Non-cured rubber asphalt waterproofing coating with flame retardance property and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, which can be used in asphalt coatings, fireproof coatings, coatings, etc., and can solve problems such as fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

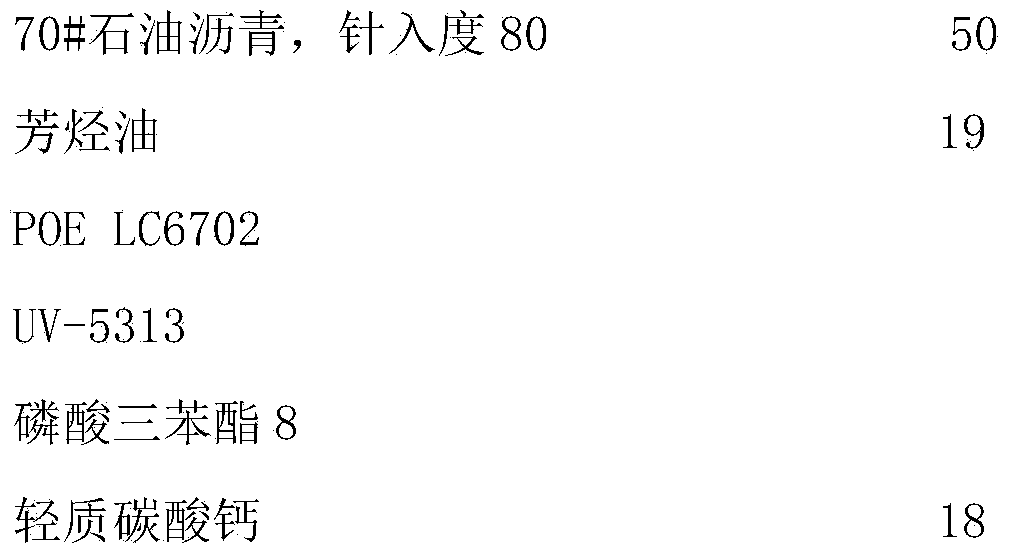

Embodiment 1

[0015]

[0016] Preparation method: Heat petroleum asphalt to 140°C, then add softener, modifier and flame retardant, stir evenly, continue to heat up to 160°C, develop at this temperature for 30 minutes, start the colloid mill to accelerate the swelling process, and make the modified The homogenization of the active agent is more complete. After 1 hour, add the anti-aging agent, stop the colloid mill, stir at a constant speed for 2 hours, add the filler, continue to develop for 45 minutes, and the product is produced after discharge.

[0017] The performance parameters of the flame-retardant non-curing rubber asphalt waterproof coating in this example are as follows: solid content 99.9%, heat resistance at 70°C without running, sliding, and dripping, low-temperature flexibility below -30°C, and extensibility at -5°C 30mm , Dry base surface and wet base surface adhesion are 100% cohesive failure, qualified self-healing, thermal aging, chemical corrosion basically no change a...

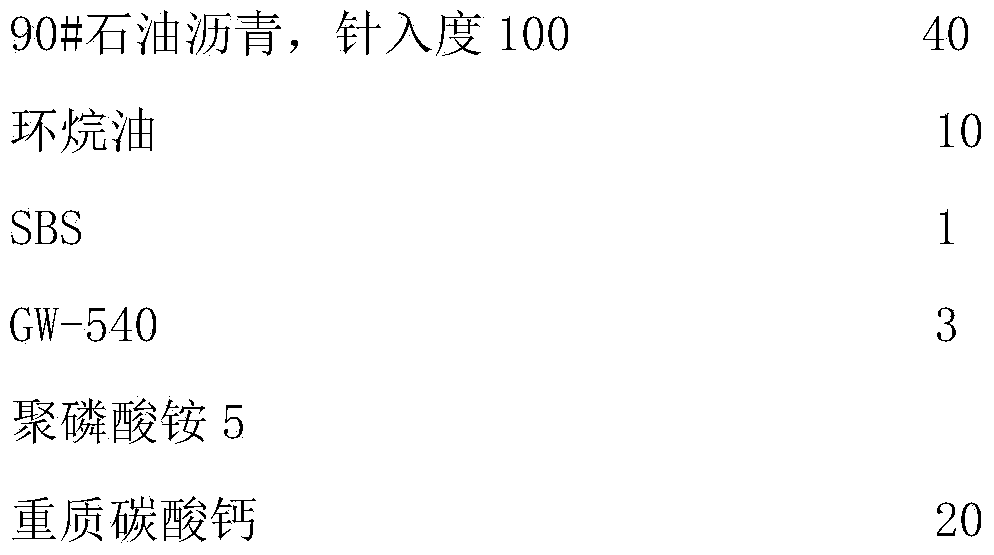

Embodiment 2

[0019]

