load ratio can be easily adjusted; battery temperatures are consistent, and batteries are more safe when being collided; cost of the vehicle body and wiring harnesses is lowered; starting driving force is strong, and steering is flexible; electric energy can be saved when the vehicle passes through an uneven road face; the electric vehicle arranging structure is scientific, convenient to operate and more attractive.

Owner:崔玲

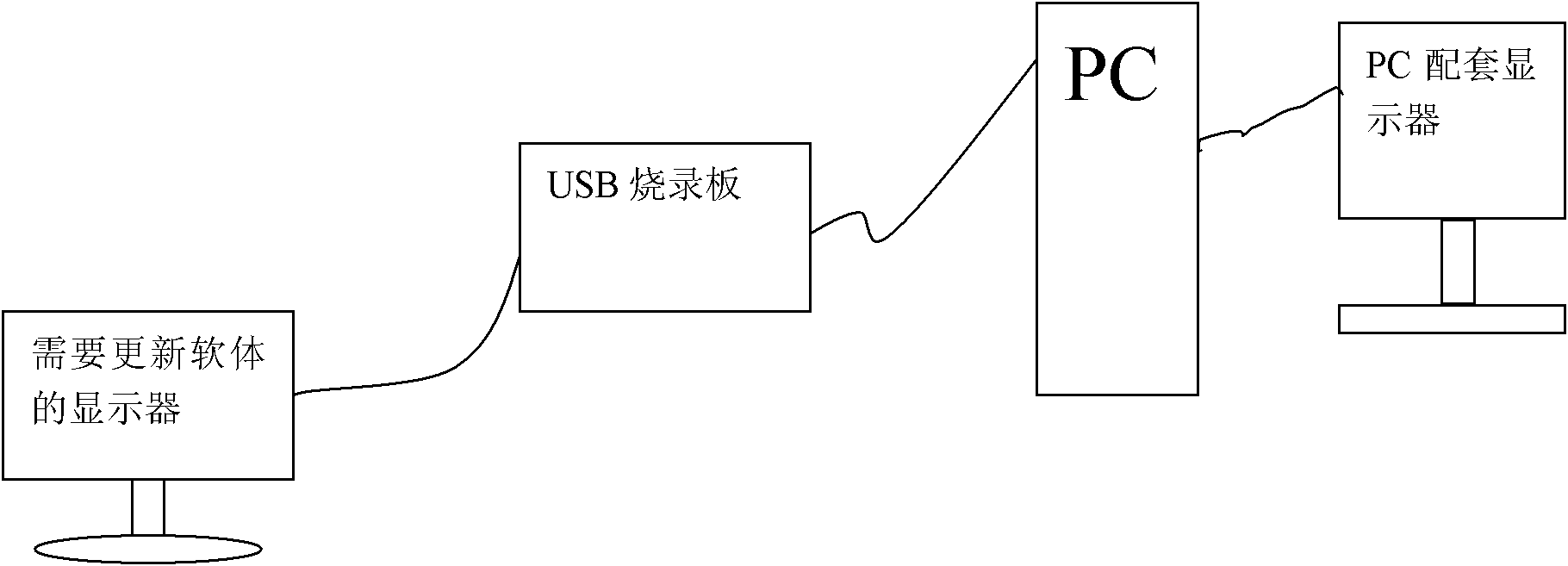

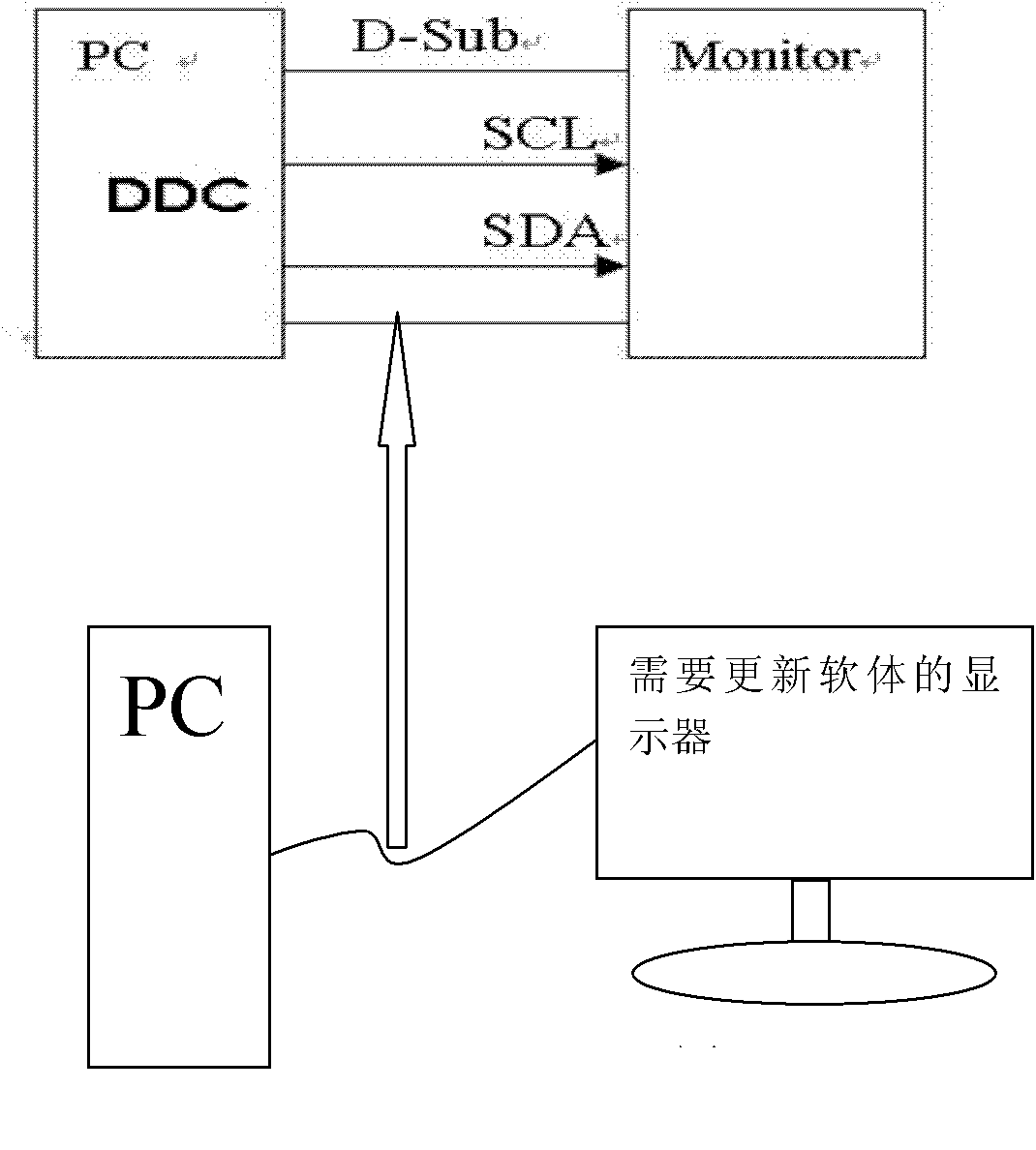

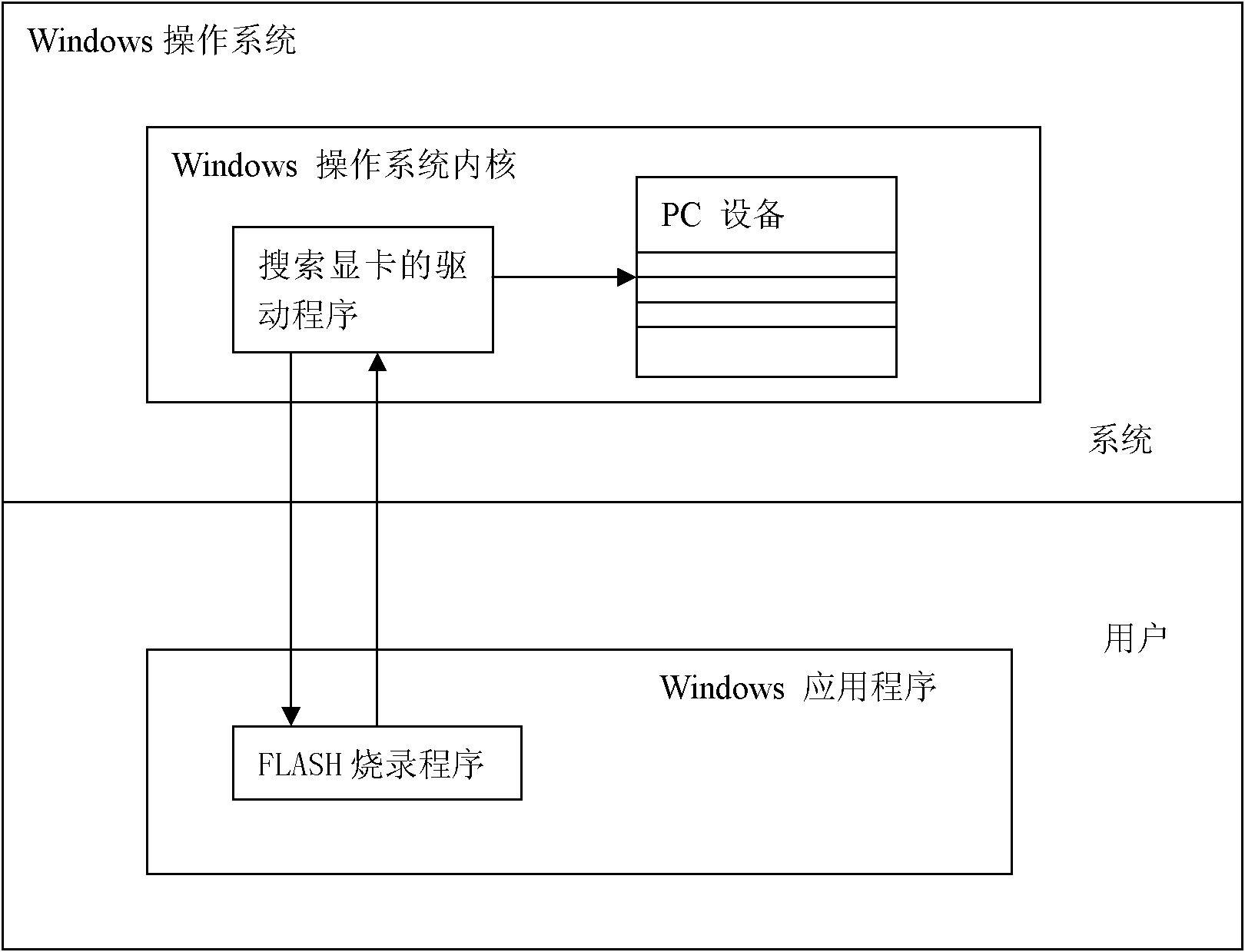

Display equipment software updating method

InactiveCN101937709AReduce after-sales maintenance costsSave the cost of bad maintenance in the marketRead-only memoriesProgram loading/initiatingLiquid-crystal displayRepair time

The invention relates to the field of display equipment, in particular to liquid crystal display manufacture and after-sales repair and a display equipment software updating method. Software data is sent to an FLASH of display equipment to update software by using an in-built display card of a terminal user PC (Personal Computer) as burning equipment and using an DDC (Digital Display Channel) port of the display card through an I2C (Inter-Integrated Circuit) protocol. Compared with the prior art, the invention has the advantages that since the in-built display card of the terminal user PC can be used as the burning equipment, a professional after-sales personnel does not need for home repair or an end user for sent repair, and the end user does not need to have professional equipment and professional knowledge. A large number of after-sales repair cost can be saved, and the goals of saving the repair time and saving repair cost of bad products in the market are achieved.

Owner:TPV DISPLAY TECH WUHAN

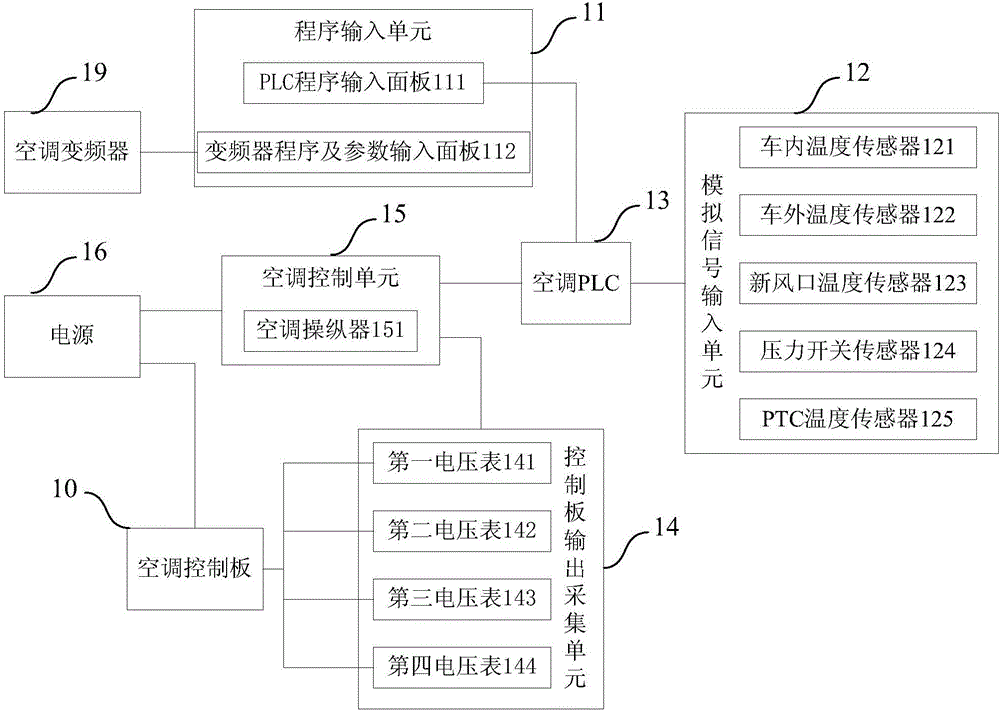

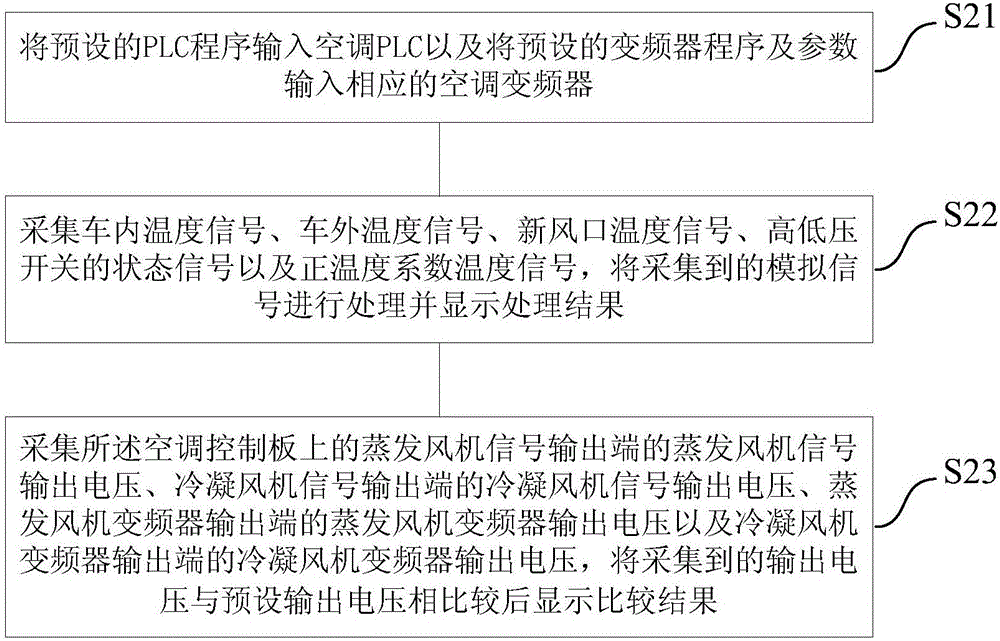

Testing device and testing method of air conditioner control panel for electric vehicle

InactiveCN106094806ASimple structureEasy to assembleElectric testing/monitoringFunctional testingWorking environment

The invention discloses a testing device and a testing method of an air conditioner control panel for an electric vehicle. The testing device comprises a program input unit, an analog signal input unit, an air conditioner PLC, a control panel output acquisition unit and an air conditioner control unit. According to the testing device of the air conditioner control panel for the electric vehicle, an existing testing facility is improved; and each output of the air conditioner control panel is monitored through simulating an electric vehicle air conditioner working environment and controlling of a controller, thereby testing the air conditioner control panel and realizing function testing on the air conditioner control panel for the electric vehicle. Furthermore the testing device has advantages of simple structure and easy assembling. Testing can be performed on all existing products through changing connecting wires between different assemblies according to real products, thereby realizing high flexibility. After-sale maintenance cost is indirectly reduced and product reliability is improved.

