Patents

Literature

65results about How to "The control system is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

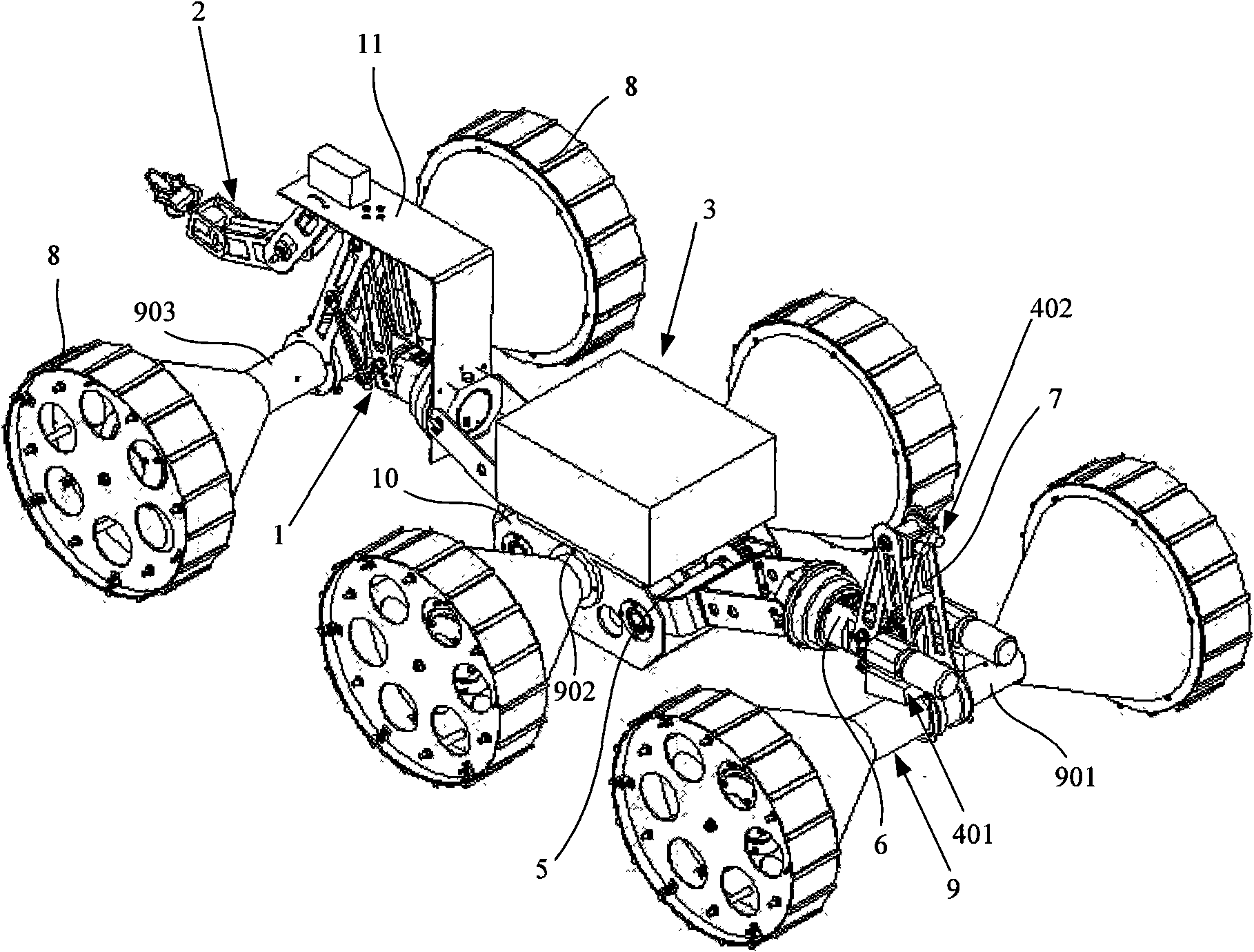

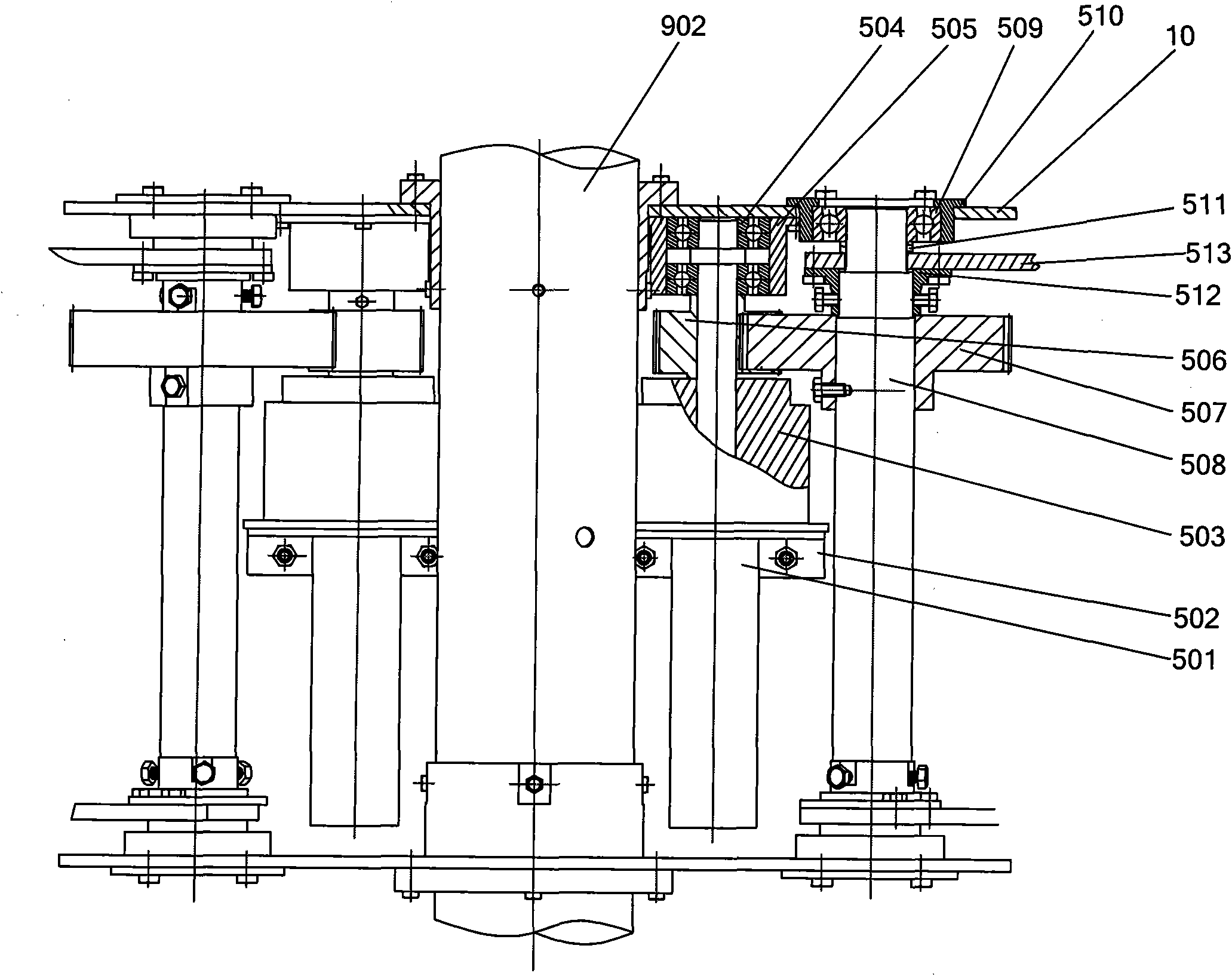

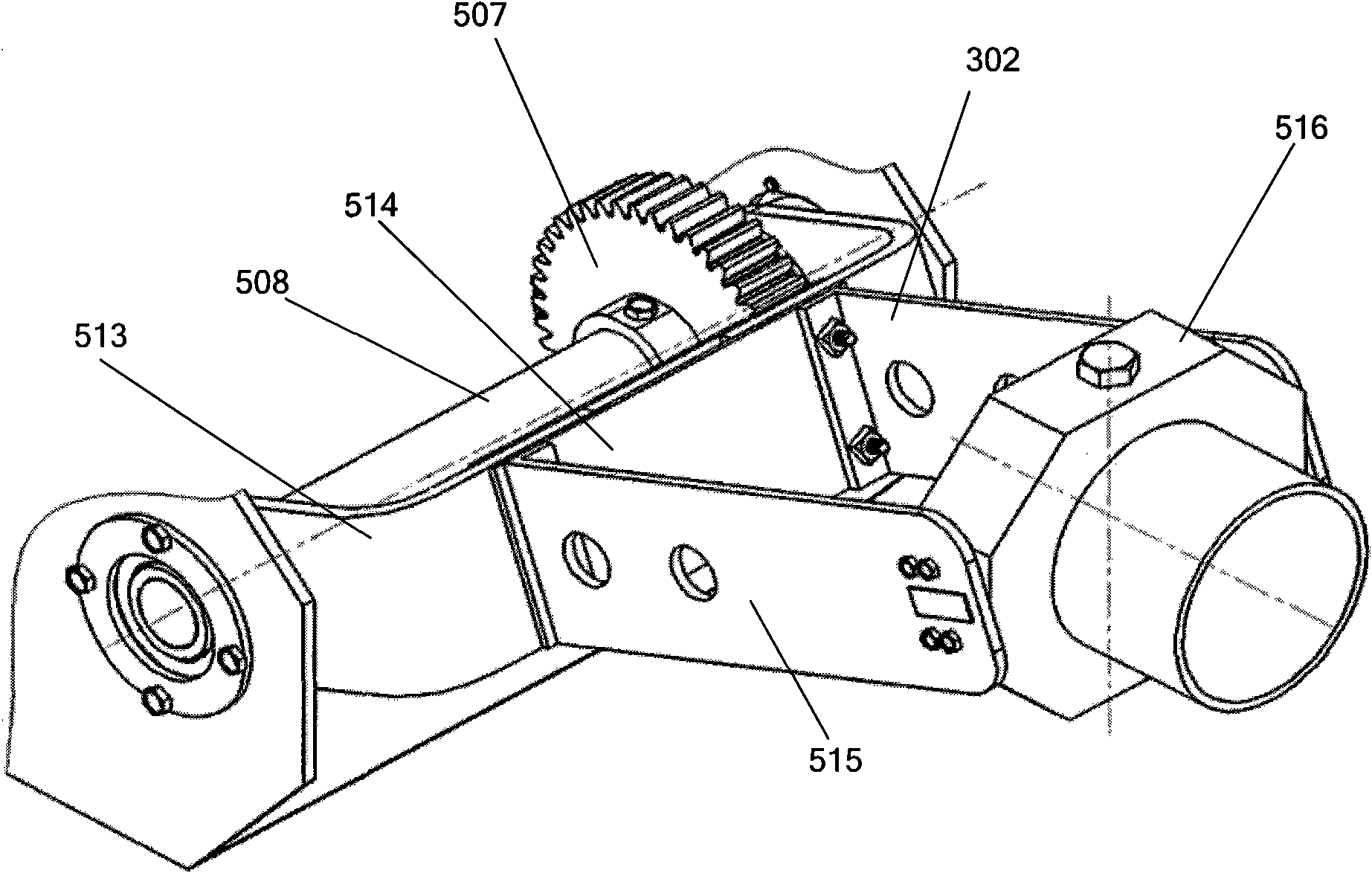

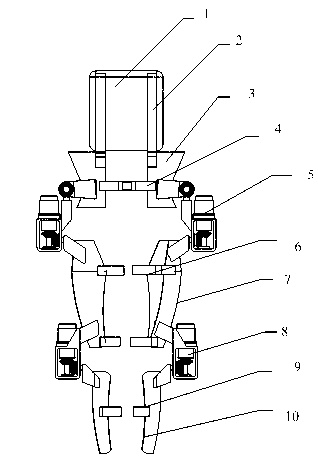

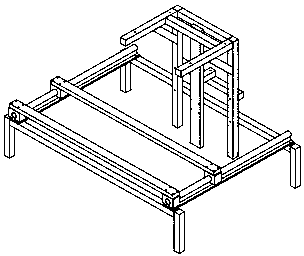

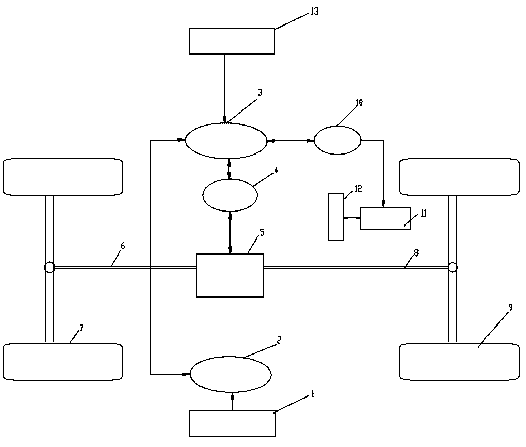

Multi-joint series wheeled mobile robot

InactiveCN101973028AGuaranteed work efficiencyThe control system is stableProgramme-controlled manipulatorArmsControl systemEngineering

The invention discloses a multi-joint series wheeled mobile robot. A middle box body is arranged on a middle axle of the robot, a control system is arranged above the middle box body, a pitching joint is fixed in the middle box body, each pitching joint is symmetrical to the middle axle and is respectively connected with a torsion joint, each torsion joint is respectively connected with a swinging joint which is respectively connected with a front axle and a rear axle, both ends of the front axle, the rear axle and the rear axle are provided with wheels, the torsion joint of the rear end is connected with a mechanical arm installing bracket, a mechanical arm is arranged on the mechanical arm installing bracket, and the front part of the robot is provided with a navigation system. The whole structure of the robot is in central axis symmetry by taking the middle axle as a symmetrical central axis. The gravity is evenly distributed on the wheels to furthest exert the work efficiency of a direct current motor. The multi-joint series wheeled mobile robot can measure and regulate the posture of the middle box body in real time, ensures the relative stabilization of the control system and has simple structure and light weight.

