Patents

Literature

61results about How to "Realize infinitely variable speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

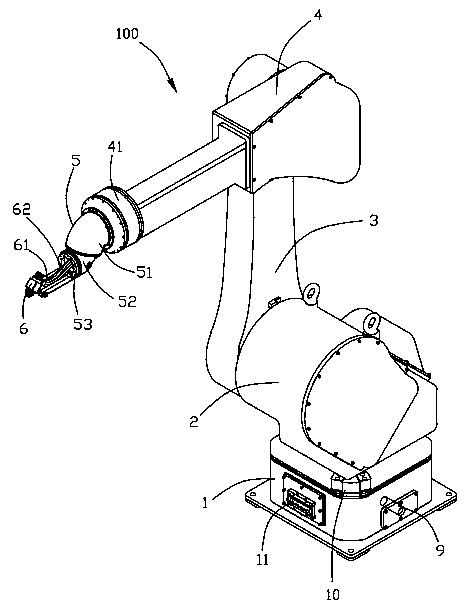

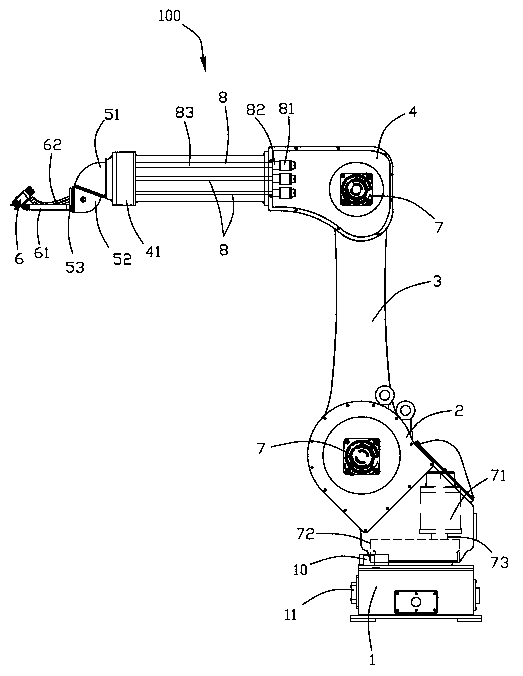

Six-freedom-degree spray coating robot

InactiveCN103538053AHigh transmission precisionImprove precision controlProgramme-controlled manipulatorJointsDrive shaftSpray coating

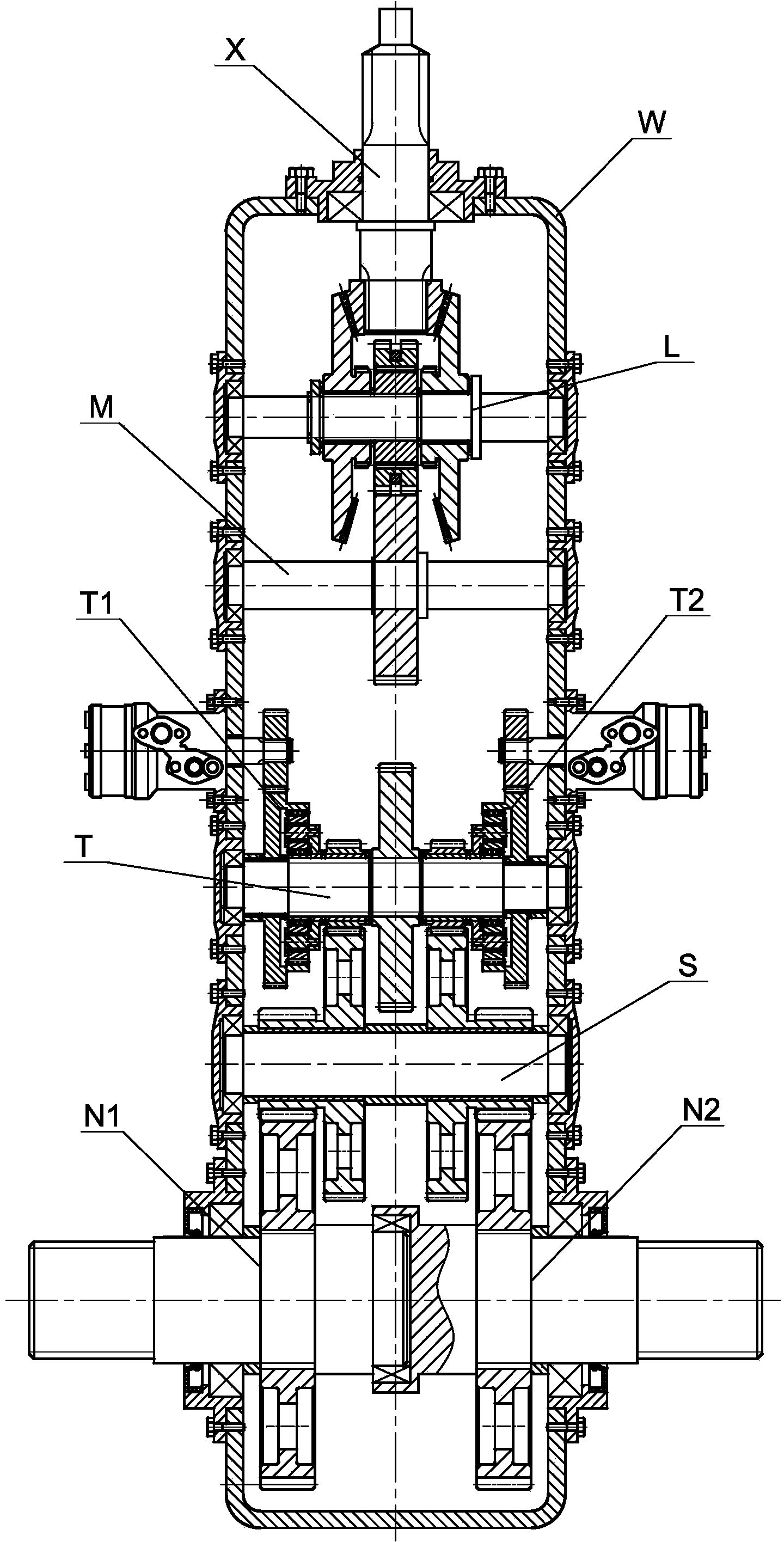

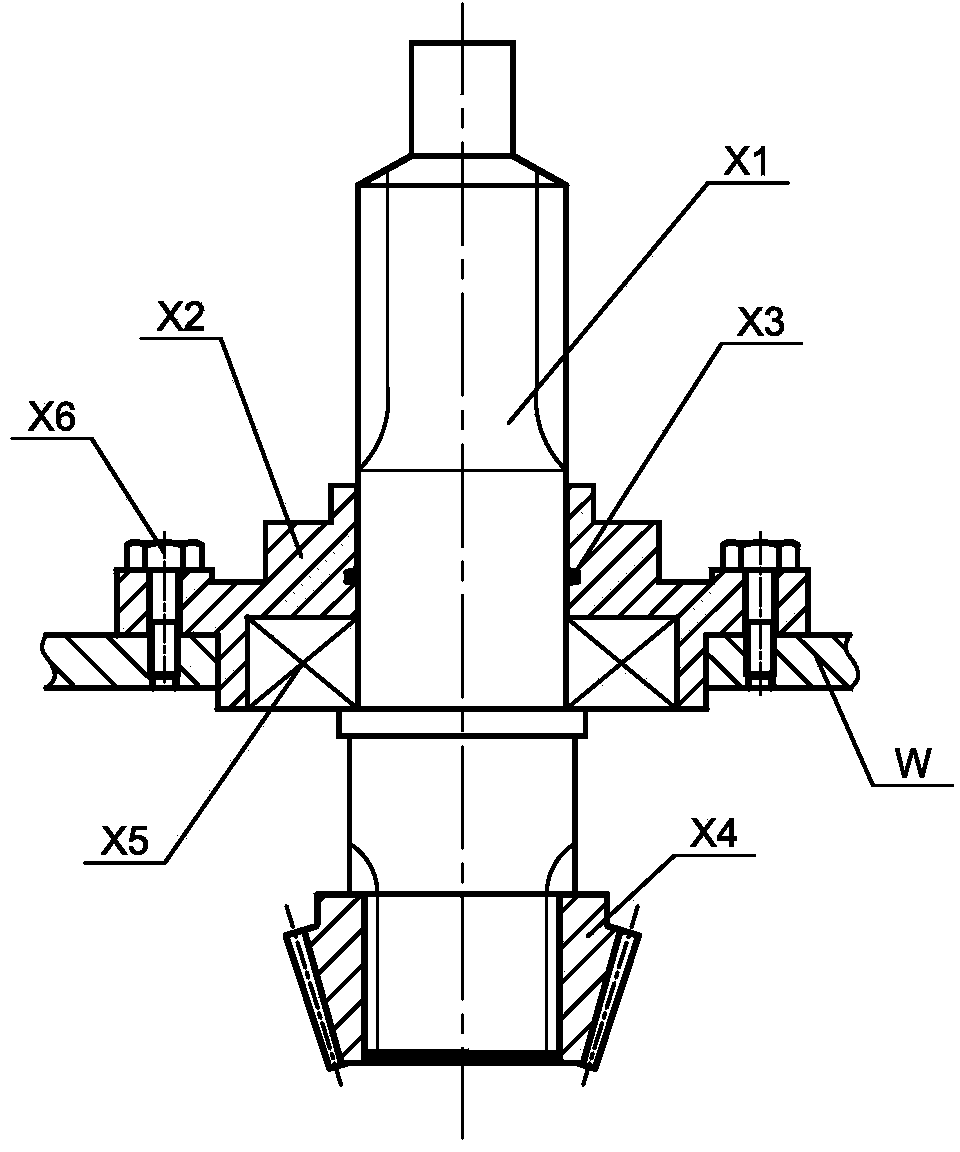

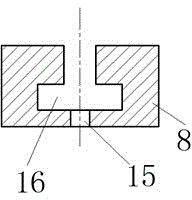

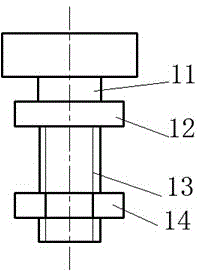

The invention provides a six-freedom-degree spray coating robot which comprises a base, a waist joint, a big arm joint, a small arm joint, a three-freedom-degree obliquely crossed wrist, a spray gun support, flanges, bearings, a plurality of first drive mechanisms and second drive mechanisms, wherein the waist joint is movably fixed to the base, the big arm joint is movably fixed to the waist joint, the small arm joint is movably fixed to the big arm joint, the three-freedom-degree obliquely crossed base is movably fixed to the small arm joint, the spray gun support is connected to the tail end of the three-freedom-degree obliquely crossed wrist, and the flanges and the bearings are movably connected among all the joints or between the joints and the wrist. The first drive mechanisms are used for driving the waist joint, the big arm joint and the small arm joint to work, and the second drive mechanisms are used for driving the three-freedom-degree obliquely crossed wrist to work. Each first drive mechanism comprises a first servo motor and an RV speed reducer. Each second drive mechanism comprises a second servo motor, a planetary reducer, a hollow transmission shaft and a gear pair, wherein the planetary reducer is connected with the second servo motor, the hollow transmission shaft is connected with the planetary reducer in a matched mode, and the gear pair is arranged in the three-freedom-degree obliquely crossed wrist and connected with the hollow transmission shaft.

Owner:HUAHENG WELDING

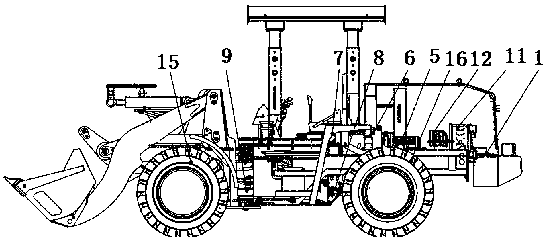

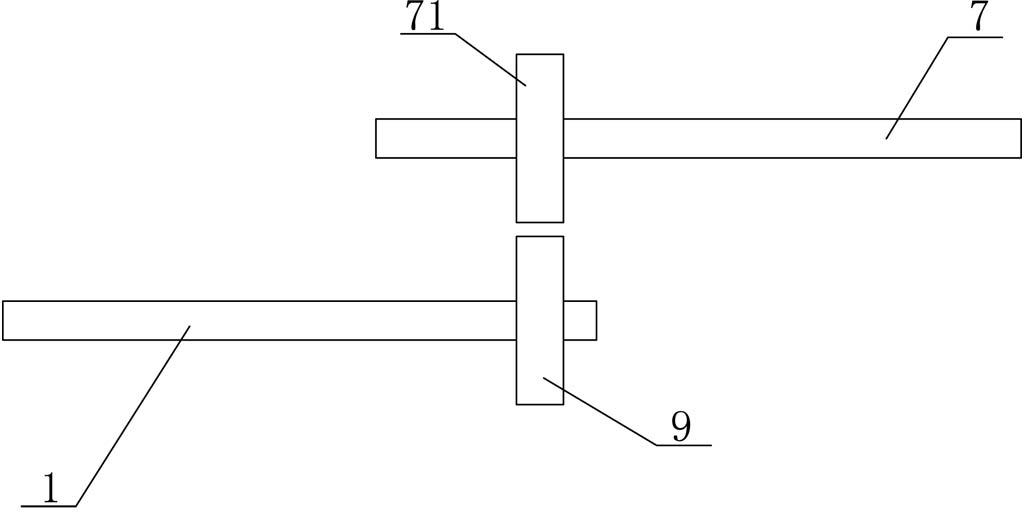

Drive control system for pure electric loader

PendingCN109457744AReduce use costReduce noiseMechanical machines/dredgersHydraulic motorTransfer case

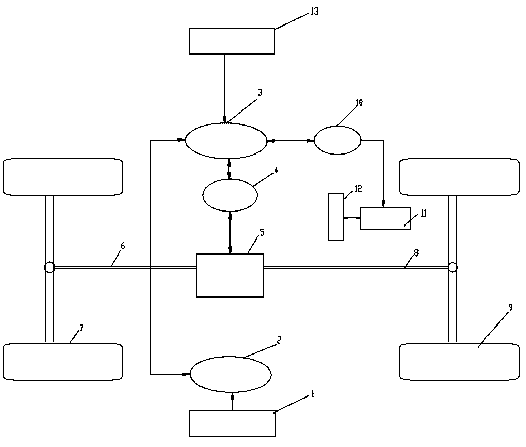

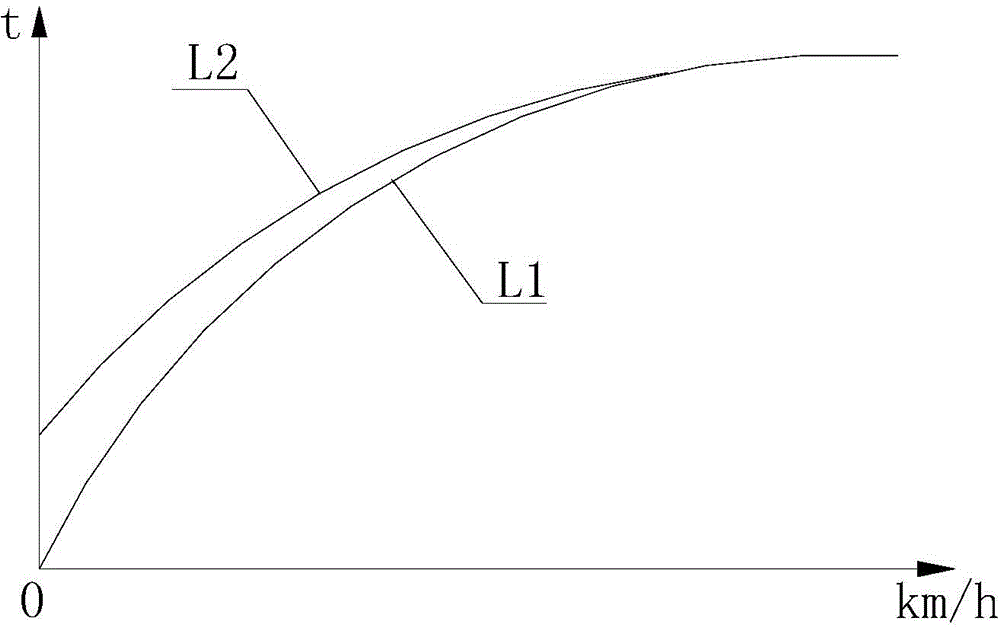

The invention discloses a drive control system for a pure electric loader and belongs to the technical field of shoveling-transferring engineering mechanical vehicles. A traveling system is connectedto the lower side of a machine body. The machine body is provided with a hydraulic system and further provided with a hydraulic motor and a traveling motor. The hydraulic motor is connected with a hydraulic pump. The hydraulic pump supplies power to the hydraulic system. The traveling motor is connected with a traveling system through a transmission system. The transmission system comprises a fully-automatic speed changing box connected with the hydraulic motor. The output end of the fully-automatic speed changing box is connected with a transfer case. The transfer case is connected with the traveling system and supplies power to the traveling system. According to the drive control system, the traveling system is driven by the traveling motor, and the hydraulic system is driven by the hydraulic motor; compared with mechanical transmission adopted in the prior art, the traveling system is high in transmission efficiency, electrodeless speed changing can be achieved, and gear shifting isachieved easily; the power is great; the hydraulic system can provide stable and efficient powerful driving force; the drive control system is great in universality and convenient to maintain; and defects of an existing loader are overcome.

Owner:XCMG CONSTR MACHINERY

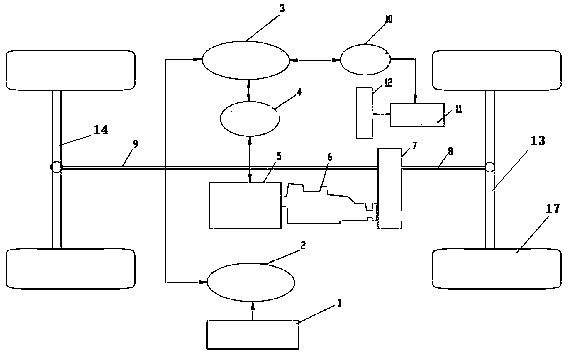

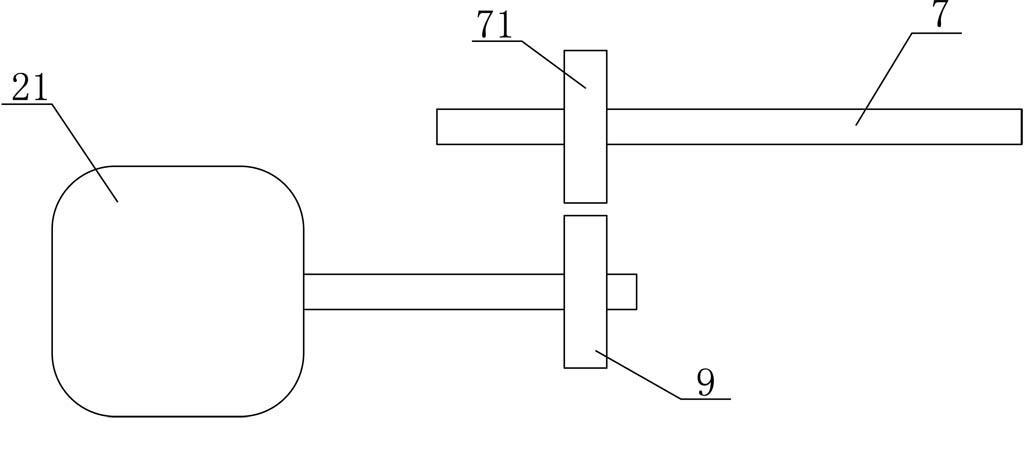

Novel energy-saving electric loader drive control system and control method

PendingCN111236353ARealize infinitely variable speedEasy to shiftSoil-shifting machines/dredgersPower batteryControl system