Owner:SHANGHAI KUFENG AUTO PARTS

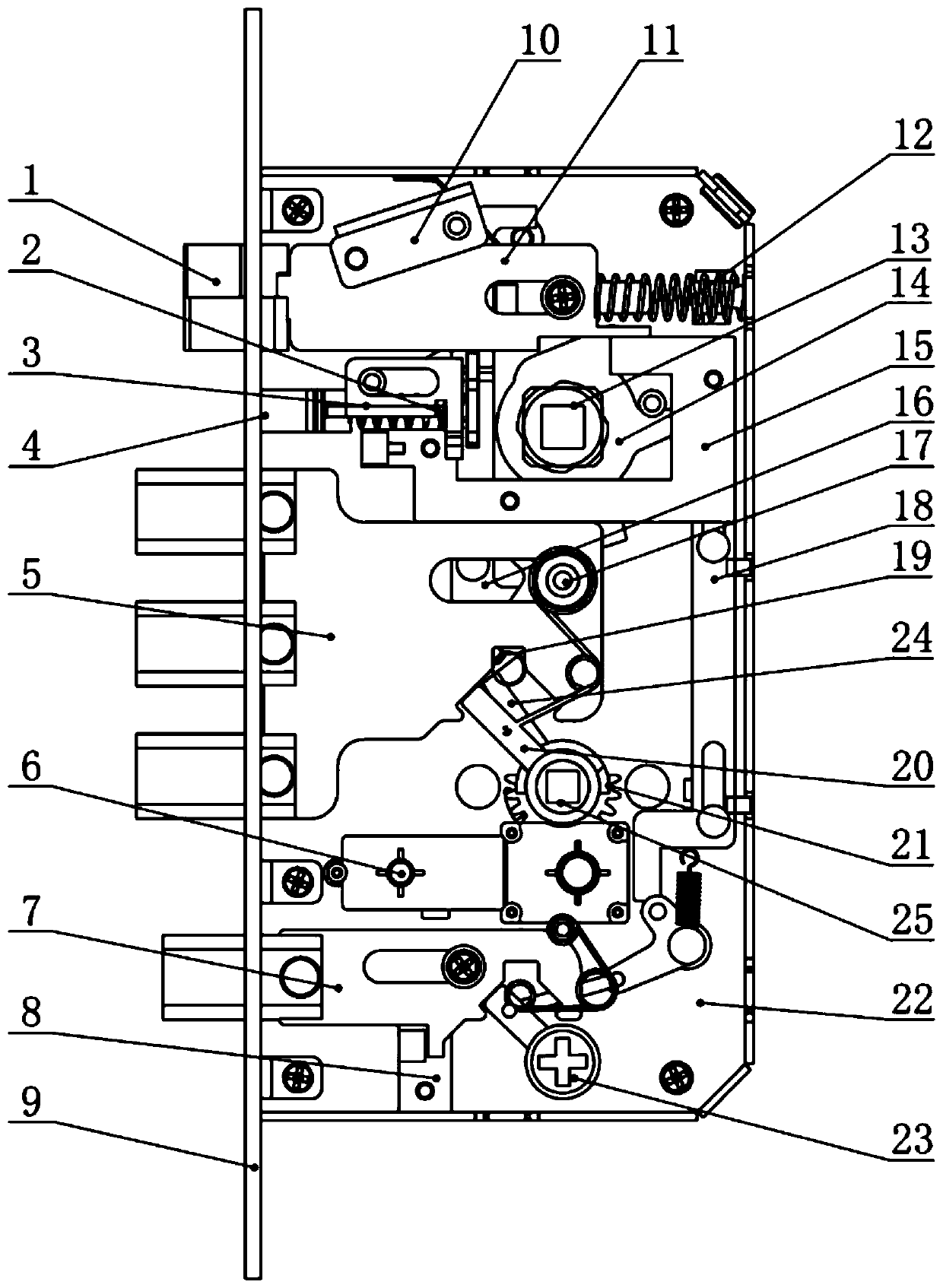

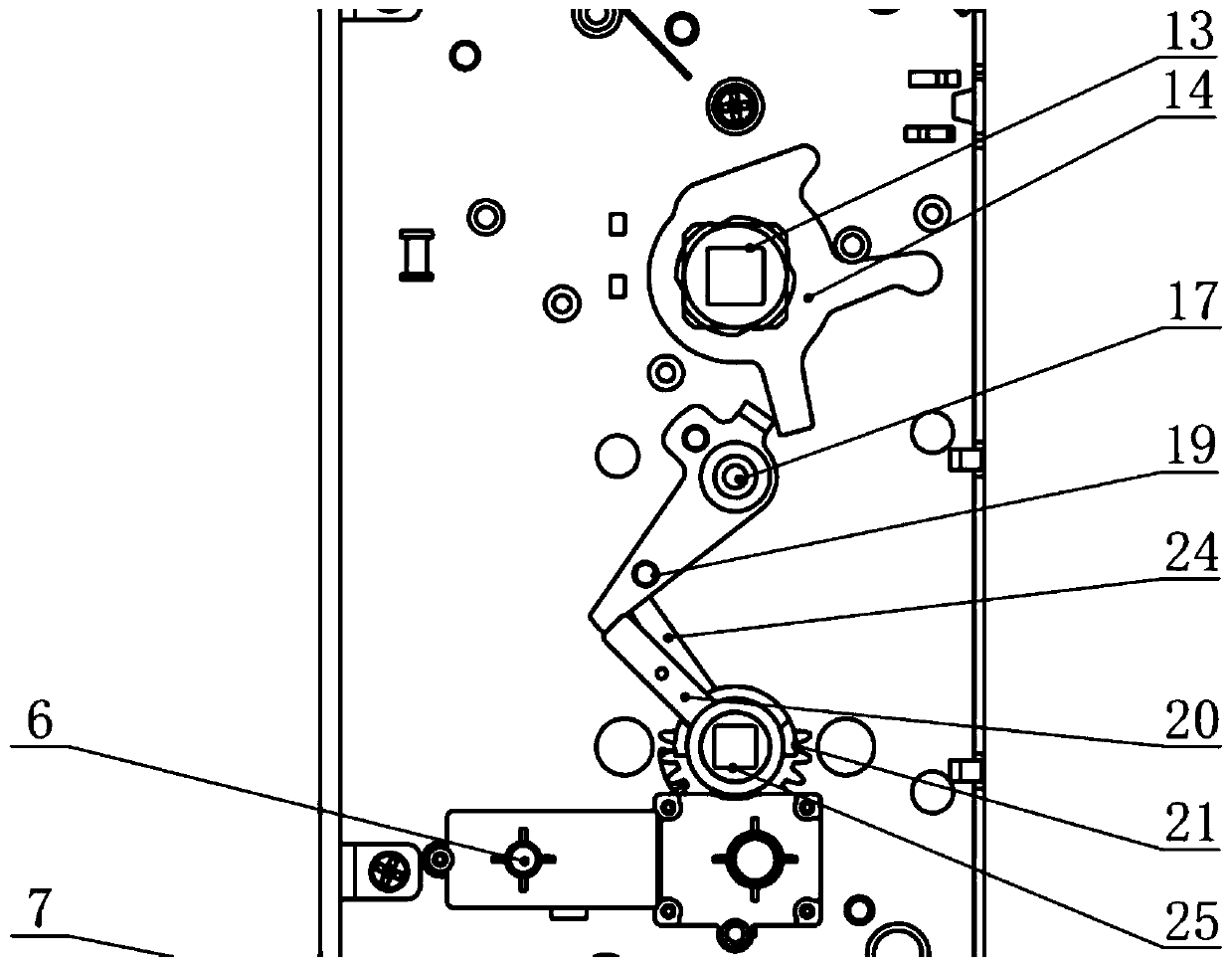

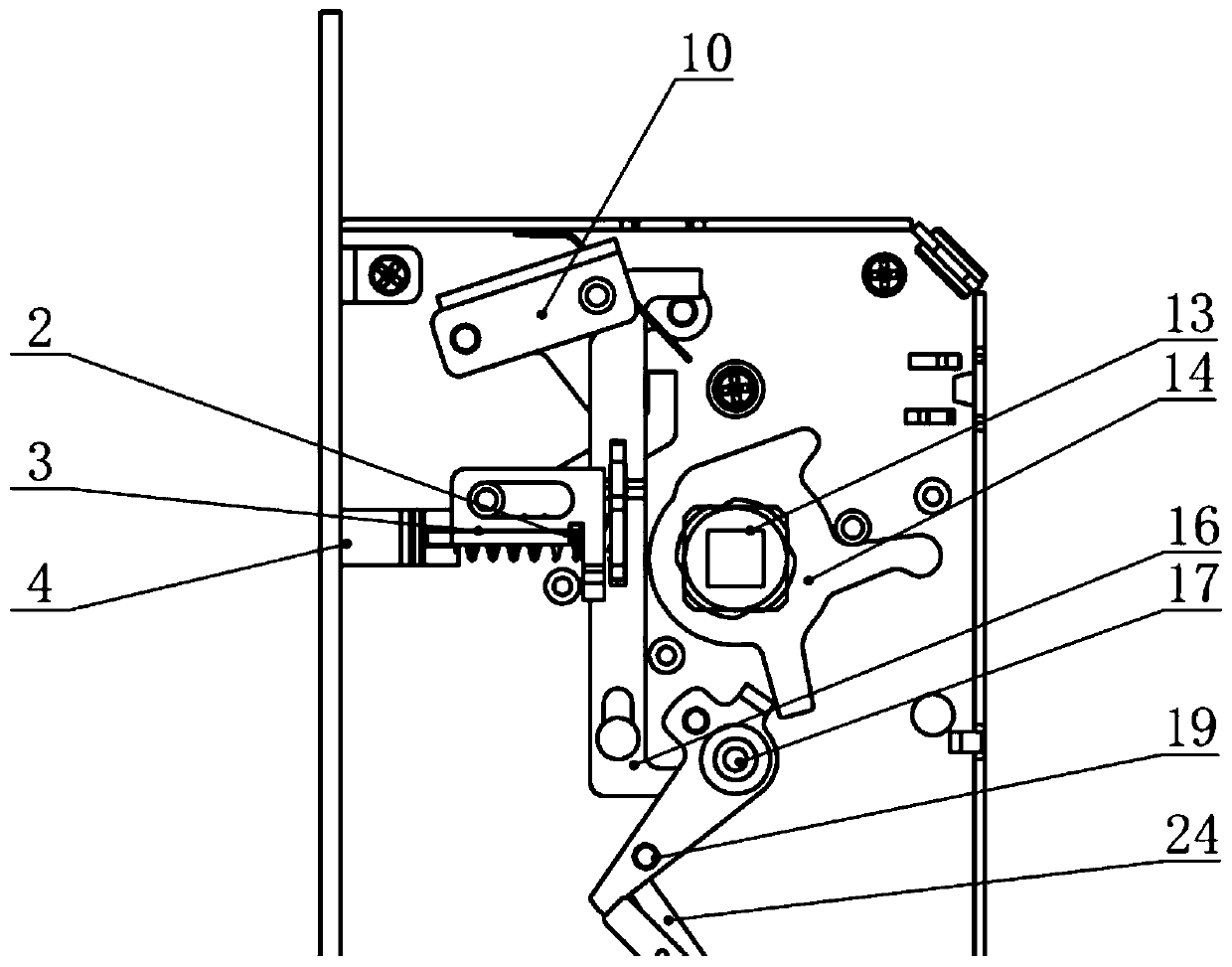

Intelligent lock

InactiveCN111364845AImprove reliabilityPrecision transmission structureNon-mechanical controlsElectric machineryEngineering

The invention provides an intelligent lock which comprises a lock shell, a spring bolt and a spring bolt driving mechanism. The spring bolt comprises a main spring bolt assembly, a touch bolt assembly and an inclined bolt assembly, the main spring bolt assembly comprises a main spring bolt, the touch bolt assembly comprises a touch bolt supporting plate, a touch bolt spring and a touch bolt, andthe touch bolt can be automatically ejected out under the action of the touch bolt spring; the spring bolt driving mechanism comprises a shifting wheel, a shifting fork, a square shaft shifting piecewhich are sequentially connected and further comprises a driving motor and a rotating handle, the main spring bolt is controlled by the shifting wheel to stretch out and draw back, and the shifting wheel can be driven by a motor, a square shaft shifting piece or a key; a safety bolt assembly can be driven to be locked through a mechanical manual knob, unlocking cannot be achieved outside a door, and locking of all the spring bolts can be mechanically relieved in one step inside the door through a handle rotating shaft; and through the combination of automatic unlocking and mechanical unlocking, automatic unlocking can be achieved through fingerprints, face recognition, cards and the like, unlocking and locking can also be achieved in the mode that the shifting wheel is driven by the key and the square shaft shifting piece is driven by the handle, the requirement of the high-performance intelligent door lock is better met, and the reliability of the lock is improved.

