Bridge arm circuit and method inhibiting fault current of large-capacity MMC submodule

A fault current and sub-module technology is applied in the bridge arm circuit that suppresses the fault current of the large-capacity MMC sub-module, and in the field of flexible DC power transmission of the converter, which can solve the problem of the limited improvement of the sub-module over-current and the fully controlled power electronic device. Overcurrent, low device utilization, etc., to achieve the effect of simple wiring, improving availability, and reducing safety margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

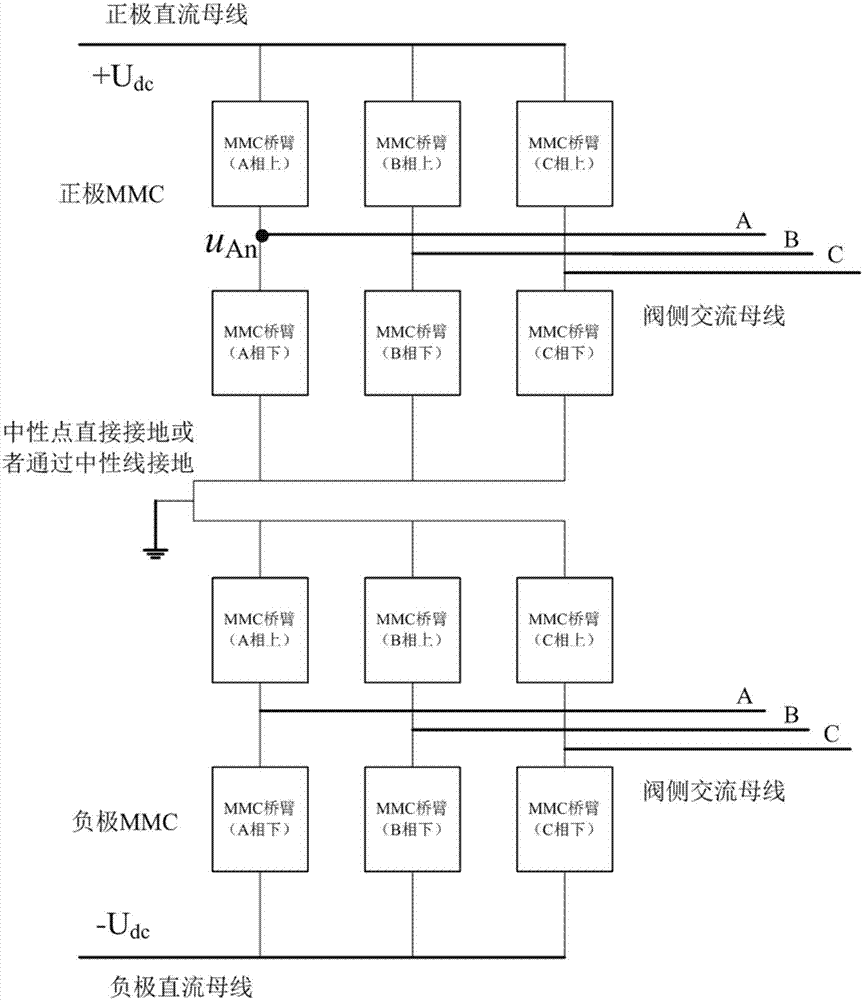

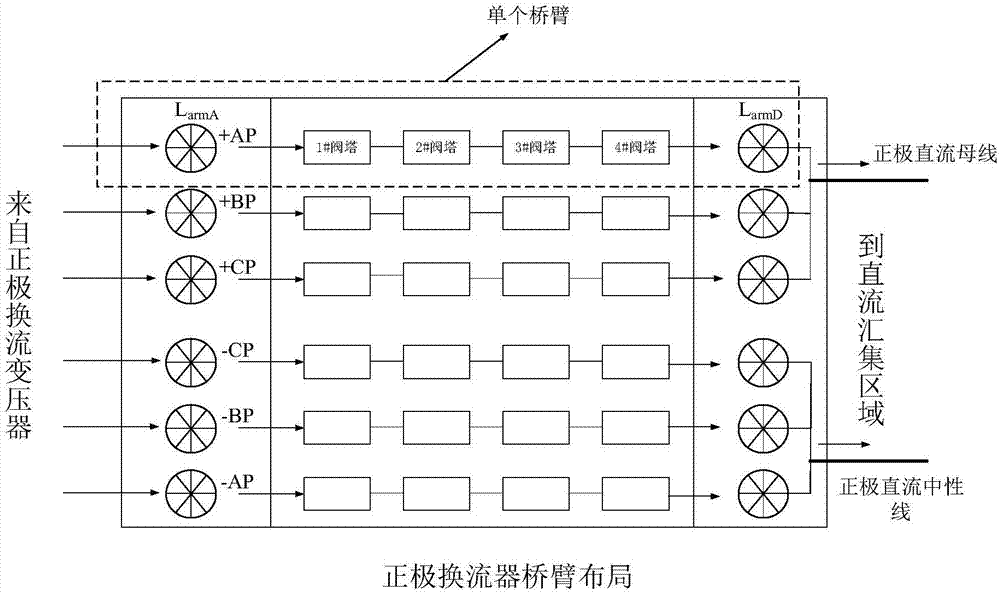

[0021] see figure 1 , Large-capacity MMC systems basically adopt a symmetrical bipolar topology. In the symmetrical bipolar system, two independent MMCs are used for the positive pole and the negative pole respectively. Each MMC is composed of 6 bridge arms (phase units). The AC sides of the bridge arms are respectively connected to the three-phase busbars on the valve side of the converter transformer. The upper and lower bridge arms are the same AC busbar (the upper arm of phase A and the lower The AC side of the bridge arm is connected to the A-phase bus of the converter transformer). The DC sides of the six bridge arms are collected to form a positive busbar (or a negative busbar) and a neutral busbar. The positive or negative MMC adopts an independent control system. The positive MMC lower arm DC bus (neutral bus) is connected to the negative MMC uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com