Construction method for full cover-excavation reverse method of underground engineering

A technology of underground engineering and construction method, which is applied in water conservancy projects, infrastructure engineering, artificial islands, etc., to achieve good waterproof effects, prevent seepage and water leakage, and ensure the quality of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

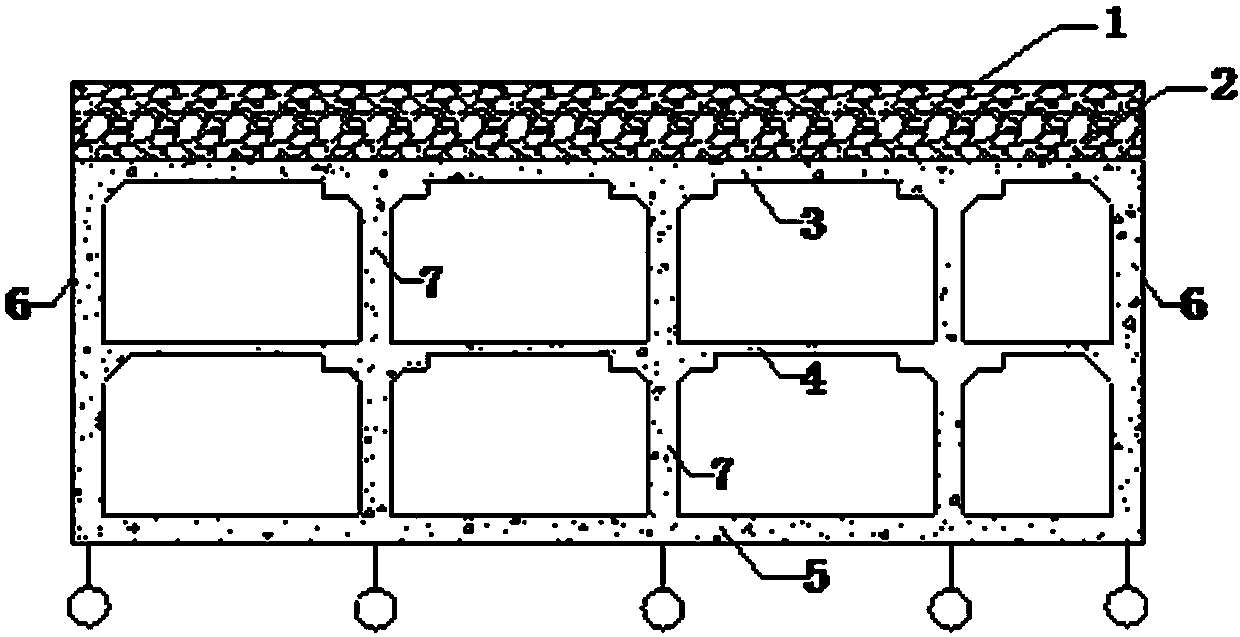

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described, figure 1 It is an overall cross-sectional view of an underground civil air defense project. The civil air defense project is located under the main traffic road. This project has a total of two basement floors, 28 stair openings from the ground and 3 car entrances leading to the second-floor underground garage. The elevation of ±0.000 of this project is the elevation of the road surface. The elevation of the roof surface of the basement structure is designed to be -3~-4 meters, the elevation of the middle surface is designed to be -8.80m, and the elevation of the bottom surface is designed to be -12.7~-13.30 meters. 1. The inter-floor floor adopts the structural type of cast-in-place integrated reinforced concrete beamless floor and column cap. The floor and foundation adopt raft foundation. The supporting structure adopts 800mm thick underground continuous wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com