Owner:苏州九邦机电有限公司

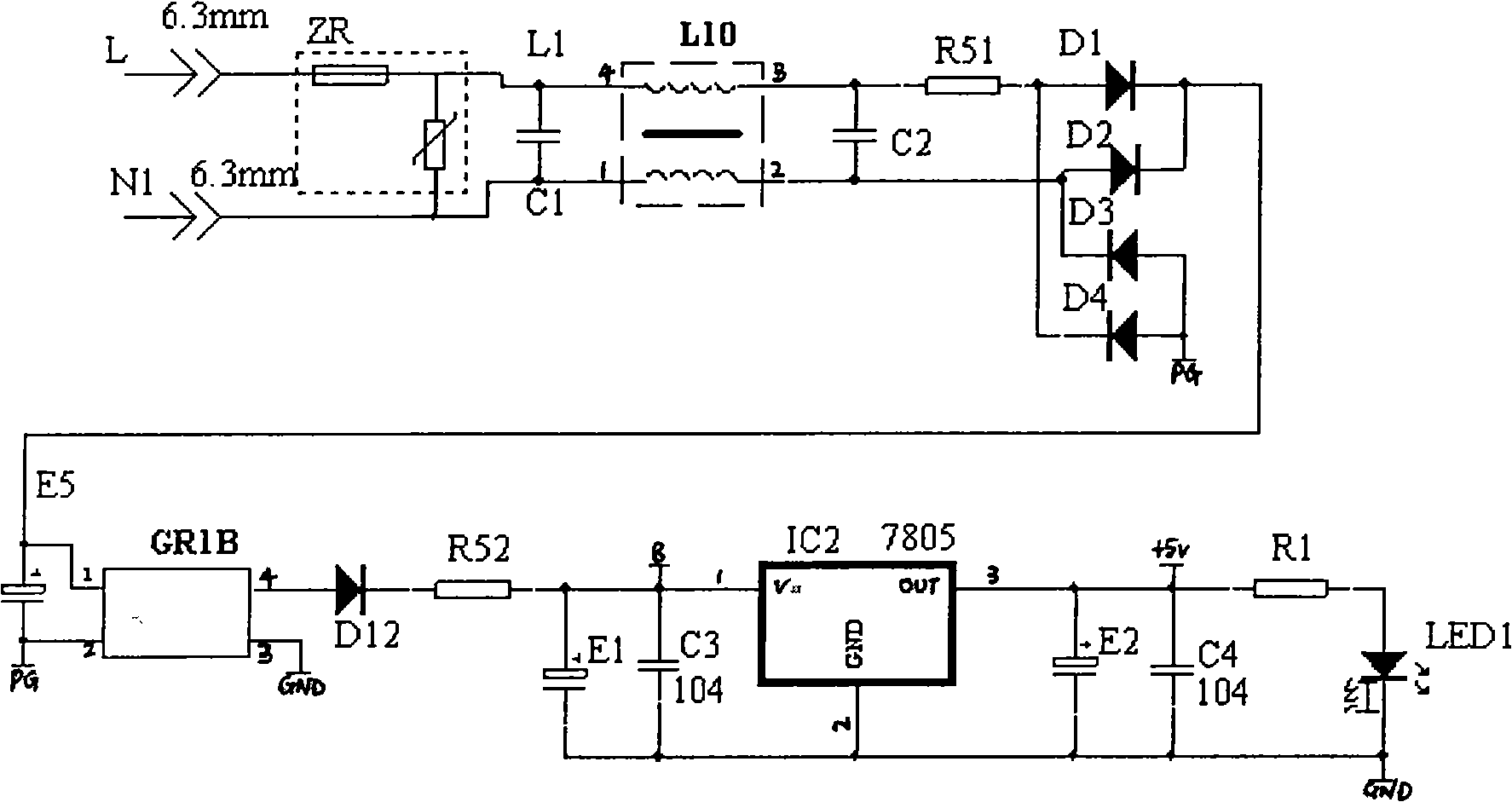

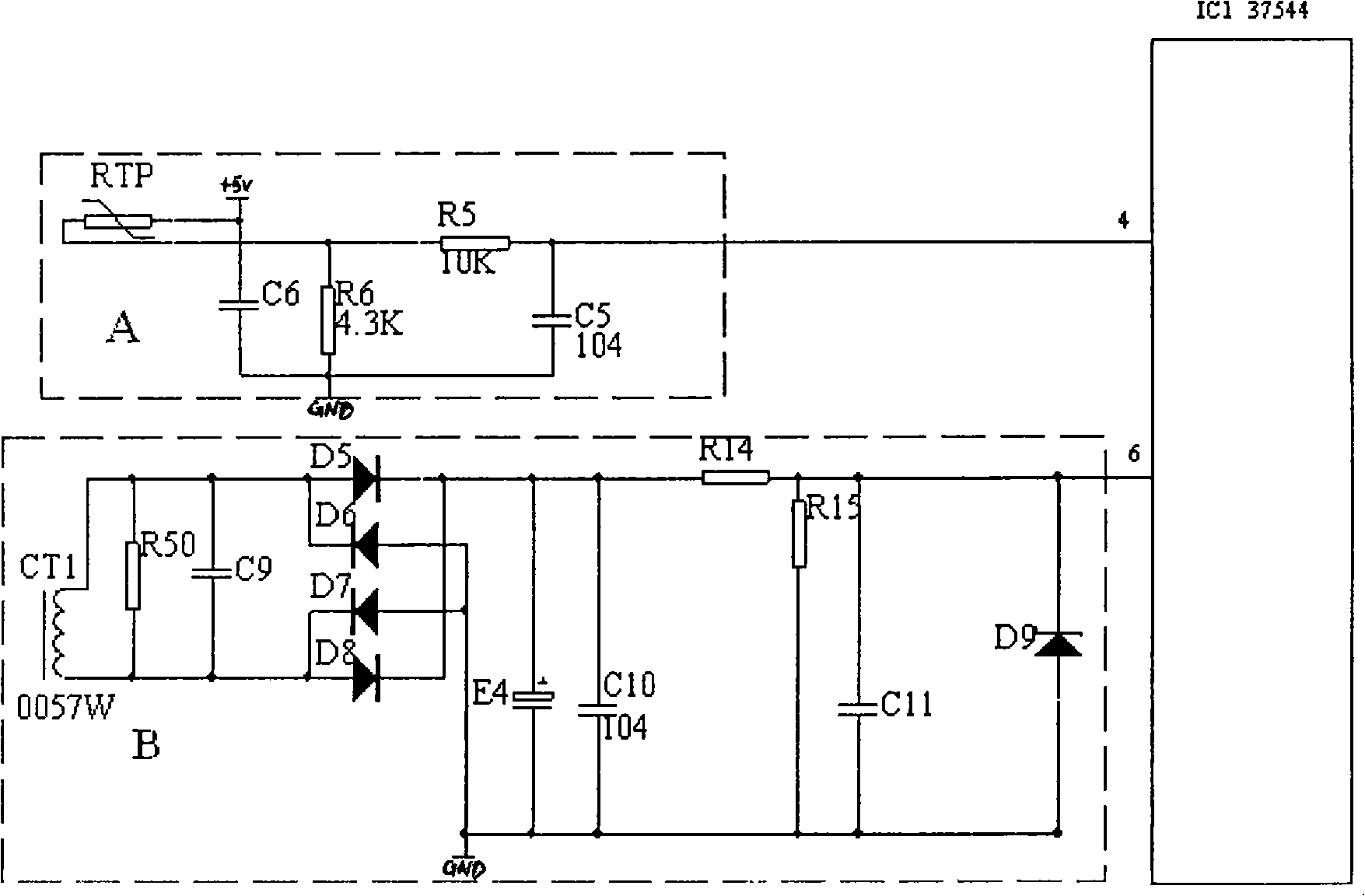

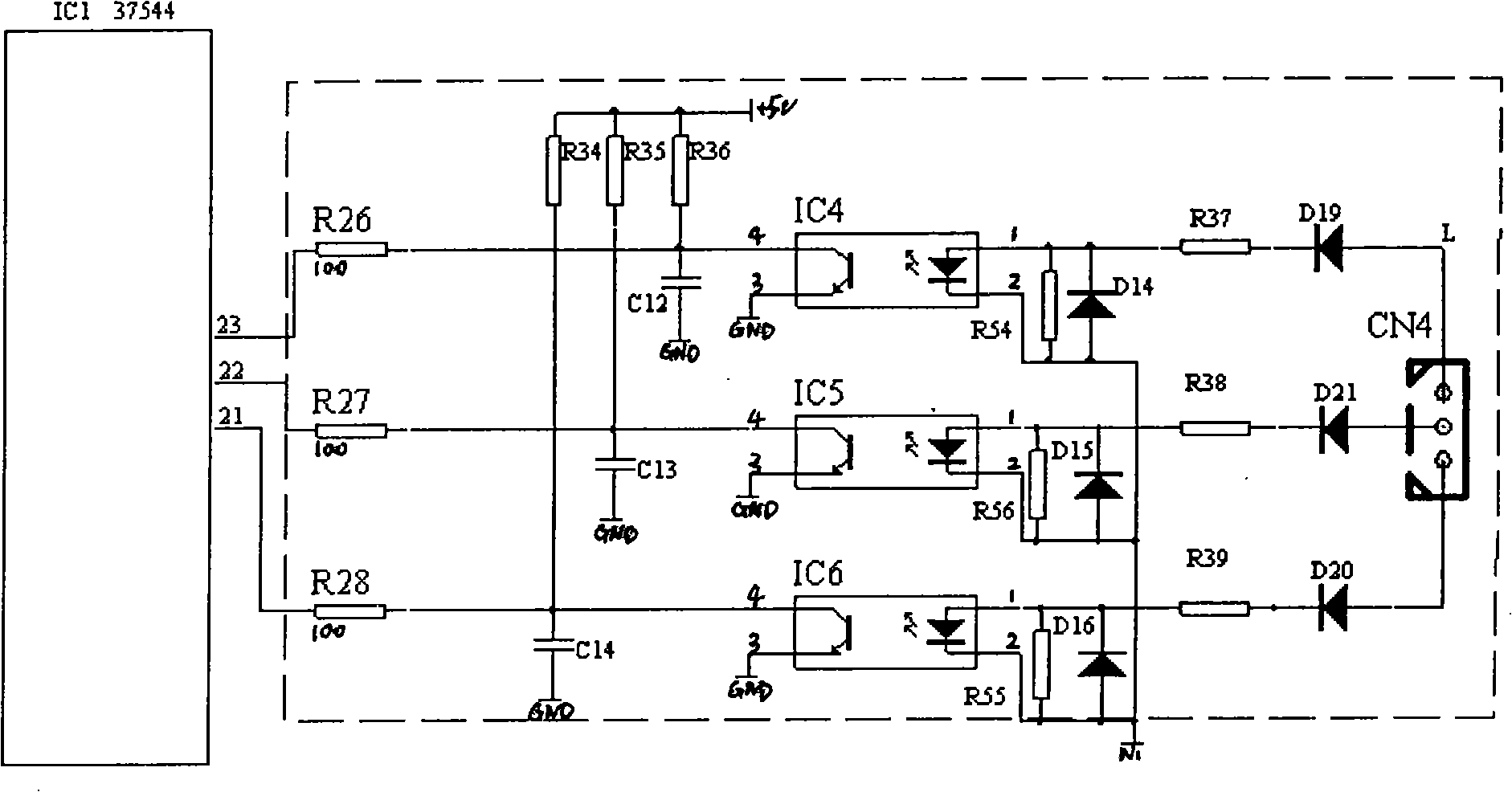

Five-in-one intelligent digital general air conditioner protector

InactiveCN101272047AImprove protectionFast fixArrangements responsive to excess currentMicrocontrollerElectrical resistance and conductance

The invention relates to a five in one intelligent digital universal air conditioner protector in particular, which includes a power circuit, a defrosting detecting circuit consisting of temperature collection and overcurrent sampling, an overcurrent protection circuit, a phase sequence detecting circuit, a communication circuit and a display debug circuit respectively connected with an SCM; the phase sequence detecting circuit includes photocouplers IC4, IC5 and IC6; three needles of a temperature sensor are respectively connected with three phases of the power; a diode D19 and a resistance R39 are connected in series with the photocoupler IC6; simultaneously the photocouplers IC4, IC5 and IC6 are respectively connected with pull-up resistances R36, R35 as well as R34 and then connected in series with the SCM ICI through pull-up resistances R26, R27 as well as R28; the invention can not only better solve the defects of a three in one board through the collection, analysis and re-control of data, but also realize the intellectualization, digitization and unification of the board; meanwhile, the maintenance cost after sales is reduced; the product quality is improved.

Owner:FOSHAN ZHONGGEWEI ELECTRONICS

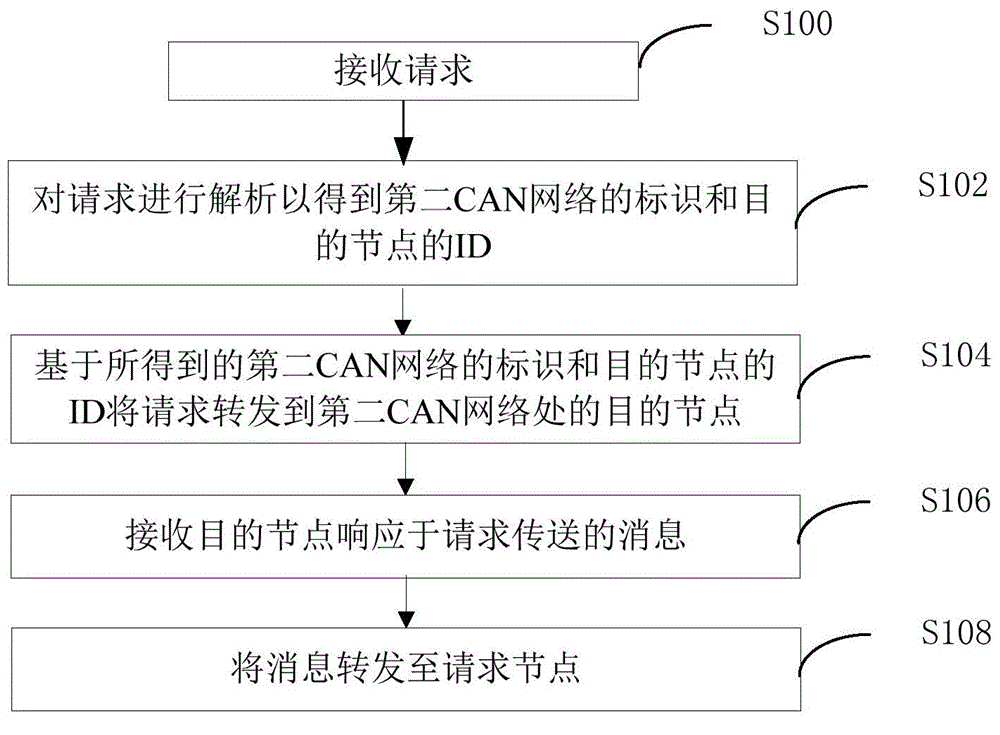

CAN bus gateway, communication method related with the CAN bus gateway, and communication system thereof

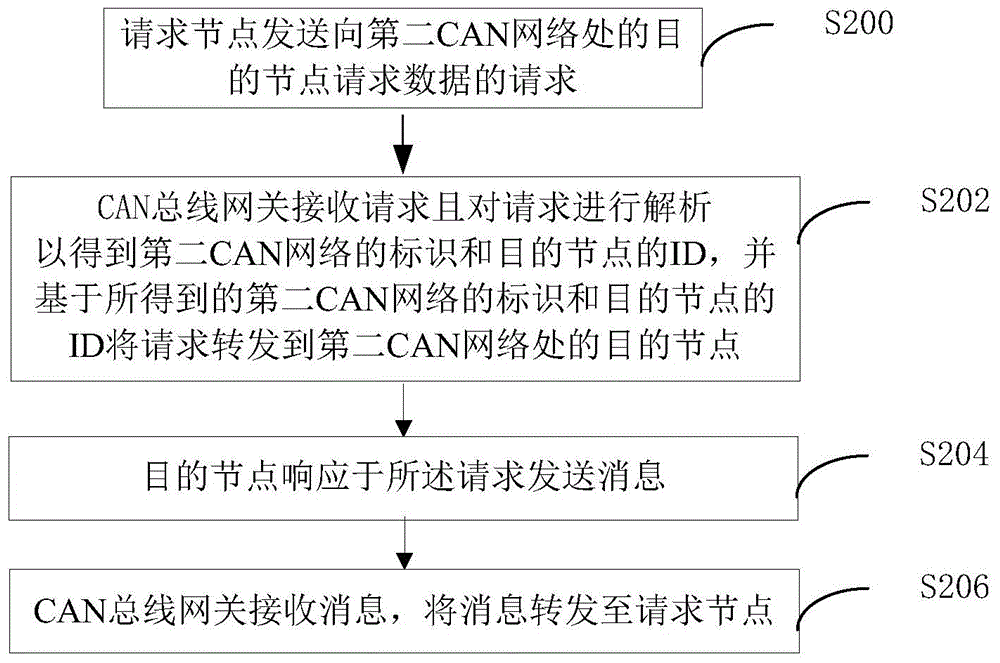

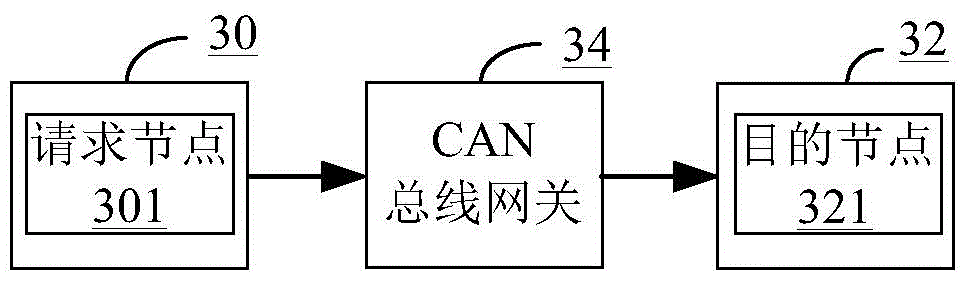

ActiveCN105376126AReduce design and development costs and product production control costsReduce after-sales maintenance costsNetwork connectionsBus networksReal-time computingCAN bus

The invention discloses a controller area network (CAN) bus gateway, a communication method related with the CAN bus gateway, and a communication system thereof, wherein the communication method applied in the CAN bus gateway comprises the steps of receiving a request which comes from a requesting node of a first CAN network and is used for requesting data from a target node in a second CAN network, wherein the request comprises the identification of the second CAN network and the ID of the target node; analyzing the request for obtaining the identification of the second CAN network and the ID of the target node; and forwarding the request to the target node in the second CAN network based on the obtained identification of the second CAN network and the ID of the target node. Through applying the CAN bus gateway, the communication method and the communication system in a vehicle, even when a certain module in the module requires acquisition for related information of other networks because of a function adding requirement, and variation or modification of the gateway is not required. Furthermore intelligent information forwarding is realized.