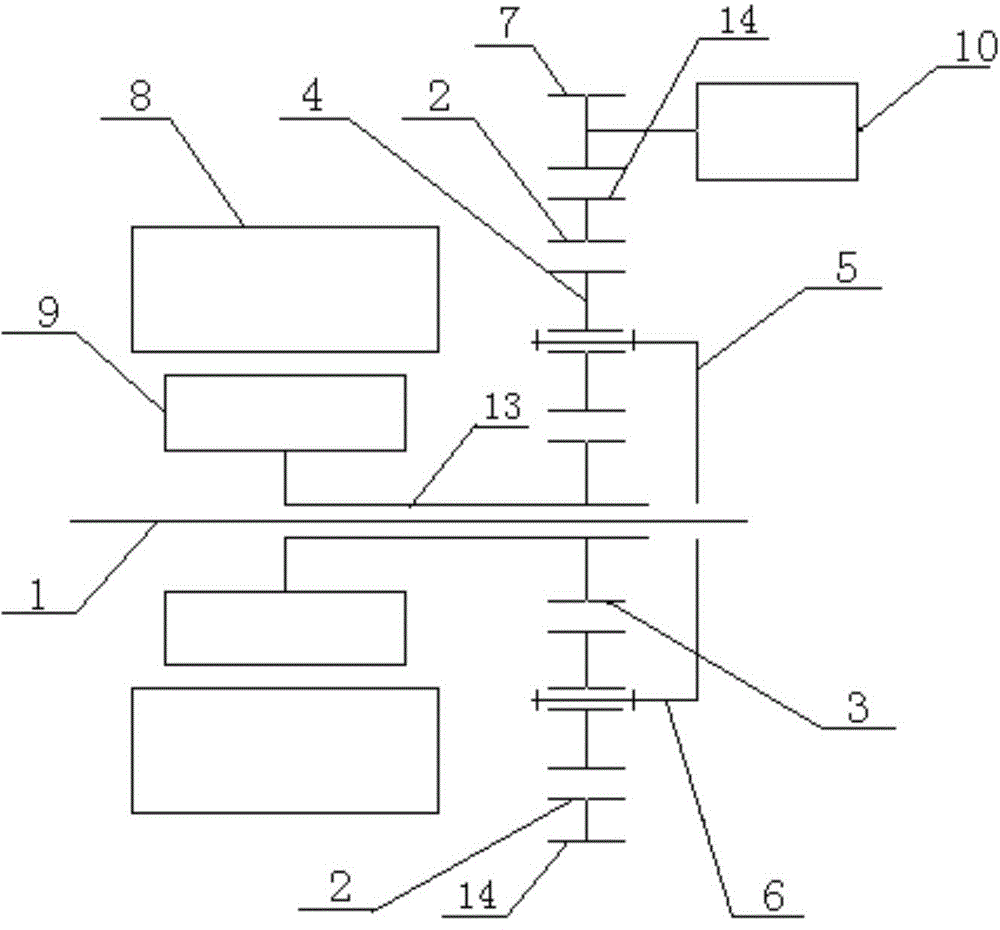

The invention discloses a novel energy-saving electric loader drive control system and control method, and belongs to the technical field of shoveling engineering machinery vehicles. A control handleis connected with a vehicle control unit (VCU); the VCU is electrically connected with a motor controller I, a motor controller II and a power battery controller BMS; the motor controller I is in control connection with a double-output-shaft walking motor, and the double-output-shaft walking motor drives front wheels and rear wheels through a front transmission shaft and a rear transmission shaft;the motor controller II is in control connection with a hydraulic pump control motor, and the hydraulic pump control motor drives a hydraulic pump to provide power for a hydraulic system of a loader;and the power battery controller BMS is in control connection with a power battery pack, and the power battery pack supplies power to the double-output-shaft walking motor and the hydraulic pump control motor. The motor is in a mode of a double-output-shaft structure, the whole machine is easy to arrange, the structure is simple and convenient, the reliability is high, the problems that an existing loader is complex in structure and control are solved, the working efficiency is high, and the good energy-saving effect is achieved.

Owner:XCMG CONSTR MACHINERY

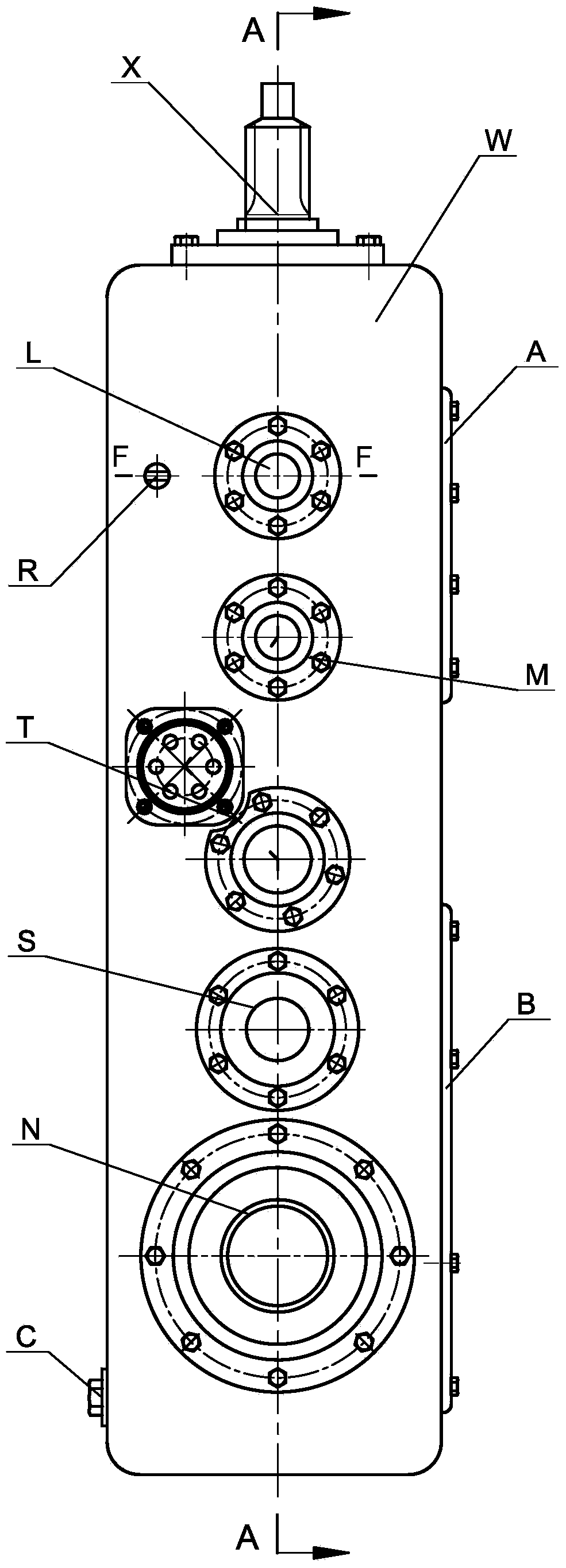

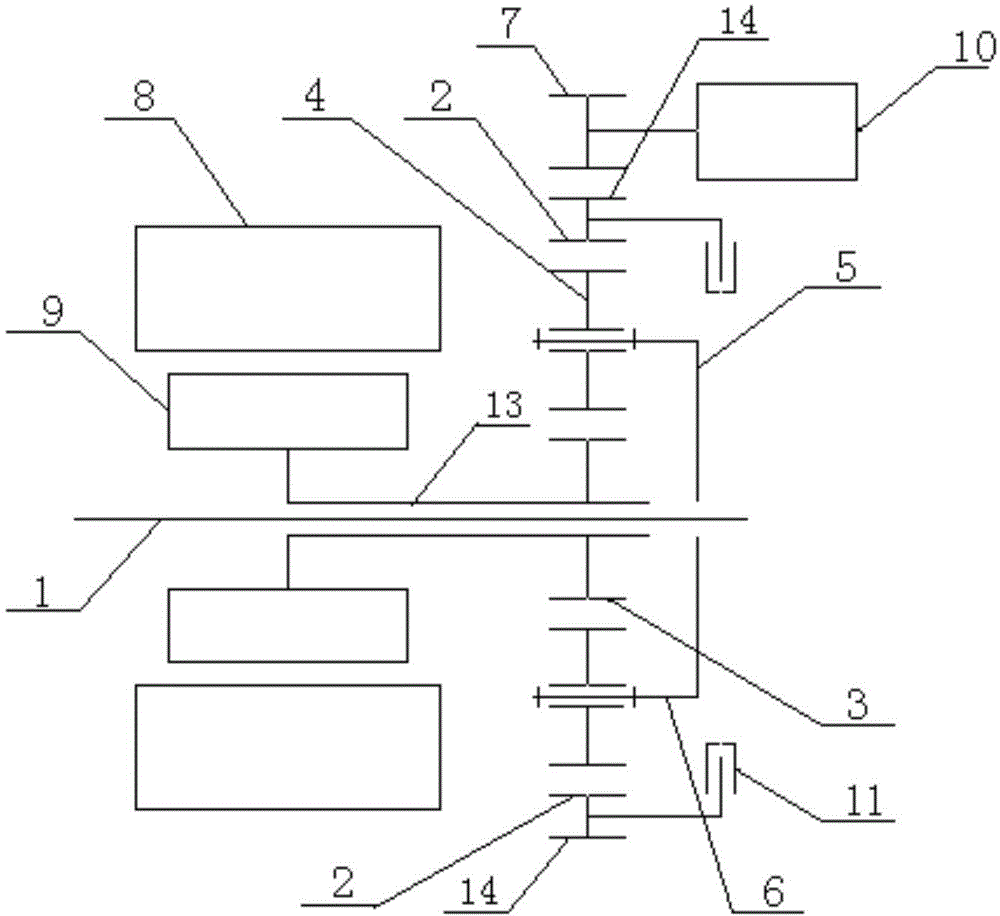

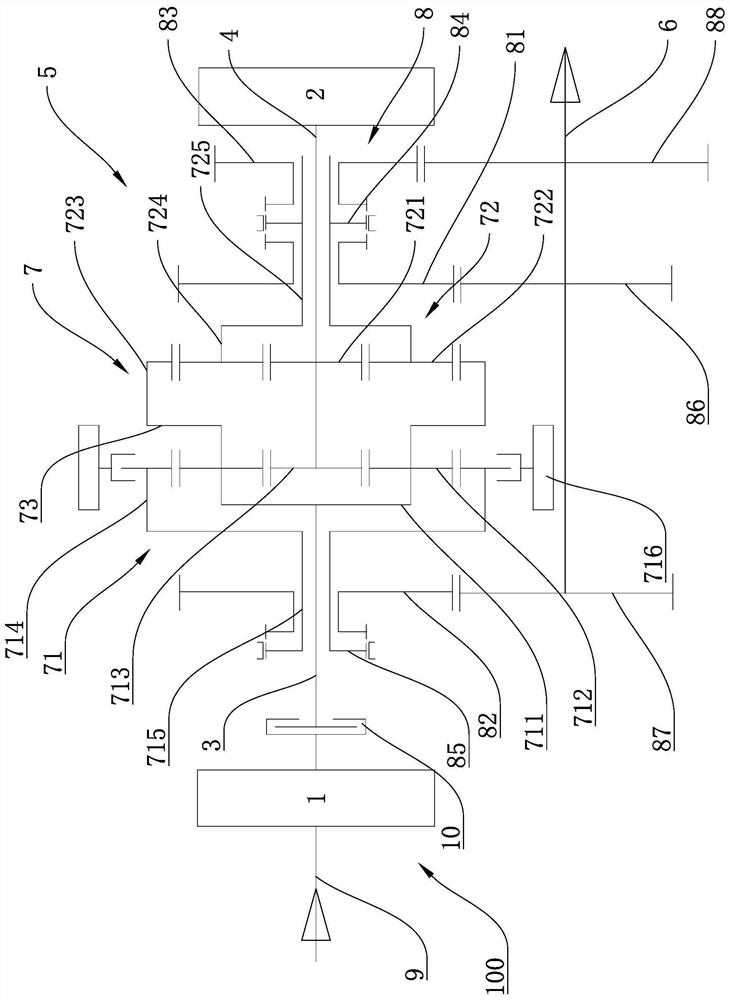

Continuously-variable transmission for mechanical direct-drive hydraulic double-control tracked vehicle

InactiveCN104141748AEasy to operateRealize infinitely variable speedToothed gearingsGearing controlVariatorSelf locking

The invention discloses a continuously-variable transmission for a mechanical direct-drive hydraulic double-control tracked vehicle. According to the continuously variable transmission, a power input portion inputs power to an advance and retreat gear deceleration portion, the advance and retreat gear deceleration portion transmits power to a differential planetary transmission stepless speed change portion through an intermediate power transmission portion, then, the differential planetary transmission stepless speed change portion outputs the power to a drive transition deceleration transmission portion, and finally the power is transmitted to a left side caterpillar band drive portion and a right side caterpillar band drive portion, wherein an advance and retreat gear control portion is used for gear switching of the advance and retreat gear deceleration portion. Double self-locking type hydraulic motors are arranged in the differential planetary transmission stepless speed change portion, so that mechanical direct drive, hydraulic stepless speed regulation and steering control are achieved. When the double self-locking type hydraulic motors are in the same working state, the tracked vehicle achieves mechanical direct drive and hydraulic stepless speed regulation drive; when the double self-locking type hydraulic motors are not in the same working state, rotating speed difference happens between left side caterpillar band output wheels and right side caterpillar band output wheels, hydraulic control steering is achieved, transmission and steering of the tracked vehicle are integrated, operation is easy and convenient to perform, and the tracked vehicle is easy to drive.

