Self-healing polyurethane resin containing disulfide bond and preparation method thereof

The technology of polyurethane resin and disulfide bond is applied in the field of self-healing polyurethane resin and its preparation, which can solve the problems of long healing time, high temperature and long time required for healing, and achieves fast healing speed, easy acquisition and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Preparation of self-healing polyurethane resin: In parts by weight, add 23.4 parts of polytetrahydrofuran diol (Mn~1810) into a three-necked flask, stir and heat to 110°C, vacuumize and keep the vacuum of the reaction system at 0.08MPa Above, dehydrate for 2 hours, then lower the temperature to 70°C, add 4.6 parts of hexamethylene diisocyanate and 0.2 parts of dibutyltin dilaurate, continue to stir and react at 70°C under nitrogen protection for 2 hours, then cool down to 25°C , dropwise add a mixed solution of 2 parts of 2-hydroxyethyl disulfide and 70 parts of dimethylacetamide, continue to react for 2 hours under the protection of nitrogen, vacuum defoaming after completion, to obtain a mass fraction of 30% Polyurethane resin solution.

[0030] Preparation of self-healing polyurethane film: coating the obtained polyurethane resin solution on a glass plate, and heating in vacuum at 50° C. for 12 hours to obtain a polyurethane film with self-healing function.

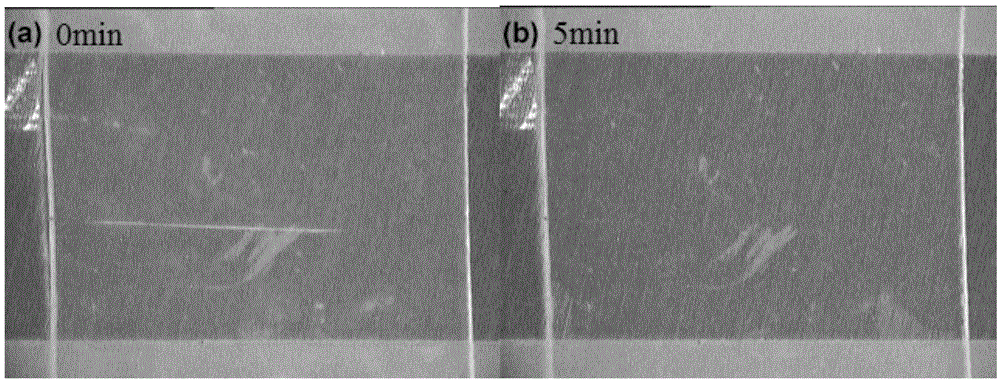

[0031] ...

Embodiment 2

[0038] Preparation of self-healing polyurethane resin: In parts by weight, add 20.5 parts of polytetrahydrofuran diol (Mn~1810) into a three-necked flask, stir and heat to 110°C, vacuumize and keep the vacuum of the reaction system at 0.08MPa Above, dehydrate for 2 hours, then lower the temperature to 70°C, add 5.9 parts of hexamethylene diisocyanate and 0.2 parts of dibutyltin dilaurate, continue to stir and react at 70°C under nitrogen protection for 2 hours, then cool down to 25°C , dropwise add a mixed solution of 3.5 parts of 2-hydroxyethyl disulfide and 70 parts of dimethylacetamide, continue to react for 2 hours under the protection of nitrogen, vacuum defoaming after completion, to obtain a mass fraction of 30% Polyurethane resin solution.

[0039] Preparation of self-healing polyurethane film: coating the obtained polyurethane resin solution on a glass plate, and heating in vacuum at 50° C. for 12 hours to obtain a polyurethane film with self-healing function.

[004...

Embodiment 3

[0045] Preparation of self-healing polyurethane resin: In parts by weight, add 18.3 parts of polytetrahydrofuran diol (Mn~1810) into a three-necked flask, stir and heat to 110°C, vacuumize and keep the vacuum of the reaction system at 0.08MPa Above, dehydrate for 2 hours, then lower the temperature to 70°C, add 7 parts of hexamethylene diisocyanate and 0.2 parts of dibutyltin dilaurate, continue to stir and react for 2 hours at a temperature of 70°C under nitrogen protection, and then cool down to 25°C , dropwise add a mixed solution of 4.7 parts of 2-hydroxyethyl disulfide and 70 parts of dimethylacetamide, continue to react for 2 hours under the protection of nitrogen, vacuum defoaming after completion, to obtain a mass fraction of 30% Polyurethane resin solution.

[0046] Preparation of self-healing polyurethane film: coating the obtained polyurethane resin solution on a glass plate, and heating in vacuum at 50° C. for 12 hours to obtain a polyurethane film with self-healin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com