Owner:BEIHANG UNIV

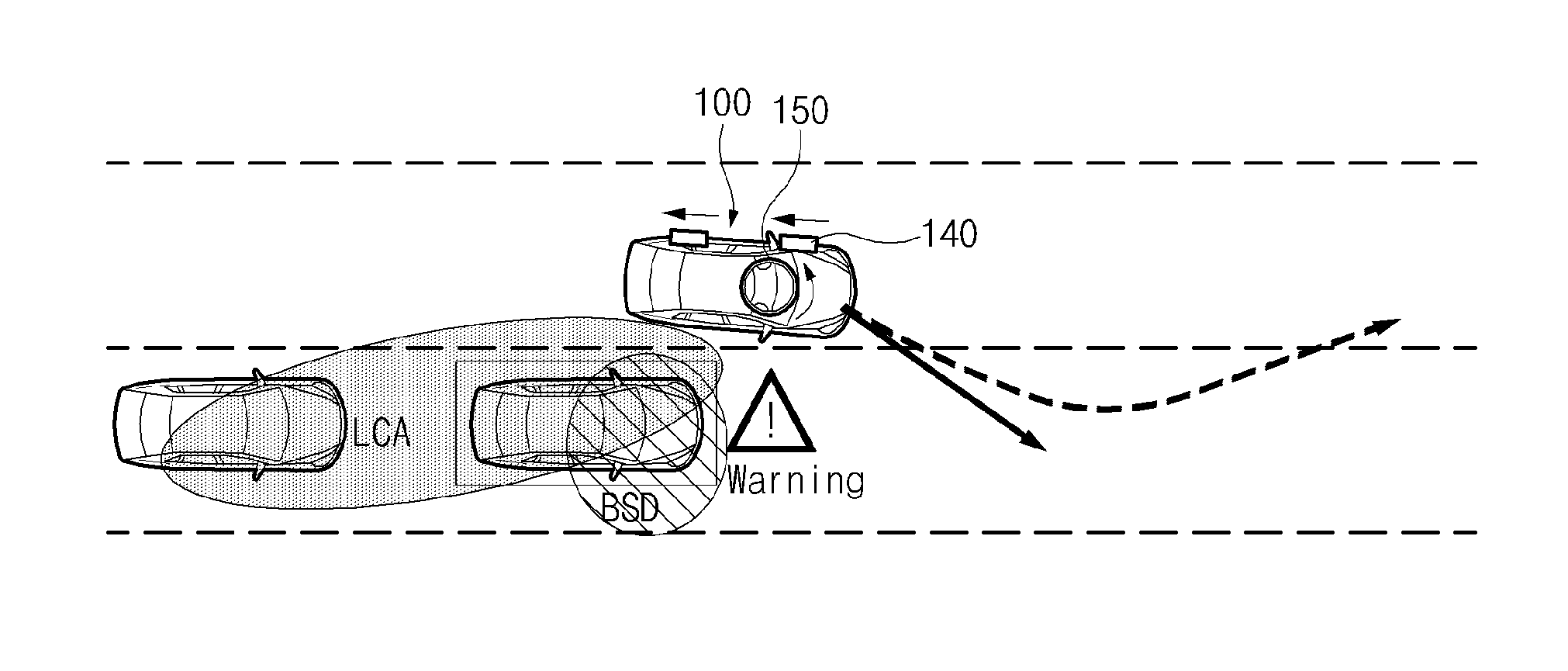

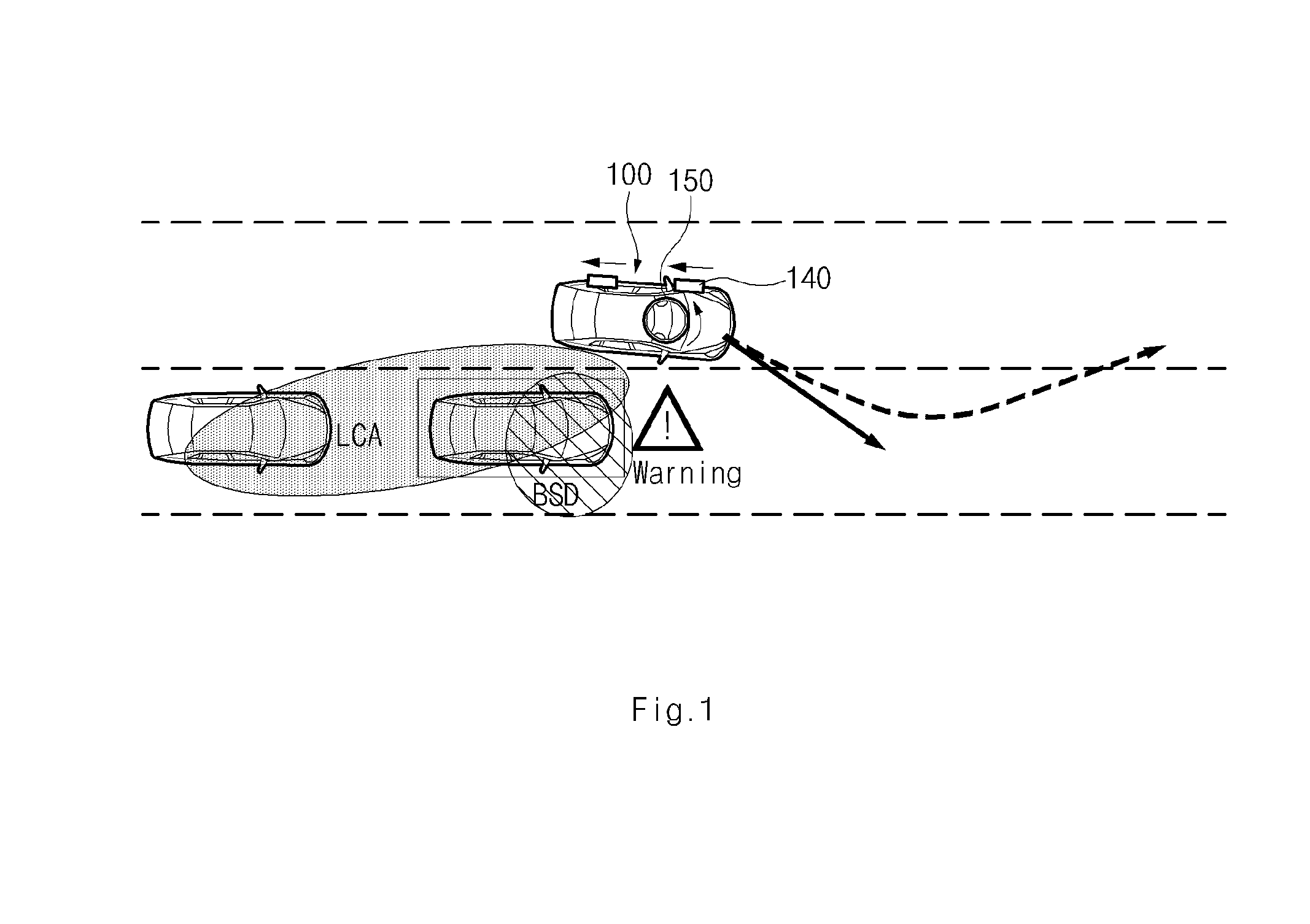

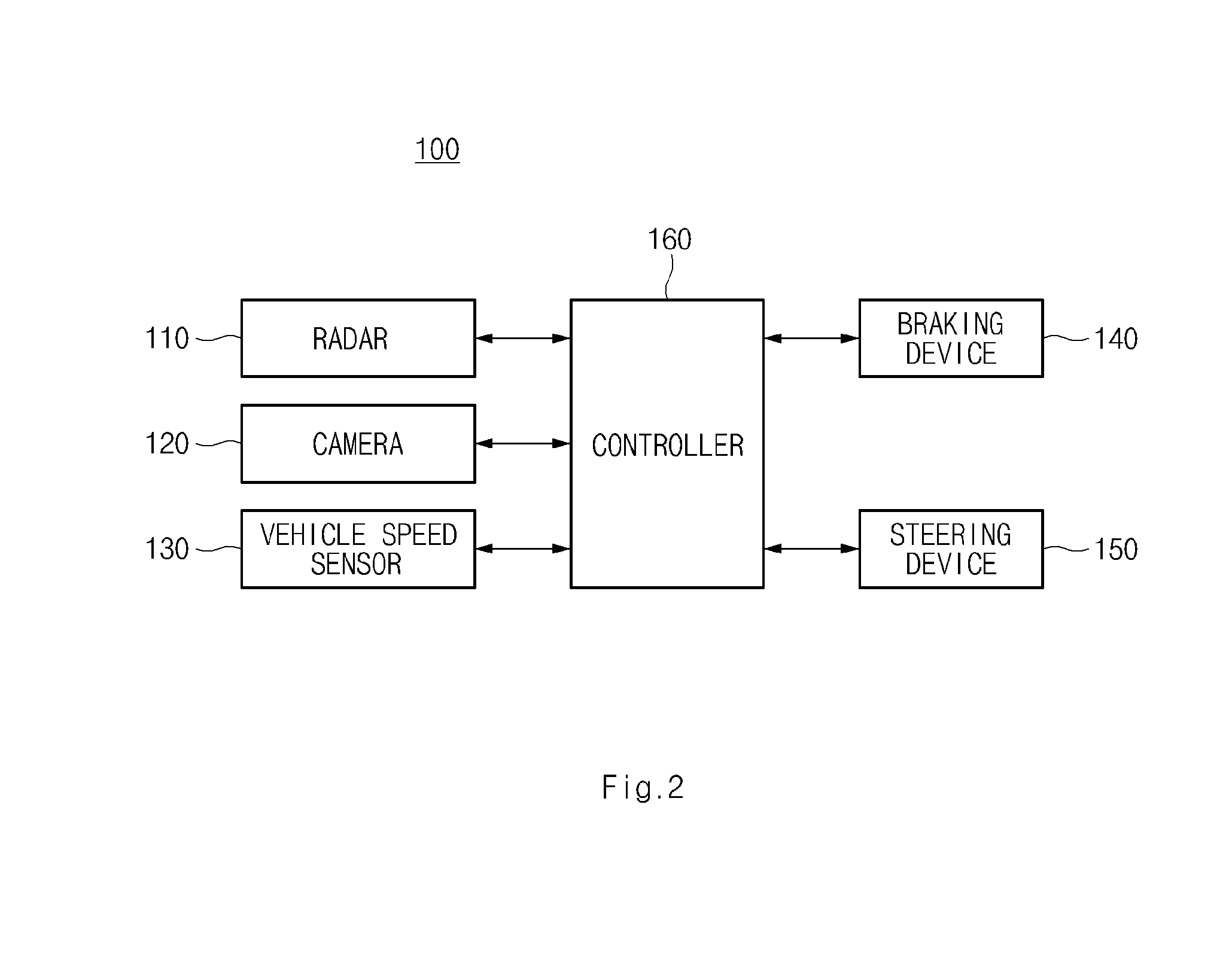

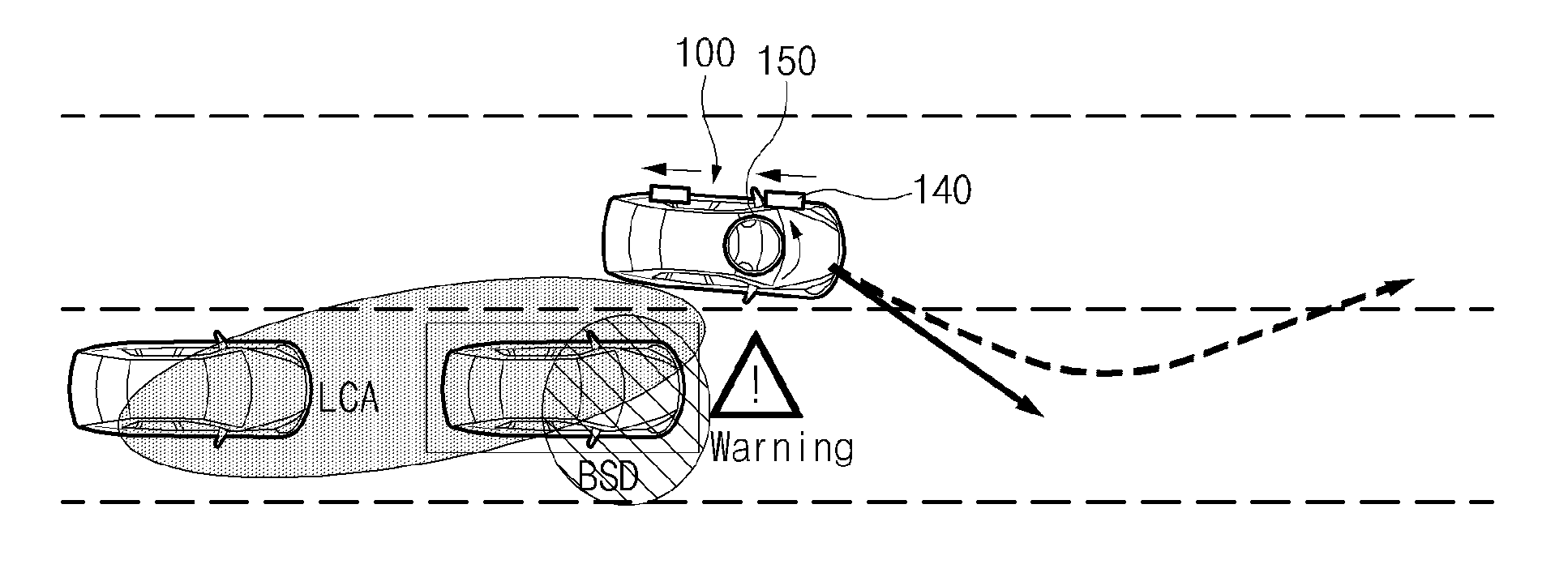

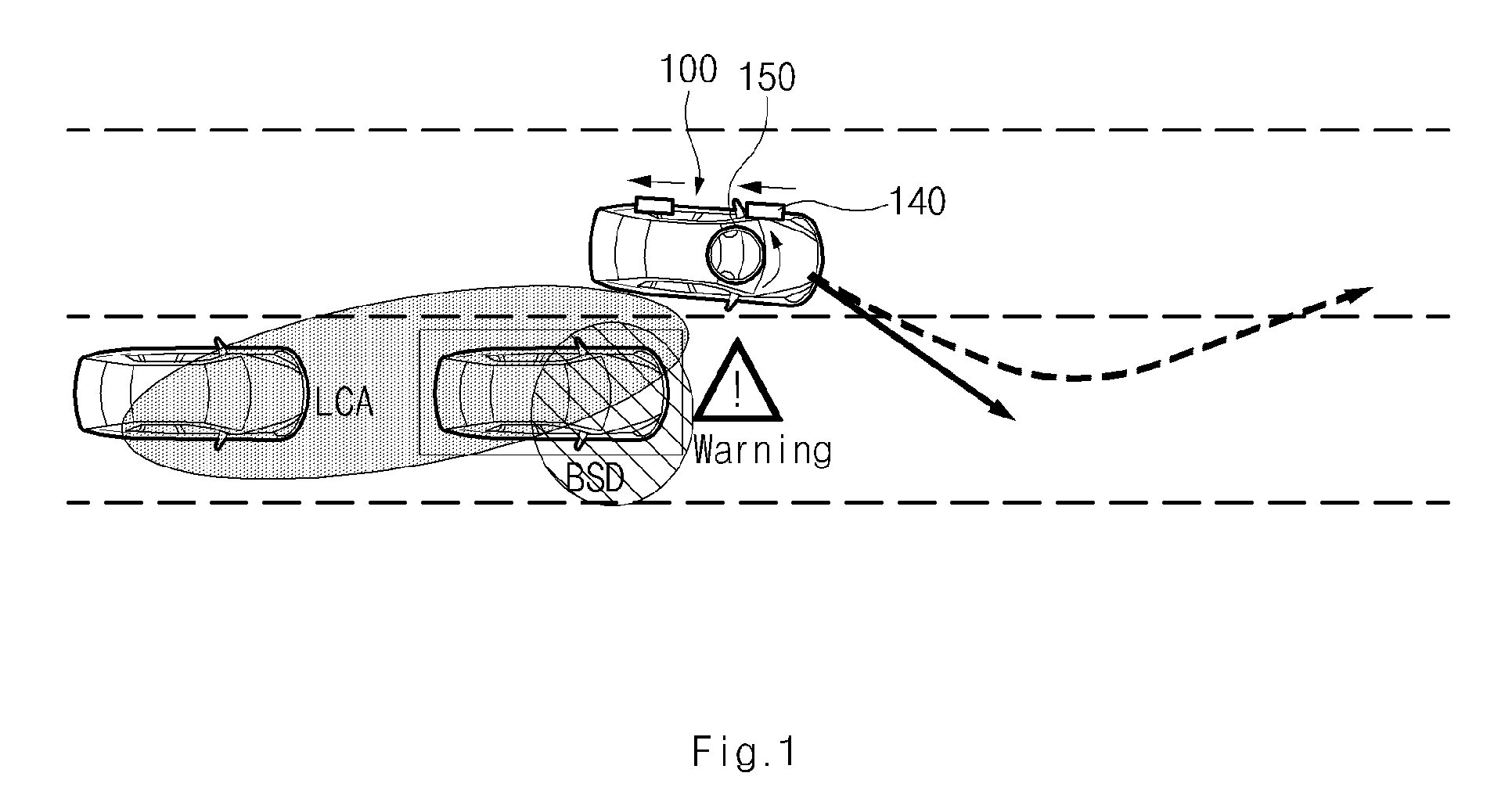

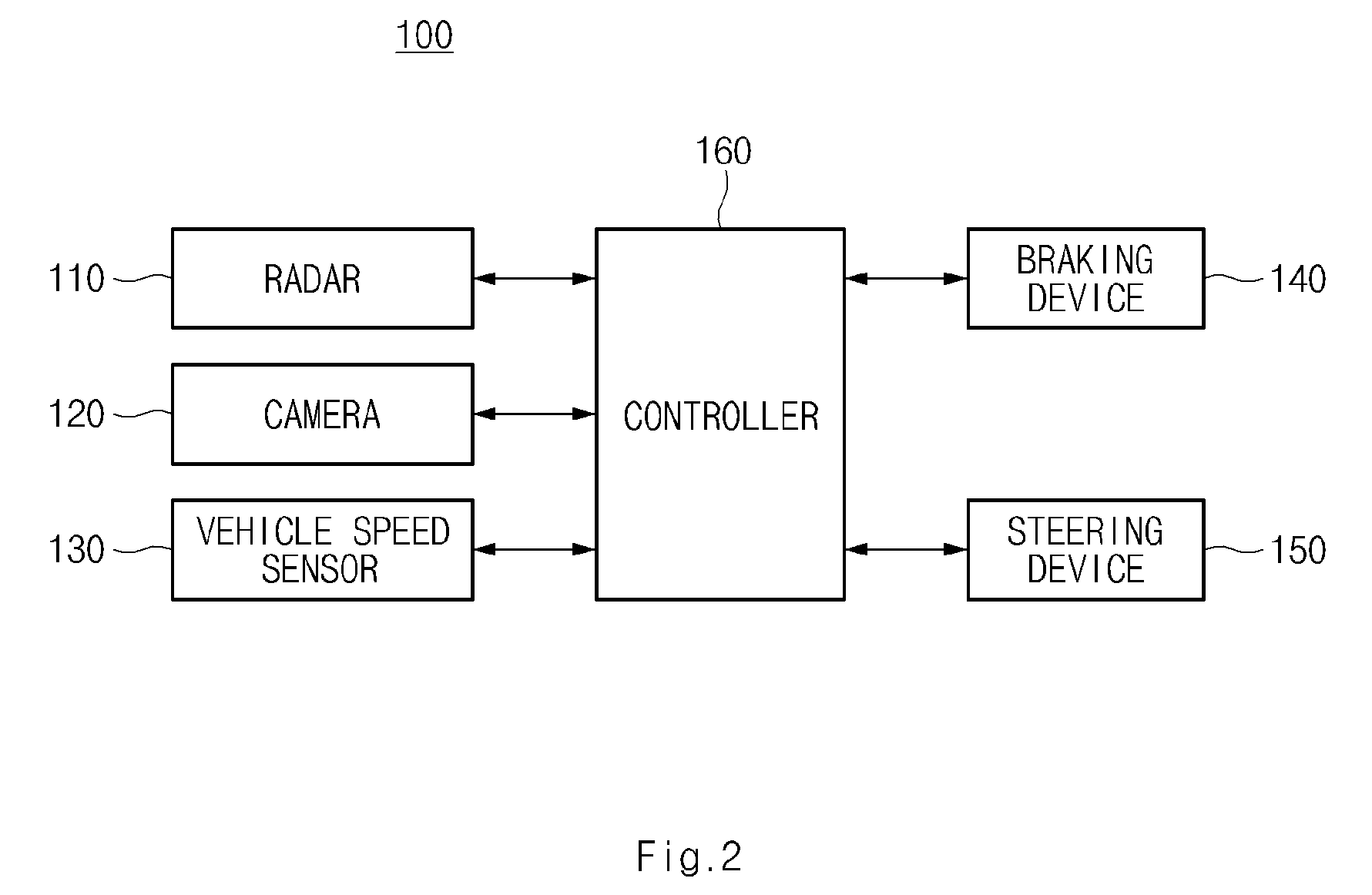

Braking control system and method for vehicle

ActiveUS20150149037A1Reducing braking control timeWithout additional part cost and development costDigital data processing detailsSteering initiationsControl systemVehicle braking

A braking control system and a method for a vehicle are provided. The braking control method includes sensing, by a controller, a rear-side collision risk and a lane change and determining a lane change intention based on a steering change of a vehicle. In addition, the controller is configured to determine a braking control for the vehicle and a magnitude of the braking control for the vehicle based on the rear-side collision risk and the lane change, and the lane change intention.

Owner:HYUNDAI MOTOR CO LTD +1

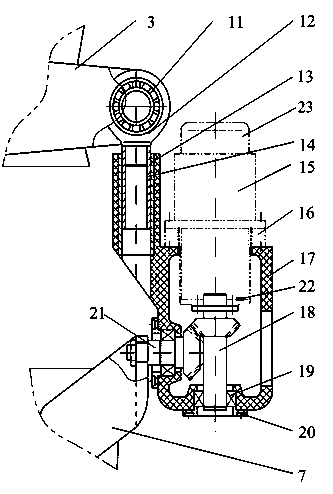

Lower limb exoskeleton boosting device and control method

ActiveCN103284822AImprove detection accuracyThe control system is stableArtificial legsSacroiliac jointExoskeleton

The invention relates to a boosting device, in particular to a lower limb exoskeleton boosting device. The lower limb exoskeleton boosting device comprises thigh connecting rods, crus connecting rods, a waist protection pad, hip joints and knee joints, the thigh connecting rods are connected with the crus connecting rods through the knee joints, the waist protection pad is connected with the thigh connecting rods through the hip joints, and a joint portion of each of the hip joints and the knee joints comprises a joint box, a servo motor, a harmonic gear, a driving worm gear and a driven worm gear, wherein the servo motor is connected on the joint box, the driving worm gear and the harmonic gear are coaxially connected with the servo motor, and the driven worm gear is meshed with the driving worm gear. The driven worm gear of each hip joint is connected with the corresponding thigh connecting rod, and the driven worm gear of each knee joint is connected with the corresponding crus connecting rod. The lower limb exoskeleton boosting device is capable of providing walking power for wearers with moving difficulty so as to save labor, and is high in reliability and stability.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

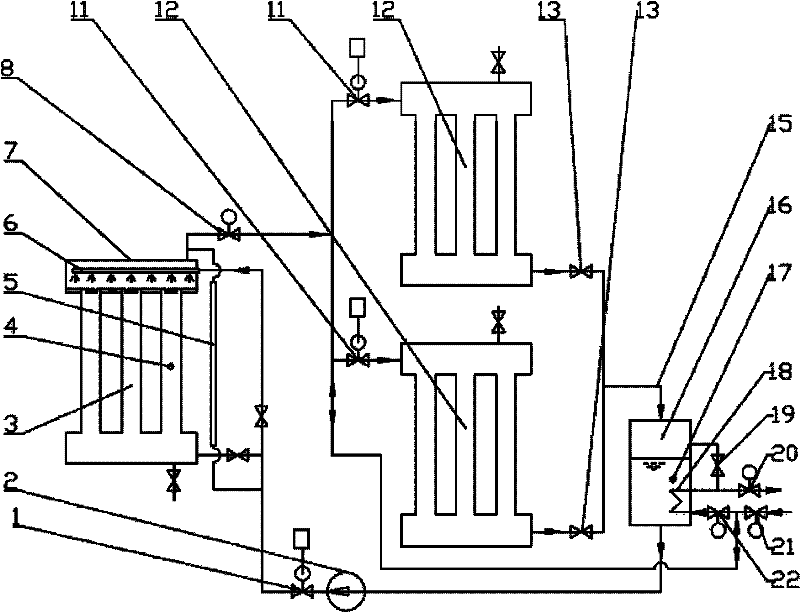

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersEngineeringLiquid storage tank

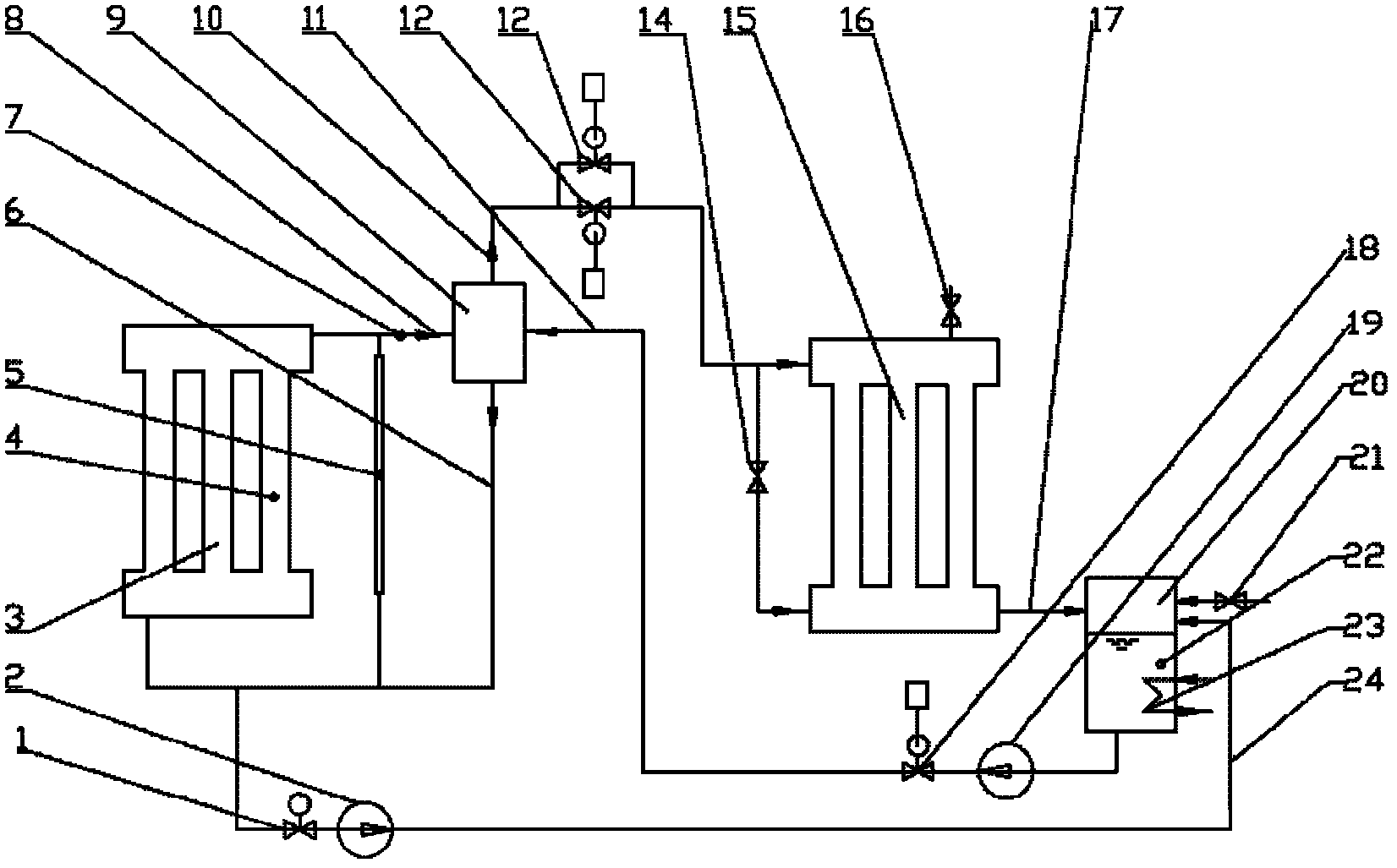

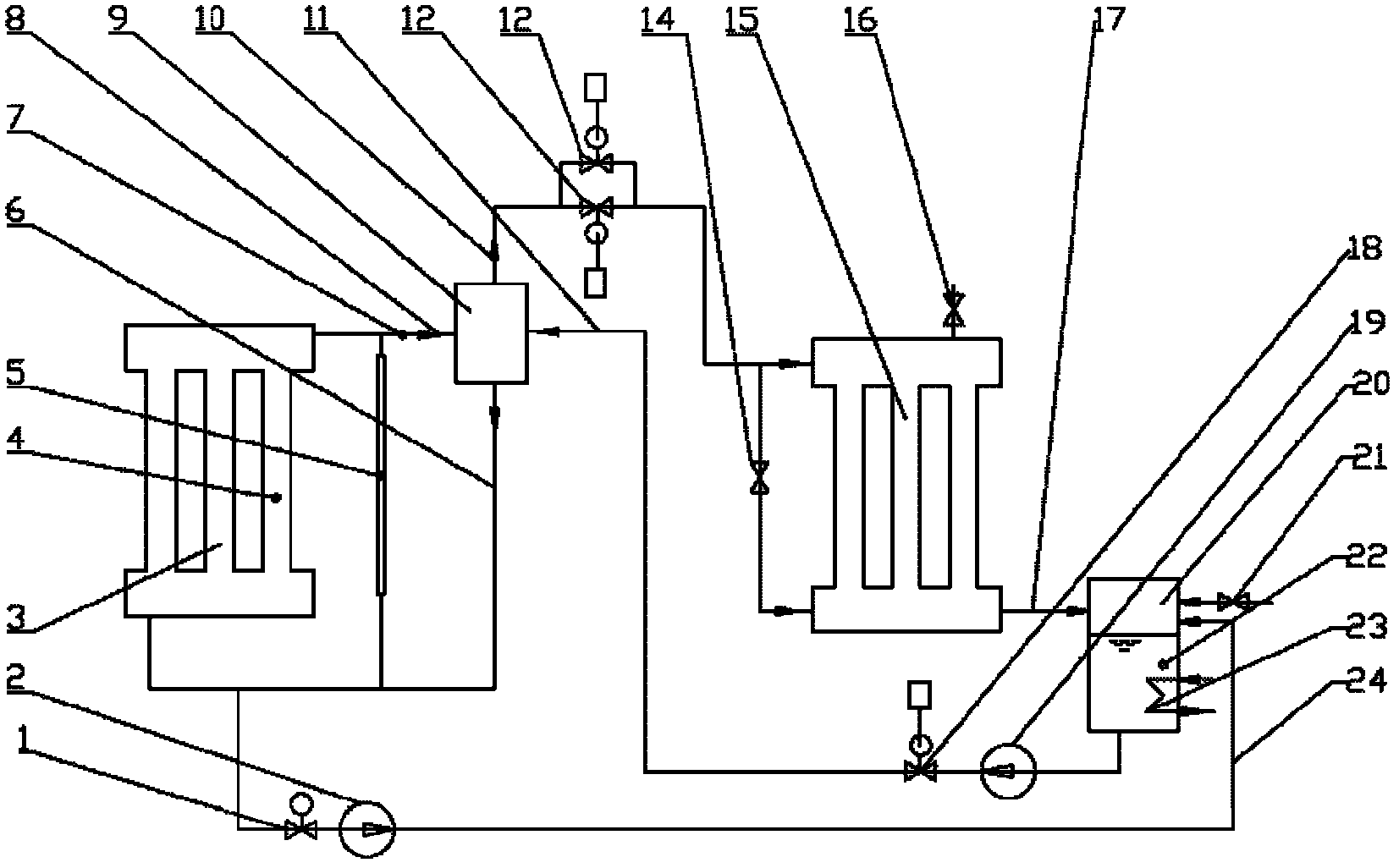

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

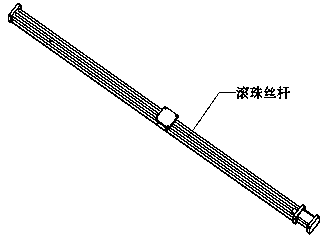

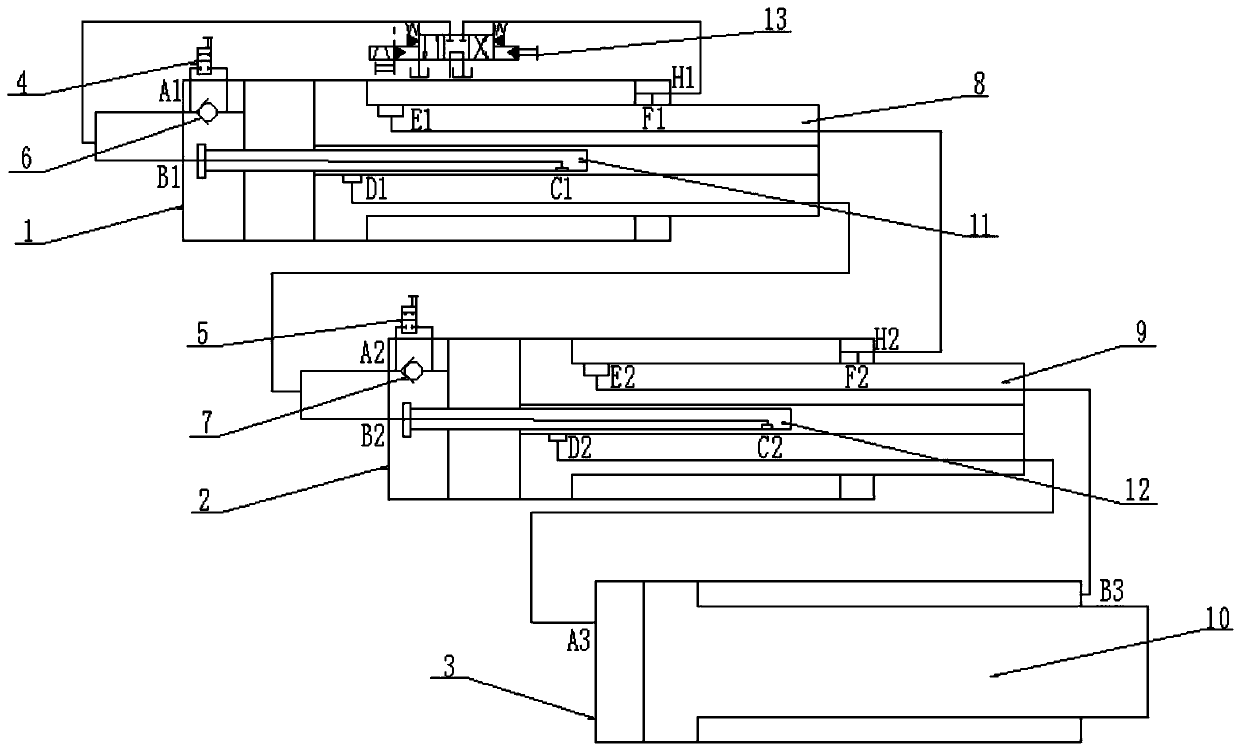

Automatic water feeding device of barreled water

InactiveCN103626089ASmall flipReduce energy consumptionLifting devicesHoisting equipmentsWater basedBall screw

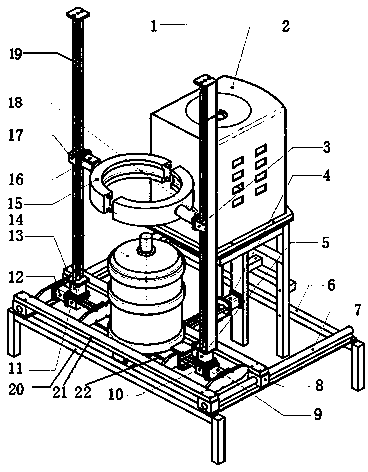

The invention relates to an automatic water feeding device of barreled water. A high frame on the rear portion of a support is provided with a water dispenser, and the two sides of the support are provided with longitudinal guide rails. The longitudinal guide rails are fixed on a support base and connected with a support cross bar through longitudinal guide rail sliding blocks. A longitudinal drive motor and a longitudinal ball screw are connected between the support base and the rear portion of the support. The longitudinal ball screw is connected with a barreled water base through a nut pair, and the two ends of the barreled water base are connected with a horizontal guide rail sliding block a and a horizontal guide rail sliding block b respectively through screw and nut pairs. The horizontal guide rail sliding block a and the horizontal guide rail sliding block b are connected with a horizontal drive motor a and a horizontal drive motor b respectively. Lifting stand columns are connected to the horizontal guide rail sliding block a and the horizontal guide rail sliding block b through a lifting drive motor a and a lifting drive motor b respectively. The lifting stand columns are connected with a grasping mechanism through lifting sliding blocks, and a rotation drive motor is connected between the lifting sliding block b on the lifting stand column b and the grasping mechanism. A limiting stop block is connected between the lifting sliding block a on the lifting stand column a and the grasping mechanism.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

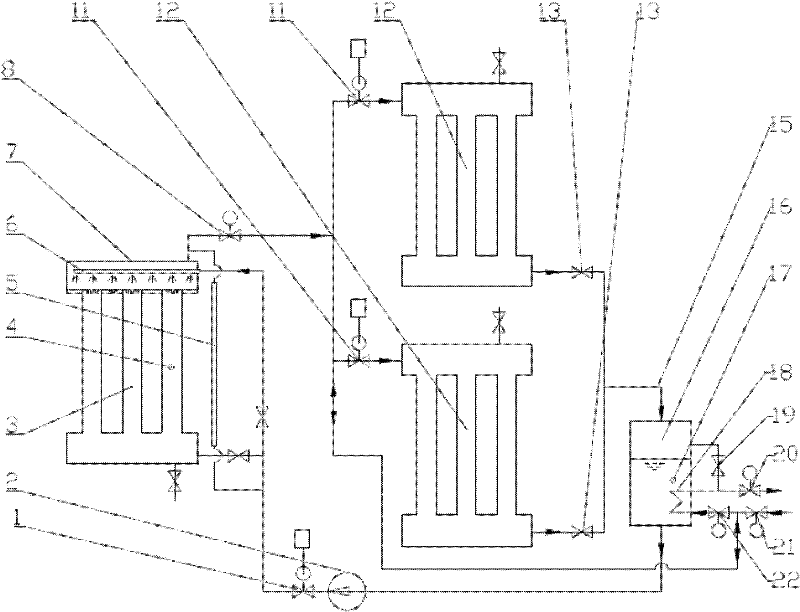

High-efficiency, sub-control and phase-change heat exchange system and method

InactiveCN102230753AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersHeat exchange apparatusAirflowEngineering

The invention relates to a high-efficiency, sub-control and phase-change heat exchange system. The heat exchange system provided by the invention comprises a heat exchanger of heat source (3) and a heat exchanger of cold source (12) which are mutually communicated through a steam tube and a condensate line to from a sub-control and phase-change heat exchange circuit. The heat exchange circuit is provided with an air flow regulating valve and a liquid flow regulating valve which can control the circuit. A reservoir tank (16) is configured on the condensate line. The header of the steam tube on the top of the heat exchanger of heat source (3) is divided into two steam sub-tubes. A first steam sub-tube is connected with the heat exchanger of heat source (12) and an air flow regulating valve (11) is configured between the first steam sub-tube and the heat exchanger of cold source (12). A second steam tube communicates with the reservoir tank (16) via a condensate heater (18) configured inside the reservoir tank (16). A liquid distribution tube (6) is configured inside the collecting chamber (7) of the heat exchanger of heat source (3), and a plurality of sprayers are configured on the liquid distribution pipe which is used for the mixing heat exchange of steam and condensate. The efficiency of the system provided by the invention is much higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