Owner:HUNAN AGRICULTURAL UNIV

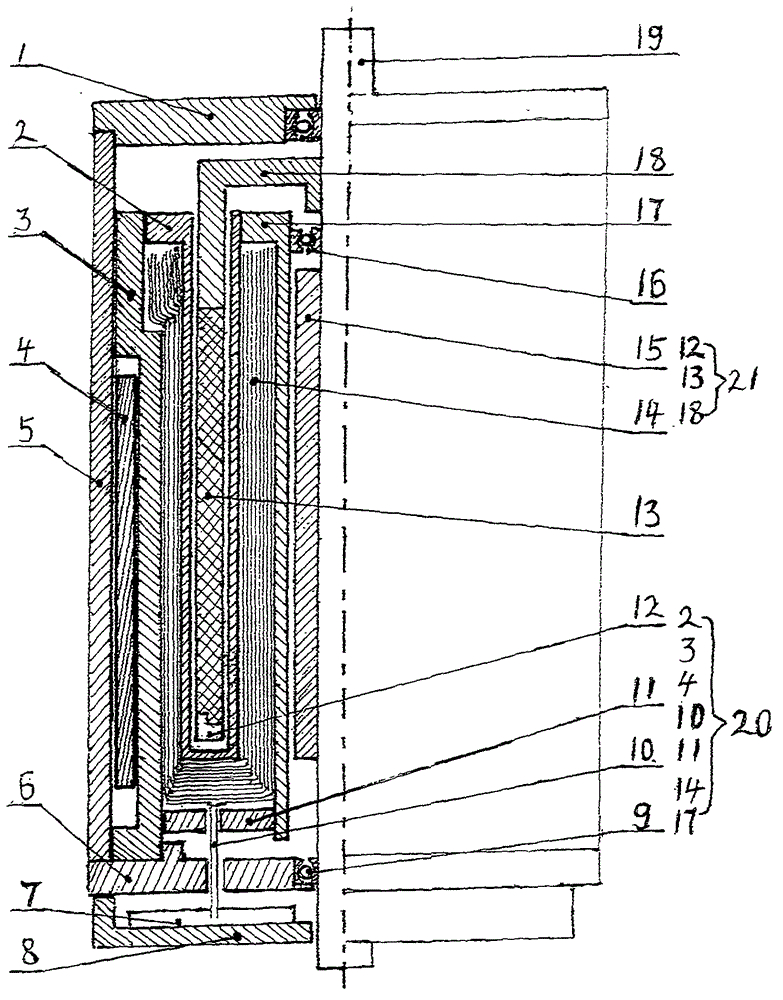

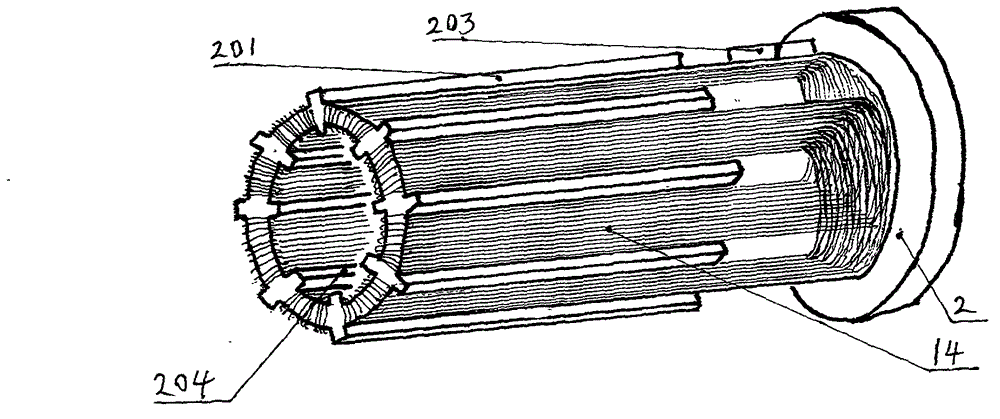

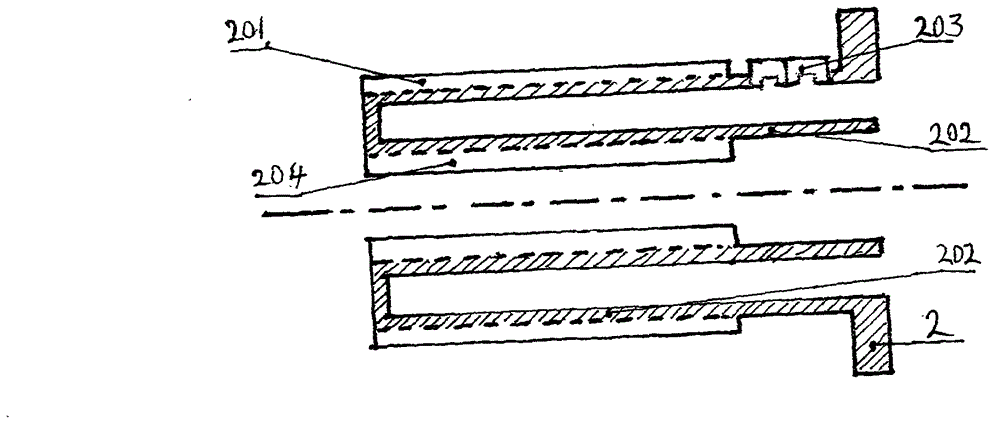

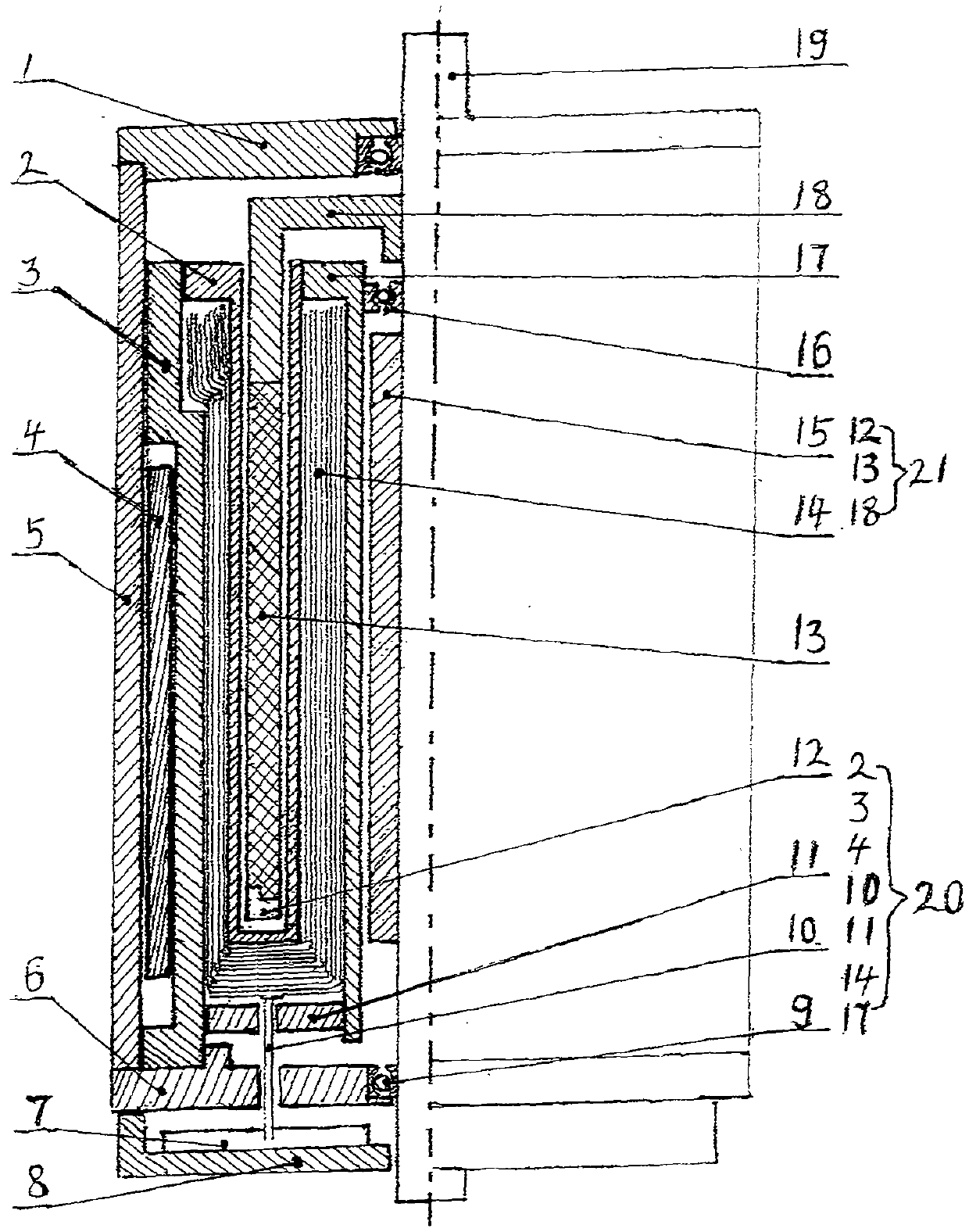

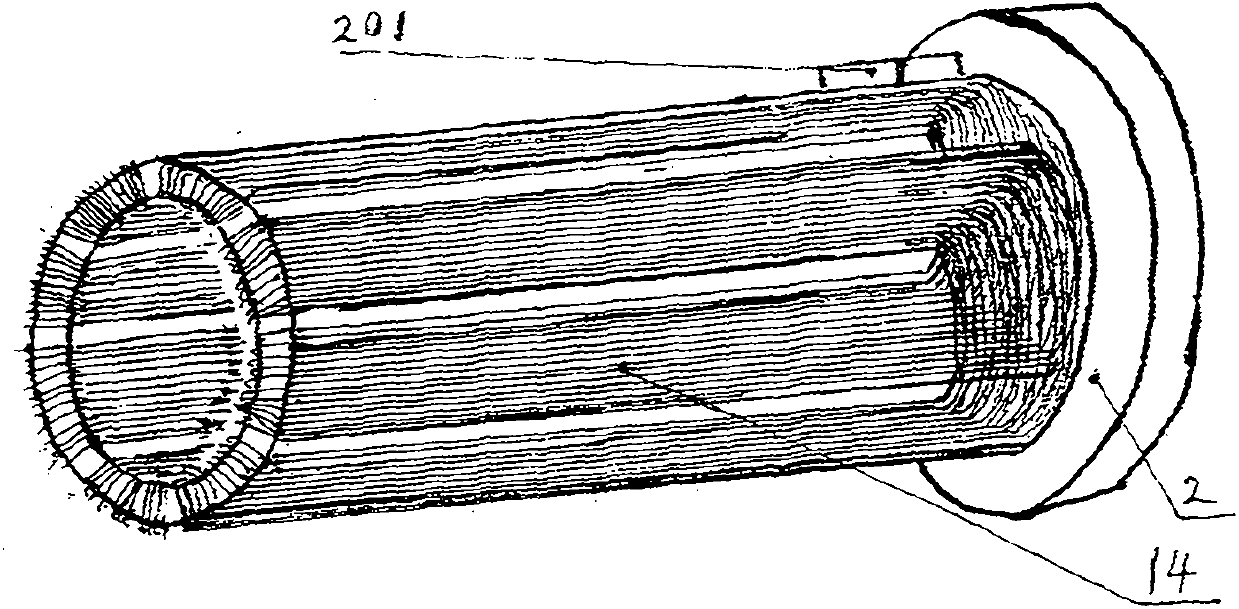

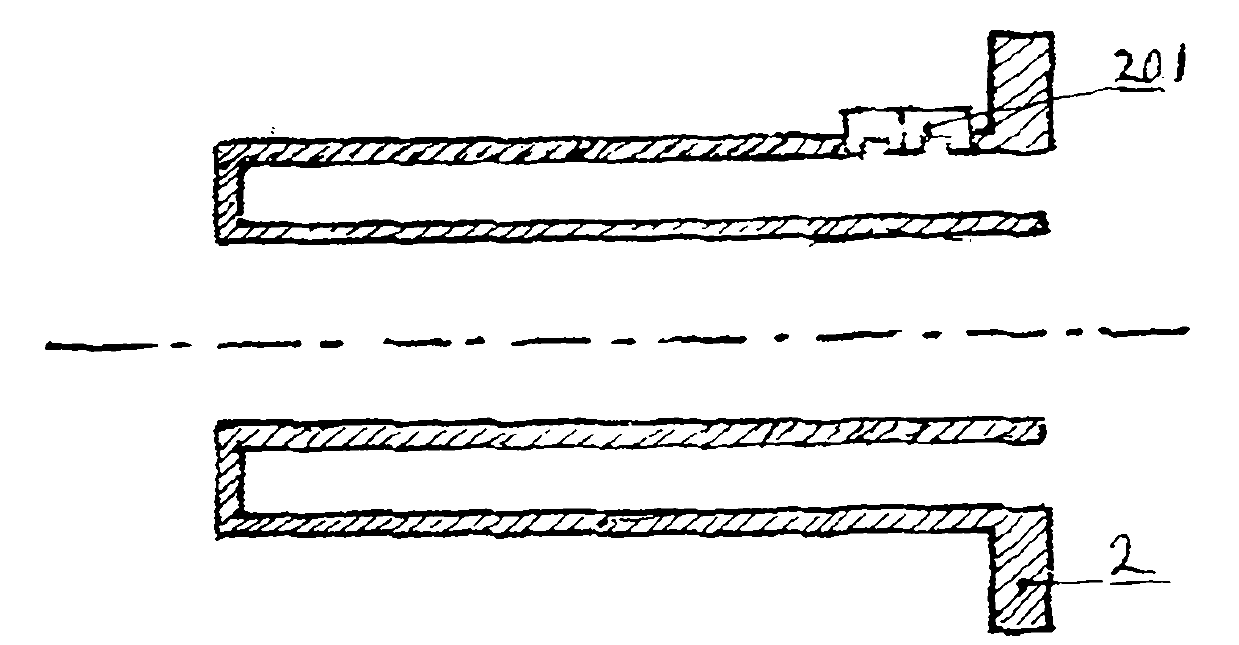

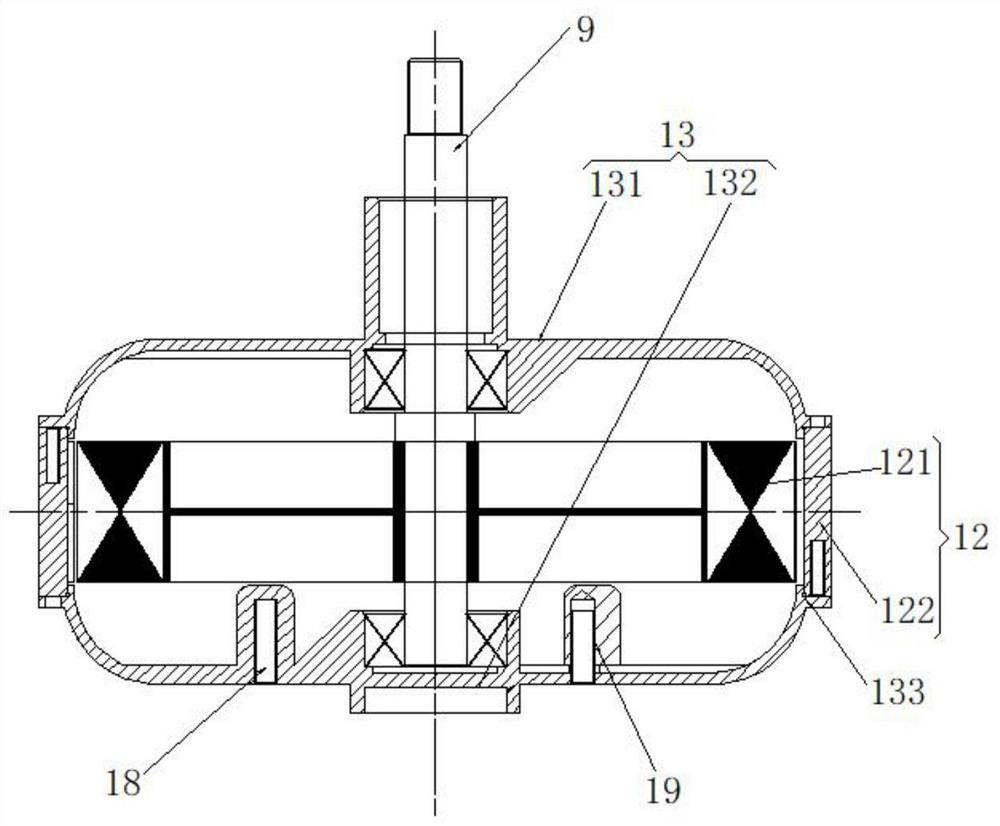

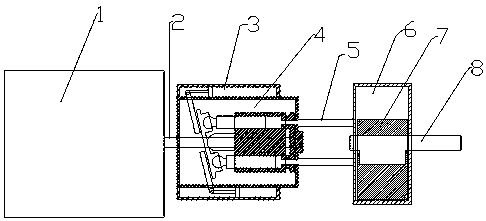

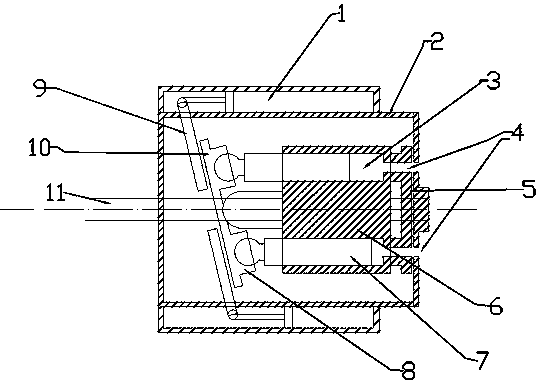

Novel motor

InactiveCN102946181AEnhanced interactionImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMotor efficiency

The invention provides a novel motor which comprise a motor casing, a stator and a cup-shaped rotor. The novel motor is characterized in that the cup-shaped rotor is provided with a magnetized multi-pole permanent magnet which is arranged on the cup-shaped cylinder wall; and the stator is provided with a stator outer sleeve which is arranged in a magnetic conductive cylinder, a coil skeleton is arranged in a stator inner sleeve, a plurality of groups of hollow coils are configured on the coil skeleton, the coils are configured at intervals, that is, the coils are arranged opposite to the inner peripheral surface of the permanent magnet and opposite to the outer peripheral surface of the permanent magnet simultaneously. The novel motor has the advantages that stator and rotor structures of a traditional motor are changed, and interaction of the coils with the permanent magnet is improved greatly by optimizing magnetic field distribution on coil tracks, accordingly, the motor efficiency is improved greatly, the starting current is reduced, and the power consumption is decreased. The stator coils are hollow coils, iron losses are decreased, the motor weight is lightened, the slot effect is removed, and the motor temperature rising is decreased simultaneously.

Owner:王九龙

Stepping type automatic feeding mechanism

Owner:ZHONGSHAN JUCHANG AUTOMATION EQUIP TECH CO LTD

Planetary reduction stepless variable speed coupling box of new energy automobile

InactiveCN104595465AGood transmission effectImprove climbing abilityGearboxesToothed gearingsDrive wheelNew energy

The invention relates to a planetary reduction stepless variable speed coupling box of a new energy automobile. The planetary reduction stepless variable speed coupling box comprises a main drive loop formed by motors, planetary reduction mechanisms and a differential mechanism, wherein the motors are connected with sun wheels of the planetary reduction mechanisms through rotor frames to be used as power input, and planet carriers of the planetary reduction mechanisms are connected with the differential mechanism to be used as power output drive wheels. The planetary reduction stepless variable speed coupling box of the new energy automobile further comprises an auxiliary drive device for driving inner gear rings of the planetary reduction mechanisms to rotate. Compared with the prior art, the main drive loop can carry out gear switching of different speed ratios on a planet gearbox according to the working conditions of the inner gear rings, and therefore the whole gear shifting process is continuous, stable and free of impact force, so that stepless variable speed of the automobile in climbing, heavy-load starting, common-load driving at the moderate speed and light-load driving at high speed can be achieved.

Owner:廉廉机电科技发展(上海)有限公司

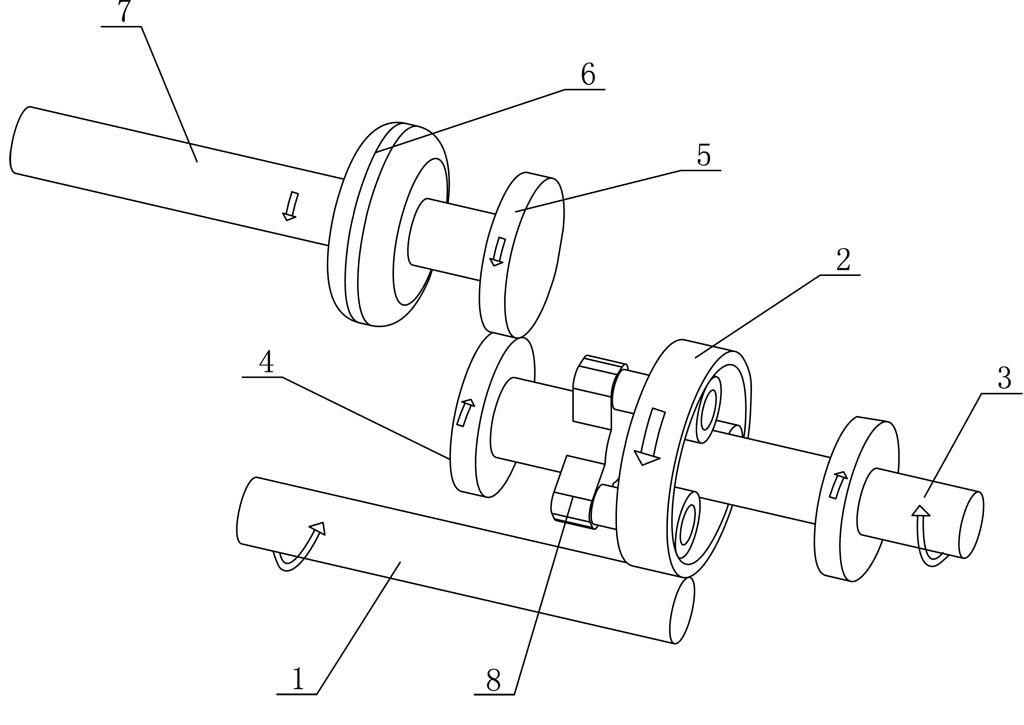

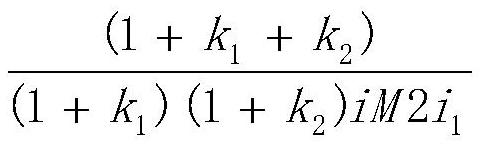

Stepless speed change structure for planetary gears

InactiveCN102537238AChange speed ratioRealize infinitely variable speedToothed gearingsGearing detailsControl powerGear wheel

The invention discloses a stepless speed change structure for planetary gears, which has the advantages of high torque bearing capability, no slipping, simple structure, less parts, low manufacture and maintenance costs, superior long service life and wide speed change range, and can be applied to heavy-duty vehicles, large-scale vehicles and mini-type vehicles. Based on the structural characteristics of the planetary gears, the stepless speed change of power input and output speeds is realized when the revolution ratio between a gear ring and a sun gear is changed by changing the rotational speed of a planetary gear rack. The stepless speed change structure comprises the gear ring, the planetary gear rack and the sun gear, wherein the gear ring is connected with the power input shaft of a vehicle engine; the sun gear is connected with the power output shaft; the planetary gears are mounted on the planetary gear rack and are connected with a power adjusting control device capable of changing the speeds of the planetary gears; and the power adjusting control device comprises a control power input shaft and a control gear arranged at one end of the control power input shaft.

Owner:宏万兵

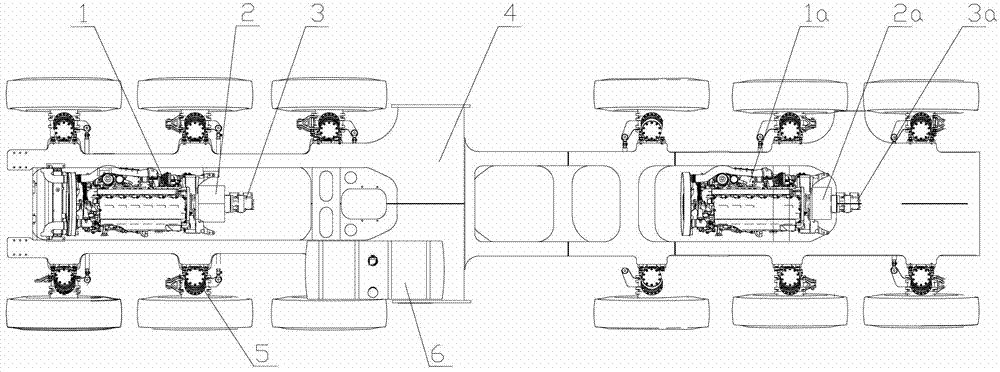

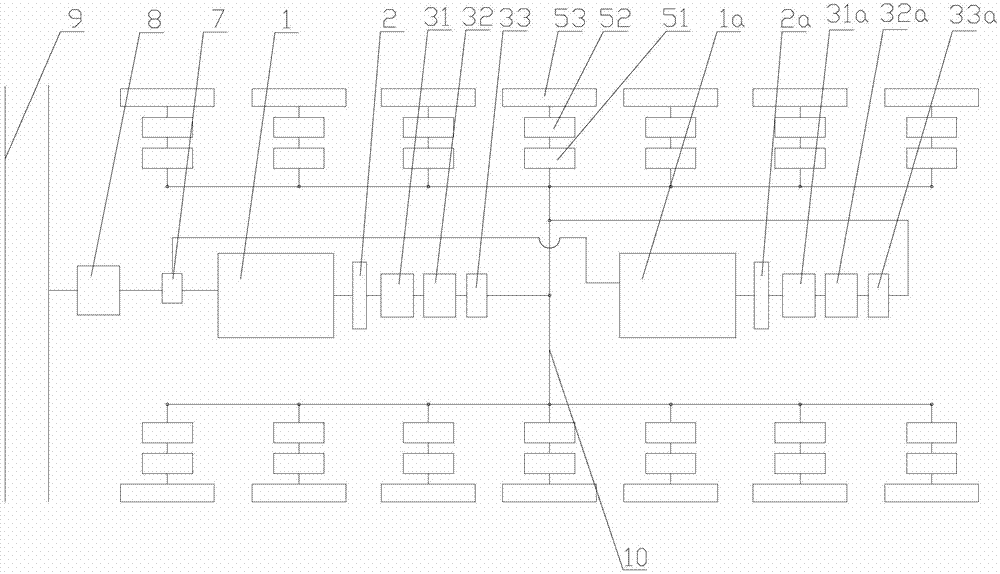

Hydraulic driving system, base plate and mechanical traveling device

The invention relates to the technical field of engineering machines, and discloses a hydraulic driving system, a base plate and a mechanical traveling device. The hydraulic driving system comprises a multi-power system, a power composite oil path and traveling units, wherein the multi-power system comprises a plurality of power sources and a driving oil pump group which is connected with each power source, and the driving oil pump groups are used for converting power provided by a power system into hydraulic driving force; the power composite oil path is used for compounding the hydraulic driving force of the driving oil pump groups which are connected with the power sources to a main oil path; and the traveling units are connected with the power composite oil path and are driven to travel by the hydraulic driving force. According to the hydraulic driving system, power of the multi-power system is converted into the hydraulic driving force, and each traveling unit is driven to move by utilizing the hydraulic driving force, so that each traveling unit can be driven to travel; and the integral driving system is stable in motion, simple in layout of an integral pipeline and convenient to operate, and infinitely variable speed is realized.