Owner:BYD CO LTD

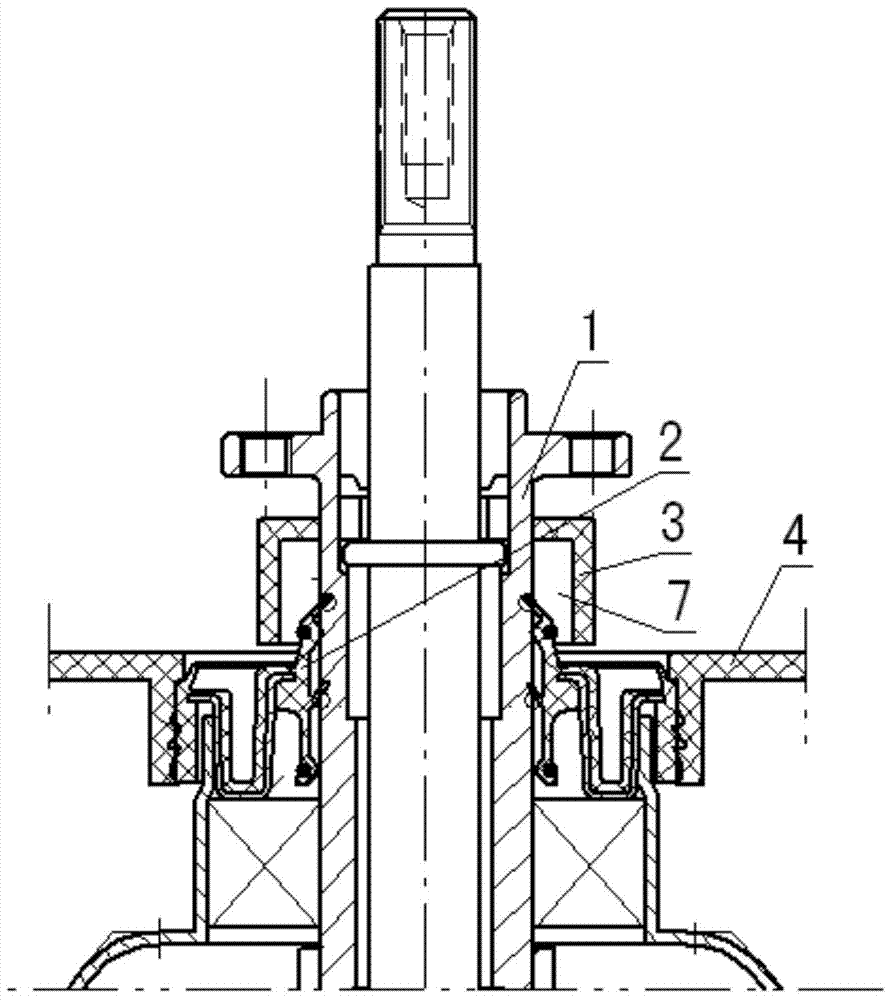

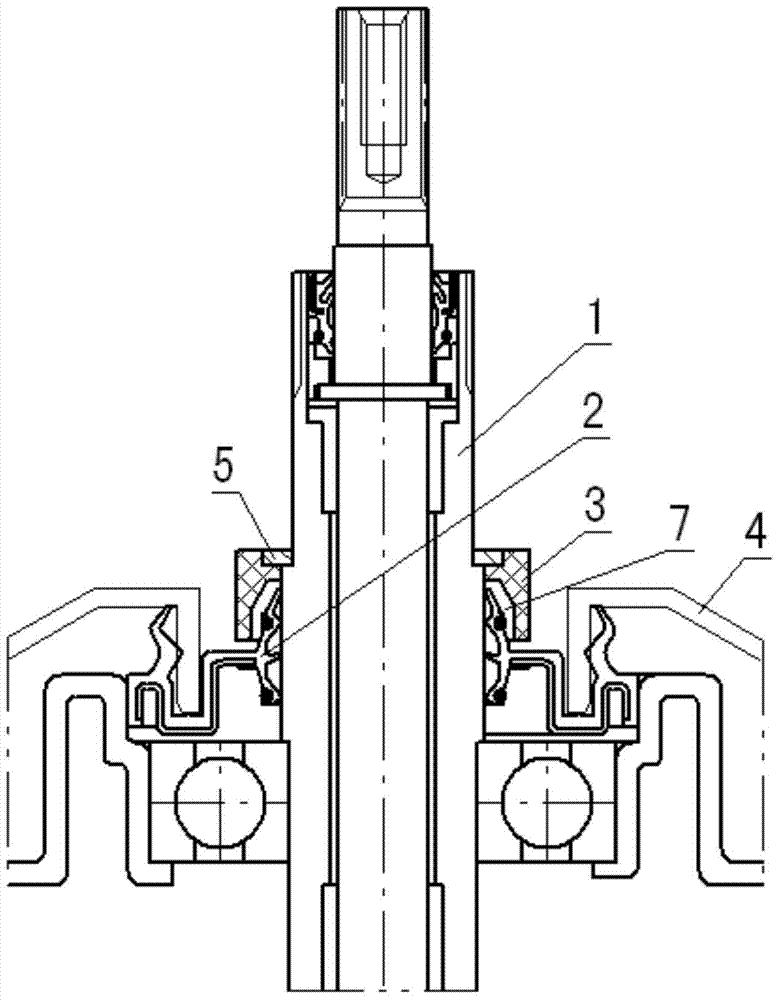

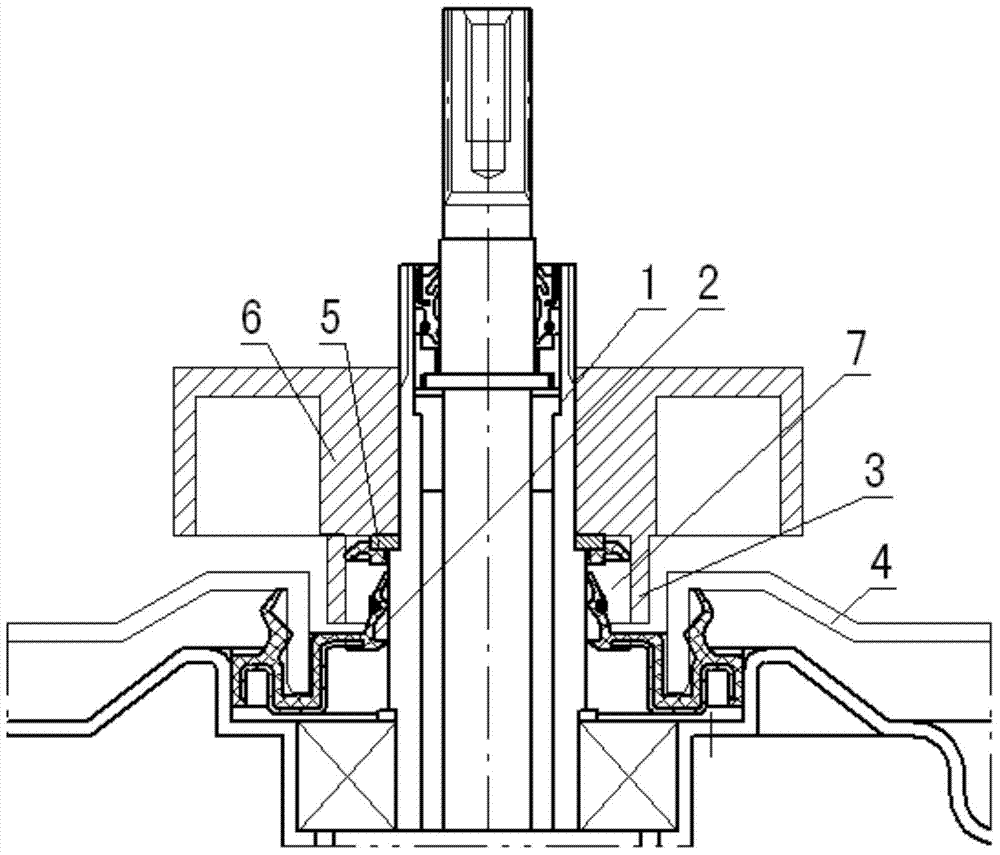

Washing machine deceleration clutch anti-seepage device and washing machine thereof

InactiveCN104746302AExtend your lifeAvoid enteringOther washing machinesTextiles and paperPulp and paper industryAir cavity

The invention relates to a washing machine deceleration clutch anti-seepage device and a washing machine thereof and relates to the technical field of washing machines. The anti-seepage device overcomes the shortcoming that a lip fails due to the fact that silt enters a water seal inner clip and a dewatering shaft of a deceleration clutch of the washing machine. The device comprises the dewatering shaft and a large water seal connected with the dewatering shaft through a soft lip opening, and an outer clip of the large water seal is connected with an outer barrel. The device is characterized by further comprising an anti-seepage part, and an air cavity with one end open is formed between the anti-seepage part and the large water seal. By means of the technical scheme, the air cavity with one end open is formed between the anti-seepage part and the large water seal by arranging the anti-seepage part, a sealing cavity is formed during working of the washing machine, water or silt is effectively prevented from entering the inner lip opening of the water seal, and the whole service life of the deceleration clutch of the washing machine and the washing machine are prolonged. The probability that the washing machine fails due to the fact that the large water seal of the clutch has water seepage is effectively reduced, after-sales maintenance cost is greatly reduced, resources are saved, and the design concept of the water seal is greatly enriched.

Owner:ANHUI JULONG TRANSMISSION TECH

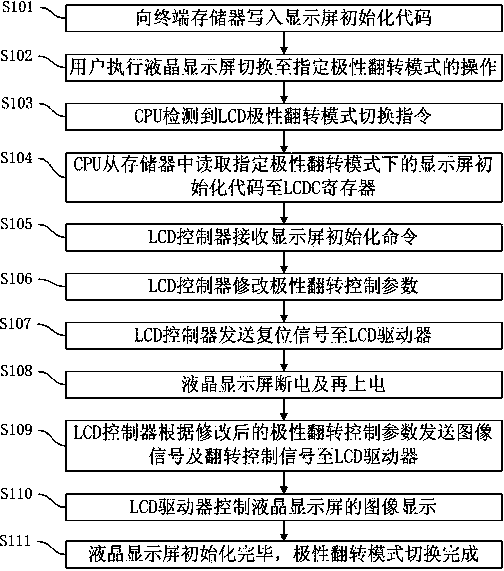

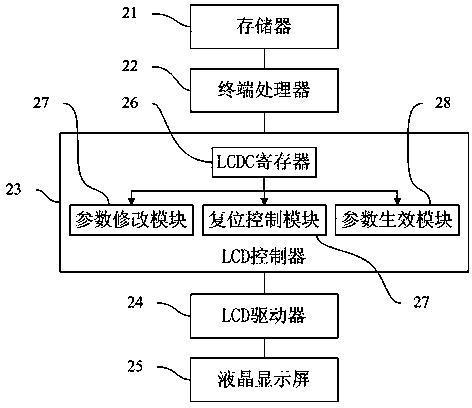

LCD (Liquid Crystal Display) polarity-overturn control method and display terminal

InactiveCN103354084AQuick and effective maintenance effectImprove experienceStatic indicating devicesElectrical polarityComputer terminal

The invention relates to an LCD polarity-overturn control method and an LCD display terminal. The method comprises the steps that 1) setup codes of a display screen respectively corresponding to different polarity overturn modes, including a frame overturn mode, a row overturn mode, a column overturn mode and a point overturn mode, are written in a memory of the LCD display terminal; a terminal processor detects a polarity-overturn mode switching instruction, and reads the setup code of the display screen in the instructed polarity mode into an LCDC (Liquid Crystal Display Controller) register; and according to the setup code of the display screen, an LCDC sends resetting signals to an LCD driver, and implements initialization of the display screen in the instructed polarity overturn mode. When the current overturn mode of the display screen causes failure of the display screen, another liquid-crystal molecule overturn mode can be directly turned to, thereby avoiding heavy load caused by replacement of control software, improving user experience, and decreasing maintenance cost of a manufacturer.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

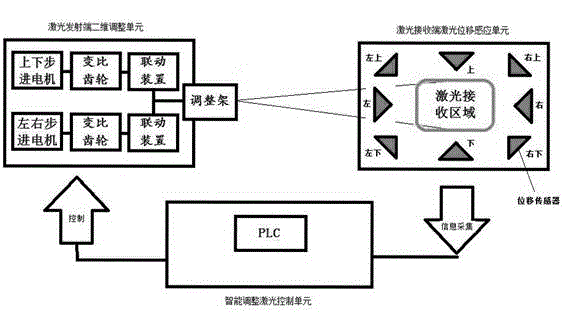

Automatic laser seeking calibration device

InactiveCN105334550AEnsure continuityReduce after-sales maintenance costsOptical detectionLoop controlClosed loop

The invention relates to an automatic laser seeking calibration device for a laser intrusion detector, which is composed of a laser transmitting end two-dimensional adjustment unit, an intelligent adjustment laser control unit and a laser receiving end laser displacement sensing unit, wherein the laser receiving end laser displacement sensing unit receives a laser irradiation position signal, the signal is transmitted to the intelligent adjustment laser control unit, data analysis is carried out by a PLC in the control unit, a stepper motor in the laser transmitting end two-dimensional adjustment unit is controlled to adjust the laser irradiation position in real time, laser calibration closed-loop control is realized, and the purpose of automatic laser seeking calibration is achieved. The automatic laser seeking calibration device has the advantages that the problem that laser can not be received due to micro deformation generated as a bearing body is subjected to external factors for a long time is solved, continuity of security work can be ensured, and after-sales maintenance fee after the project is finished is saved.

