Planar annular heavy load force bearing device for liquid rocket power system test

A plane and annular technology, applied in the field of plane annular bearing devices for liquid rocket power system testing, can solve problems such as rocket damage and affect the progress of rocket development, and achieve the effect of meeting the needs of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

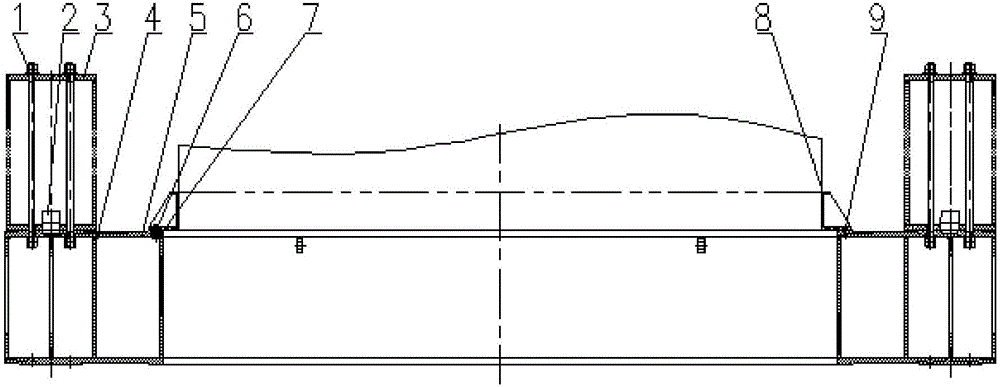

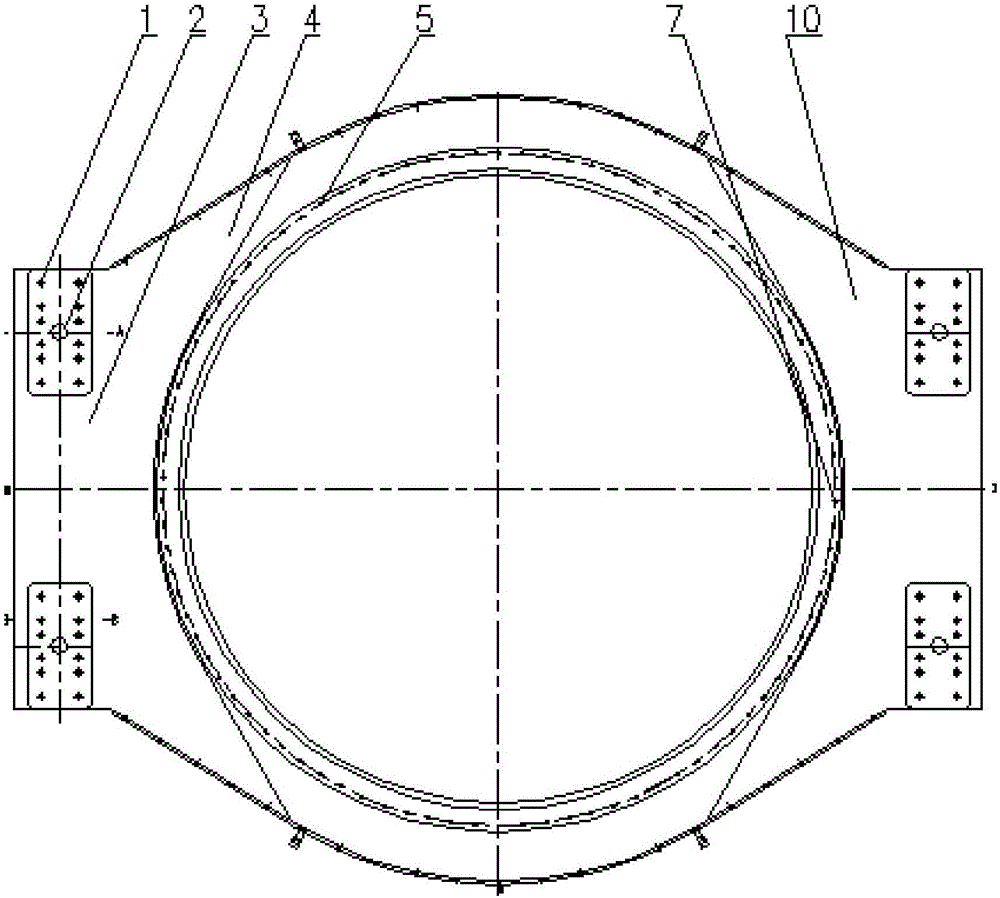

[0022] As shown in the figure, the load-bearing device is connected to the load-bearing foundation through connecting bolts 1 and round pins 2 on the two legs 4, ensuring axial fastening and lateral positioning. The load-bearing