co 2 U-shaped vapor separation heat exchanger skid

A gas separator and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, solid adsorbent liquid separation, etc., can solve the problems of inconvenient control, poor heat exchange effect, low work efficiency, etc. The effect of reducing volume, facilitating control and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

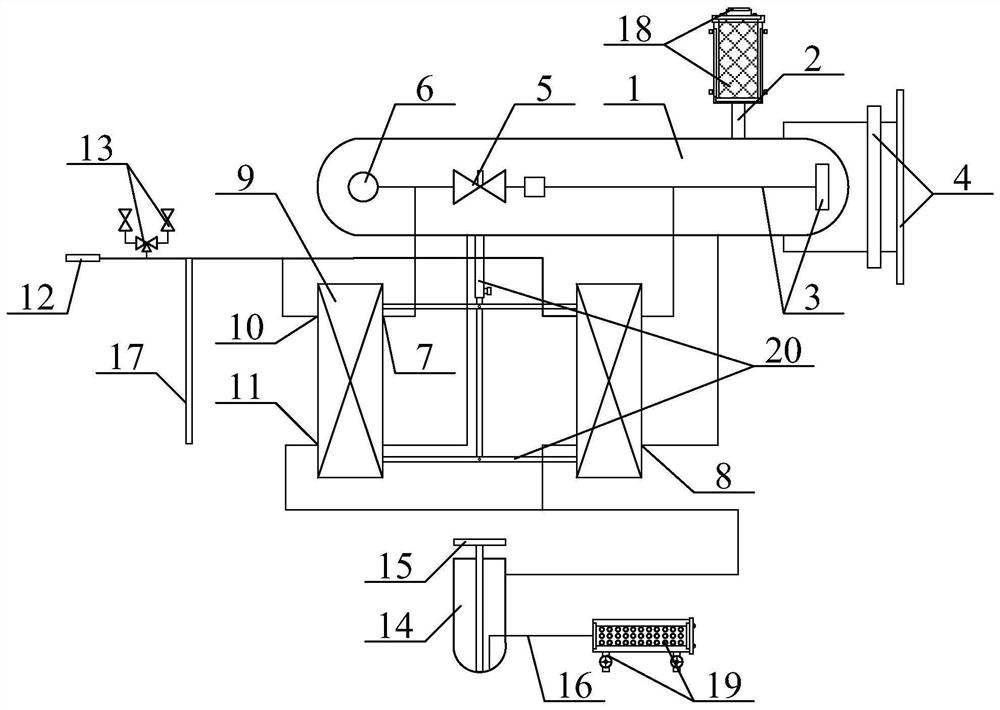

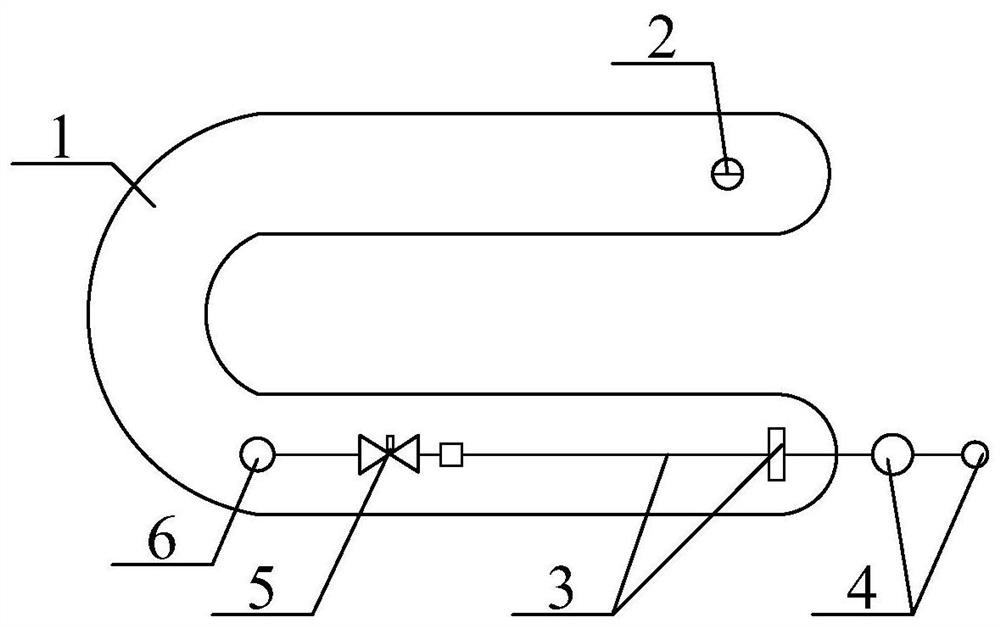

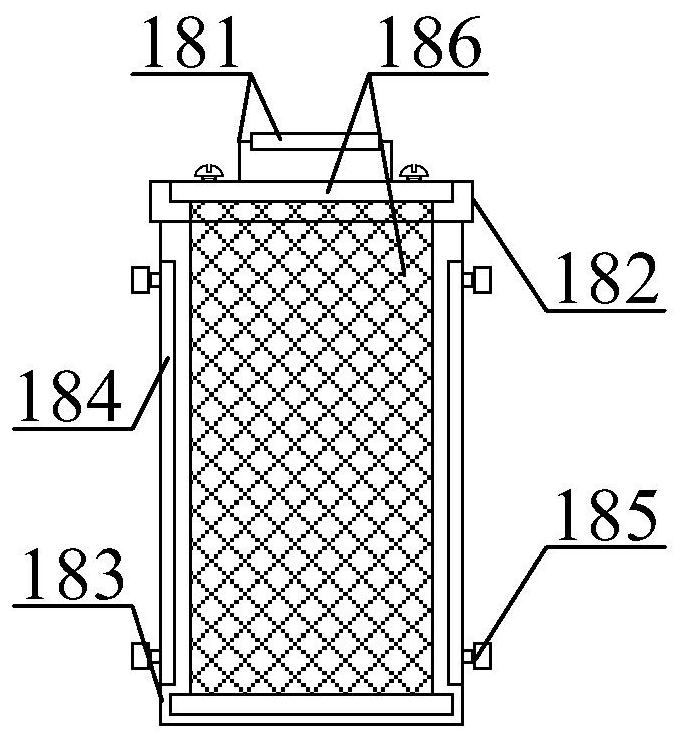

[0037]The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 to attach image 3 As shown, the U-shaped gas separation heat exchanger skid for CO2 includes U-shaped gas separator 1, U-shaped liquid separator gas outlet 2, U-shaped liquid separator liquid inlet pipe 3, and U-shaped liquid separator liquid inlet pipe. Position controller 4, U-shaped liquid separator inlet solenoid valve 5, U-shaped liquid separator liquid inlet 6, heat exchanger refrigerant gas outlet 7, heat exchanger refrigerant liquid inlet 8, refrigerant / CO2 heat exchange 9, heat exchanger CO2 gas inlet 10, heat exchanger CO2 liquid outlet 11, CO2 gas inlet pipe 12, CO2 safety valve group 13, CO2 liquid collecting pipe 14, CO2 liquid collecting pipe liquid level controller 15, set Liquid pipe CO2 liquid outlet pipe 16, circulation barrel gas outlet pipe 17, detachable cleaning and separation gas treatment cylinder structure 18, liquid discharge treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com