Prefabricated base of road or ridge temporary retaining wall

A technology for retaining walls and foundations, which is used in infrastructure engineering, water conservancy projects, artificial islands, etc., can solve the unfavorable assembly operation of prefabricated foundations, cannot meet the installation and fixing requirements of retaining walls, and reduce the applicability of prefabricated foundations, etc. problems, to meet the needs of installation and fixation, to avoid deformation or even breakage, and to achieve the effect of free and flexible installation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

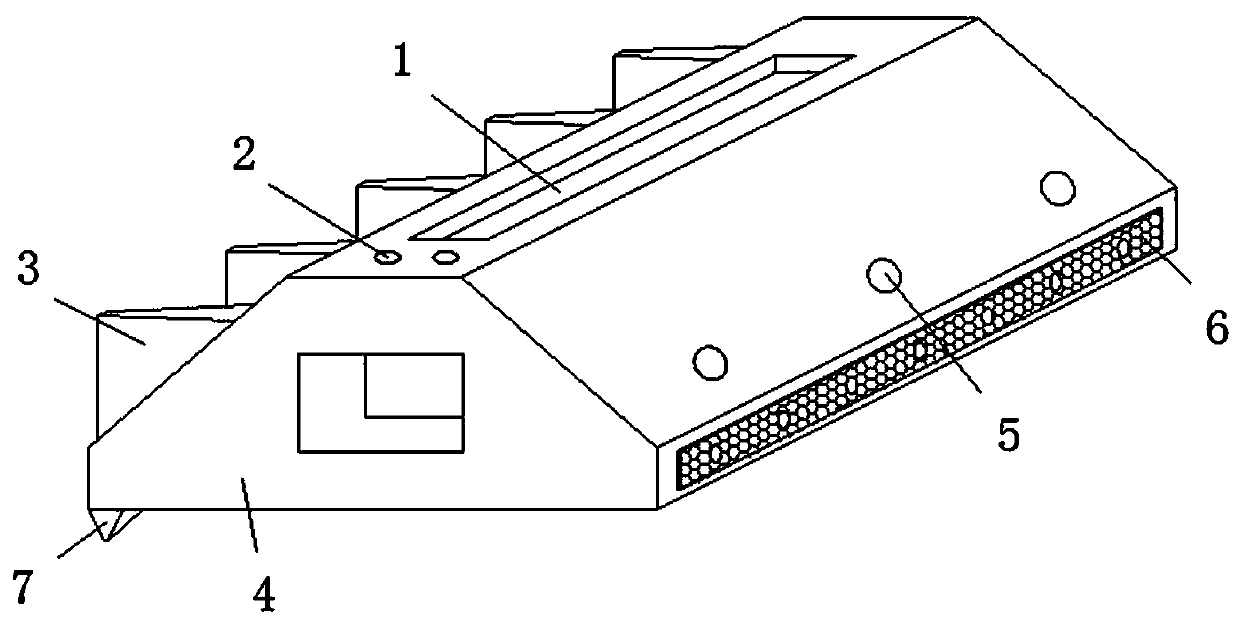

[0046] Such as Figure 1-Figure 5 As shown, the prefabricated base of the temporary retaining wall of the road or bridge includes: the base body 4;

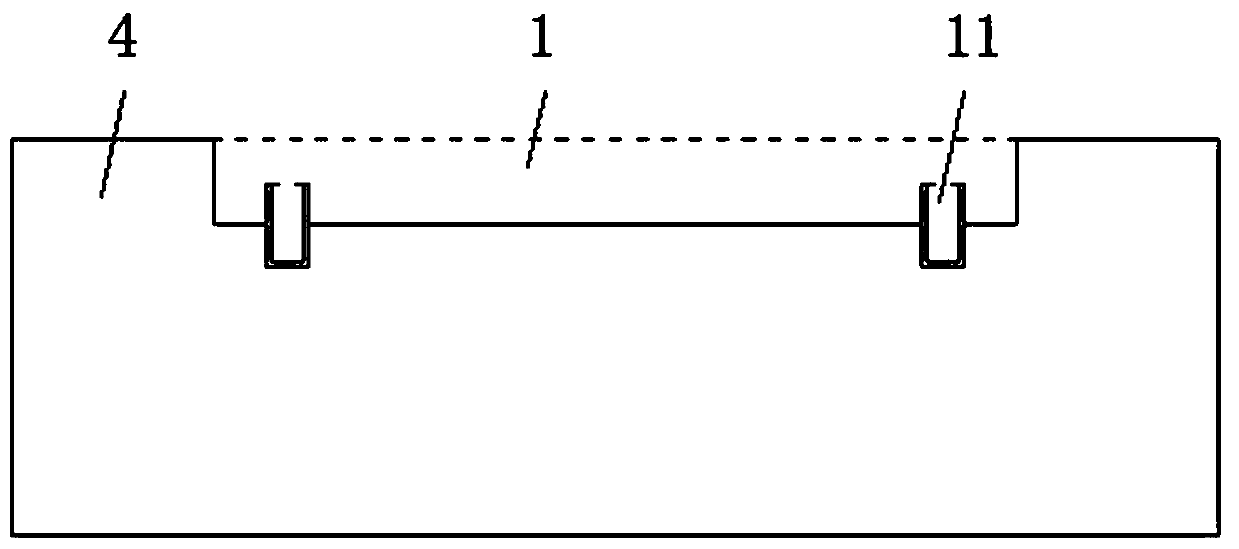

[0047] The top of the base body 4 is provided with a pouring groove 1;