Owner:SANY HEAVY IND CO LTD (CN)

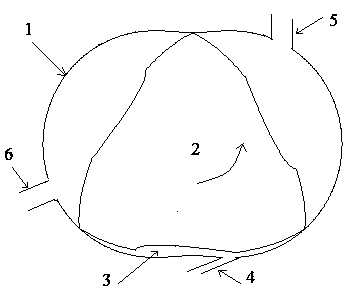

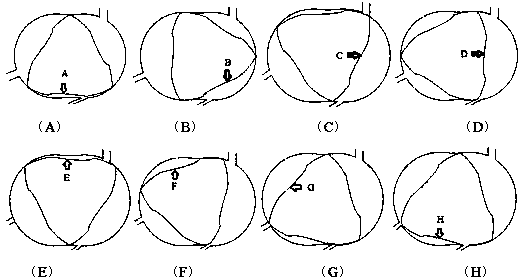

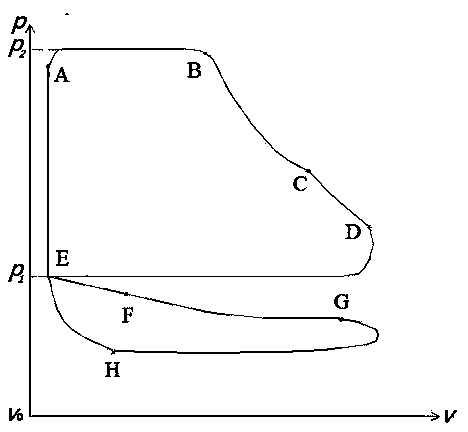

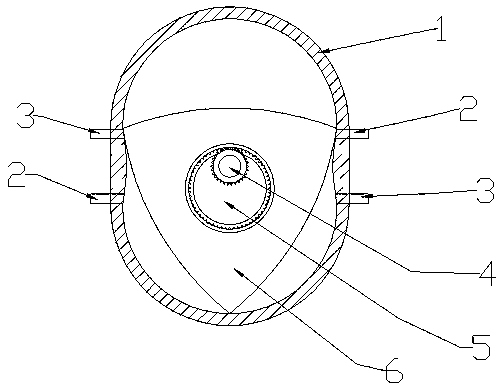

Rotor type external combustion engine air cylinder and rotor type external combustion engine

InactiveCN103423022AHigh power outputRealize infinitely variable speedHot gas positive displacement engine plantsThermodynamicsExternal combustion engine

The invention discloses a novel external combustion engine based on the pneumatic principle, and belongs to the field of external combustion engines of a power mechanical system. An external combustion engine air cylinder comprises a cylinder body, wherein a gas inlet pipe and gas exhaust pipes are arranged on the cylinder body, and the interior of the cylinder body further comprises a triangular rotor. The triangular rotor makes contact with the inner wall of the cylinder body, a working chamber is formed by the triangular rotor and the cylinder body, and the working chamber is a dynamic sealing space. The number of the gas exhaust pipes is two, and the gas exhaust pipes comprise the primary gas exhaust pipe and the secondary gas exhaust pipe. According to the rotor type external combustion engine, the advantages of an existing external combustion engine are integrated, and meanwhile the requirements for high-power output and large-range electrodeless speed change are met.

Owner:JIANGSU UNIV

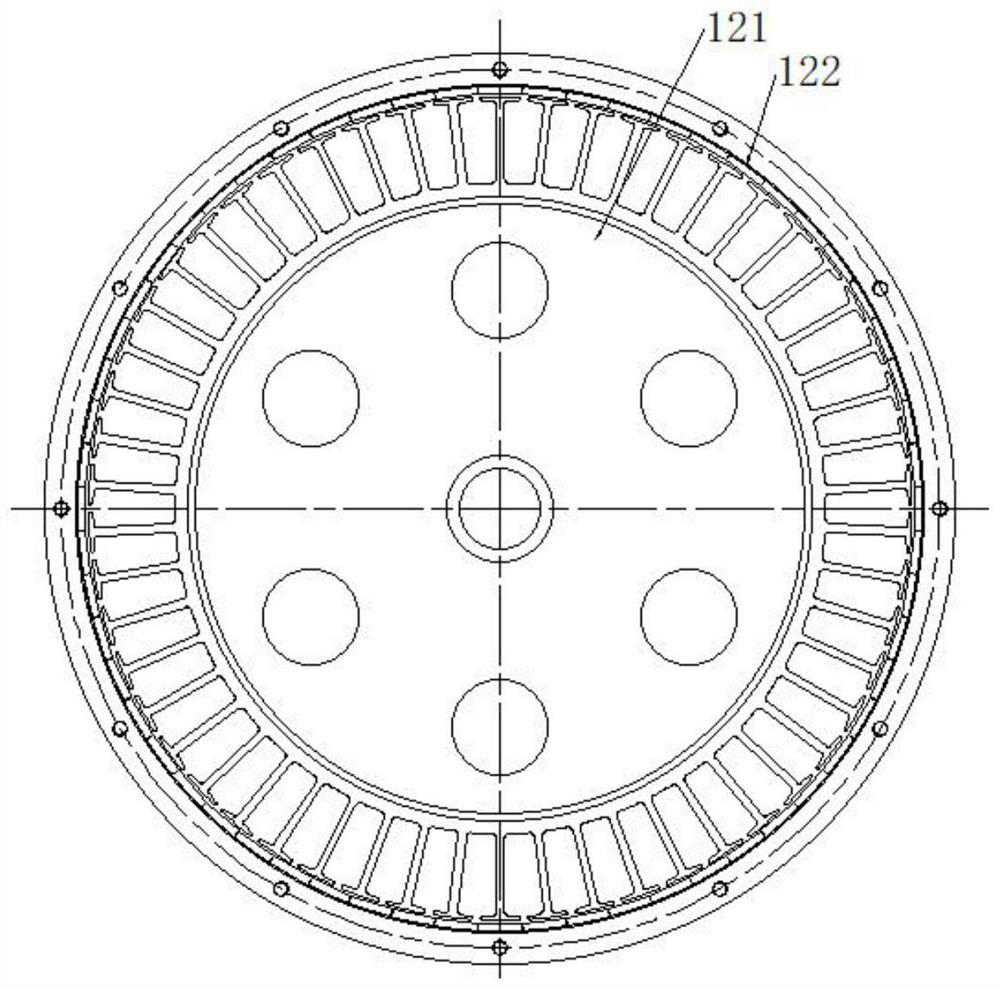

Novel motor

ActiveCN103346634AImprove efficiencyEnhanced interactionMagnetic circuit rotating partsMagnetic circuit stationary partsBobbinEngineering

The invention provides a novel motor. The novel motor comprises a motor shell, a stator and a cup-shaped rotor. The novel motor is characterized in that a magnetized multi-pole permanent magnet is arranged on the cup-shaped cylinder wall of the cup-shaped rotor, a magnetic permeable cylinder is arranged on a stator jacket, a coil bobbin is arranged inside the stator jacket and provided with a plurality of sets of hollow coils, and the coils arranged on the inner wall of the inner cylinder of the coil bobbin are opposite to the corresponding coils in the radial direction on the outer wall of the outer cylinder of the coil bobbin. The novel motor has the advantages that a stator and rotor structure of a traditional motor is changed, the magnetic field distribution on a coil track is optimized, the mutual effect of the coils and a permanent magnetic field is improved greatly, and therefore efficiency of the motor is improved greatly, the starting current is reduced and the power consumption is reduced. Due to the fact that the coils of the stator are hollow, iron loss is reduced, the weight of the motor is reduced, the slot effect is eliminated, and the temperature rise of the motor is lowered at the same time.

Owner:赤峰力华龙电器有限责任公司

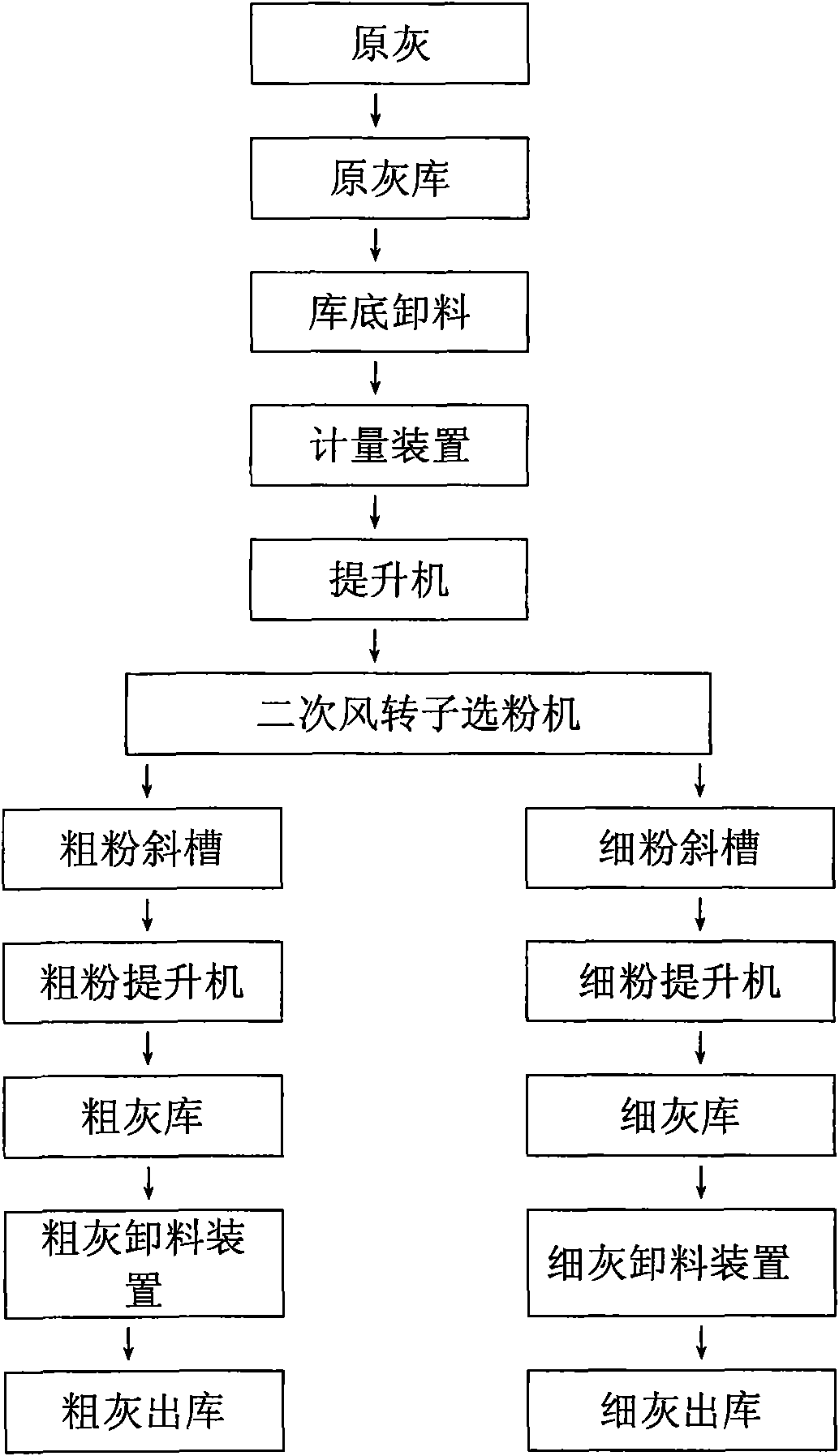

Method for processing fly ash

InactiveCN101628284ARealize infinitely variable speedImproved particle size distributionSievingGas current separationTruckFly ash

The invention discloses a method for processing fly ash, which comprises the following steps that: 1, original fly ash is taken out from an original fly ash cabin and directly enters an original fly ash hoisting machine through a feeding metering device; 2, the original fly ash is fed into a secondary air rotor separator for separation, crude ash obtained after separation enters a crude ash silo through a crude ash pneumatic conveying chute and a crude ash hoisting machine, and fine ash obtained after separation enters a fine ash silo through a fine ash pneumatic conveying chute and a fine ash hoisting machine; and 3, the crude ash and the fine ash are loaded on a truck to be delivered out of a storage by discharging devices respectively, the crude ash enters an cement producing fly ash silo, the fine ash enters an concrete producing fly ash silo, and thus the separation of the crude ash and the fine ash is realized. The method is low in production cost, high in separation efficiency and low in separation power consumption, saves crude ash and is used in cement as an admixture.

Owner:泰州市华荣水泥有限公司

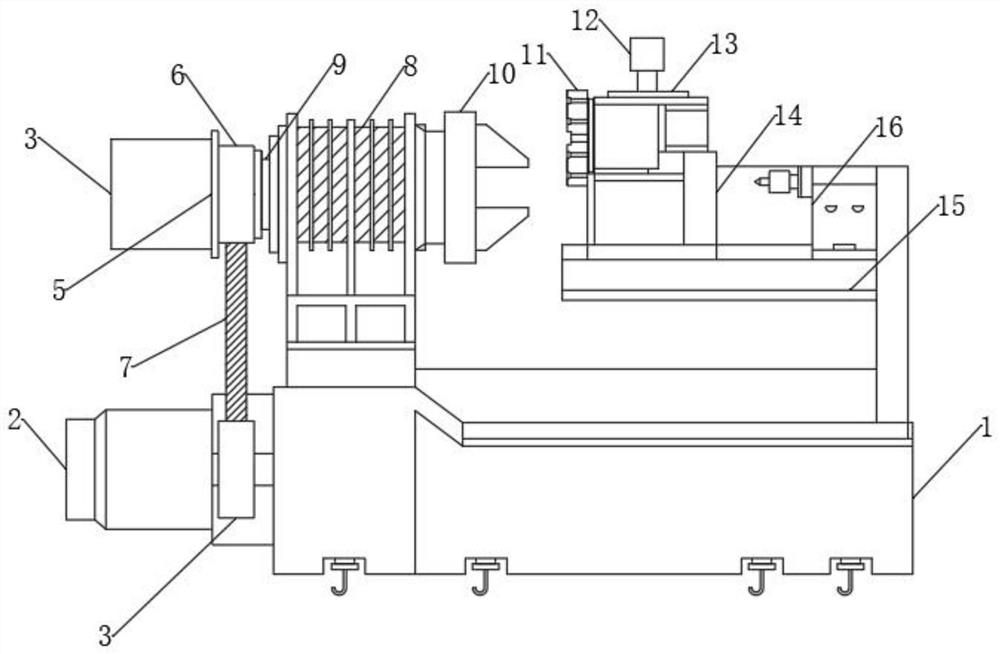

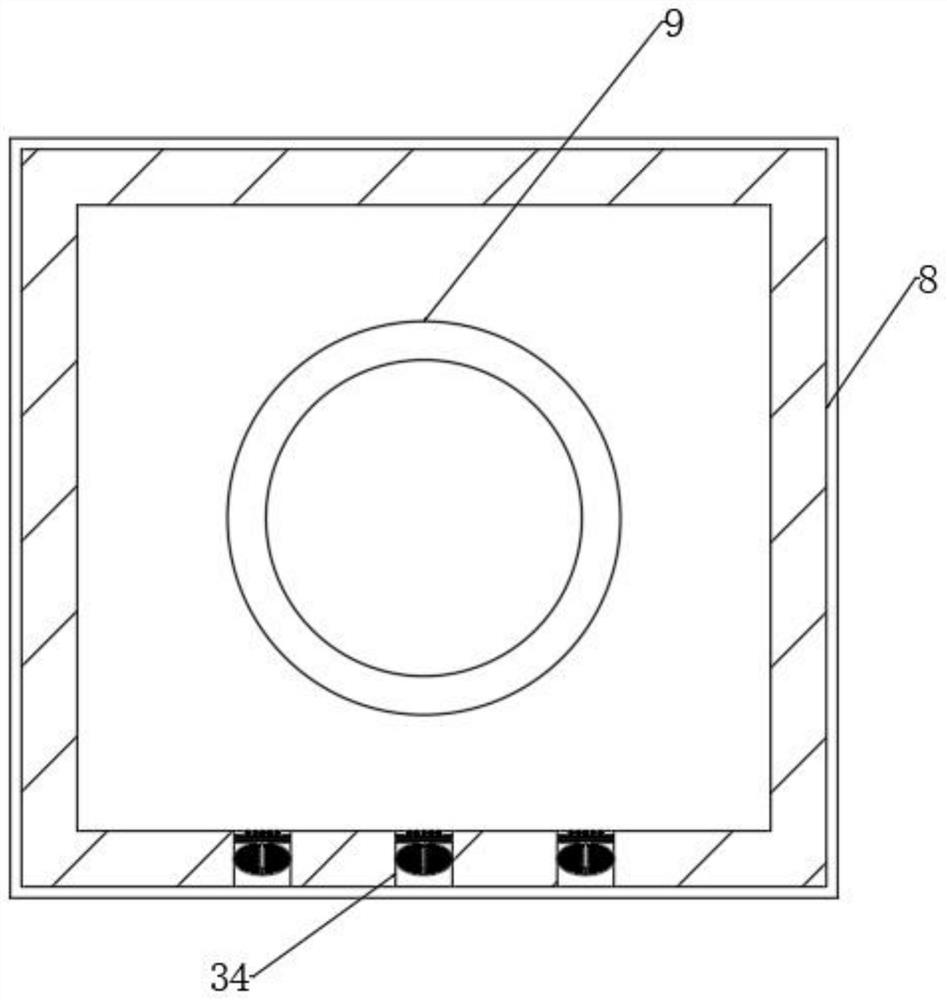

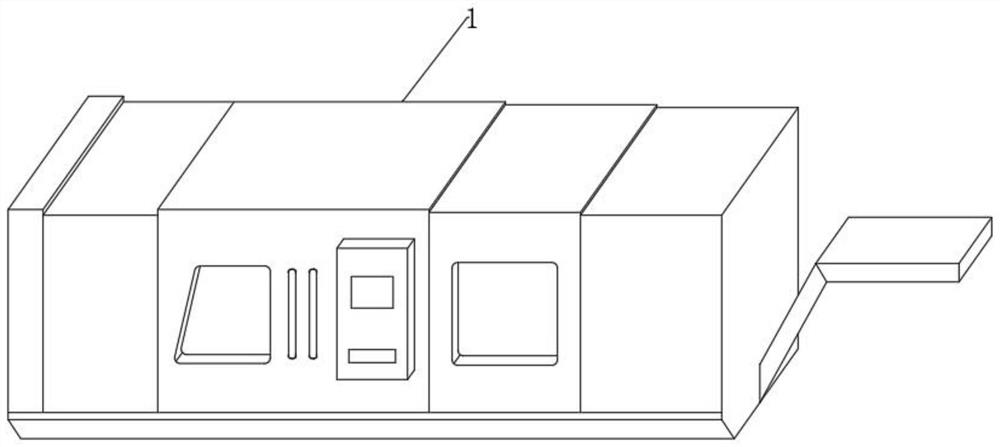

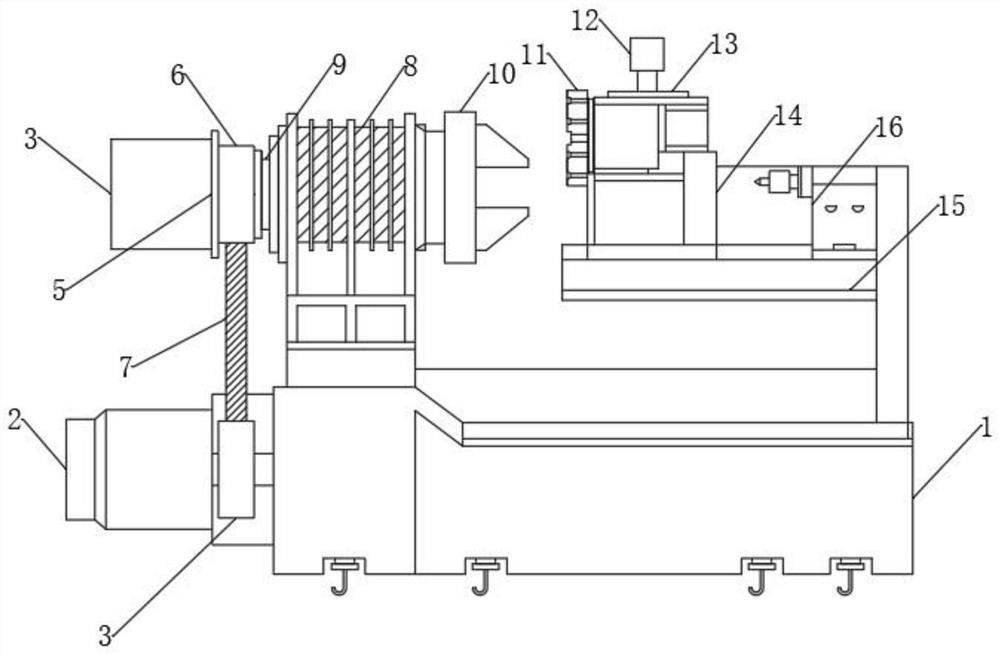

Numerical control lathe for precision machining

ActiveCN113579266AAvoid interferenceReduce distractionsAutomatic/semiautomatic turning machinesDriving apparatusNumerical controlElectric machinery

The invention discloses a numerical control lathe for precision machining, and belongs to the field of numerical control lathes. A main motor drives a main shaft body to rotate after speed reduction through a motor belt wheel, a synchronous belt and a main shaft belt wheel, stepless speed change is achieved, heat generated by movement of the main shaft body promotes ammonium chloride powder to be heated and decomposed into hydrogen chloride gas and ammonia gas, an elastic balloon is driven to expand to extrude a flexible heat absorption pad to be bent and expands to drive a magnetic rod to be close to a magnetic plate, an elastic telescopic pipe and the magnetic plate are driven to extend out through repulsive force, and a deformation memory spring is heated to extend to drive the magnetic plate to be unfolded, so that sufficient adsorption of scrap iron is achieved, and the scrap iron is prevented from interfering with rotation of the main shaft body; and along with cooling of cooling liquid in a bent hose and decomposition and heat absorption of the ammonium chloride powder, the temperature in a main shaft box is reduced, so that the influence of too high temperature on lubrication in the main shaft box body is avoided, interference on rotation of the main shaft body is reduced, and the precision is improved.