Owner:TENGZHOU FEITIAN LASER AUTOMATION TECH

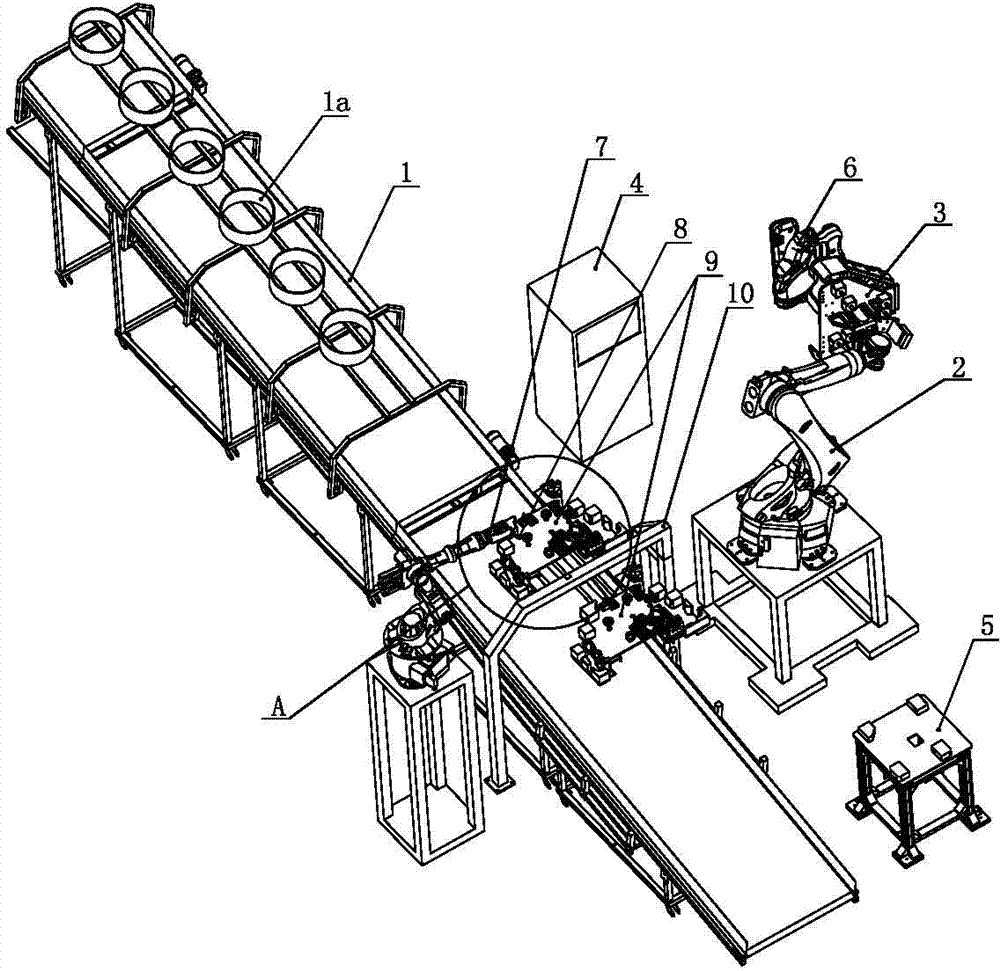

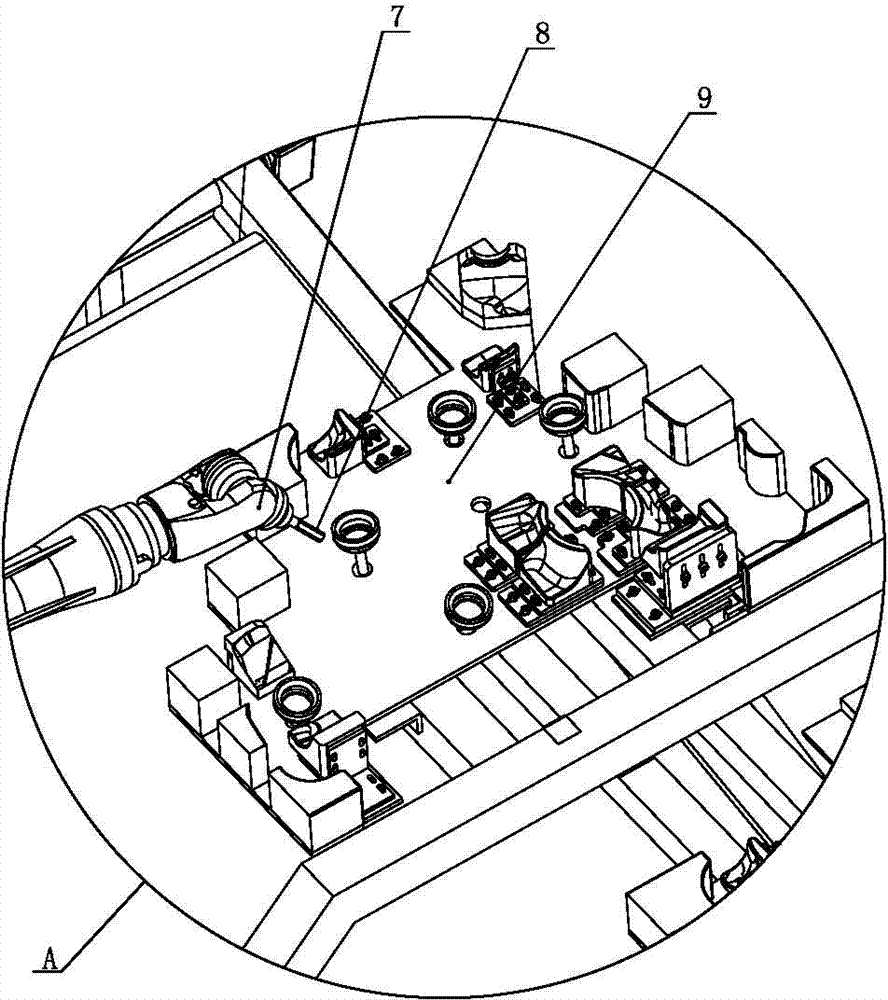

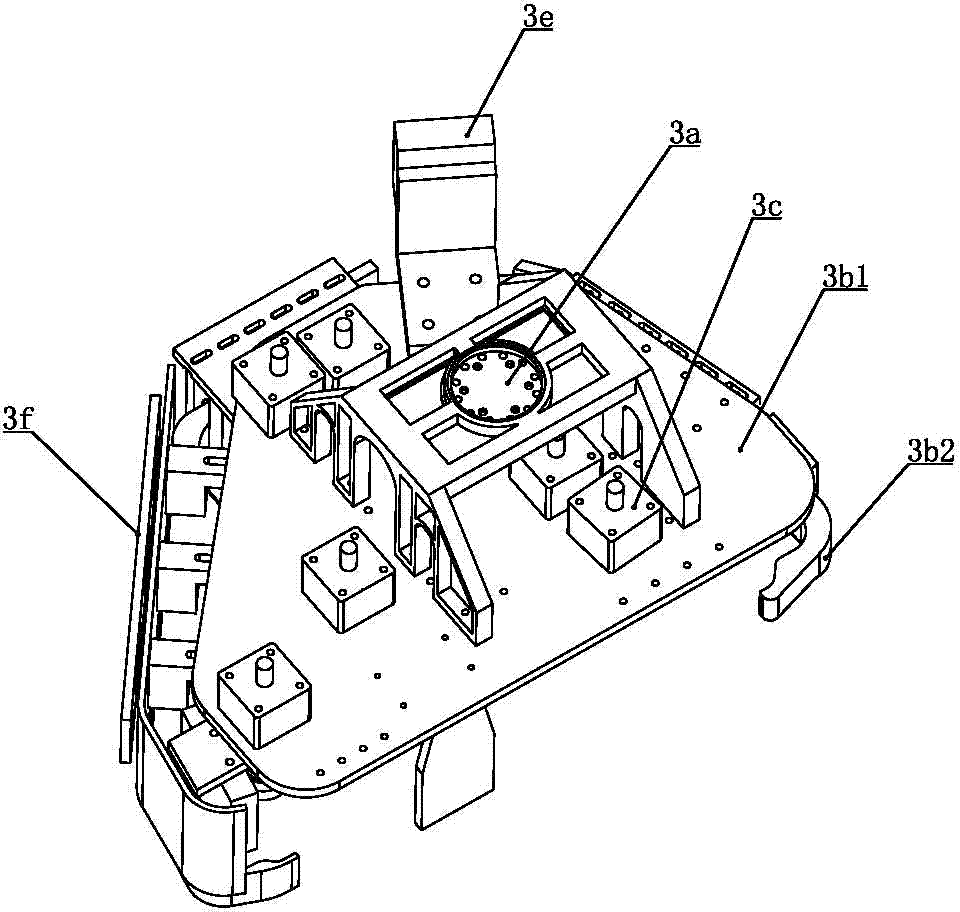

Trimming mechanism of plastic oil tank and method of trimming oil tank

The invention relates to a trimming mechanism of a plastic oil tank and a method of trimming the oil tank. The trimming mechanism comprises a big robot, a barcode printer, a weighing table and a trimming conveying line, wherein the big robot, the barcode printer and the weighing table are all located at the right side of the trimming conveying line, an oil tank grasping mechanism capable of grasping the plastic oil tank is arranged on the end of a mechanical arm of the big robot, the barcode printer and the weighing table are respectively arranged in a working travel range of the mechanical arm of the big robot, a small robot is arranged on a position, which is opposite to the big robot, at the left side of the trimming conveying line, a trimming knife capable of cutting trimmings of joint lines of the plastic oil tank is arranged on the end of a mechanical arm of the small robot, two trimming tables with the consistent shape and size are arranged between the big robot and the small robot in parallel, and the two trimming table are both fixed above the trimming conveying line. When one plastic oil tank is trimmed by the small robot, waiting, grasping, barcode pasting and weighing of another plastic oil tank can be completed by the big robot, and the trimming speed is quick, so that the production period is shortened, and the production efficiency is improved.

Owner:YAPP AUTOMOTIVE PARTS

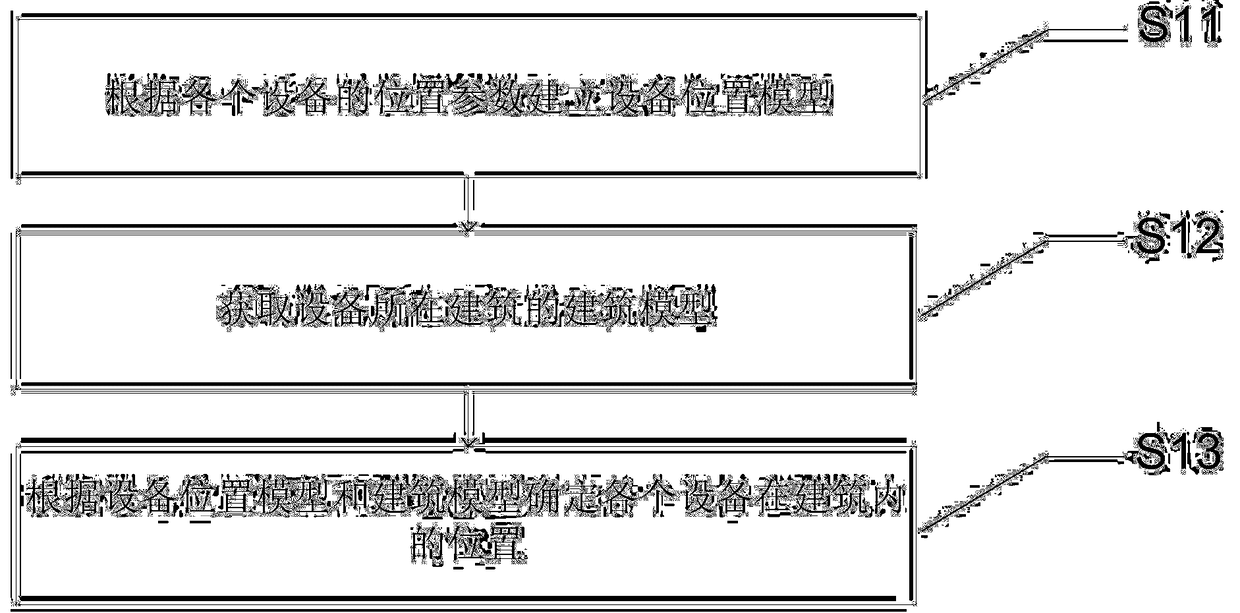

Method and system for determining positions of devices in building, and air conditioner

PendingCN109341681AImprove stabilityEfficient automatic configurationNavigation by terrestrial meansBuilding model

The invention provides a method and a system for determining the positions of devices in a building, and an air conditioner. The method comprises the following steps of: establishing a device positionmodel according to the position parameters of each device; obtaining a building model of the building where the devices are located; and determining the position of each device in the building according to the device position model and the building model. The method and the system can be used to efficiently and accurately perform automatic configuration on the corresponding relation between eachdevice and each position, thereby eliminating errors caused by manual transcription.

Owner:GREE ELECTRIC APPLIANCES INC

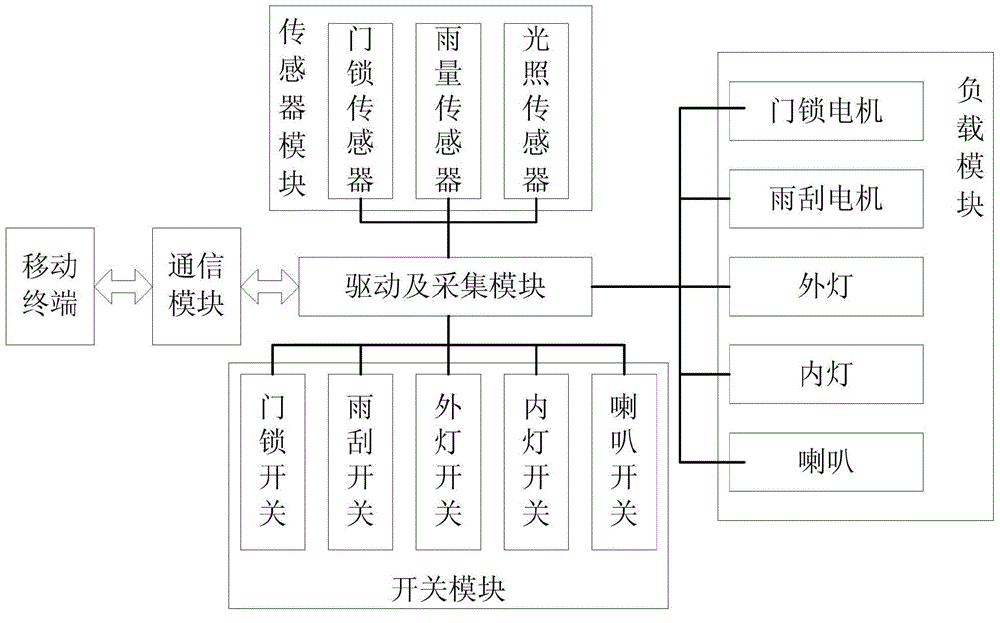

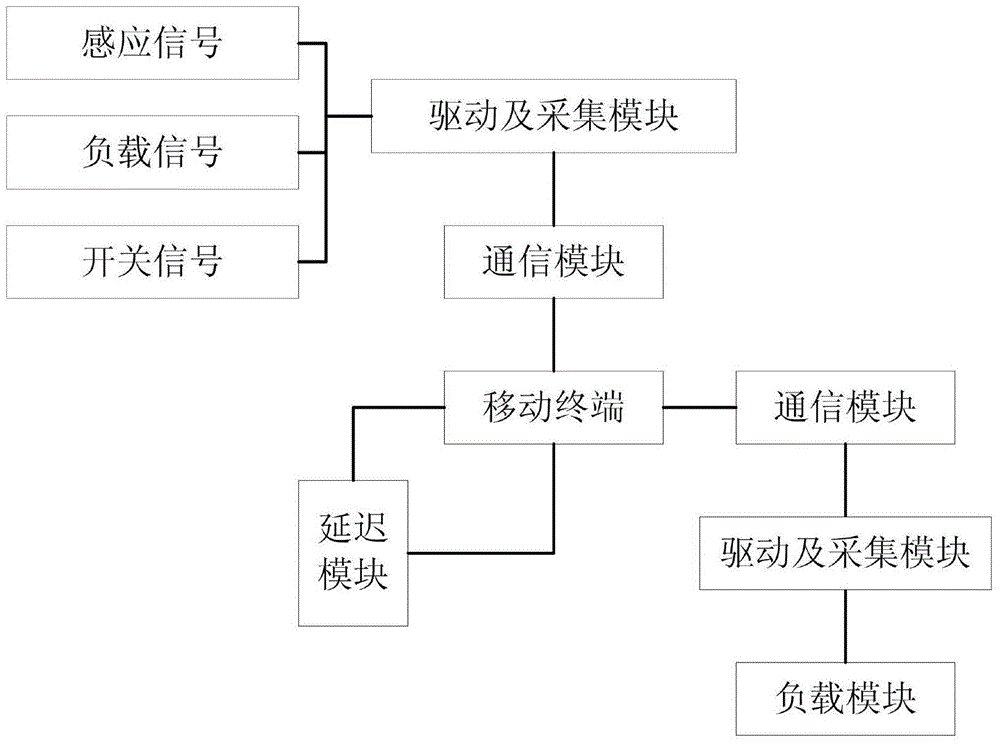

Intelligent automobile body control system

InactiveCN104925004ALow costReduce maintenance costsElectric/fluid circuitControl systemControl signal

The invention relates to an automobile body control system, in particular to an intelligent automobile body control system. The intelligent automobile body control system comprises a switching module, a load module, a driving and collecting module, a communication module and a mobile terminal, wherein the switching module is used for generating a switching signal; the driving and collecting module is used for collecting the switching signal and sending the switching signal to the mobile terminal through the communication module; the mobile terminal is used for processing the received switching signal so as to generate a control signal and sending the control signal to the driving and collecting module through the communication module; then, the driving and collecting module controls the load module according to the received control signal. The intelligent automobile body control system can better save hardware cost and reduce the cost for later maintenance.

Owner:HANGZHOU YUELE VEHICLE TECH CO LTD

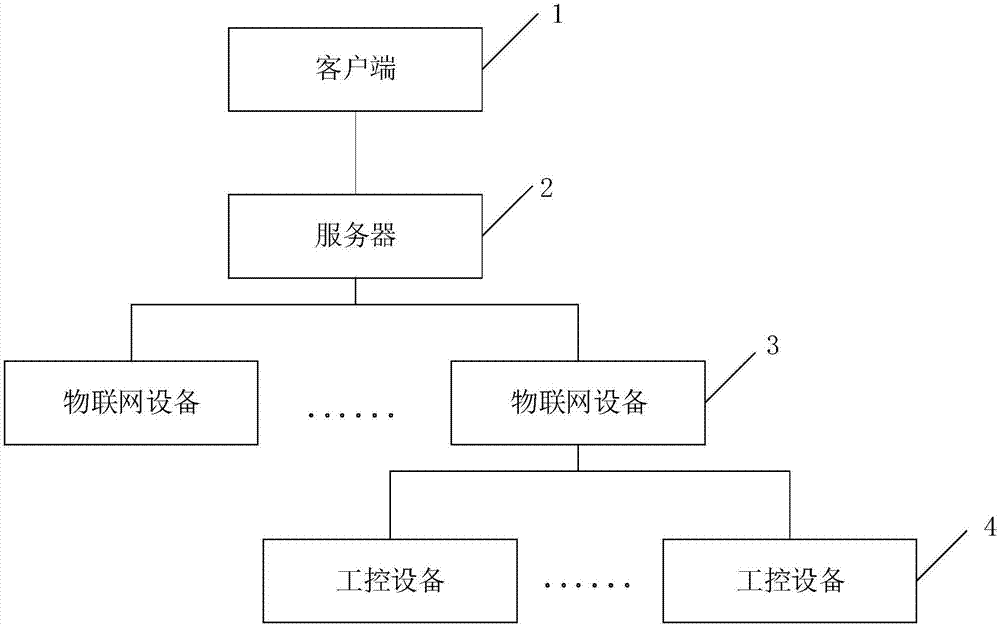

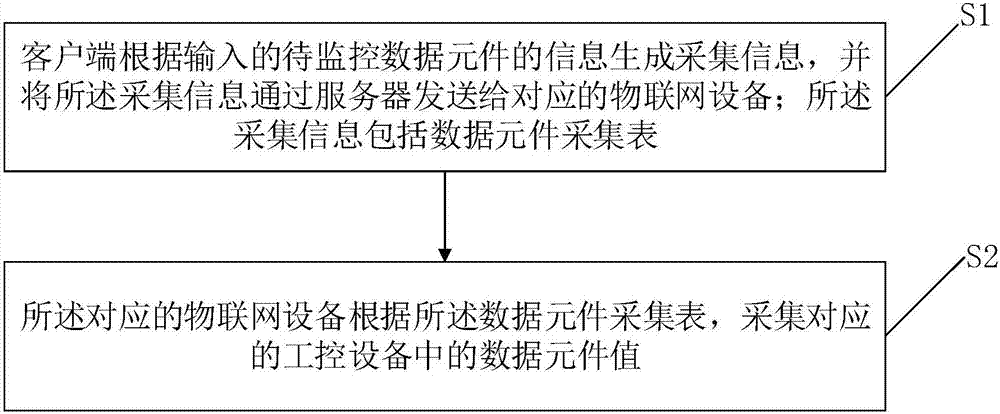

Internet of things data acquisition system and method

ActiveCN107241385AImprove experienceReduce after-sales maintenance costsTransmissionData acquisitionThe Internet

The invention discloses an Internet of things data acquisition system. The system comprises a client, a server, at least one Internet of things device and at least one industrial control device, wherein the client is used for generating acquisition information according to input information of a data element to be monitored and sends the acquisition information to the corresponding Internet of things device through the server; the acquisition information comprises a data element acquisition table; and the Internet of things device is used for acquiring a data element value in the corresponding industrial control device according to the data element acquisition table. Correspondingly, the invention further discloses an Internet of things data acquisition method. By use of the system and method provided by the embodiments of the invention, the data acquisition efficiency can be improved, and user experience is improved.

