Patents

Literature

58results about How to "Reduced safety margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

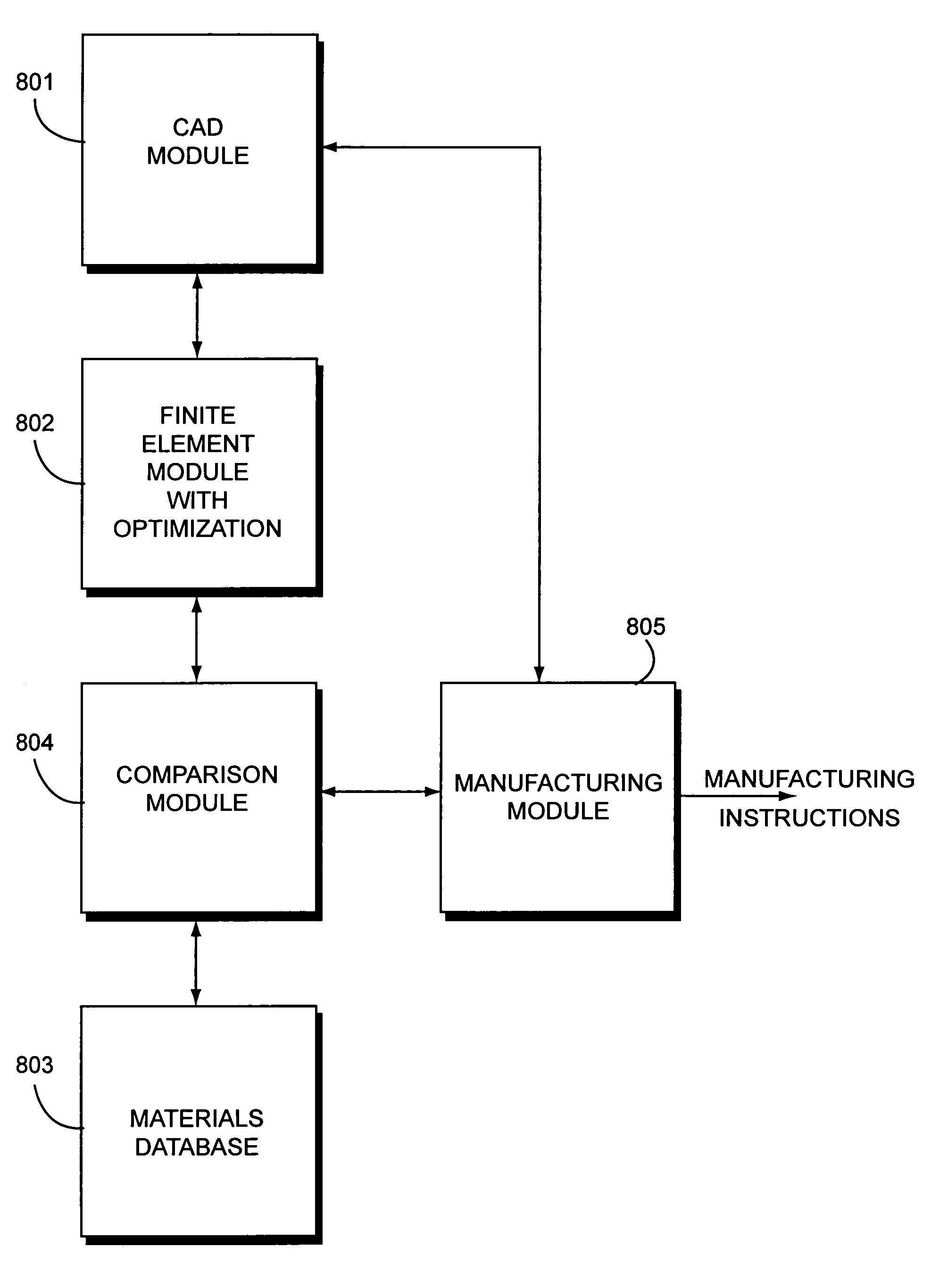

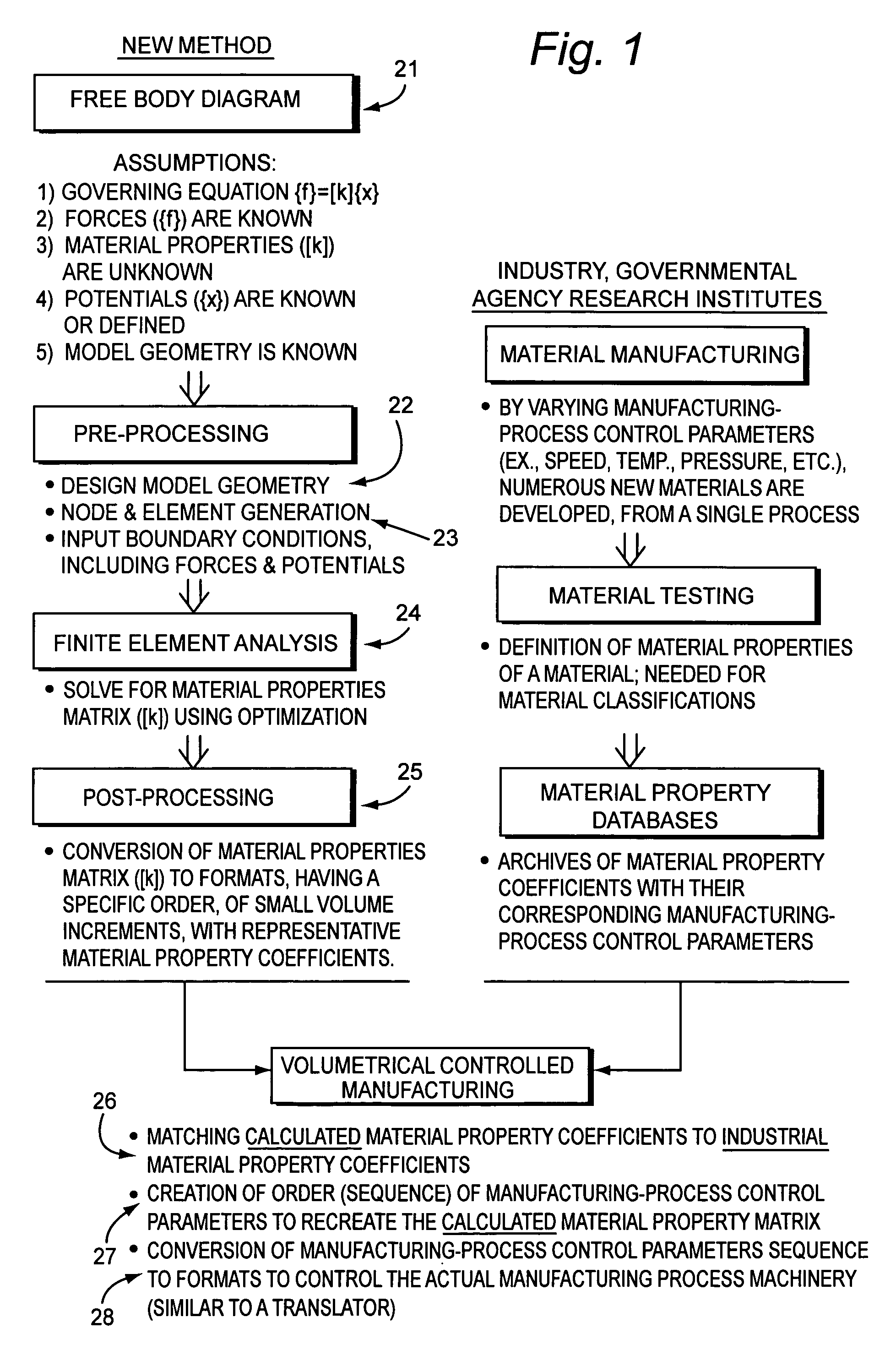

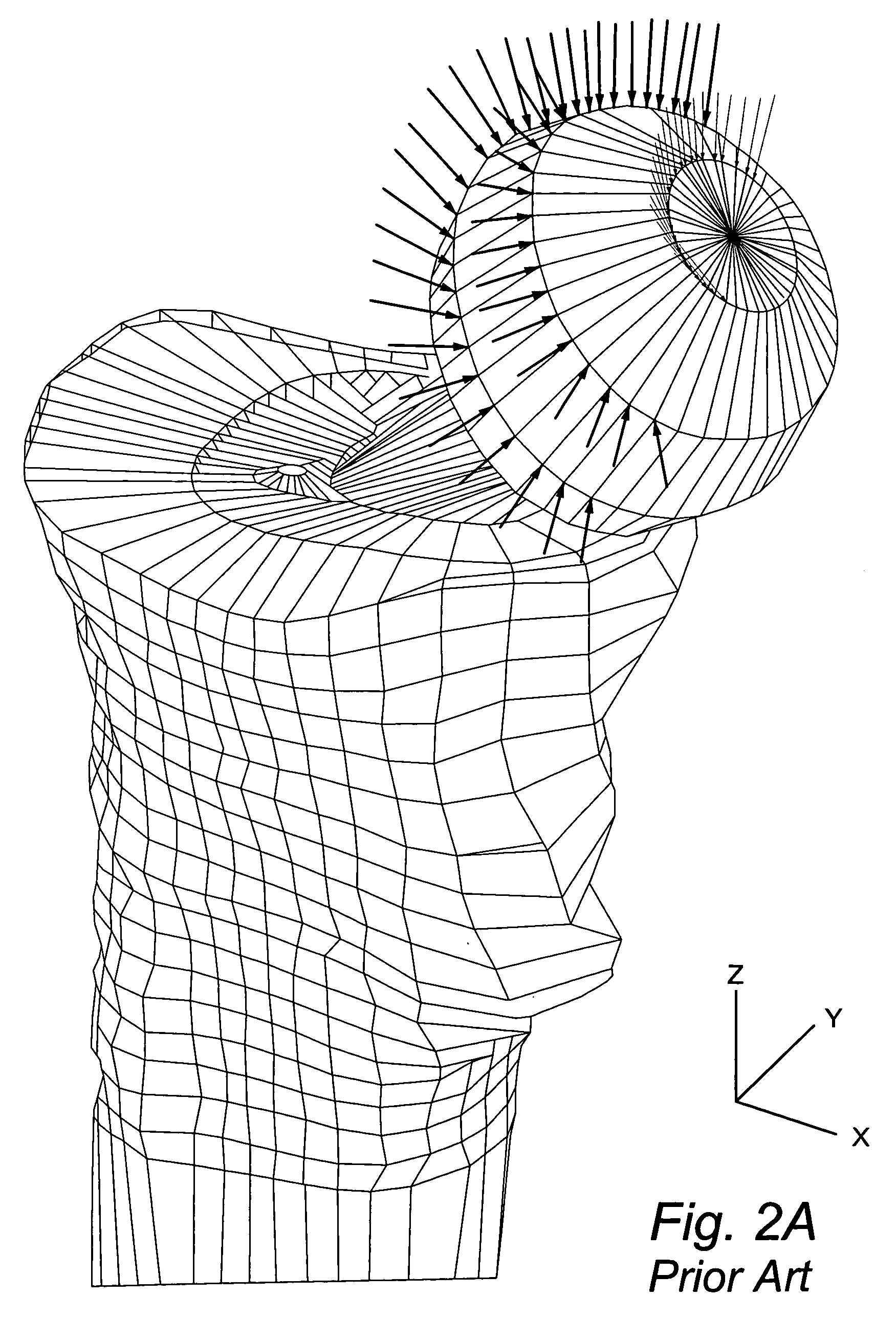

Manufacturing system and method

InactiveUS7203628B1Reduced safety marginMaintain the patient's physiological capability of normal walking motionJoint implantsTotal factory controlMathematical modelParameter control

A method for manufacturing an object having a potential {x} that is generated in response to a field {f} applied thereto. A computerized mathematical model of the object is generated by discretizing a geometric model of the object into a plurality of finite elements and specifying values for the field {f} and potential {x} relative to the finite elements. The material properties of the finite elements are specified to have a particular symmetry and a material property matrix [k] is calculated based on the relationship {f}=[k]{x} and the specified symmetry. Material property coefficients are extracted from the material property matrix [k] for each finite element in the computerized mathematical model and the extracted material property coefficients are compared to material property coefficients for known materials to match the extracted material property coefficients to the material property coefficients for known materials. Manufacturing parameters for controlling manufacturing equipment are determined based on the matched material property coefficients and the manufacturing equipment is controlled in accordance with the determined manufacturing parameters to thereby manufacture the object.

Owner:AZTEC IP

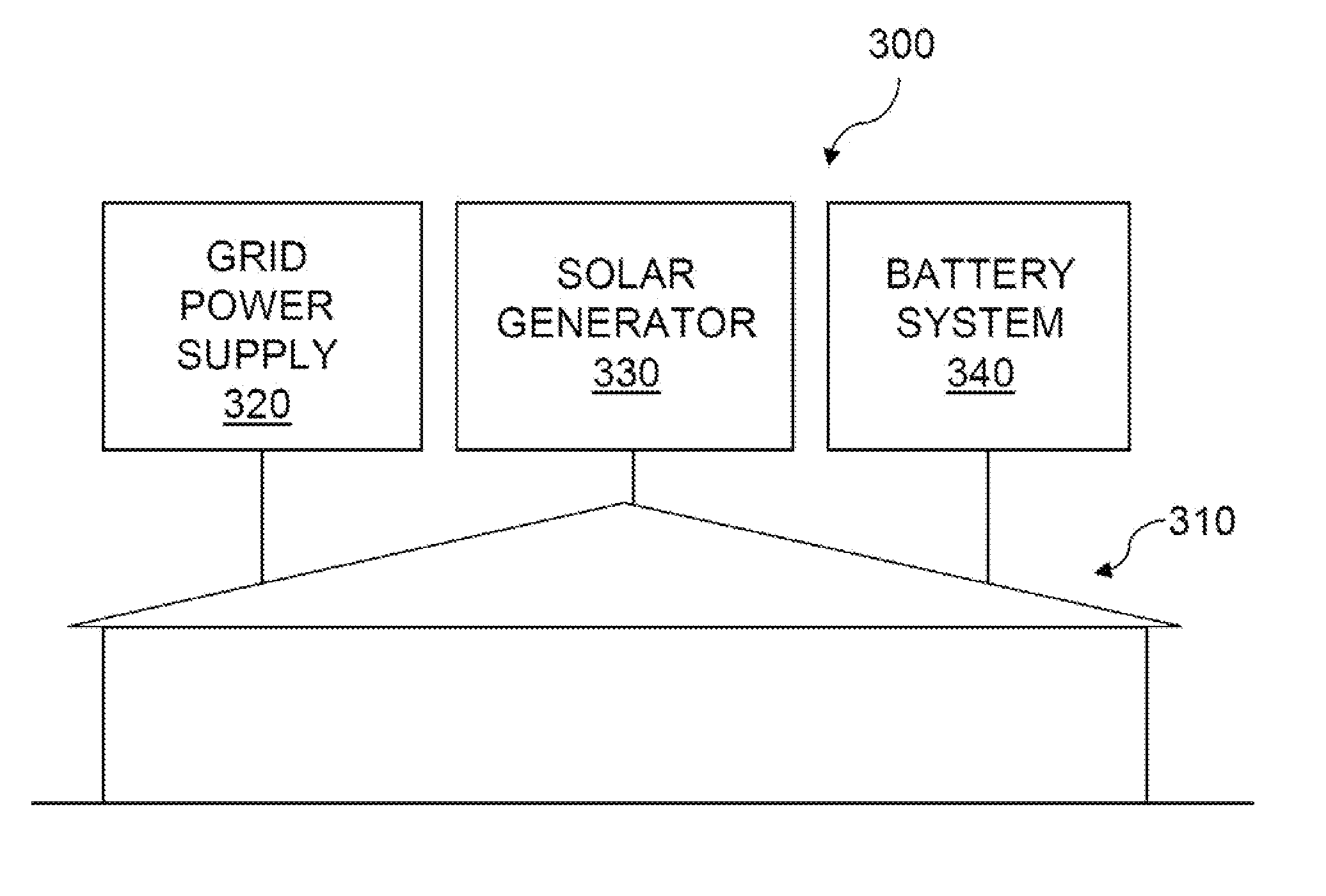

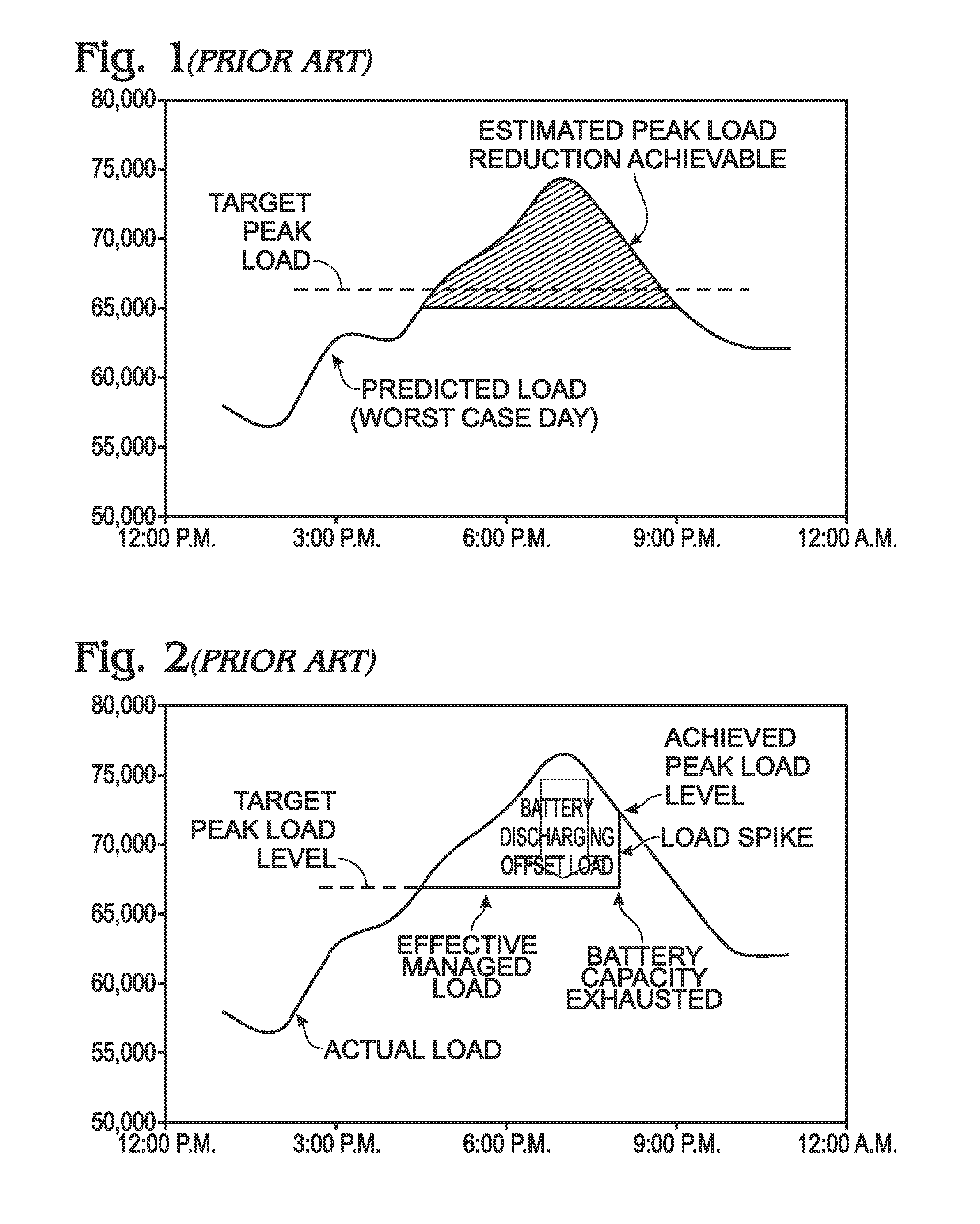

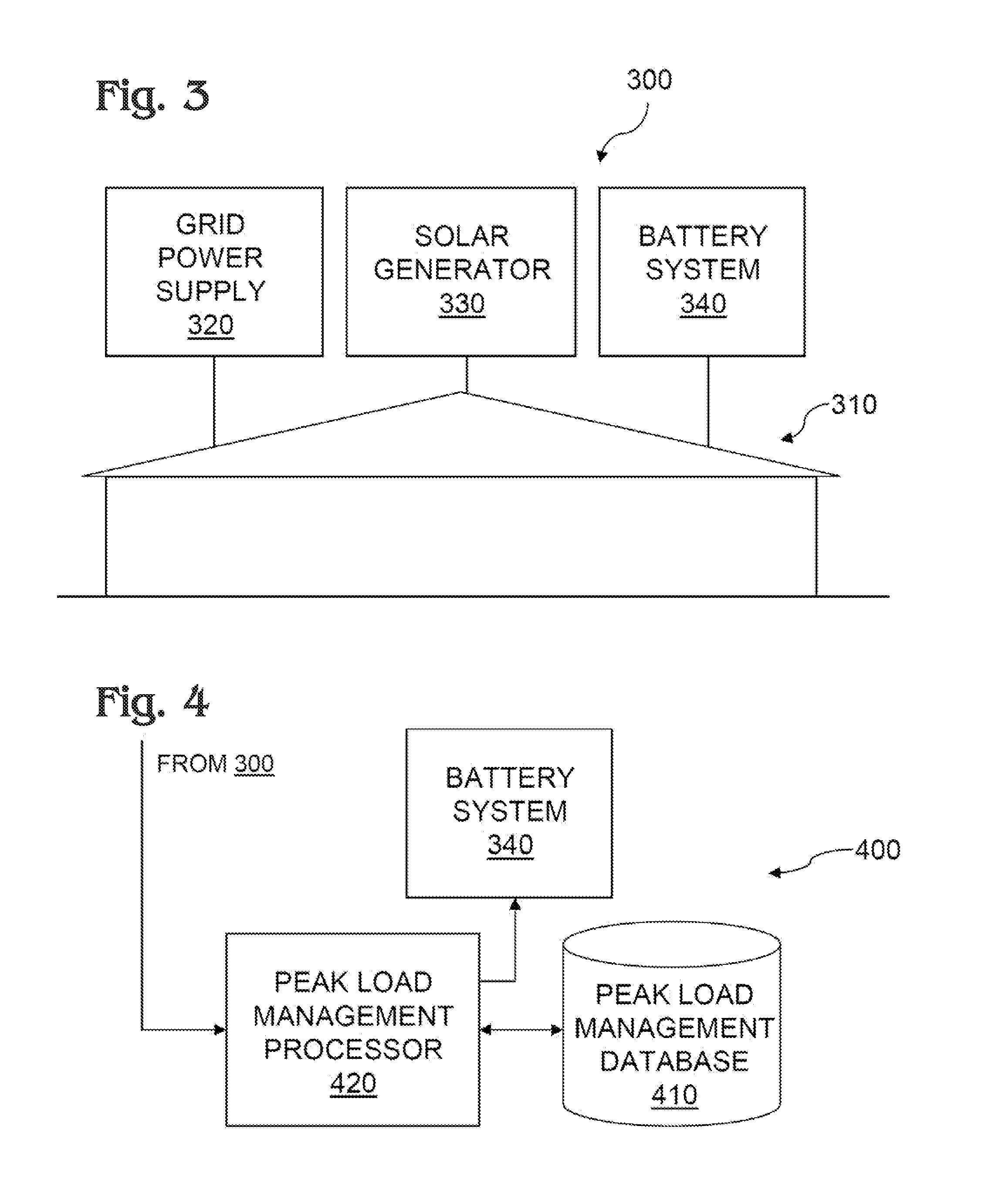

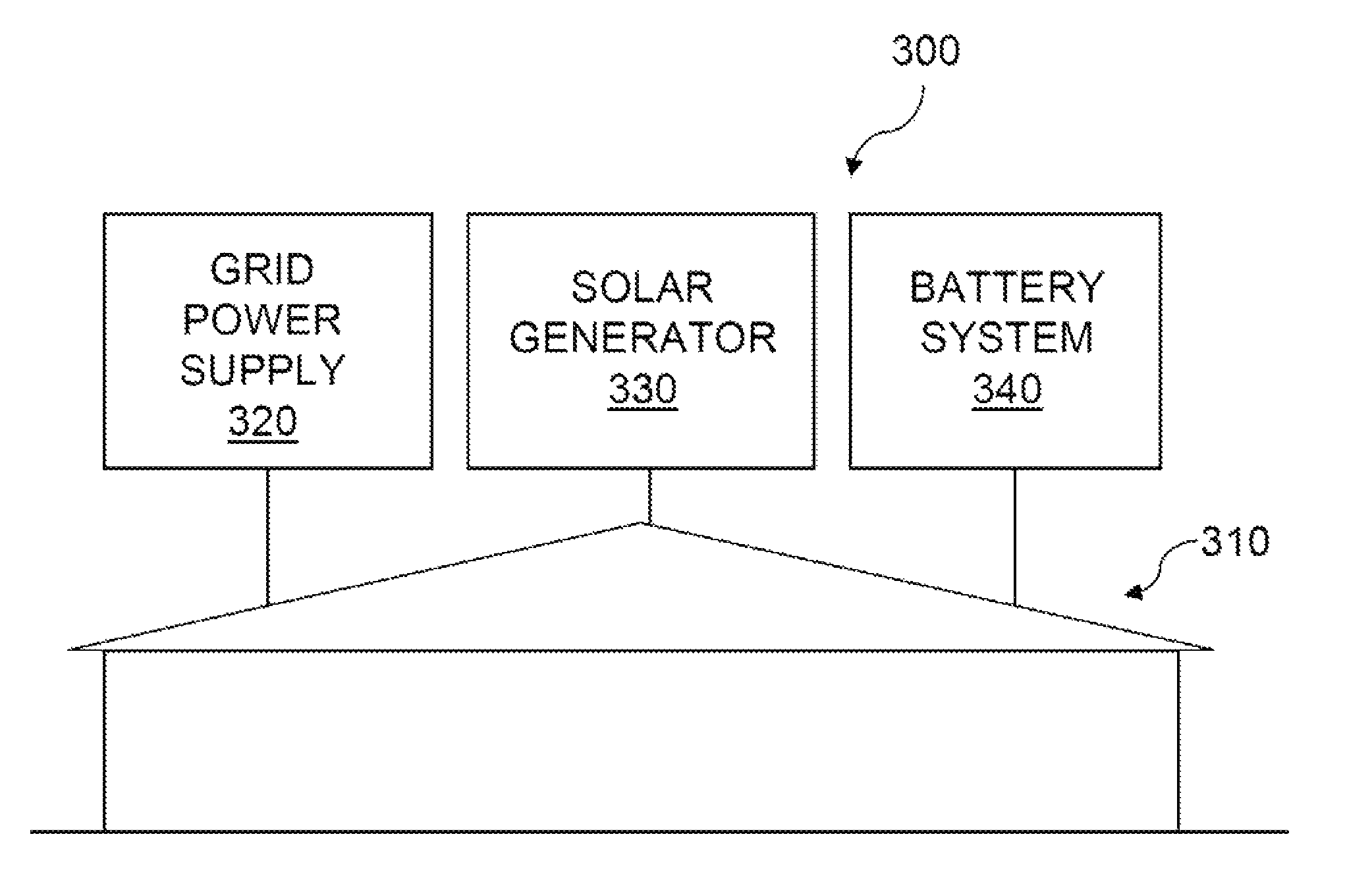

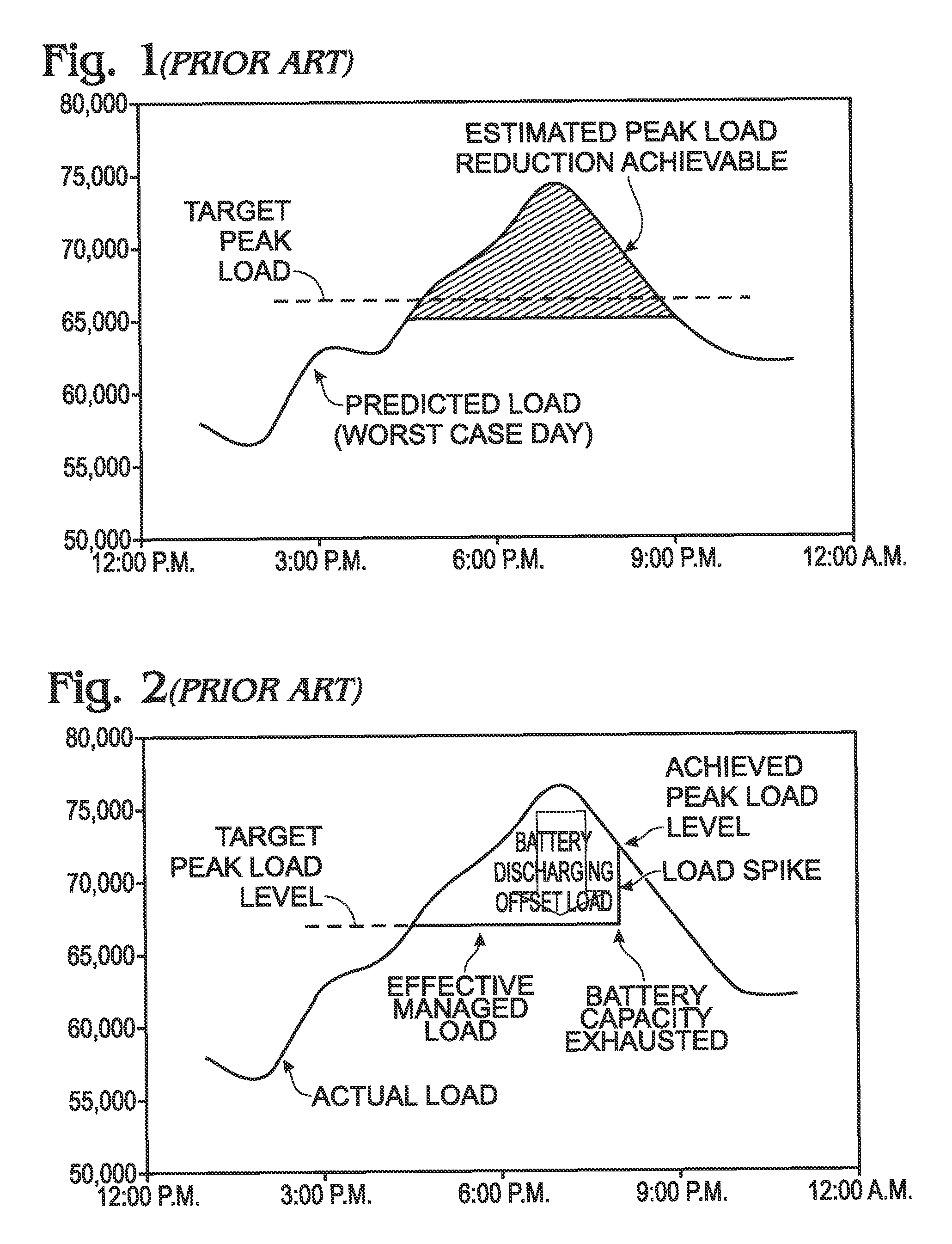

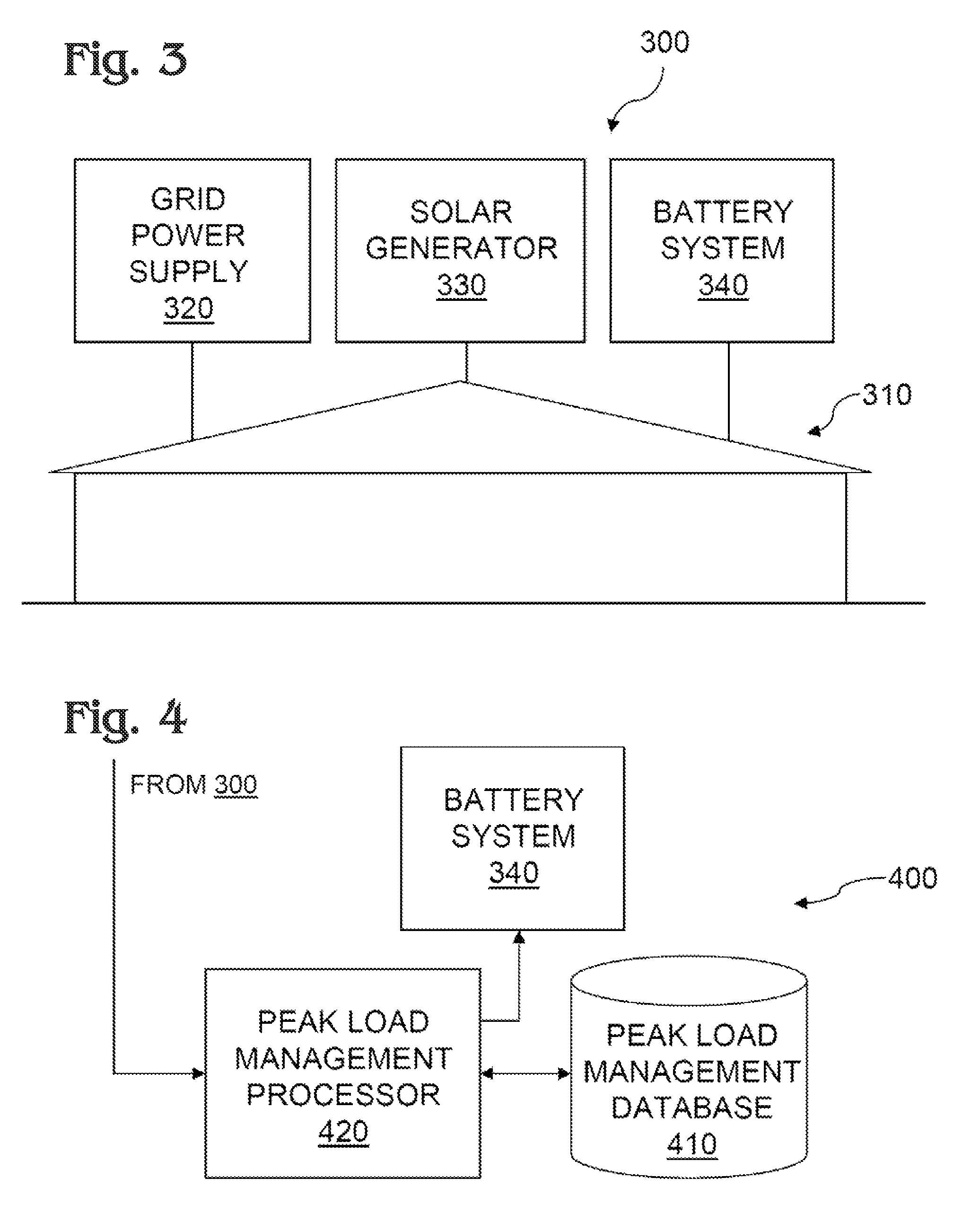

Method and System for Reducing Peak Load Charge on Utility Bill Using Target Peak Load and Countermeasures

InactiveUS20130325197A1Reduce riskReduced safety marginMechanical power/torque controlLevel controlCountermeasurePower grid

A peak load management system and method take countermeasures to reduce the risk of a spike in grid power use above a target peak load due to battery exhaustion. The countermeasures replace or at least reduce the safety margins built into target peak load peak load management systems and increase the cost savings realized from peak load management.

