Numerical control lathe for precision machining

A CNC lathe and precision machining technology, applied in the field of CNC lathes, can solve problems such as reducing processing efficiency, iron filings entering, affecting product quality, etc., and achieve the effects of reducing interference, avoiding interference, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

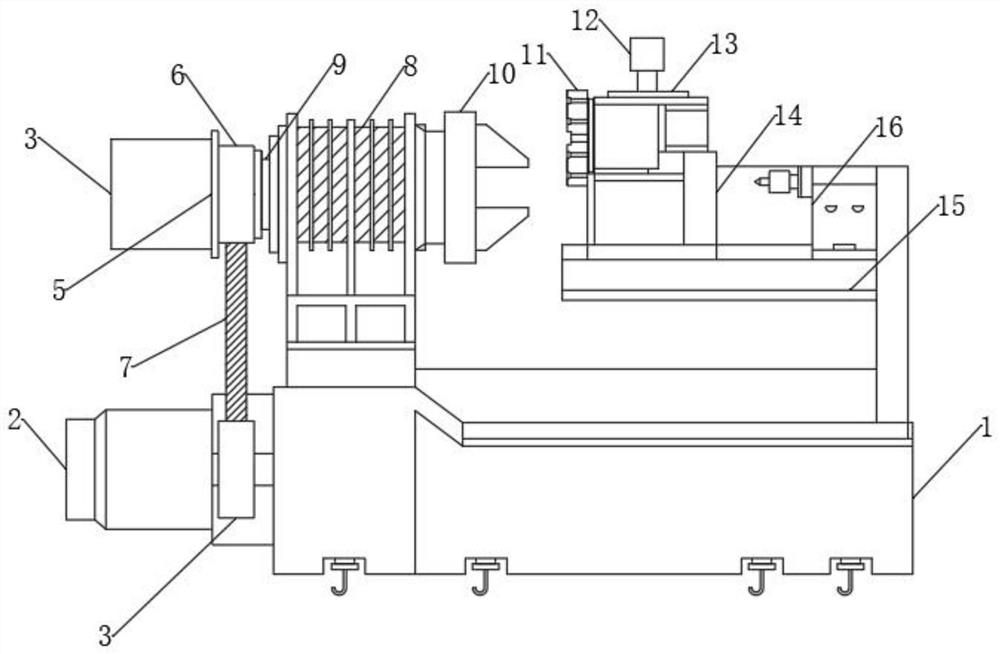

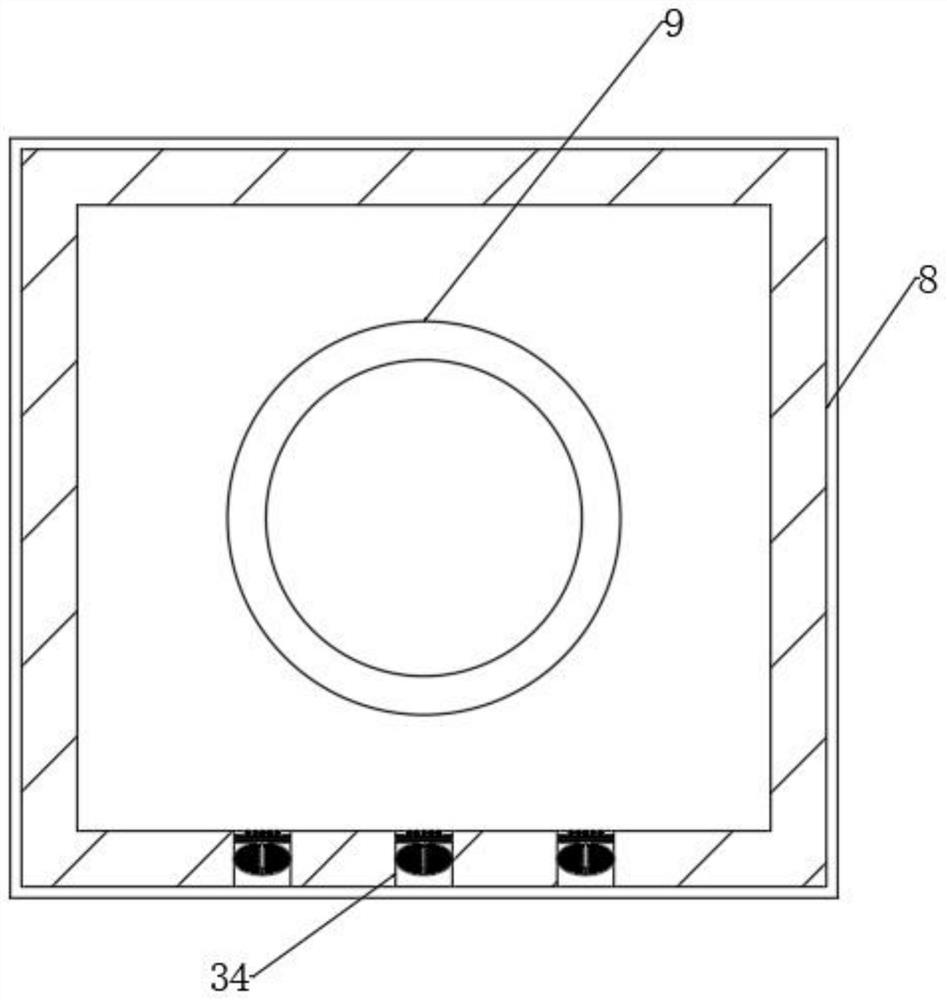

[0034] see Figure 1-2 , a precision-machined numerical control lathe, comprising a bed 1, a main motor 2 is installed on the inner side wall of the bed 1, a motor pulley 4 is rotatably connected to the inner side wall of the bed 1, and the output shaft of the main motor 2 is connected to the motor pulley The left end of 4 is fixedly connected, and the inner side wall of the bed 1 is fixedly connected with the main shaft housing 8, and the main shaft housing 8 is installed with the main shaft body 9, and the left end of the main shaft body 9 is fixedly connected with the main shaft pulley 6, the motor pulley 4 and the main shaft There is a synchronous belt 7 engaged between the pulleys 6, a brake disc 5 is installed on the left end of the main shaft pulley 6, a rotary gland 3 is installed on the left end of the brake disc 5, and a hydraulic chuck 10 is fixedly connected to the right end of the main shaft housing 8. The inner wall of the bed 1 is equipped with a hydraulic tails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com