Owner:SHENZHEN INOVANCE TECH

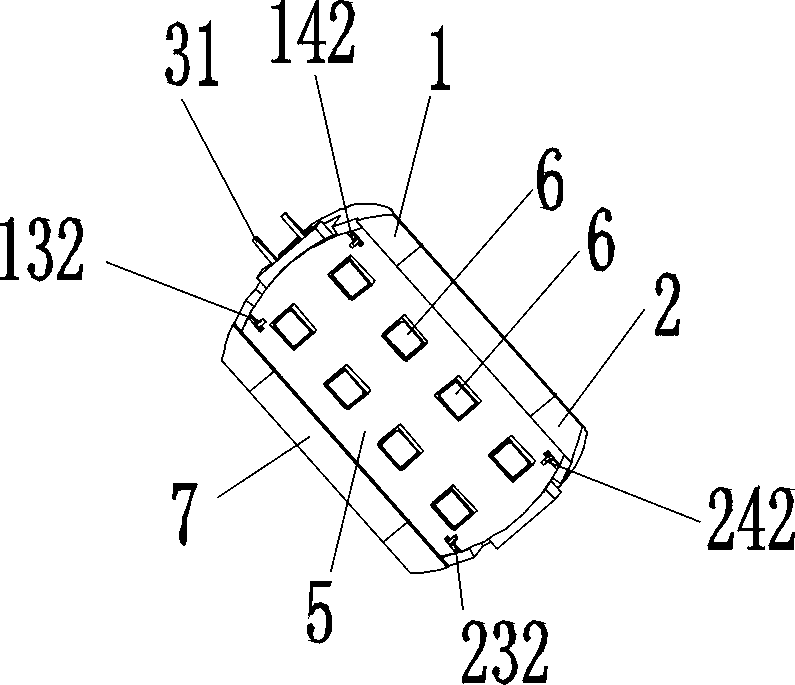

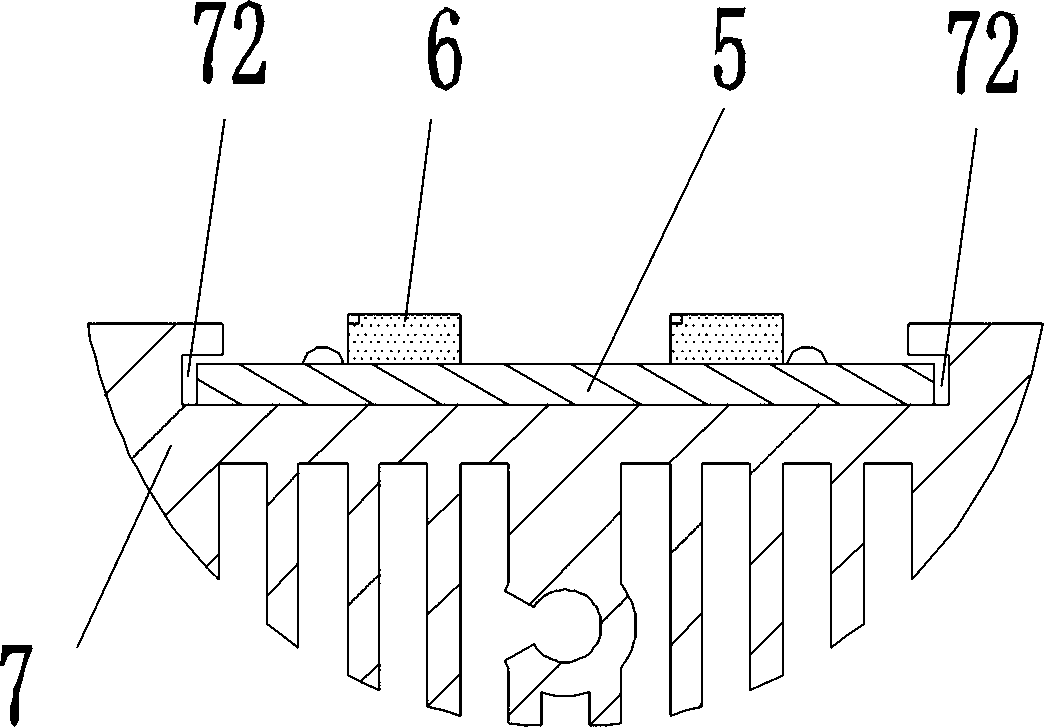

LED (Light Emitting Diode) lamp tube assembly

InactiveCN103016990AReduce manufacturing costReduce equipmentPoint-like light sourceLighting support devicesElectricityNegative power

The invention relates to an LED (Light Emitting Diode) lamp tube assembly, which comprises a radiator and an LED light source assembly, wherein the LED light source assembly comprises a substrate and a plurality of LED light sources, and the substrate is fixedly arranged on the surface of the radiator; the LED light sources are arranged on the substrate, and a positive power supply connecting line and a negative power supply connecting line are arranged on the substrate; the LED light sources are electrically connected between the positive power supply connecting line and the negative power supply connecting line, and the front and back ends of the radiator are respectively and fixedly provided with a front splicing piece and a back splicing piece; the front splicing piece is provided with a first sunken area, and a plug is rotatably arranged in the first sunken area; and the back splicing piece is provided with a second sunken area, and a socket is rotatably arranged in the second sunken area. The LED lamp tube main body of various shapes and sizes can be self-spliced and combined.

Owner:广东爱华新光电科技有限公司

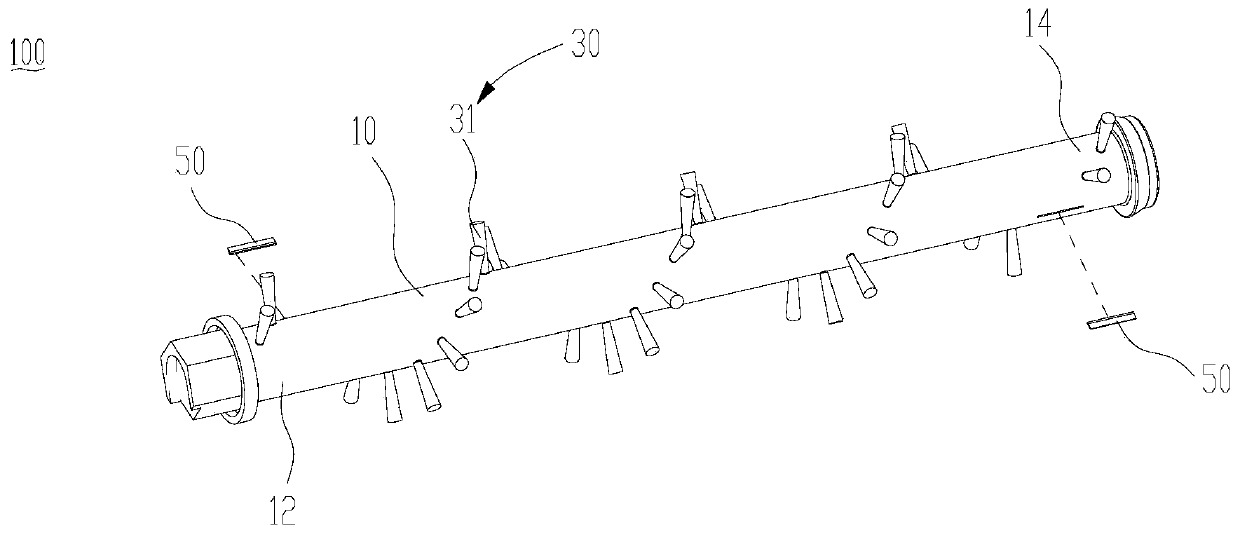

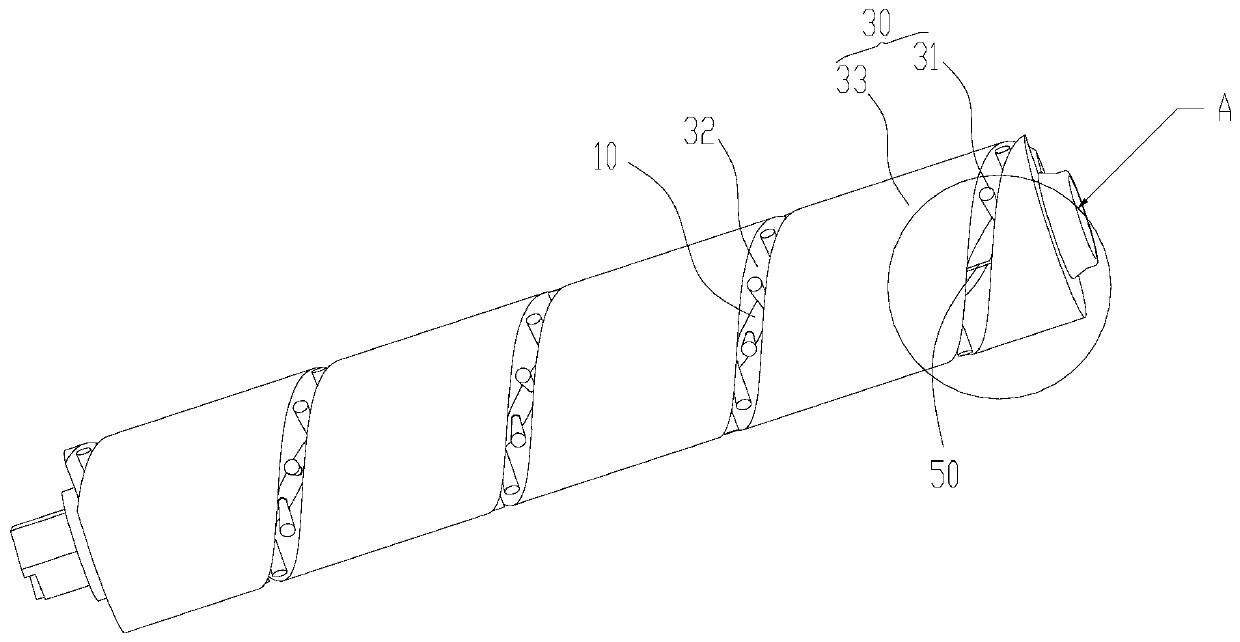

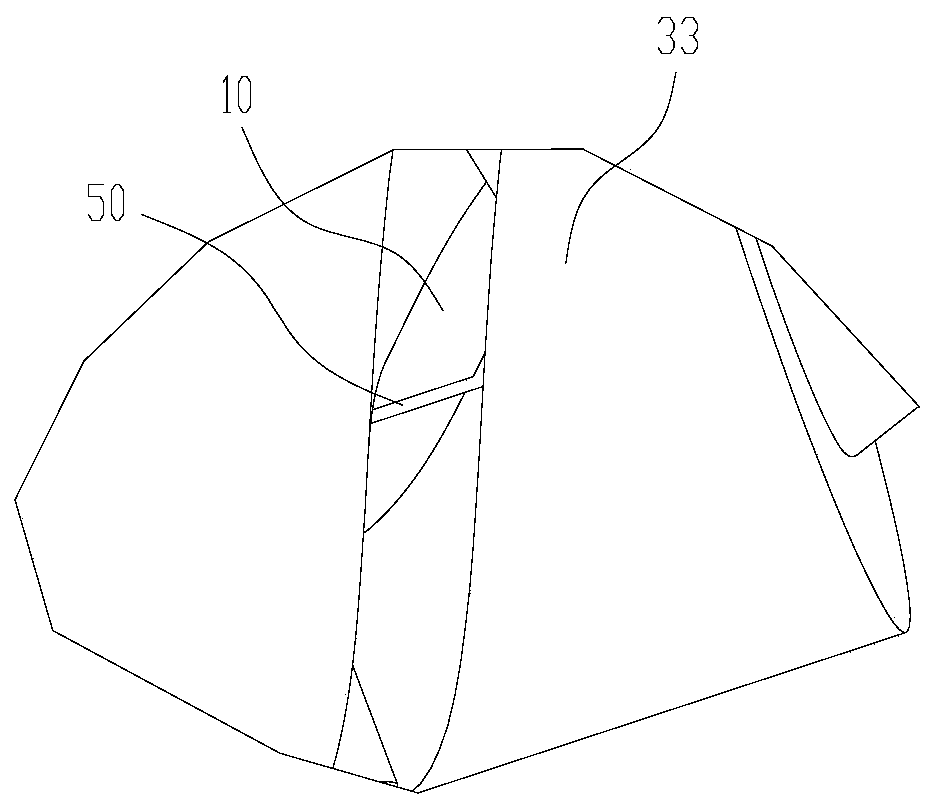

Dust collector, floor brush device and rolling brush

PendingCN110236450ARotation effectReduce after-sales maintenance costsSuction nozzlesEngineeringBrush device

The invention relates to a dust collector, a floor brush device and a rolling brush. The rolling brush comprises a rolling brush shaft, a cleaning part and cutting parts, wherein the cleaning part is connected to the outer peripheral face of the rolling brush shaft, the rolling brush shaft drives the cleaning part to rotate when rotating around the self axis, and thus the floor is cleaned through the rotating cleaning part. The cutting parts are assembled to the outer peripheral face of the rolling brush shaft, and the cutting edges of the cutting parts are exposed out of the outer surface of the cleaning part, namely, the cutting parts are arranged visually through the outer surface of the cleaning part. For example, the cutting edges of the cutting parts are level with the outer surface of the cleaning part, or the cutting edges of the cutting parts sink relative to the outer surface of the cleaning part, when the winding articles such as hair are adsorbed and are about to wind the rolling brush shaft, the winding articles are cut by the cutting edges of the cutting parts, namely, the winding articles including hair and the like being about to wind the rolling brush shaft finally are cut off under the effect of the cutting parts arranged on the outer surface of the rolling brush shaft, the winding articles which are cut off then fall off from the rolling brush shaft, and the phenomenon that the winding articles influence the rotation of the rolling brush is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