Owner:NANTENERGY INC

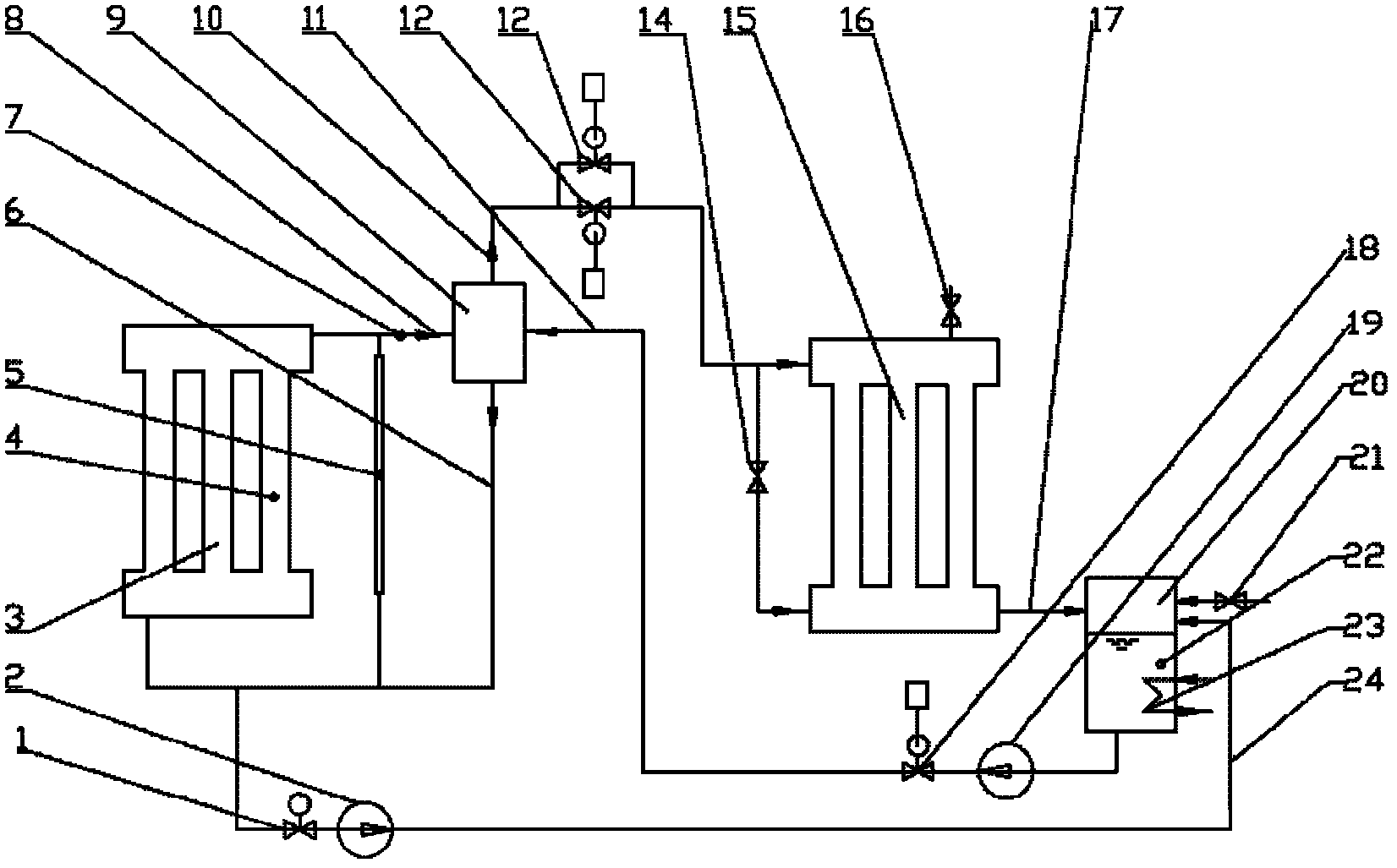

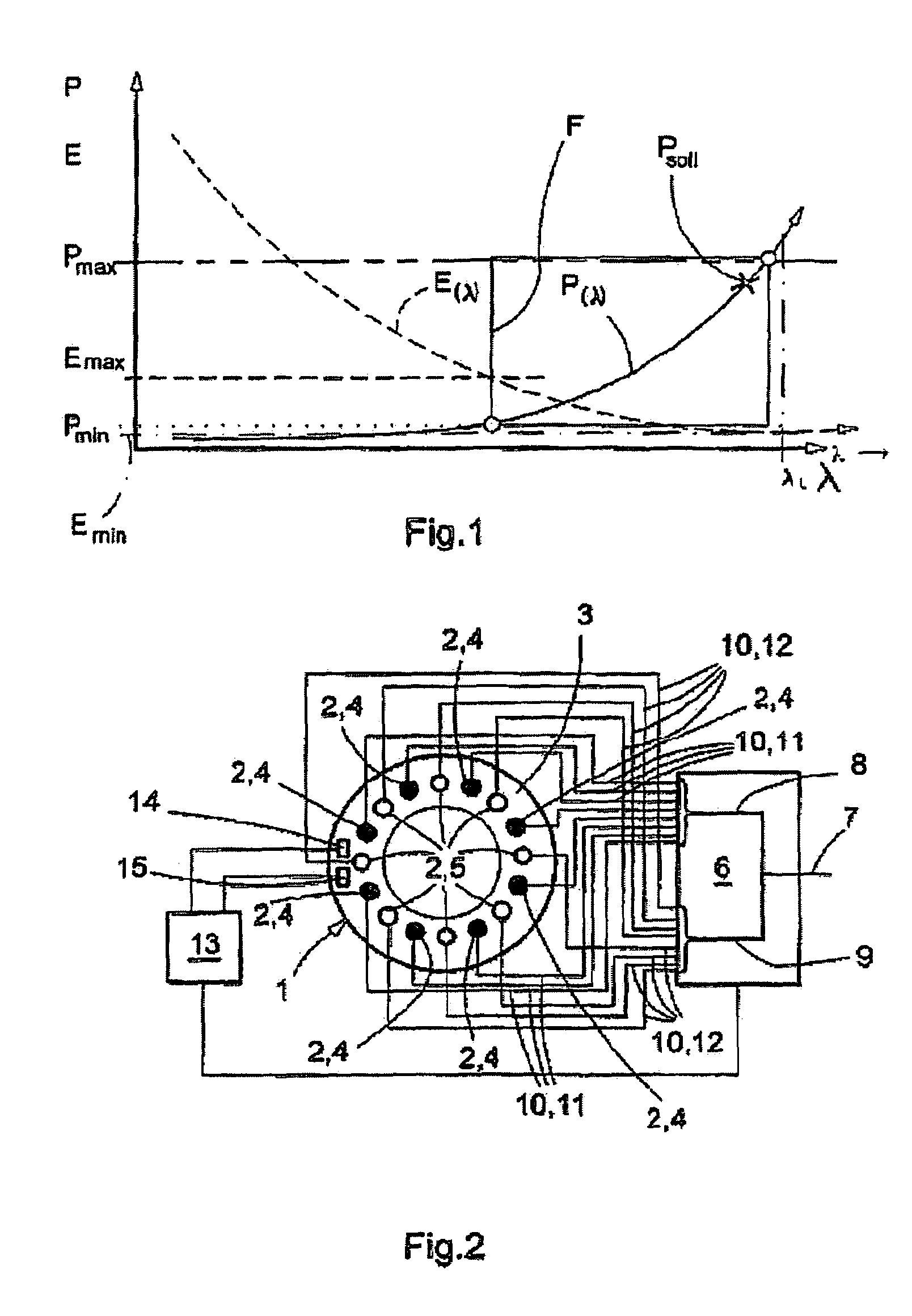

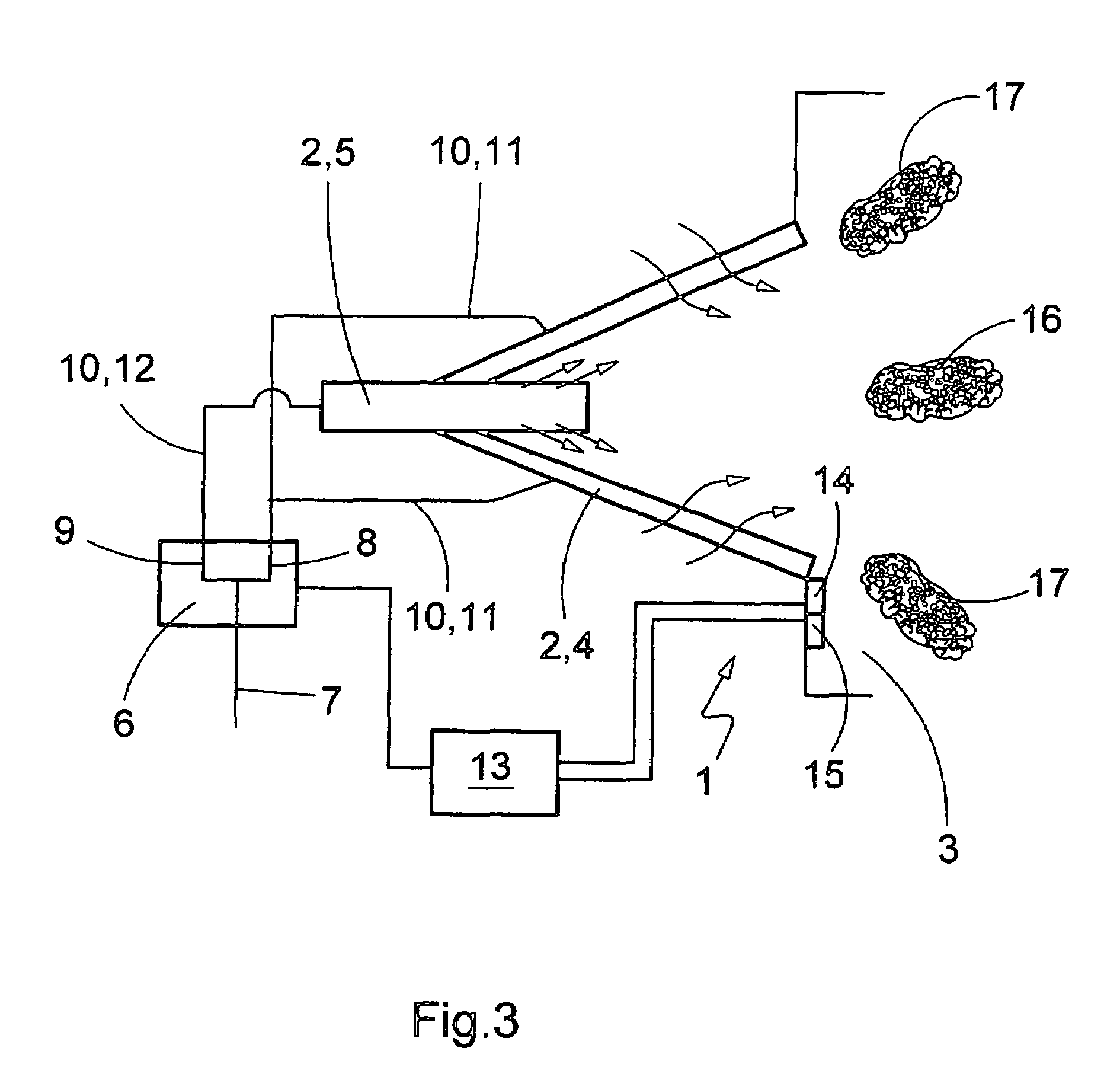

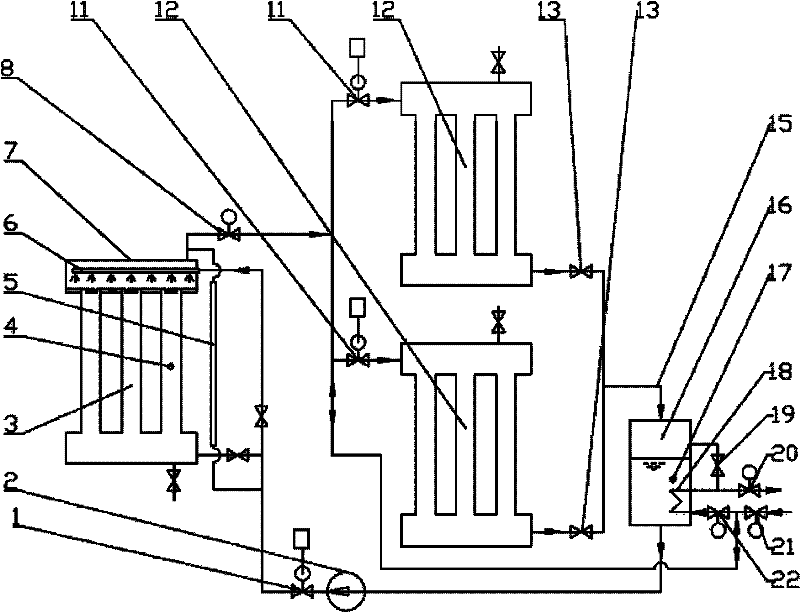

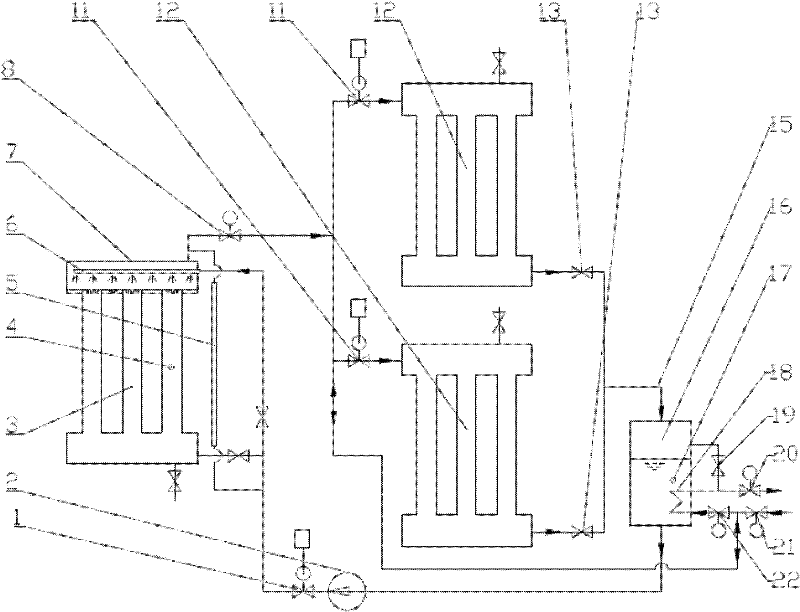

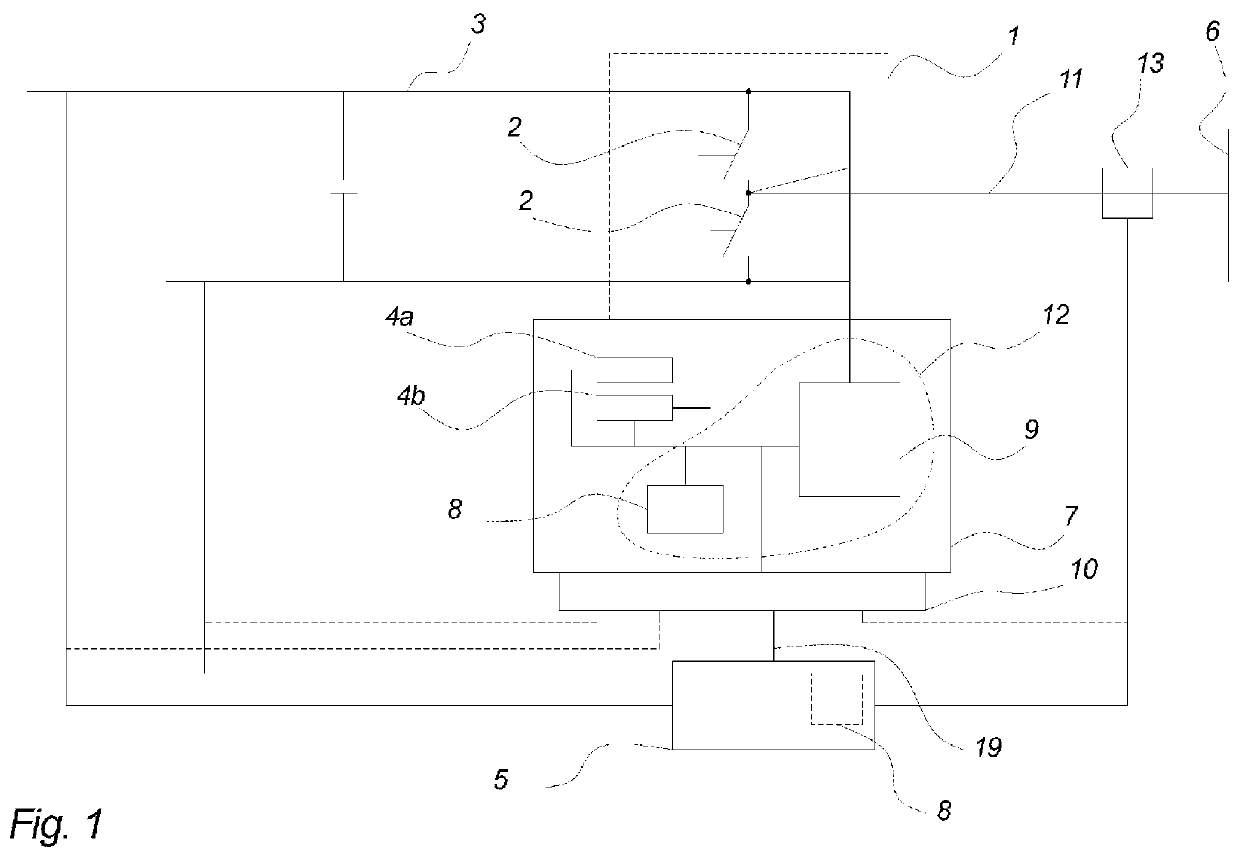

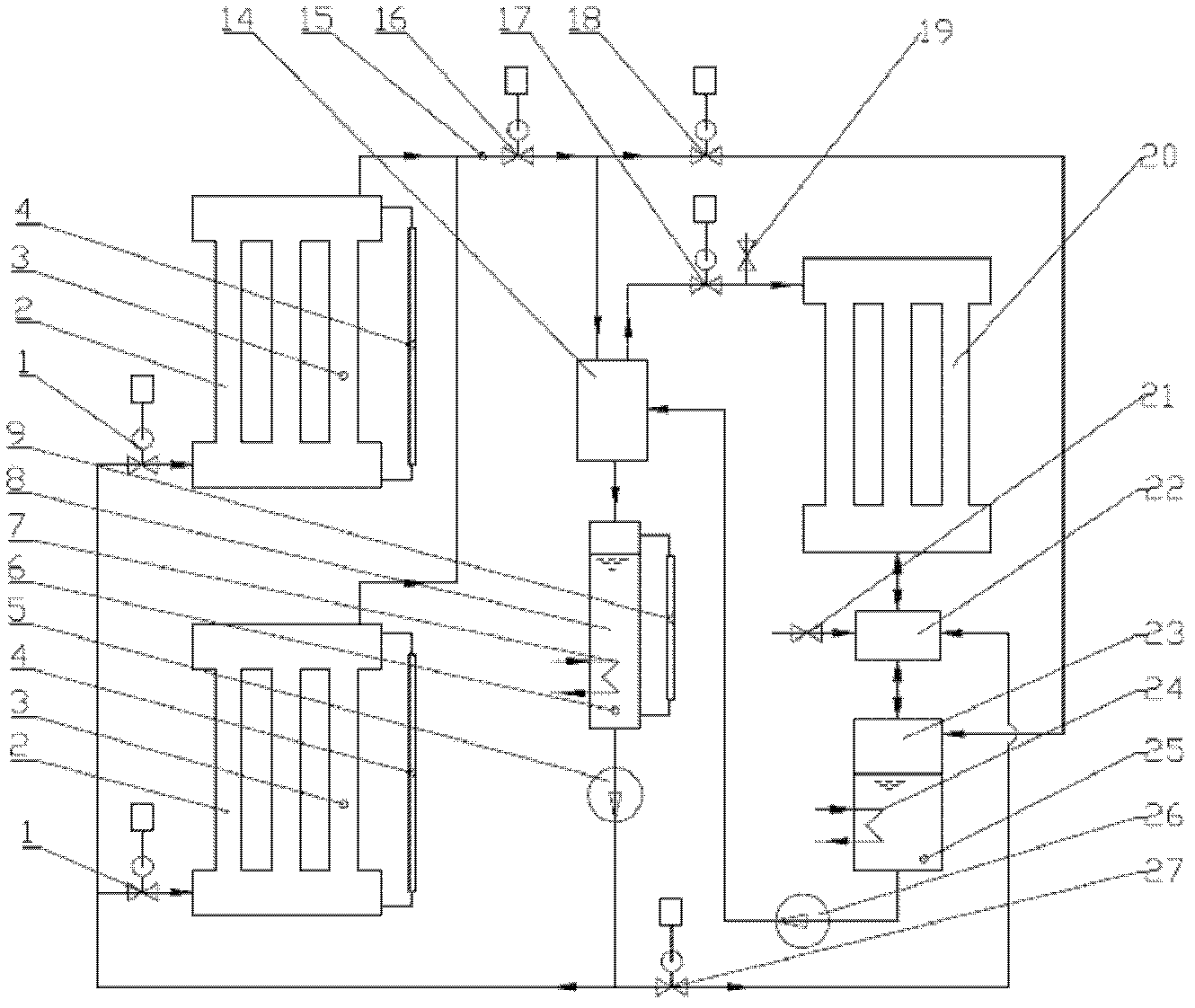

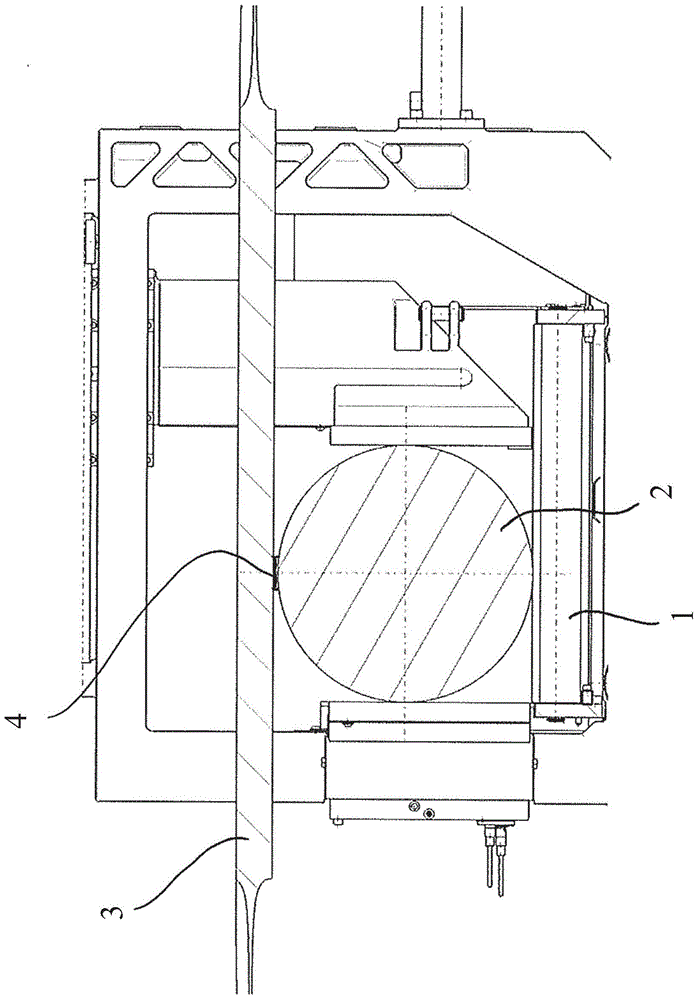

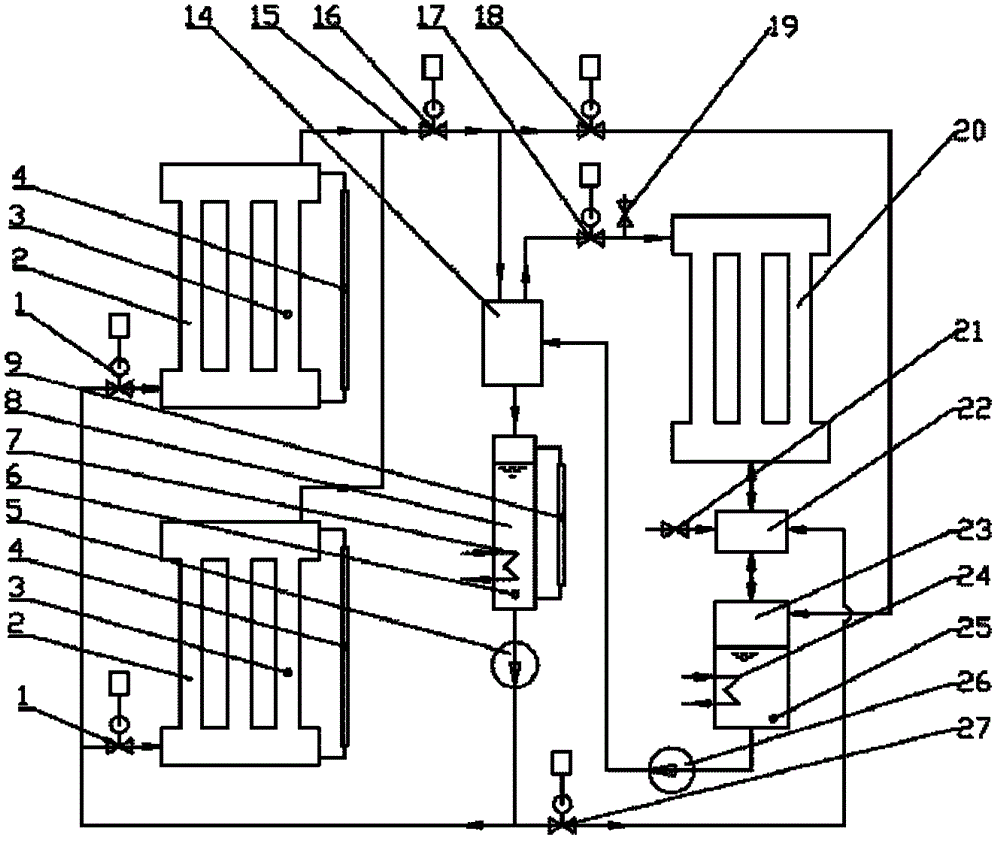

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersEngineeringLiquid storage tank

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

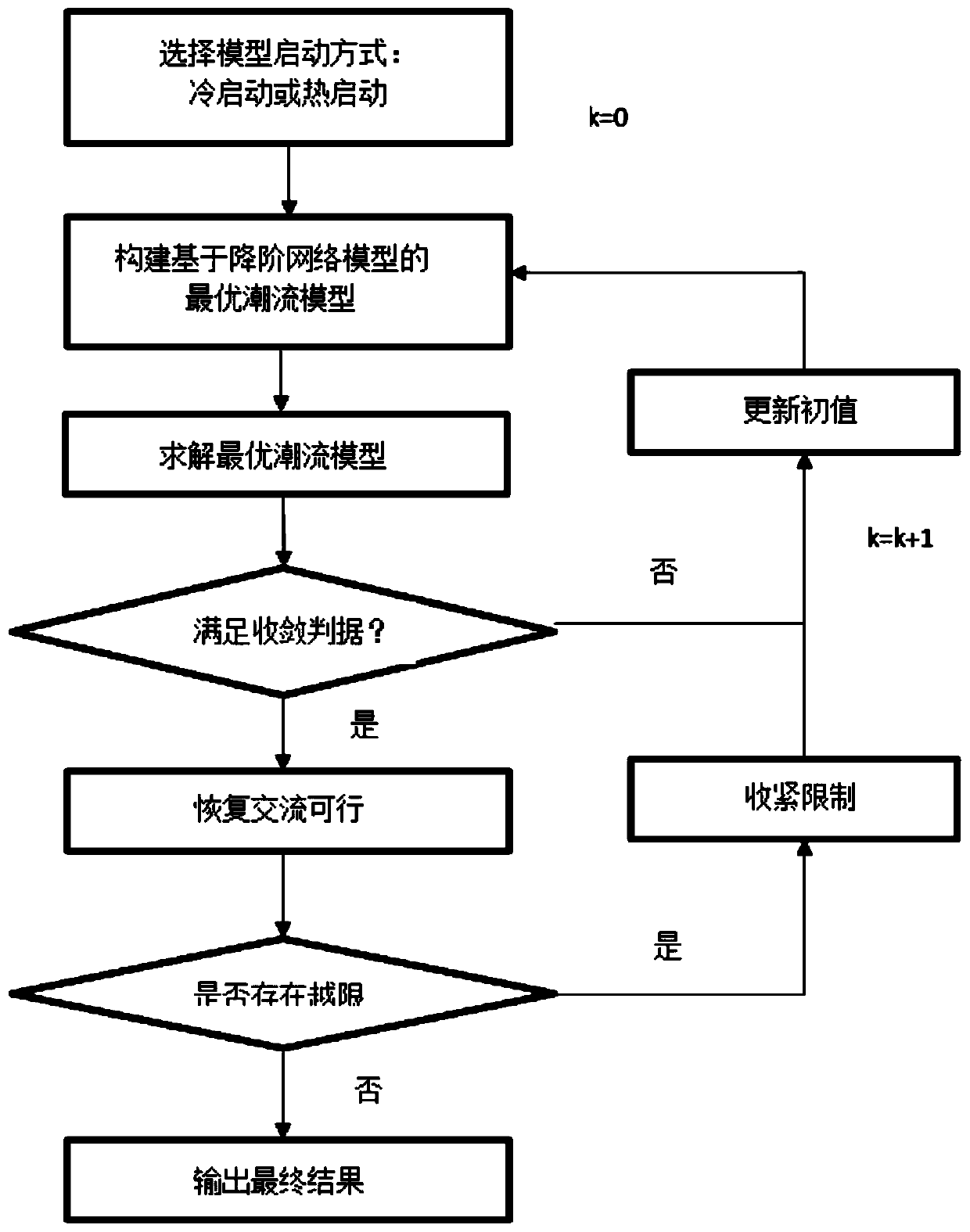

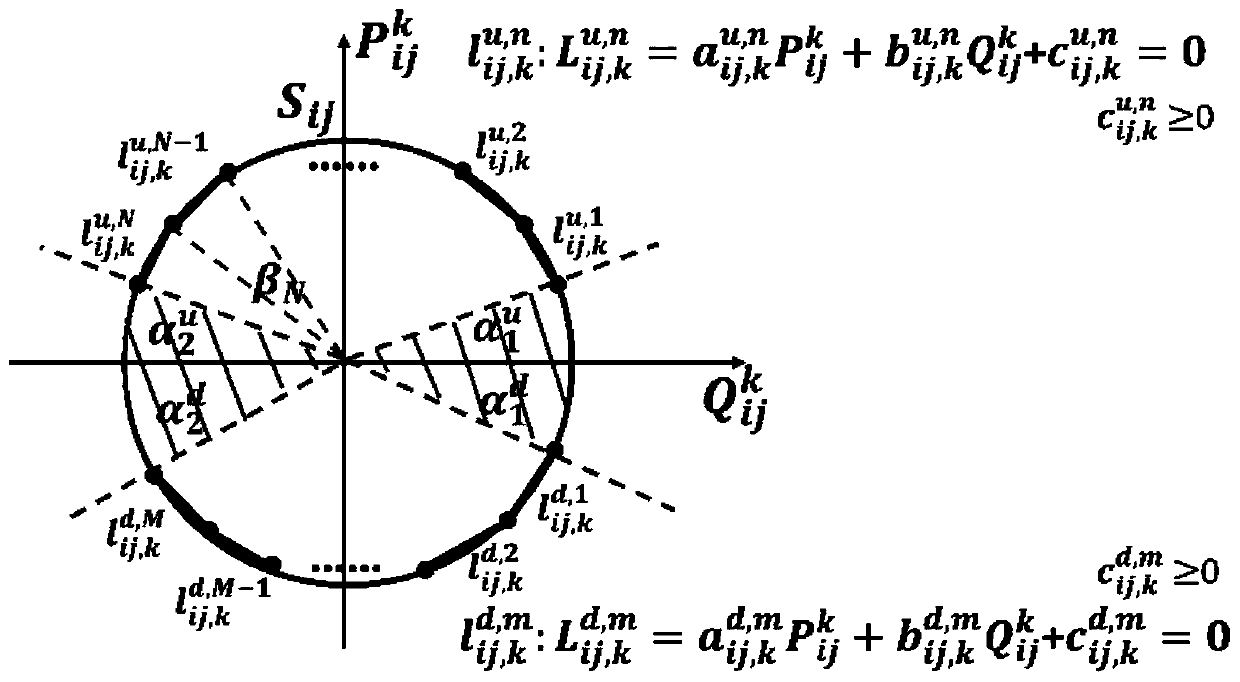

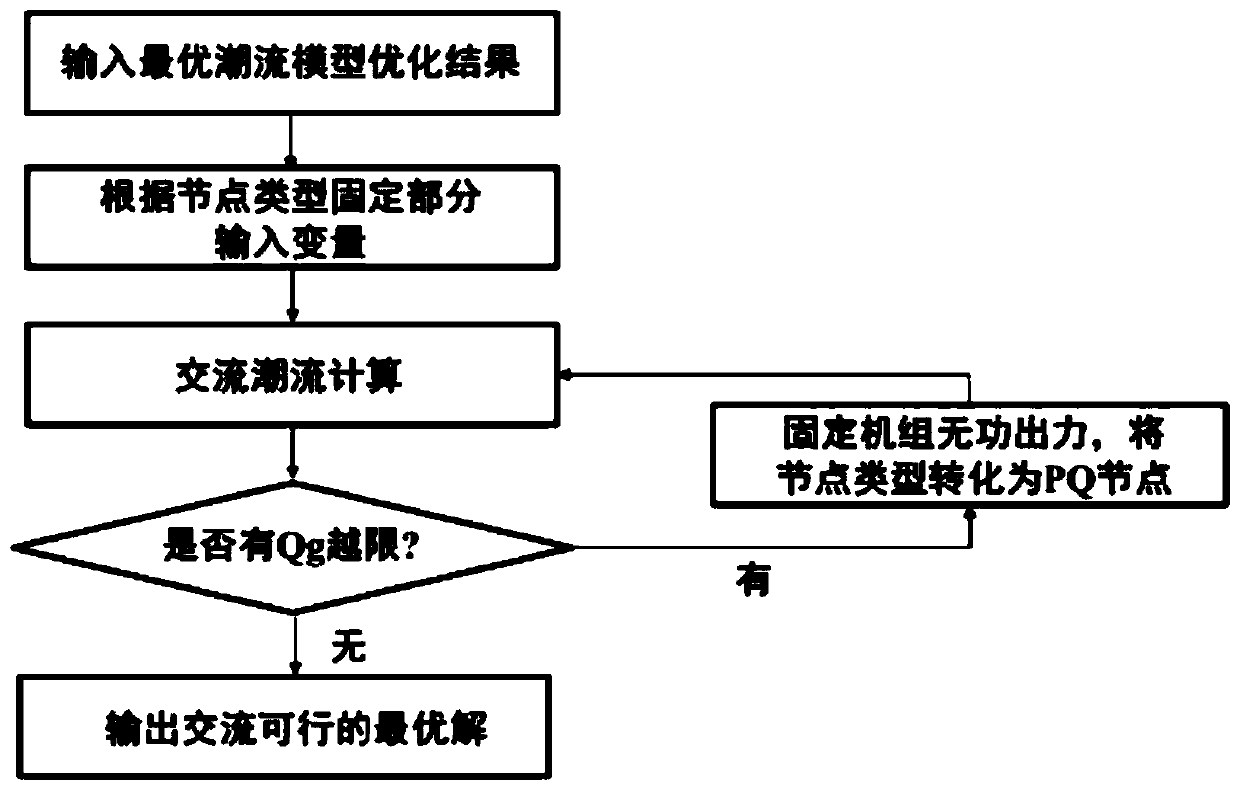

Safety constraint economic dispatching method for embedded reactive power and voltage