[0020] Preparation method: Heat petroleum asphalt to 160°C, then add softener, modifier and flame retardant, stir evenly, continue to heat up to 180°C, develop at this temperature for 40 minutes, start the colloid mill to accelerate the swelling process, and make the modified The homogenization of the agent is more complete. After 1.5 hours, add the anti-aging agent, stop the colloid mill, stir at a constant speed for 1.5 hours, add the filler, continue to develop for 80 minutes, and the product is produced after discharge.

[0021] The performance parameters of the flame-retardant non-curing rubber asphalt waterproof coating in this example are as follows: solid content 99.9%, heat resistance 75°C without running, sliding, dripping, low temperature flexibility below -30°C, extensibility at -5°C 30mm 100% cohesive failure of dry base surface and wet base surface, qualified self-healing property, basically no change after heat aging and chemical corrosion for 160 hou...

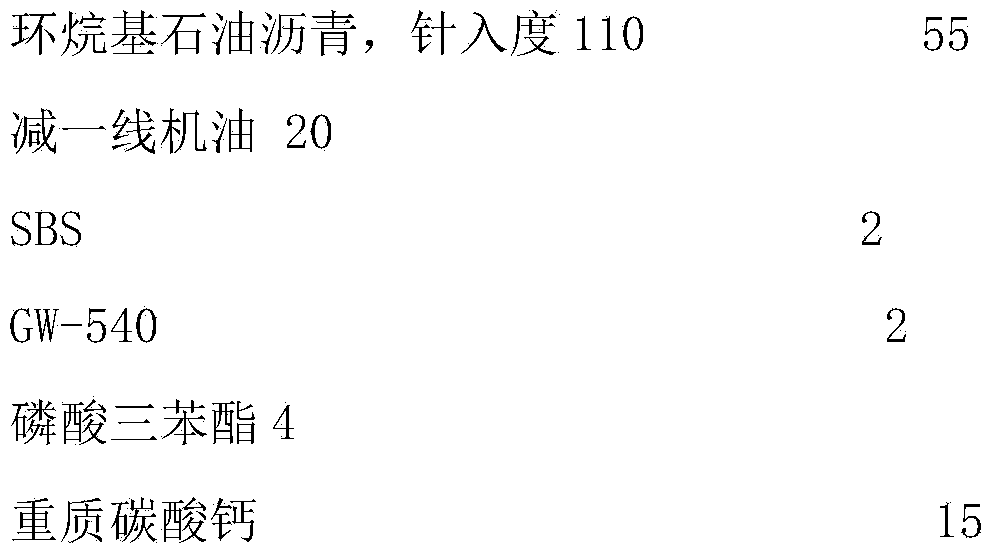

Embodiment 3

[0023]

[0024] Preparation method: Heat petroleum asphalt to 160°C, then add softener, modifier and flame retardant, stir evenly, continue to heat up to 180°C, develop at this temperature for 50 minutes, start the colloid mill to accelerate the swelling process, and make the modified The homogenization of the active agent is more complete. After 1.5 hours, add the anti-aging agent, stop the colloid mill, stir at a constant speed for 2 hours, add the filler, continue to develop for 80 minutes, and the product is produced after discharge.

[0025] The performance parameters of the flame-retardant non-curing rubber asphalt waterproof coating in this example are as follows: solid content 99.9%, heat resistance 85°C without running, sliding, dripping, low temperature flexibility below -30°C, extensibility 30mm at -5°C , Dry base surface and wet base surface adhesion are 100% cohesive failure, qualified self-healing, no change after heat aging, chemical corrosion 200h, flame reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com