Owner:浙江重力智能装备有限公司

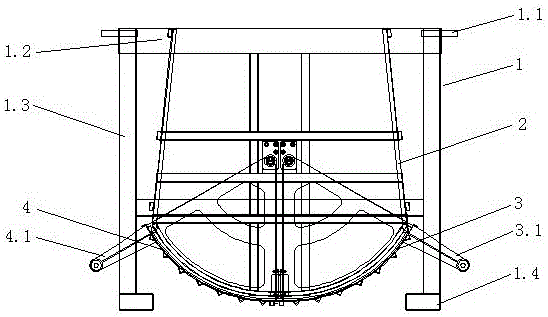

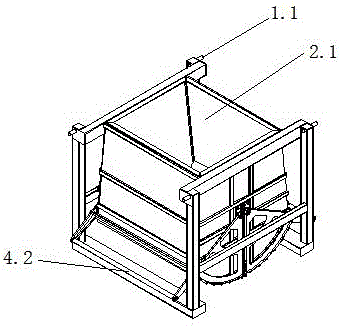

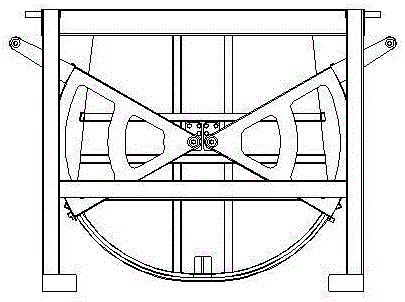

Plastic bucket and plastic bucket feeding, discharging and conveying system

ActiveCN106697642ARealize infinitely variable speedFlexible designConveyorsLarge containersMotor driveReciprocating motion

The invention provides a plastic bucket and a plastic bucket feeding, discharging and conveying system. The plastic bucket is characterized in that a bucket body of the plastic bucket is provided with a feed inlet, a discharge outlet and discharge doors; and the bucket body is arranged in the middle of a frame-shaped base, the upper portion of the frame-shaped base is provided with a sling matched with an aerial conveying line, the bottom of the frame-shaped base is provided with a supporting portion matched with a ground conveying line, and the first discharge door and the second discharge door which are hinged to the discharge outlet are closed through the self weight. The bottom of each of two frames of a discharge mechanism is provided with a motor, wherein the motor drives a guide rail in a lifting frame assembly to do up-down reciprocating motion through a chain wheel and a chain, and the lifting frame assembly comprises a lifting arm extending towards the middle to be out of the frame. The two lifting arms are matched with rollers on inclined opening arms of the first discharge door and the second discharge door correspondingly when ascending, so that the first discharge door and the second discharge door are lifted up. The plastic bucket not only can achieve aerial conveying, but also can operate on the ground conveying line, and the plastic bucket feeding, discharging and conveying system is flexible to use and high in conveying efficiency.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG

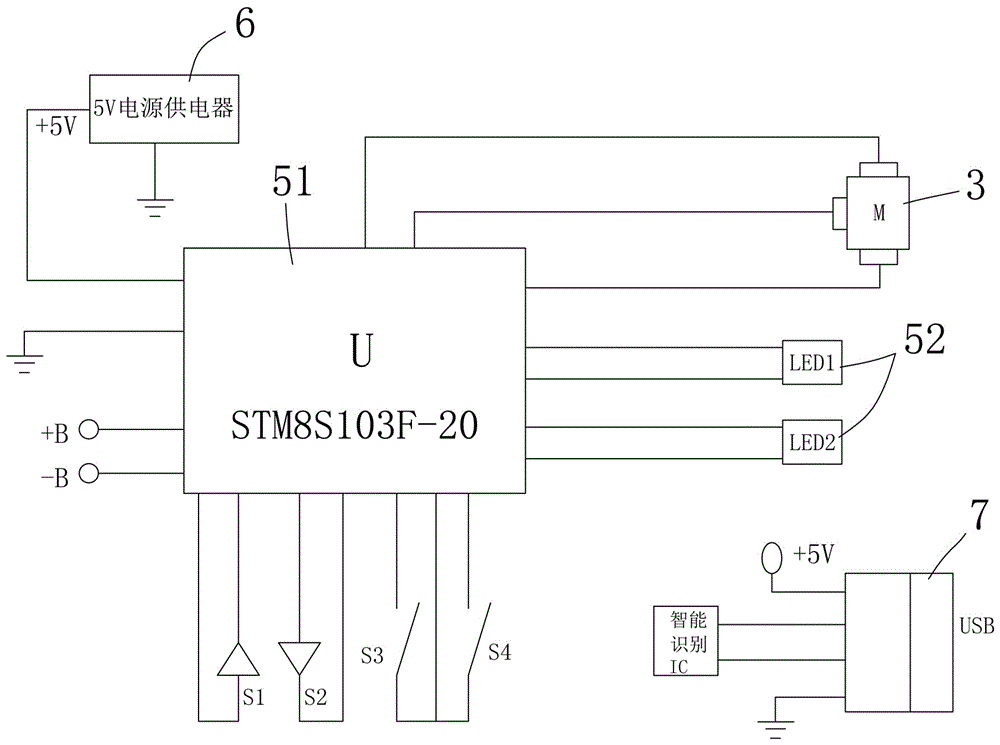

Healthy sleep assisting machine

InactiveCN106730235AGood sleep aidGood adaptabilitySleep inducing/ending devicesSleep/relaxation inducing devicesAir volumeEngineering

The invention relates to the technical field of healthy products, in particular to a healthy sleep assisting machine. The healthy sleep assisting machine comprises a base, a cover, and a direct current motor, fan blades and a controller which are arranged in a cavity surrounded by the base and the cover, wherein the cover is formed by stacking an upper cover and a lower cover; the upper cover and the lower cover can rotate relatively; the lower cover is fixedly connected with the base; the upper cover is provided with first adjustment air holes; the lower cover is provided with second adjustment air holes; the first adjustment air holes and the second adjustment air holes are crosswise arranged, so that the sizes of overlapping regions among the first adjustment air holes and the second adjustment air holes can be adjusted when the upper cover and the lower cover rotate relatively; the controller controls the direct current motor according to a pulse width modulation signal; the direct current motor drives the fan blades to rotate; air generated by the fan blades is blown out from ventilating openings formed in the cover. The healthy sleep assisting machine make a purely natural wind sound based on a physical principle, and the air volume can be adjusted randomly; furthermore, the direct current motor is controlled through the pulse width modulation signal, so as to realize stepless speed change and obtain various working modes; the healthy sleep assisting machine is good in sleep assisting effect and extremely high in adaptability to a human body.

Owner:深圳市太业时代实业有限公司

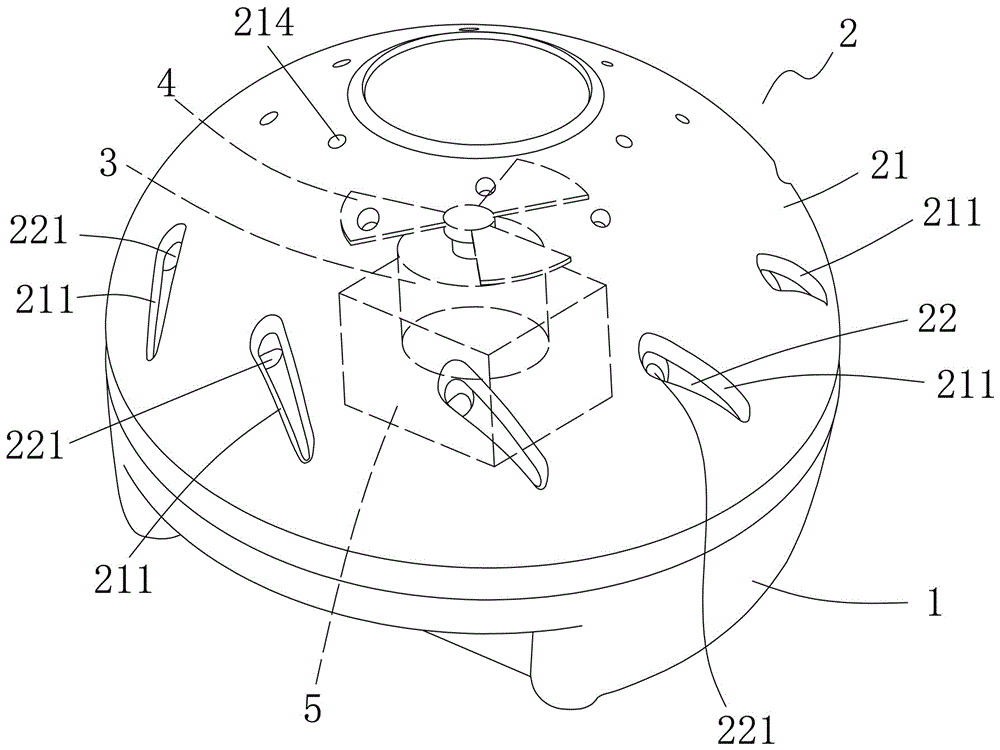

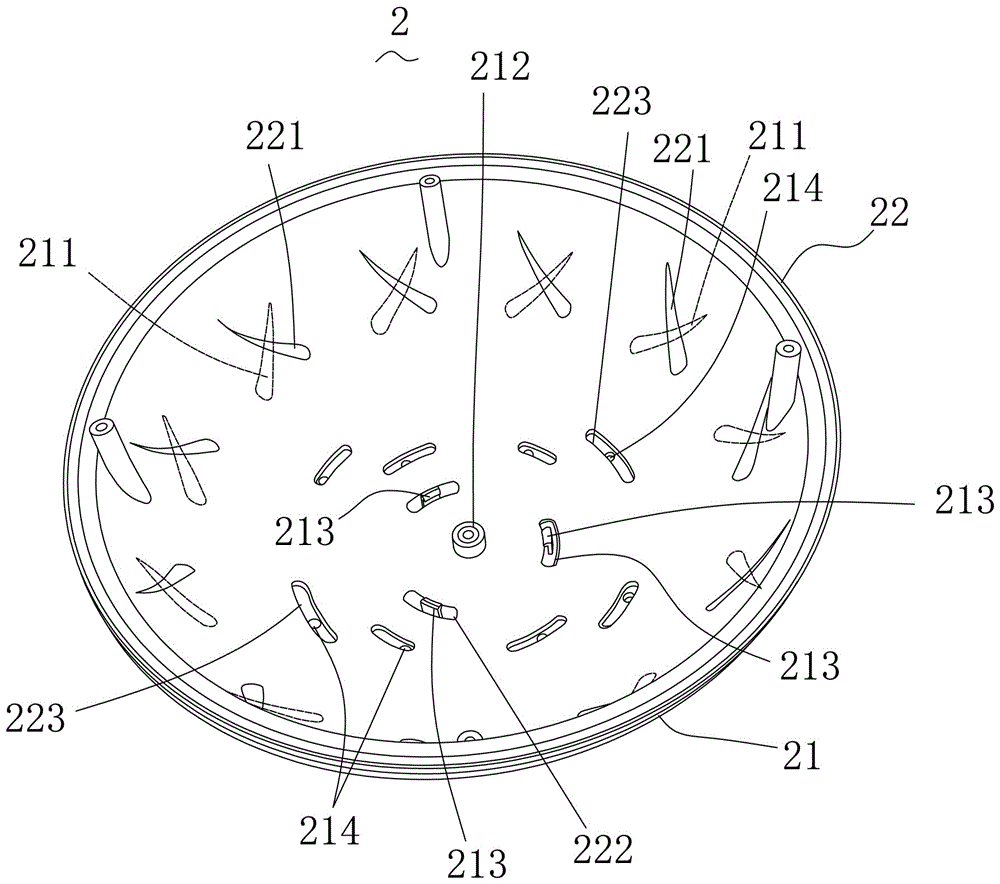

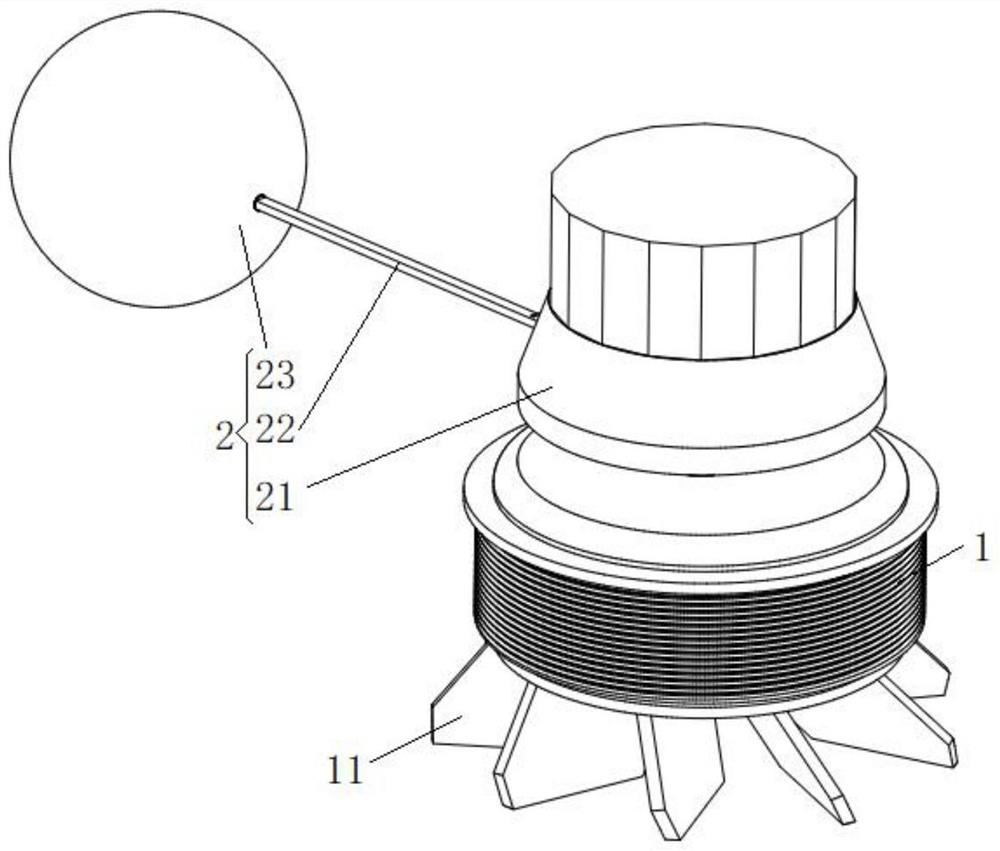

Permanent magnet outer rotor aerator

ActiveCN112544552AReduce installation work in waterImprove disassembly efficiencyPisciculture and aquariaSustainable biological treatmentImpellerElectric machinery

The invention relates to a permanent magnet outer rotor aerator which comprises a stirring piece and a suspension piece. The stirring piece is connected with and arranged in a water area below the suspension piece; an impeller is assembled at the bottom of the stirring piece; a motor is arranged in the stirring piece in a sealing manner; the motor drives the impeller to stir water; the suspensionpiece realizes a stable operation posture in water by utilizing a floating ball which is unfolded in a central symmetry manner; and the floating ball adopts a double-layer structure, and a buoyancy block is arranged at the interlayer, so that semi-inflatable launching can be realized, the shore volume of the permanent magnet outer rotor aerator is effectively controlled, and the carrying difficulty is reduced.