ActiveCN108054789AGuaranteed economyEnsure safetyProgramme controlSingle network parallel feeding arrangementsVoltage amplitudePower flow

The invention provides a safety constraint economic dispatching method for embedded reactive power and voltage, and belongs to the field of electric power system safety constraint economic dispatching. According to the method, first an optimal power flow model of safety constraint economic dispatching formed by an objective function and a constraint condition is built; after the model is iteratively solved, a per unit error is checked for all branch lines; if a line exists which does not meet the per unit error, a power flow equation constraint is updated, iteration of a next time is performedtill all the lines meet the per unit error, the model converges, iteration ends, and a whole set of electric power system safety constraint economic dispatching scheme containing node voltage amplitude, a voltage phase angle, unit active power output and reactive power output is obtained. The safety constraint economic dispatching method for embedded reactive power and voltage can maximally meetelectric power system economic operation requirements, and reduce electric power system operation cost; and is high in precision, is good in convergence, and has very high practical application value.

Owner:TSINGHUA UNIV

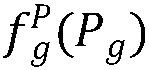

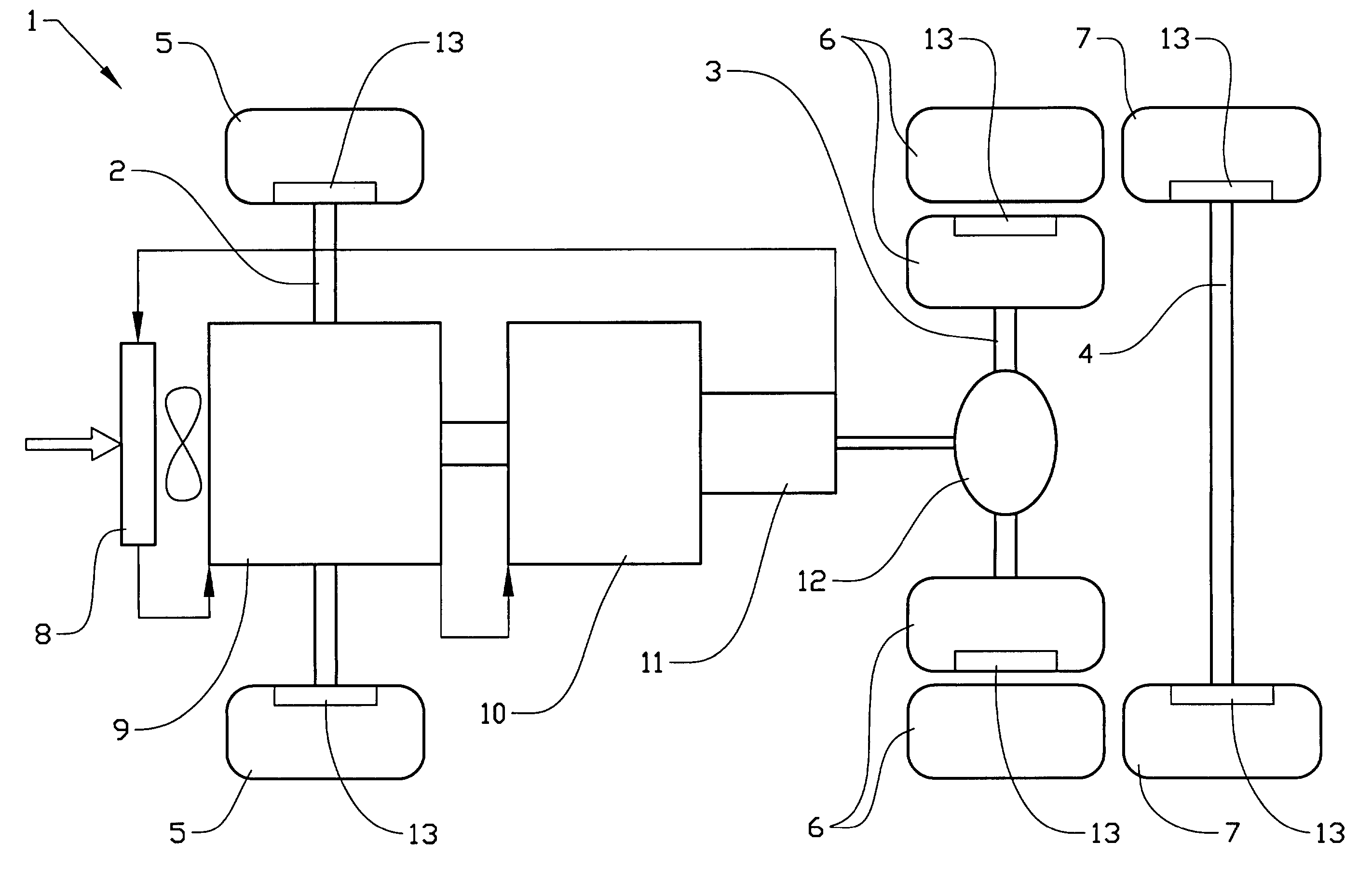

Method and apparatus for the distribution of brake torque on a vehicle

InactiveUS20060113833A1Improve vehicle performanceReduced safety marginBraking action transmissionBrake actuating mechanismsBrake torqueDrive wheel

Method and apparatus for distributing brake torque between at least a first and a second braking device on a motor vehicle having at least two wheel pairs. The first braking device is a friction brake which acts on at least one wheel pair and the second braking device acts on at least one driven wheel pair. The distribution of brake torque between the first braking device and the second braking device takes account of brake torque required and also the maximum brake torque the first braking device and the second braking device can deliver. The distribution of brake torque takes place when the vehicle is driven with a cruise control function.

Owner:VOLVO LASTVAGNAR AB

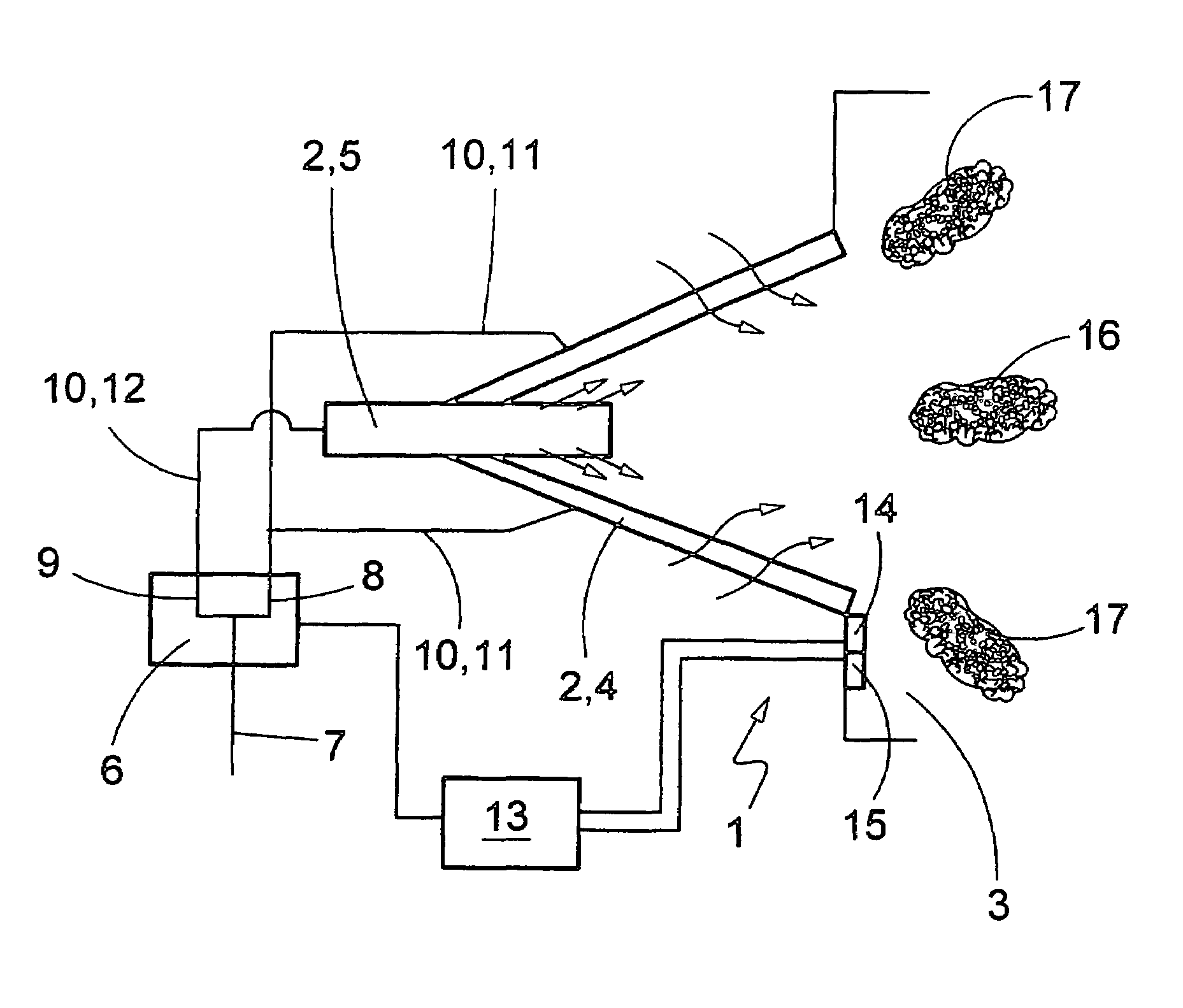

Method for operating a furnace

InactiveUS7513117B2Safe operation of the combustion chamber close to the lean extinguishing limit is simplifiedReduced safety marginFuel supply regulationContinuous combustion chamberPower stationCombustion chamber

Owner:ANSALDO ENERGIA IP UK LTD

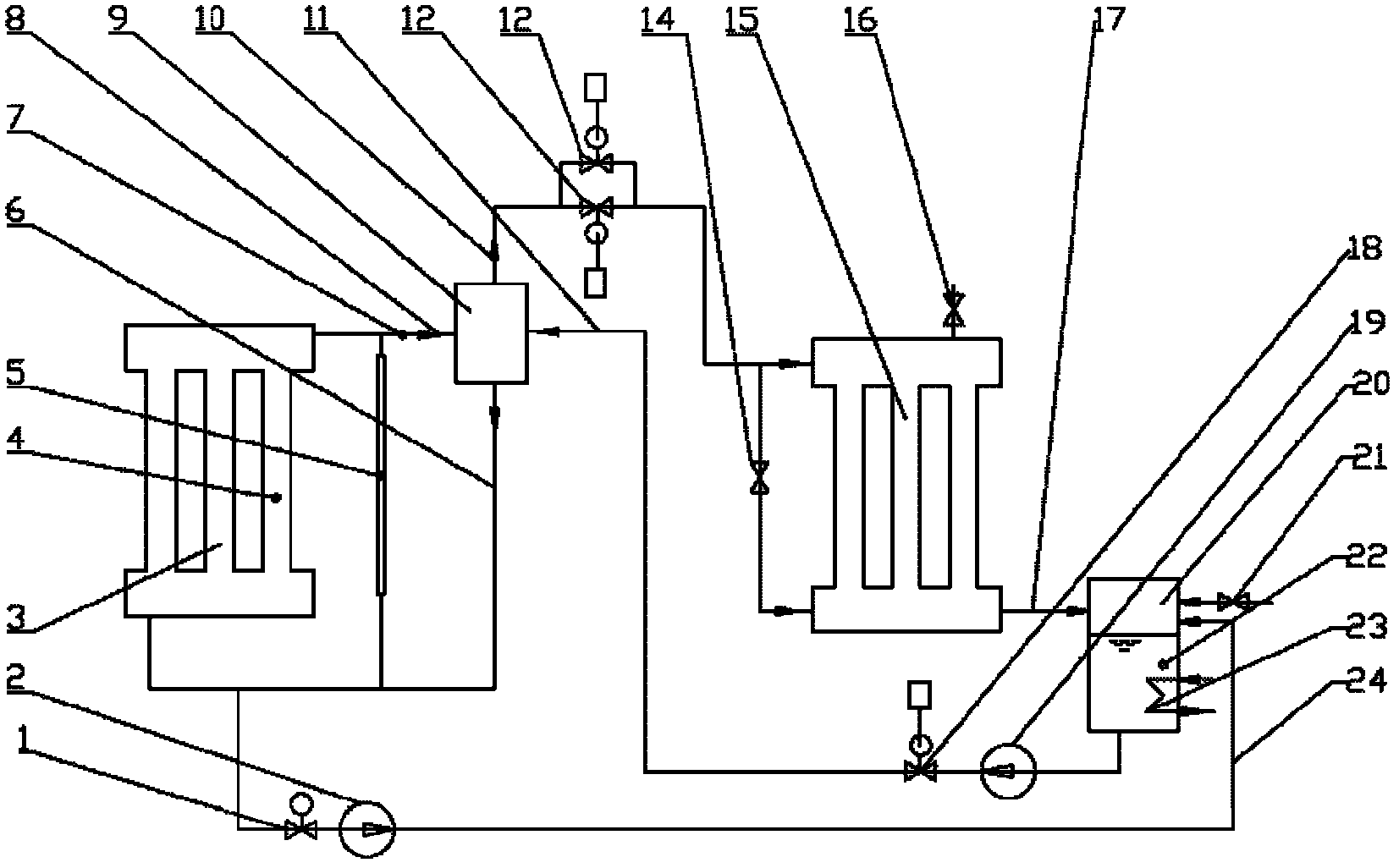

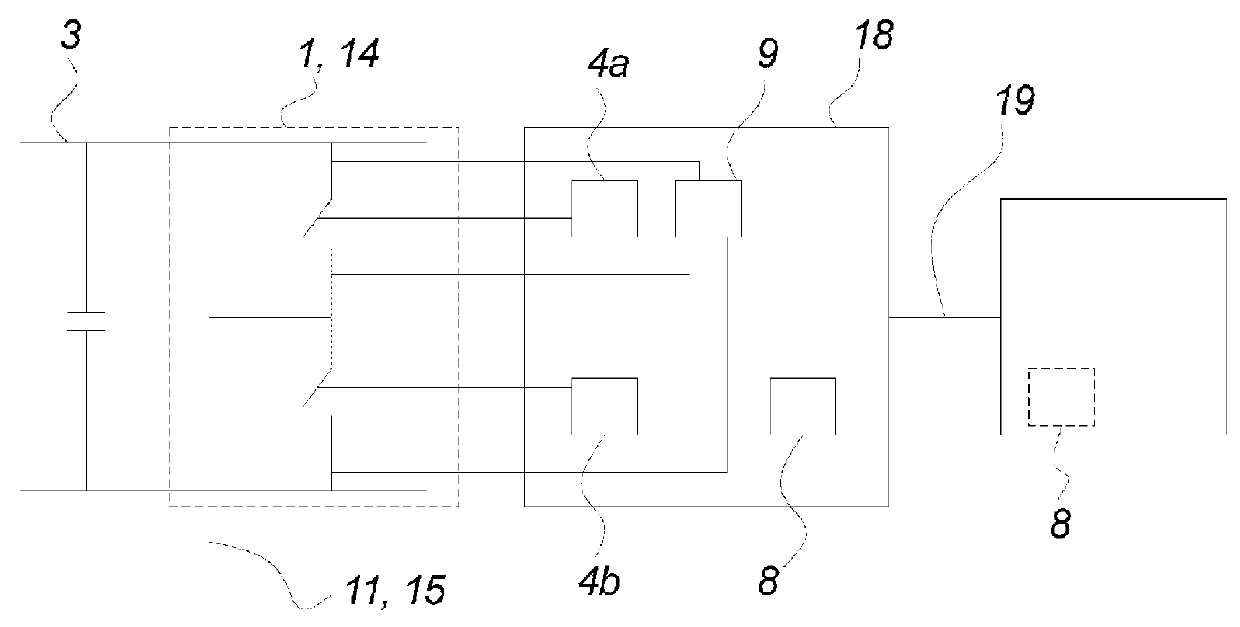

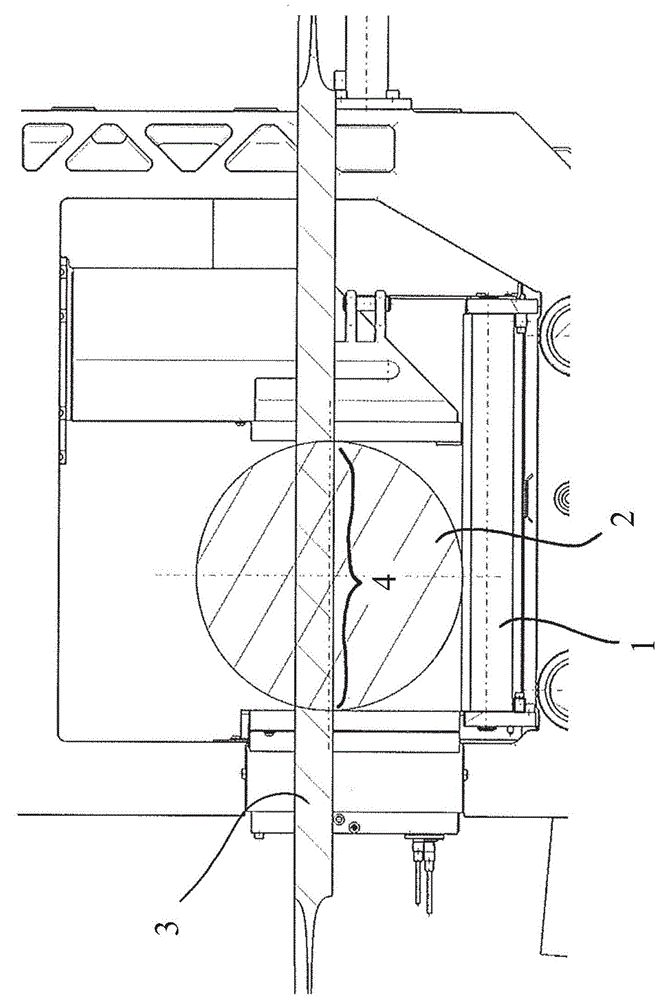

High-efficiency, sub-control and phase-change heat exchange system and method

InactiveCN102230753AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersHeat exchange apparatusAirflowEngineering

The invention relates to a high-efficiency, sub-control and phase-change heat exchange system. The heat exchange system provided by the invention comprises a heat exchanger of heat source (3) and a heat exchanger of cold source (12) which are mutually communicated through a steam tube and a condensate line to from a sub-control and phase-change heat exchange circuit. The heat exchange circuit is provided with an air flow regulating valve and a liquid flow regulating valve which can control the circuit. A reservoir tank (16) is configured on the condensate line. The header of the steam tube on the top of the heat exchanger of heat source (3) is divided into two steam sub-tubes. A first steam sub-tube is connected with the heat exchanger of heat source (12) and an air flow regulating valve (11) is configured between the first steam sub-tube and the heat exchanger of cold source (12). A second steam tube communicates with the reservoir tank (16) via a condensate heater (18) configured inside the reservoir tank (16). A liquid distribution tube (6) is configured inside the collecting chamber (7) of the heat exchanger of heat source (3), and a plurality of sprayers are configured on the liquid distribution pipe which is used for the mixing heat exchange of steam and condensate. The efficiency of the system provided by the invention is much higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