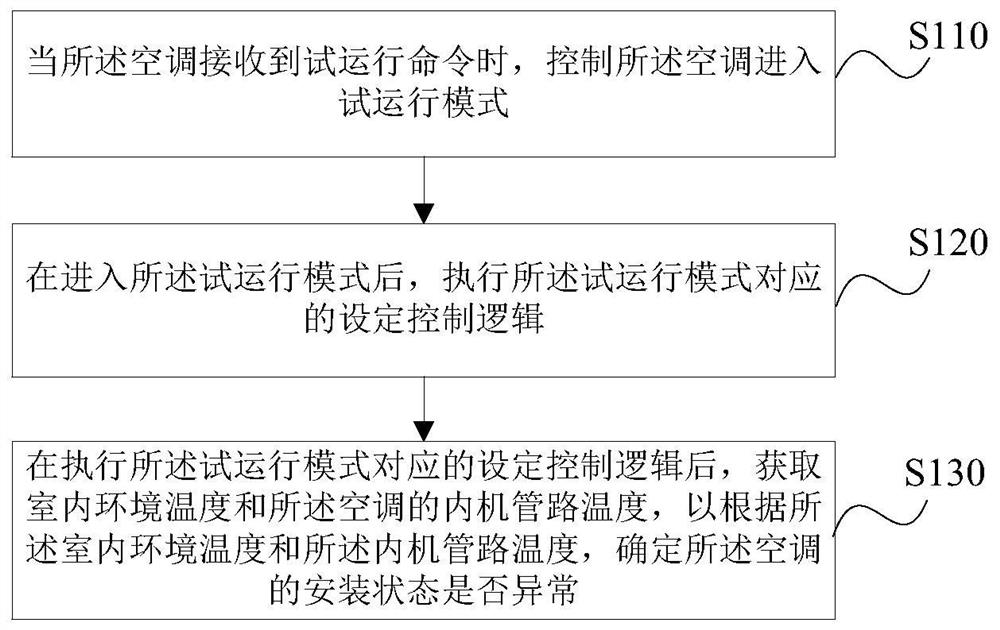

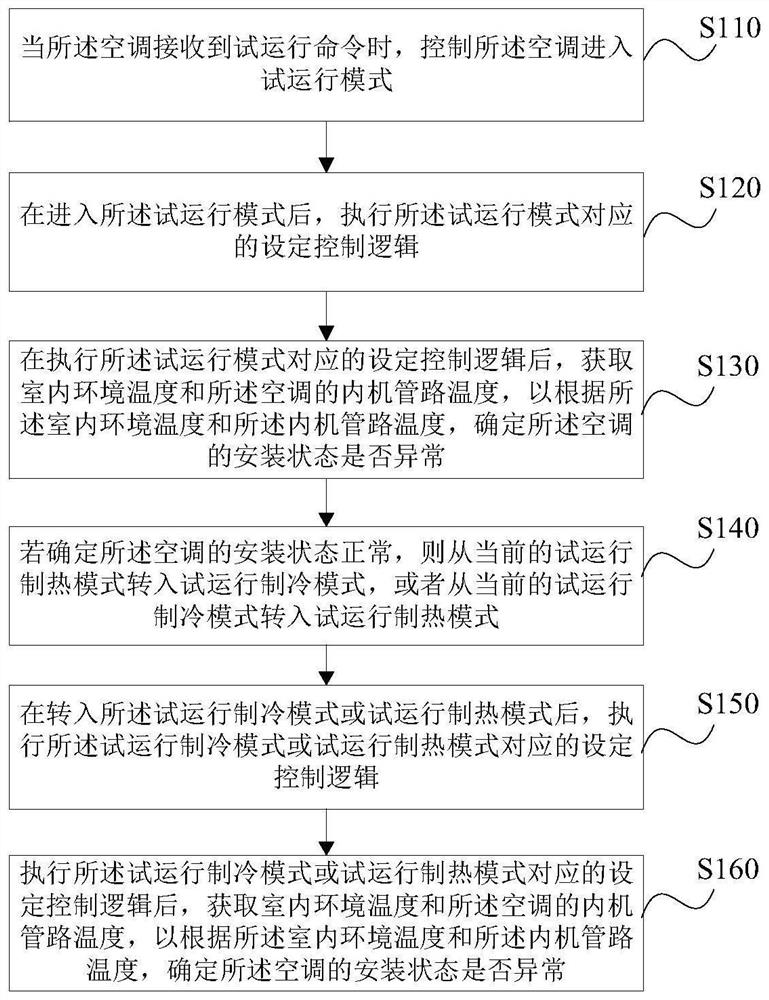

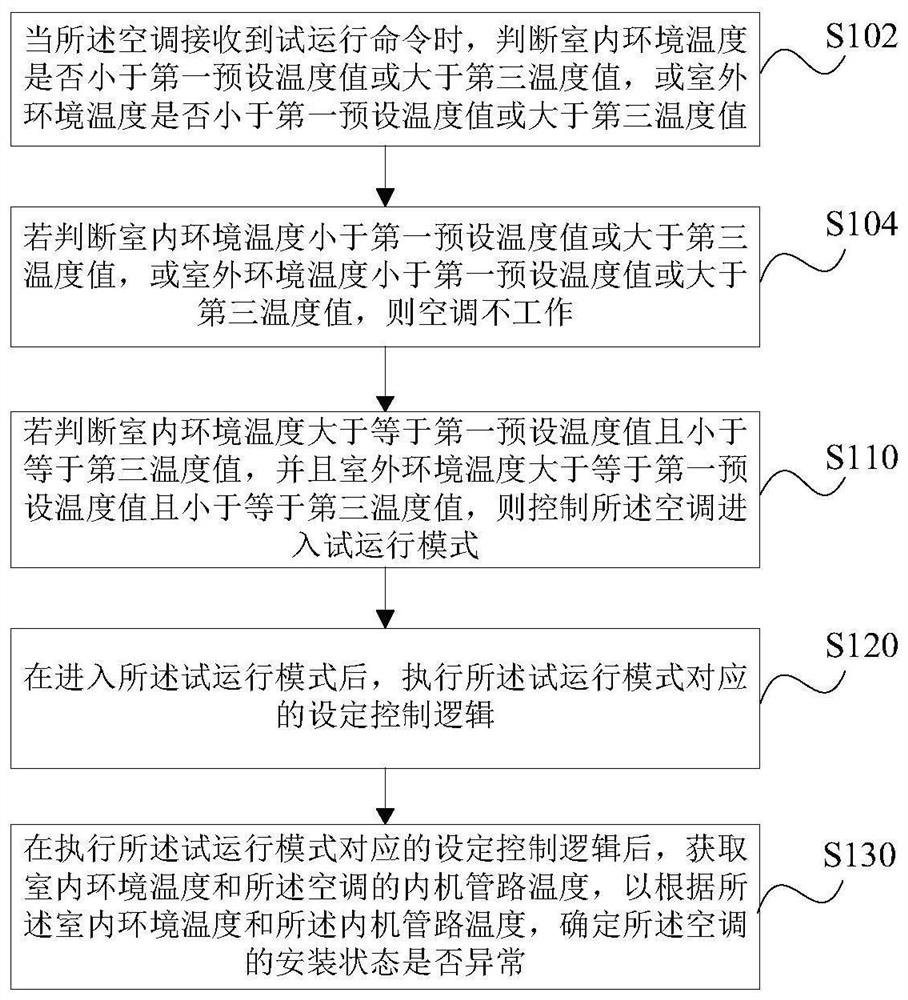

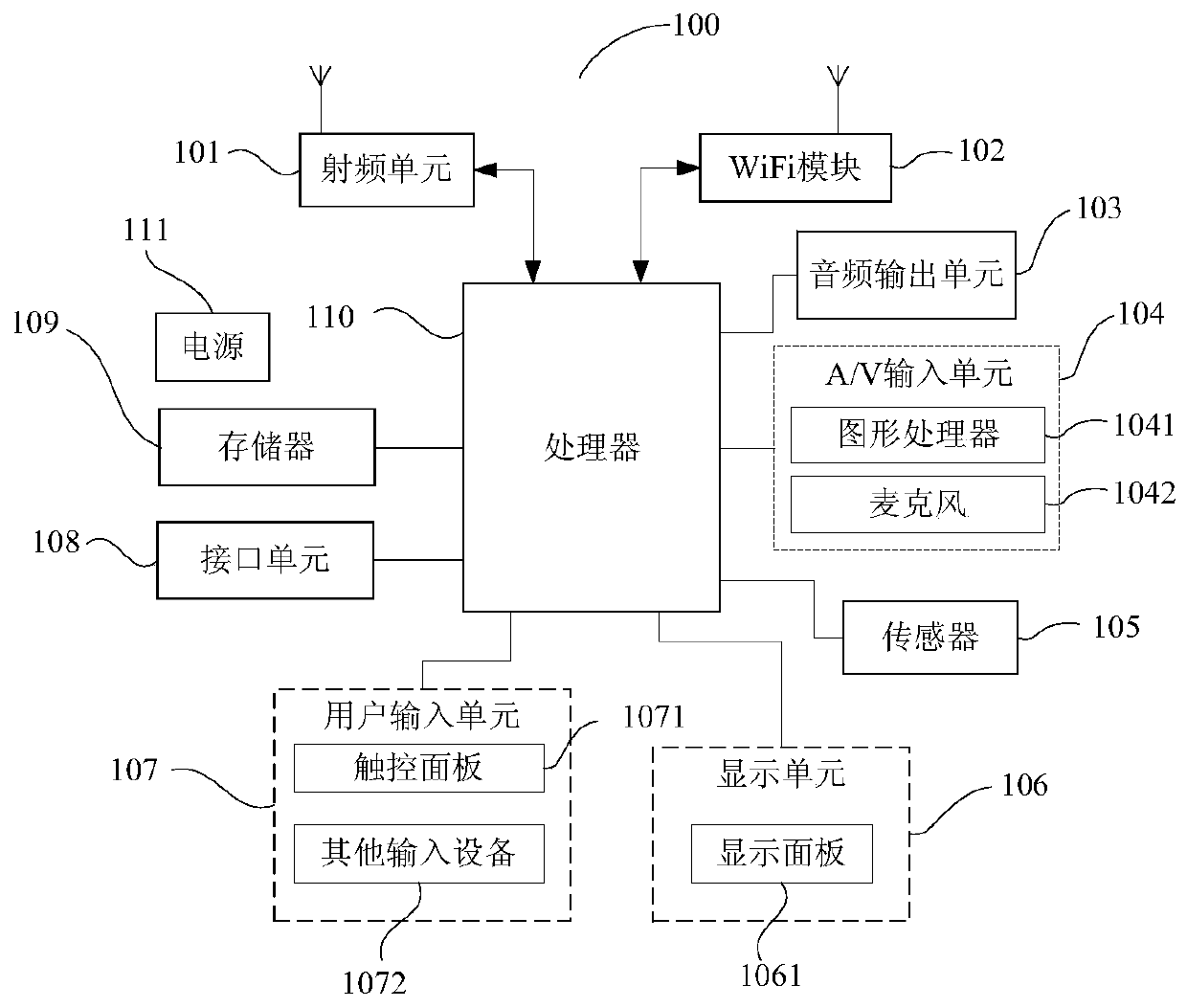

Air conditioner installation state detection method and device, storage medium and air conditioner

ActiveCN112082250ASolve the installationEasy aftermarket installationMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringControl logic

The invention provides an air conditioner installation state detection method and device, a storage medium and an air conditioner. The method comprises the steps that the air conditioner is controlledto enter a trial operation mode when the air conditioner receives a trial operation command; after entering the trial operation mode, a set control logic corresponding to the trial operation mode isexecuted; and after the set control logic corresponding to the trial operation mode is executed, the indoor environment temperature and the indoor unit pipeline temperature of the air conditioner areobtained, and whether the installation state of the air conditioner is abnormal or not is determined according to the indoor environment temperature and the indoor unit pipeline temperature. Accordingto the scheme, whether the installation state of the air conditioner is abnormal or not can be determined.

Owner:GREE ELECTRIC APPLIANCES INC

Multi-battery parallel charging circuit and method, and wearable device having multi-battery parallel charging circuit

ActiveCN110401242ARealize constant current chargingReliable Charging MechanismBatteries circuit arrangementsElectric powerCharge currentComputer module

The present invention relates to a multi-battery parallel circuit, a multi-battery parallel charging method, and a wearable device. The multi-battery parallel circuit comprises a charging controller,current control modules, current detecting modules and battery modules; an output end of the charging controller is connected to the input ends of the plurality of current control modules; the outputends of the current control modules are respectively connected with the input ends of the current detection module; the output ends of the current detection modules are respectively connected with thebattery modules, and the current detection modules are used for detecting whether the charging current of each access is larger a distributed threshold value or not; the circuit control modules are used for controlling the input currents of the battery modules according to the detection results of the current detection modules, distributing rechargeable threshold values under the control of the charging controller and controlling the detected charging current to be regulated in a rechargeable threshold value range according to the detected charging current so as to achieve charging in a constant current and ensure that the condition that each battery cannot be subjected to over-charging or slow charging.

Owner:北京晟运能源科技有限公司

Pneumatic pipeline transmission system and transmission method thereof

InactiveCN101774489ASimple system structureReduce failure rateConveyorsAerospace engineeringTransmission system

The invention discloses a pneumatic pipeline transmission system and a transmission method thereof, relating to the field of pipeline transmission and being invented due to the simple structure and low occurrence rate of failure of the pneumatic pipeline transmission system. The pneumatic pipeline transmission system comprises a transmission pipeline, and is characterized in that the transmission pipeline comprises at least two vertical pipelines and a bent pipeline which communicates the tops of the at least two vertical pipelines, the lower end of each vertical pipeline is provided with a transceiving port, air draft devices are arranged at the positions of the bent pipeline, which are close to the tops of the vertical pipelines, a door body is pivoted at the transceiving port at the lower end of each vertical pipeline and is adaptive with the transceiving port, and the lower end of each vertical pipeline is also provided with an air inlet. The invention is applied to the occasions of pneumatic pipeline transmission.

Owner:BEIJING RINRONG TECH

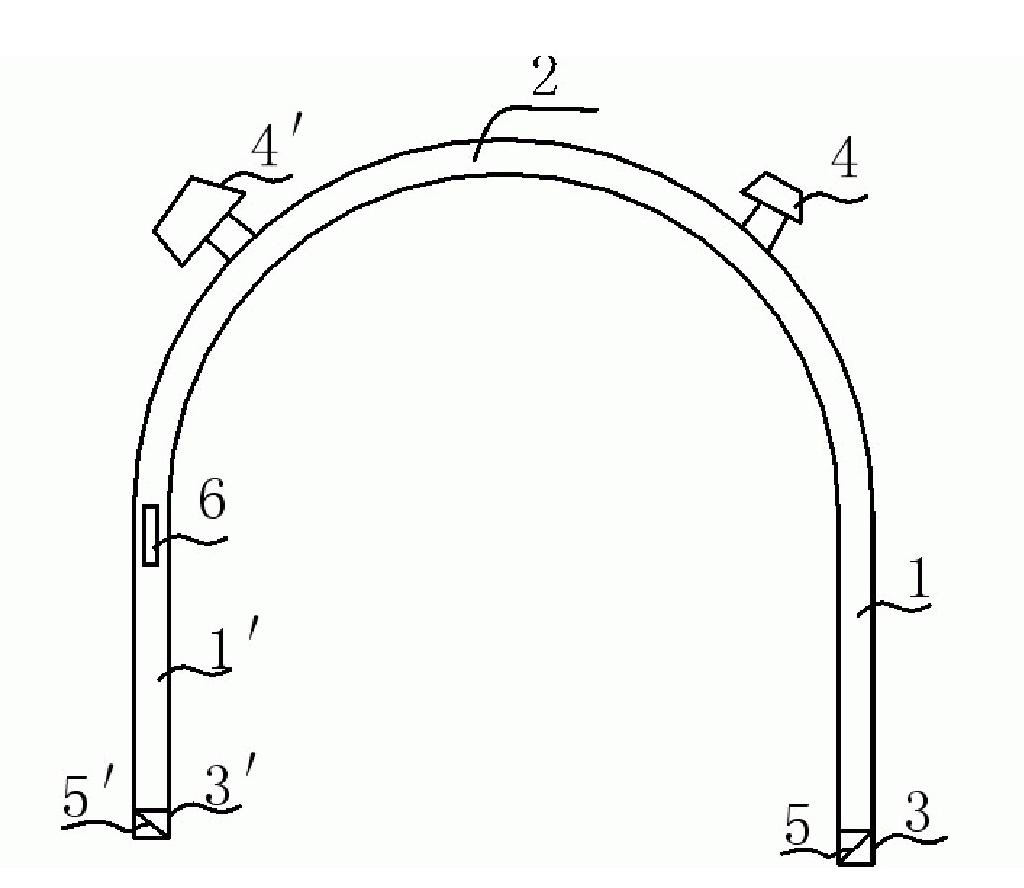

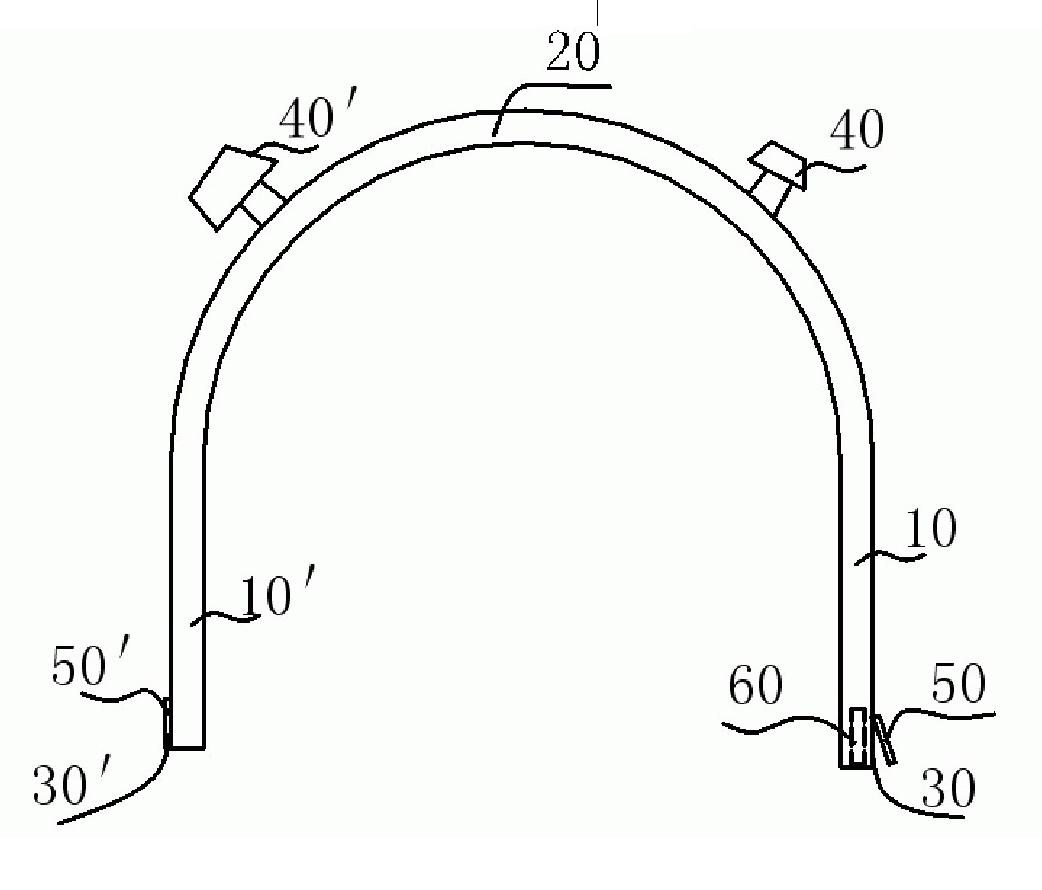

Air conditioner

PendingCN108413487AReduce difficultyReduce after-sales maintenance costsLighting and heating apparatusSupports/enclosures/casingsEngineeringControl theory