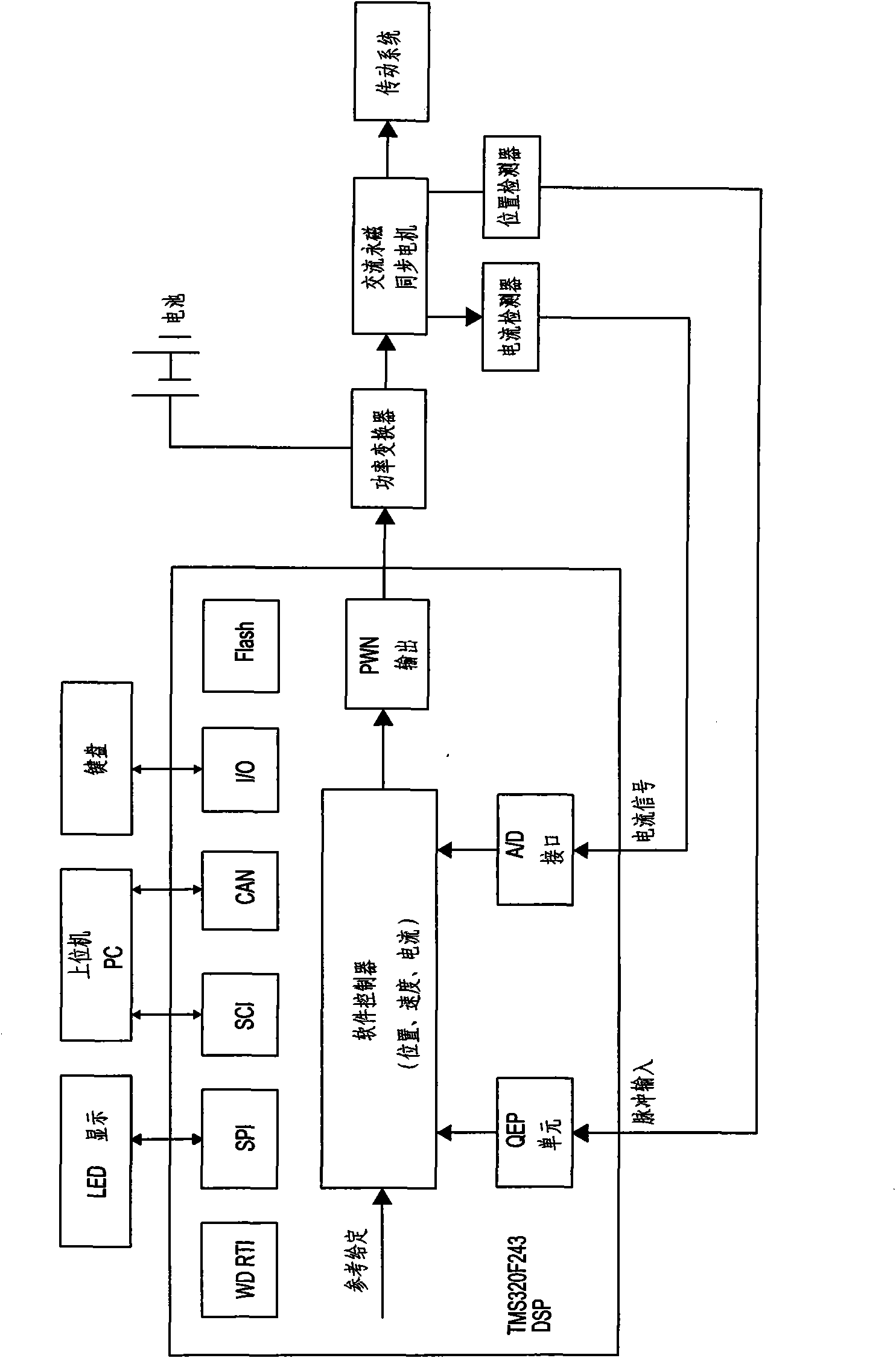

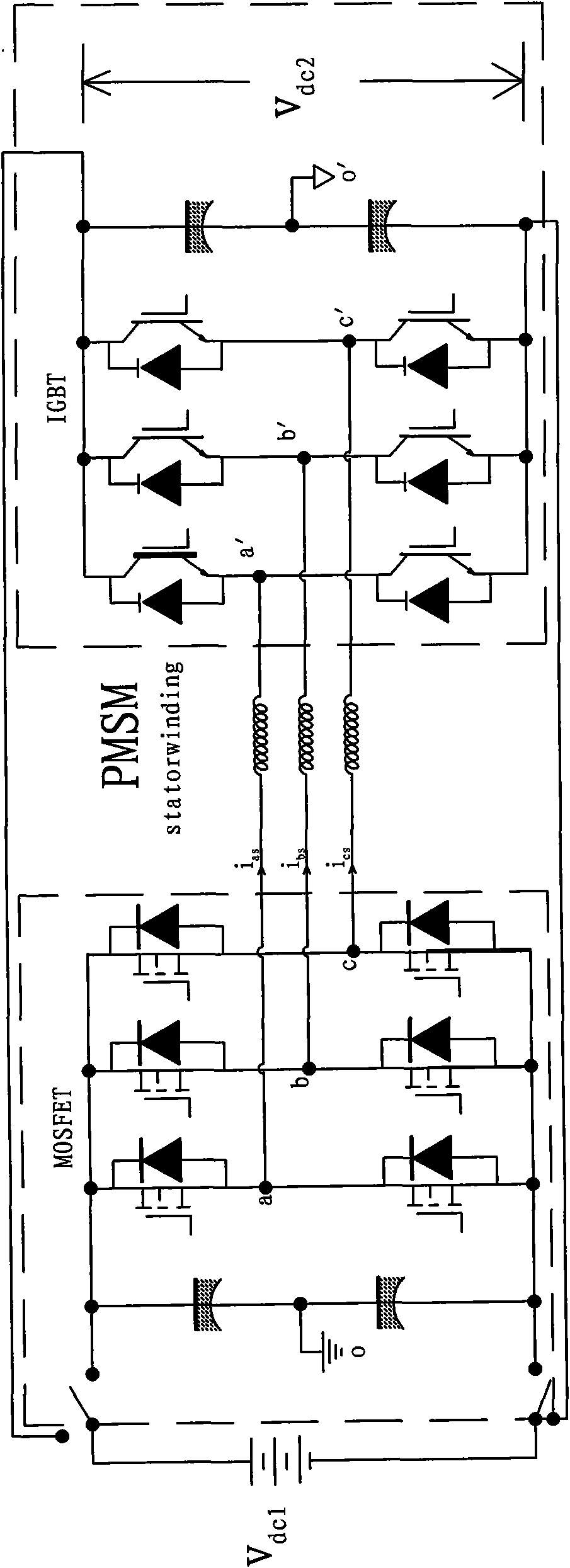

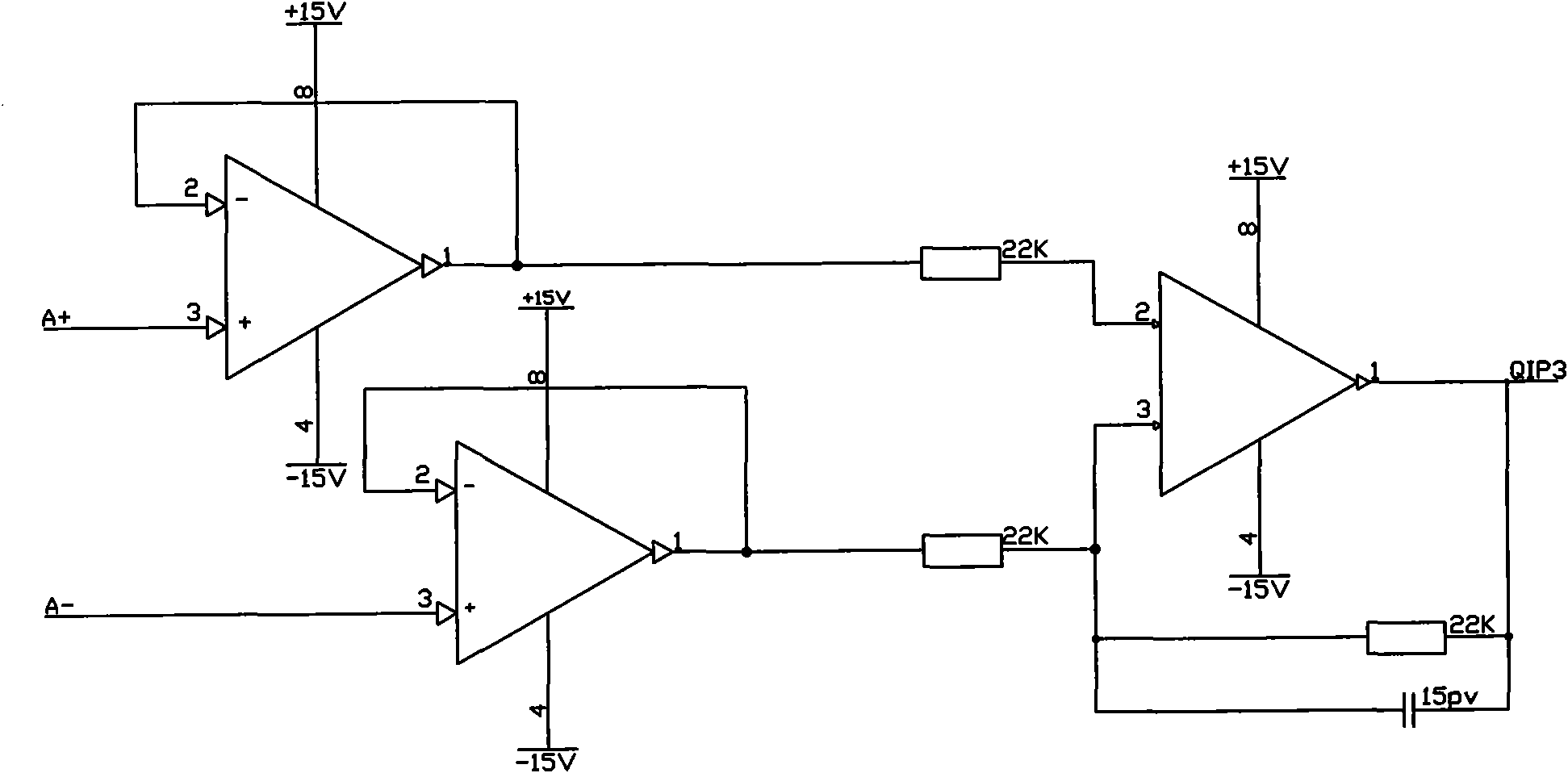

Alternating current permanent magnet synchronous machine control system for electric vehicle

InactiveCN102377380AIncrease low speed torqueNo current shock phenomenonAC motor controlSingle motor speed/torque controlMOSFETPermanent magnet synchronous machine

The invention discloses an alternating current permanent magnet synchronous machine control system for an electric vehicle. The system comprises an alternating current permanent magnet synchronous machine, a power convertor, a controller and detectors; the controller is a digital signal processor (DPS); the detectors comprise a position detector and a current detector; the position detector and the current detector input rotor positions / speed signals and current signals, which are detected by the position detector and the current detector respectively, of the alternating current permanent magnet synchronous machine to the DSP; the DSP calculates the given value of the current according to the input rotor positions / the speed signals and compares the given value and the input current detection value to obtain a corresponding control signal, and the alternating current permanent magnet synchronous machine is driven by the power convertor; and the power convertor has a three-phase double-inversion bridge structure consisting of a metal-oxide-semiconductor field effect transistor (MOSFET) inverter and an insulated gate bipolar transistor (IGBT) inverter. The system has the advantages of compact and firm structure, reliable performance, high control efficiency and accuracy and the like and runs stably and a circuit is simple.

Owner:程基江

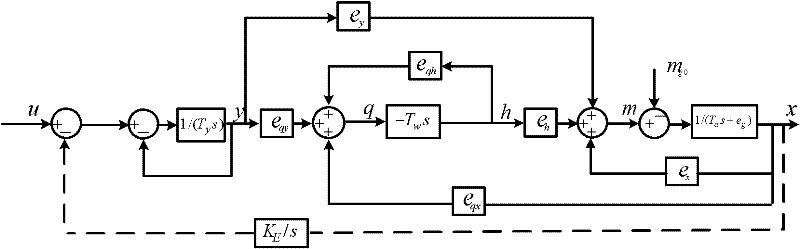

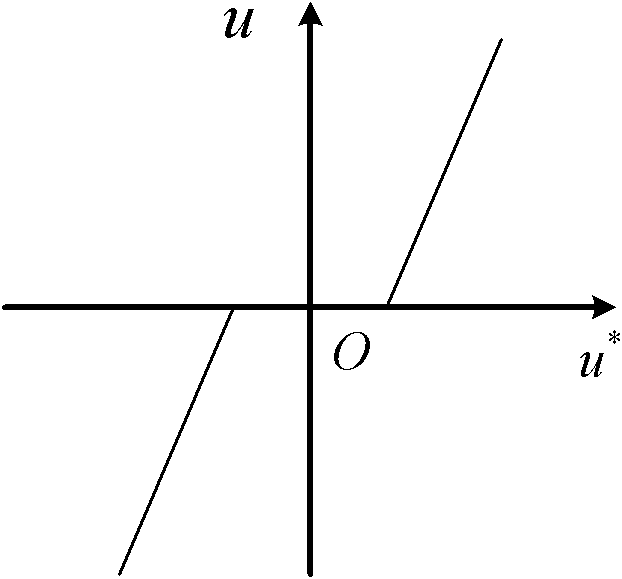

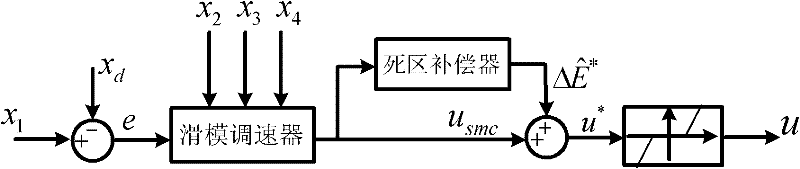

Sliding mode-based hydro turbine governing system dead zone nonlinear compensation method

InactiveCN102352812AOmit identificationStrong real-timeHydro energy generationMachines/enginesAutomotive engineeringState-space representation

The invention discloses a sliding mode-based hydro turbine governing system dead zone nonlinear compensation method in the technical field of hydro turbine control. The method comprises the following steps of: constructing a state space model for a hydro turbine governing system, and introducing an additional state variable; designing a sliding mode governor, and making an ideal hydro turbine governing system approximately stable by regulating the controlling quantity of the sliding mode governor; and designing a dead zone nonlinear compensator to compensate dead zone nonlinearity of an actual hydro turbine governing system. By the method, the automation level of the hydro turbine governing system is improved, the safety of a set is improved, the mechanical wear of the set is reduced, the equipment maintenance cost is reduced, and the economic performance of a hydro electric generating set is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

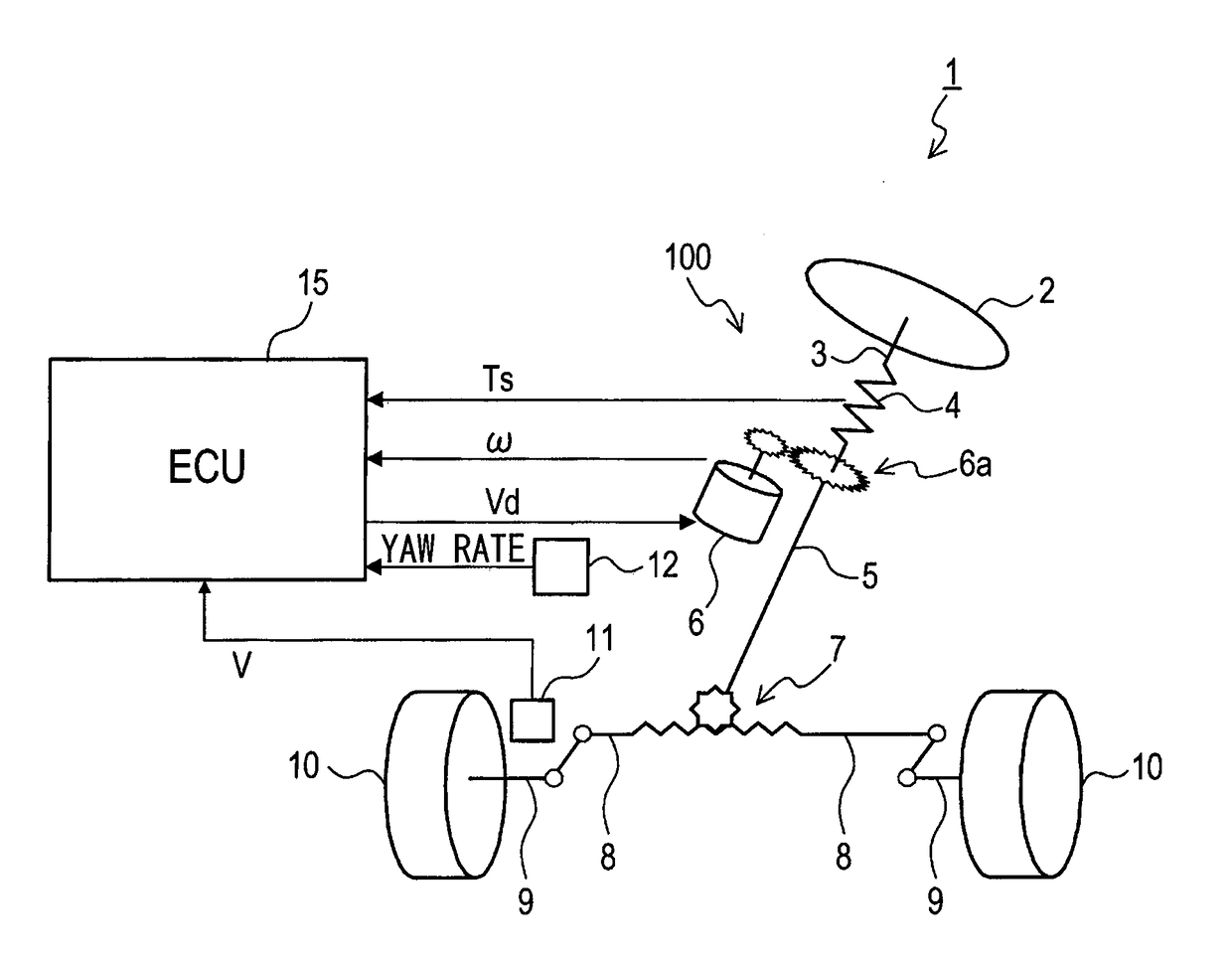

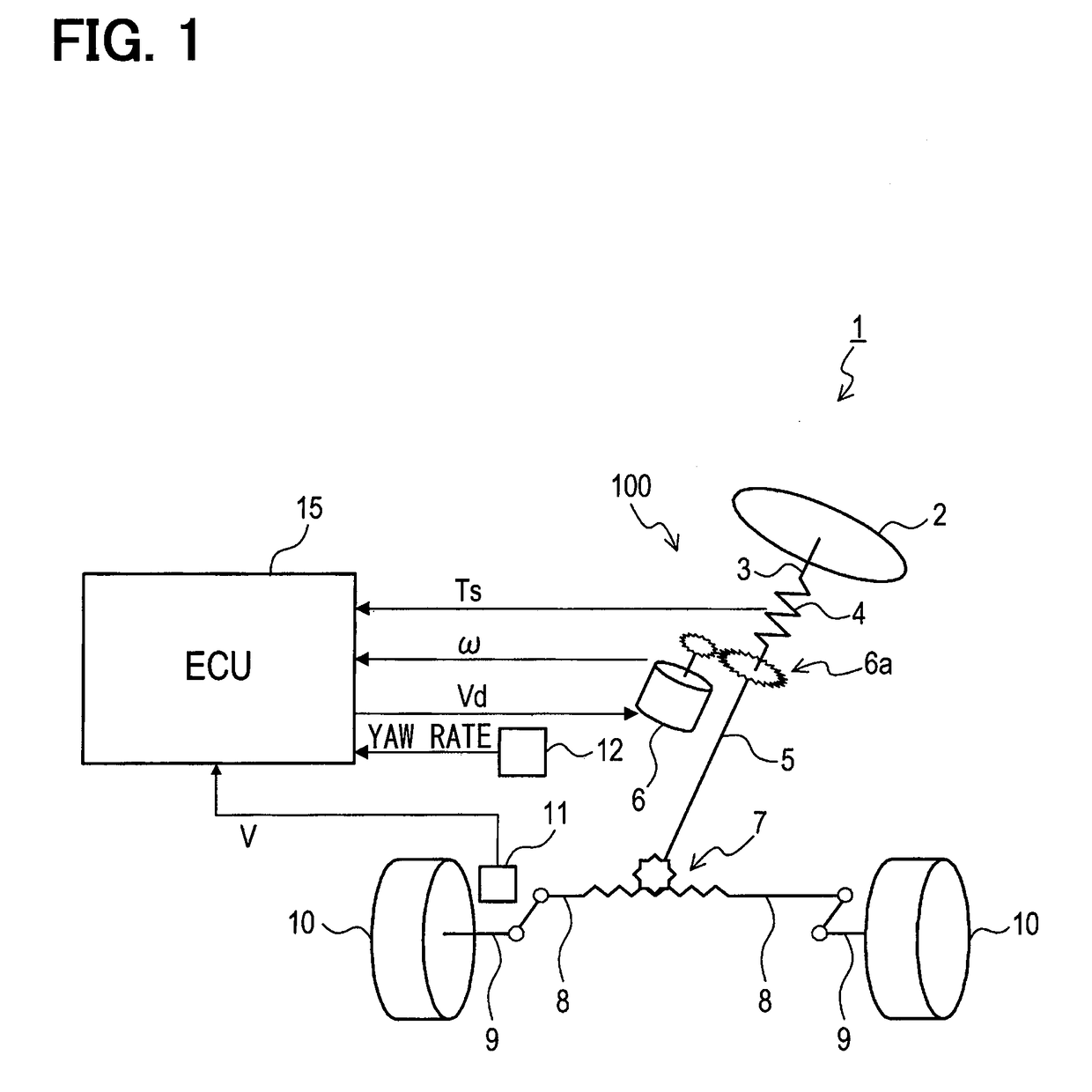

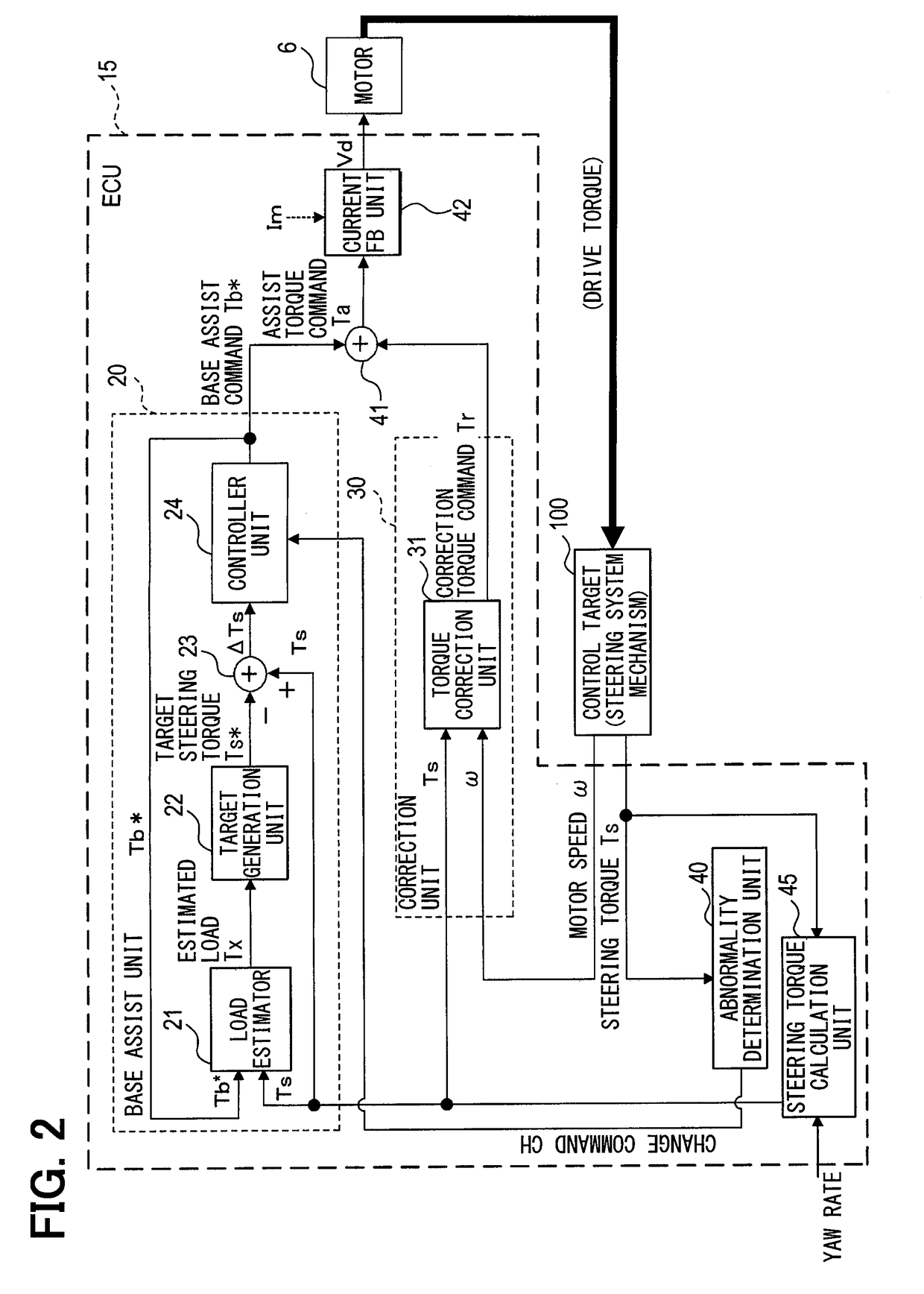

Electric power steering control apparatus

ActiveUS20180118253A1Reduce vibrationGuaranteed uptimeSteering linkagesAutomatic steering controlElectric power steeringSteering angle

An electric power steering control apparatus that assists a steering operation made by a driver with a motor includes: a target torque calculation unit calculating a target steering torque; an assist torque calculation unit calculating an assist torque which enables an actual steering torque follows close to the target steering torque according to a difference therebetween; a motor drive unit driving a motor acting on a steering system mechanism so that a steering angle of vehicle is changed according to the assist torque; and a followability change unit that detects an abnormality of a torque sensor for detecting the actual steering torque. When abnormality is detected in the torque sensor, a followability of the actual steering torque to the target steering torque controlled by the assist torque is degraded compared with a case where no abnormality is detected in the torque sensor.