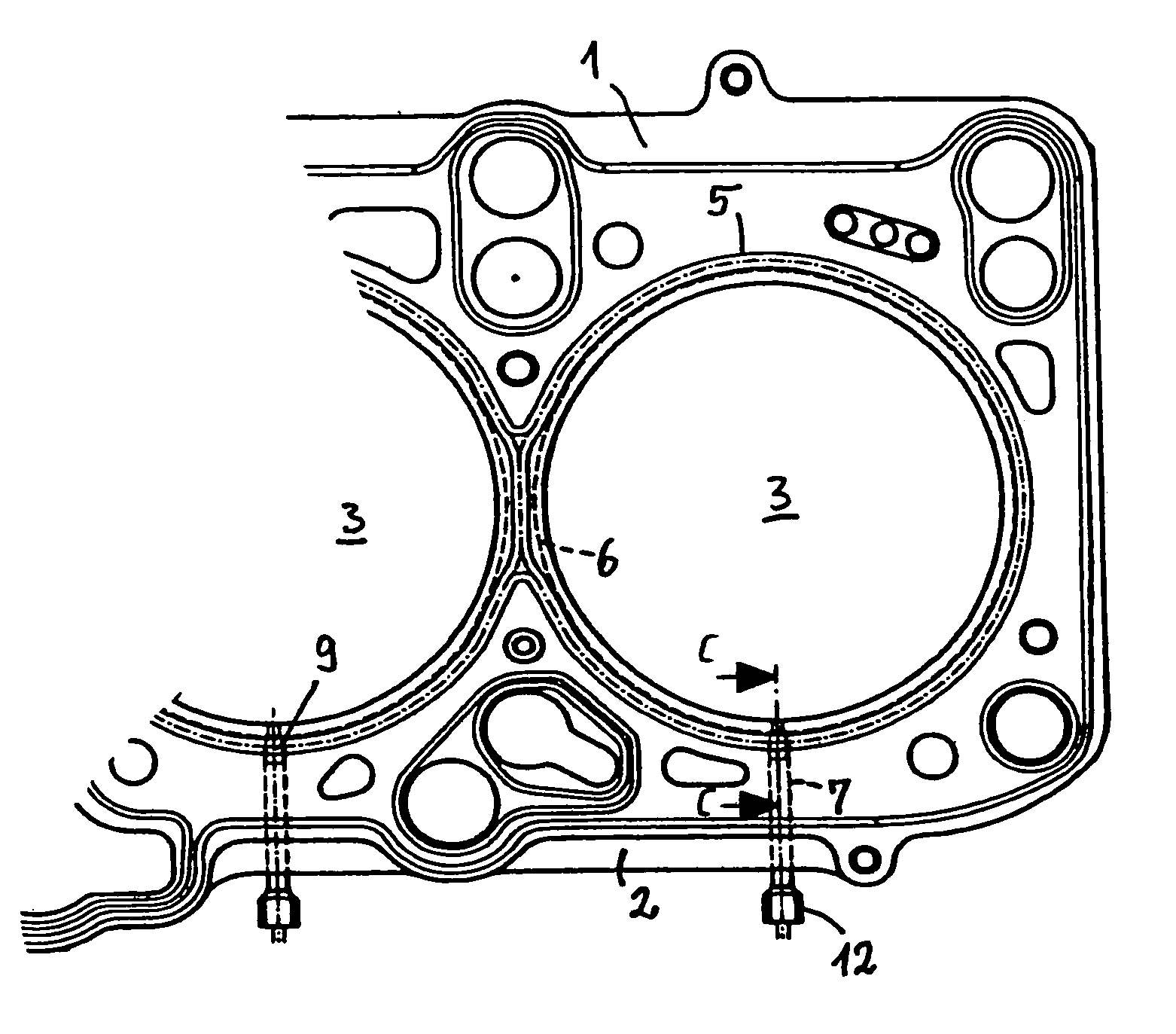

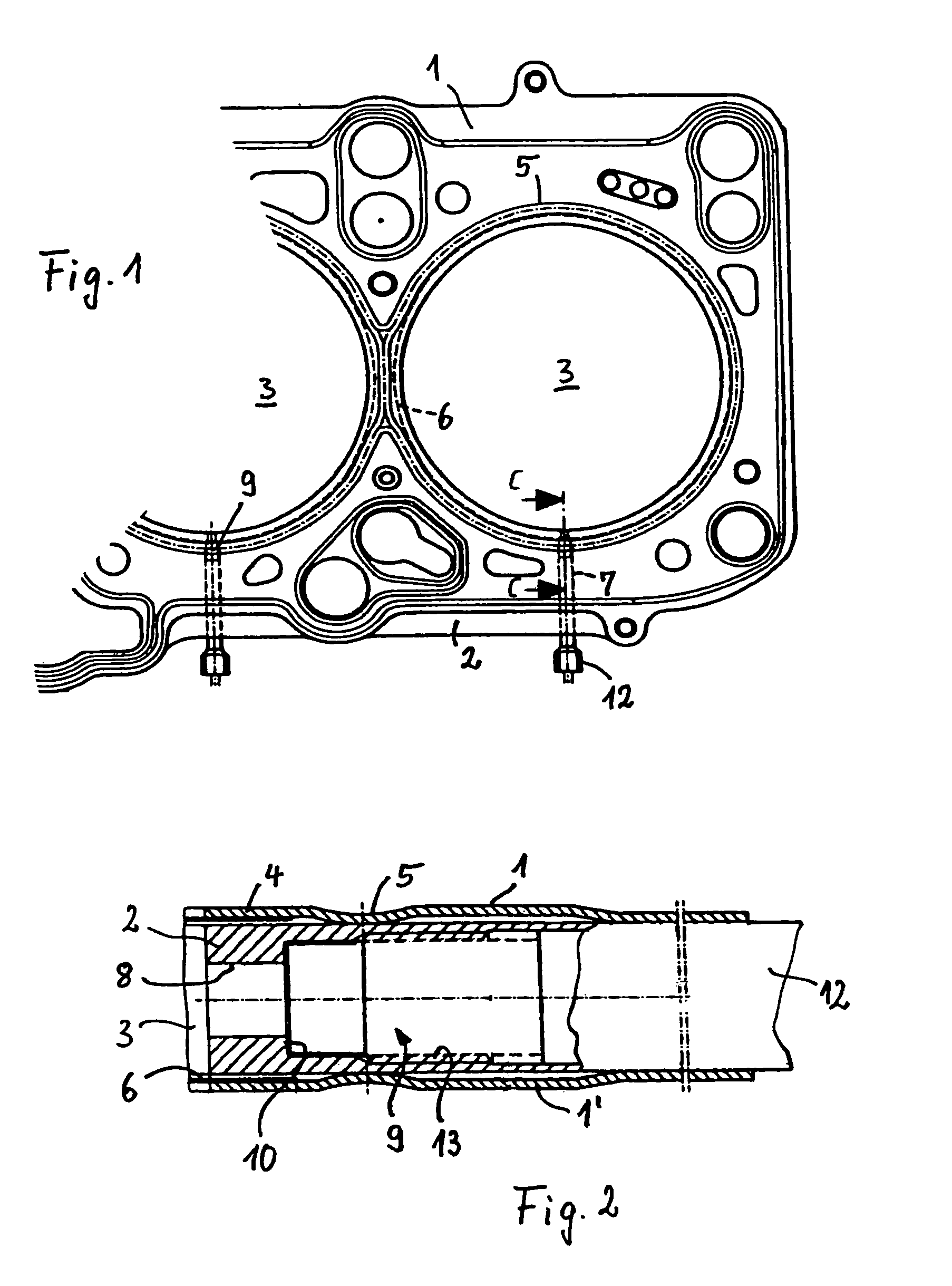

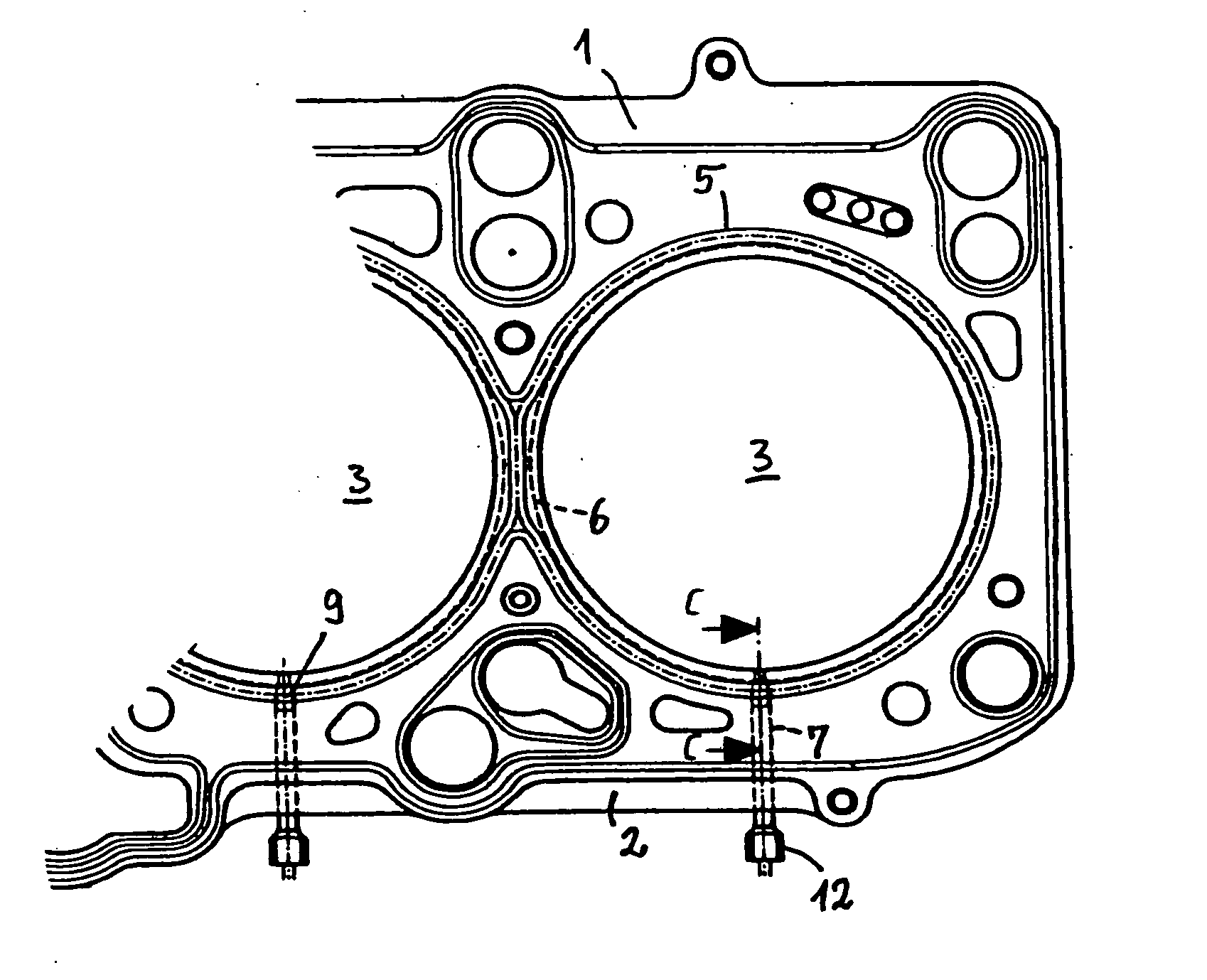

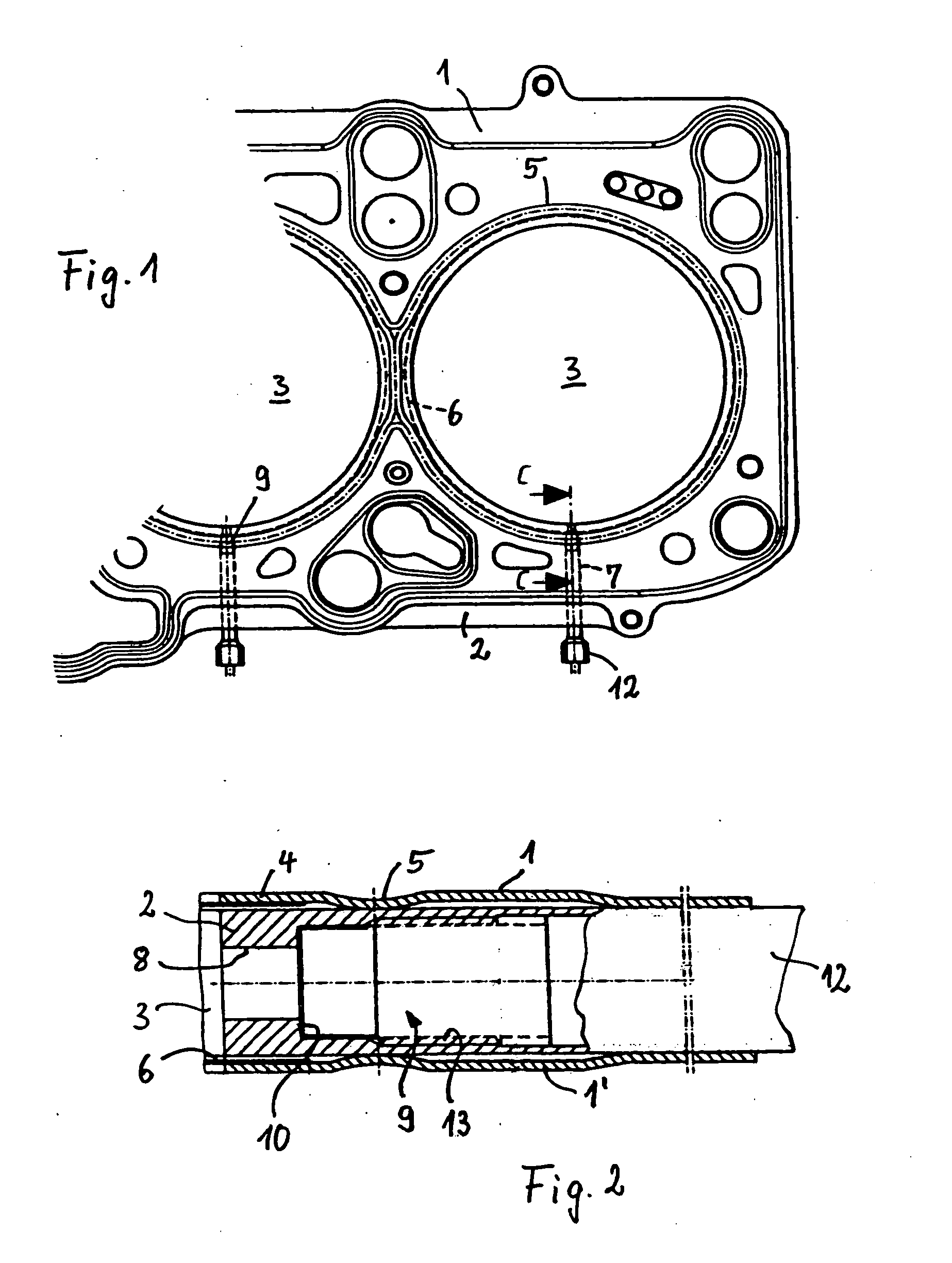

Cylinder head gasket

A metallic cylinder head gasket for an internal combustion engine having at least one combustion chamber. The gasket includes at least one sheet-metal layer having at least one opening corresponding to the at least one combustion chamber of the internal combustion engine and at least one bore extending from the outer edge to the edge of the opening. A membrane, closing the bore at the combustion-chamber side is exposed to the gas pressure of the combustion chamber. A pressure sensor disposed in the sheet-metal layer is pressurized axially relative to the bore by movement of the membrane by the gas pressure of the combustion chamber.

Owner:ELRINGKLINGER AG +1

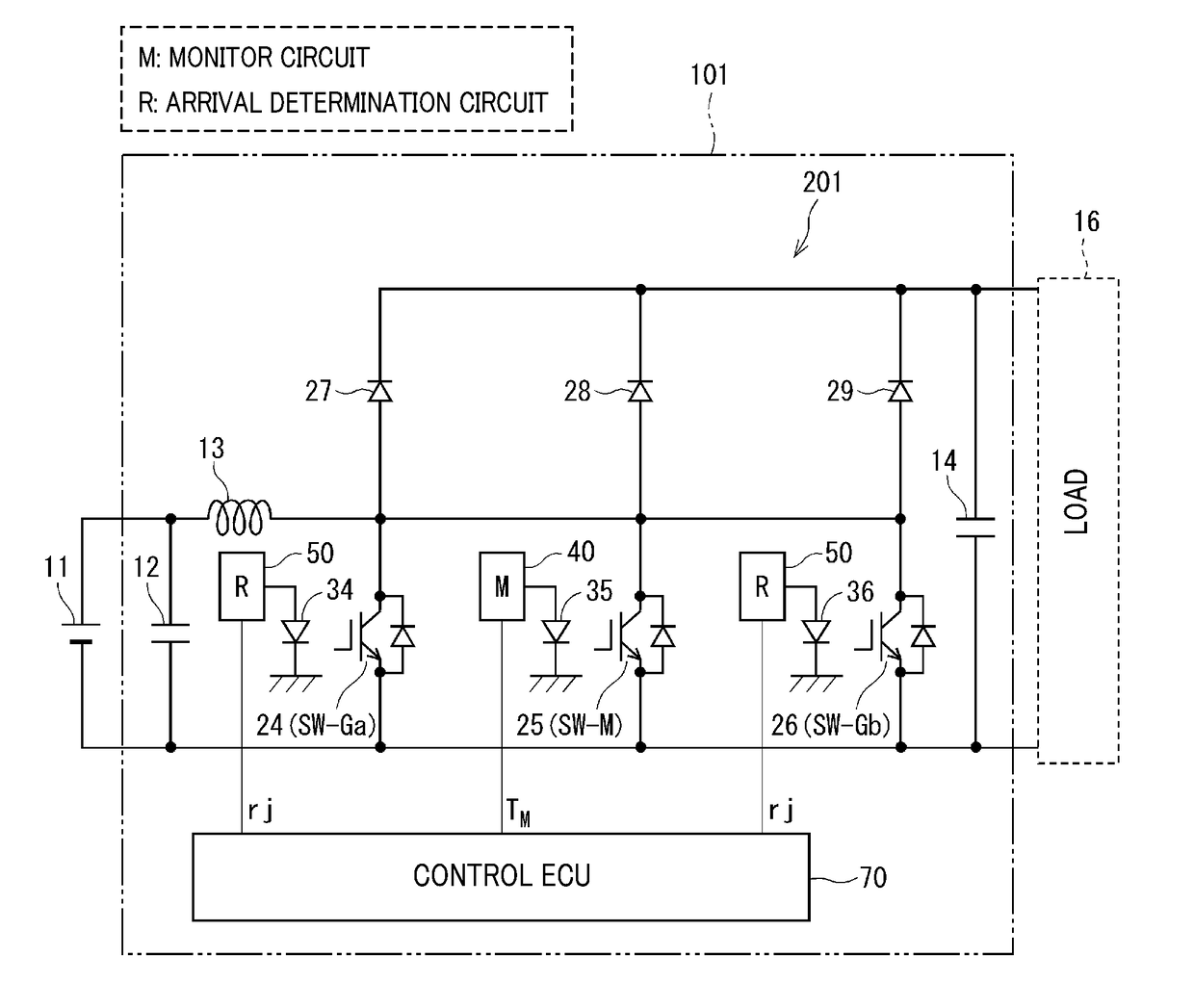

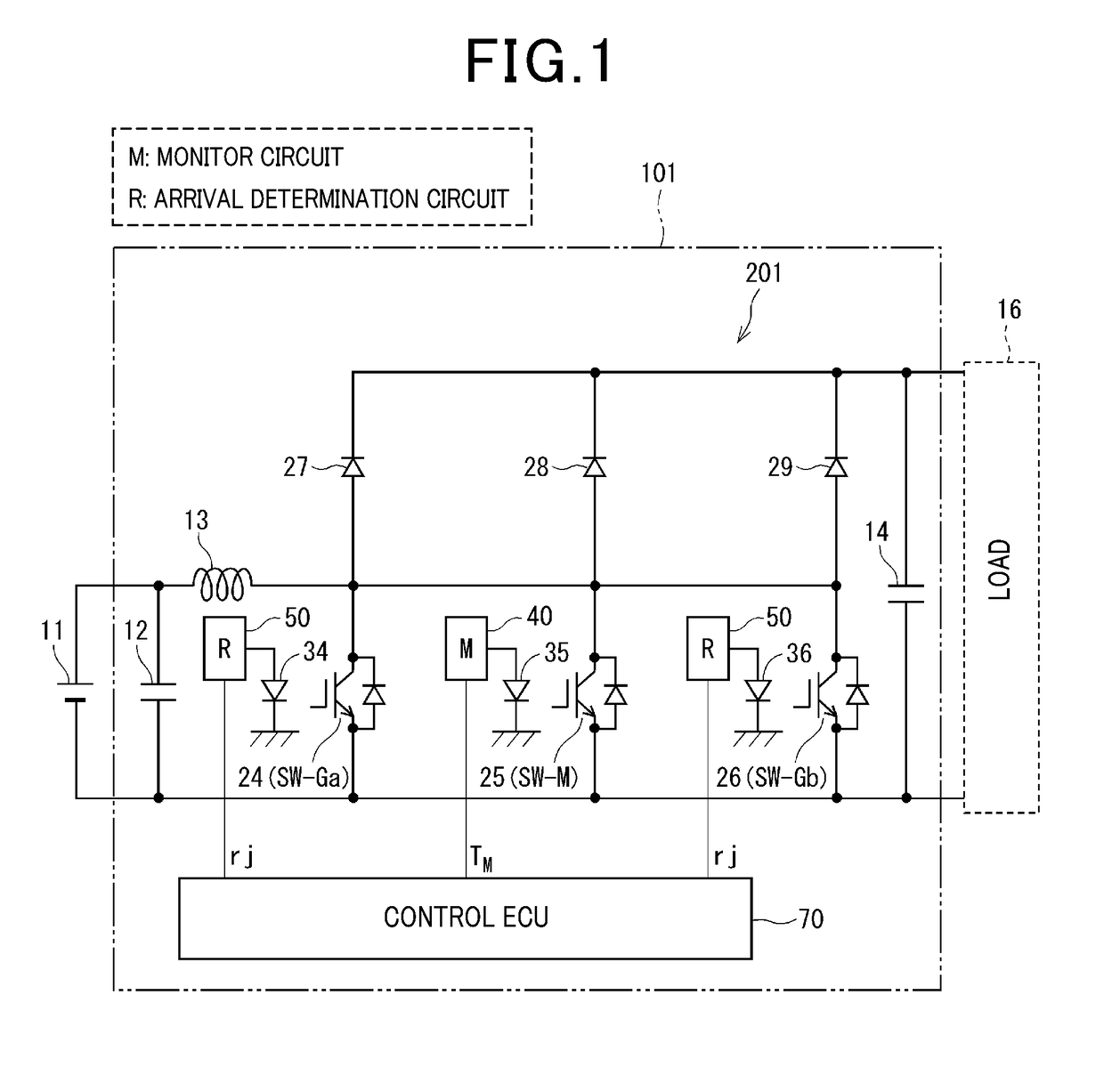

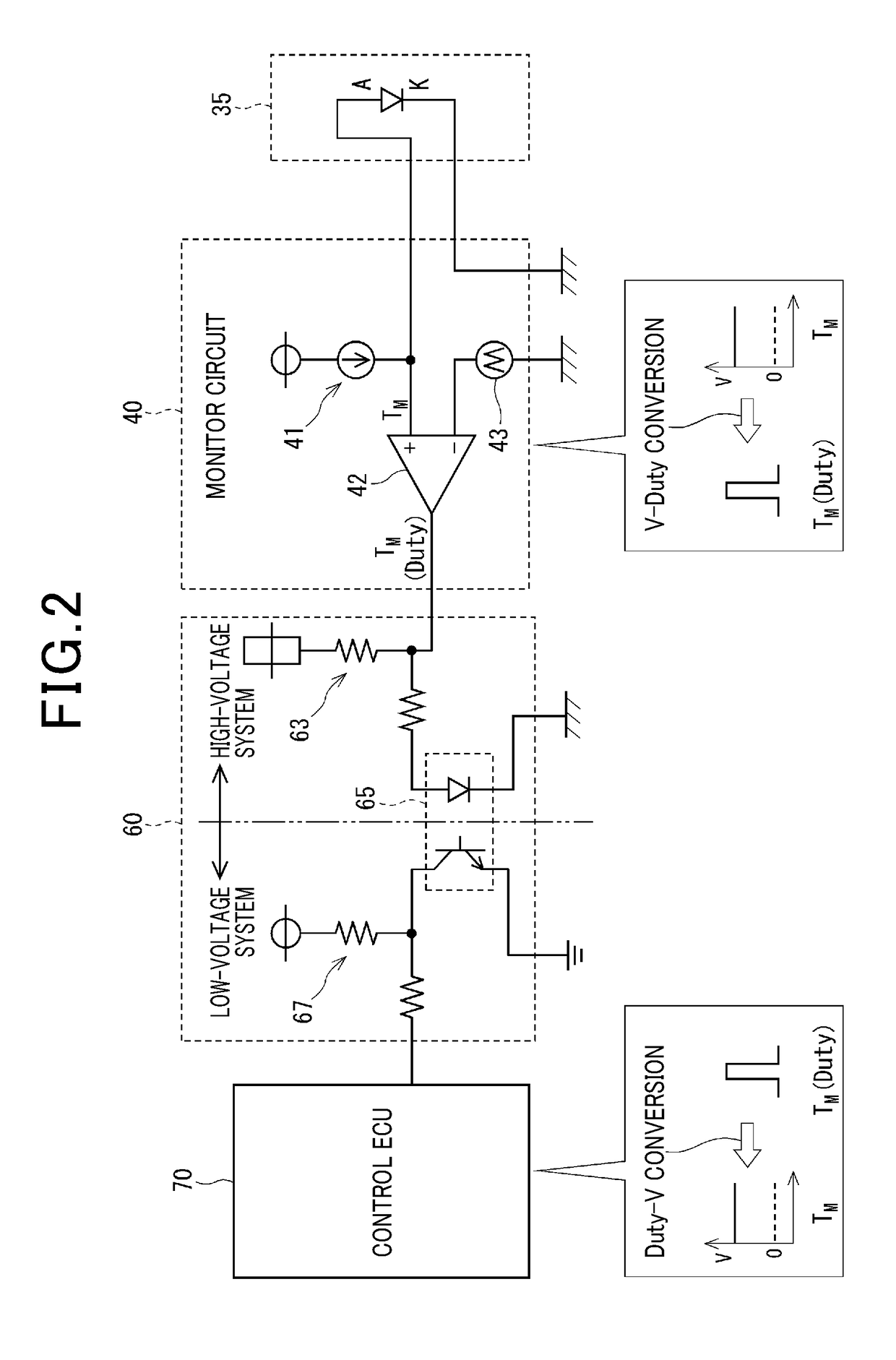

Intelligent gate drive unit

An intelligent gate drive unit and related method for controlling one or more semiconductor switches of one or more power modules, the intelligent gate drive unit comprises at least a gate driver and an analog measuring circuit, wherein the gate driver facilitates control of the one or more semiconductor switches and wherein the analog measuring circuit facilitates measuring the switch voltage when the one or more semiconductor switches are in a conducting mode.

Owner:K B ELECTRONICS INC

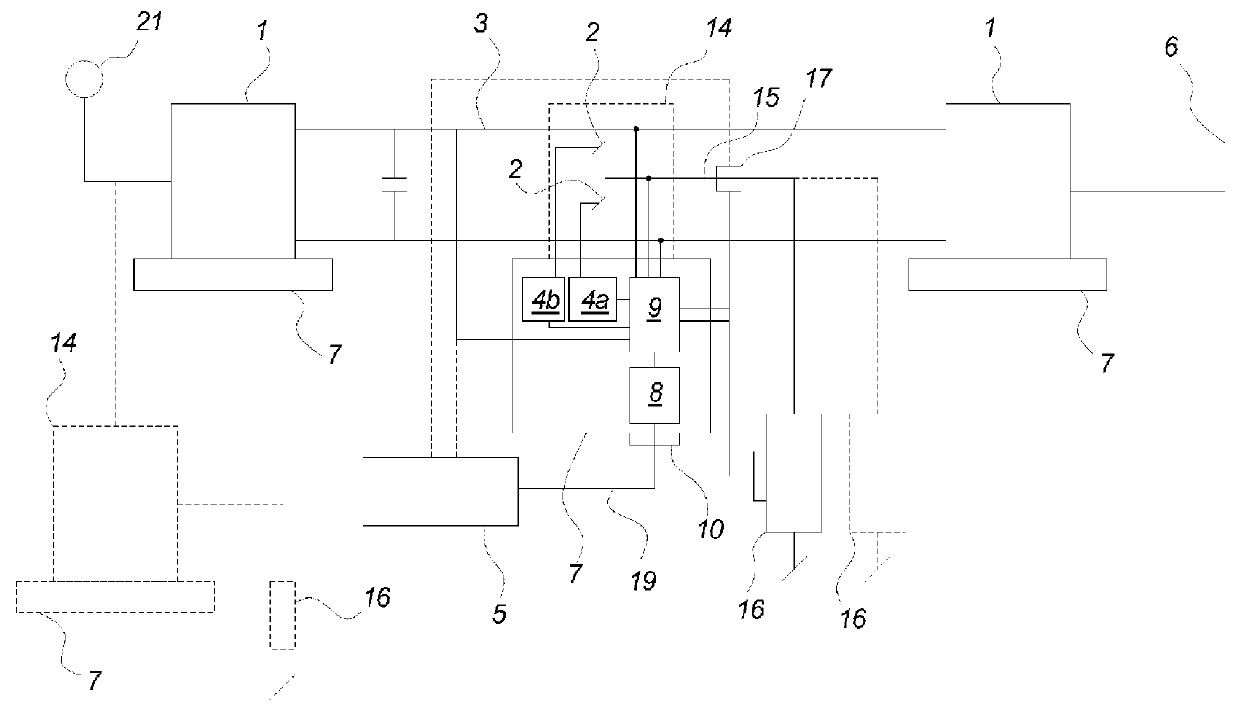

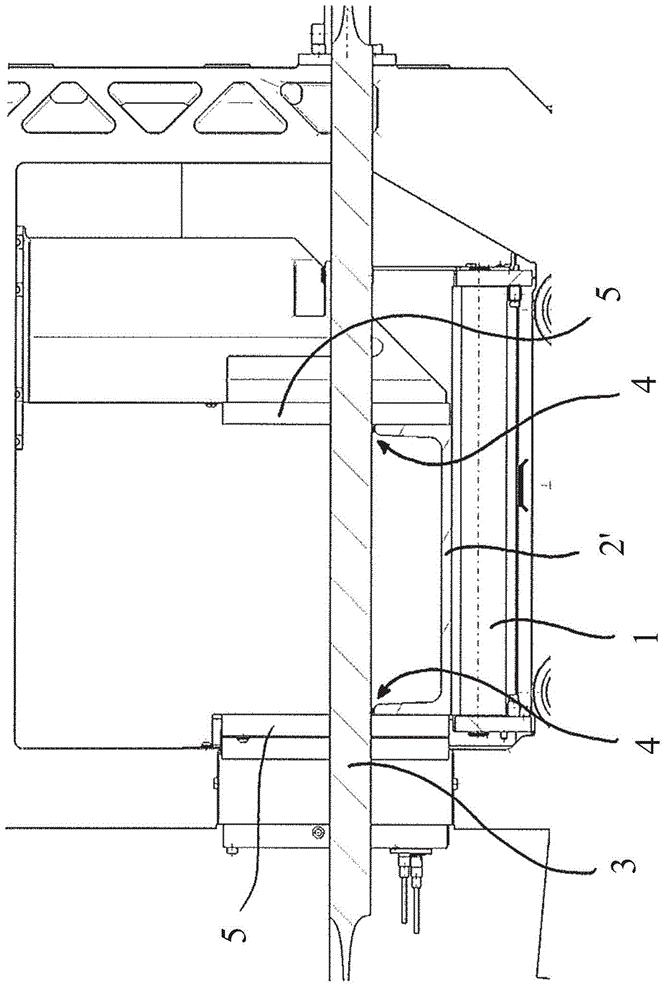

Branch-control and phase-change heat exchange system and method based on two-stage steam-liquid heat exchanger

ActiveCN102200403ANo disturbance effectReliable sub-control performanceIndirect heat exchangersHeat exchange apparatusControl systemEngineering

The invention relates to a branch-control and phase-change heat exchange system and method based on a two-stage steam-liquid heat exchanger. The system comprises a heat source heat exchanger (2), a cold source heat exchanger (20) and a low temperature liquid tank (23), and the system further comprises a high temperature heat exchanger (14), a low temperature heat exchanger (22) and a high temperature liquid tank (8); a main heat source steam pipe at the top part of the heat source heat exchanger (2) is divided into two branch pipes after passing through a heat source steam exhaust adjusting valve (16), the two branches are respectively communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (20), and control systems are respectively arranged on the branches; the low temperature liquid tank (23) is communicated with the high temperature heat exchanger (14) through a condensate pipeline, the bottom of the high temperature heat exchanger (14) is communicated with the high temperature liquid tank (8) through a condensate pipeline, and the condensate pipeline at the bottom of the high temperature liquid tank (8) is respectively communicated with the low temperature heat exchanger (22) and the heat source heat exchanger (2). According to the branch-control and phase-change heat exchange system disclosed by the invention, overheat and over-cold phenomenon of steam and condensate are solved, and the heat exchange efficiency is further improved.

Owner:SHANXI SANHESHENG IND TECH

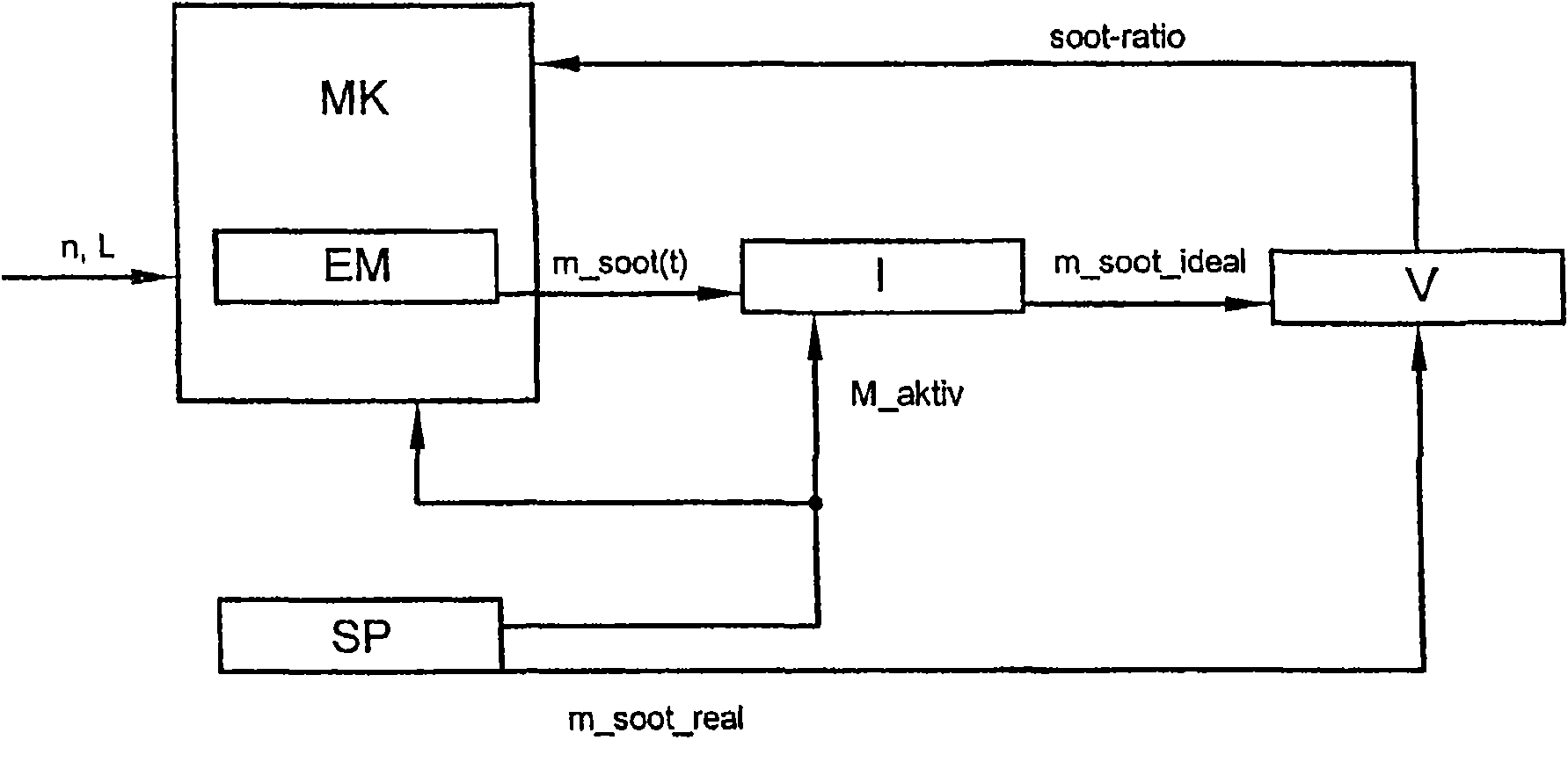

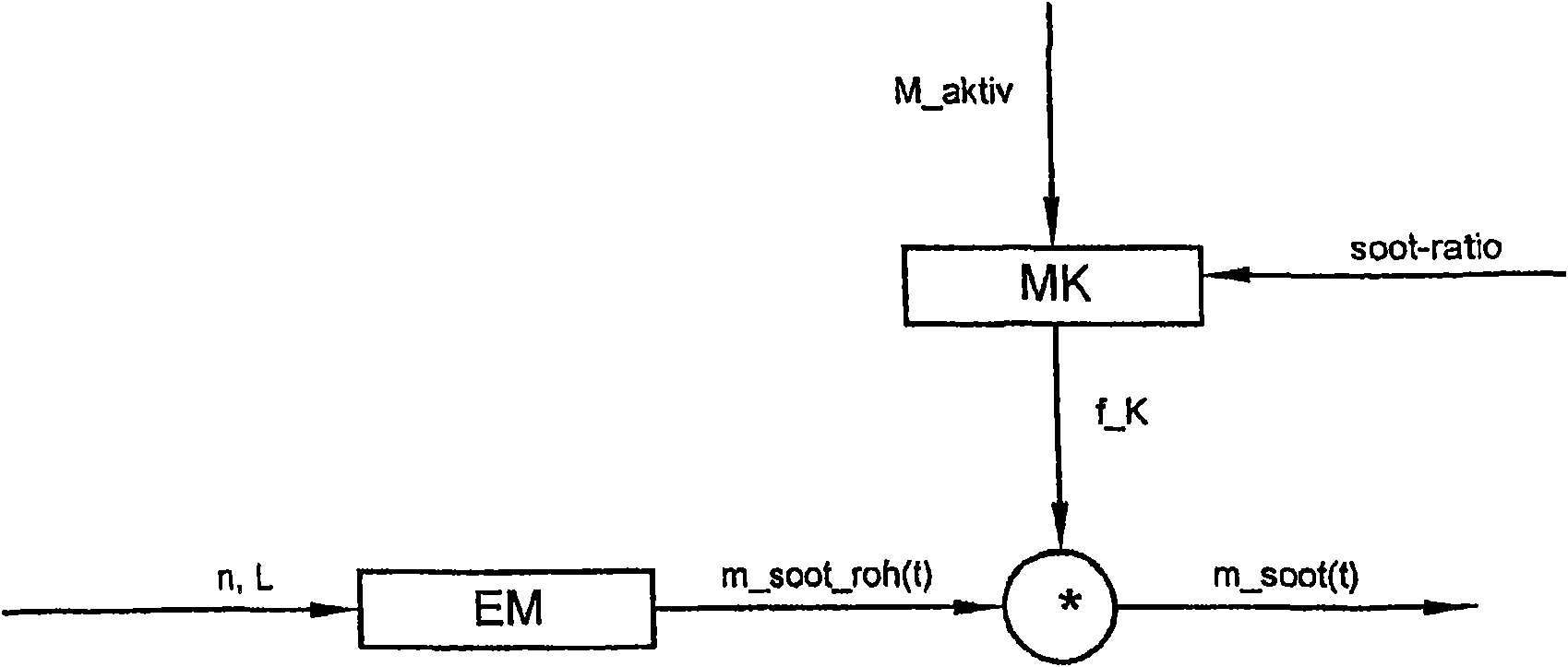

Process for determining particle emission in the exhaust fume stream from an internal combustion engine

InactiveCN101652552AReduce additional fuel consumptionReduced safety marginElectrical controlInternal combustion piston enginesParticle emissionExhaust fumes

A process for determining particle input into a particle filter arranged in the exhaust fume stream of an internal combustion engine makes it possible to determine the mass of deposited particles by taking into account particle and nitrogen oxide emission. The process involves preparing an emission model, measuring the actual particle emissions during a fixed or variable measuring interval, and integrating emissions over this interval; reporting the ideal particle emissions and comparing the actual ones with them; setting a correction factor based on the difference, and taking the correction factor into account in setting the ideal particle emissions.