The invention provides an air conditioner. The air conditioner comprises a motor assembly; the motor assembly comprises a motor support and a motor, wherein the motor support is arranged on a base part, and the motor is arranged on the motor support; and the motor support is matched with the base part in a pull-out mode and is detachably arranged on the base part in a pull-out mode. The air conditioner has the advantages that the motor support in the motor assembly of the air conditioner can be assembled and disassembled a pull-out mode relative to the base part, when the motor assembly in theair conditioner needs to be subjected to after-sales maintenance, the motor assembly at the working position only needs to be pulled out from the interior of the air conditioner to be disassembled after a side panel is disassembled, the disassembly work of the motor assembly does not need to be carried out in the air conditioner, and therefore the difficulty of after-sales maintenance of the motor assembly in the air conditioner can be lowered, and the after-sales maintenance cost can be saved.

Owner:GREE ELECTRIC APPLIANCES INC

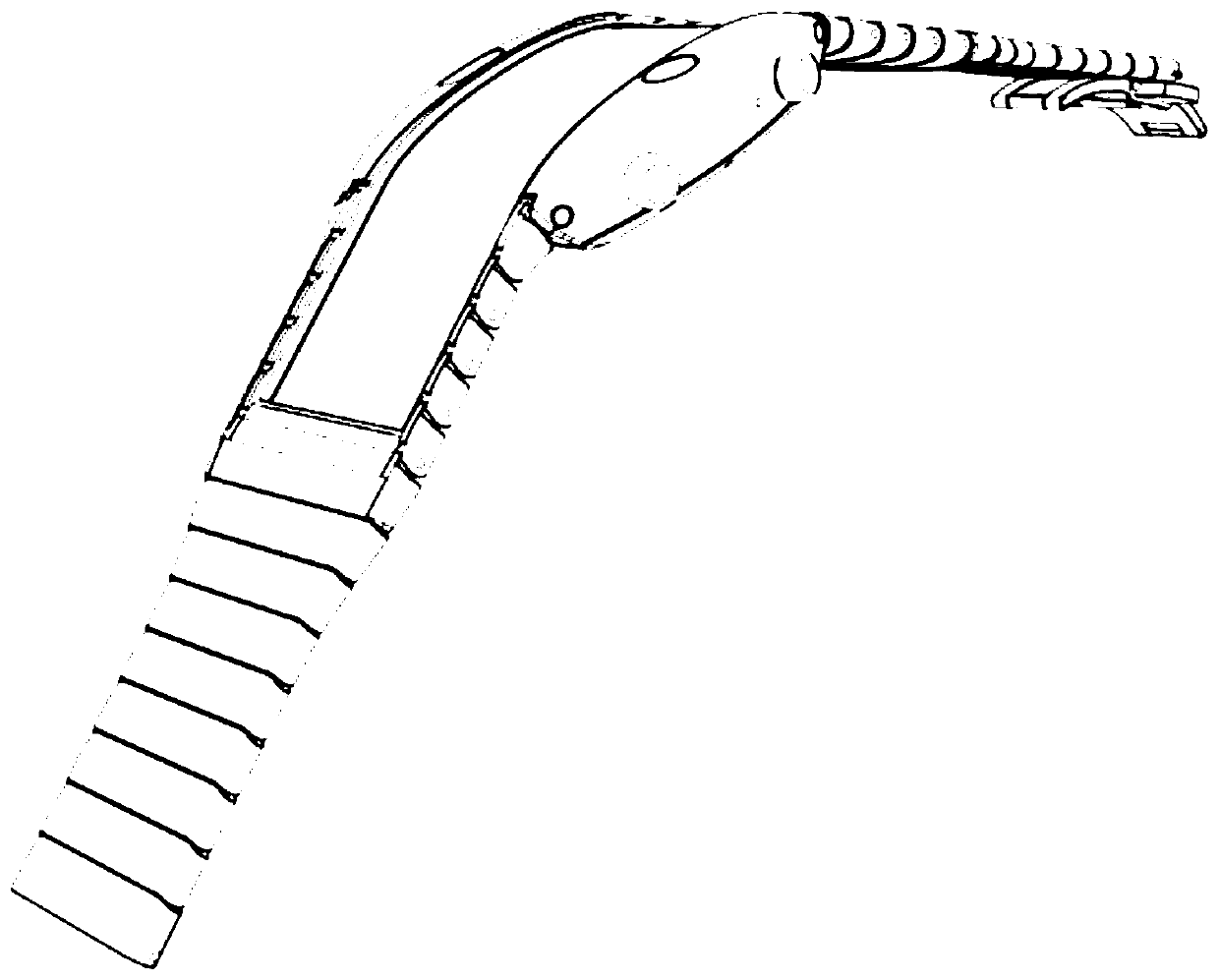

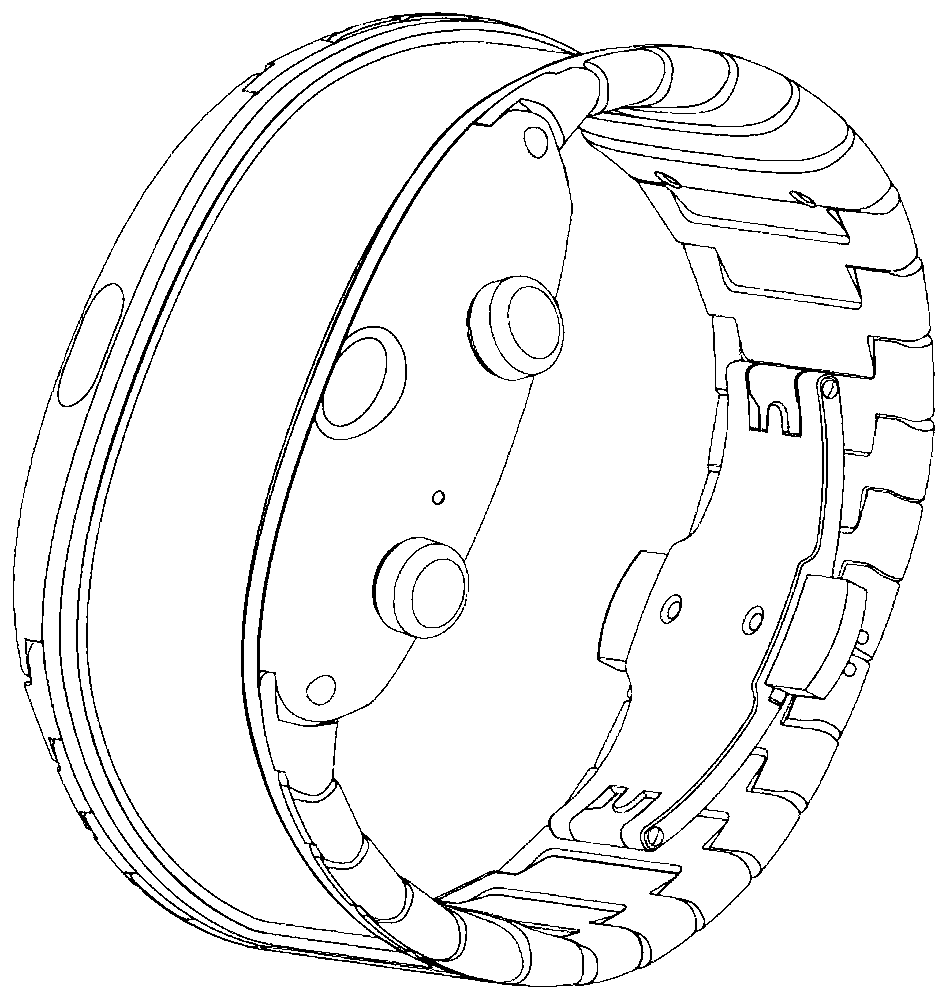

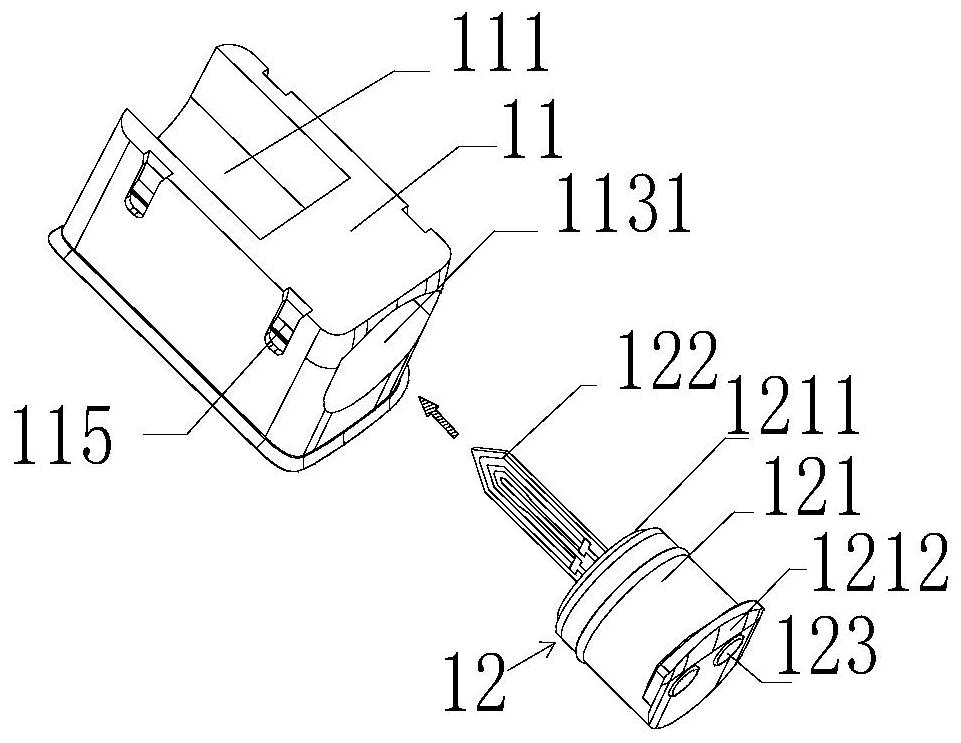

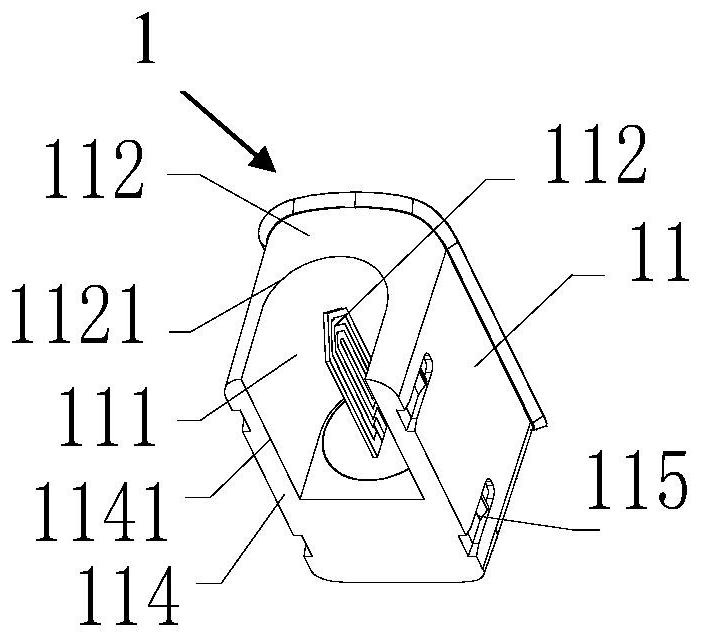

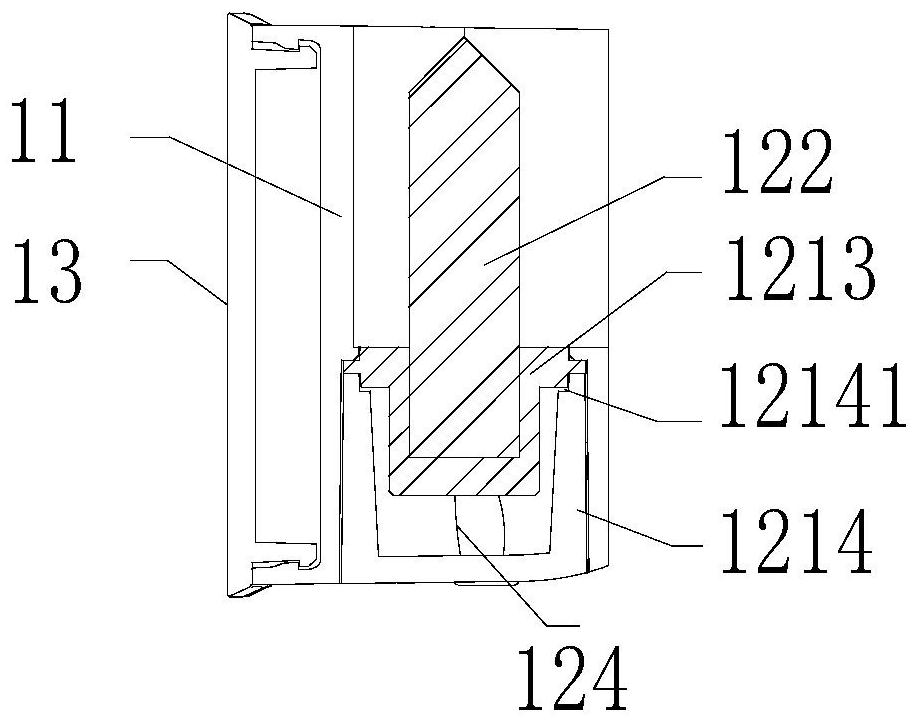

Heating module and aerosol generating device

The invention relates to the technical field of aerosol generating devices, and particularly discloses a heating module and an aerosol generating device. The heating module comprises a body and a heating assembly, the body is provided with a first end part and an opposite second end part, an accommodating cavity is arranged in the body, the first end part is provided with a first opening, and thesecond end part is provided with a second opening; the accommodating cavity is respectively communicated with the first opening and the second opening; the heating assembly comprises a fixing piece, aheating element and an electrode piece, the fixing piece is provided with a third end part and an opposite fourth end part, the heating element is fixed at the third end part, the electrode piece isfixed at the fourth end part, and the heating element is electrically connected with the electrode piece; the fixing piece is installed in the accommodating cavity from the second opening, so that theheating element is located in the accommodating cavity. The heating module serves as an independent module and is arranged in a detachable and replaceable mode, a consumer can easily and rapidly disassemble the heating module for cleaning operation, and the maintenance cost of the consumer after the machine is damaged is reduced.

Owner:SHENZHEN JIYOU TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com