Owner:湖北梨威机械设备有限公司

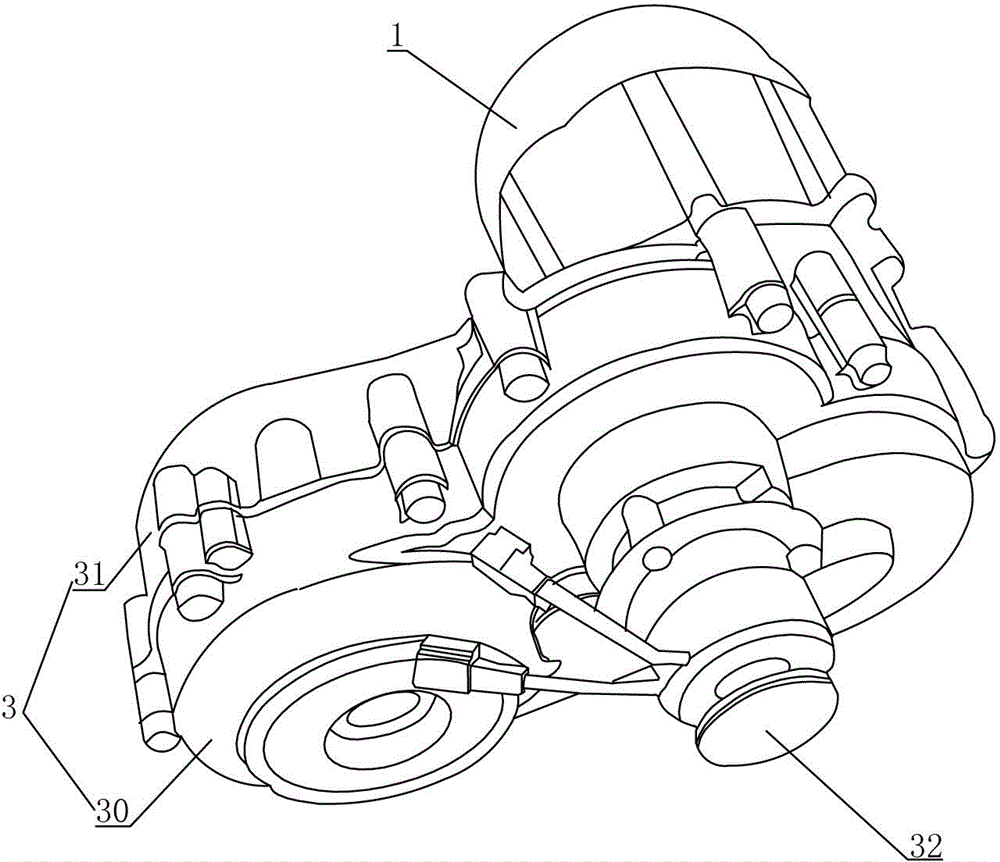

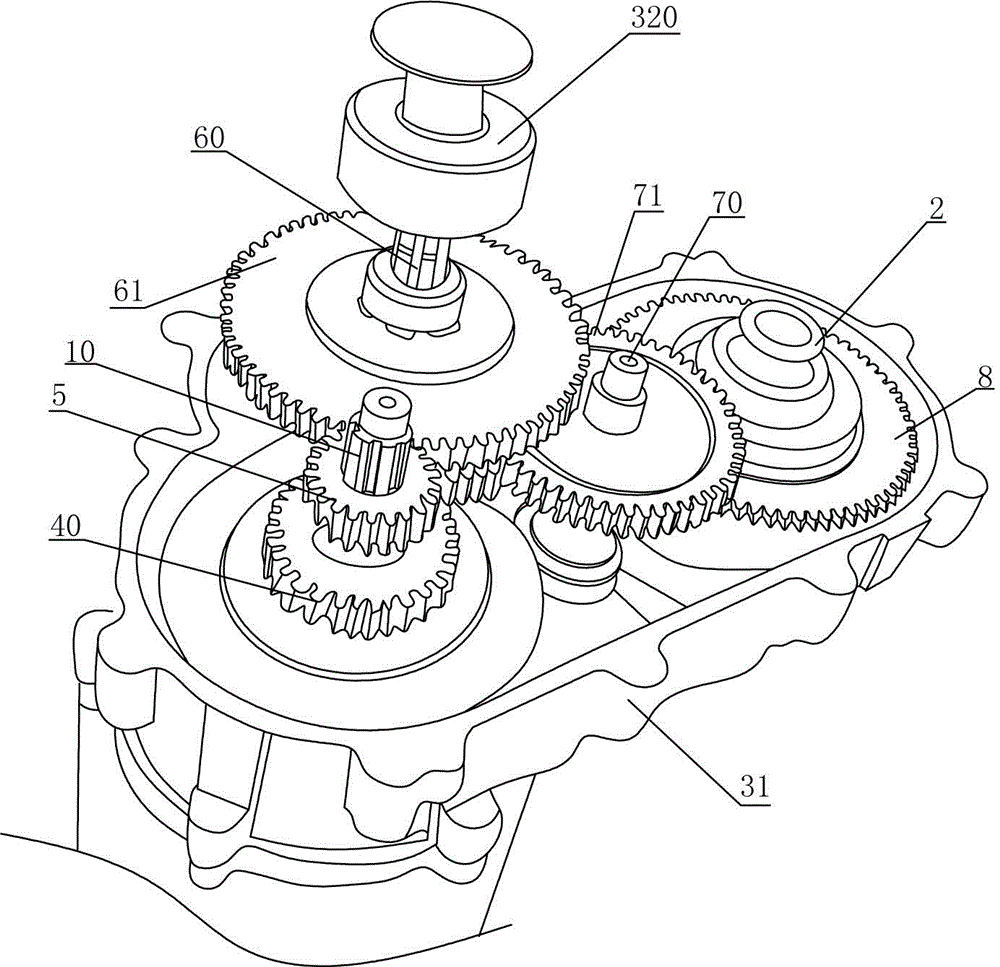

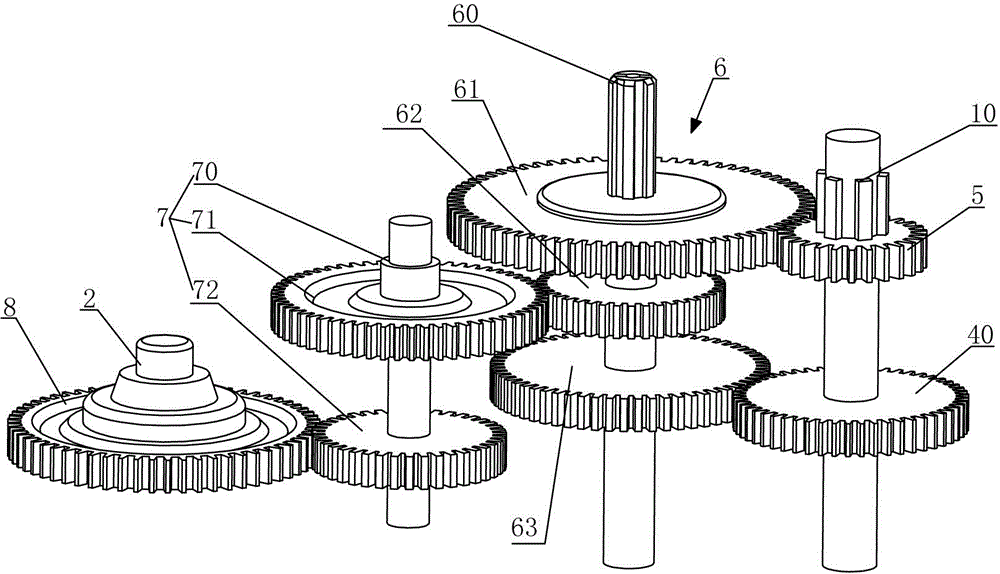

Gearbox of electric tricycle

InactiveCN104482131AHigh transmission efficiencyReduce wear and tearToothed gearingsGearing controlGear transmissionVariator

The invention relates to a gearbox of an electric tricycle. Automatic infinitely variable speed of the gearbox is realized by conducting gear transmission between a motor and an output shaft and introducing an automatic transmission and the like, the electric tricycle is enabled to run safely under the conditions of load bearing, climbing and the like, and simplicity in operation and stability and reliability in performance are achieved. The gearbox is driven by the motor and comprises the output shaft and a box body, the box body comprises an upper cover and a lower cover, and the automatic transmission, a drive gear, a first intermediate gear set, a second intermediate gear set and a driven gear are arranged in the box body. The automatic transmission and the motor are coaxially connected through a spline, and a transmission gear is fixed onto the automatic transmission. The drive gear and the motor are coaxially connected through a spline and positioned above the automatic transmission. The first intermediate gear set comprises a limiting spline, an upper gear, a middle gear and a lower gear, and the upper gear, the middle gear and the lower gear are concentric and coaxial and fixedly sleeve the limiting spline. The second intermediate gear set comprises a rotating shaft, a first intermediate gear and a second intermediate gear, and the first intermediate gear and the second intermediate gear are concentric and coaxial and fixedly sleeve the rotating shaft.

Owner:厦门跃众机电科技有限公司

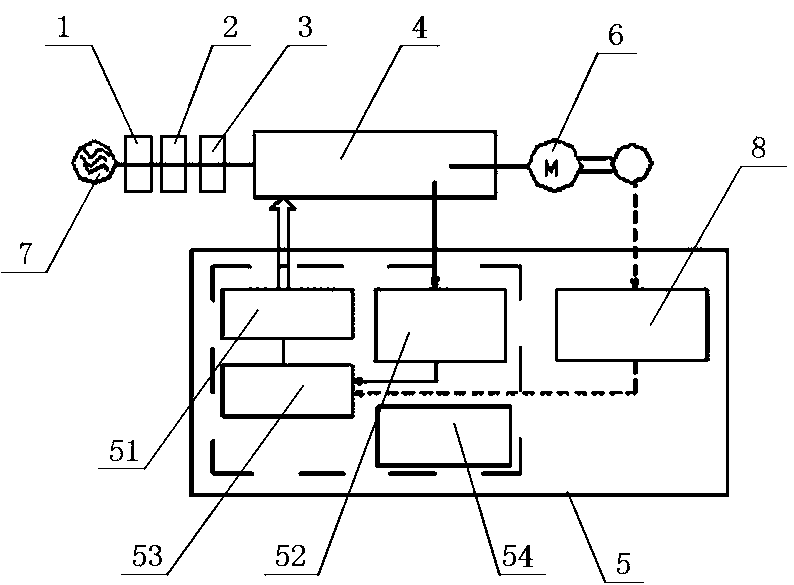

Variable frequency speed regulation system of high-speed electronic sectional warping machine

InactiveCN103628210ARealize infinitely variable speedGuaranteed uptimeAC motor controlWarping machinesFrequency changerComputer module

The invention relates to a variable frequency speed regulation system of a high-speed electronic sectional warping machine. The system comprises a rectifier, a filter, an inverter, a frequency converter, a control module and a motor, wherein the rectifier, the filter, the inverter, the frequency converter and the motor are connected in sequence, the control module is arranged on the frequency converter, and a driving sub-module, a voltage / current output sub-module, an operating sub-module and a protecting circuit are arranged in the control module. According to the variable frequency speed regulation system of the high-speed electronic sectional warping machine, due to the fact that the frequency converter and the control module are arranged, stepless speed changing can be achieved, the equipment can operate stably, and the warping effect is better.

Owner:SHAOXING UNIVERSITY

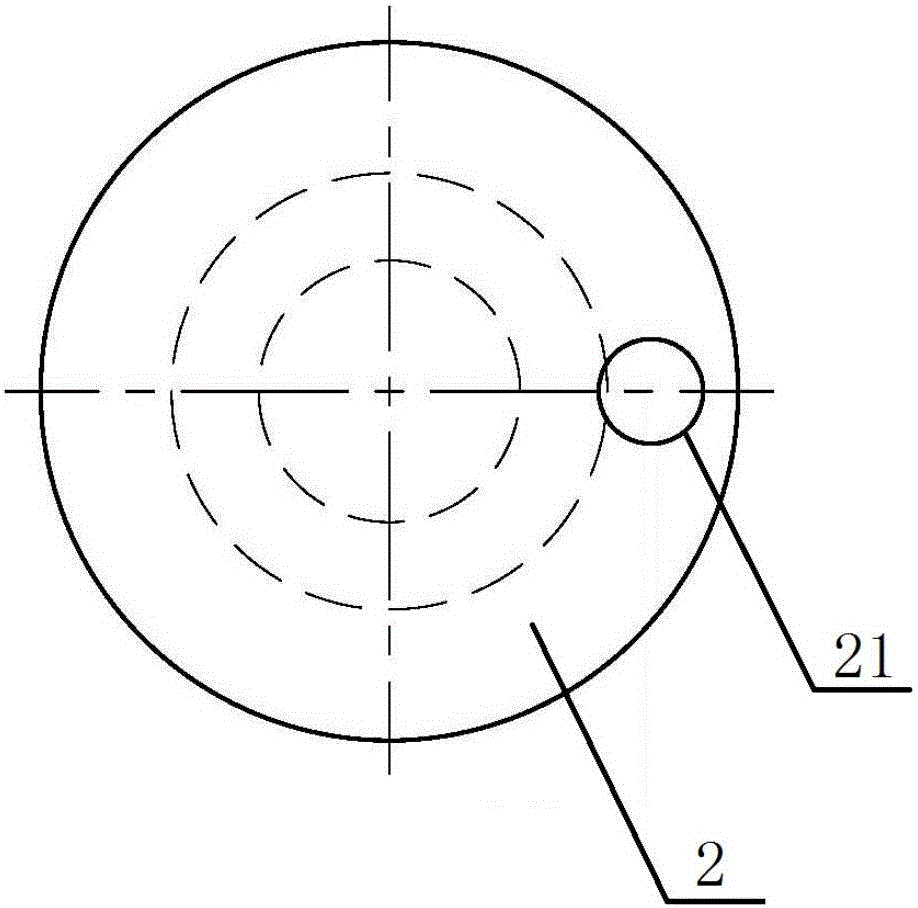

Belt wheel structure for harvester

ActiveCN104221611ARealize infinitely variable speedEasy to adjustHarvestersPortable liftingDrive shaftAgricultural engineering

Owner:湖州思达机械制造有限公司

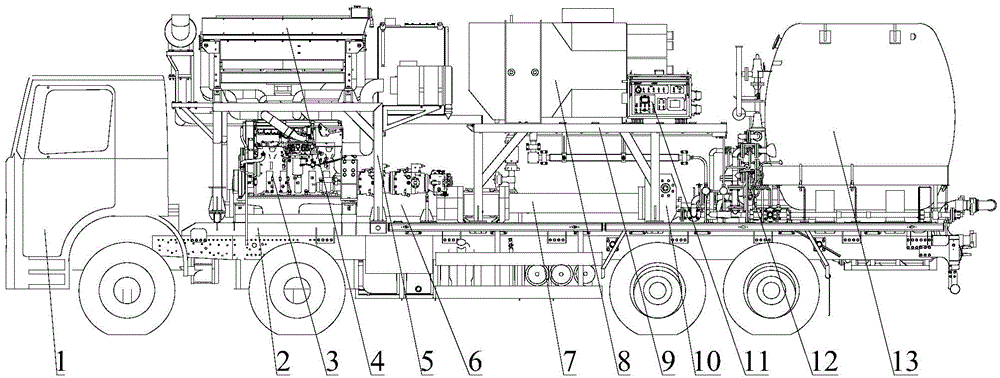

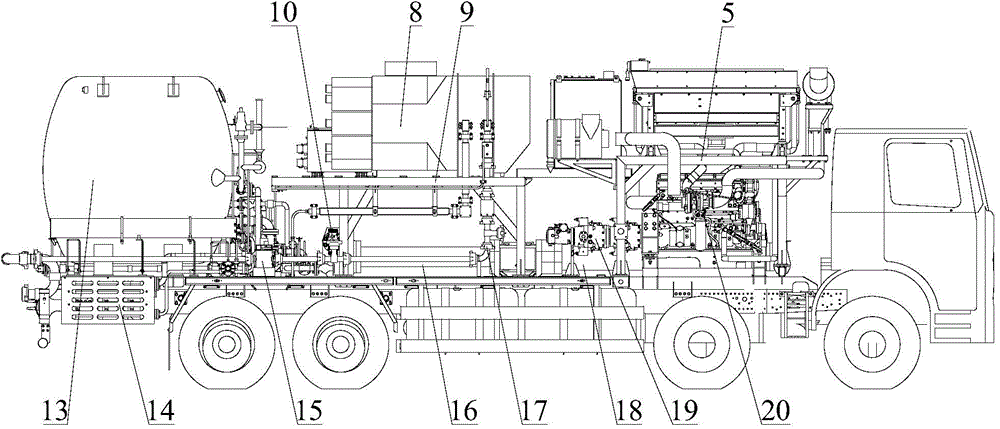

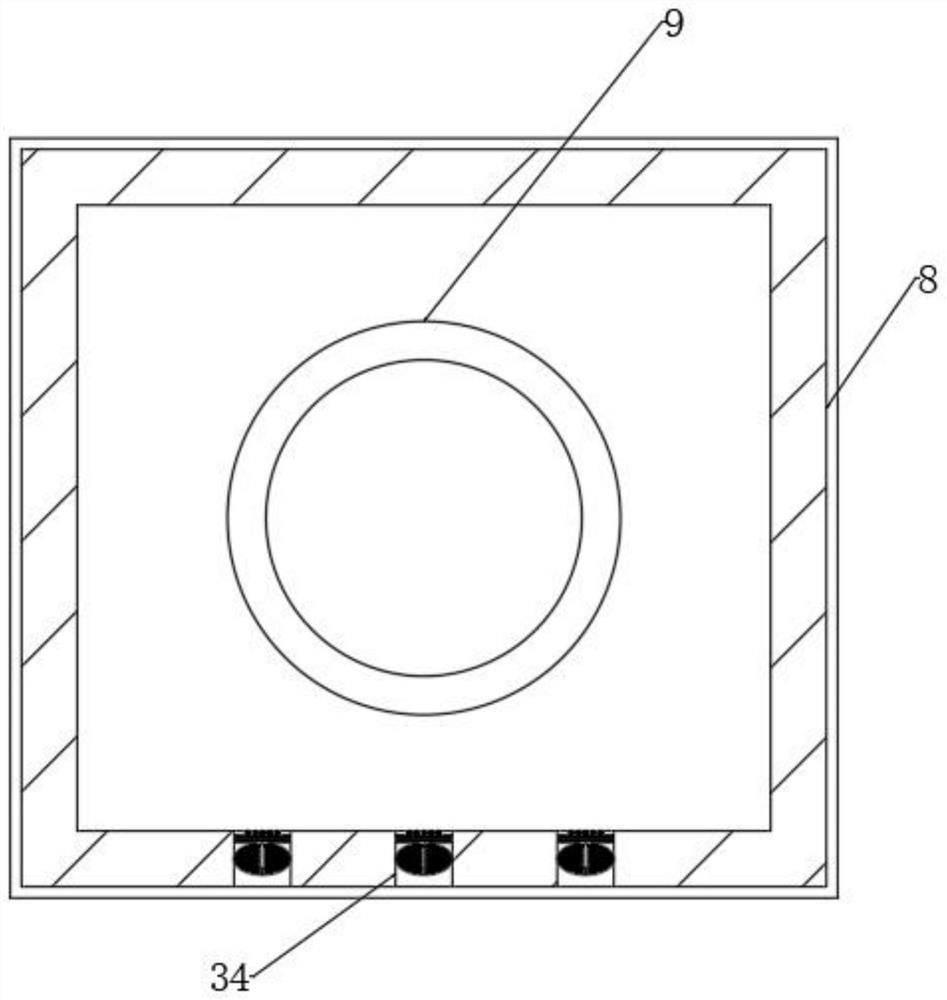

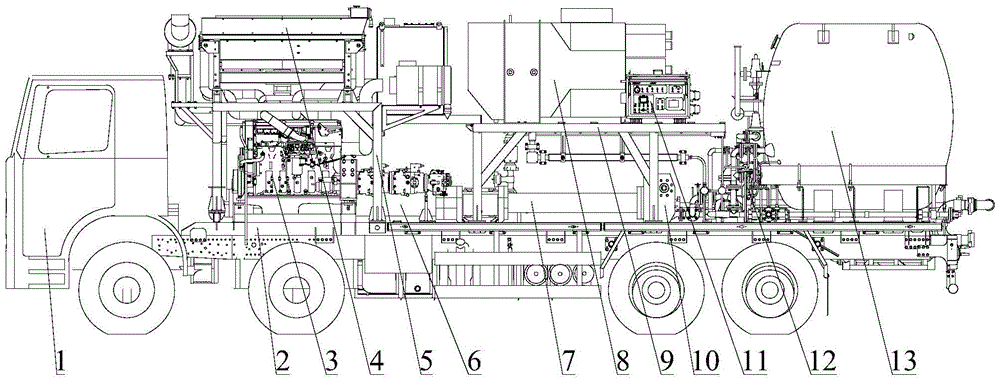

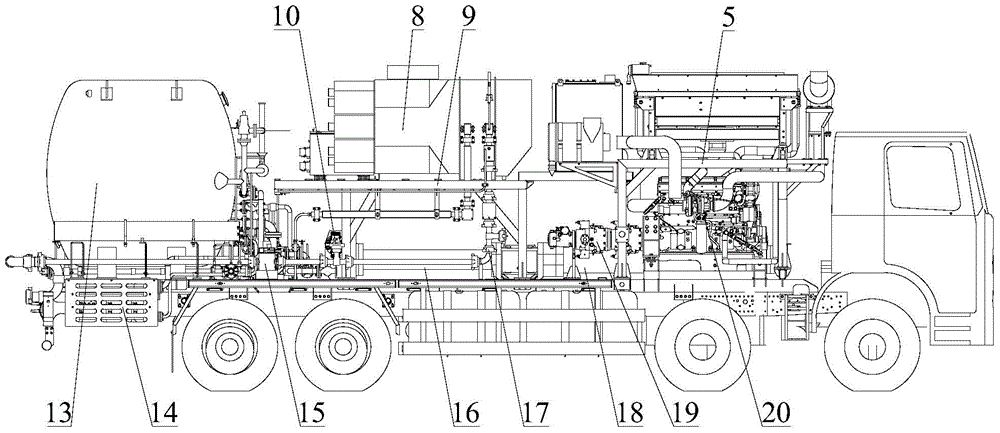

Liquid nitrogen pump truck

ActiveCN104482402ALow costCompact structurePressure vesselsPiston pumpsHydraulic cylinderExhaust valve

The invention relates to the technical field of nitrogen operations and discloses a liquid nitrogen pump truck. According to the liquid nitrogen pump truck, a first engine is used for driving at least one hydraulic pump; a second engine is used for driving other hydraulic pumps; the hydraulic pumps are used for providing pressure oil for a first hydraulic cylinder and a second hydraulic cylinder; the piston rod extension ends of the first hydraulic cylinder and the second hydraulic cylinder are respectively and movably arranged in a first plunger type cylinder and a second plunger type cylinder by virtue of plungers; and rodless cavities of the first plunger type cylinder and the second plunger type cylinder are respectively connected to an outlet of a low-pressure manifold and an inlet of a liquid nitrogen high-pressure manifold by virtue of a suction valve and an exhaust valve. According to the liquid nitrogen pump truck disclosed by the invention, the overall cost can be effectively reduced when the requirement on output power is met, infinitely variable transmission is realized, and the coverage range of the liquid nitrogen displacement and pressure is widened, so that the overall structure is compact, and the maintenance convenience is improved.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

Hydraulic transmission speed change system

InactiveCN110319170AContinuous and stable deliveryChange the direction of power transmissionNon-mechanical gearing transmissionFluid gearingsHydraulic motorVery High Level

The invention discloses a hydraulic transmission speed change system. According to a power transmission speed change system, the gear shifting speed change can be truly realized and the transmission direction of the force can be changed on the basis that continuous stable transmission of power, the structure is simple and the manufacturing cost is low. According to the hydraulic transmission speedchange system, a variable plunger pump is adopted to convert mechanical power into hydraulic power, and then a rotary wheel line type hydraulic motor is used for converting the hydraulic power into the mechanical power. By adjusting the inclination angle of a swash plate, the flow rate of a transmission liquid can be adjusted, the rotating speed and the torque of the power output can be changed,and therefore the purpose of speed change is achieved. Due to the fact that the inner cavity of the variable plunger pump and the inner cavity of the rotary wheel line type hydraulic motor are both continuous closed lines (surfaces) so that the mechanical efficiency of the system can reach a very high level.