Owner:AVL LIST GMBH

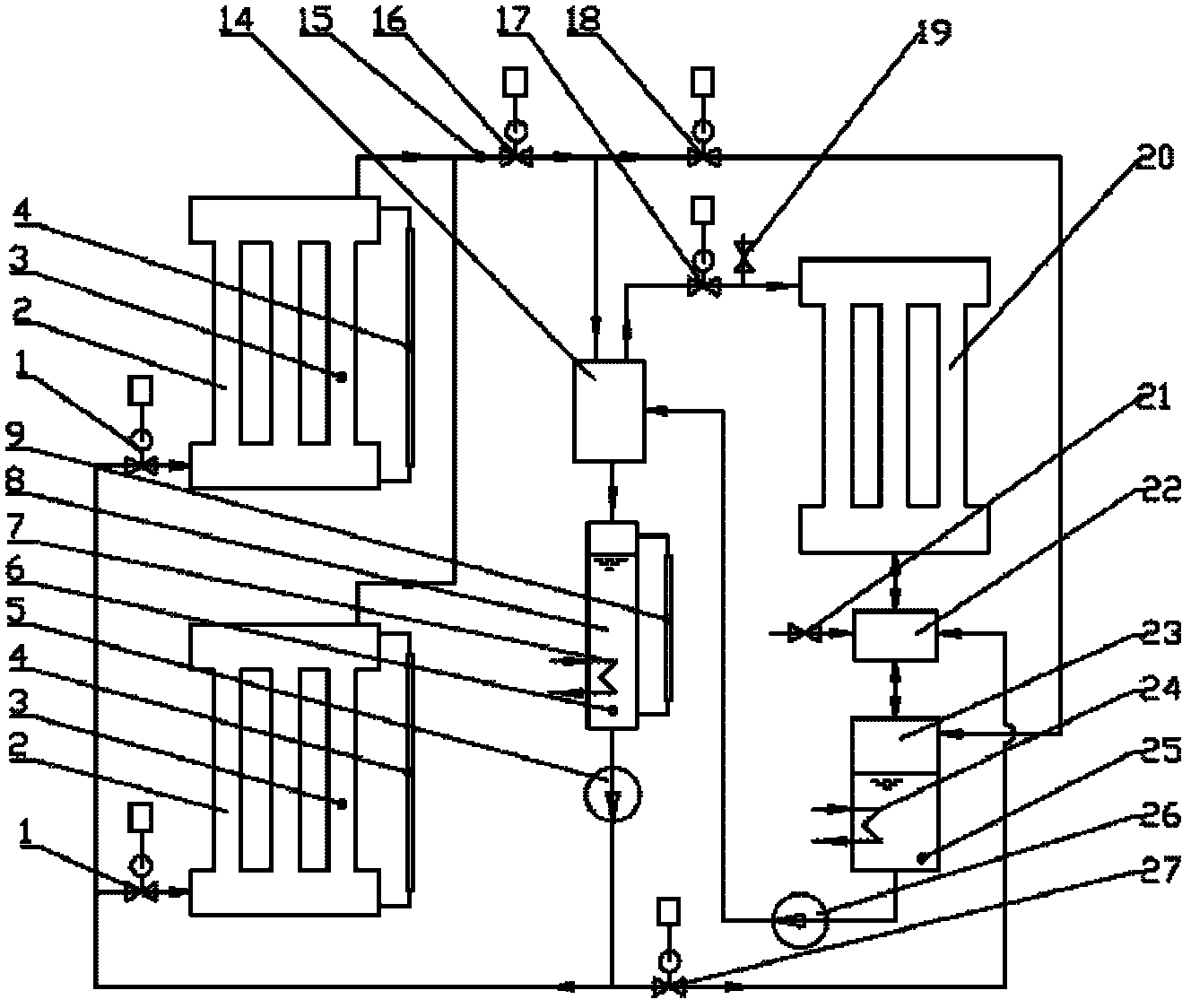

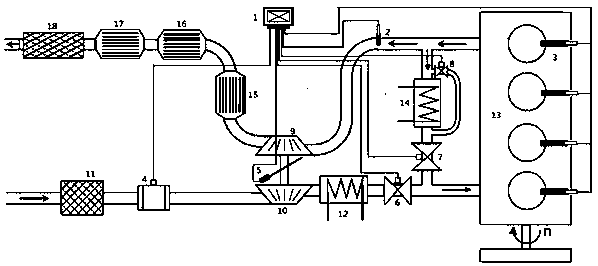

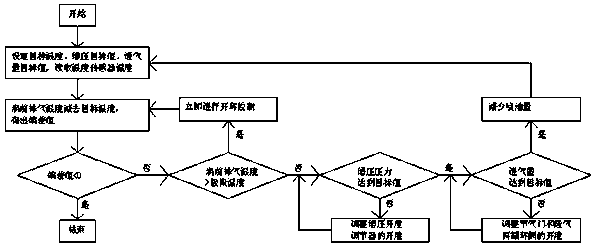

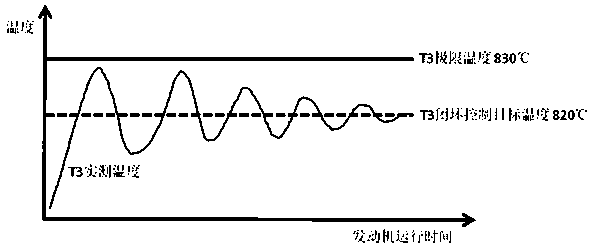

Turbine front exhaust temperature closed-loop control device and method adopting temperature sensor

ActiveCN108730056AReduced safety marginHigh energyElectrical controlInternal combustion piston enginesLoop controlClosed loop

The invention discloses a turbine front exhaust temperature closed-loop control device and method adopting a temperature sensor. The temperature sensor (2) is arranged between an oil atomizer (3) anda waste gas turbine (9) and connected with an engine control unit (1). The closed-loop control target temperature value of T3 is set, the engine control unit reads the actual measurement temperature of T3, and if T3 is smaller than the closed-loop control target temperature, control is not conducted; if T3 is larger than or equal to the closed-loop control target temperature and smaller than the extreme temperature, closed-loop control is conducted; if the deviation value is larger than 0, whether the supercharge pressure reaches the target value or not is judged, if the supercharge pressure does not reach the target value, the aperture of a supercharge aperture adjuster (5) is adjusted, and if the supercharge pressure reaches the target value, whether the air inlet volume reaches the target value or not is judged; if the air inlet volume does not reach the target value, the aperture of a waste gas recirculation valve (7) and the aperture of a throttle valve (6) are adjusted; and if T3is larger than or equal to the extreme temperature and the maintaining time is larger than 3 s, open-loop control is immediately conducted, in other words, the oil injection amount is reduced to thepreset value till the T3 is smaller than the closed-loop control target temperature, and the maintaining time is larger than 3 s.

Owner:SAIC MOTOR

Cylinder head gasket

InactiveUS20050006854A1Small defect toleranceSmall toleranceEngine sealsPiston ringsCombustion chamberCylinder head

A metallic cylinder head gasket for an internal combustion engine having at least one combustion chamber. The gasket includes at least one sheet-metal layer having at least one opening corresponding to the at least one combustion chamber of the internal combustion engine and at least one bore extending from the outer edge to the edge of the opening. A membrane, closing the bore at the combustion-chamber side is exposed to the gas pressure of the combustion chamber. A pressure sensor disposed in the sheet-metal layer is pressurized axially relative to the bore by movement of the membrane by the gas pressure of the combustion chamber.

Owner:ELRINGKLINGER AG +1

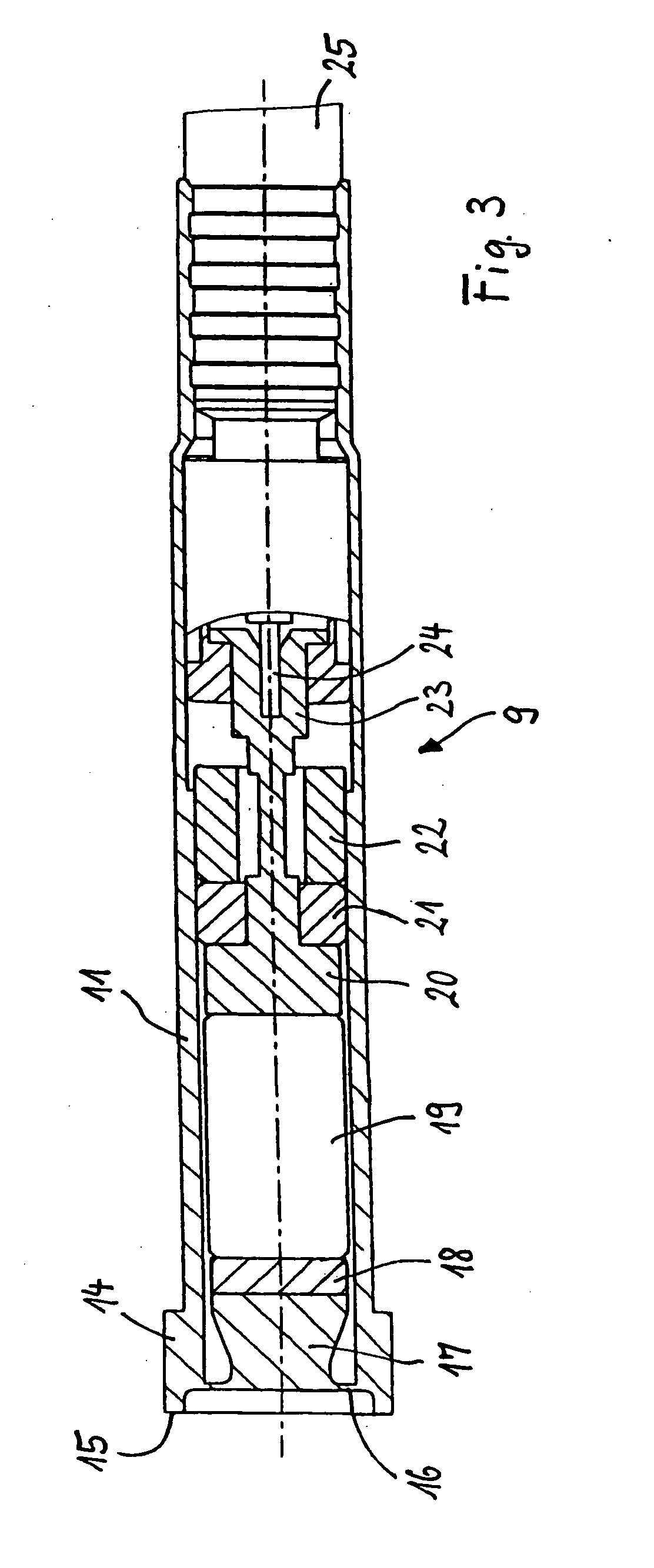

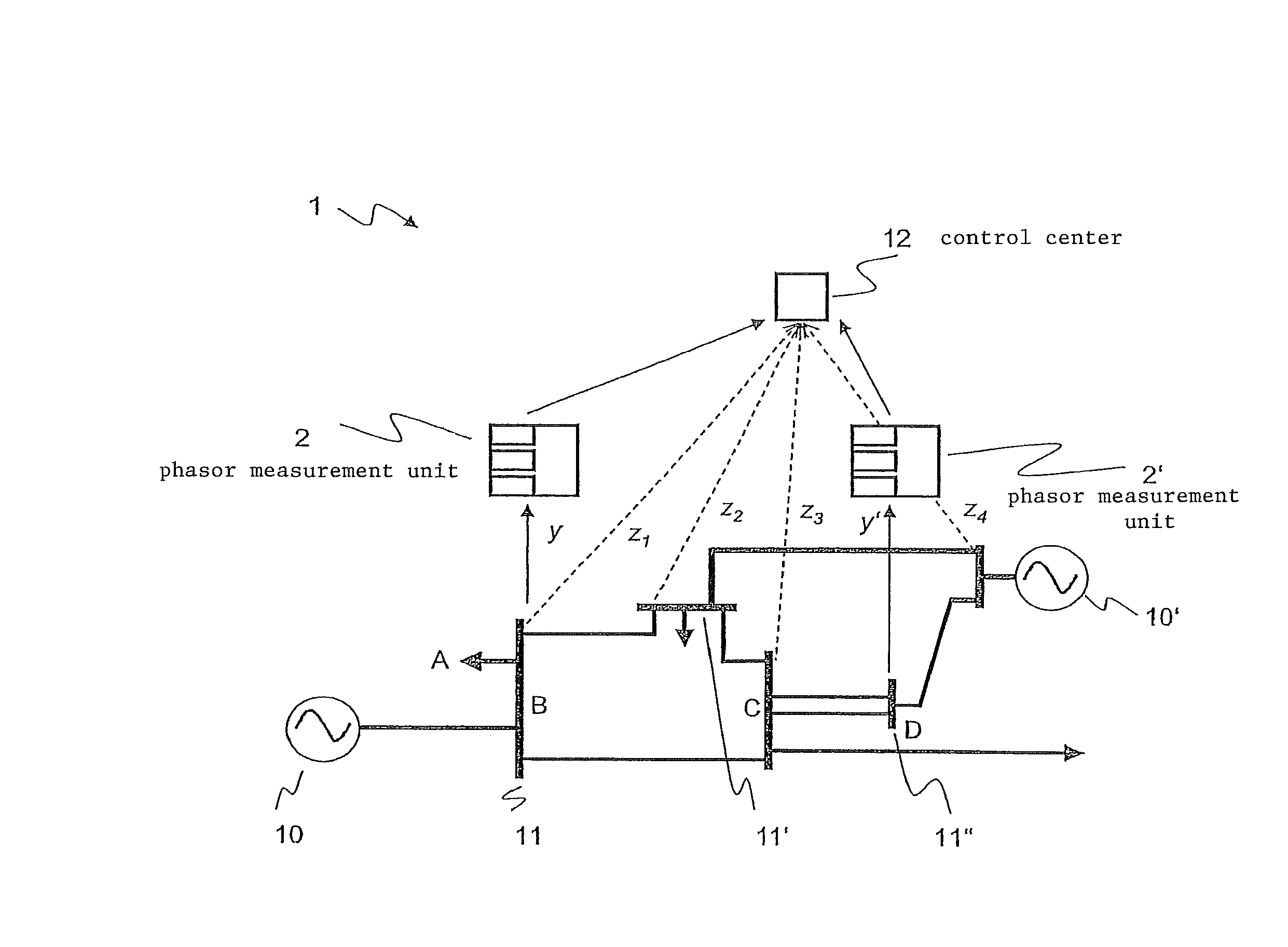

Verifying an accuracy of a state estimation

ActiveUS8190379B2Reduced safety marginWithout jeopardizing safetyMechanical power/torque controlLevel controlTransmitted powerNetwork conditions

The present disclosure is concerned with the reduction of an operational security margin of a power system without jeopardizing the safety of the power system or incurring heavy investments. According to the disclosure, a check for basic accuracy or correctness of a conventional State Estimation (SE) procedure allows to increase a level of confidence in the results of the procedure. To this end, an accuracy of the estimated states is verified by comparing the latter with the results (y, y′) of independent phasor measurements performed at selected locations of the power system. Unless a discrepancy is reported by this comparison, the results of the SE can be assumed to be sufficiently accurate, and any conservative or additional security margin intended to compensate for SE uncertainty can be relaxed. Hence, established trustworthiness in the estimated states allows increasing the transmitted power where the estimated states do indicate such a possibility, i.e. in particular in fringe areas and / or transmission corridors between countries, and especially under stressed network conditions.

Owner:HITACHI ENERGY SWITZERLAND AG

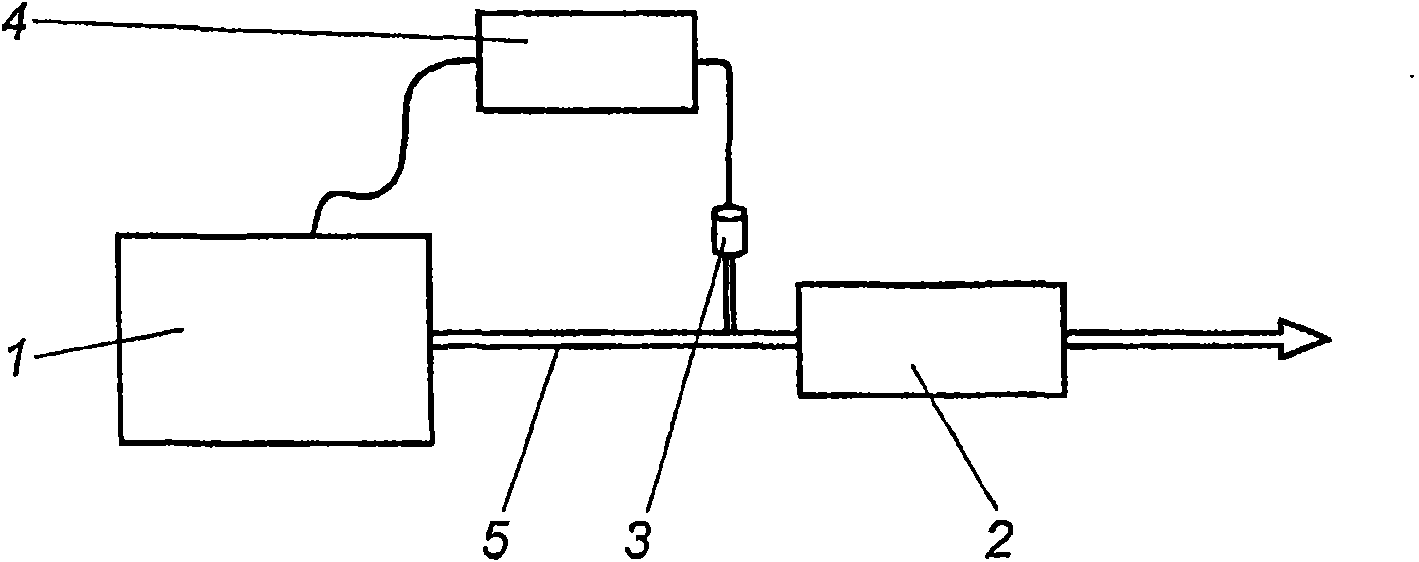

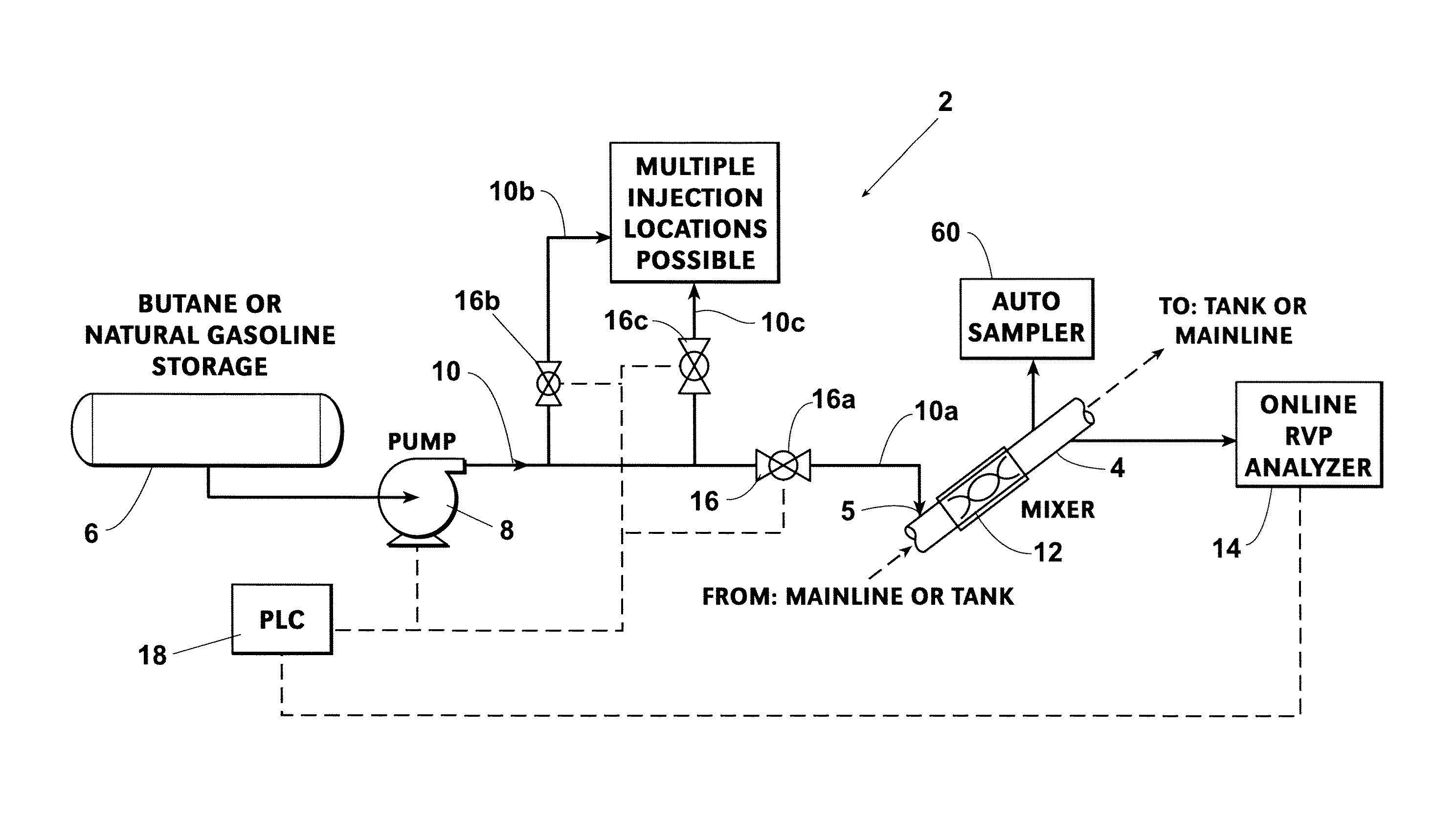

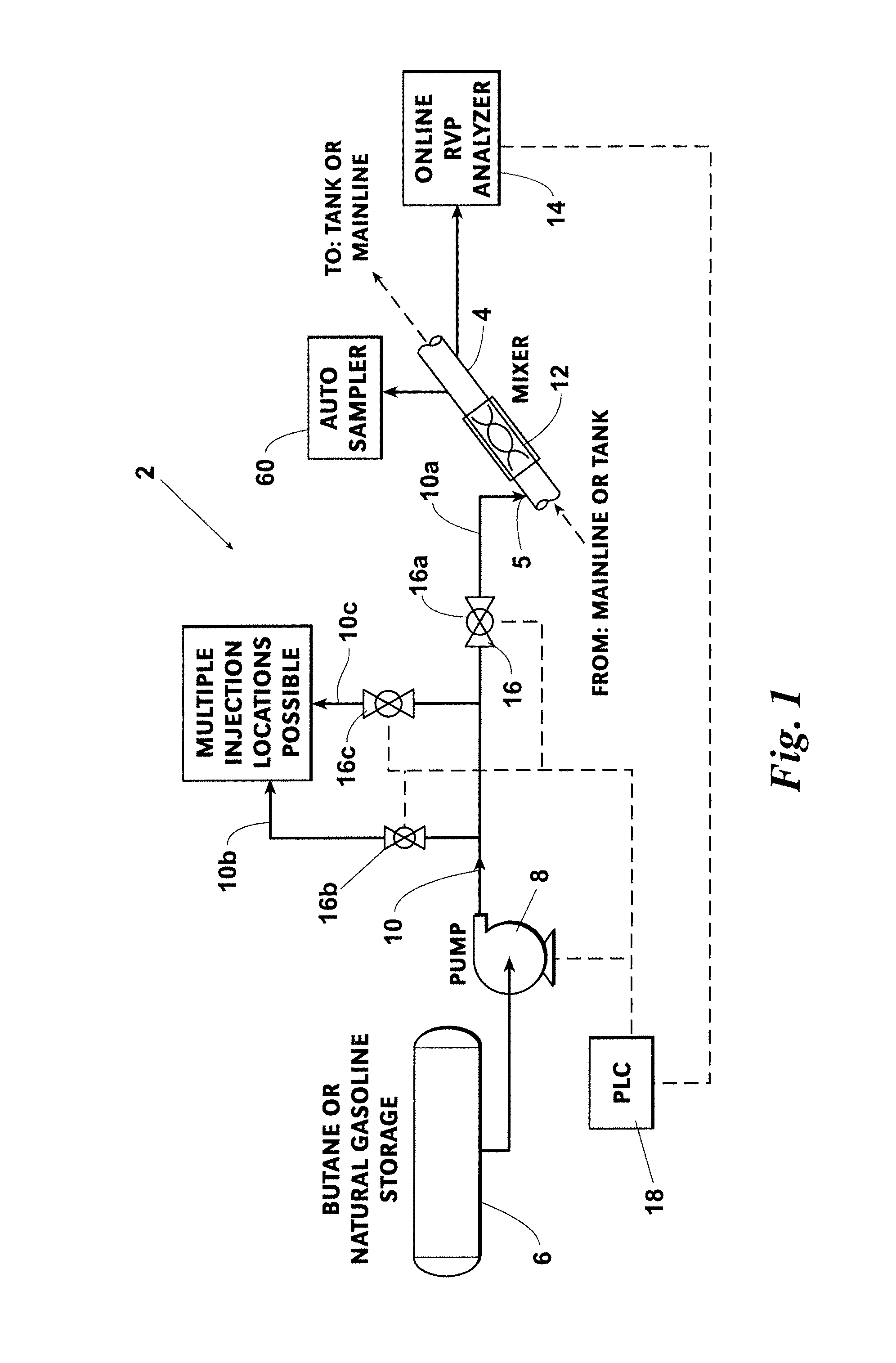

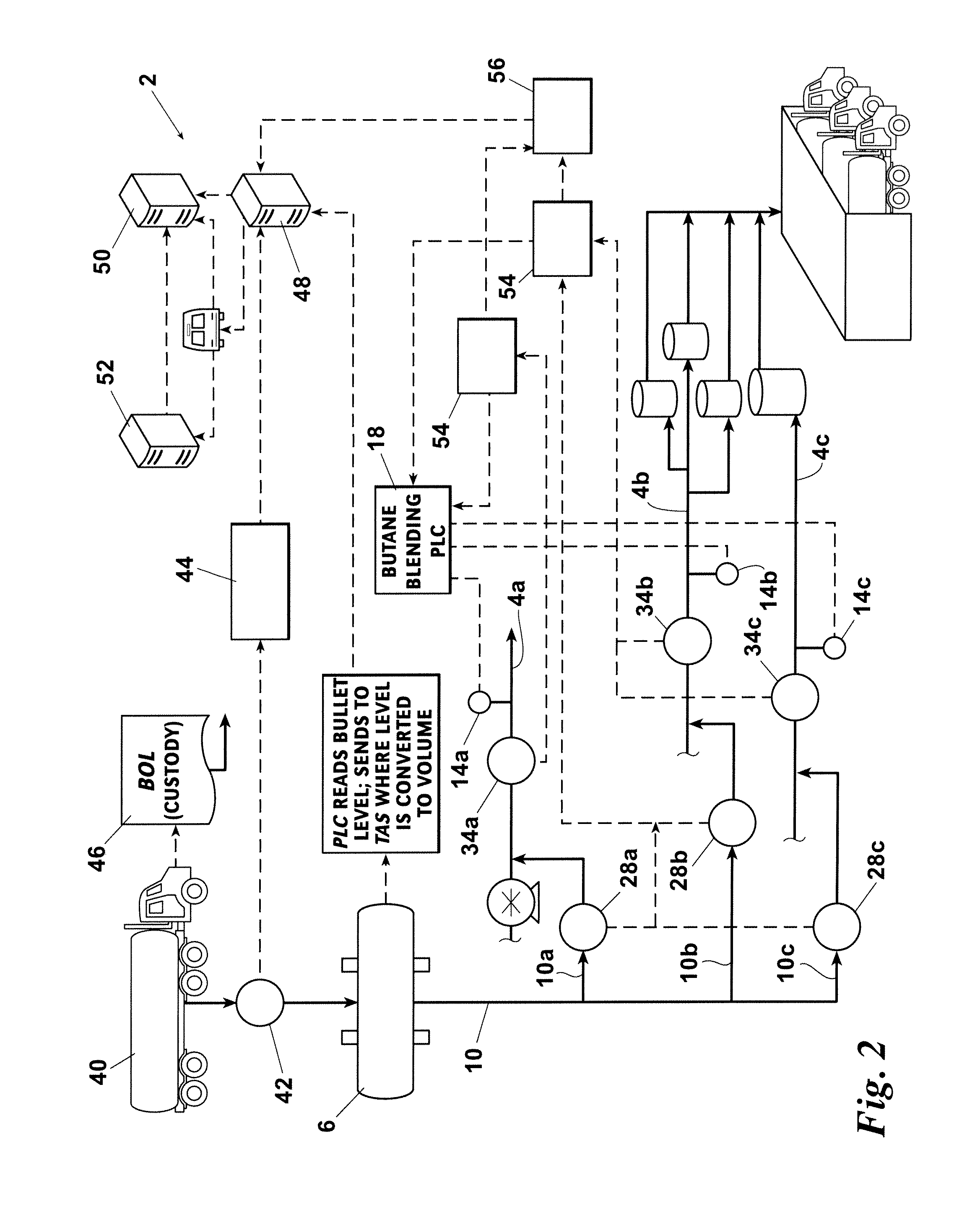

System and method for adding blend stocks to gasoline or other fuel stocks

ActiveUS9080111B1Improve abilitiesIncrease volumeHydrocarbon oils refiningHydrocarbon oils treatmentAutomatic controlGasoline

A method, system, and apparatus for addition of a blending stock to a fuel stock flowing through a line in order to blend up the fuel stock, and / or to blend up a heel material contained in a tank to which the blended product is to be delivered. The actual volatility of the blended product flowing through the line is monitored using an automated volatility analyzer. The blending stock is added to the fuel stock in the line at a blending rate which is automatically controlled by comparing the measured actual volatility value to either a target volatility value for the blended product or a modified target volatility value which can be implemented for the purpose of also blending up a tank heel.

