LED (Light Emitting Diode) lamp tube assembly

A technology of LED light tubes and LED light sources, which is applied to the components of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of high processing and molding costs of LED light tubes, and increase the difficulty of management for manufacturers, so as to ensure Reliability and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

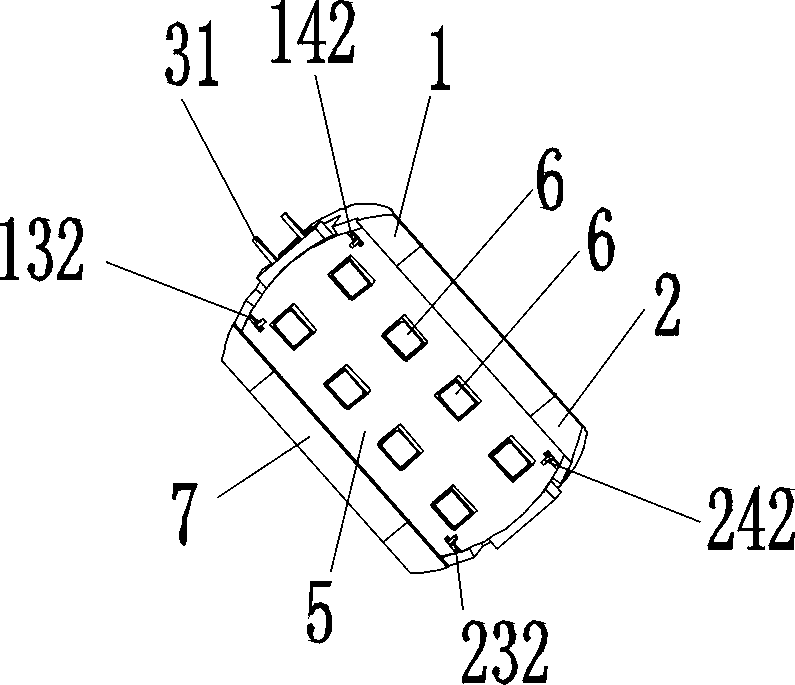

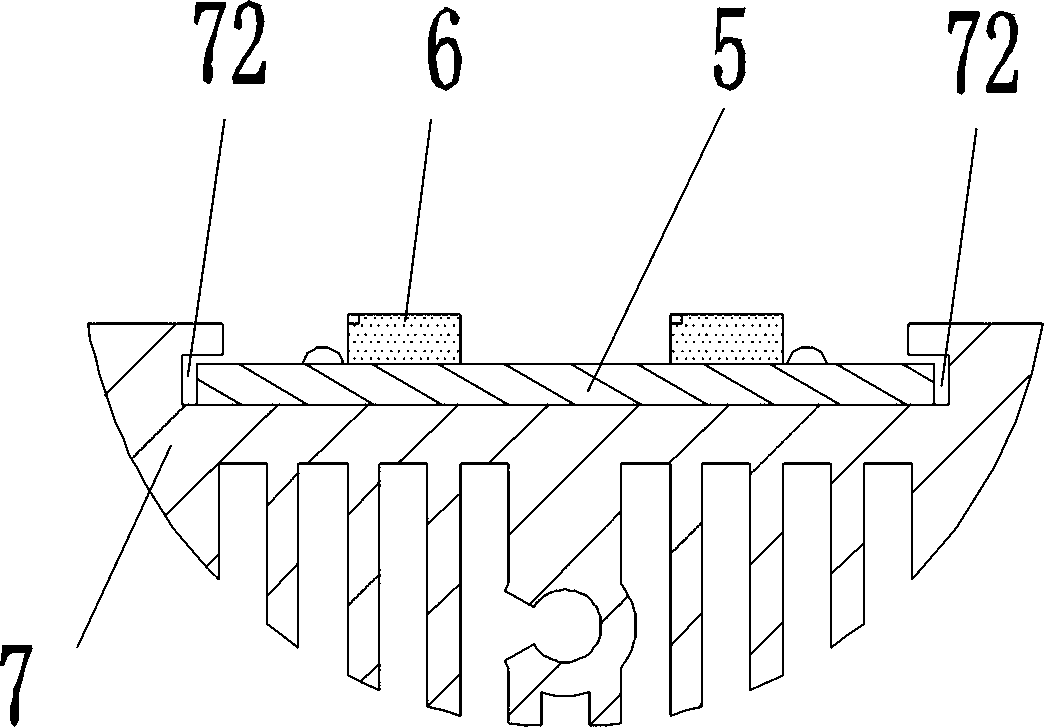

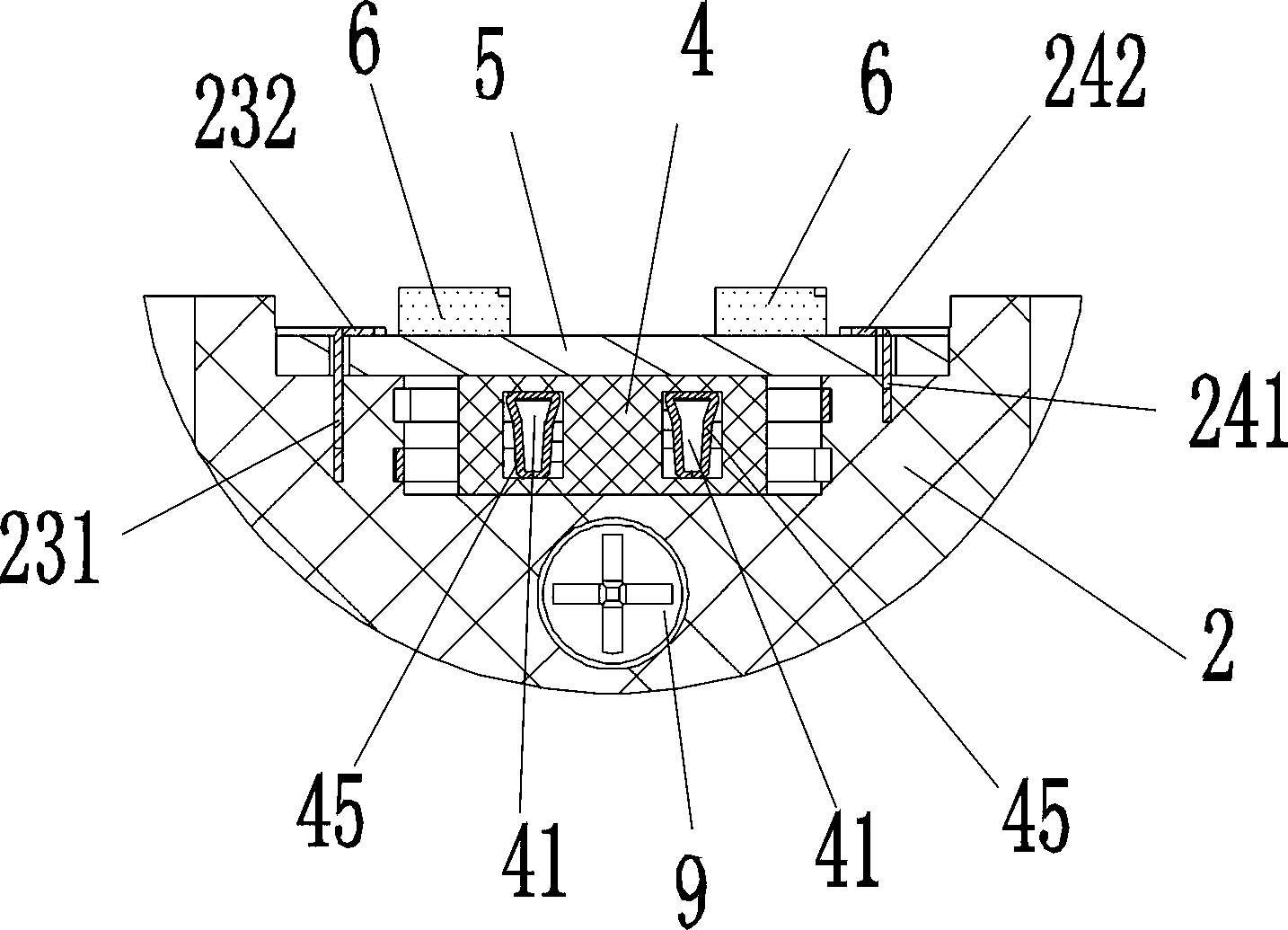

[0052] figure 1 , figure 2 , image 3 , Figure 10 , Figure 19 As shown, the LED light tube assembly of this embodiment includes a radiator 7 and an LED light source assembly; the LED light source assembly includes a substrate 5 and eight LED light sources 6, and the substrate 5 is fixedly installed on the surface of the radiator 7, wherein the radiator Grooves 72 are set on the left and right sides of the surface, and the left and right sides of the substrate are embedded in the corresponding grooves 72; eight LED light sources 6 are installed on the substrate 5, and the substrate 5 is provided with a positive power supply connection 61 and a negative power supply connection 62. The positive power supply connection 61 and the negative power supply connection 62 are copper foil wires laid on the upper surface of the substrate, and the eight LED light sources 6 are electrically connected between the positive power supply connection 61 and the negative power supply connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com