Owner:董鹏

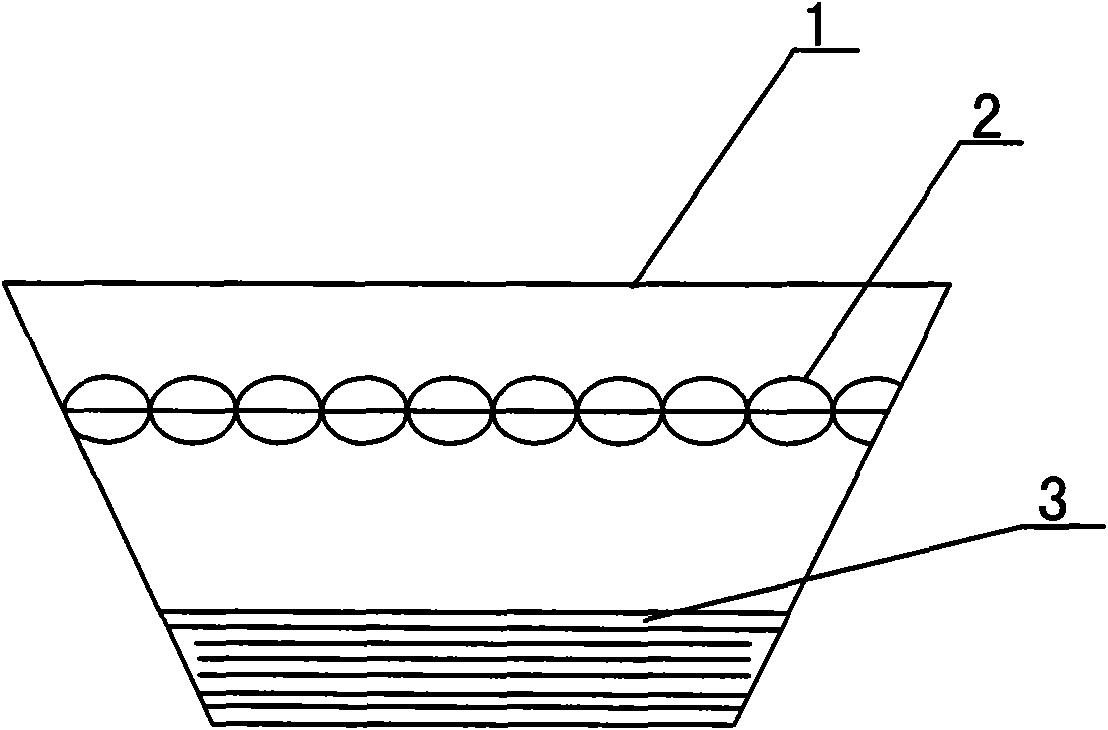

Transmission belt with transverse curtain

The invention provides a transmission belt with transverse curtain, which comprises a V-shaped belt body and a curtain strengthening layer arranged at bottom of the V-shaped belt body, wherein the curtain strengthening layer is composed by sequentially stacking a plurality of curtains with certain length and arranged at bottom of the V-shaped belt body. The invention has advantages that the V-shaped belt has good rigidity and can bear large side pressure, impulsion load and strong shaking, thereby realizing limit-free speed changing and greatly increasing the service life of the belt.

Owner:锐牛股份有限公司

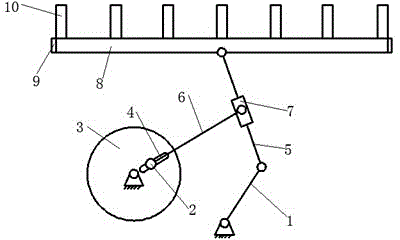

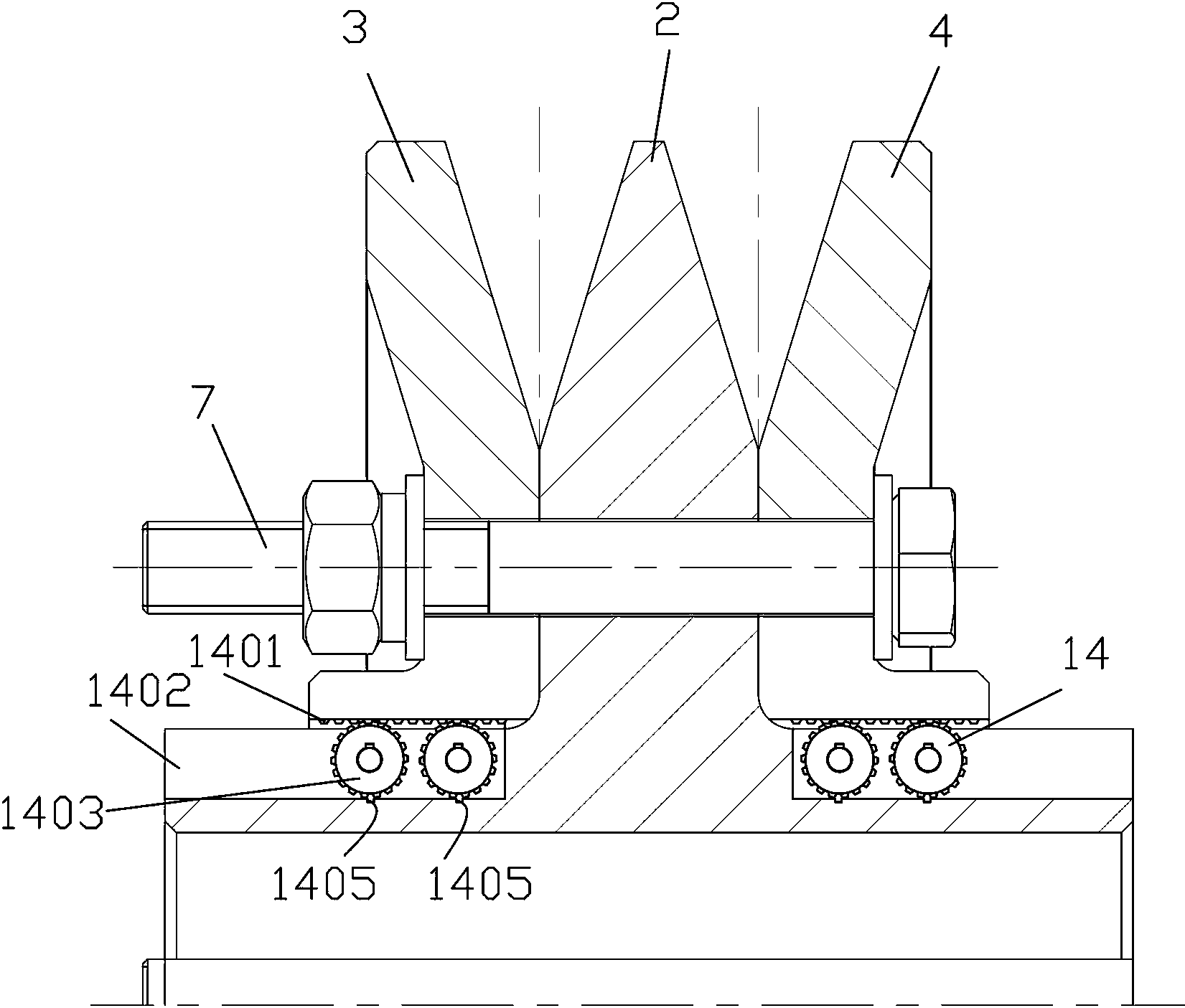

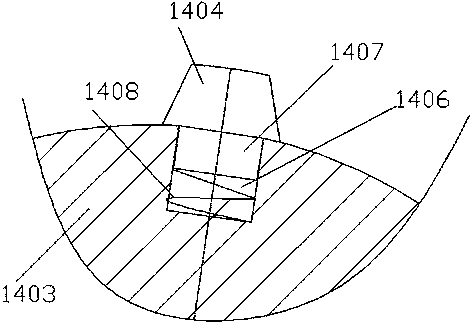

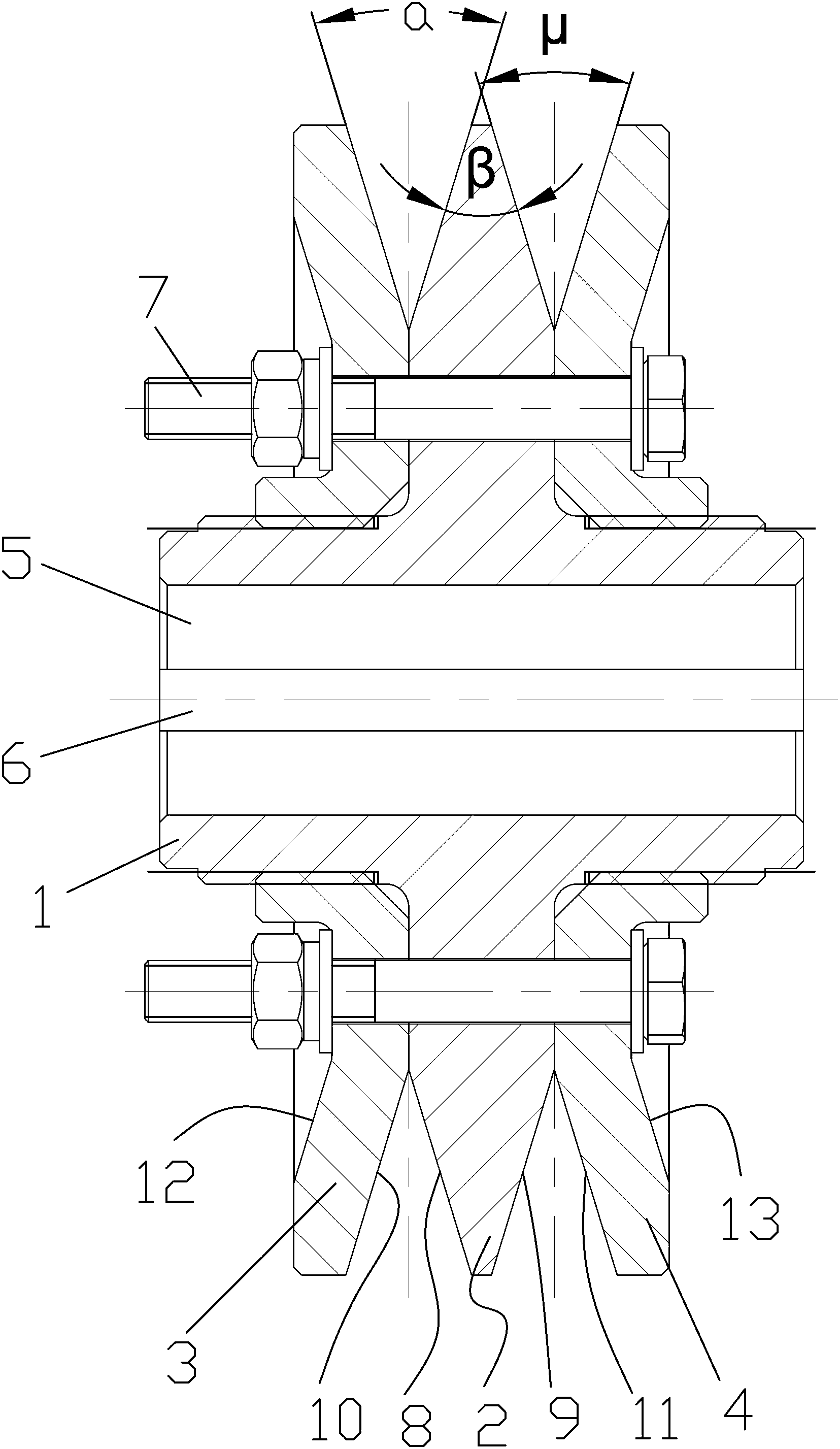

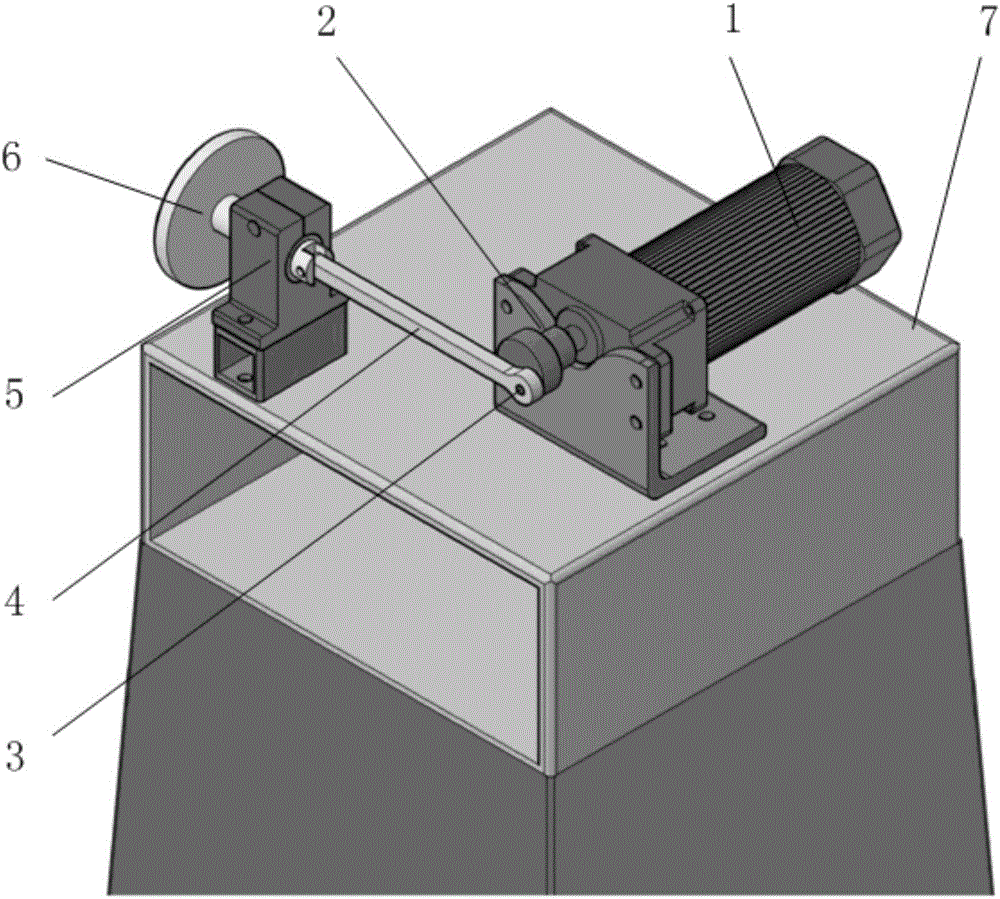

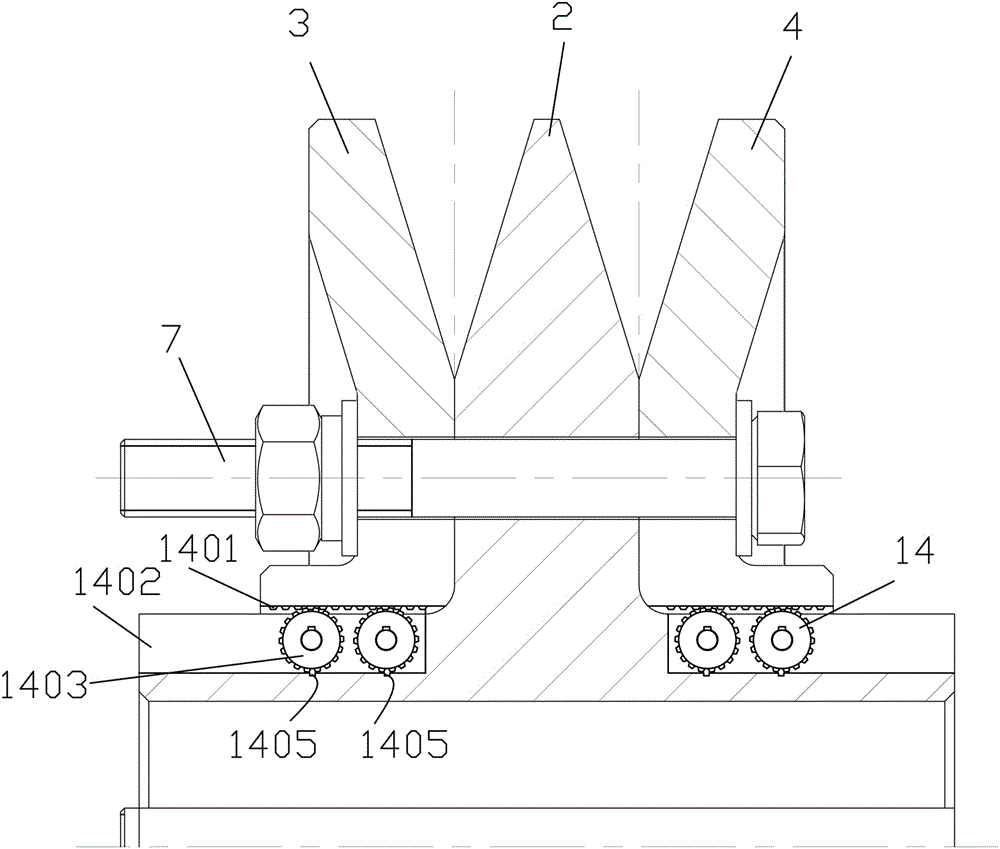

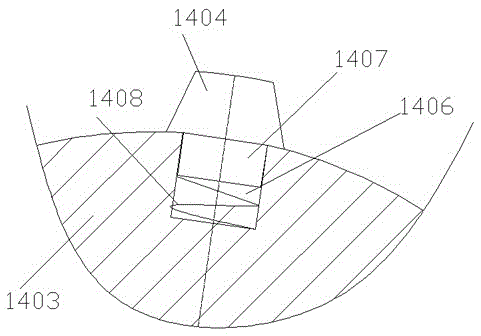

Stepless speed change automatic feeding device for centerless grinder

InactiveCN106272043ASolve human efficiency problemsAvoid demagnetizationGrinding feedersEngineeringControl theory

The invention discloses a stepless speed change automatic feeding device for a centerless grinder, which comprises a servo motor, an eccentric rotating wheel, a connecting rod, a linear guide rail, a material returning head and a base, wherein the servo motor is arranged on the base; the eccentric rotating wheel is connected with an output shaft of the servo motor; and one end of the connecting rod is connected with an eccentric hole of the eccentric rotating wheel through a bolt for the eccentric hole, and the other end of the connecting rod is arranged on the linear guide rail and is connected with the material returning head. The eccentric rotating wheel and the output shaft of the servo motor are in fastening connection through a bolt and a key, and the eccentric distance of the eccentric hole of the eccentric rotating wheel is determined according to the required material returning stroke. The stepless speed change automatic feeding device for the centerless grinder has the advantages that the servo motor is used for driving the rotating wheel and the connecting rod to operate at constant speed without other auxiliary force, so the human efficiency problem, the demagnetization problem and the material breaking and blocking problem are solved, linear operation and feeding are reliable and balanced, and the device is stepless adjustable and does not need demagnetization.

