Process for determining particle emission in the exhaust fume stream from an internal combustion engine

A technology of internal combustion engine and exhaust gas flow, applied in the direction of internal combustion piston engine, electronic control of exhaust gas treatment device, diagnosis device of exhaust gas treatment device, etc., can solve problems such as less regeneration cycle, reduce safety margin and reduce additional The effect of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

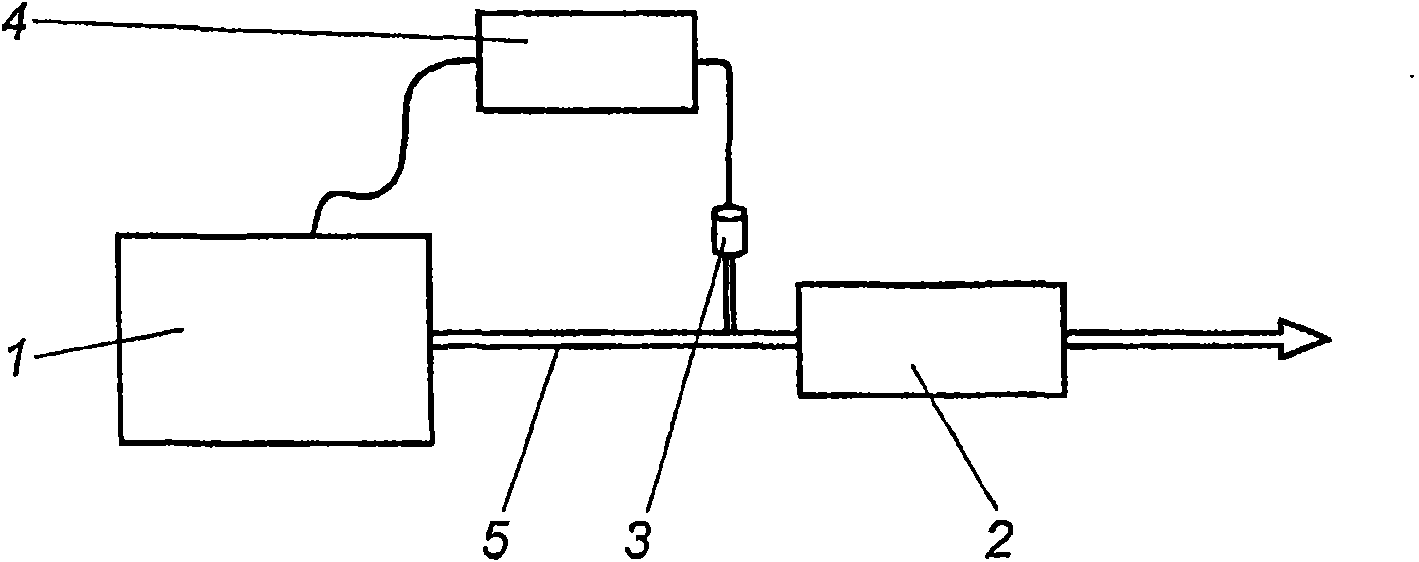

[0069] figure 1 The basic configuration of the system is shown: a particulate filter 2 is arranged in the exhaust tract of an internal combustion engine 1 . A particle sensor 3 is also provided in the exhaust pipe 5 , preferably in front of the particle filter 2 . The internal combustion engine 1 is controlled by an electronic control unit ECU. The particle sensor 2 is also connected to the control unit ECU. There may also be more sensors such as differential pressure sensors, but this is not strictly required for the method of the invention.