Owner:DENSO CORP

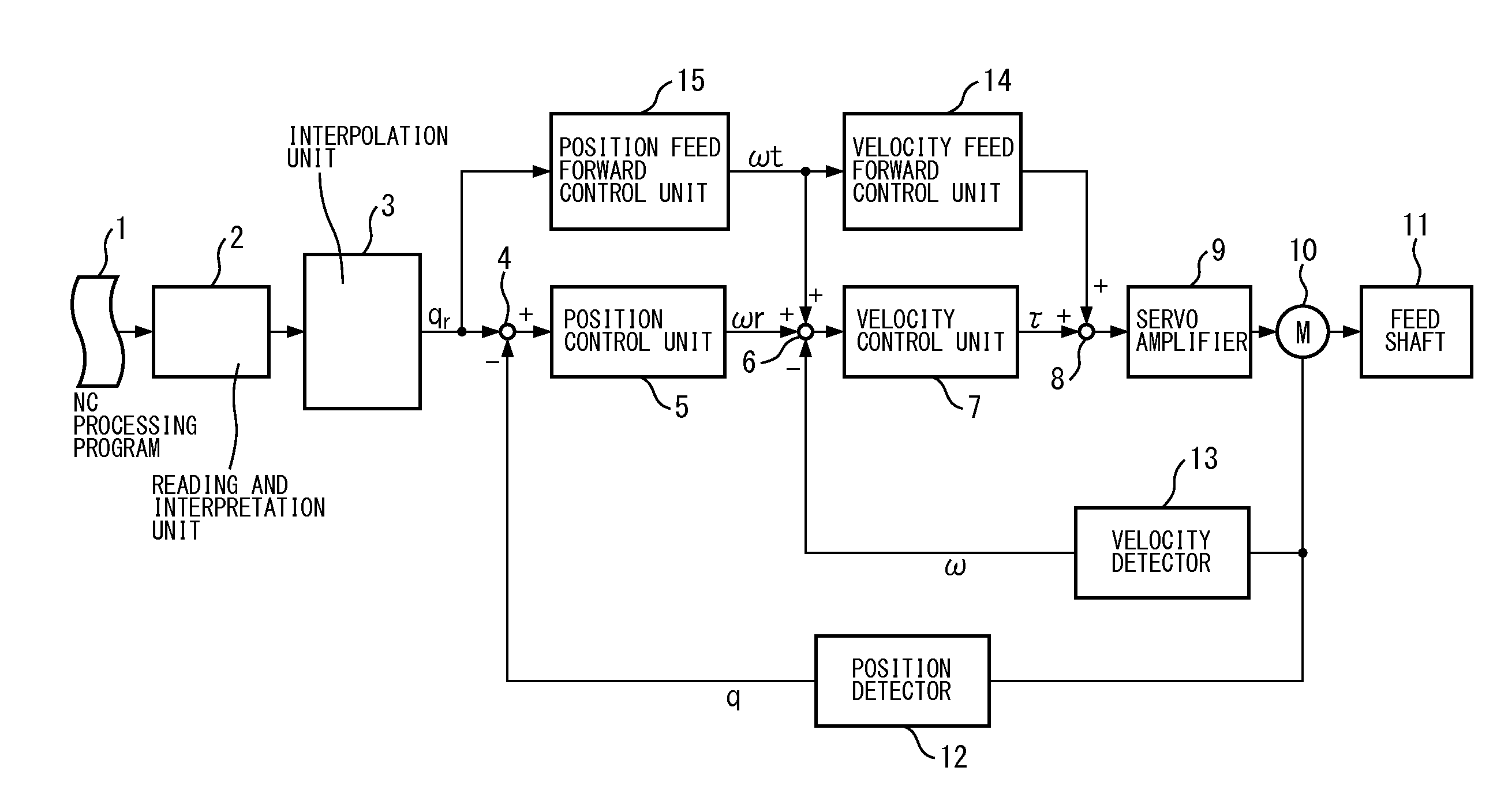

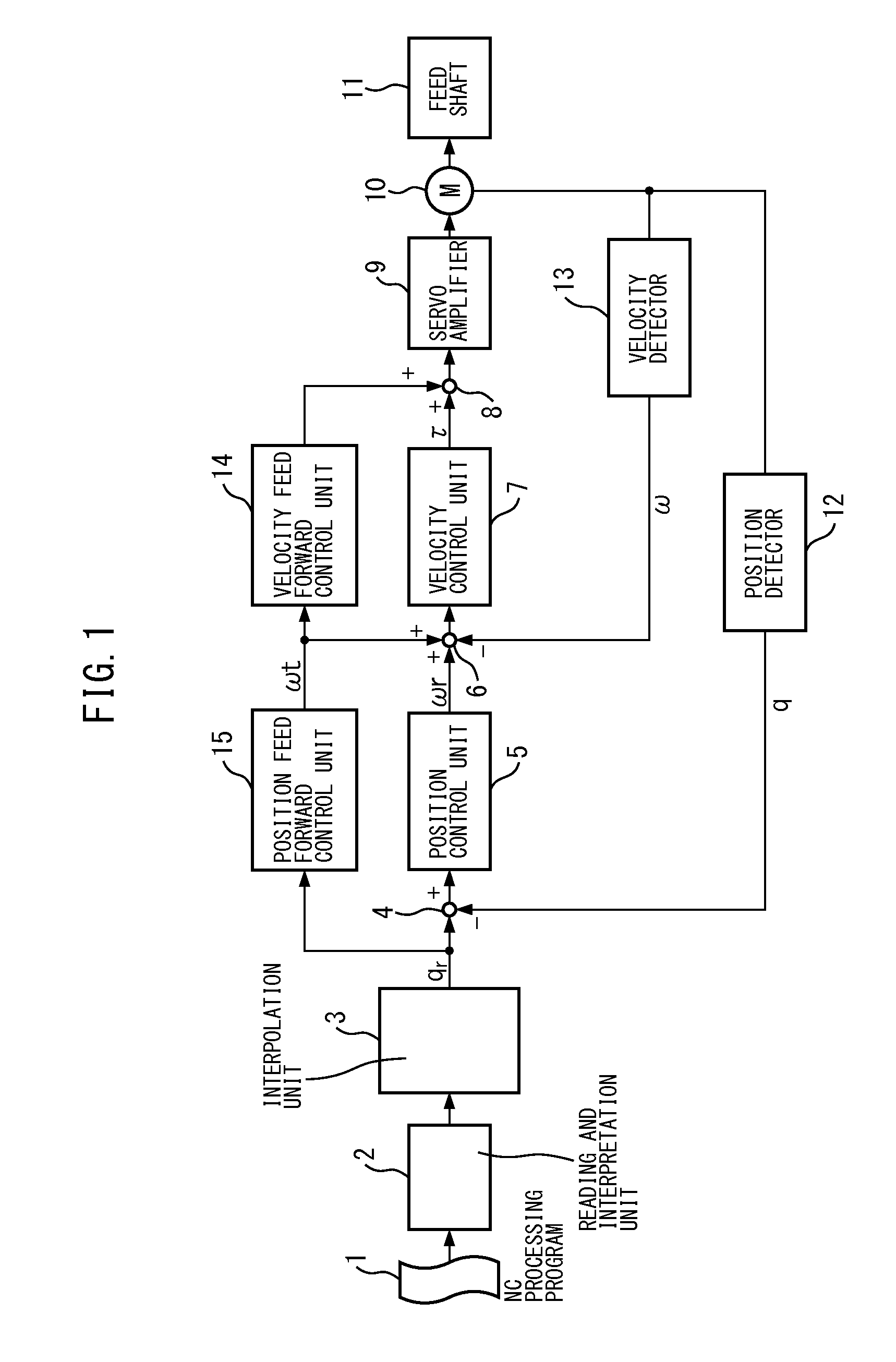

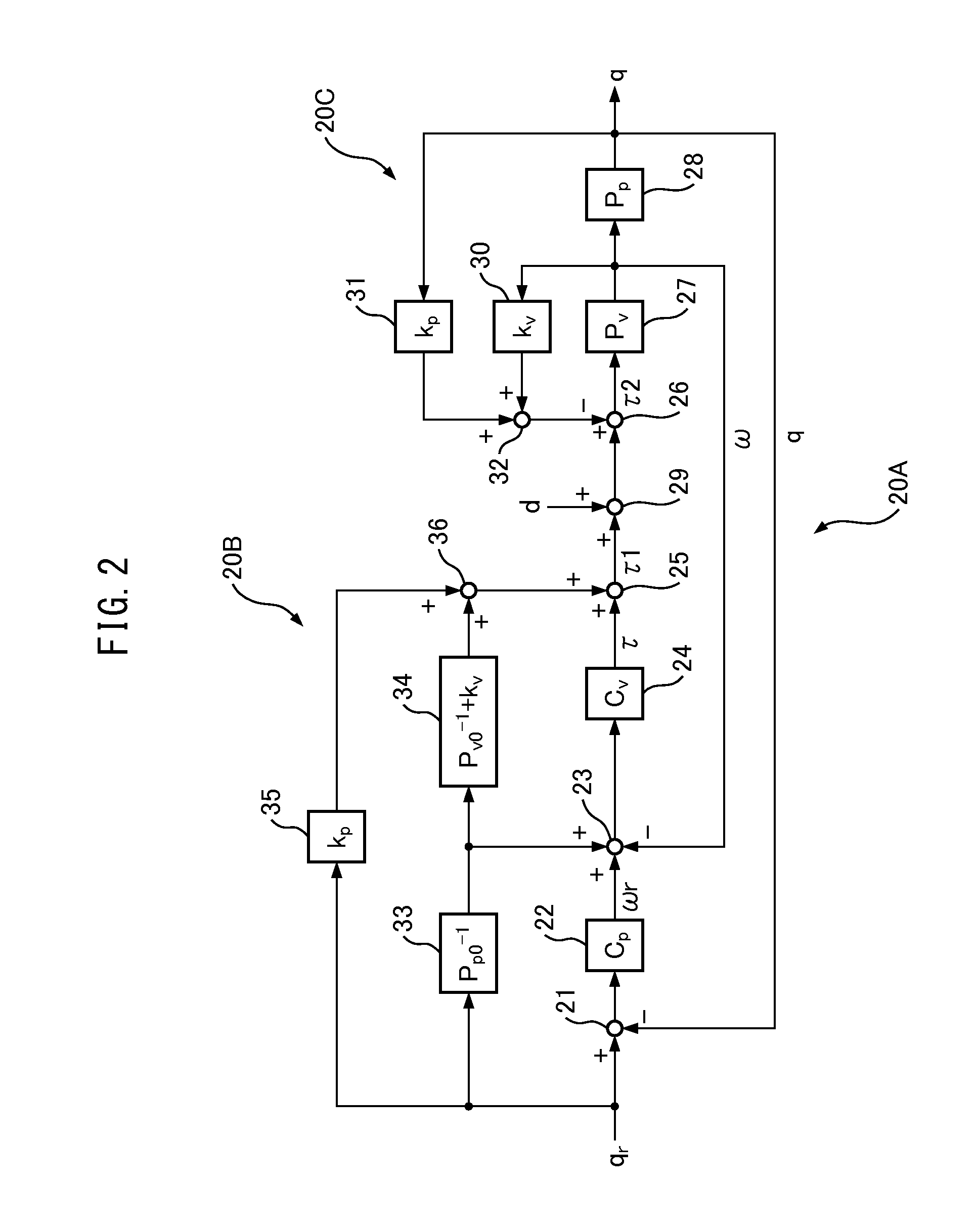

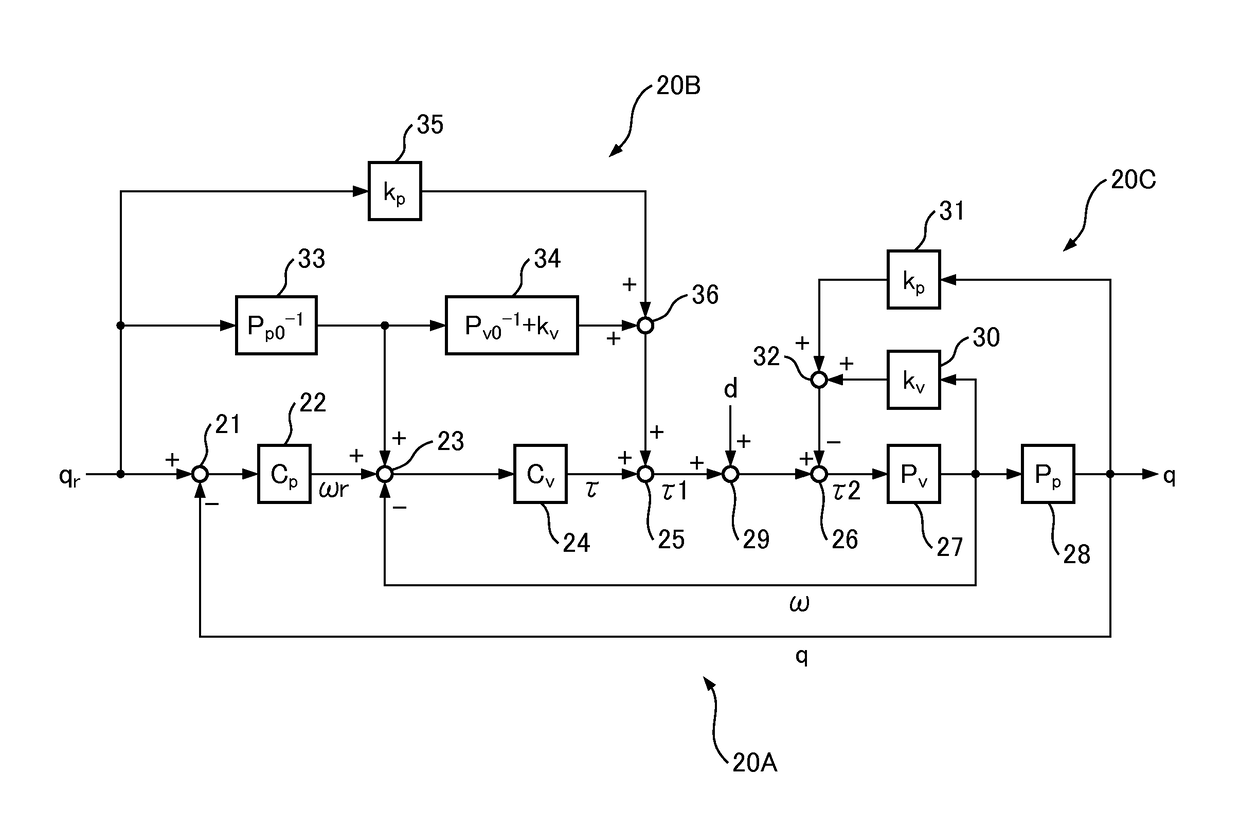

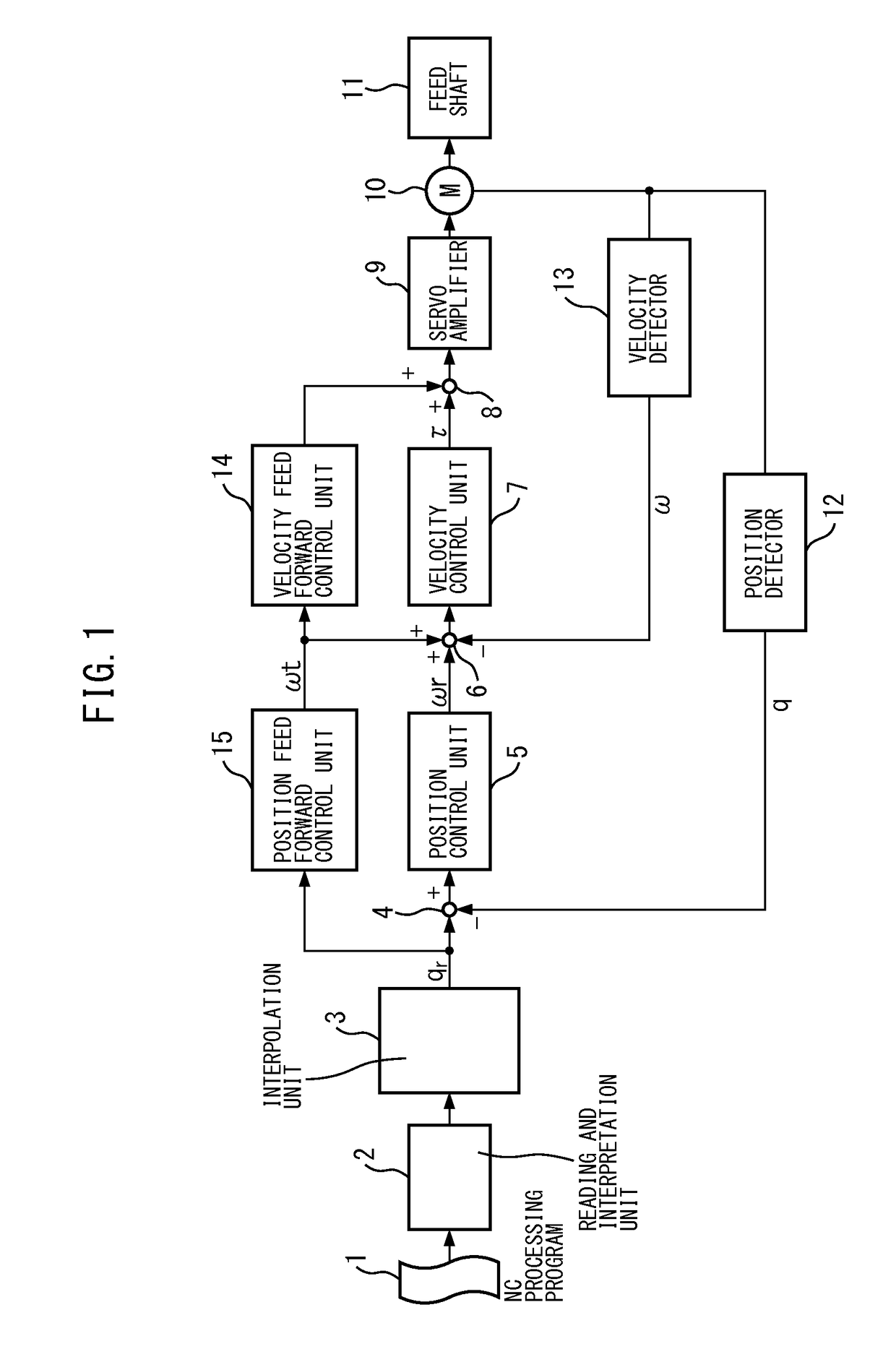

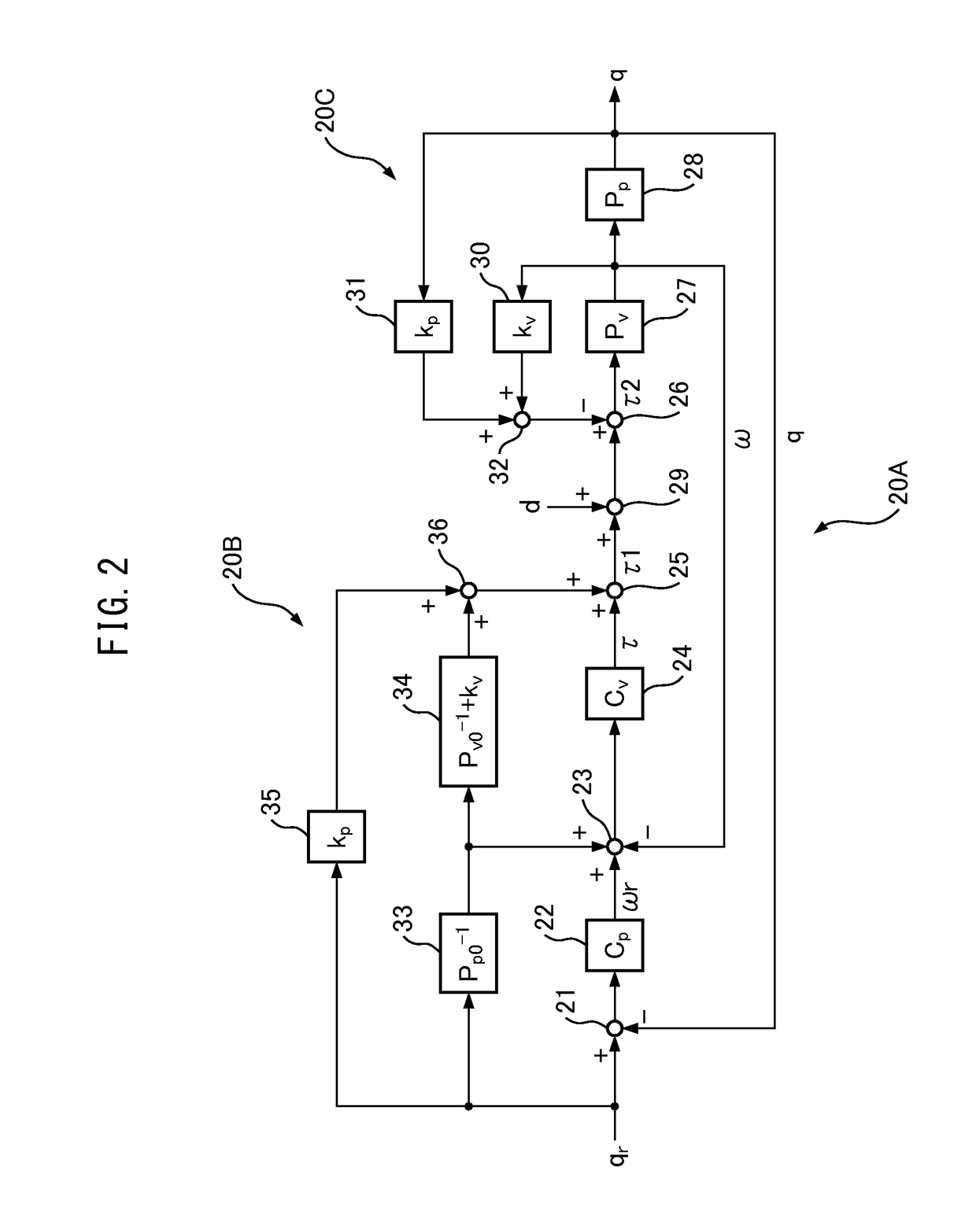

Working machine feed axis control method and feed axis control device

ActiveUS20160004248A1Process stabilityFeedback gain is increasedSpecial data processing applicationsNumerical controlCouplingGain setting

A working machine feed axis control device: disposes a velocity feedback loop and forms a cascade coupling on the inner side of a location feedback loop; comprises a velocity gain setting apparatus (30) which multiplies the output of the velocity feedback look by a first gain (kv), and a location gain setting apparatus (31) which multiplies the output of the location feedback loop by a second gain (kp); subtracts the output of the velocity gain setting apparatus (30) and the output of the location gain setting apparatus (31) from a torque instruction (τ); and outputs the remaining torque instruction (τ) to a subject to be controlled (27).

Owner:MAKINO MILLING MASCH CO LTD

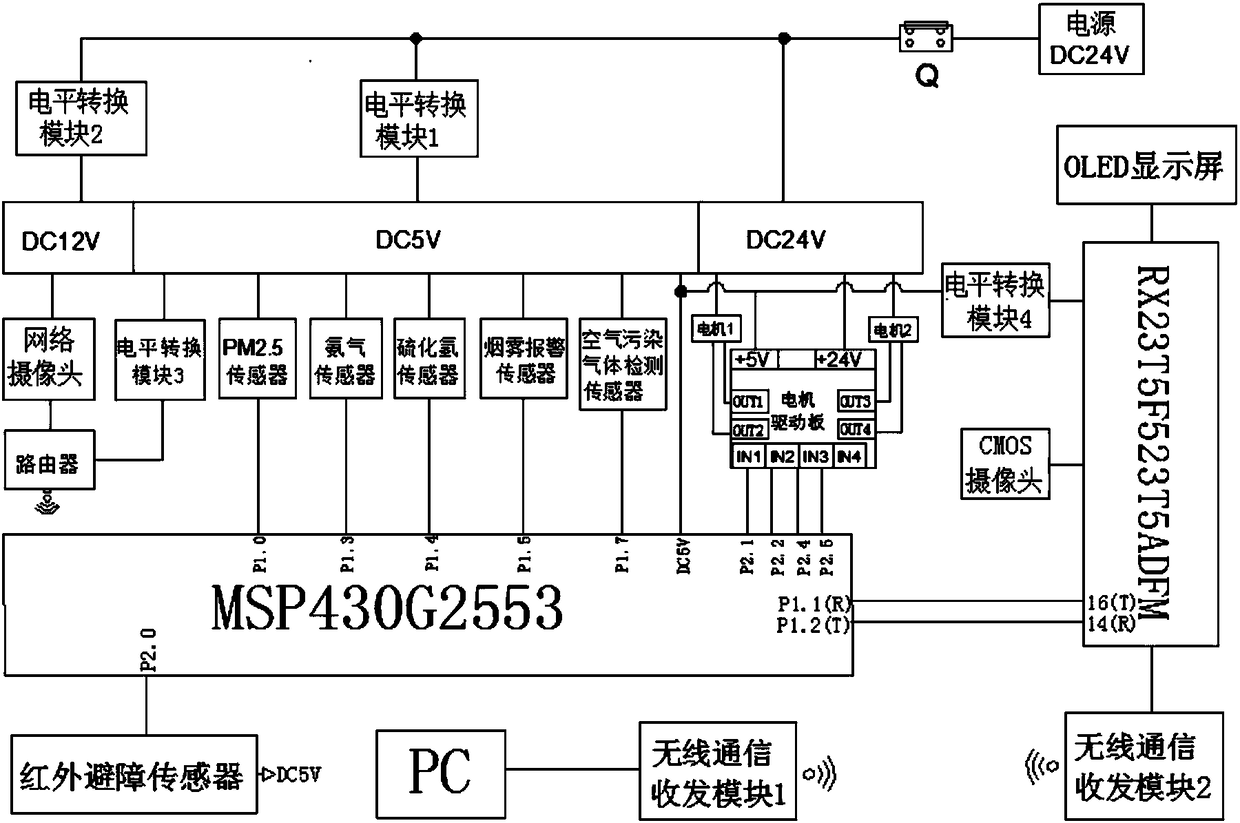

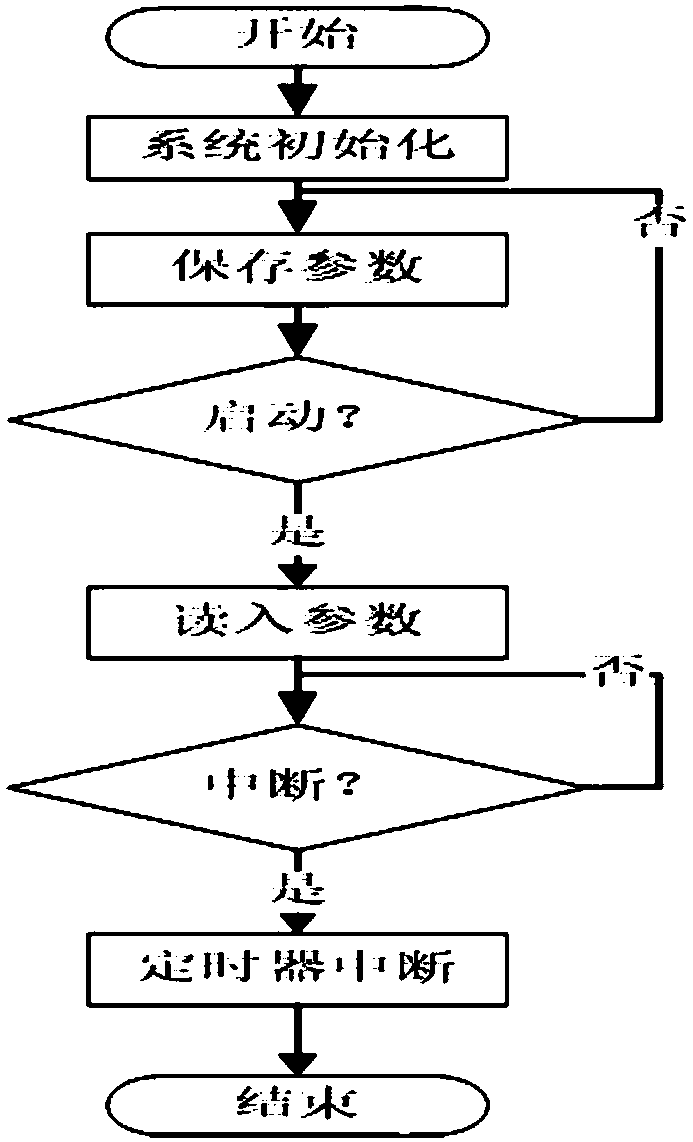

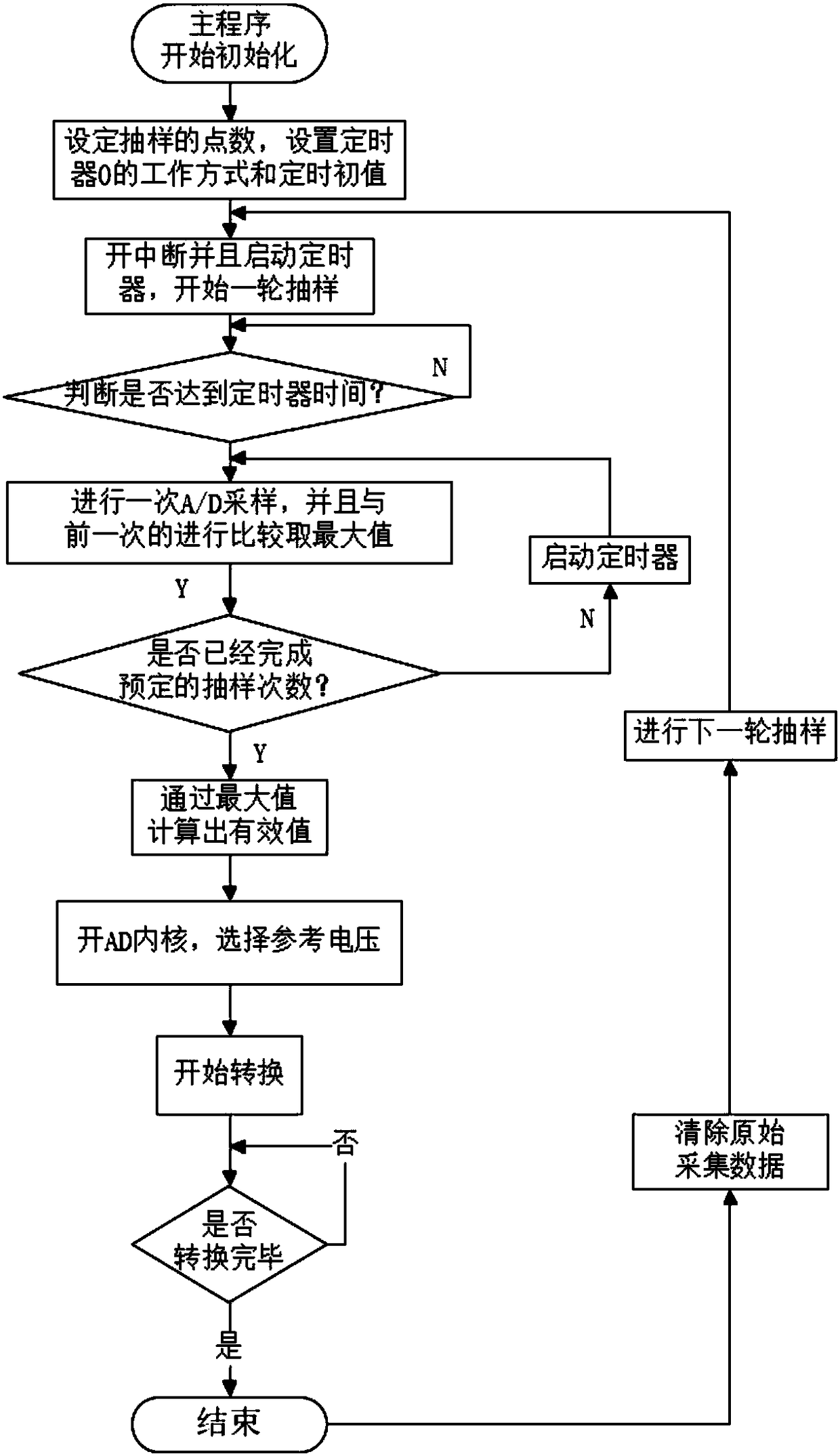

Multifunctional polling robot based on distributed control and working method thereof

PendingCN108132670AImprove processing precisionThe calculation process is simpleMeasurement devicesPosition/course control in two dimensionsMicrocontrollerComputer monitoring

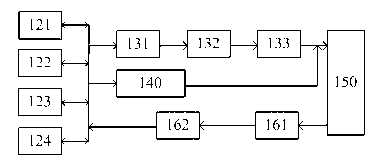

The present invention relates to the technical field of robots, especially to a multifunctional polling robot based on distributed control. The multifunctional polling robot based on distributed control comprises a control module, a cruise module, a motion module, an image collection module, a gas detection module, a soil sampling module, a wireless communication transmitting-receiving module andan upper computer monitoring module. The control module employs an MSP430G2553 single-chip microcomputer, the cruise module employs a RX23T5F523T5ADFM single-chip microcomputer, the RX23T5F523T5ADFM single-chip microcomputer reads image information collected by a CMOS camera in real time through an SCCB communication mode and transmits the position information to the MSP430G2553 single-chip microcomputer through a serial communication mode. An MSP430 processor is taken as a main control core, a RX23T is taken as an auxiliary control system, the distributed control reduces computing errors on data processing and increases data processing precision.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

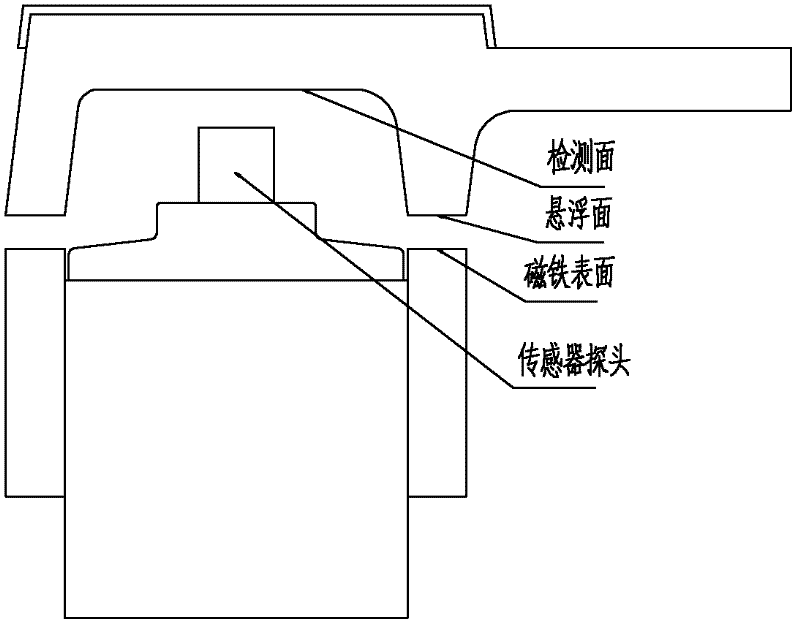

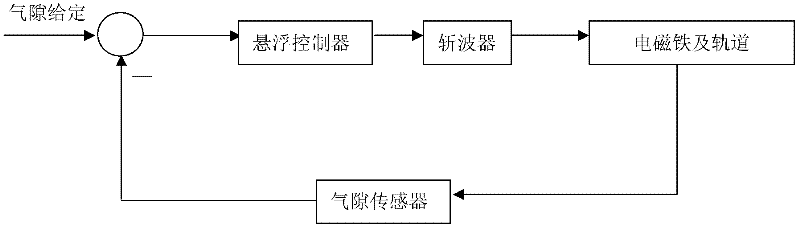

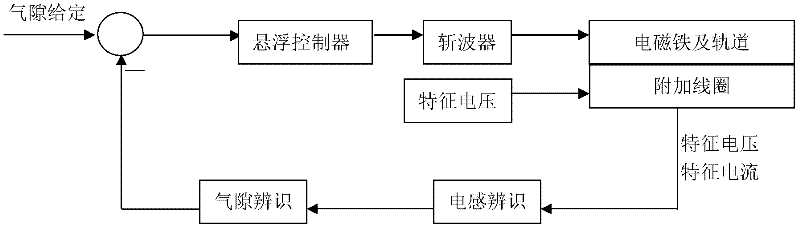

Interpole-coil-based air-gap-free sensor electromagnetic attraction suspension control method

InactiveCN102358206ALower requirementSolve problems such as crossing track seamsElectric propulsionCoil inductanceInstability

The invention discloses an interpole-coil-based air-gap-free sensor electromagnetic attraction suspension control method. In the method, an interpole coil is added on a suspension coil; voltage with a certain feature is applied to the interpole coil; inductance of the interpole coil is identified according to input voltage and output current of the interpole coil; a suspension air gap value is acquired according to the inductance of the interpole coil; and closed loop control is realized by using the air gap value. The method is applicable to electromagnetic attraction suspension control; as an air gap sensor is avoided, a system is simplified greatly, a precision requirement on a system track of a maglev train is reduced, instability of control over the system caused by inaccurate measurement of the sensor can be avoided, and problems that the maglev train passes through a track gap and the like can be solved; furthermore, the method has the advantages of high dependability, low cost, safety, reliability and the like.