Owner:MAGELLAN MIDSTREAM PARTNERS

Method and system for reducing peak load charge on utility bill using target peak load and countermeasures

InactiveUS8774976B2Reduce riskReduced safety marginMechanical power/torque controlLevel controlElectrical batteryUtility industry

Owner:NANTENERGY INC

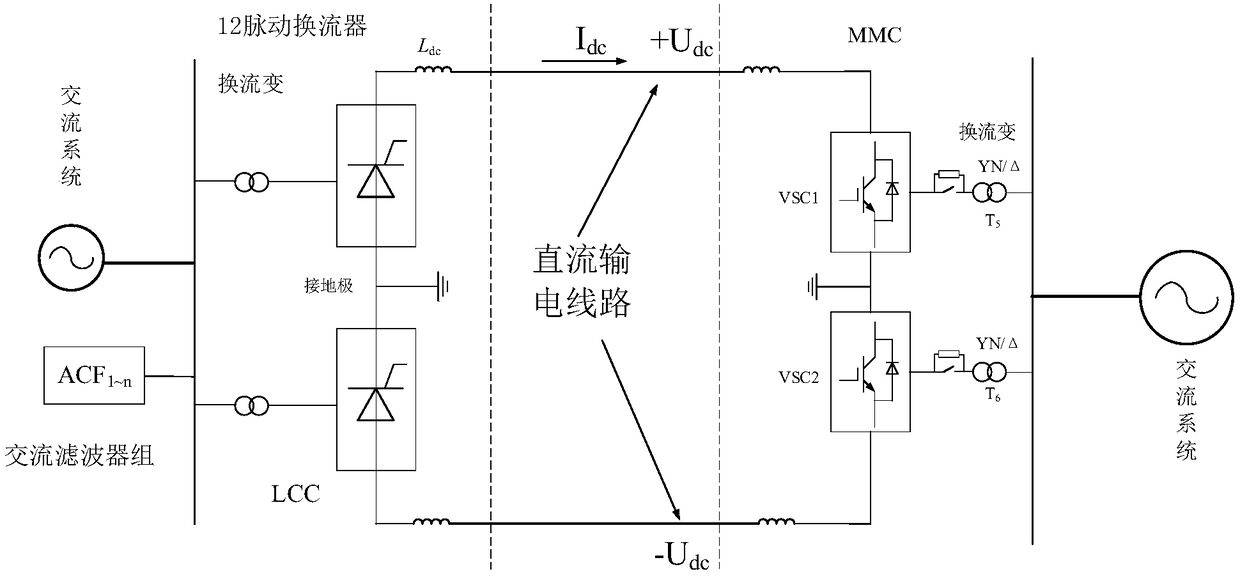

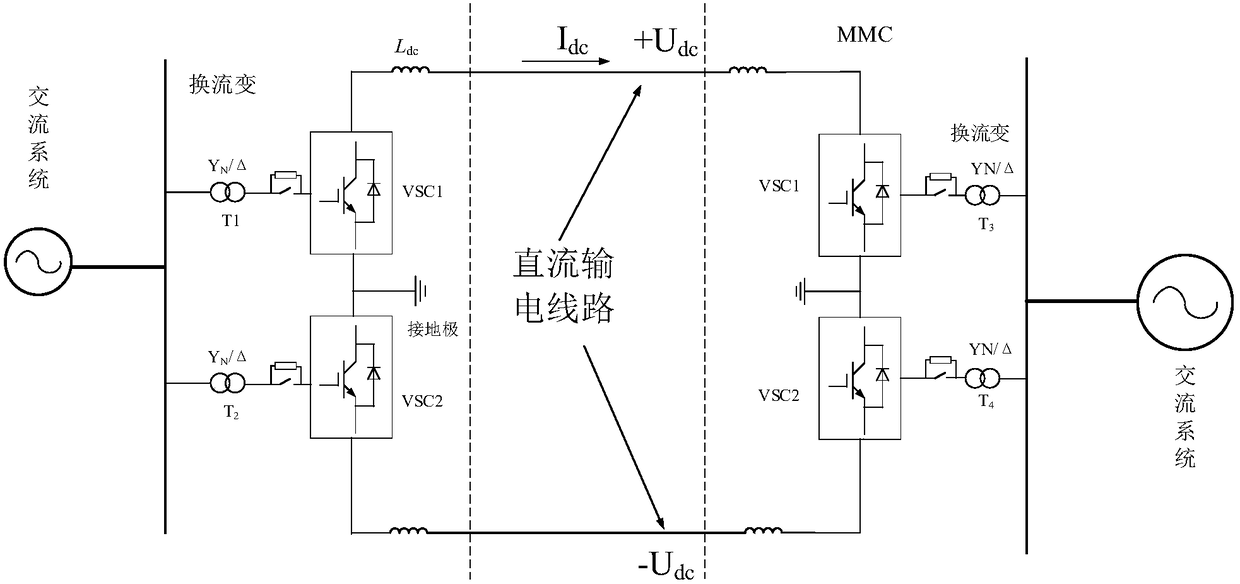

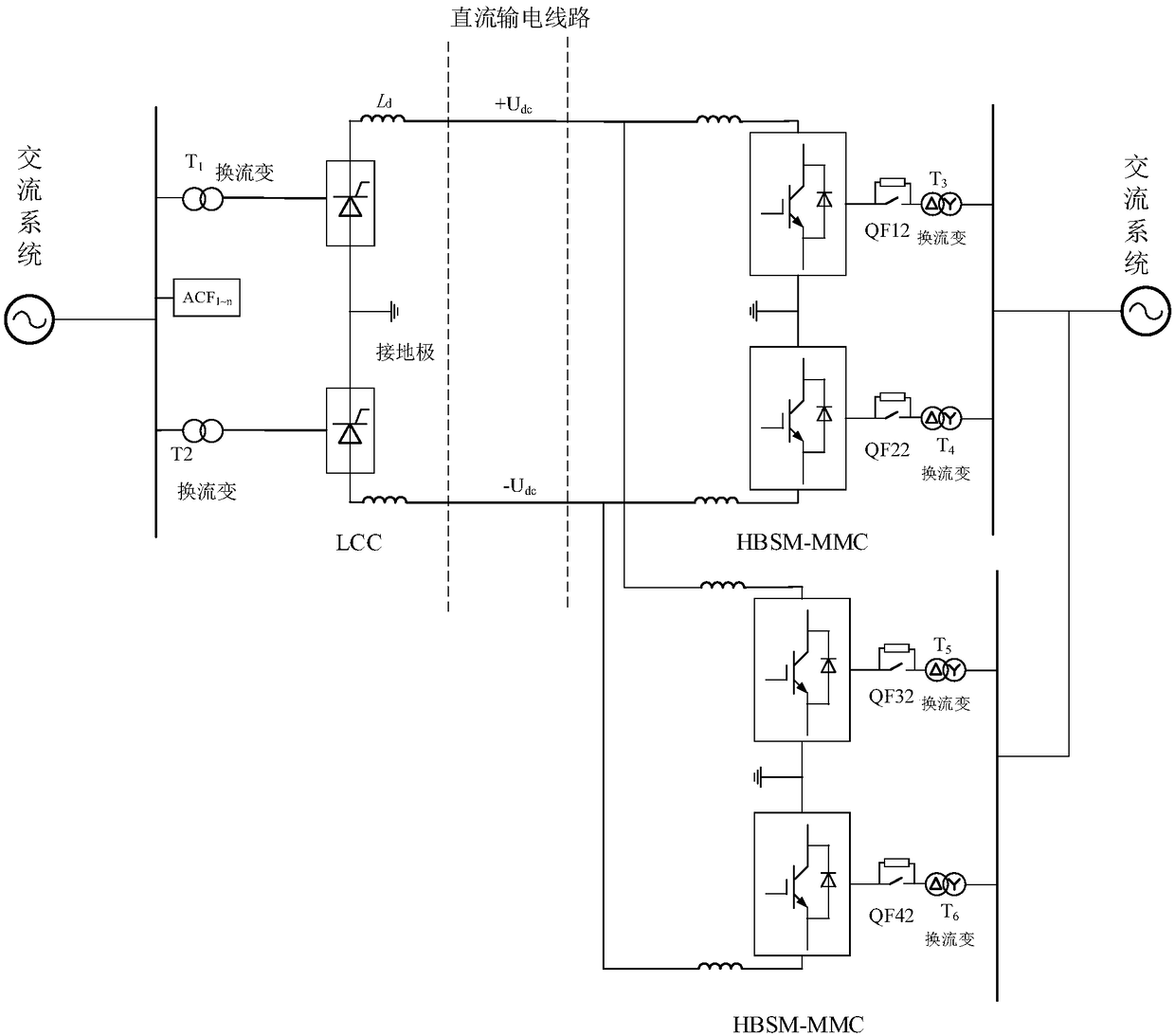

Submodule structure and MMC topology structure with AC-DC fault removing capability

InactiveCN108448542AHigh cost of solutionReduce overvoltage levelsEmergency protective circuit arrangementsElectric power transfer ac networkControl switchTower

The invention relates to a submodule structure and MMC topology structure with an AC-DC fault removing capability; two control switches are arranged; the first control switch is connected the submodule topology structure in parallel; the second control switch is connected in series on a connecting line between a voltage anode port or a voltage cathode port of the submodule and the submodule topology structure; when the submodule structure steadily operate, the first control switch is closed, and the second control switch is conducted; when the AC side has faults, the first control switch is triggered to conduct, and the fault current injected in the a MMC can be induced to the ground; when the DC side has faults, the second control switch is controlled to close. Therefore, the submodule structure can realize isolation of AC-DC faults, and can effectively reduce the voltage stress and current stress of the submodule power device. In addition, the scheme is the secondary design reconstruction of an existing submodule, and only small influences can be caused on existing valve tower and valve hall designs; the submodule structure and MMC topology structure is very low in cost, and simple in a realization process.

Owner:XUJI GRP +3

Power conversion apparatus

ActiveUS20170264199A1Reduced safety marginExcessive of output limitation can be suppressedThermometer detailsThermometers using value differencesTemperature differenceEngineering

At least one monitor circuit monitors a temperature of at least one monitored element of switching elements of a power conversion circuit. At least one arrival determination circuit determines that a temperature of at least one non-monitored element of the switching elements has increased and reached a passing temperature. Based on the temperature of the monitored element and arrival determination signals, a temperature estimating unit obtains a temperature difference by subtracting a current temperature of the monitored and non-monitored element at the arrival determination time from an output limitation temperature set for each of the monitored and non-monitored element, and estimates a limitation subject temperature of the monitored or non-monitored element having a smallest temperature difference among the temperature differences. An output limiting unit starts output limitation of the power conversion circuit when the limitation subject temperature reaches the output limitation temperature of the monitored element or the non-monitored element.

Owner:DENSO CORP

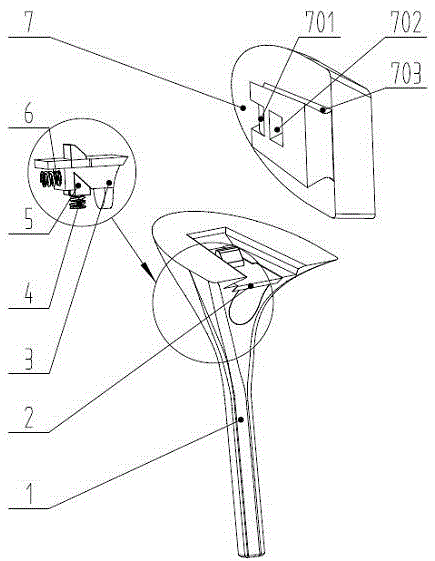

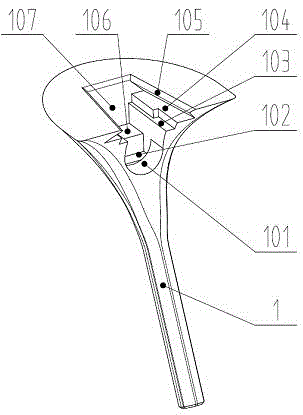

Hidden button type heel-replaceable high-heeled shoes

InactiveCN105639849AEasy to remove and replaceImprove the firmness of useHeelsTop-piecesEngineeringPush-button

The invention discloses hidden button type heel-replaceable high-heeled shoes, wherein each of the high-heeled shoes comprises a heel, a pressing plate, a button, a first compression spring, a jacking rod, a second compression spring and a sole, wherein a first groove, a second groove and a third groove are formed in the middle of the heel; the button and the jacking rod are arranged inside the first groove; the pressing plate is arranged inside the second groove; the button can move forwards and backwards along the first groove; the jacking rod can move upwards and downwards along the first groove; the pressing plate is fixedly connected with the bottom surface of the second groove. According to the hidden button type heel-replaceable high-heeled shoes, the heel is connected with the molded surface of the sole in a matched manner, through the interaction among the button, the jacking rod and the spring, the bulge of the jacking rod can ascend or descend, so that the heel can be connected with or separated from the sole, the button can move inwards along the bottom surface of the pressing plate by only slightly pressing the button inwards, then the jacking rod can be driven to move downwards, the bulge of the jacking rod can be separated from a fifth groove in the sole, and the heel can be separated from the sole by pulling down the heel with a slight force at the moment, so that the heel can be conveniently and rapidly disassembled and replaced.

Owner:HANGZHOU JIUBA HONGTU TECH CO LTD

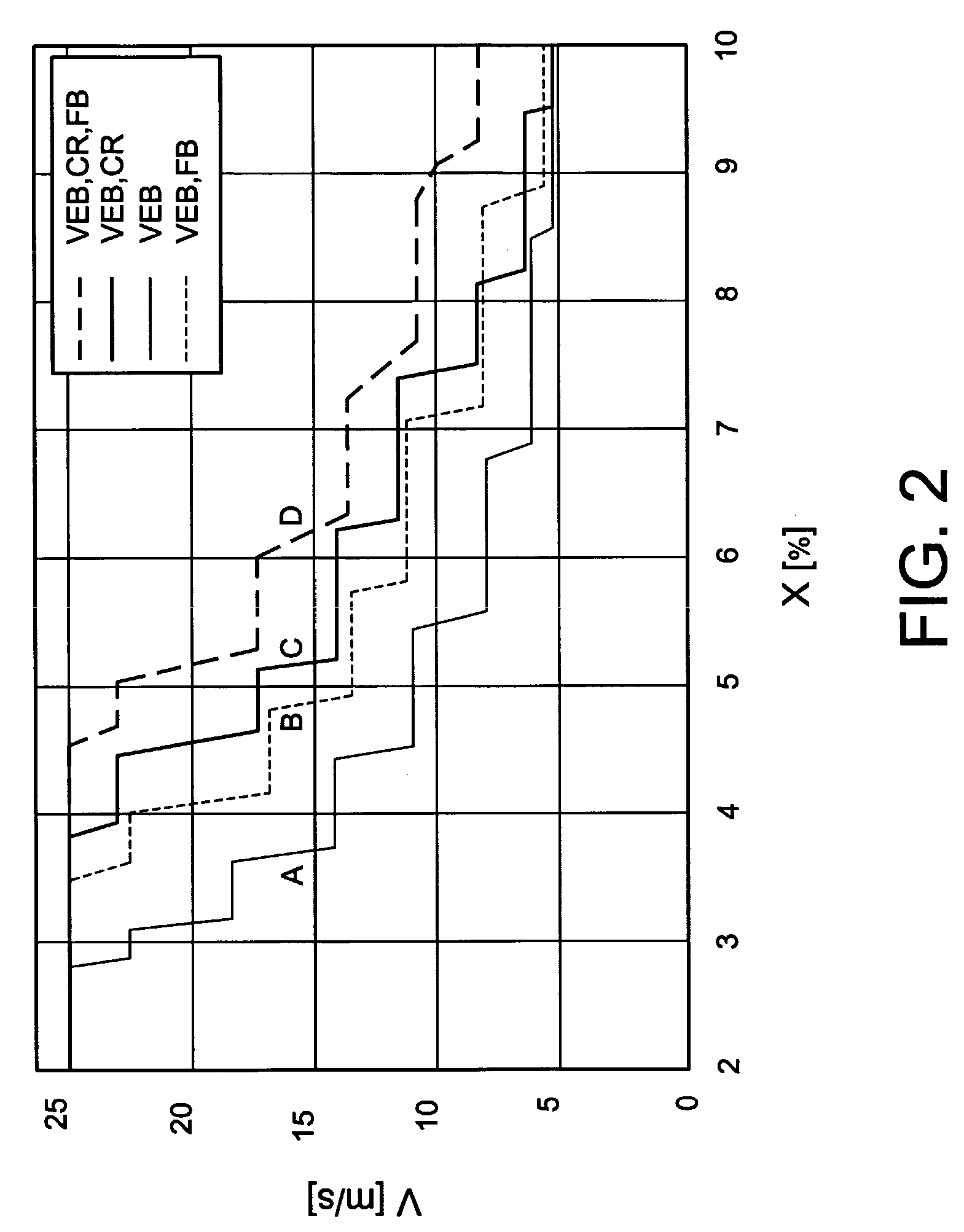

Sawing machine and method for controlling sawing machine

ActiveCN105081446AMachining feed rate increasedQuick responseMetal sawing devicesAutomatic control devicesMaximum torqueFrequency changer

A method for controlling a sawing machine is provided. For a first cut in a workpiece, a working feed rate that is specific to the workpiece geometry, the workpiece material and the sawing tool is defined in advance. During the first cut, an instantaneous value of a physical variable is determined at a frequency converter, that is related to the torque transmitted by the sawing tool drive to the sawing tool, and this value is transmitted as an instantaneous torque value to a machine controller. The instantaneous torque value is continuously evaluated, a maximum torque value of the first cut is determined and a maximum value for the torque value is defined based thereon. For subsequent cuts in the same workpiece, the working feed rate is regulated, using the instantaneous torque value as a regulating variable, such that the instantaneous torque value is kept constant, close to the maximum valve.

Owner:KEURO BESITZ & EDV DIENSTLEISTUNGS

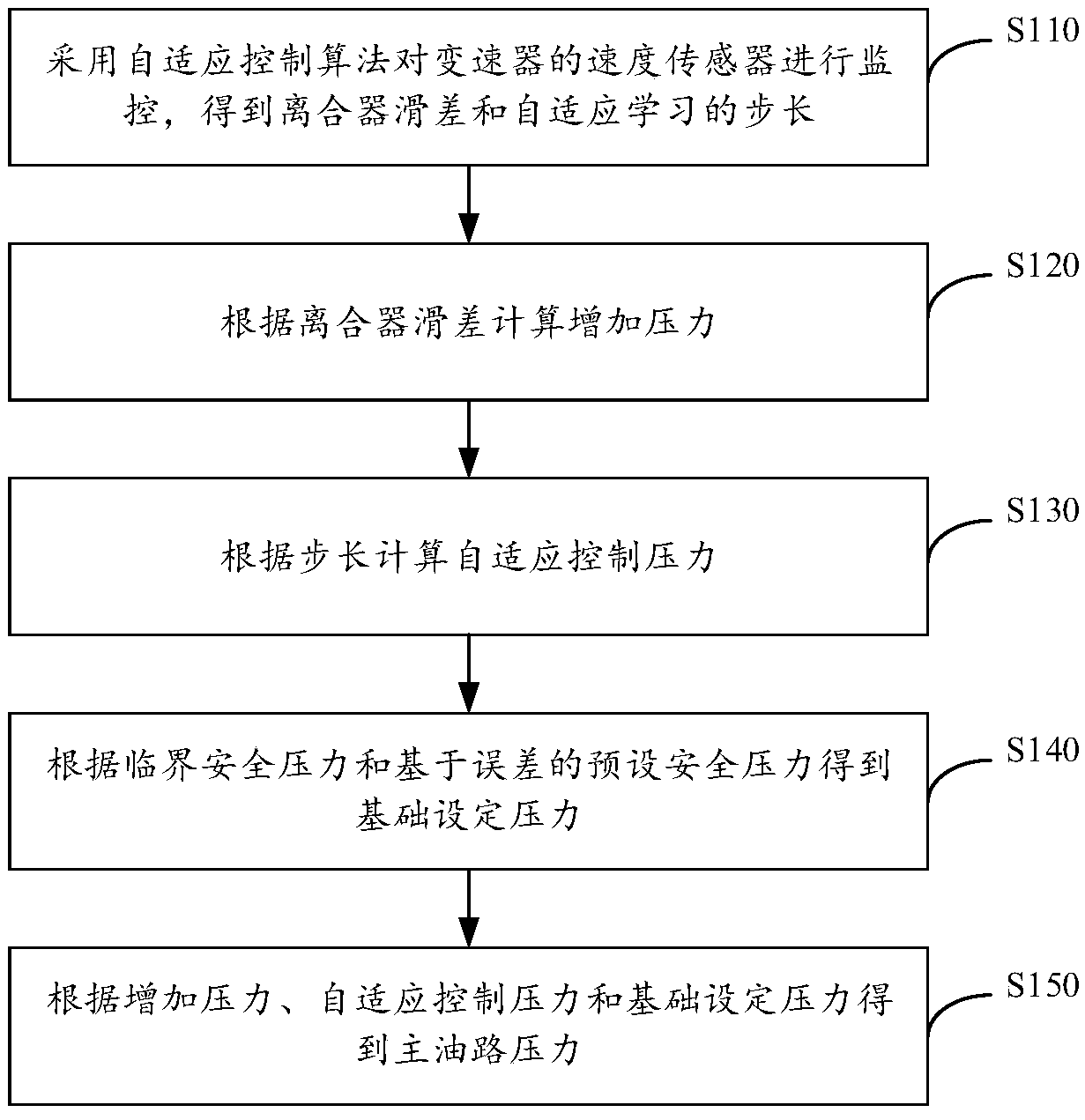

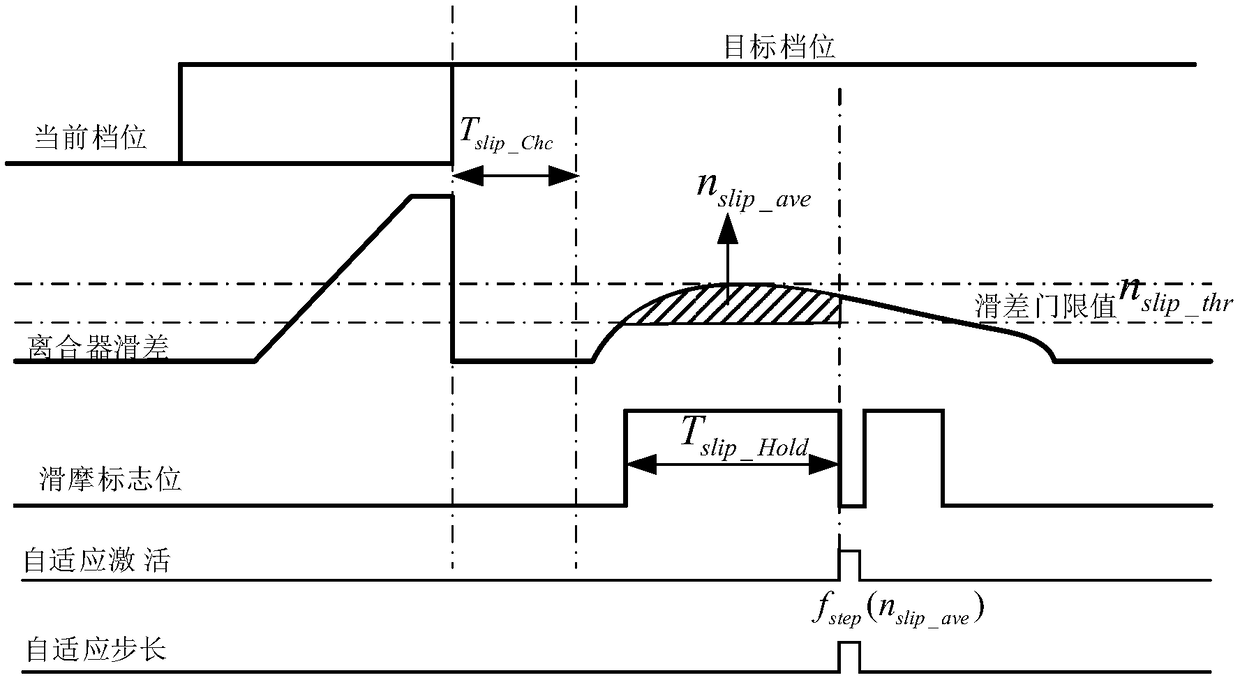

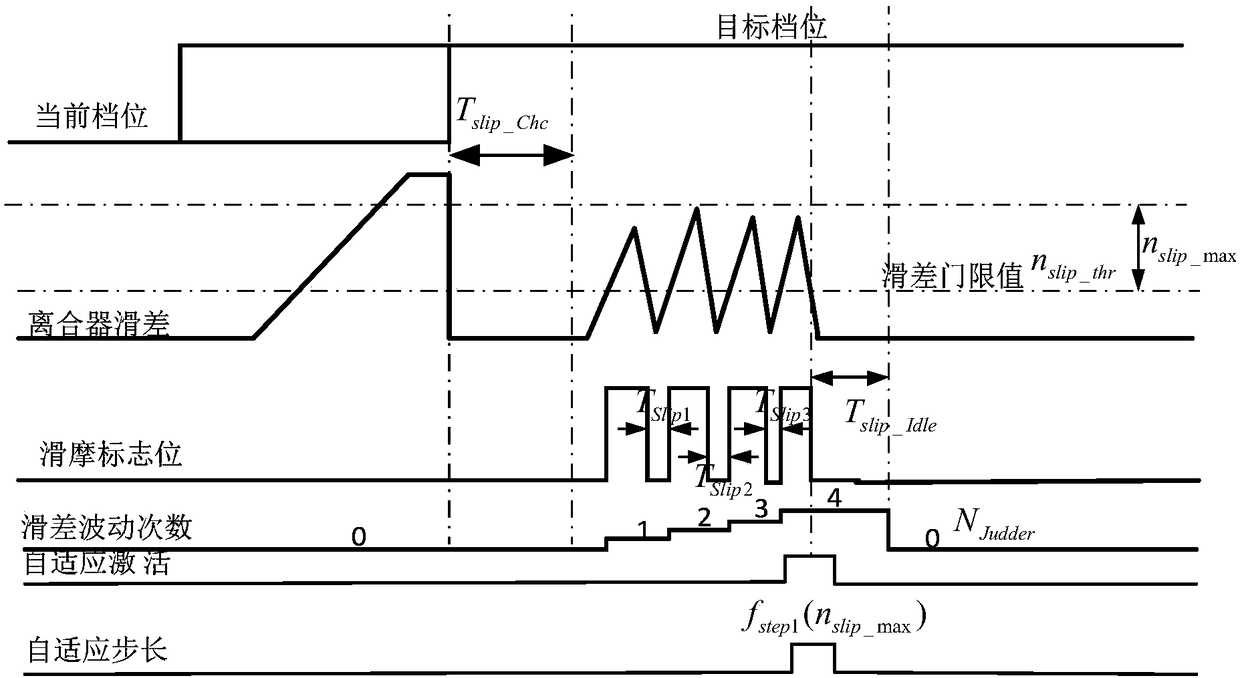

Method, system and electronic equipment for adaptively controlling main oil circuit pressures

ActiveCN109253247AImprove transmission efficiencyGuaranteed uptimeGearing controlAdaptive learningEngineering

The invention provides a method, a system and electronic equipment for adaptively controlling main oil circuit pressures, and relates to the technical field of automatic gearbox control. The method includes monitoring speed sensors of transmissions by the aid of adaptive control algorithms to obtain slip of clutches and step lengths of adaptive learning; computing boost pressures according to theslip of the clutches; computing adaptive control pressures according to the step lengths; acquiring basic set pressures according to critical safety pressures and preset safety pressures on the basisof errors; acquiring the main oil circuit pressures according to the boost pressures, the adaptive control pressures and the basic set pressures. The method, the system and the electronic equipment have the advantages that the main oil circuit pressures can be adaptively controlled by the aid of slip change conditions, which are computed by the speed sensors of the transmissions, of the clutches,accordingly, the safety coefficients of main oil circuit pressure control parameters can be lowered, the safety margin can be diminished, the transmission efficiency of the transmissions can be improved, and the transmissions further can safely run without sliding friction.

Owner:SHENGRUI TRANSMISSION

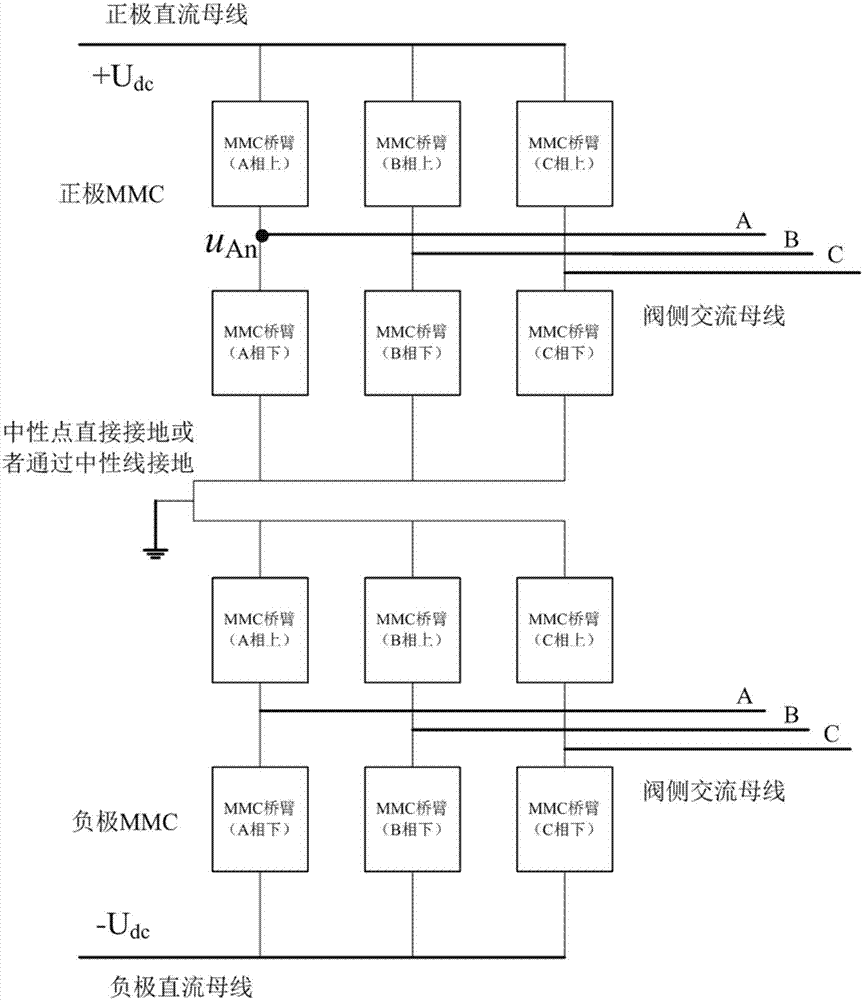

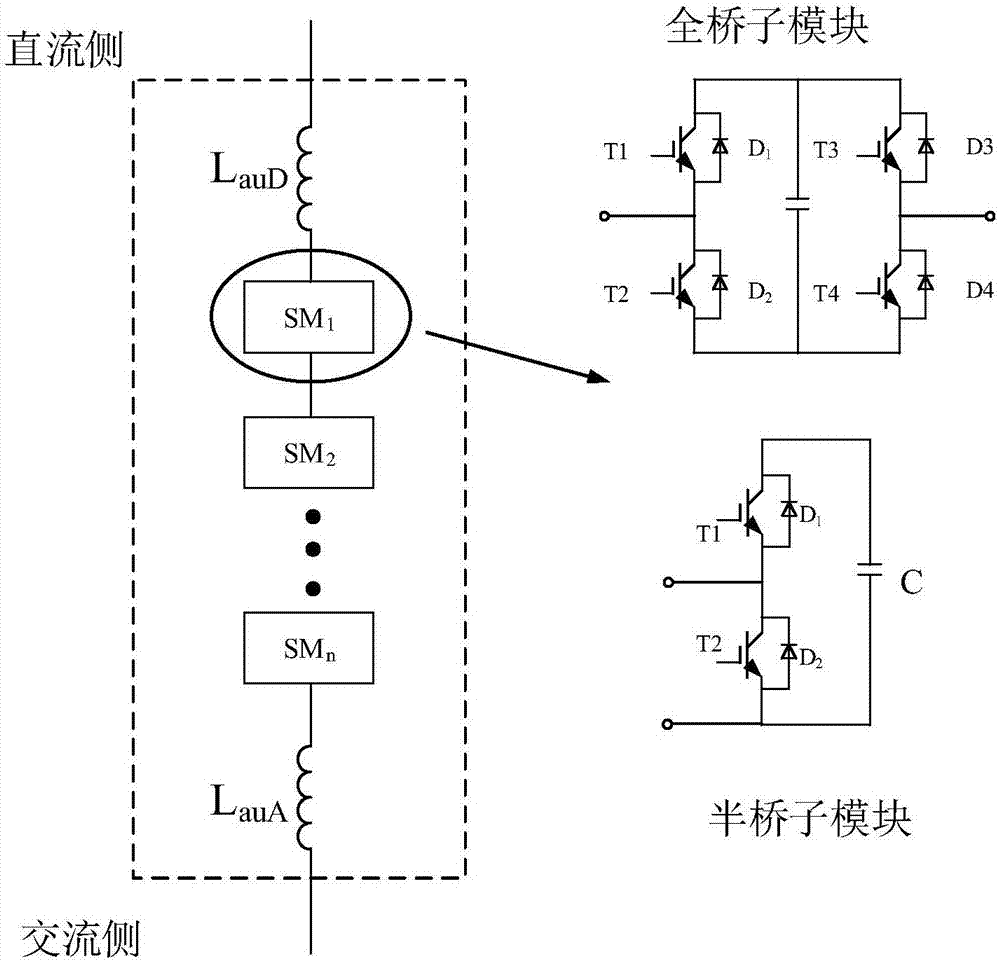

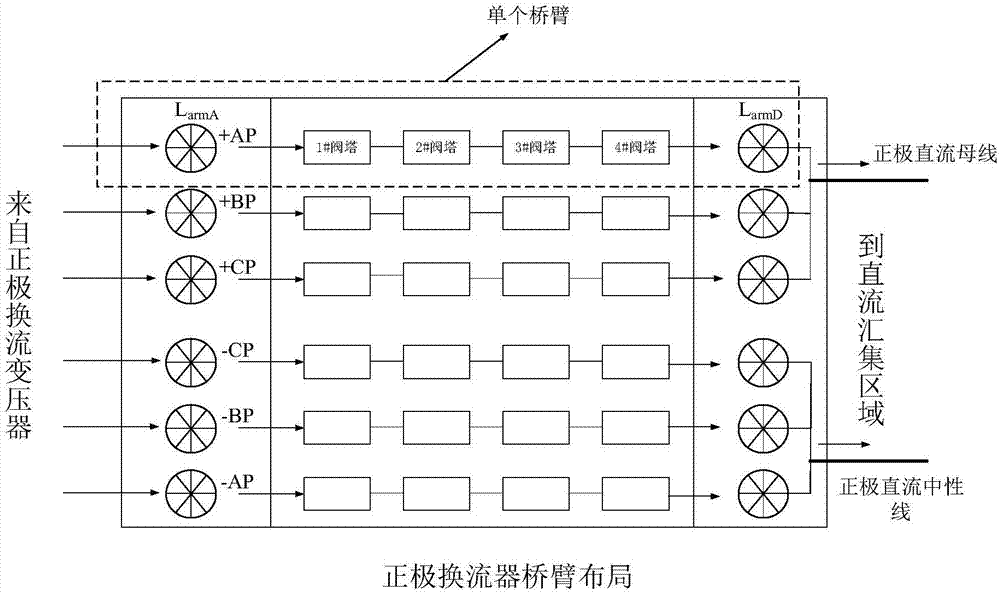

Bridge arm circuit and method inhibiting fault current of large-capacity MMC submodule

ActiveCN106936303AReduce fault currentReduced safety marginPower conversion systemsElectricityWeight coefficient

The invention provides a bridge arm circuit and method inhibiting a fault current of a large-capacity MMC submodule, and mainly aims at inhibition of the fault current of the large-capacity MMC submodule. In a design scheme of bridge arms of a large-capacity MMC, each bridge arm (phase unit) in the converter is designed as an integral body, and reactors are arranged in DC and AC sides of each bridge arm respectively in a manner that bridge arm reactors are dispersed. The total inductance value of the reactors in each bridge arm is kept constant, and the weight coefficients of the reactance in the AC and DC sides in the reactance of the bridge arm are checked according to system parameters. Each arm is connected to the external via the reactors in the AC and DC wire outlets. The bridge arm design scheme of the invention can be used to reduce the peak value of the fault current of the submodule and inhibit the rise rate of the fault current effectively, and further improve utilization rate of power devices in equipment, the cost of primary equipment is not increased, and the economical performance is high.