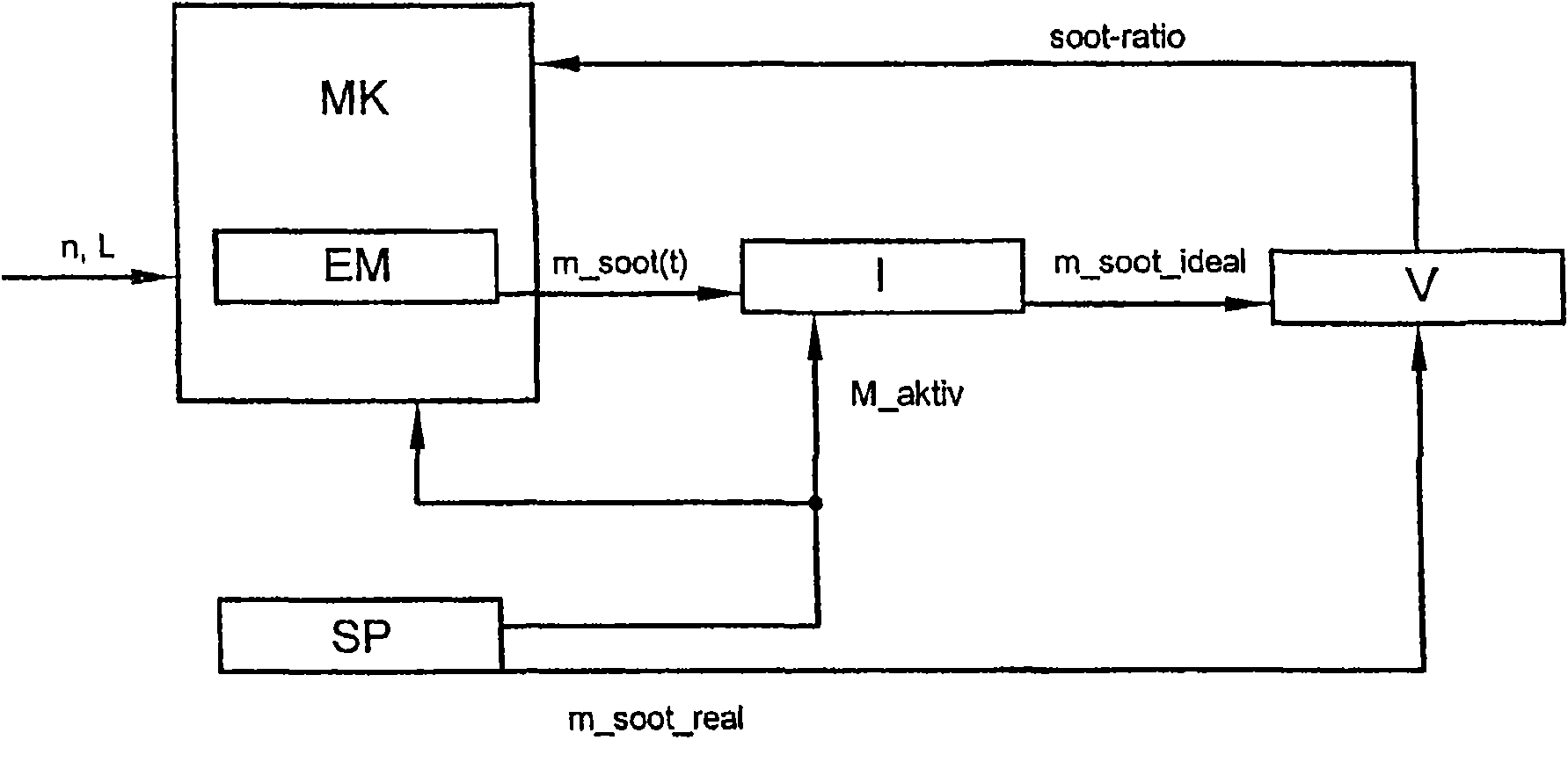

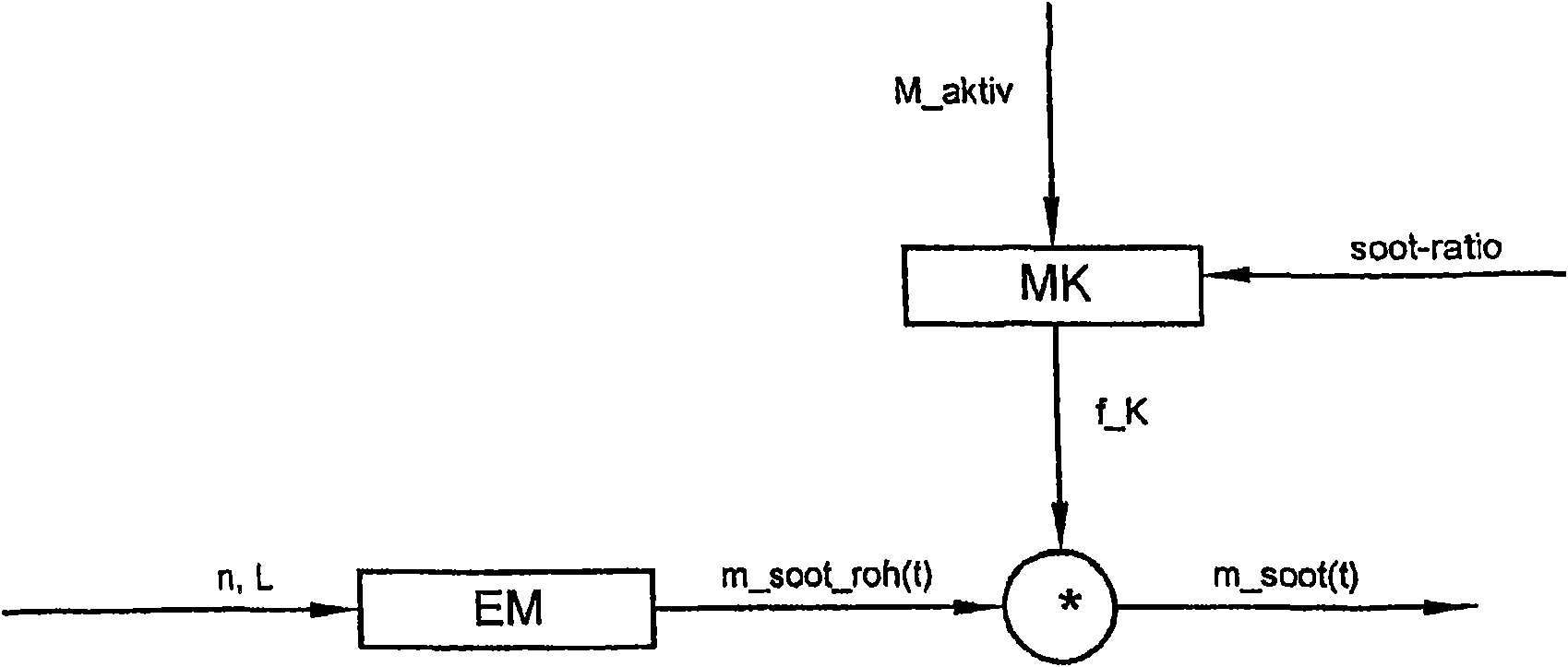

[0070] figure 2 Relevant parts of the control algorithm in the internal combustion engine control unit 4 are shown. From engine operating data such as engine speed n, engine torque M, etc., the conventional emission model EM provides an ideal value m_soot(t) of the particle mass emitted by the engine. Enter this value into integrator I. In addition to the signal input port for the particle mass, the integrator I also has a contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com