Novel motor

A new type of motor housing technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of large starting current, large power consumption, and high use cost, and achieve reduced starting current and extended use. Longevity, improve the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

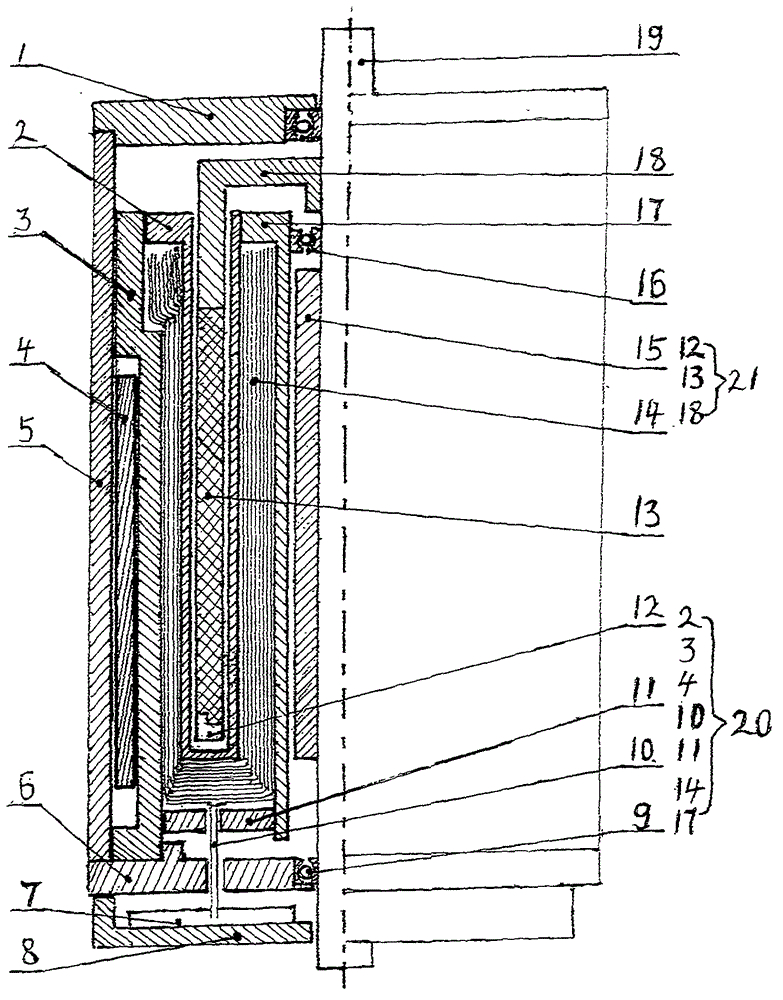

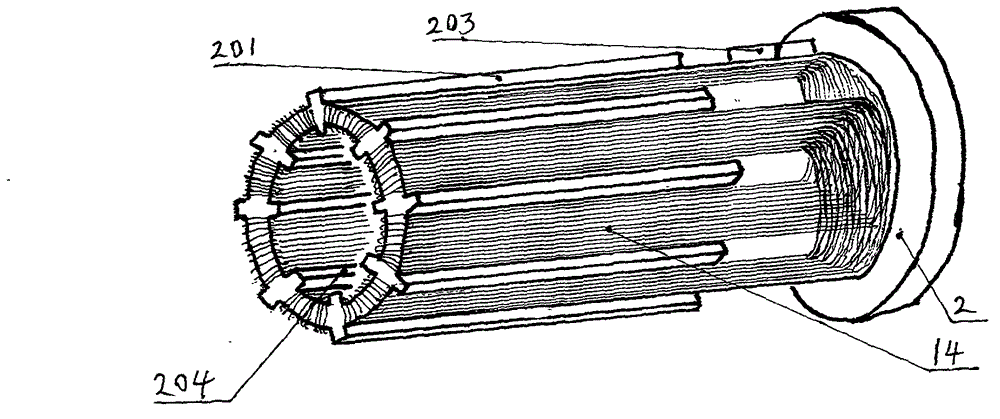

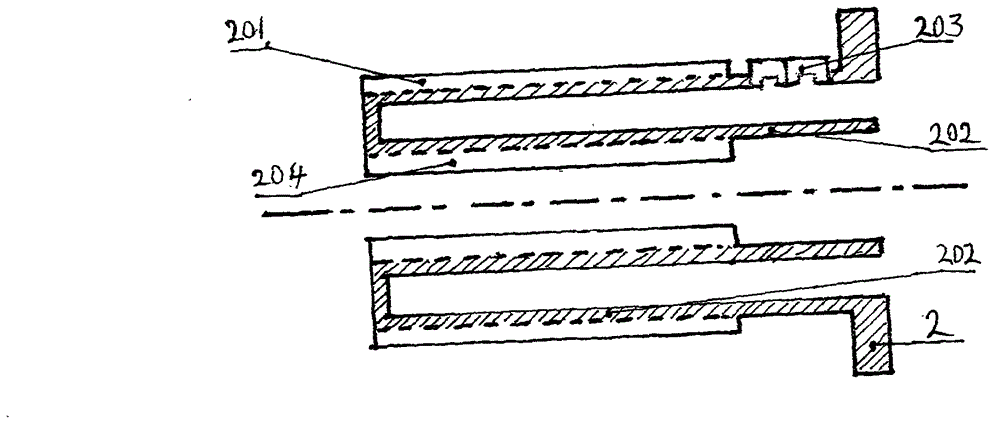

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] See attached figure 1 to attach Figure 12 As shown, a new type of motor includes; 20. The cup-shaped rotor 21 is equipped with a front end cover 1 and a rear end cover 6 on both sides of the motor casing 5, and a bearing 9 is arranged at the center of the front end cover 1 and the rear end cover 6, and the two ends of the motor shaft 19 pass through the bearing 9 and the front end cover. The cover 1 is connected to the rear end cover 6, and one end of the magnetic sleeve 15, the stator inner sleeve bearing 16 and the cup-shaped rotor 21 are respectively connected with the motor shaft 19, the stator 20 is arranged in the motor casing 5, and one end of the stator 20 is connected to the rear end The covers 6 are connected concentrically. The cup-shaped rotor 21 includes: permanent magnets 13, rotor brackets 18 and rotor end plates 12, and multiple pairs of circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com