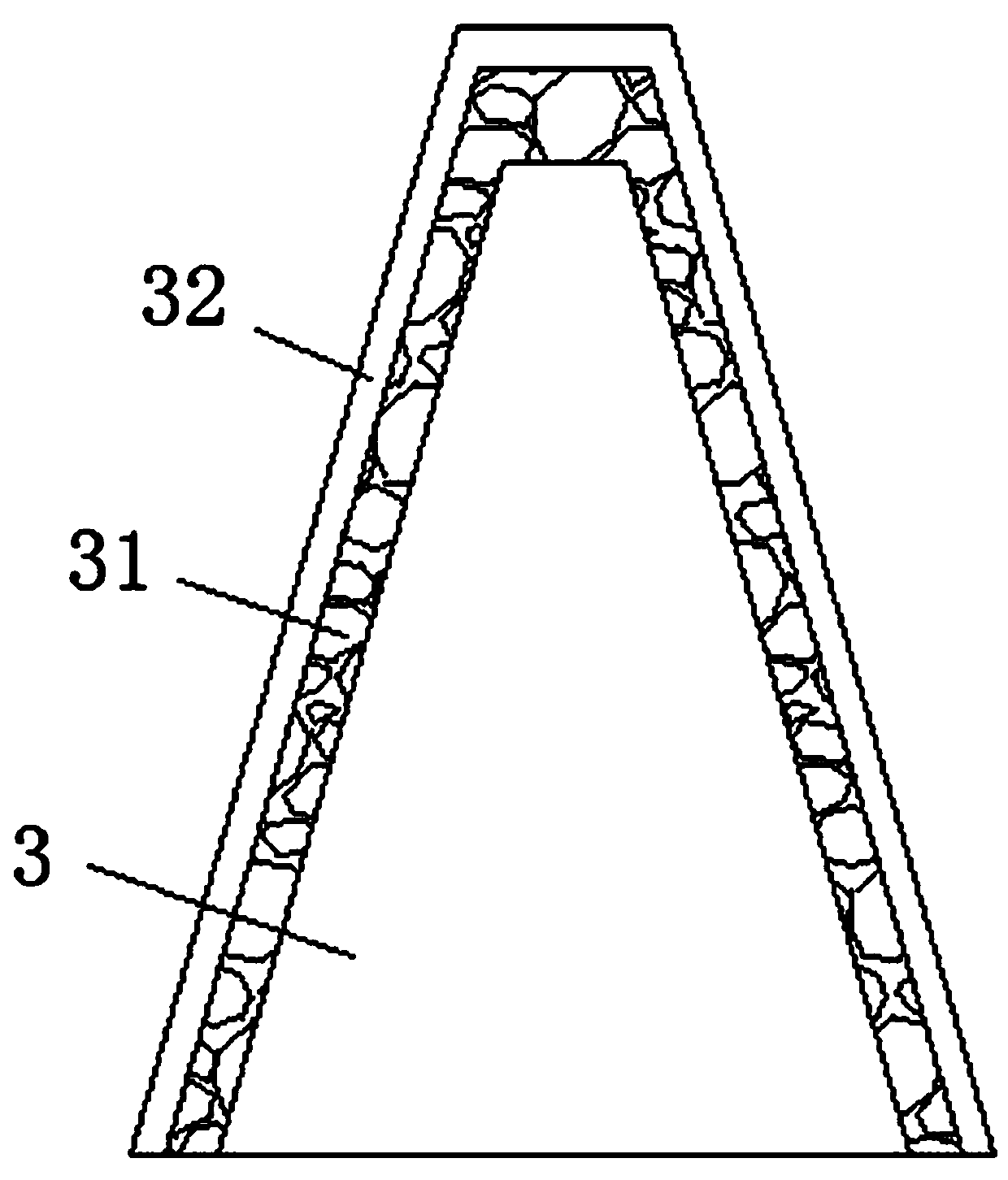

[0048] One side of the pedestal body 4 is equidistantly poured with reinforcement ribs 3, and the other side is equidistantly provided with anchor holes 5;

[0049] One side of the vertical end outer wall of the base body 4 is provided with an assembly groove 43, and the other vertical end outer wall is provided with an assembly block 45 that cooperates with the assembly groove 43;

[0050] A water leakage hole 44 is opened transversely through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com