Owner:XIAN XJ POWER ELECTRONICS TECH

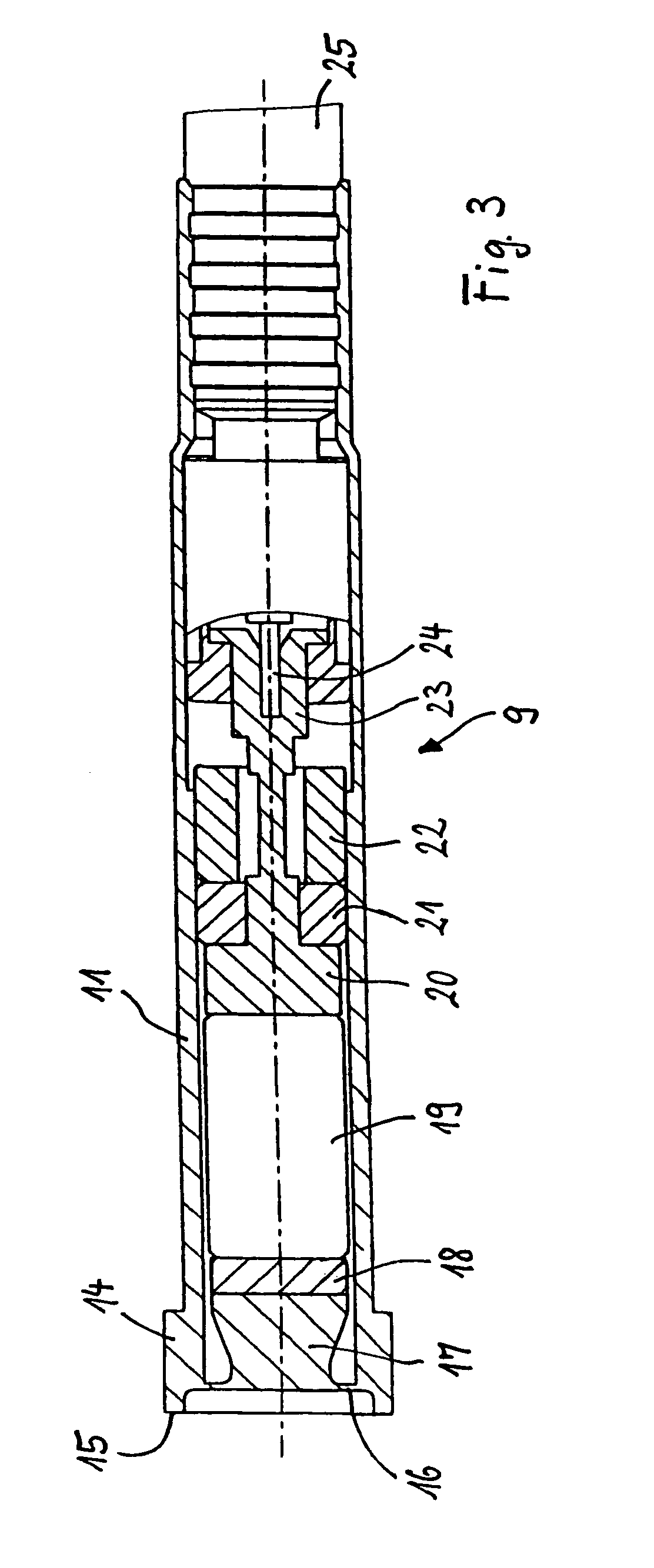

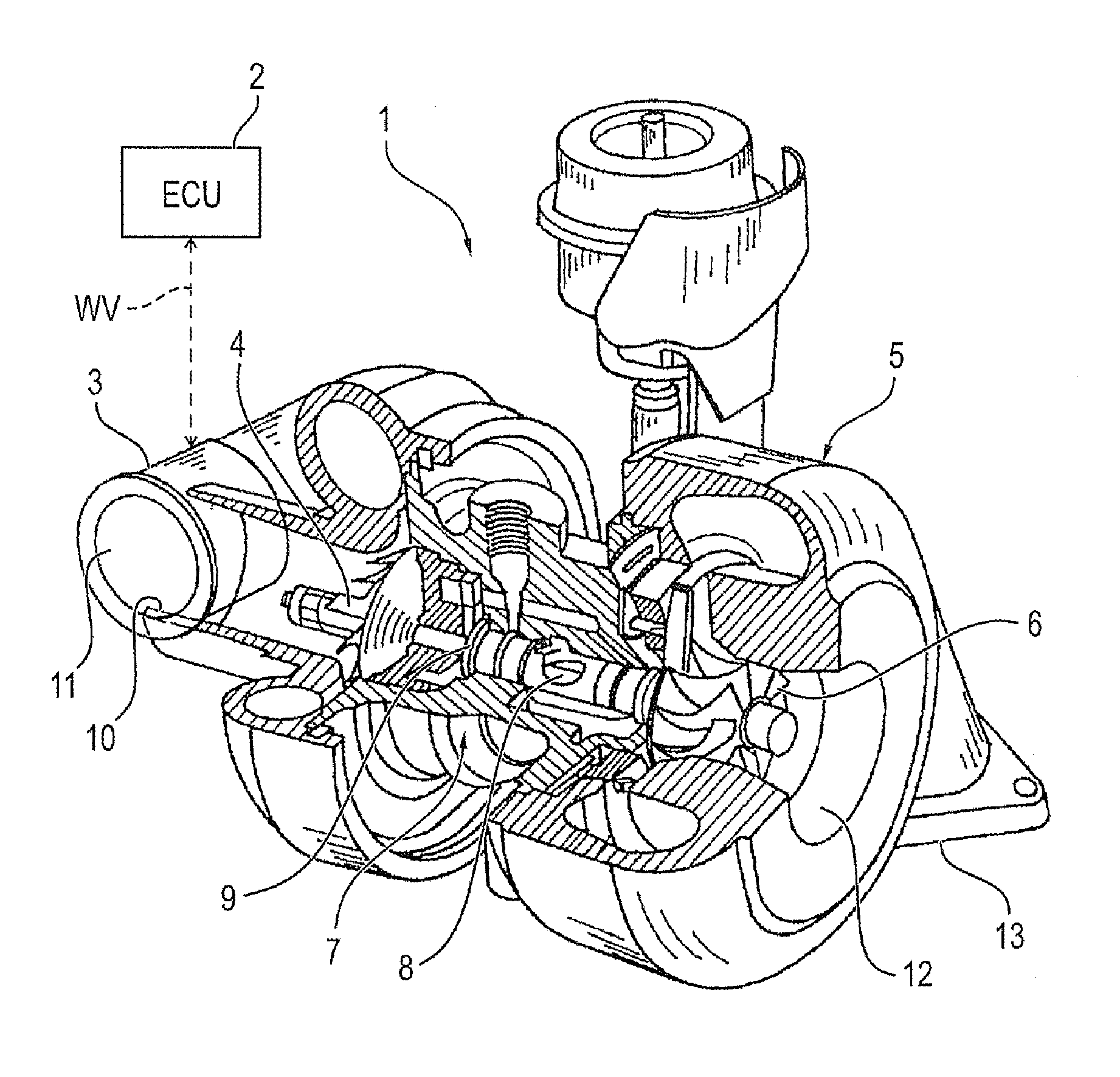

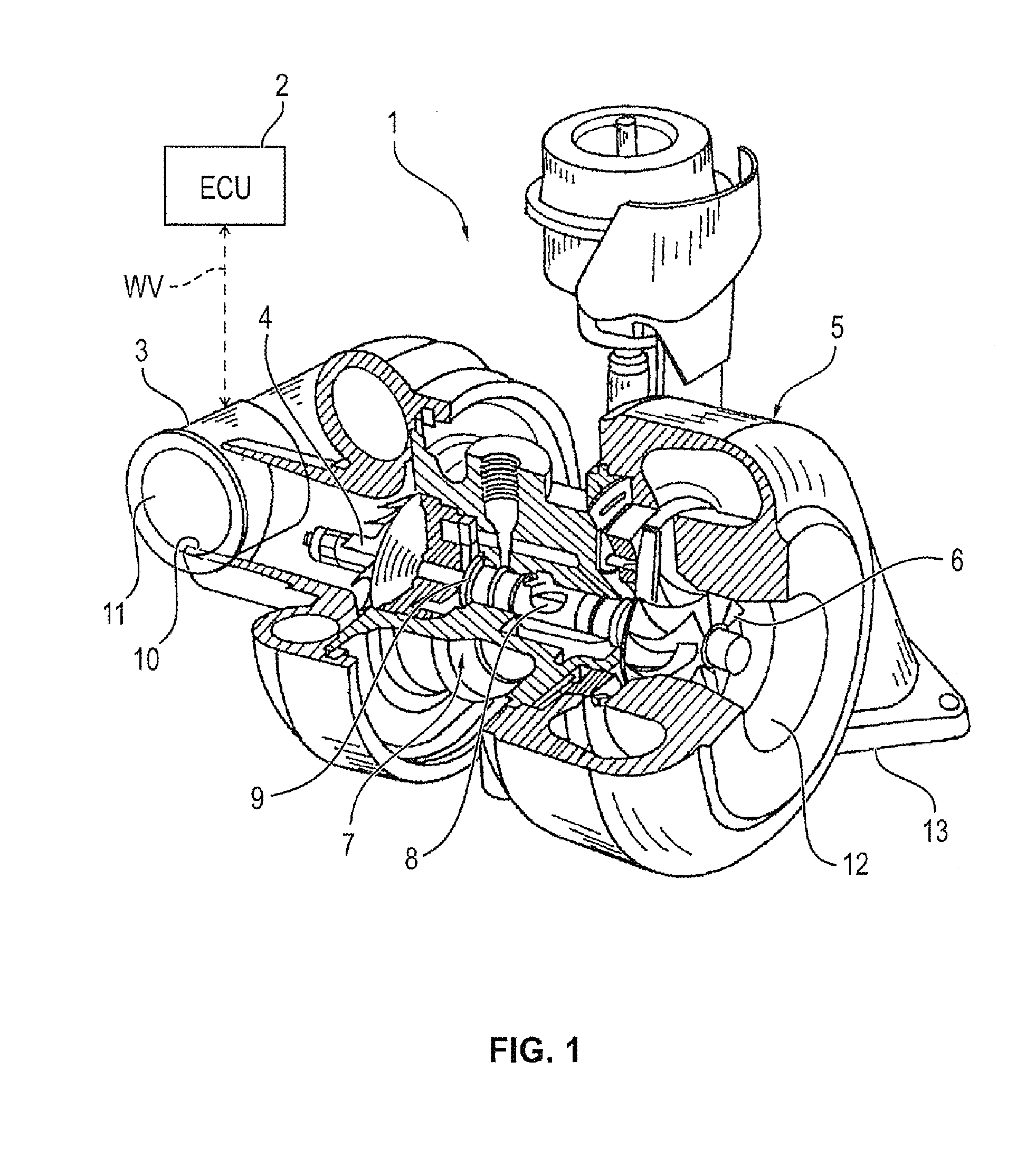

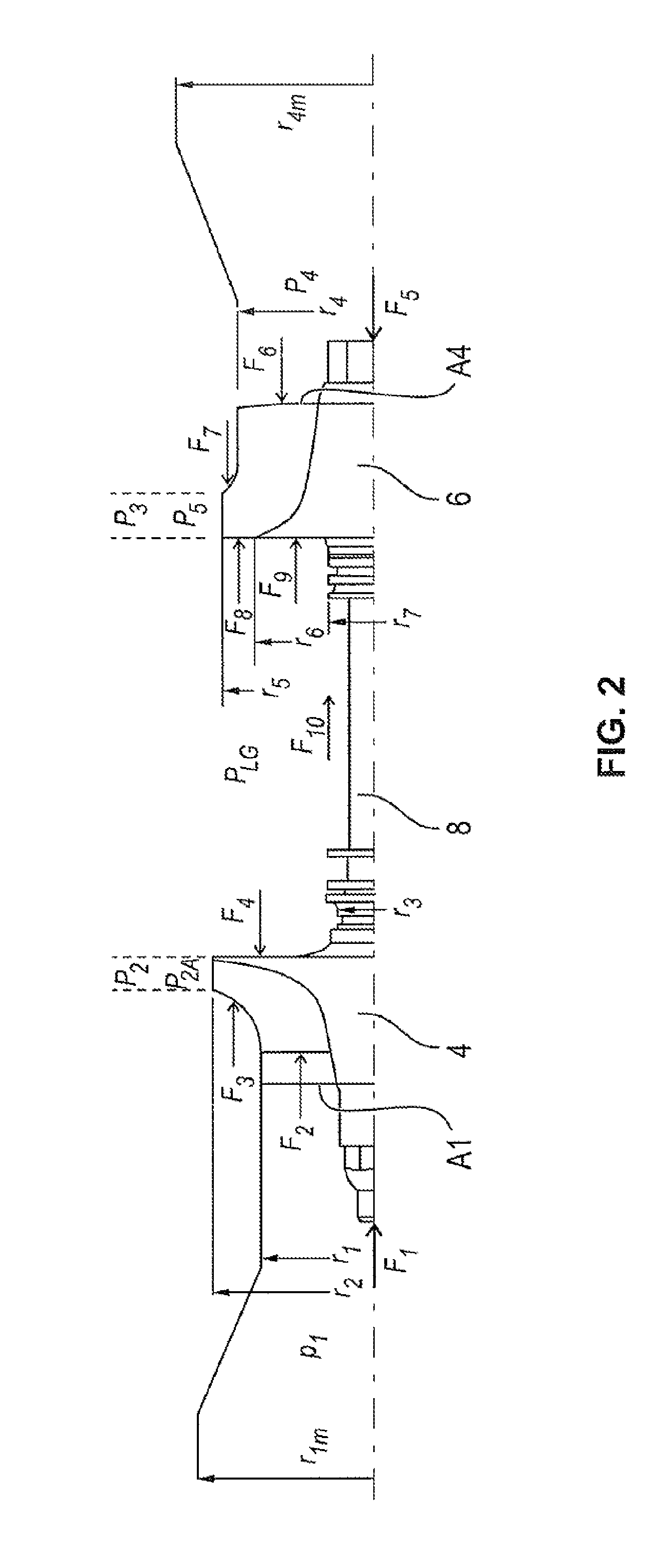

Method for detecting, avoiding and/or limiting critical operating states of an exhaust gas turbocharger

InactiveUS20150377062A1Reduce total pressure lossReduced safety marginEngine fuctionsBlade accessoriesCurrent loadTurbocharger

A method for detecting, avoiding and / or limiting critical operating states of an exhaust gas turbocharger which is operatively connected to a control unit, with the following method steps:a) estimating calculation of an axial thrust (FAX) on the basis of geometric variables of the exhaust gas turbocharger (1) and on the basis of signals and controlled variables of the control unit (2);b) determining a current load of an axial bearing (9) of a charger shaft (8) of the exhaust gas turbocharger (1) on the basis of the calculated axial thrust (FAX);andc) if appropriate, executing control interventions as a function of the determined axial bearing load.

Owner:BORGWARNER INC

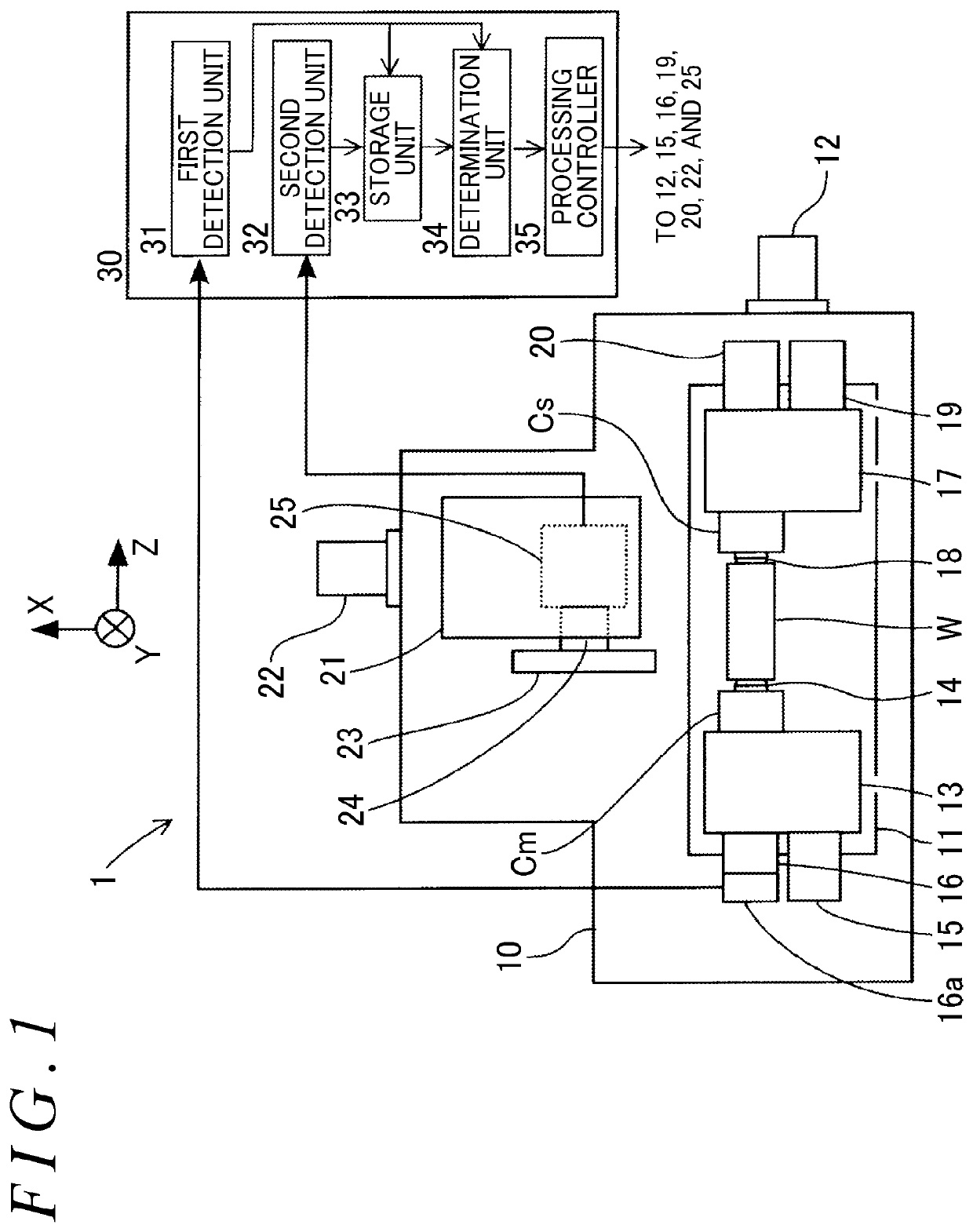

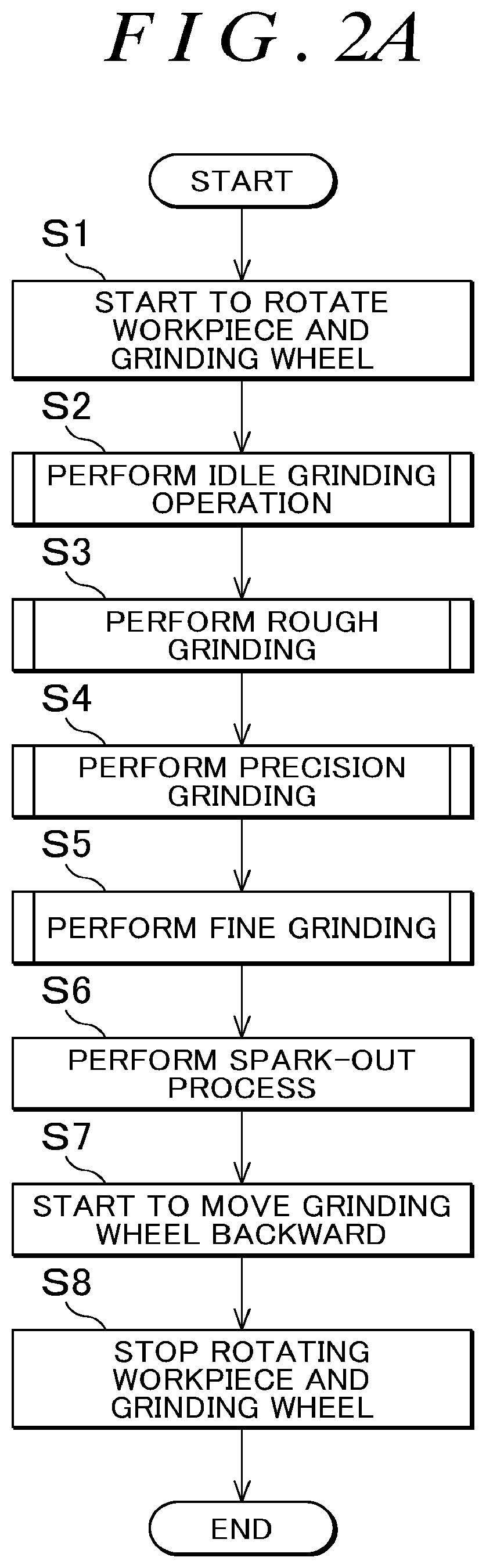

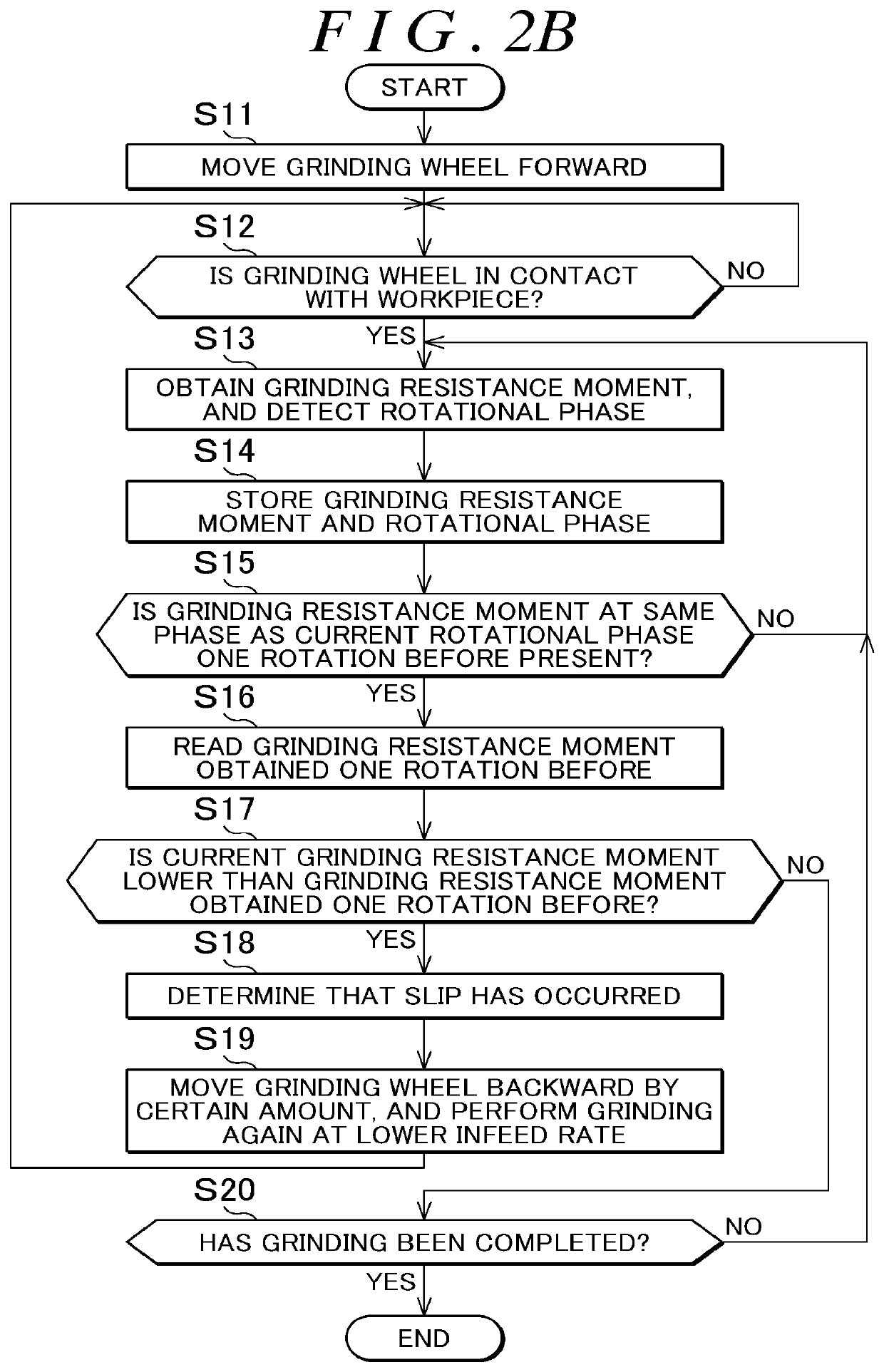

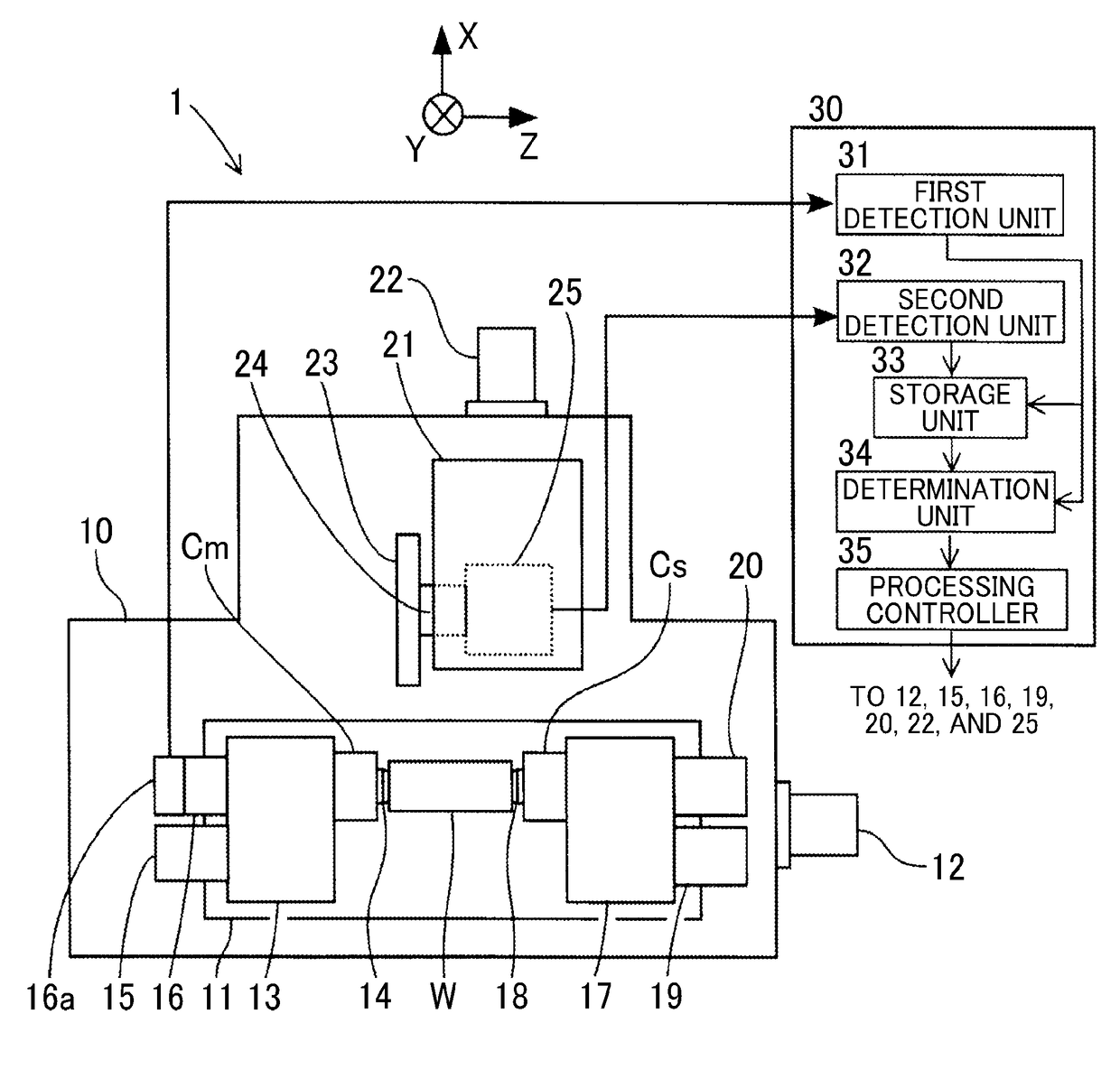

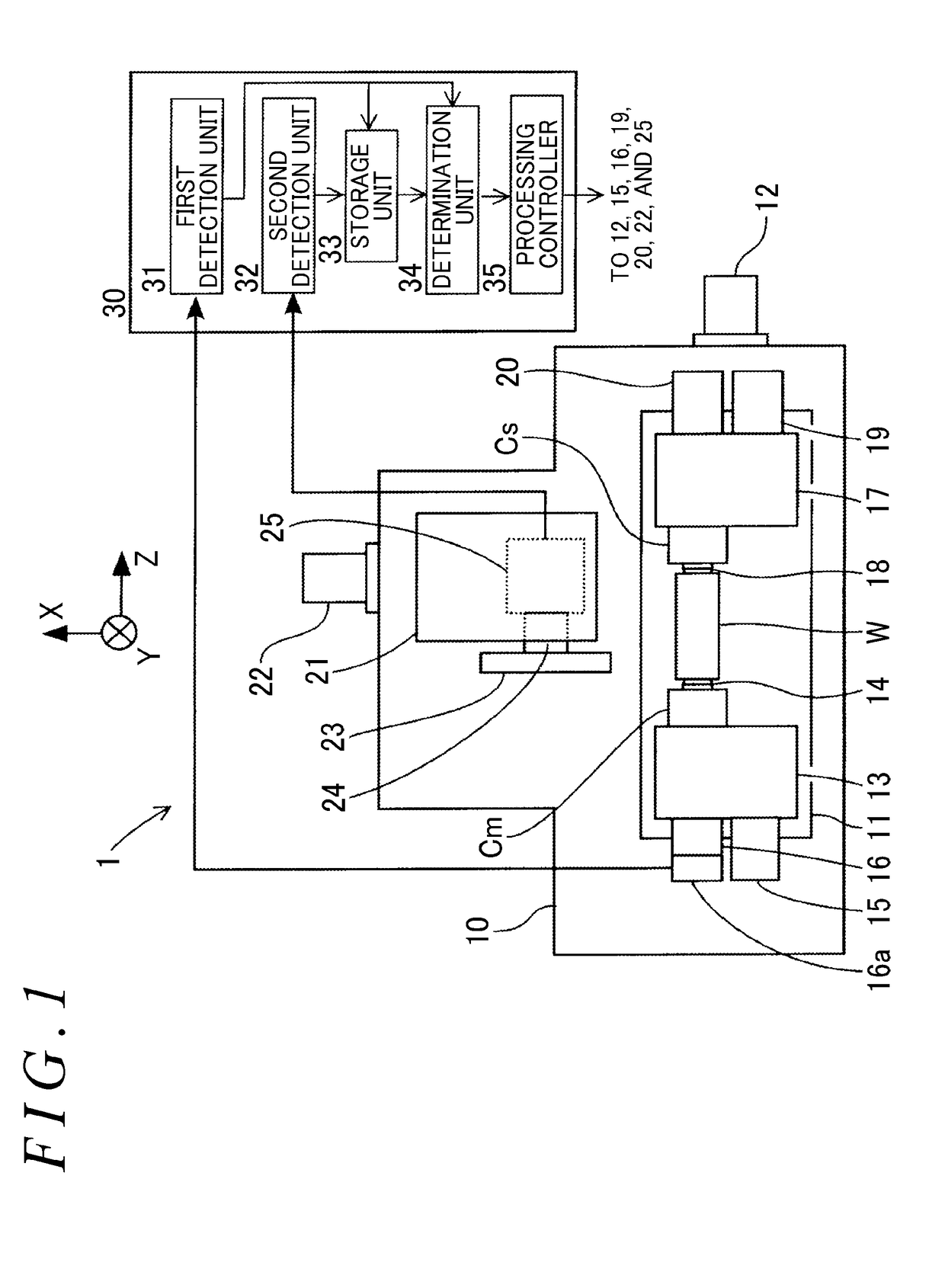

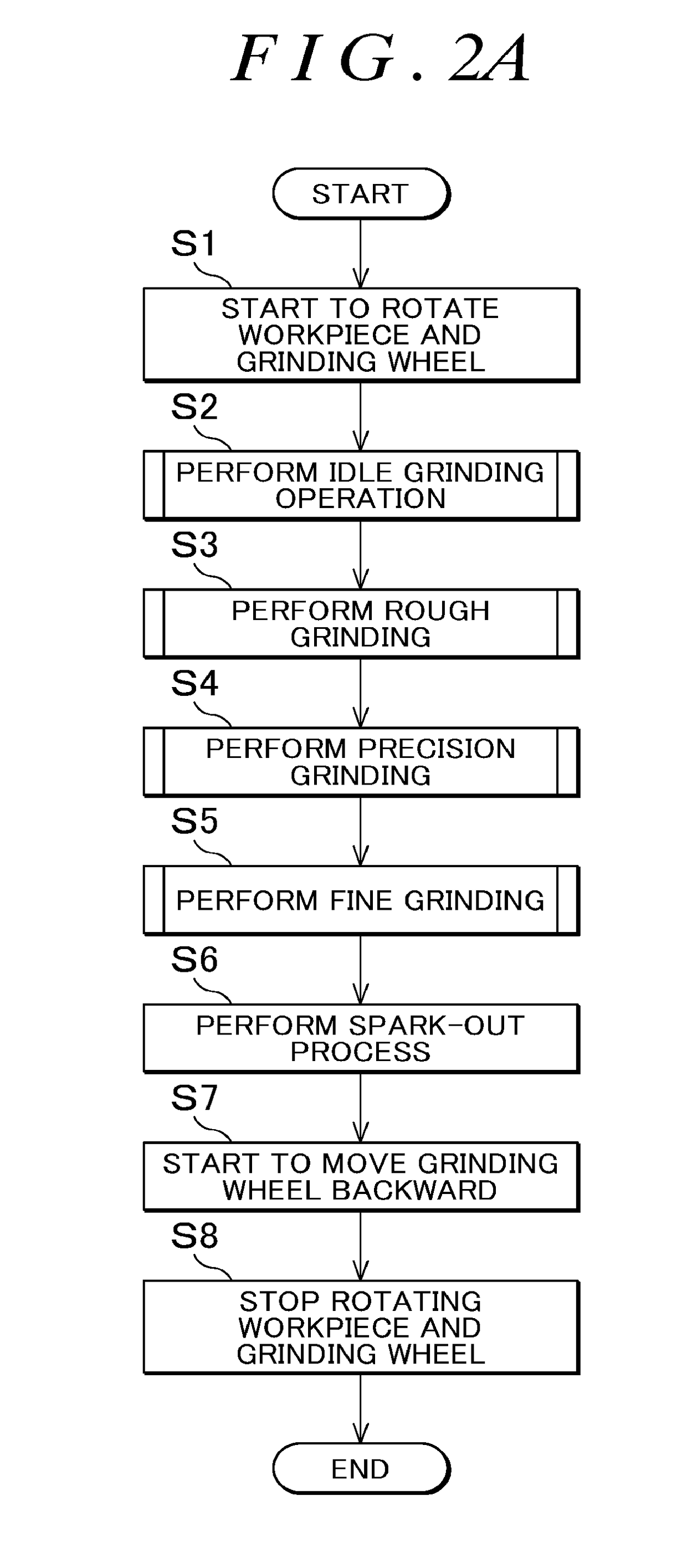

Grinding apparatus and grinding method

ActiveUS11117240B2Reliably occurrenceReliably determinedRevolution surface grinding machinesBelt grinding machinesDriving currentGrinding wheel

A grinding apparatus grinds a workpiece by rotating the workpiece held by main spindles and a grinding wheel held by a wheel spindle, and by relatively moving the grinding wheel toward and away from the workpiece. The grinding apparatus includes a first detection unit that detects a rotational phase of the workpiece; a second detection unit that detects a grinding resistance moment at a grinding point between the grinding wheel and the workpiece, or detects a drive current of a rotary drive unit of the workpiece or a rotary drive unit of the grinding wheel; a storage unit that stores the grinding resistance moment or the drive current in a manner associated with the rotational phase; and a determination unit that determines a slip between the workpiece and the main spindles based on the grinding resistance moment or the drive current at a current rotational phase, and on the grinding resistance moment or the drive current at the same phase as the current rotational phase of a previous time.