Owner:黄石哈特贝尔精密锻造有限公司

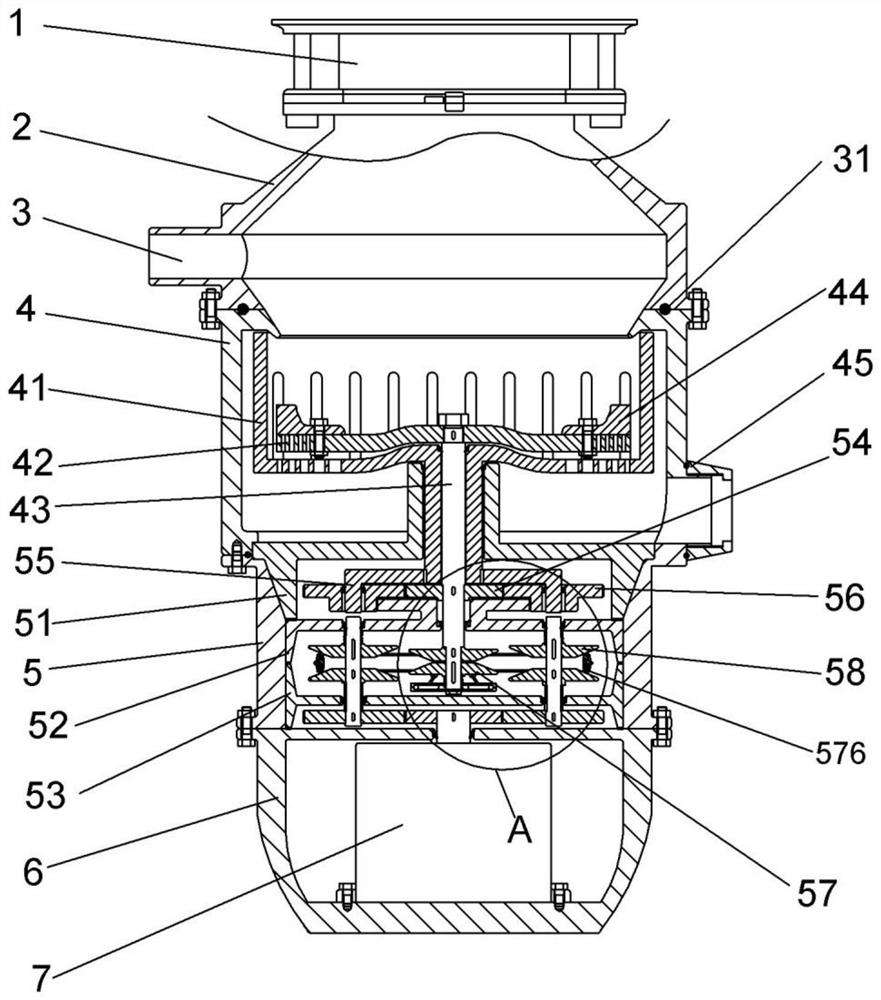

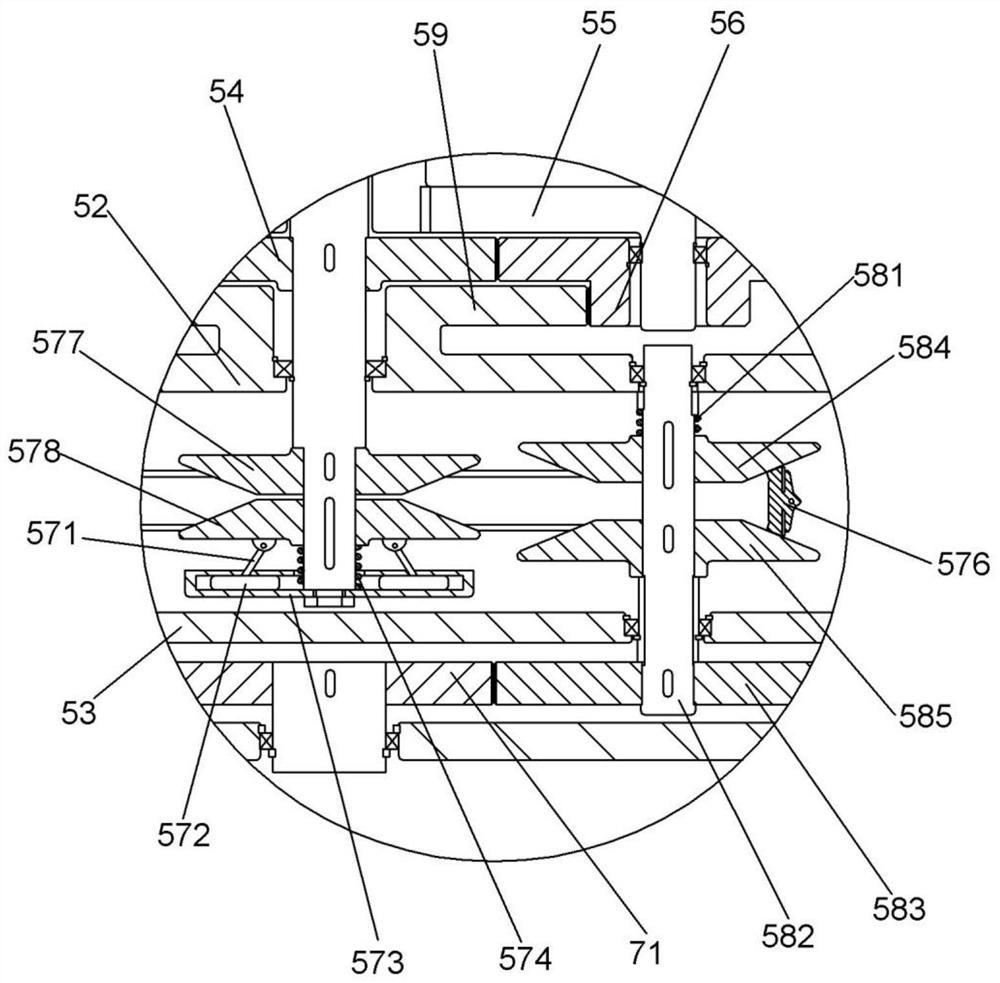

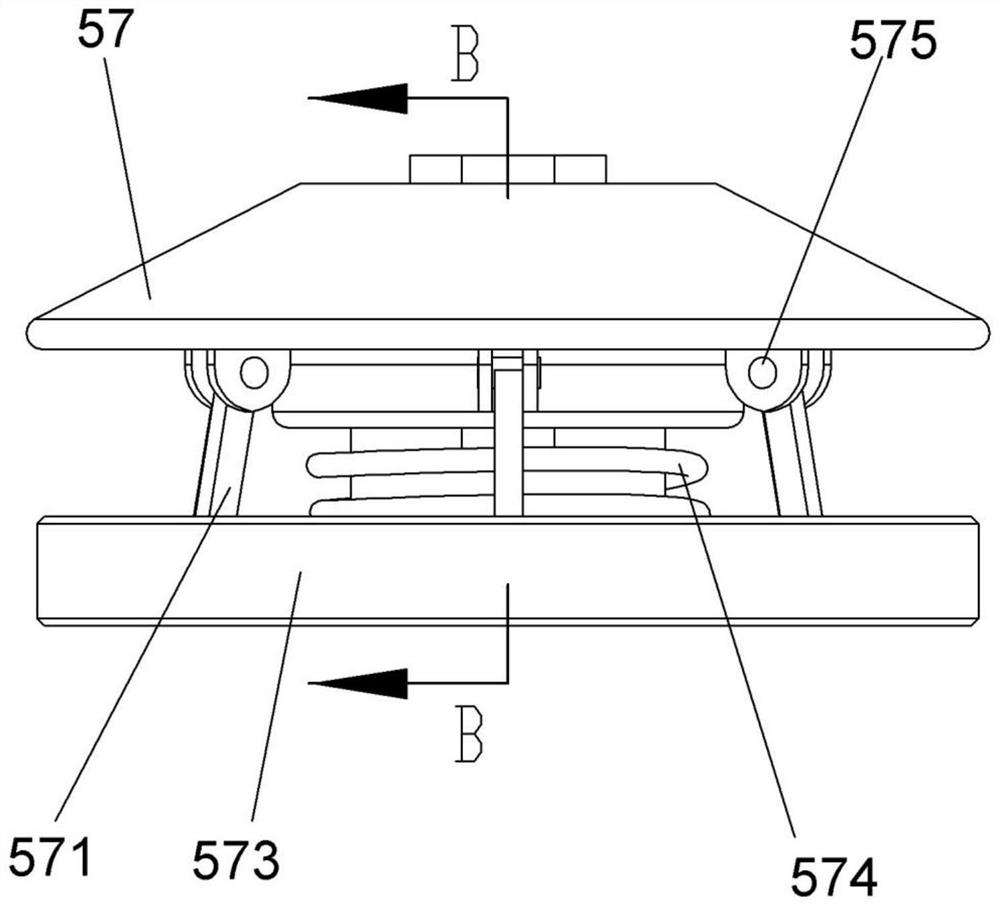

Energy-saving kitchen waste processor and energy-saving green building

ActiveCN112343135AImprove grinding effectSpeed ratio changes continuouslyDomestic plumbingDrive wheelAgricultural engineering

The invention relates to the technical field of buildings, in particular to an energy-saving kitchen waste processor and an energy-saving green building. The energy-saving kitchen waste processor comprises a shell, a grinding assembly, a speed changing assembly and a transmission assembly. A feeding port is formed in the upper end of the shell, and the grinding assembly is located in the shell andis configured to receive kitchen waste from the feeding port and performs grinding. The speed changing assembly is located below the grinding assembly and comprises a driving wheel, a driven wheel and a steel belt, wherein the driving wheel and the driven wheel are arranged in a split mode, the steel belt is wound around the driving wheel and the driven wheel, and an adjusting device is arrangedbelow the driven wheel. The speed changing assembly can automatically adjust the output rotating speed and torque according to the magnitude of grinding resistance, and the jamming phenomenon caused by insufficient output torque when the grinding resistance is increased is prevented; and meanwhile, through combination of the transmission assembly and the speed changing assembly, a grinding cylinder and a grinding disc of the grinding assembly can rotate in opposite directions and can further change the speed at the same time, stability is improved, and grinding is more sufficient.

Owner:于梦广

Electromechanical hybrid transmission stepless speed change structure and vehicle

ActiveCN112606674ASimple and compact structureEasy to install and set upGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchEngineering

The invention belongs to the technical field of electric vehicle transmission, and particularly relates to an electromechanical hybrid transmission stepless speed change structure and a vehicle. The invention provides an electromechanical hybrid transmission stepless speed change structure and a vehicle to solve the problems that in the prior art, stepless speed change cannot be achieved through a driving structure of a hybrid electric vehicle, and the driving experience is reduced due to the jerking feeling in the gear shifting process. The structure comprises a second driving motor and a second power input shaft. An engine power input assembly is connected with the first power input shaft through a clutch, the first power input shaft and the second power input shaft are in driving connection with an output shaft through a transmission mechanism, the transmission mechanism comprises a power collecting assembly and a gear shifting assembly, and the power collecting assembly comprises at least one stepless speed change planet row. The hybrid power driving is achieved through the engine power input assembly and the second driving motor, and meanwhile the stepless speed change is achieved through the power collection assembly comprising the continuously variable transmission planet row.

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

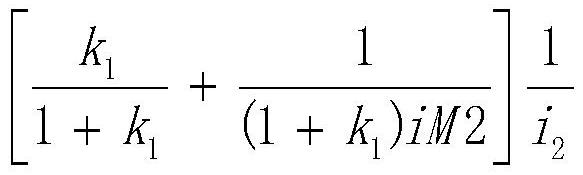

Wheeled Structures for Harvesters

ActiveCN104221611BRealize infinitely variable speedEasy to adjustHarvestersPortable liftingDrive shaftAgricultural engineering

The invention discloses a pulley structure for a harvester, which comprises a transmission shaft, an intermediate wheel fixed on the transmission shaft, a left side wheel which is installed on the intermediate wheel and can move axially, and is installed on the The right side wheel on the intermediate wheel and capable of moving axially, the axial through hole arranged on the transmission shaft, the connecting mechanism arranged in the axial through hole and the left side wheel, the right side wheel The adjustment connection mechanism that connects the side wheel and the middle wheel. The pulley structure used for the harvester of the present invention adjusts the distance between the left pulley, the right pulley and the middle pulley by adjusting the connection mechanism to achieve the purpose of matching with belts of different specifications. The adjustment is convenient and fast, and can realize stepless speed change.

Owner:湖州思达机械制造有限公司

A precision machining CNC lathe

ActiveCN113579266BAvoid interferenceReduce distractionsAutomatic/semiautomatic turning machinesDriving apparatusElectric machineryEngineering

The invention discloses a precision-machined numerically-controlled lathe, belonging to the field of numerically-controlled lathes. The ammonium chloride powder is decomposed into hydrogen chloride gas and ammonia gas by heating, which drives the expansion of the elastic balloon, squeezes the flexible heat-absorbing pad to bend, and at the same time, the expansion of the elastic balloon drives the magnetic rod to approach the magnetic plate, and drives the elastic expansion tube and the magnetic plate through the repulsive force. It extends out, and the deformation memory spring is heated and extended to drive the magnetic plate to expand, so as to realize the full adsorption of iron filings and avoid the interference of iron filings on the rotation of the main shaft. It absorbs heat to reduce the temperature in the spindle box, avoids the influence of excessive temperature on the lubrication inside the spindle box, reduces the interference to the rotation of the spindle box, and improves the accuracy.

Owner:浙江重力智能装备有限公司

A liquid nitrogen pump truck

ActiveCN104482402BLow costCompact structurePressure vesselsPiston pumpsHydraulic cylinderExhaust valve

The invention relates to the technical field of nitrogen operations and discloses a liquid nitrogen pump truck. According to the liquid nitrogen pump truck, a first engine is used for driving at least one hydraulic pump; a second engine is used for driving other hydraulic pumps; the hydraulic pumps are used for providing pressure oil for a first hydraulic cylinder and a second hydraulic cylinder; the piston rod extension ends of the first hydraulic cylinder and the second hydraulic cylinder are respectively and movably arranged in a first plunger type cylinder and a second plunger type cylinder by virtue of plungers; and rodless cavities of the first plunger type cylinder and the second plunger type cylinder are respectively connected to an outlet of a low-pressure manifold and an inlet of a liquid nitrogen high-pressure manifold by virtue of a suction valve and an exhaust valve. According to the liquid nitrogen pump truck disclosed by the invention, the overall cost can be effectively reduced when the requirement on output power is met, infinitely variable transmission is realized, and the coverage range of the liquid nitrogen displacement and pressure is widened, so that the overall structure is compact, and the maintenance convenience is improved.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

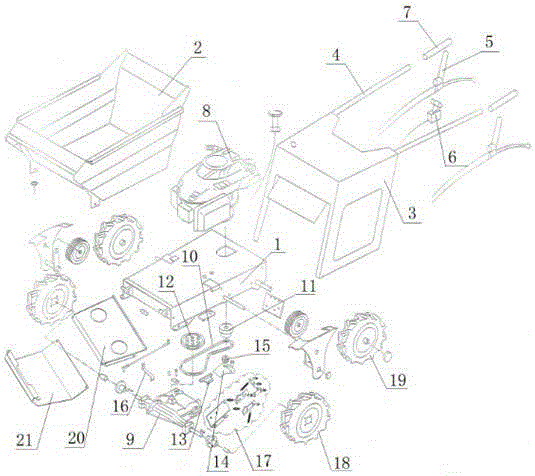

Stepless speed change carrier vehicle

InactiveCN105172916ARealize infinitely variable speedReasonable functional structure designVehiclesControl devicesEngineeringHinge point

The invention relates to a stepless speed change carrier vehicle. The stepless speed change carrier vehicle comprises a baseplate, a hopper, a driving system and a panel, wherein the baseplate is horizontally arranged; a through hole is formed in the middle of the back end of the baseplate; the panel and the hopper are arranged at the upper end of the baseplate in the advancing direction of the carrier vehicle in sequence; the two sides of the front end of the hopper are respectively hinged to the two sides of the front end of the baseplate; the hopper can rotate by surrounding a hinge point for unloading; the panel is of a hollow structure; the two sides of the upper part of the panel are backwards extended to be provided with two operation rods; a handle is arranged at the tail end of each operation rod; an accelerator switch is arranged in middle of the upper end of the panel; the driving system comprises an engine, a drive axle, a transmission mechanism and a driving wheel; and the transmission mechanism comprises an engine belt wheel, a transmission belt and a drive axle belt wheel. The stepless speed change carrier vehicle has the following advantages: the control over the movement direction of the carrier vehicle is realized through arranging an advancement and retreat control system; and the adjustment of the operation speed of the carrier vehicle is realized through arranging the drive axle.

Owner:NANTONG ANT MACHINERY

Intelligent hybrid electric vehicle, fan cooling system and method

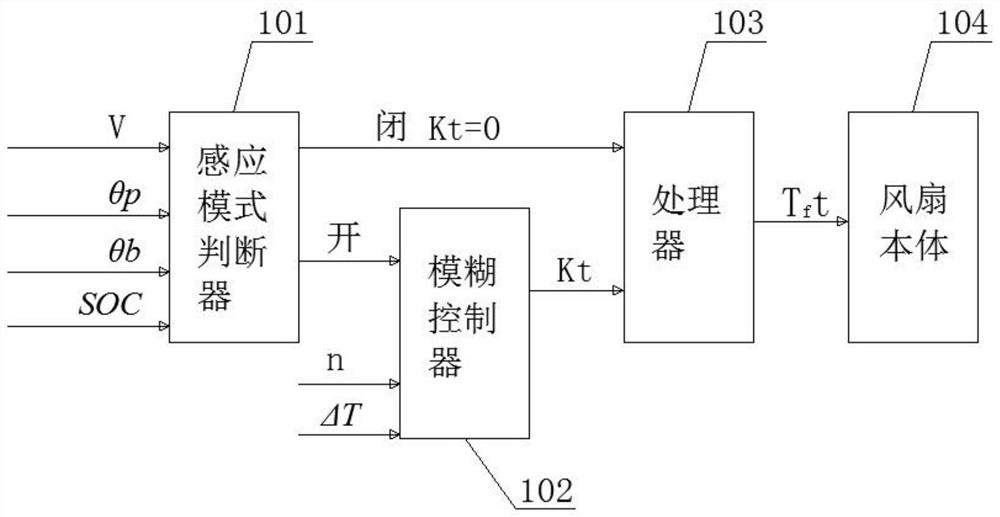

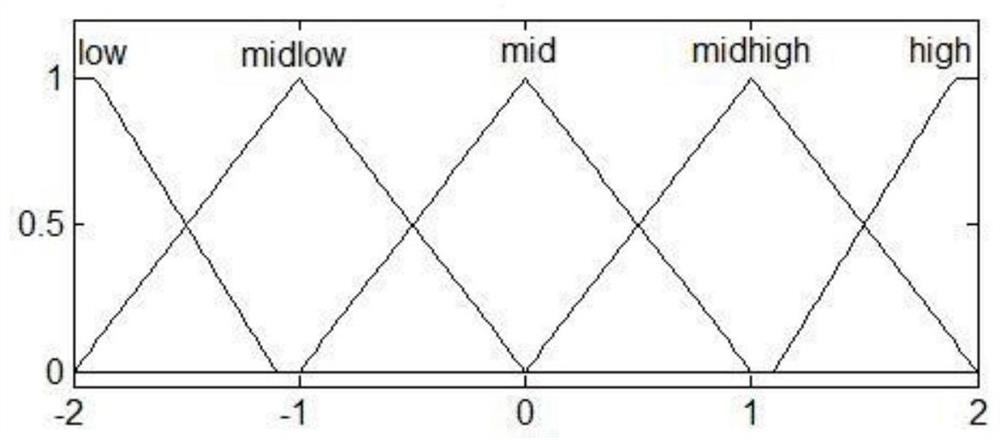

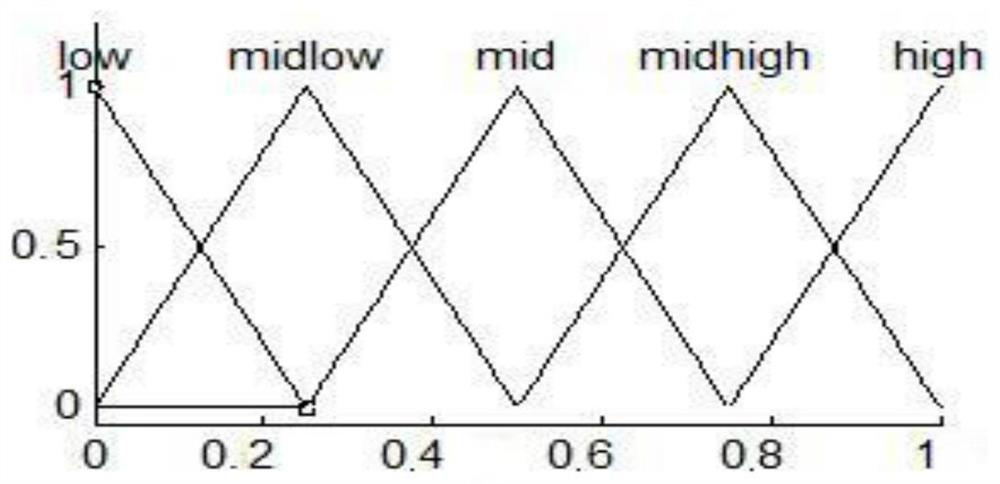

ActiveCN108583473BReduce the temperatureTemperature drops more slowlyElectric/fluid circuitPropulsion coolingControl signalFuzzy control system

The invention relates to an intelligent hybrid electric vehicle, a fan cooling system and a method. The fan cooling system includes an induction mode judger, a fuzzy controller, a processor and a fan body; When the car is in non-pure electric mode, it outputs a shutdown signal to the processor; when it senses that the car is not in pure electric mode, it outputs a startup signal to the fuzzy controller; the fuzzy controller detects the engine speed n; also detects the actual temperature T of the coolant t , to obtain the coolant temperature difference ΔT; the fuzzy controller processes the engine speed n, the coolant temperature difference ΔT and the opening signal, generates a processed signal and transmits it to the processor; the processor processes the processed signal or the closed signal, and generates a control signal It is transmitted to the fan body, and the fan body controls the operation status of the fan body. Compared with the prior art, the invention enables the hybrid electric vehicle to dissipate heat faster, which is beneficial to the starting of the vehicle and the improvement of fuel economy.

Owner:GUILIN UNIV OF AEROSPACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com