device is connected to the product through several connecting bolts 6 and load-bearing pins 9, among which high-strength bolts are used for axial fastening, and the tight fit of load-bearing pins and pin holes is used to bear lateral loads and eliminate lateral displacement.

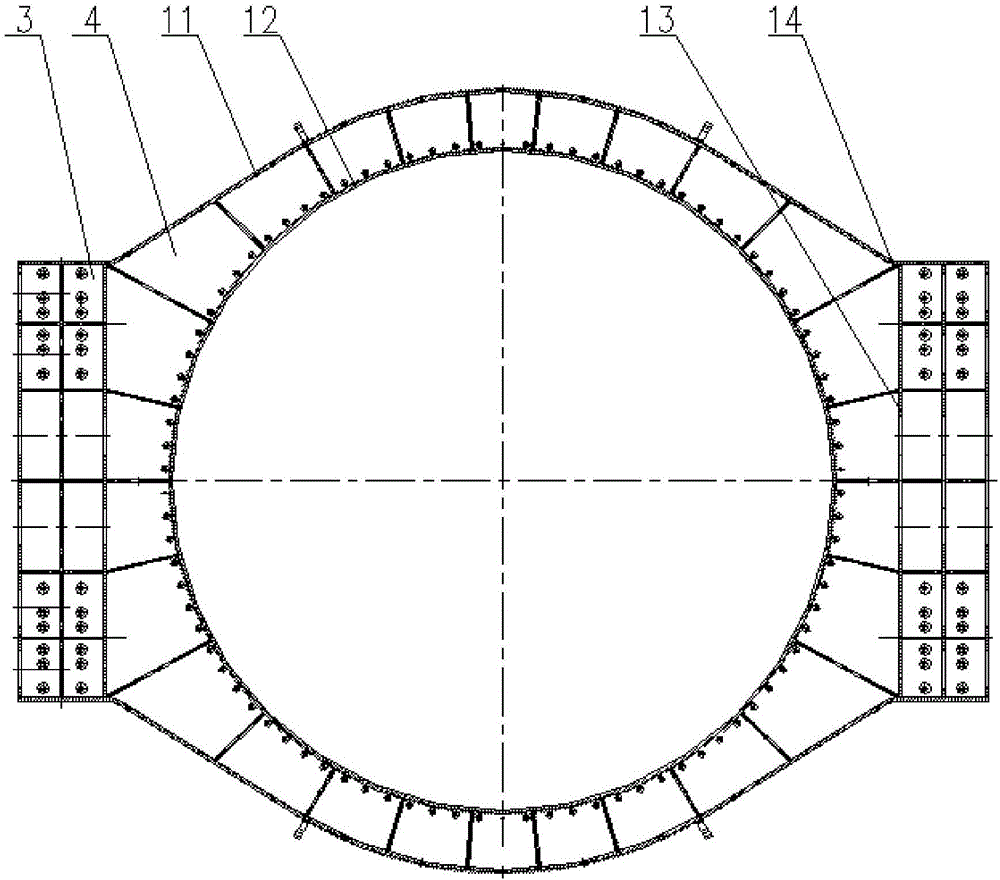

[0023] The load-bearing device has a maximum load capacity of 100t and adopts a box-shaped structure. The main structure includes an annular center 5 and two outriggers 4 . The frame structure of the ring center is composed of panels 10, arc risers 11, ring risers 12, side plates 13, and ribs 14 are evenly arranged inside. The plates are we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com