Owner:SOUTHWEST JIAOTONG UNIV

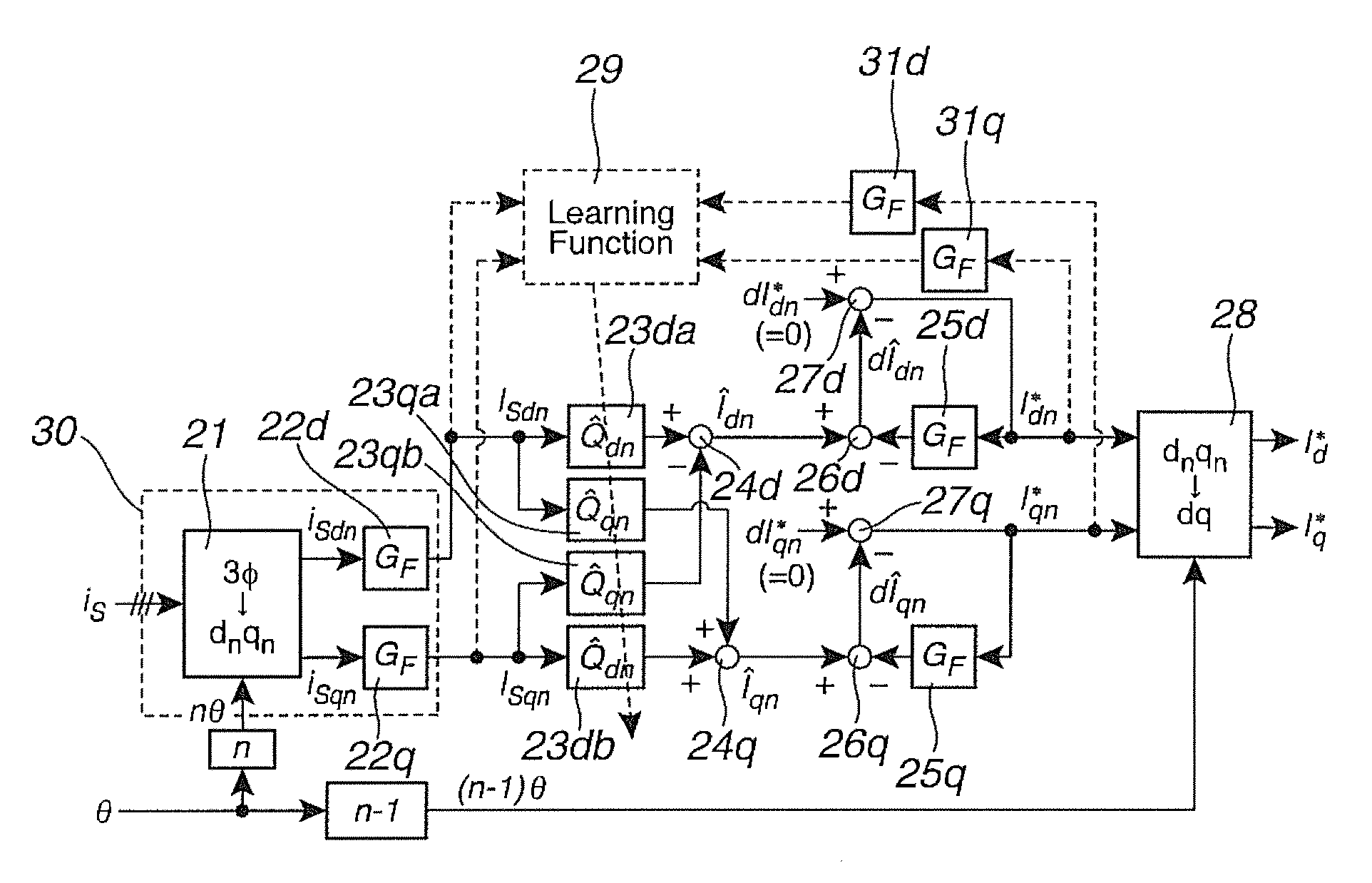

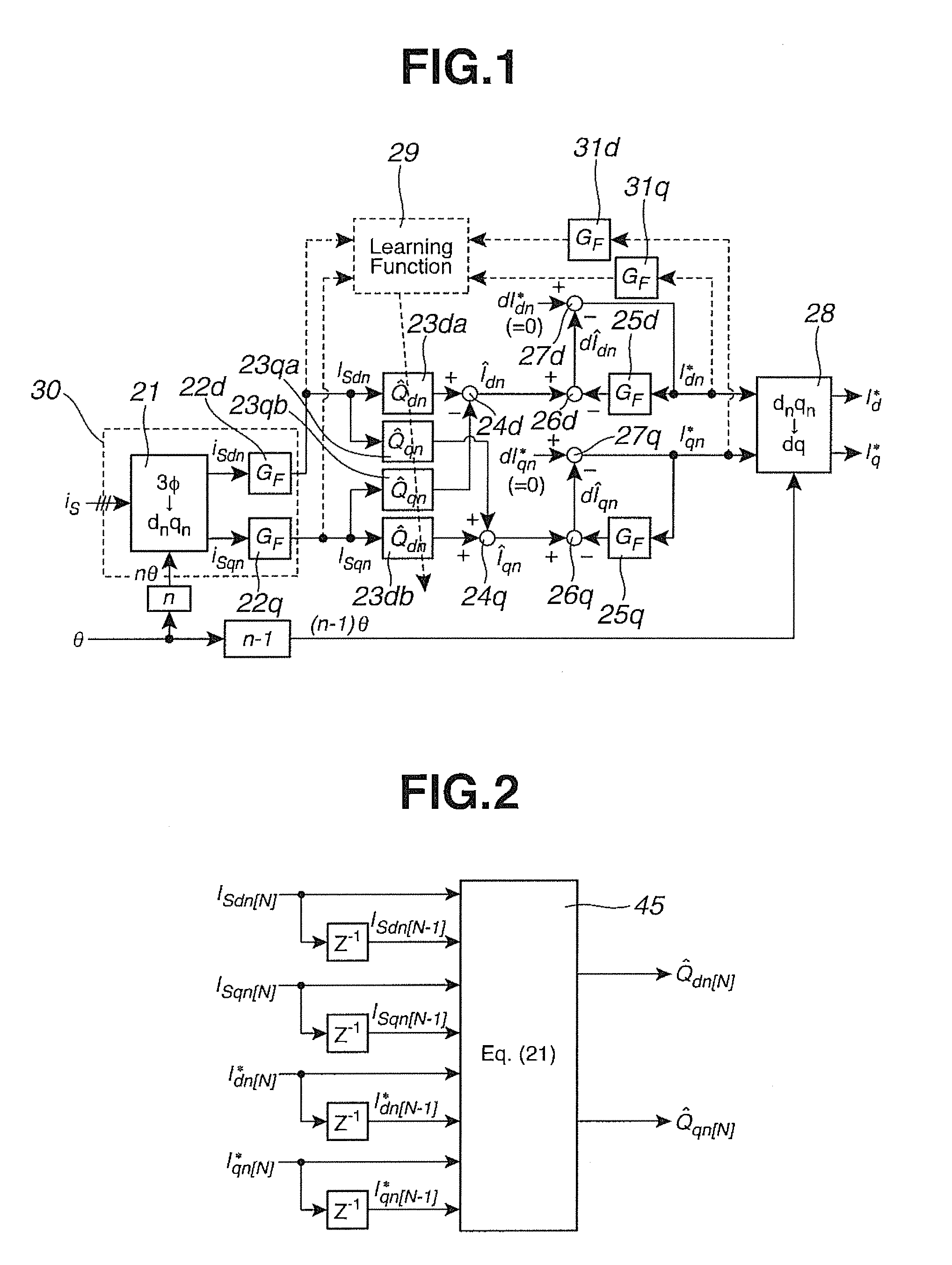

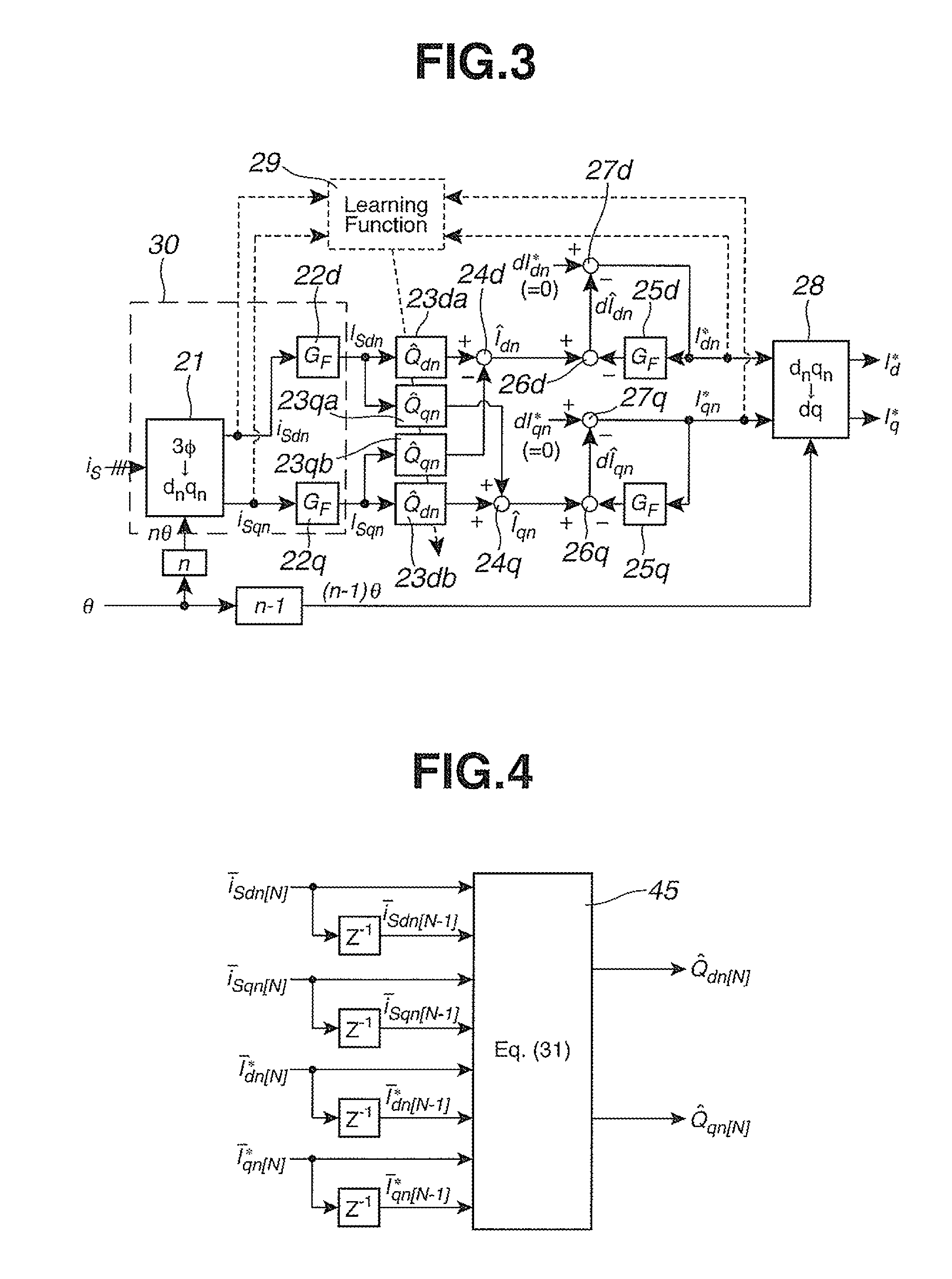

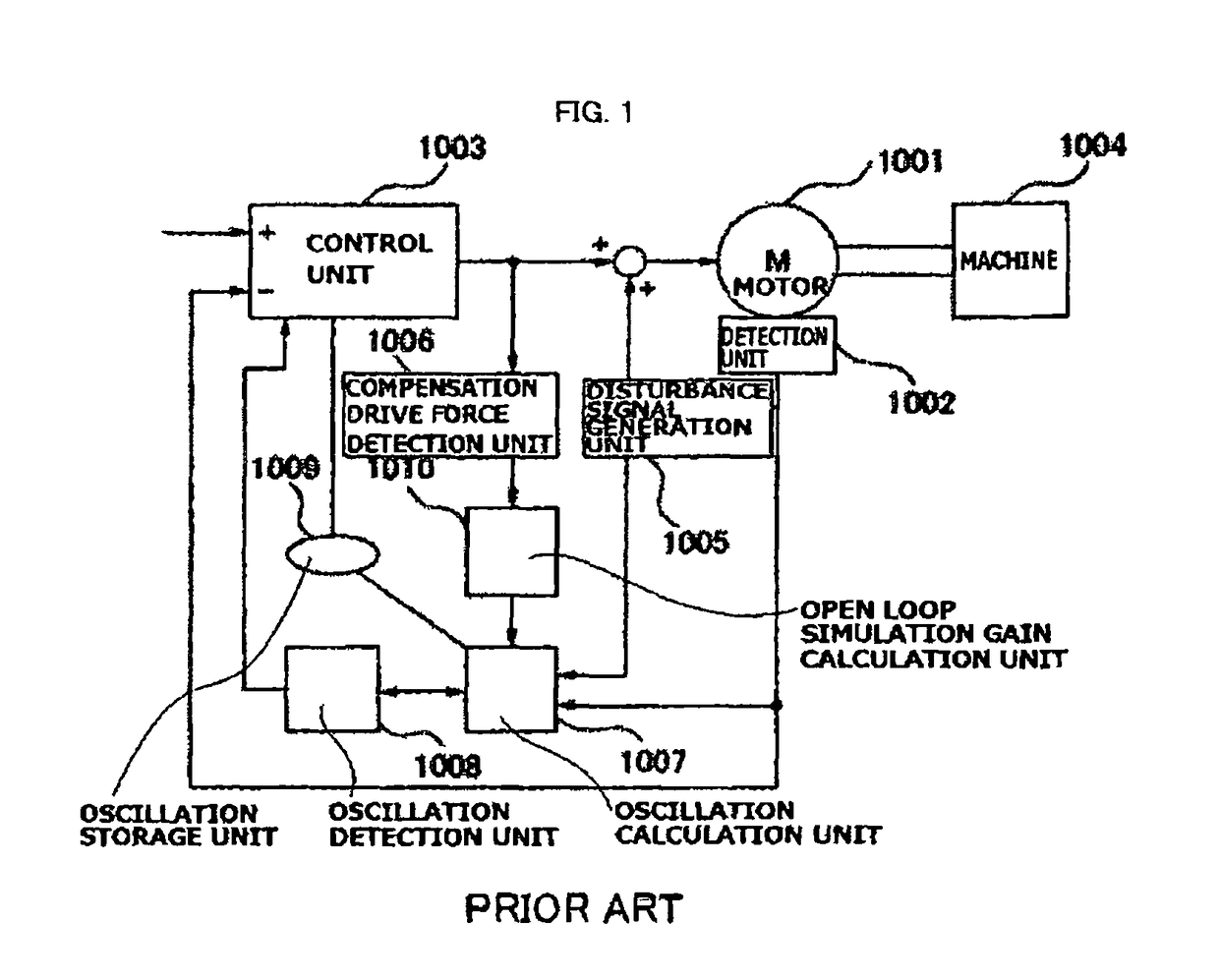

Periodic external disturbance suppression control device

ActiveUS20160349717A1Limit amplitudeThe control system is stableAnti-hunting elementsAdaptive controlControl systemReal systems

A periodic disturbance suppressing control apparatus is designed to estimate and correct an inverse model of a transfer characteristic of a real system successively even in case of large condition change in the real system, and to realize a stable control system.A periodic disturbance of an object to be suppressed is outputted as a sensed periodic disturbance ISdn, ISqn of a direct current component. A difference between a signal obtained by multiplication of the sensed periodic disturbance ISdn, ISqn with a multiplier using a reciprocal Qn of a transfer characteristic, and a signal obtained by adding only a detection delay to a periodic disturbance suppressing command I*dn, I*qn, to estimate the periodic disturbance dÎdn, dÎqn. Thee periodic disturbance suppressing command is calculated by calculating a deviation between the estimated periodic disturbance dÎdn, dÎqn. A learning control section 29 corrects the reciprocal Qn of the transfer characteristic in accordance with a quantity obtained by diving a difference of the periodic disturbance suppressing command I*dn, I*qn during one sample interval by a difference of the sensed periodic disturbance during the one sample interval.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Novel energy-saving electric loader drive control system and control method

PendingCN111236353ARealize infinitely variable speedEasy to shiftSoil-shifting machines/dredgersPower batteryControl system

The invention discloses a novel energy-saving electric loader drive control system and control method, and belongs to the technical field of shoveling engineering machinery vehicles. A control handleis connected with a vehicle control unit (VCU); the VCU is electrically connected with a motor controller I, a motor controller II and a power battery controller BMS; the motor controller I is in control connection with a double-output-shaft walking motor, and the double-output-shaft walking motor drives front wheels and rear wheels through a front transmission shaft and a rear transmission shaft;the motor controller II is in control connection with a hydraulic pump control motor, and the hydraulic pump control motor drives a hydraulic pump to provide power for a hydraulic system of a loader;and the power battery controller BMS is in control connection with a power battery pack, and the power battery pack supplies power to the double-output-shaft walking motor and the hydraulic pump control motor. The motor is in a mode of a double-output-shaft structure, the whole machine is easy to arrange, the structure is simple and convenient, the reliability is high, the problems that an existing loader is complex in structure and control are solved, the working efficiency is high, and the good energy-saving effect is achieved.

Owner:XCMG CONSTR MACHINERY

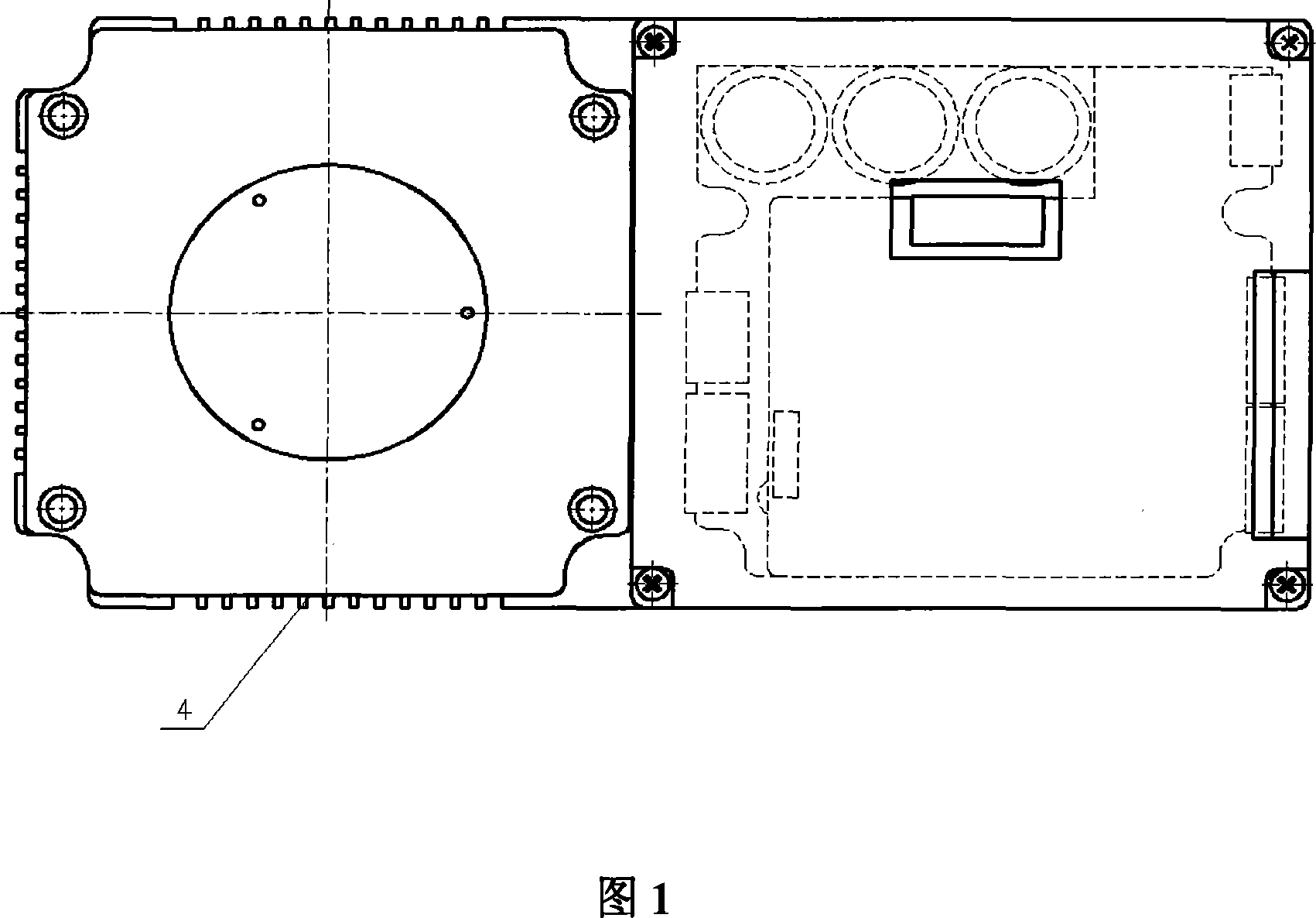

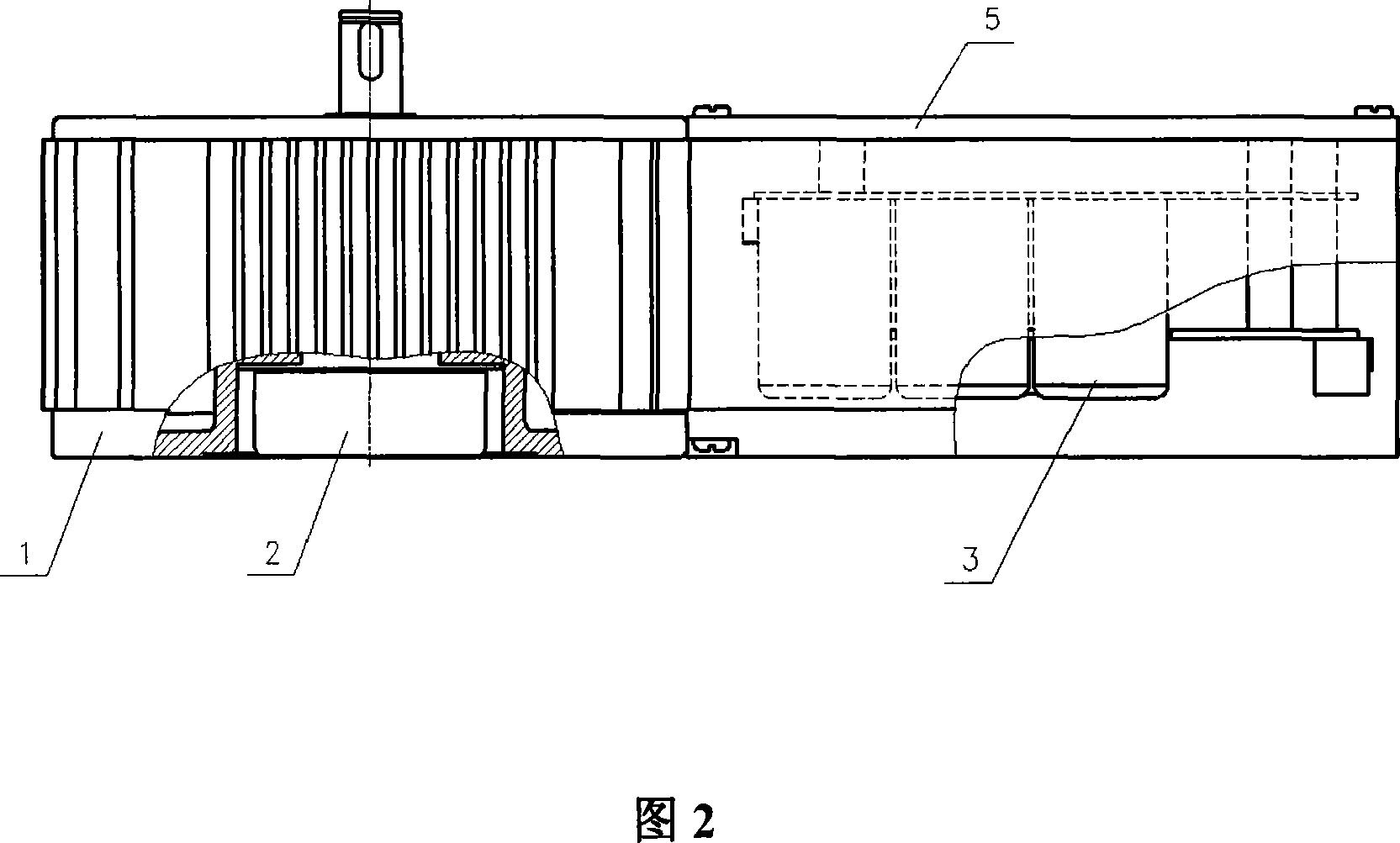

Permanent magnet motor for door motor

ActiveCN101060268ACompact structureSimple structureAssociation with control/drive circuitsSynchronous machine detailsFrequency changerPermanent magnet synchronous motor

The related elevator-used permanent magnet motor comprises: a permanent magnet synchronous motor, a coder embedded in the cavity of motor end cover, and a frequency converter using / sharing the heat fin of shell on bottom, wherein all three members are integrated in a shell. This invention has compact and simple structure, high transfer efficiency, and low cost.