Owner:JTEKT CORP

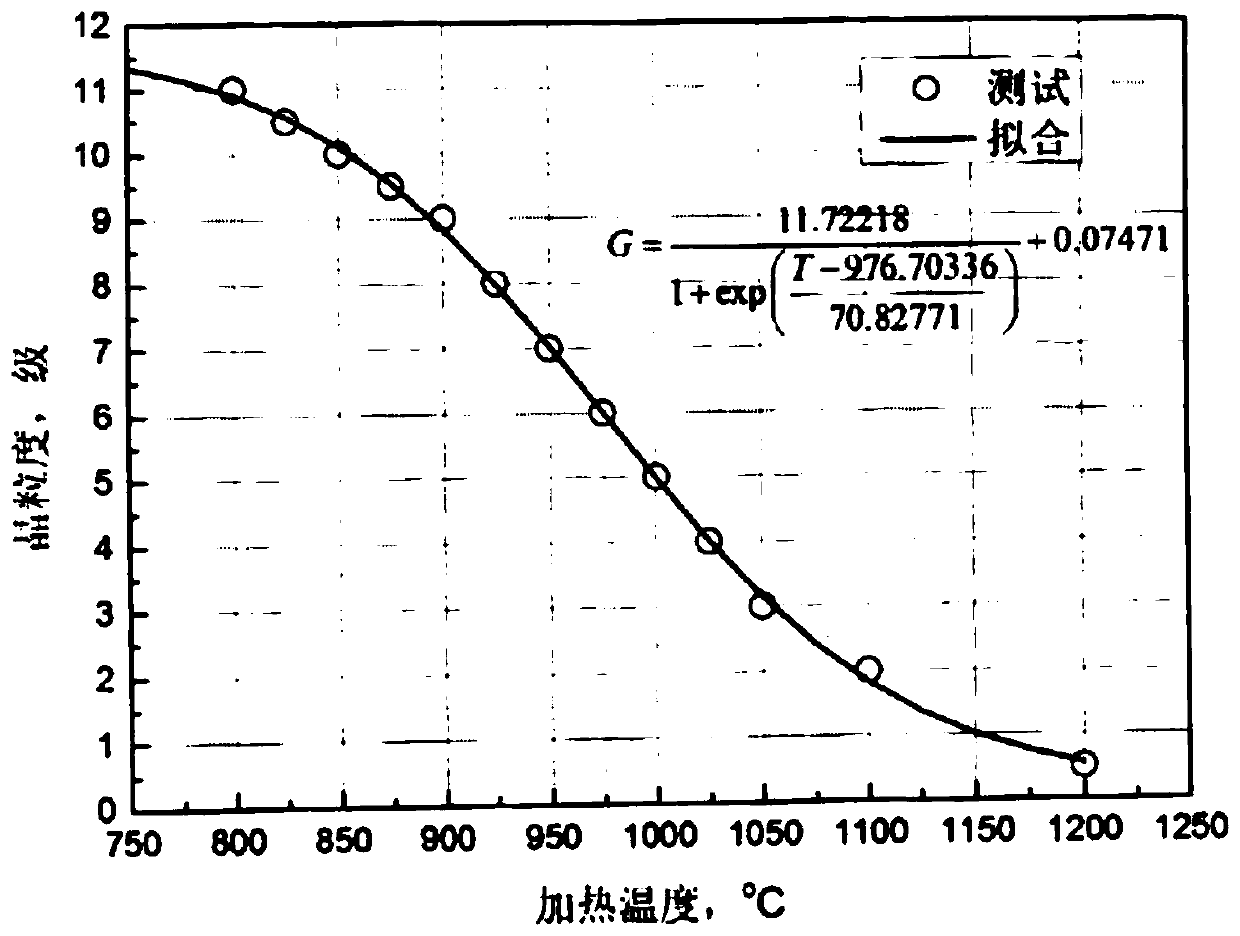

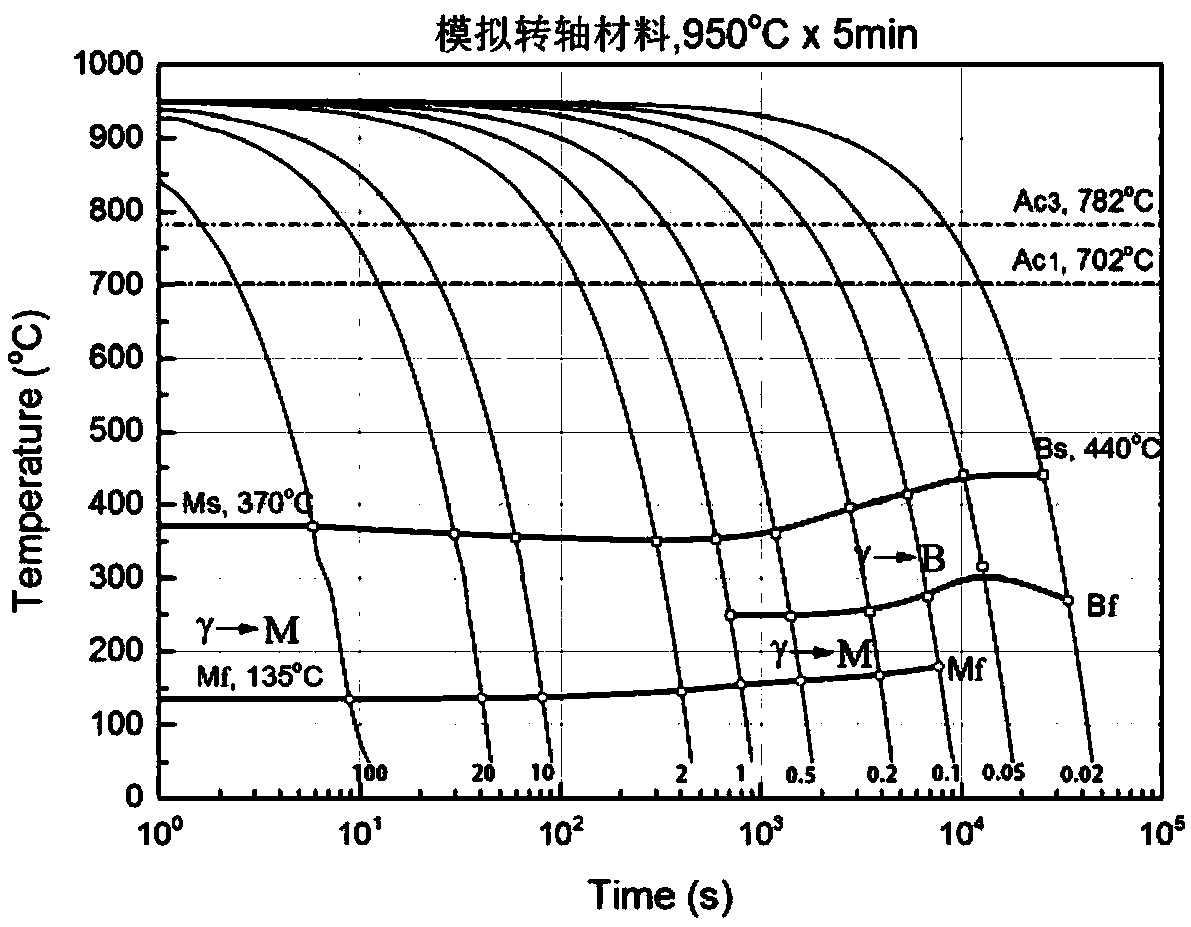

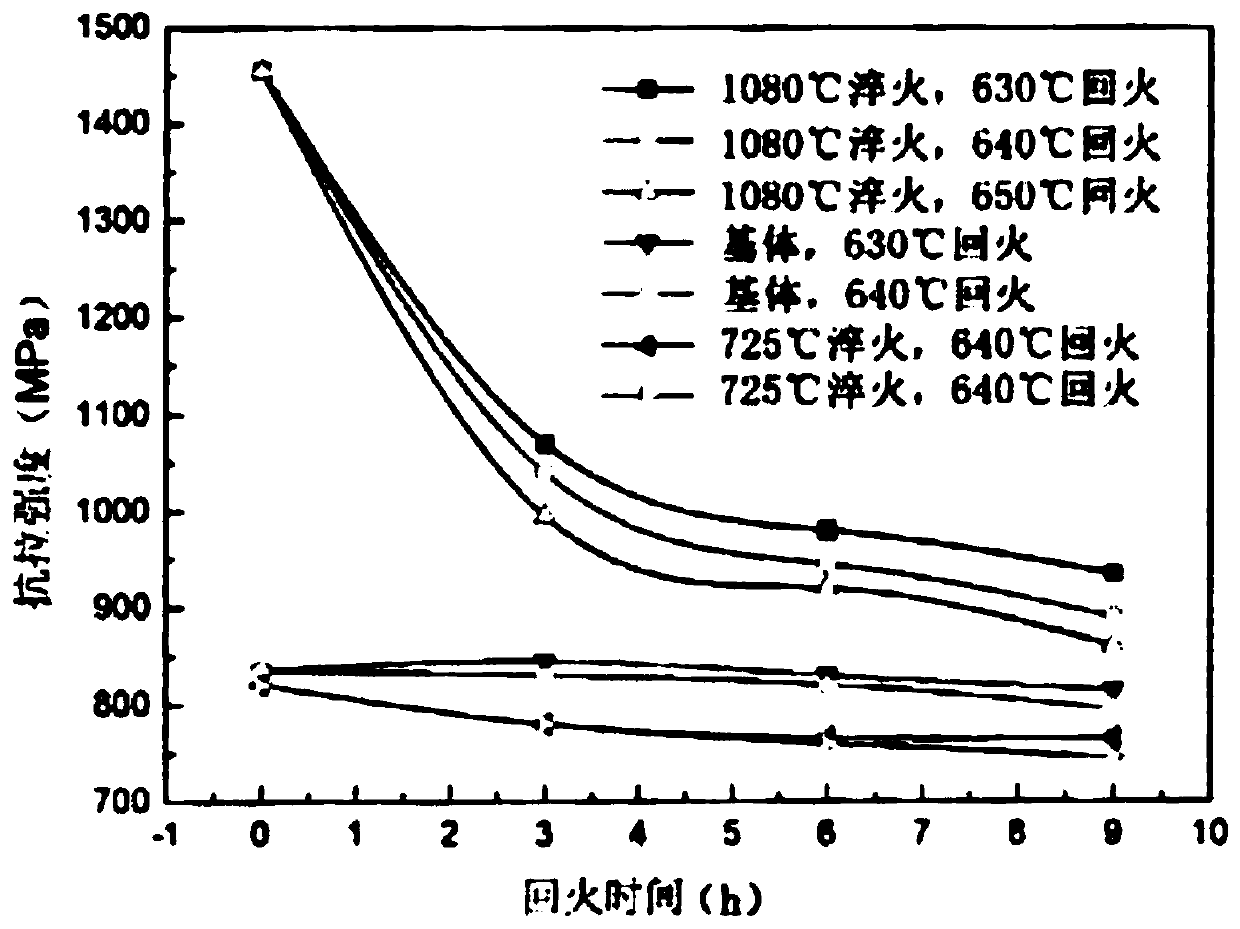

Method for locally tempering rotor tooth head of turbogenerator

ActiveCN109593938AQuickly determine temperatureQuickly determine the cooling rateFurnace typesHeat treatment process controlThermal impactUltimate tensile strength

The invention relates to a method for locally tempering a rotor tooth head of a turbogenerator, which is used for tempering a generator rotor whose heating temperature is higher than Ac1 and lower than Ac2. The method has the following beneficial effects that after the technical scheme of the invention is adopted, the temperature and cooling rate of the generator rotor which is abnormally heated can be determined quickly, a correct local tempering process is developed to successfully eliminate the martensite structure at the burnt position and take into account the softened over-tempering zoneas to prevent further over-tempering during tempering from reducing the strength and reduce the thermal impact on the normal matrix, thus avoiding the introduction of large thermal stress on the rotor teeth.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

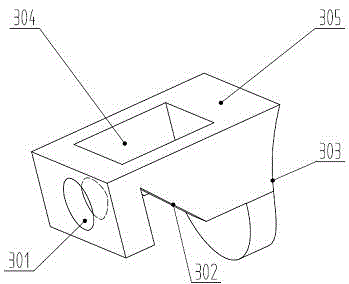

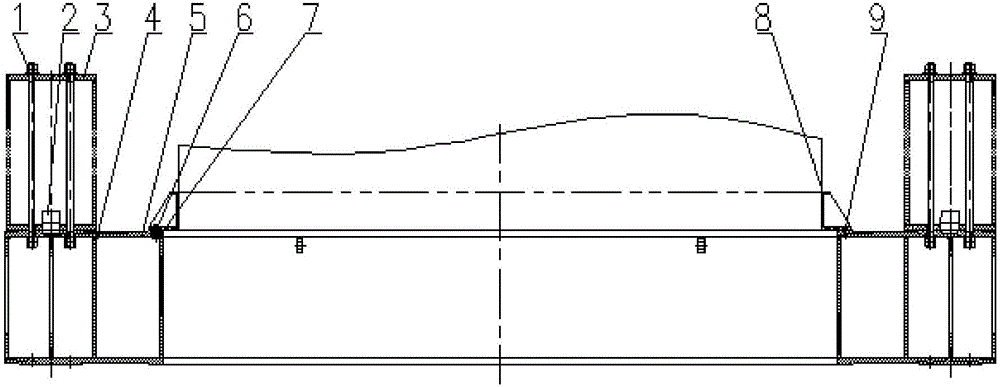

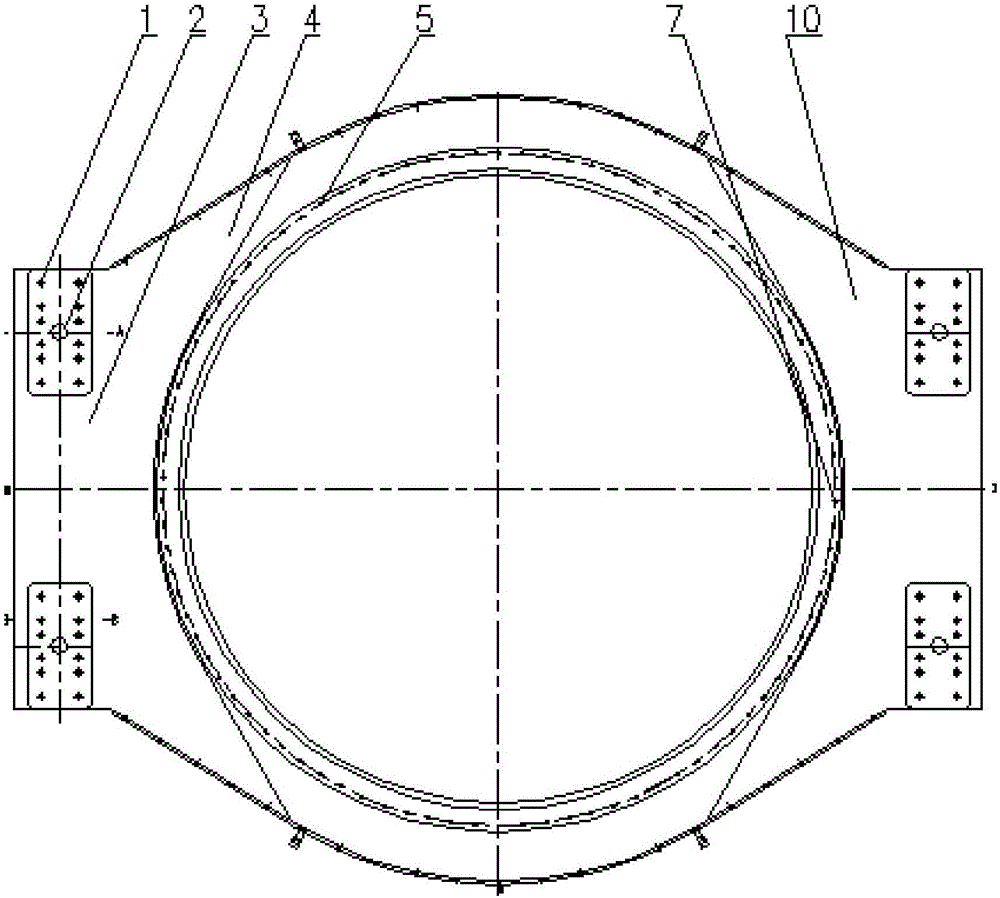

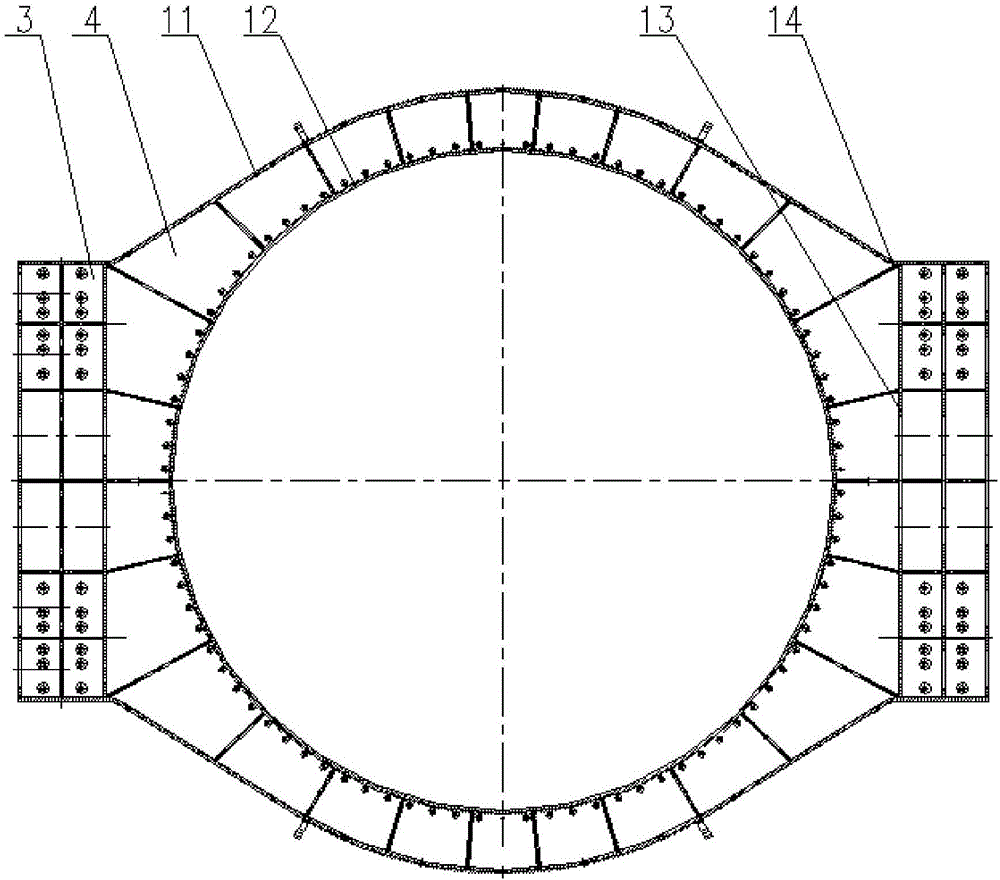

Planar annular heavy load force bearing device for liquid rocket power system test

InactiveCN106525438AMeet the needs of installation and fixingQuick switchEngine testingStress distributionButt joint

The invention discloses a planar annular heavy load force bearing device for a liquid rocket power system test. The device comprises two supporting legs, an annular center and a built-in moving supporting plate nut. The annular center is connected with a product, and the two supporting legs are connected with a force bearing foundation. The beneficial effects of the planar annular heavy load force bearing device for the liquid rocket power system test are that a force bearing ring satisfies a requirement for fixing of a module with zero height difference between butt joint height and a pivot through arrangement of a plane beam structure. The force bearing ring adopts the structural form of the two supporting legs and the annular center, is linearly concise and attractive, and is uniform in stress distribution. Steel plates of different thickness are adopted to weld to construct a box-shaped structure, can satisfy a requirement for hundreds of tons of bearing capacity, and can also reduce weight. By adoption of the prearranged moving supporting plate nut, position-adjustable nut prearrangement in the box-shaped structure is realized, and the problem of bolt tightening and installation in the box-shaped structure is solved. Axial fastening is realized by adoption of a high-strength bolt, and a lateral load is borne and lateral displacement is eliminated by adoption of close fit of a force bearing pin and a pin hole.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

Branch-control and phase-change heat exchange system and method based on two-stage steam-liquid heat exchanger

ActiveCN102200403BNo disturbance effectReliable sub-control performanceIndirect heat exchangersHeat exchange apparatusControl systemEngineering

The invention relates to a branch-control and phase-change heat exchange system and method based on a two-stage steam-liquid heat exchanger. The system comprises a heat source heat exchanger (2), a cold source heat exchanger (20) and a low temperature liquid tank (23), and the system further comprises a high temperature heat exchanger (14), a low temperature heat exchanger (22) and a high temperature liquid tank (8); a main heat source steam pipe at the top part of the heat source heat exchanger (2) is divided into two branch pipes after passing through a heat source steam exhaust adjusting valve (16), the two branches are respectively communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (20), and control systems are respectively arranged on the branches; the low temperature liquid tank (23) is communicated with the high temperature heat exchanger (14) through a condensate pipeline, the bottom of the high temperature heat exchanger (14) is communicated with the high temperature liquid tank (8) through a condensate pipeline, and the condensate pipeline at the bottom of the high temperature liquid tank (8) is respectively communicated with the low temperature heat exchanger (22) and the heat source heat exchanger (2). According to the branch-control and phase-change heat exchange system disclosed by the invention, overheat and over-cold phenomenon of steam and condensate are solved, and the heat exchange efficiency is further improved.

Owner:SHANXI SANHESHENG IND TECH

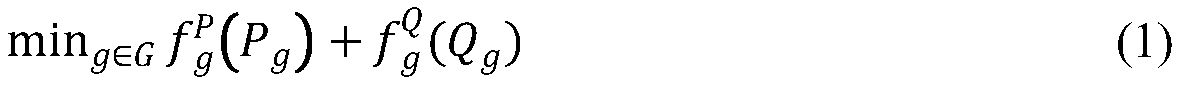

A Security Constrained Economic Dispatch Method with Embedded Reactive Power and Voltage

ActiveCN108054789BGuaranteed economyEnsure safetyProgramme controlSingle network parallel feeding arrangementsVoltage amplitudePower grid

The invention proposes a safety-constrained economic dispatching method with embedded reactive power and voltage, which belongs to the field of electric power system safety-constrained economic dispatching, so that each node and line flow in the power grid is within the safety-constrained range, and the power grid operation cost is minimized. This method first constructs the optimal power flow model of safety-constrained economic dispatch composed of objective functions and constraints; after solving the model iteratively, check the per-unit error for all branches: if there is a line that does not meet the per-unit error, then Update the constraints of the power flow equation, and proceed to the next iteration until all lines meet the per unit error, the model converges, and the iteration ends. A complete set of power system security including node voltage amplitude, voltage phase angle, unit active output, and reactive output is obtained. Constrained economic dispatch schemes. The invention can meet the requirements of economical operation of the power system to the greatest extent, reduce the operating cost of the power system, has high precision, good convergence, and has strong practical application value.

Owner:TSINGHUA UNIV

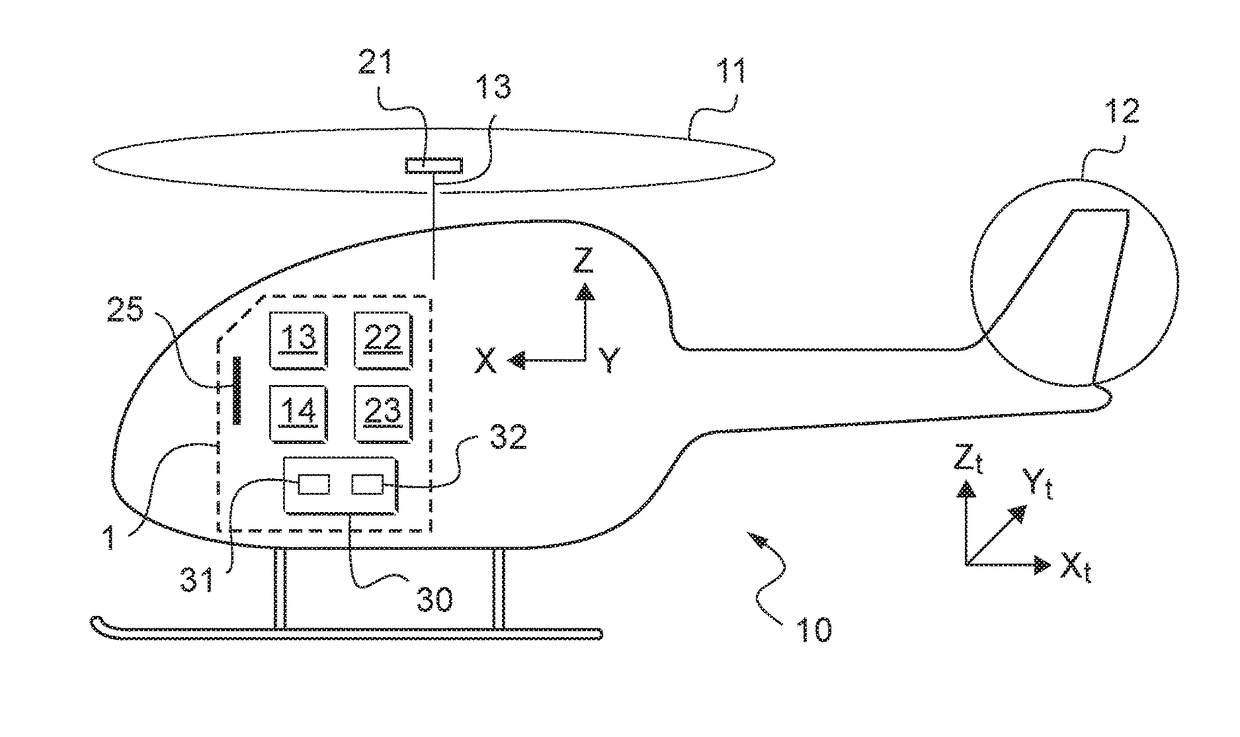

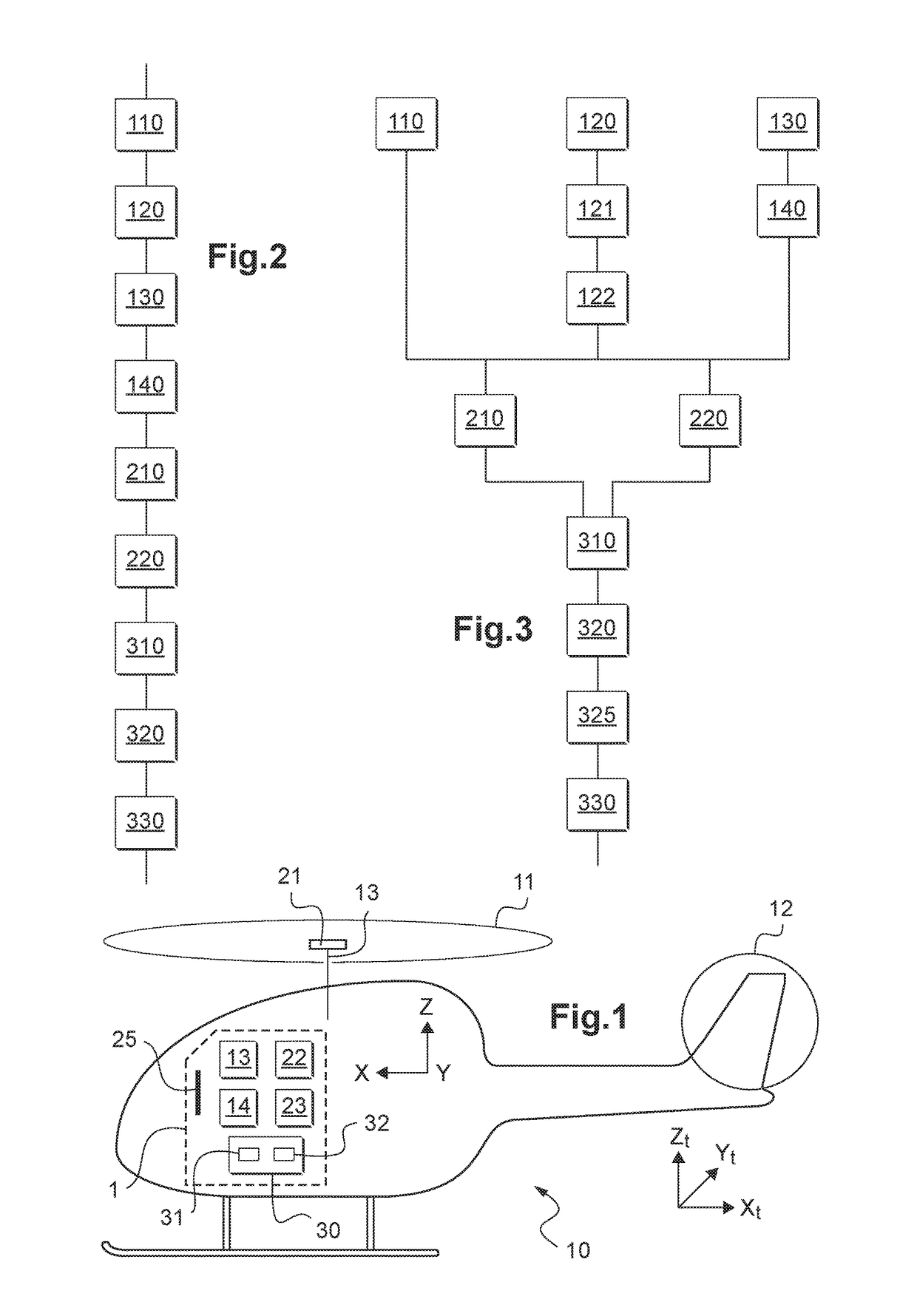

Method and a device for determining the wind speed to be taken into account in order to optimize the takeoff weight of an aircraft

ActiveUS9728092B2Reduced safety marginImprove performanceAircraft componentsTesting/calibration of speed/acceleration/shock measurement devicesInstabilityEngineering

A method of determining the speed of the wind to be taken into account for determining a maximum authorized takeoff weight of an aircraft. A measured speed TASmes of the local wind is calculated from at least one current speed TASinst of the local wind and an observed speed TASobs of the local wind on the basis of weather observations and on the basis of a heading value. The measured speed TASmes is compared with the observed speed TASobs in order to determine a calculated speed TASperfo of the local wind while also making use of at least one instability criterion of the local wind as supplied by the weather observations and weather forecasts. The calculated speed TASperfo is then for taking into account in order to optimize the maximize authorized takeoff weight of the aircraft.

Owner:EUROCOPTER

Grinding apparatus and grinding method

ActiveUS20180193978A1Reliably occurrenceReliably determinedRevolution surface grinding machinesGrinding feed controlDriving currentPower flow

Owner:JTEKT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com