Owner:HANGZHOU XO ELEVATOR

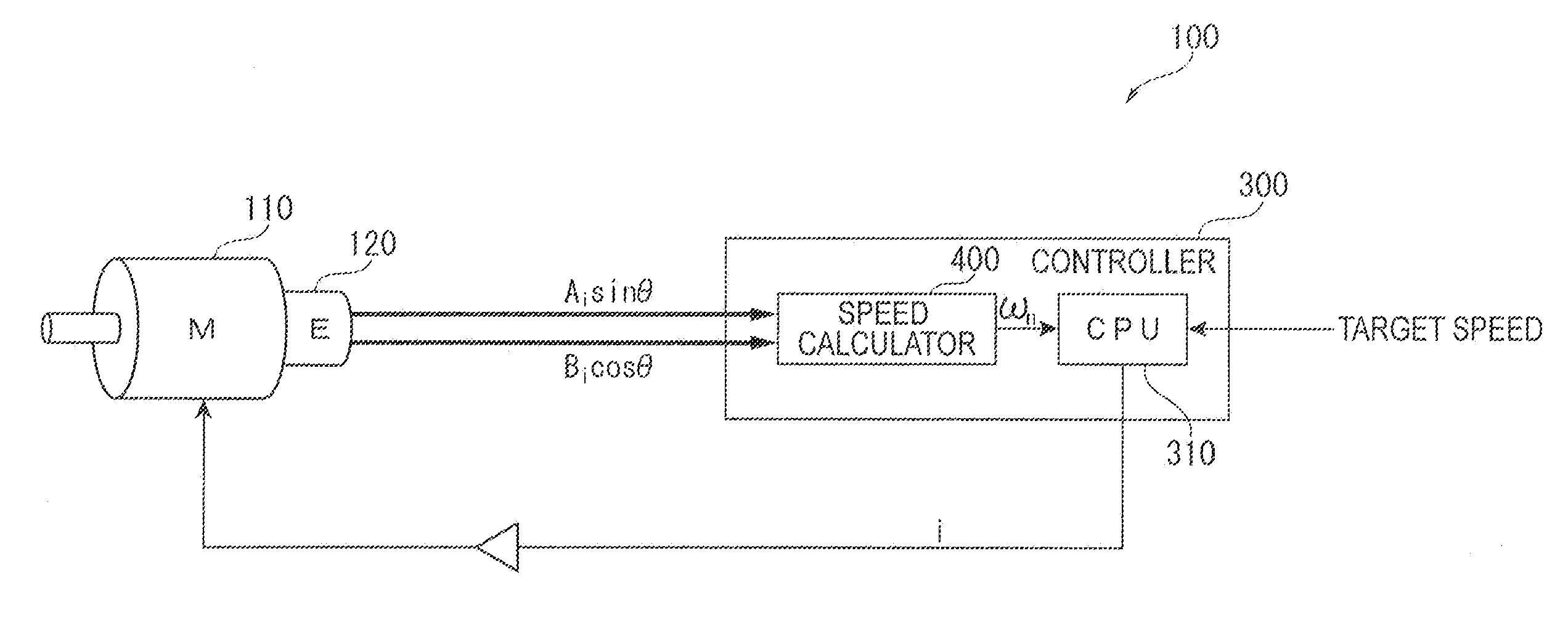

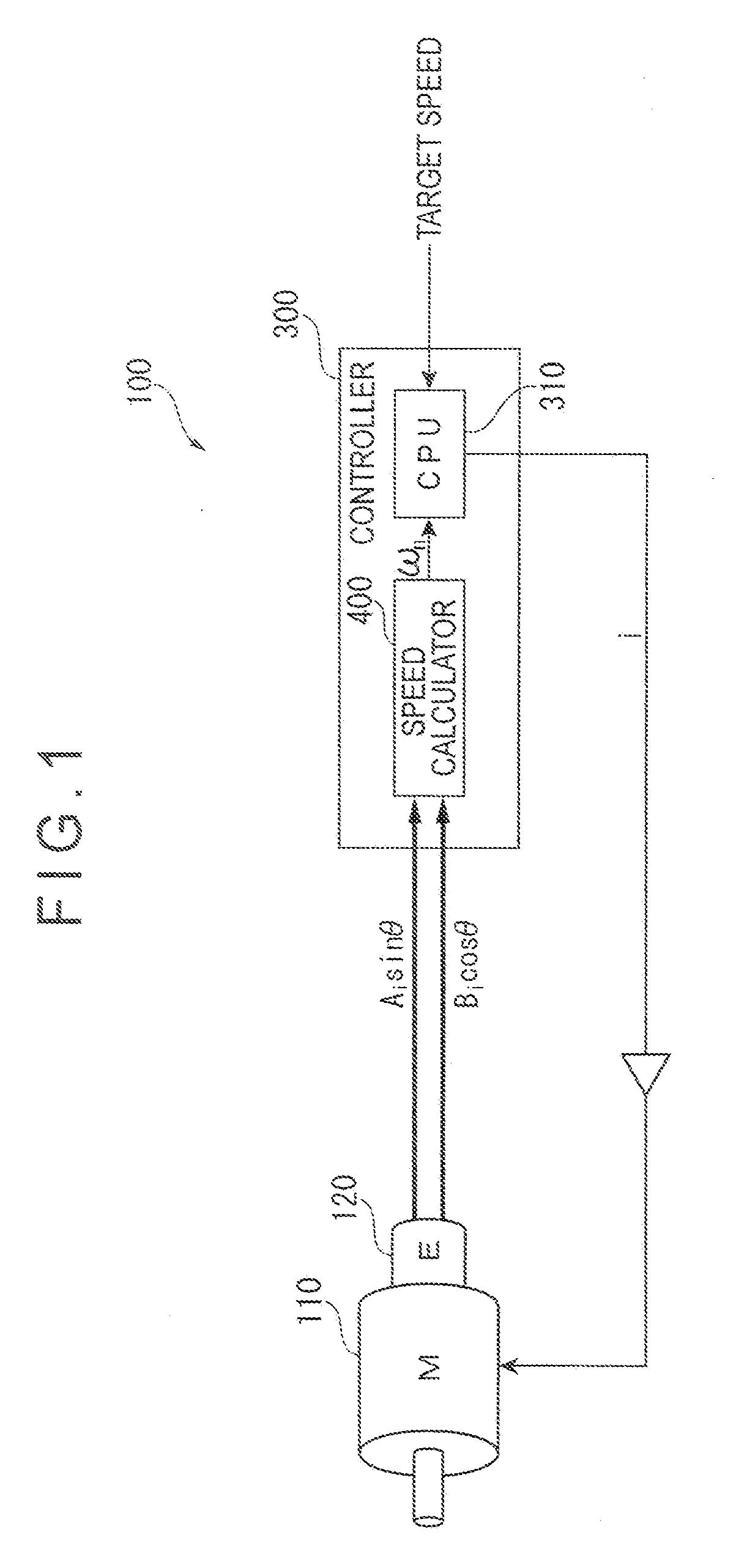

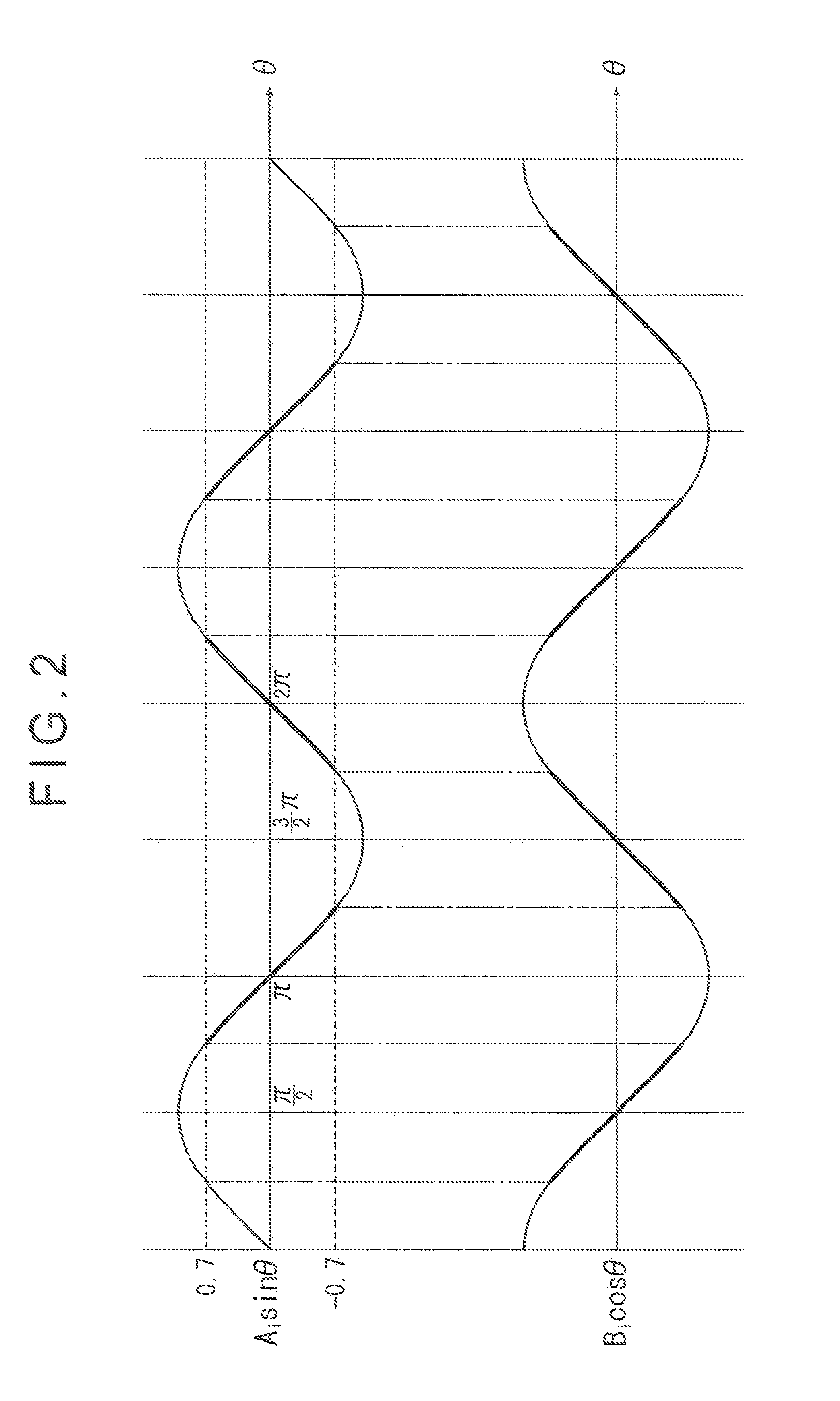

Signal processing device, velocity detecting device and servo mechanism

InactiveUS20080061723A1The control system is stableStable controlProgramme controlAC motor controlEngineeringServomechanism

A driving velocity of a motor is detected by processing a position information signal output from a sensor in accordance with a driving position of a motor. The signal processing device includes a position information signal processor (410) that processes the position information signal and calculates driving velocity information of the motor, and an internal position information generator (460) that reflects a latest driving velocity information (ωn) calculated by the position information signal processor (410) and generates a latest presumed position of the motor as internal position information. An amplitude correcting unit (465) detects the amplitude of the position information signal from the sensor and corrects the amplitude of the internal position information signal based on the detected amplitude.

Owner:TOSHIBA MASCH CO LTD

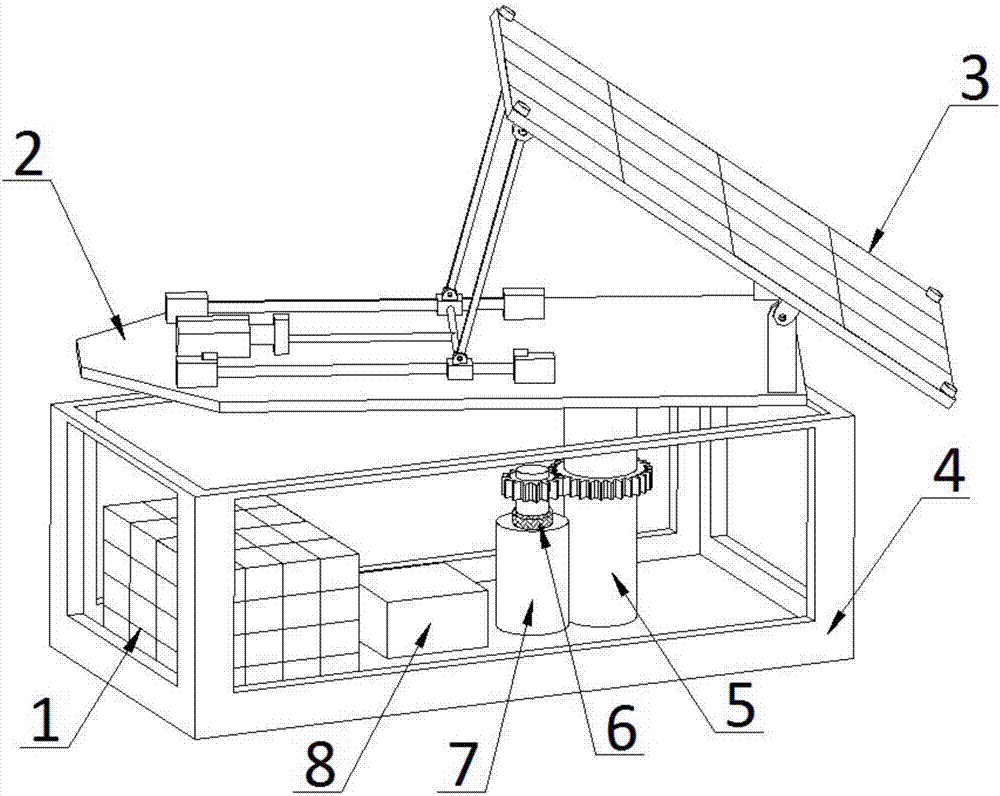

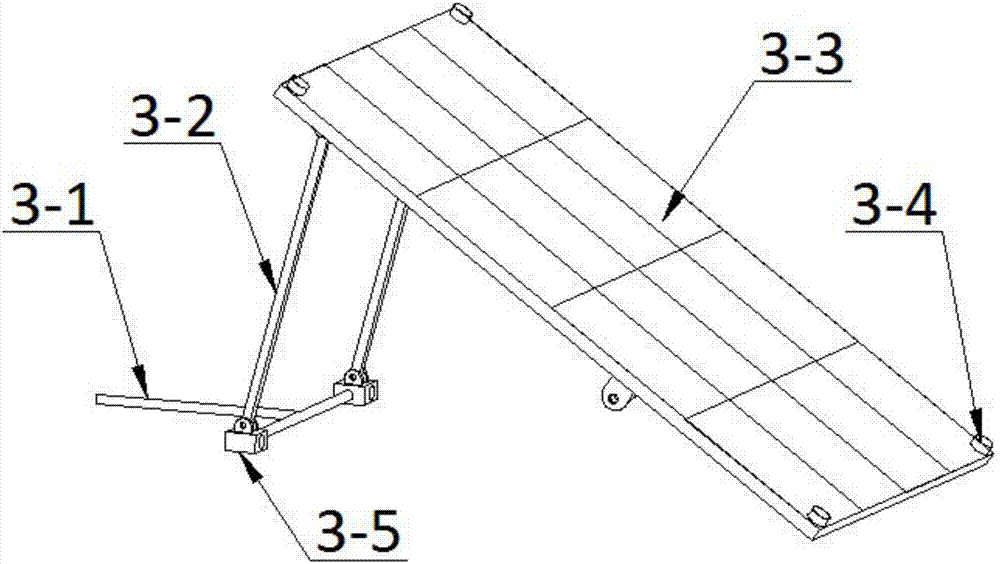

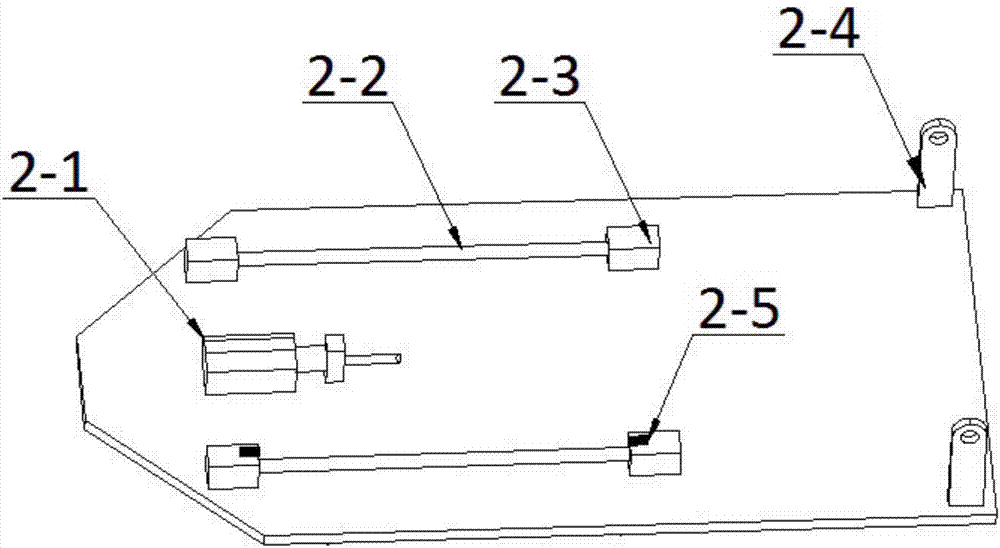

Automatic tracking device of solar panel for sewage treatment and usage method thereof

ActiveCN107102652AStable structureThe control system is stableControl using feedbackDrift angleEngineering

The invention provides an automatic tracking device of a solar panel for sewage treatment and a usage method thereof. The device is characterized in that the upper part of a displacement platform is fixedly provided with a push motor, two slide bars and two support columns, and two ends of one slide bar are provided with a position sensor respectively; the center of the bottom plate of a fixing bracket is rotatably provided with a rotation shaft which is driven by a rotary motor and a rotation angle sensor is also mounted on an output shaft; the solar panel includes a push rod, two support bars, a solar cell module, two sliders and four sun light drift angle sensors; and a storage battery, a sun light drift angle sensor, the rotation angle sensor and the rotary motor are connected with a controller. The method comprises steps that the sun light drift angle sensor monitors the sunlight incidence angle and communicates with the controller; and the controller controls the rotary motor and the push motor to move for adjusting movement of the displacement platform and the solar cell module. The device is simple in structure, wide in tracking range, and convenient in maintenance. The method can improve the tracking efficiency.

Owner:XUZHOU UNIV OF TECH

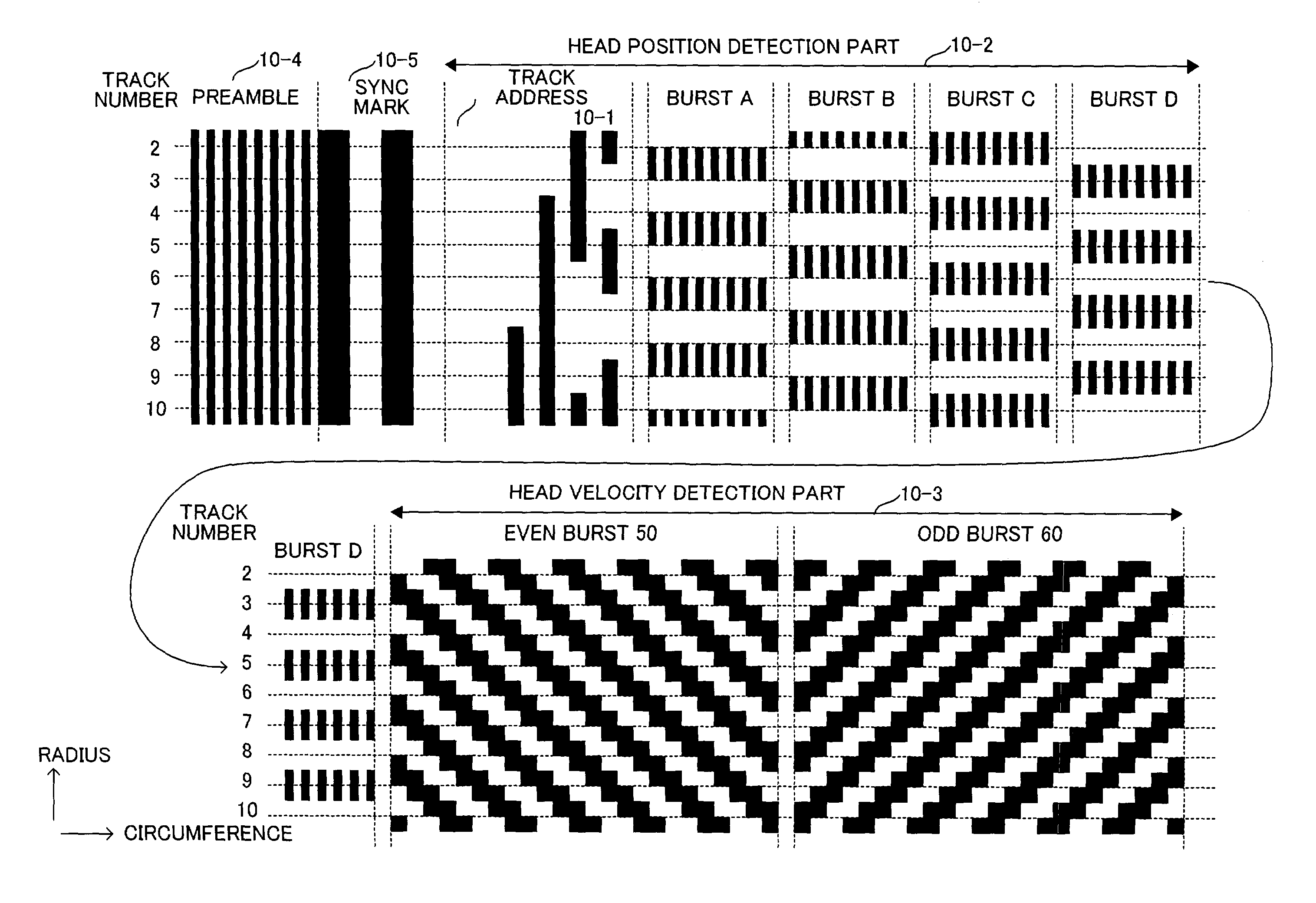

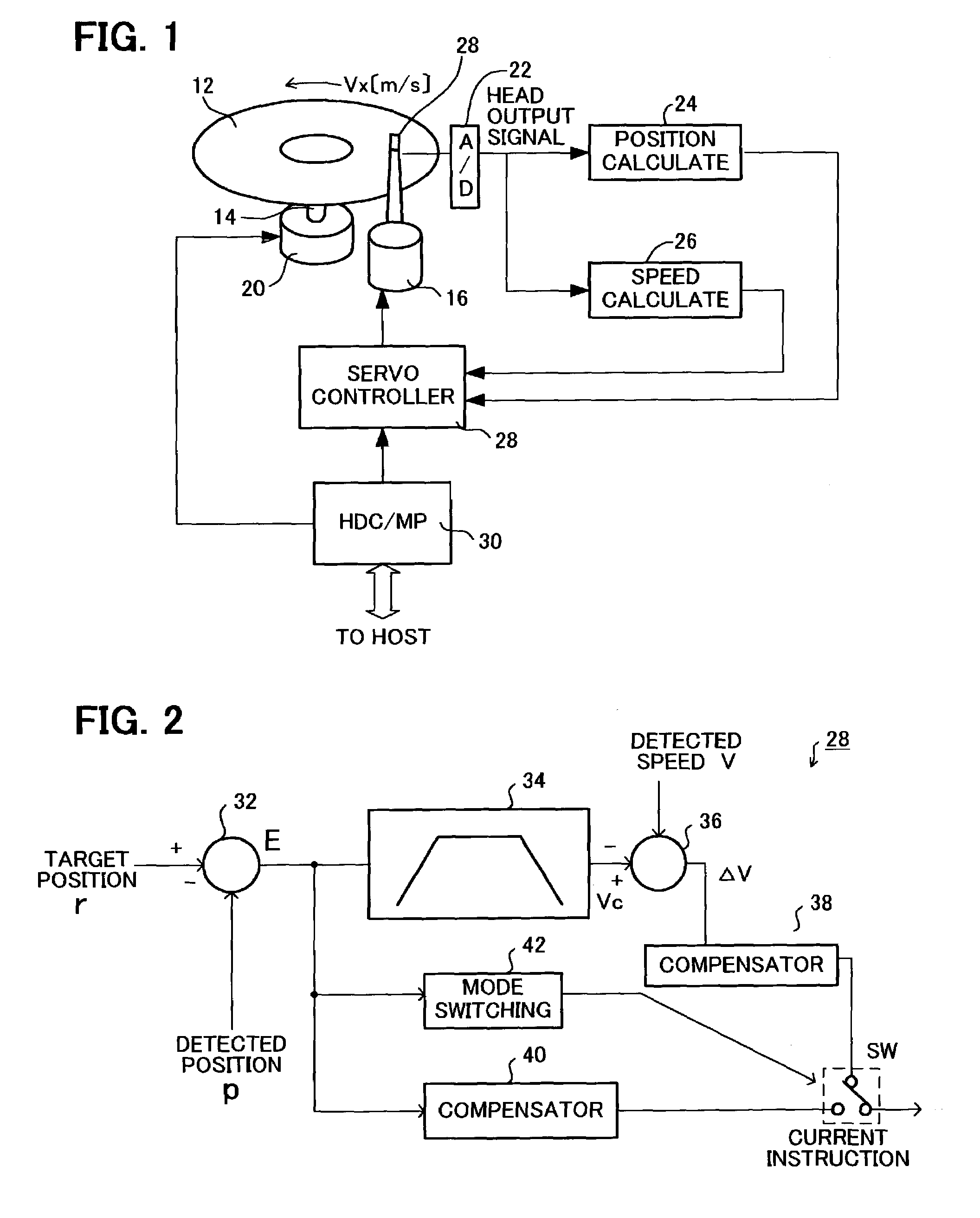

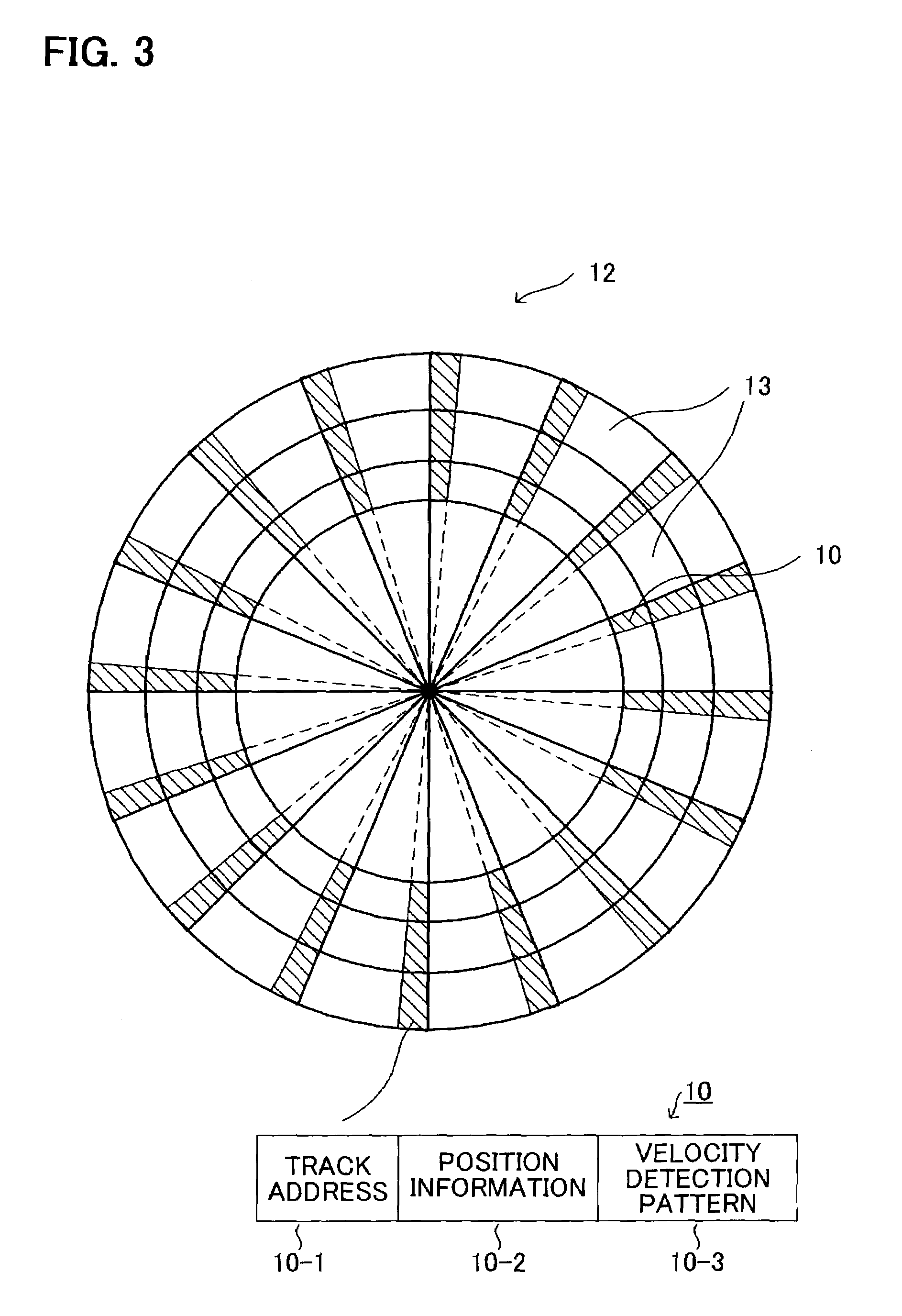

Head position control method and disk storage device

InactiveUS6961204B2Easy to operateHead speed can be accuratelyRecord information storageAlignment for track following on disksControl systemHead position

A head position control method controls the speed of the head using the position and the speed detected from the servo information on the disk and directly detects the head speed. The speed detection pattern is assigned to the servo area of the disk, and the speed of the head is detected at the frequency of the regeneration signal. Therefore the speed of the head can be directly detected at the timing of the servo reading. By this, information on the head speed can be obtained with less error. Since there is no delay in the speed detection, the phase margin of the control system increases and stability improves.

Owner:TOSHIBA STORAGE DEVICE CORP

Braking control system and method for vehicle

ActiveUS9180881B2Without additional part cost and development costThe control system is stableDriver input parametersRadio wave reradiation/reflectionControl systemVehicle braking

A braking control system and a method for a vehicle are provided. The braking control method includes sensing, by a controller, a rear-side collision risk and a lane change and determining a lane change intention based on a steering change of a vehicle. In addition, the controller is configured to determine a braking control for the vehicle and a magnitude of the braking control for the vehicle based on the rear-side collision risk and the lane change, and the lane change intention.

Owner:HYUNDAI MOTOR CO LTD +1

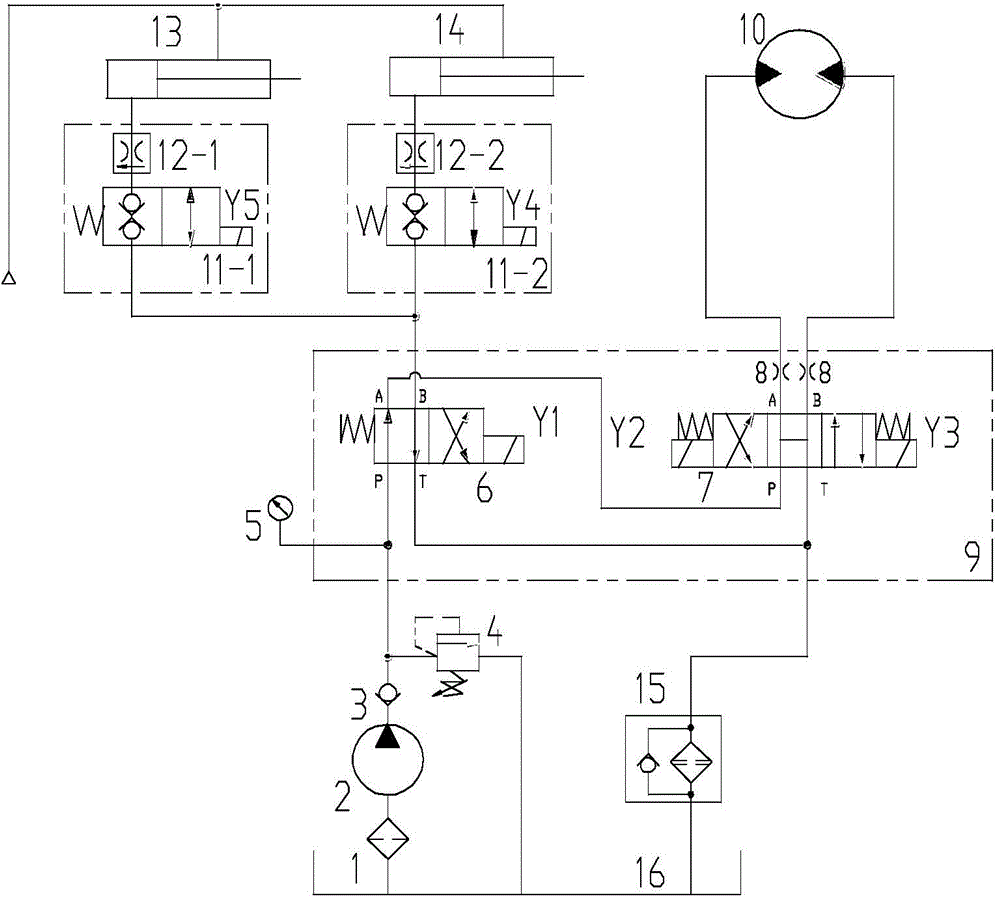

Hydraulic system of aerial operation truck with two folding booms

InactiveCN104564867AReliable controlSmooth turning actionServomotor componentsServomotorsTruckRotary valve

The invention relates to a hydraulic system of an aerial operation truck with two folding booms. The hydraulic system is provided with an oil cylinder I, an oil cylinder II and a rotary motor, wherein the oil cylinder I is a lower boom variable-amplitude oil cylinder, the oil cylinder II is an upper boom variable-amplitude oil cylinder, and the rotary motor is a cycloid hydraulic motor. The hydraulic system is characterized in that the oil cylinder I is connected with a reversing valve I-A through a flow valve I, the oil cylinder II is connected with a reversing valve I-B through a flow valve II, the rotary motor is connected with a reversing valve III, the reversing valve II is simultaneously communicated with the reversing valve I-A, the reversing valve I-B and the reversing valve III, and is communicated with a hydraulic valve, the hydraulic pump is communicated with an oil tank, the oil tank is communicated with the hydraulic pump through an oil absorbing filter, the oil tank is communicated with the reversing valve III through an oil return filter, the oil cylinder I and the oil cylinder II are respectively communicated with atmosphere through pipelines, and a damping throttling plug is arranged between the reversing valve III and the rotary valve. The hydraulic system has the advantages that under the condition of low cost, the hydraulic system of a boom frame is stably and reliably controlled, and the problems of shaking, instability and large impact when the aerial working truck operates and controls the boom frame to lift are solved.

Owner:XUZHOU HANDLER SPECIAL VEHICLE

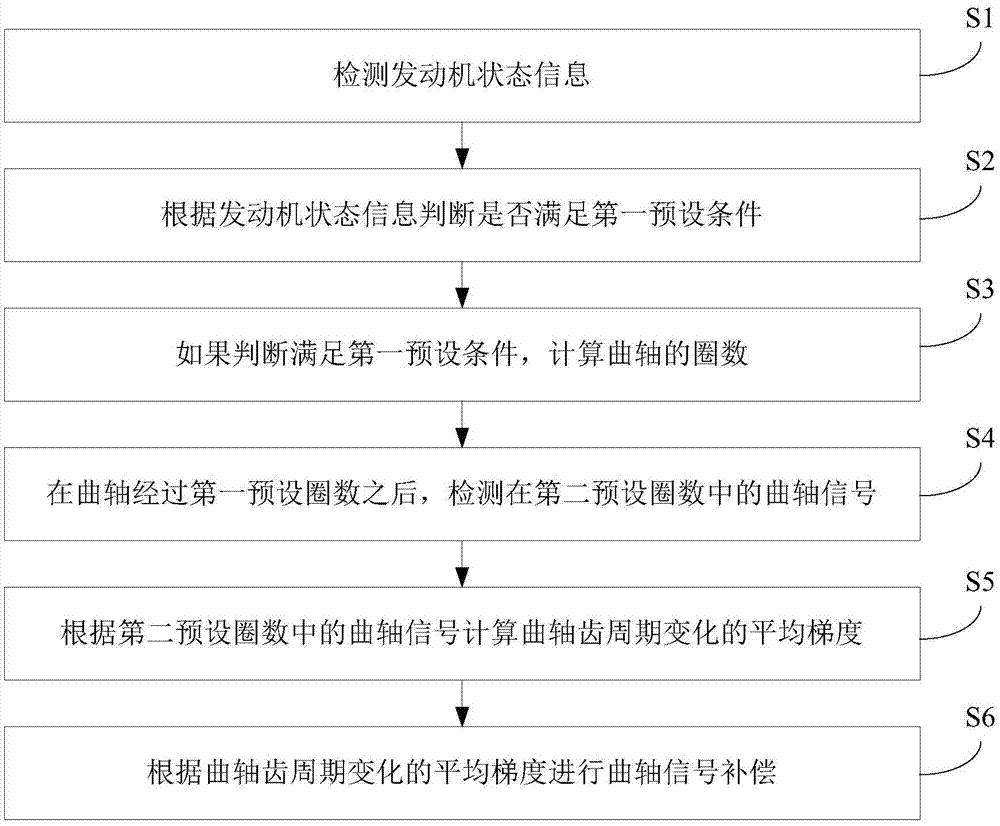

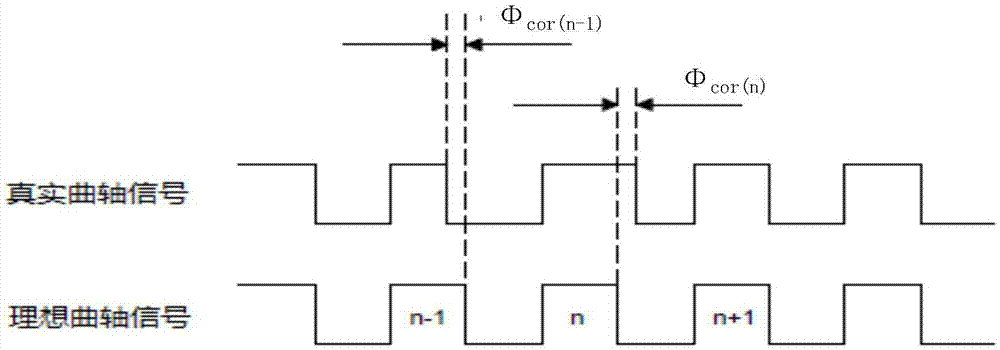

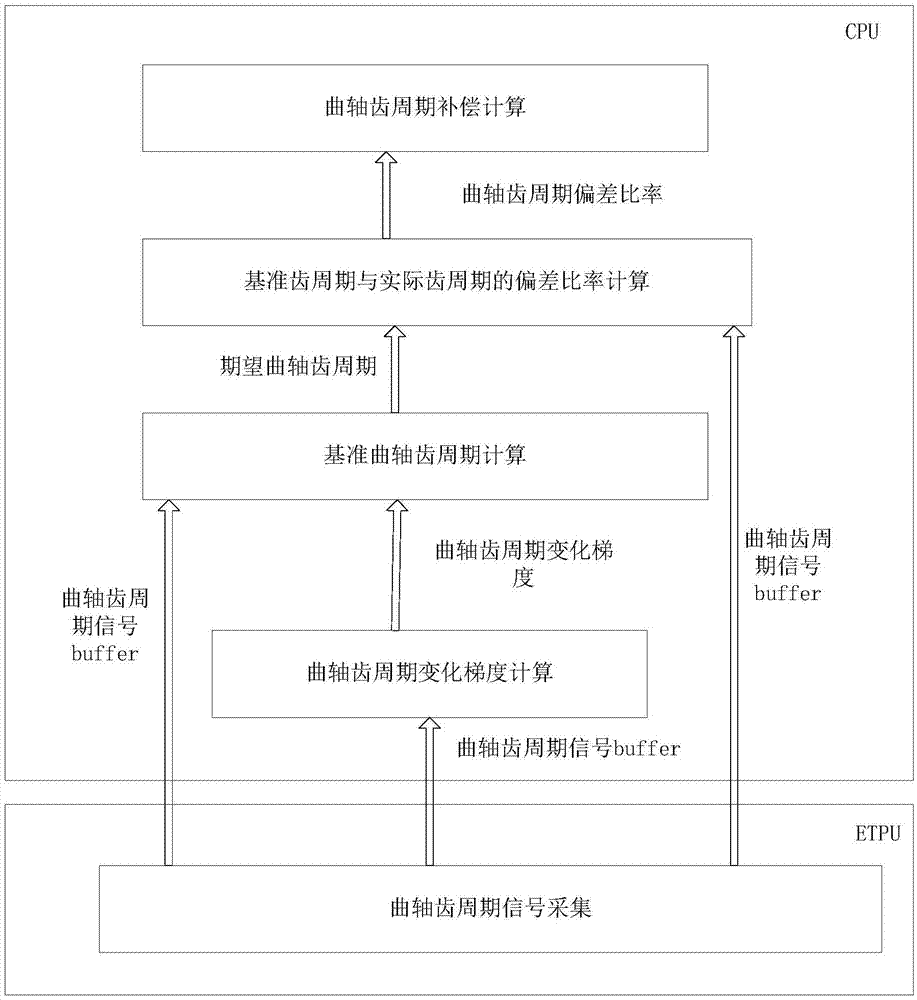

Compensation method and device for engine crankshaft signal and automobile

ActiveCN106934085AThe control system is stableImprove accuracyGeometric CADSpecial data processing applicationsControl systemCrankshaft

The invention discloses a compensation method and device for an engine crankshaft signal and an automobile. The compensation method comprises the steps that engine state information is detected; whether a first preset condition is met or not is judged according to the engine state information; if it is judged that the first preset condition is met, the number of circles of a crankshaft is calculated; after the crankshaft rotates by a first preset number of circles, a crankshaft signal in a second preset number of circles is detected; the average gradient of crankshaft tooth cycle change is calculated according to the crankshaft signal in the second preset number of circles; and crankshaft signal compensation is performed according to the average gradient of the crankshaft tooth cycle change. Through the compensation method for the engine crankshaft signal in the embodiment, the accuracy of a crankshaft tooth cycle is improved, therefore, the accuracy of engine speed obtained through calculation according to the crankshaft tooth cycle is improved, and accordingly a control system of an engine is more stable.

Owner:GREAT WALL MOTOR CO LTD

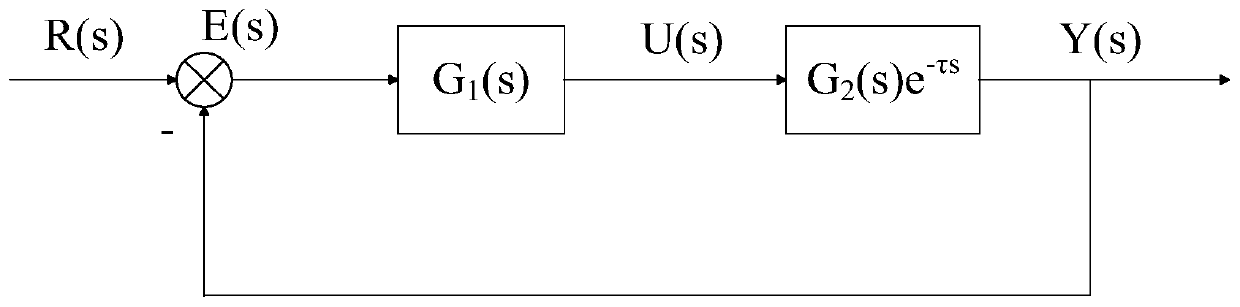

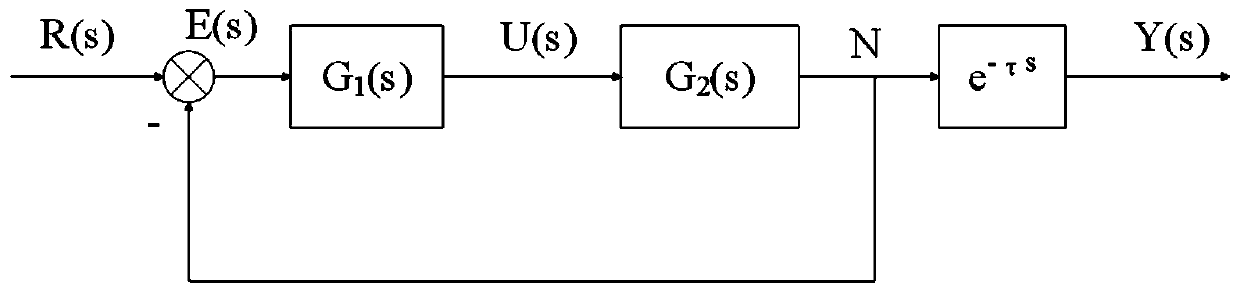

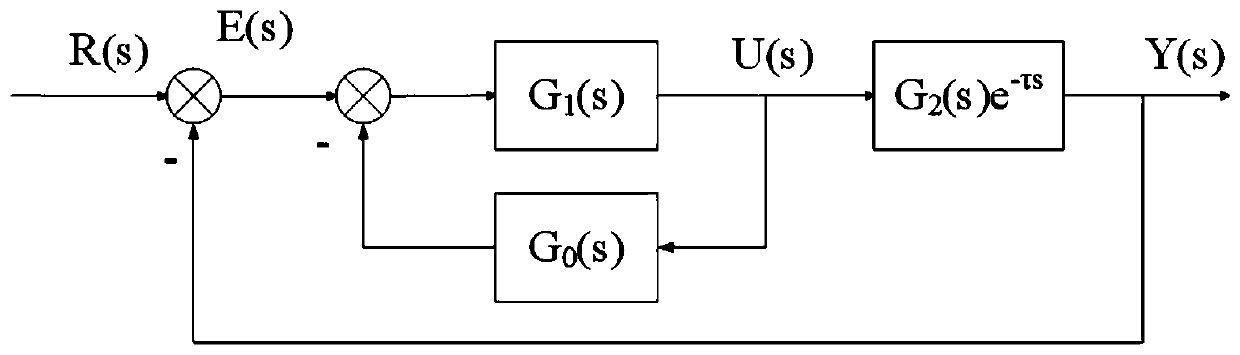

Air conditioner temperature control system based on pole assignment and control method thereof

InactiveCN111381494ASimple methodShort response timeAuxillary controllers with auxillary heating devicesControllers with particular characteristicsTemperature controlControl system

The invention relates to an air conditioner temperature control system based on pole assignment and a control method thereof. The system comprises a PID controller and a controlled object which are sequentially connected between the input end of the system and the output end of the system, a Smith estimation compensator which is connected between the output end and the input end of the PID controller, and a feed-forward controller which is connected between the output end of the PID controller and the input end of the system. The parameters of the PID controller are determined based on the poles of a transfer function of a closed-loop system. According to the method, the parameters of the PID controller are determined based on the poles of the transfer function of the closed-loop system, the method is simple, and the system can have good dynamic and static performance; and meanwhile, the Smith estimation compensator and the feed-forward controller are added, so that the time lag influence in the control system is reduced, the response time is shorter, and the control quality is improved.

Owner:SUZHOU UNIV OF SCI & TECH

Working machine feed axis control method and feed axis control device

ActiveUS9785139B2The control system is stableEasy to FeedbackSpecial data processing applicationsNumerical controlCouplingEngineering

A working machine feed axis control device: disposes a velocity feedback loop and forms a cascade coupling on the inner side of a location feedback loop; comprises a velocity gain setting apparatus (30) which multiplies the output of the velocity feedback look by a first gain (kv), and a location gain setting apparatus (31) which multiplies the output of the location feedback loop by a second gain (kp); subtracts the output of the velocity gain setting apparatus (30) and the output of the location gain setting apparatus (31) from a torque instruction (τ); and outputs the remaining torque instruction (τ) to a subject to be controlled (27).

Owner:MAKINO MILLING MASCH CO LTD

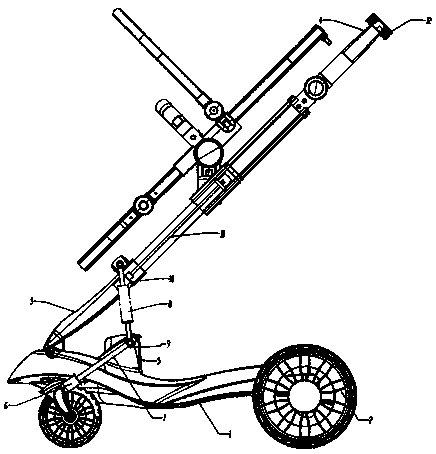

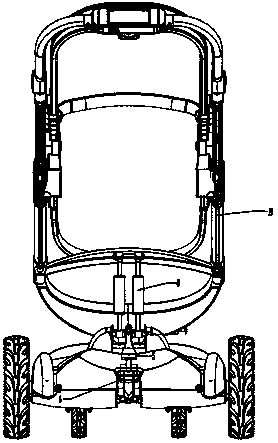

Baby stroller

PendingCN107618559AThe control system is stableImprove stabilityCarriage/perambulator with multiple axesControl systemEngineering

An embodiment of theinvention discloses a baby stroller, which includes a stroller floor, wheels disposed under the vehicle floor, and a strollerframe disposed above the stroller floor, wherein the stroller frame is disposed obliquely above the stroller floor, one end, close to the ground, of the stroller frame is connected with the front end of the stroller floor in hinge mode, the middle of thestroller frame is in a foldable connection with the stroller floor through a telescopic part, the uppermostend of the strollerframe is a handle part, the handle part is provided with a control device,and the control deviceis connected with the telescopic part. The baby strolleris foldable by an electric operation way, the stability of the product is improved, and shock absorbing parts adopted bythe baby stroller make the product more secure and stable. The use performance of the product is also greatly improved. The baby stroller can be operated through a button. A control system adopted by the product expands functions of the baby stroller.

Owner:王庆太

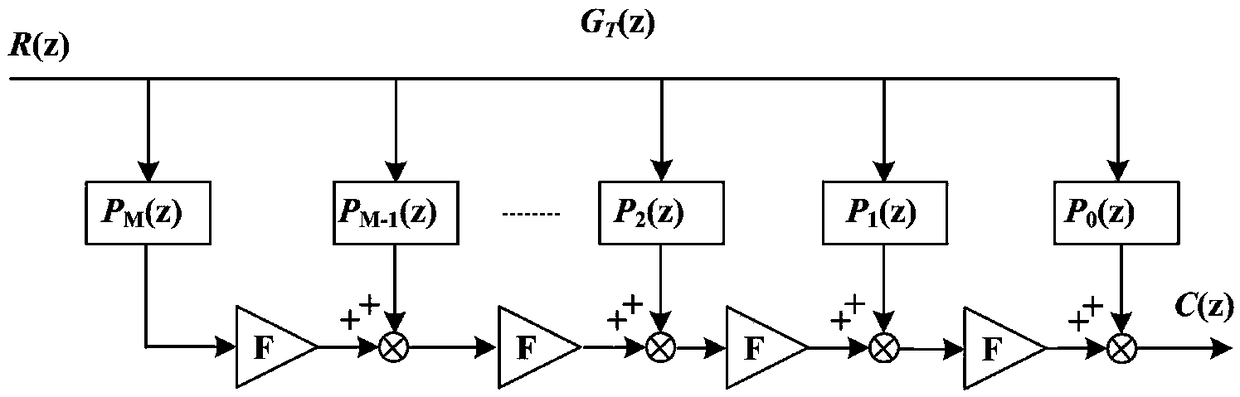

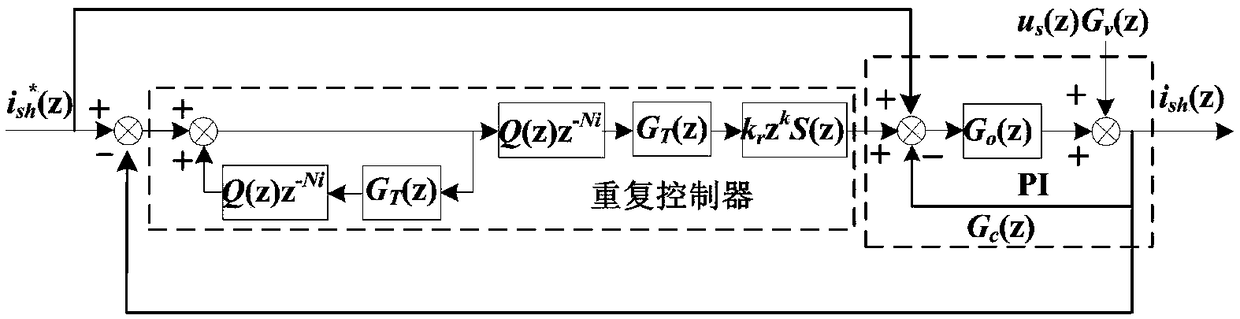

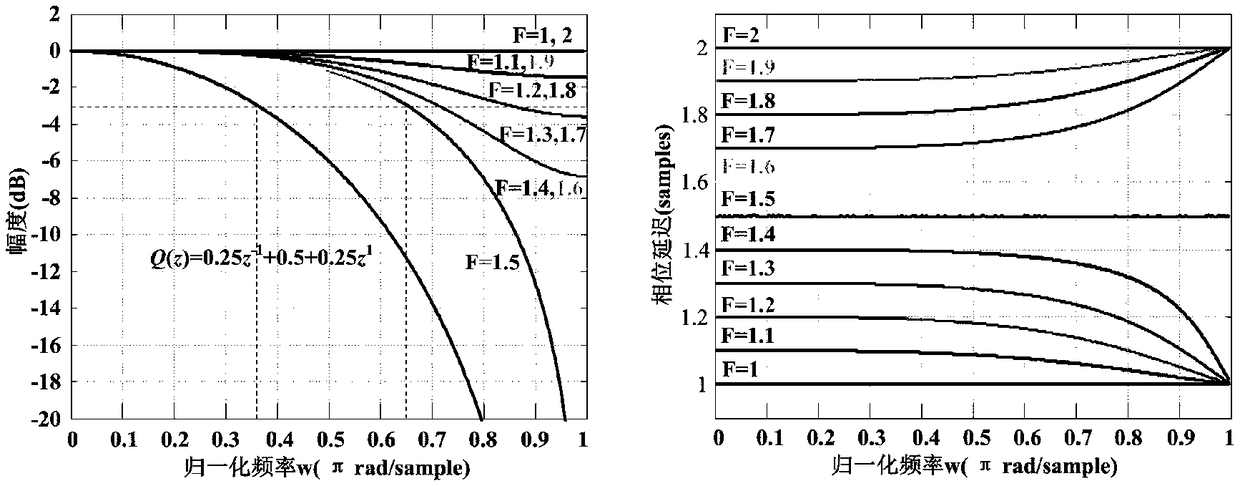

Repetitive control fractional delay filter design method based on Taylor series expansion

InactiveCN108631315AEffective online tuning capabilityThe control system is stableHarmonic reduction arrangementAc network to reduce harmonics/ripplesSelf adaptiveSeries expansion

Provided is a repetitive control fractional delay filter design method based on Taylor series expansion, belonging to the field of fractional delay filters, and the Taylor series expansion converts the design problem of the fractional delay filter into a differentiator sub-filter design, the structure provides the effective on-line tuning capability, that is, when the delay parameters change, andthe fractional delay filter can easily generate any required fractional delay without redesign of the filter. The method is applied to a repeated controller, and the fractional delay filter structureis improved, the harmonic compensation under the condition of the variable frequency reference signal is realized, and compared with the FORC, the repeated controller based on the Taylor series expansion only has one delay parameter to be calculated and updated in real time, so that the control system is stable, and the harmonic frequency self-adaptive tracking can be realized through the combination with the design method of an optimal fractional delay filter, and an ideal harmonic compensation effect is achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

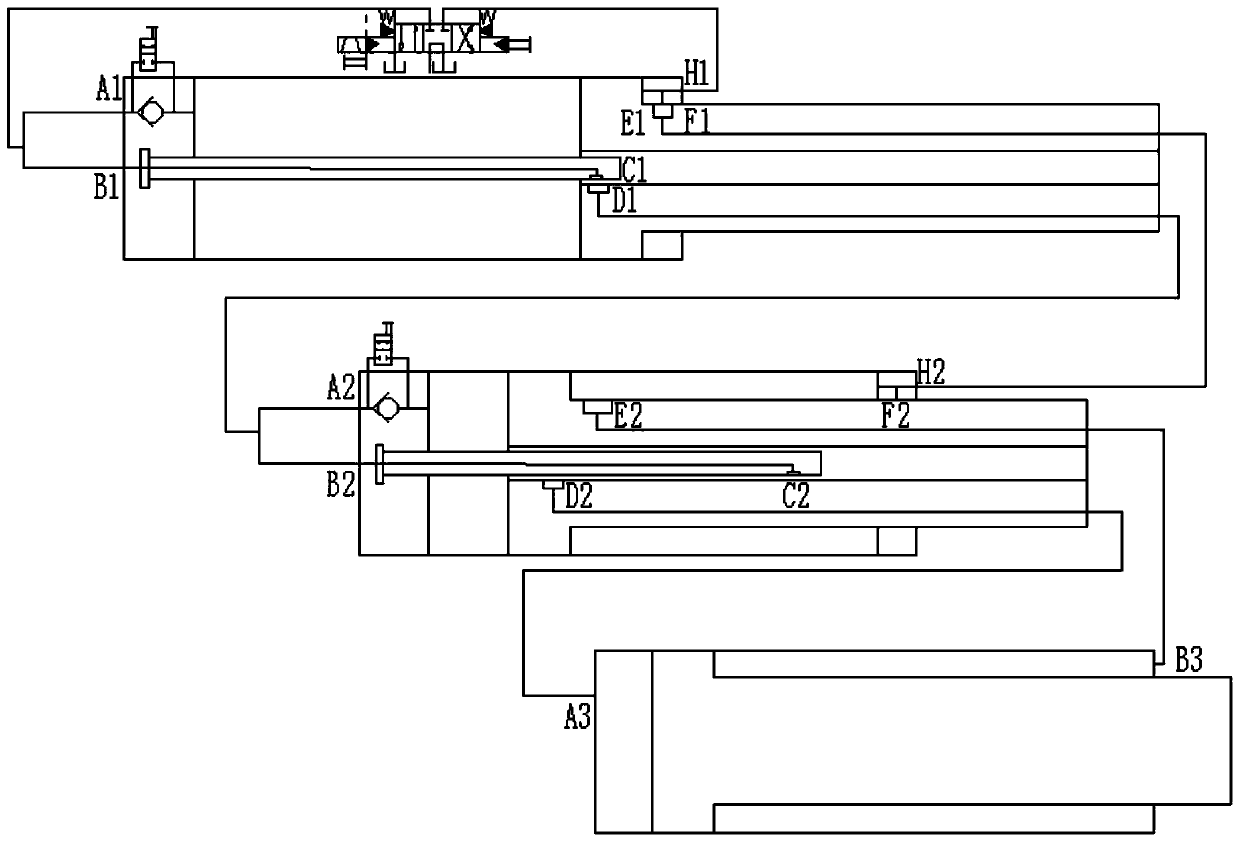

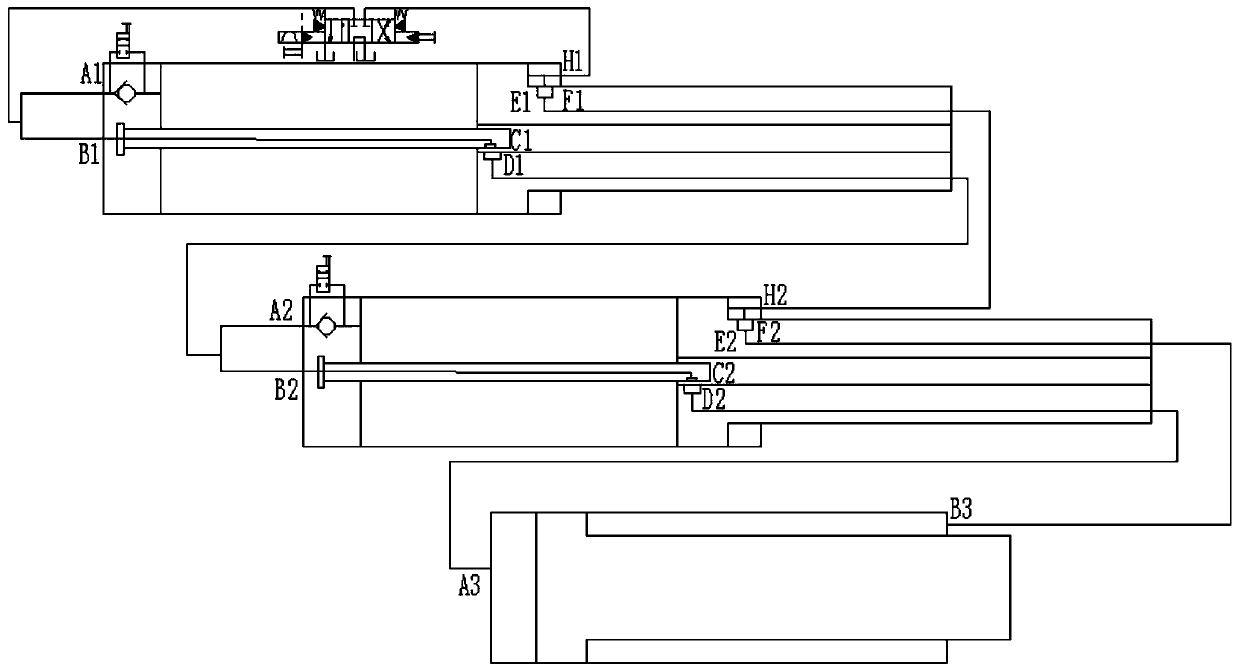

Folding jib type lorry-mounted crane multi-cylinder sequential telescopic hydraulic system

PendingCN111442006AThe control system is stableReduce system pressureServomotor componentsServomotorsEngineeringCylinder block

The invention discloses a folding jib type lorry-mounted crane multi-cylinder sequential telescopic hydraulic system, and relates to the field of engineering, in particular to the folding jib type lorry-mounted crane multi-cylinder sequential telescopic hydraulic system. The folding jib type lorry-mounted crane multi-cylinder sequential telescopic hydraulic system which is compact in structure andstable is proposed. The system involves a first hydraulic cylinder, a first central pipe, a primary two-position two-way reversing valve, a first one-way valve, a second hydraulic cylinder and a three-position four-way reversing valve, wherein one end of the first central pipe is fixedly connected with the bottom of a cylinder body of the first hydraulic cylinder, the other end of the first central pipe extends into a central hole I of a first piston rod of the first hydraulic cylinder and is connected with the first piston rod in a sliding seal mode, and the first central pipe and another first central pipe are hollow pipe bodies with one ends closed. The system has the characteristics of being compact in structure, stable and the like.

Owner:江苏宏昌天马物流装备有限公司

Method for neutralizing industrial wastewater by jump-type automatic feeding

InactiveCN102923834ALow costReach environmental indicatorsWater/sewage treatment by neutralisationIndustrial effluentControl system

The invention discloses a method for neutralizing industrial wastewater by jump-type automatic feeding. The method comprises the following steps of: electronically measuring the PH value, namely, measuring the PH value according to hydrogen ion content and hydroxyl ion content; performing acid-base neutralization titration on the wastewater to be treated periodically to determine jump points; recording the jump points and a jump range of the PH value; deducing the relationship between the feeding amount and the wastewater flow; and feeding back the feeding amount which serves as a preset value of flow control to an automatic feeding control system. The method has the advantages that cost of materials for treating the wastewater is saved; the treated wastewater can reach an environment standard; the control system is stable; the normal production can be guaranteed; and an aim of environment protection is fulfilled.

Owner:ANGANG STEEL CO LTD

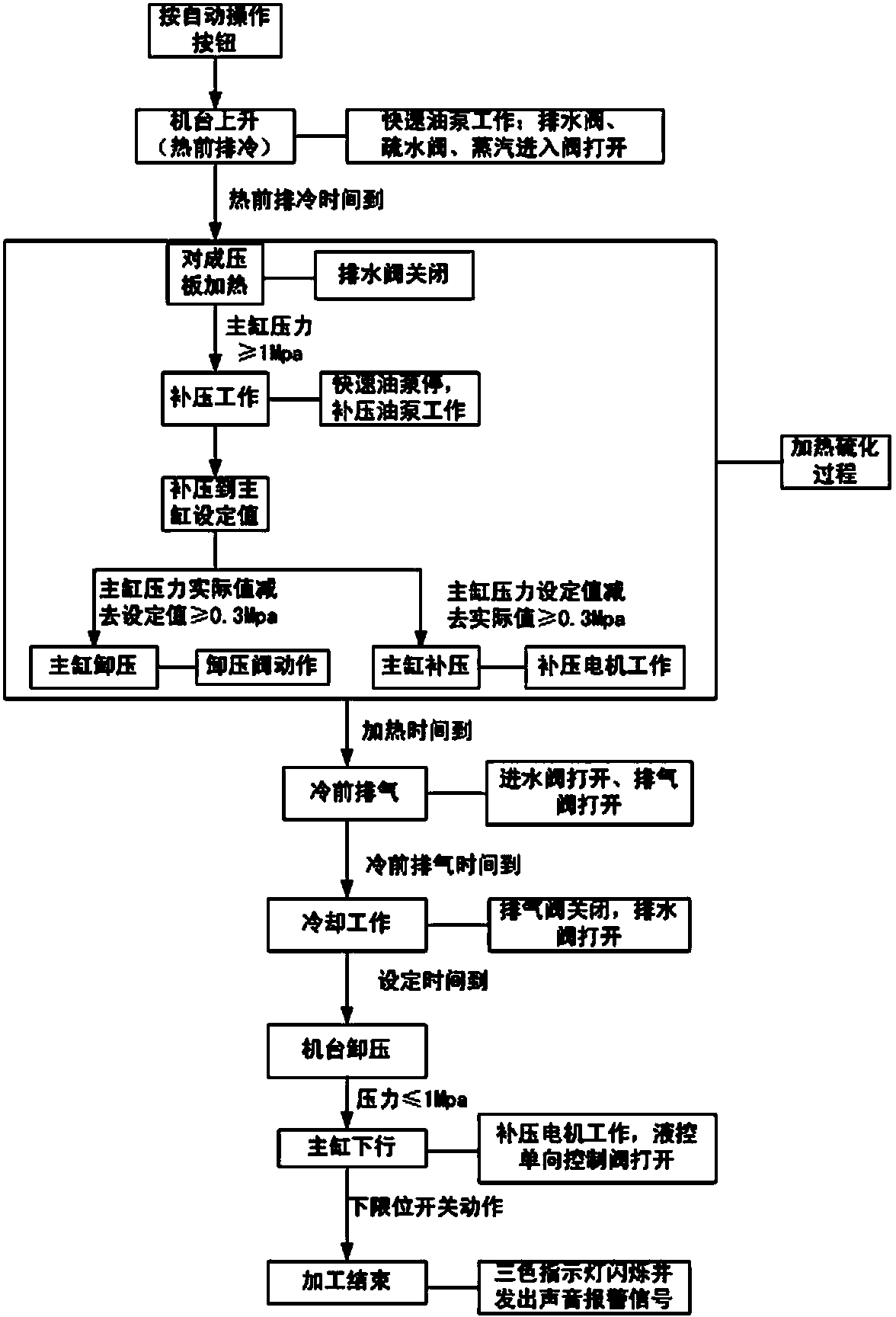

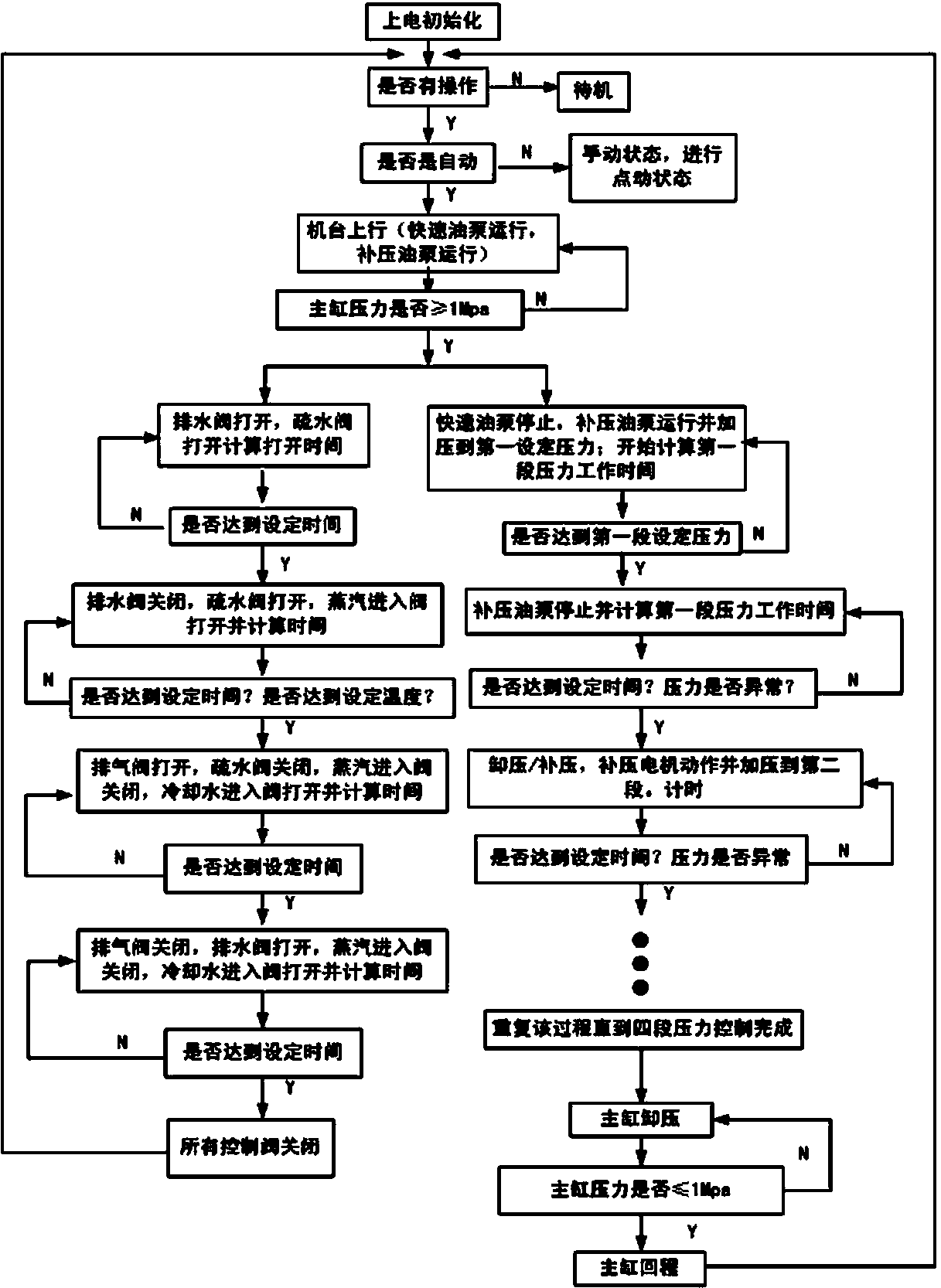

PLC (Programmable Logic Controller) control system of plastic floor vulcanizing machine and control method thereof

ActiveCN103737771AAvoid WeldingThe control system is stableProgramme control in sequence/logic controllersTemperature controlProgrammable logic controller

The invention discloses a PLC (Programmable Logic Controller) control system of a plastic floor vulcanizing machine and a control method thereof. The PLC control system of the plastic floor vulcanizing machine comprises a fuser, a touch screen, a PLC, a pressure sensor, an A / D (Analogue to Digital) conversion module, a control relay, an alternating current contactor, a thermal overload relay, a temperature controller, a transistor drive panel and a switch power supply. Original relay control is replaced by the PLC, the control method is disclosed, and the purposes of stabilizing the control system and preventing the contactor from being subjected to fusion welding are realized.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

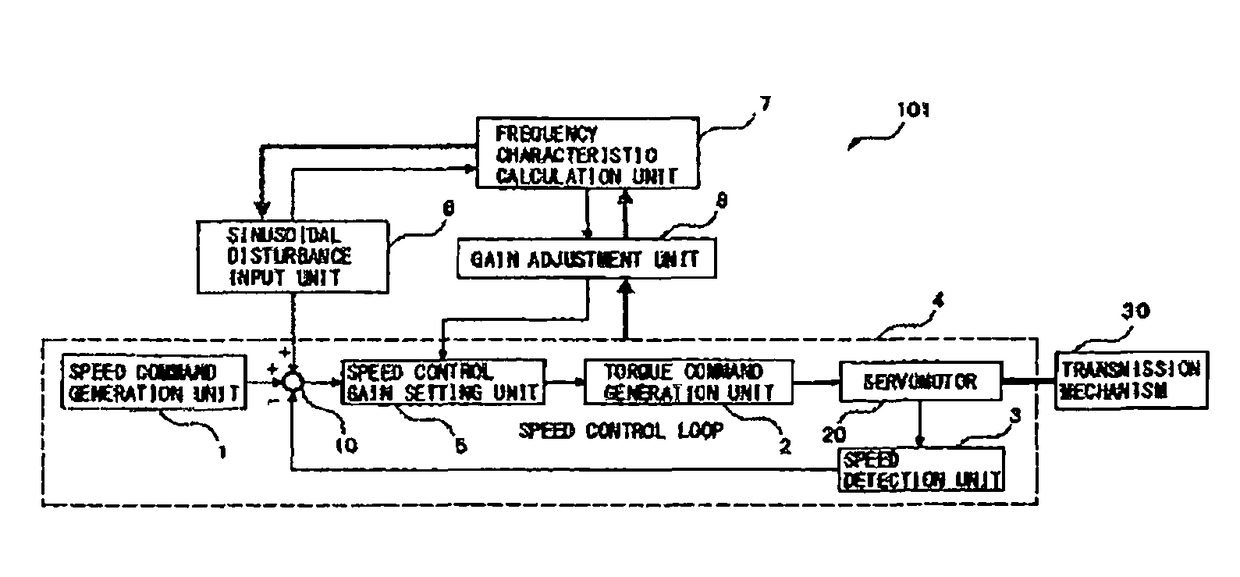

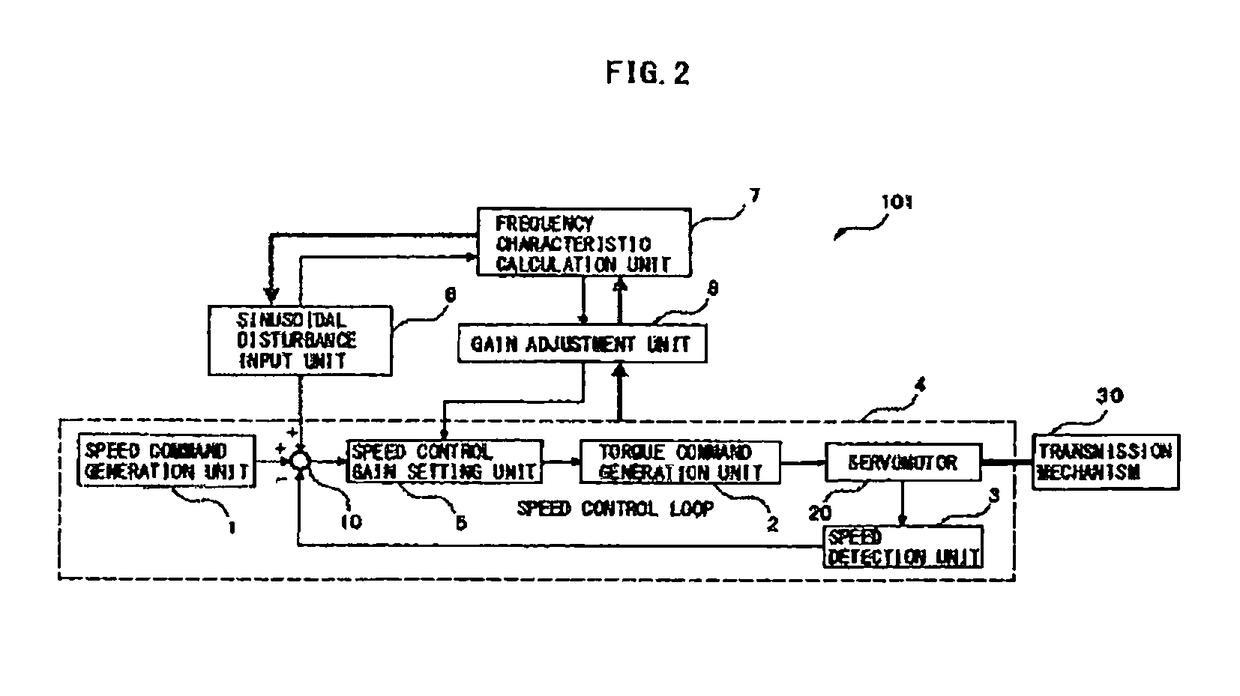

Servo control device having function of automatically adjusting control system with autonomous stabilization

ActiveUS10108152B2The control system is stableProgramme controlElement comparisonTemporary StoppingControl system

A servo control device according to the present invention includes a speed command generation unit, a torque command generation unit, a speed detection unit, a speed control loop, a speed control gain setting unit for setting a speed control gain for the speed control loop, a sinusoidal disturbance input unit for performing a sinusoidal sweep on the speed control loop, a frequency characteristic calculation unit, and a gain adjustment unit. When the speed control loop has fallen into an oscillation state and has become unstable owing to the increased speed control gain, the speed control gain is reduced and the sinusoidal sweep is temporarily stopped. After the speed control loop is stabilized using the speed control gain which is lower than in the unstable state, the sinusoidal sweep is restarted.

Owner:FANUC LTD

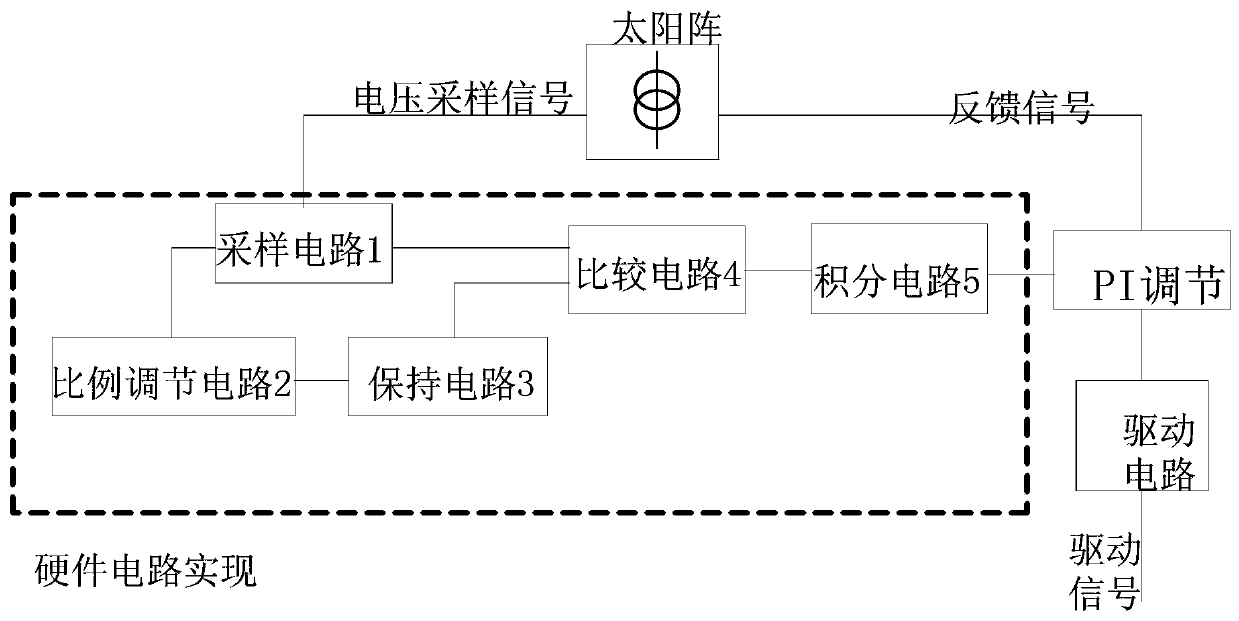

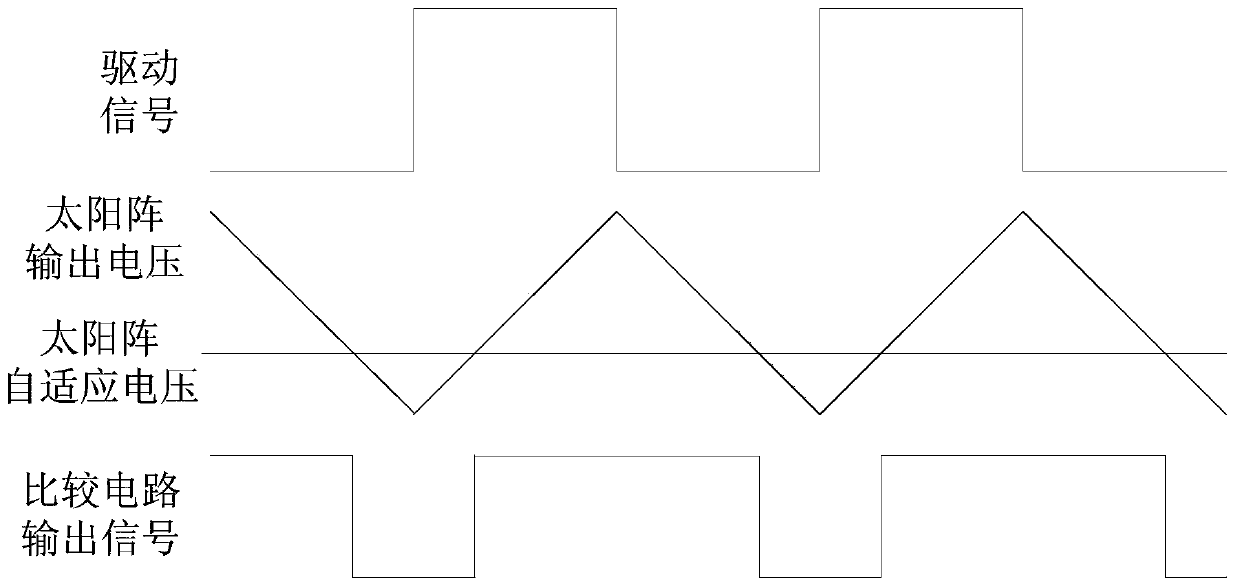

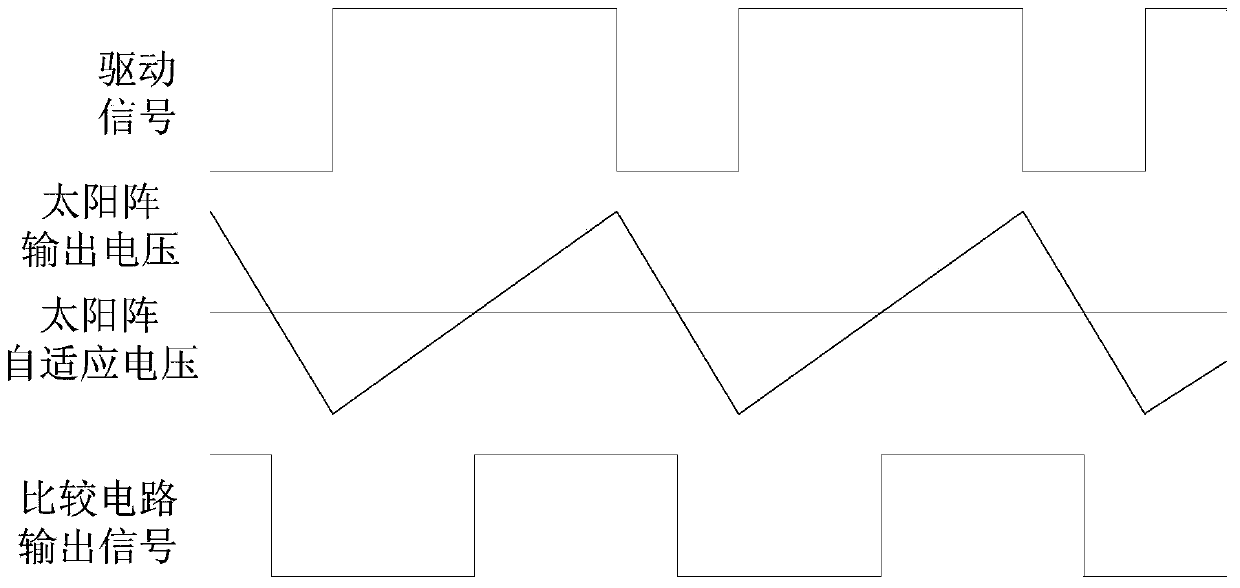

Maximum power tracking system and method based on self-adaptive voltage

ActiveCN110275565ASimple structureThe control system is stablePhotovoltaic energy generationElectric variable regulationSatelliteSelf adaptive

The invention discloses a maximum power tracking system and method based on a self-adaptive voltage. The system comprises a sampling circuit, a proportion adjusting circuit, a holding circuit, a comparison circuit, an integrating circuit, a PI adjusting circuit and a driving circuit. The sampling circuit obtains a solar array real-time voltage signal; the proportion adjusting circuit obtains a voltage-dividing signal of the solar array real-time voltage; the holding circuit obtains a self-adaptive solar array output voltage; the comparison circuit is used for comparing the solar array real-time voltage signal with the self-adaptive output voltage to obtain a solar array voltage control signal; and the integrating circuit is used for integrating the control signal obtained by the comparison circuit to obtain the reference of the control system. The maximum power tracking method provided by the invention is simple in structure and stable in control system, and provides a mode of effectively improving the output power of the solar cell, reducing the area of the solar array and reducing the weight of the power supply for a satellite powered by the solar array.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com