Transmission belt with transverse curtain

A technology for transmission belts and cord fabrics, applied in the field of transmission belts, can solve the problems of poor lateral rigidity, short service life, and poor lateral pressure resistance, and achieve the effect of good rigidity and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

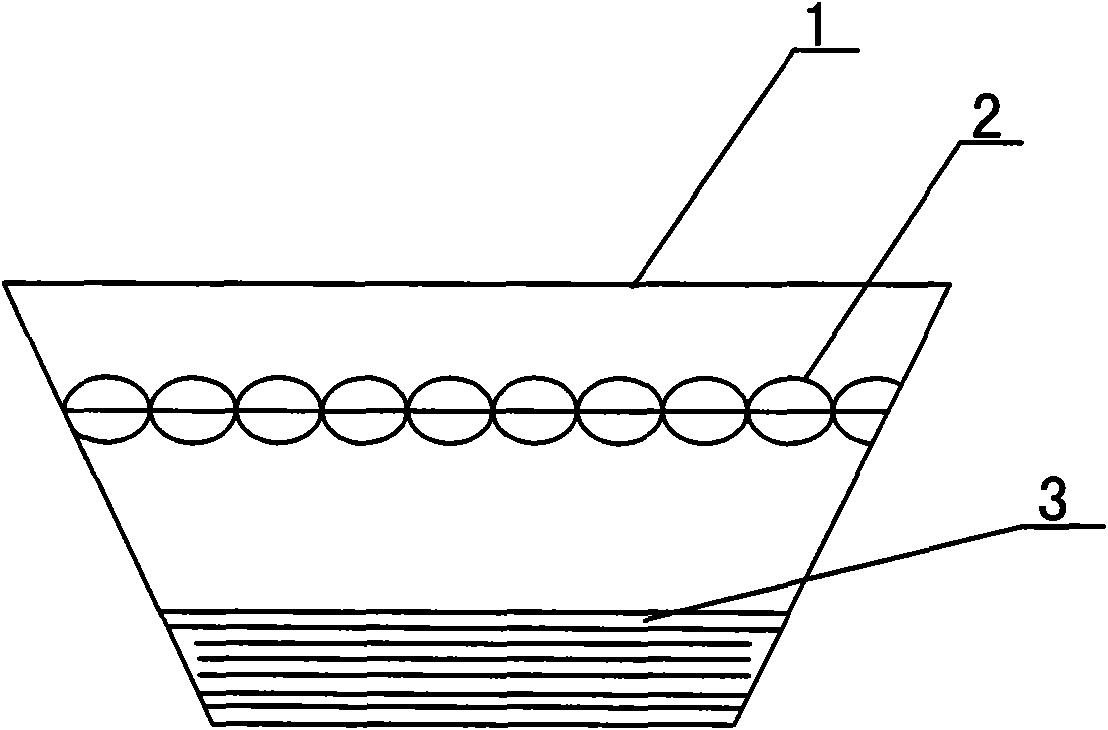

[0011] Such as figure 1 As shown, the transmission belt with transverse cords according to the present invention includes a V-shaped belt body 1, and the bottom of the V-shaped belt body 1 is provided with a cord reinforcement layer 3, and the cord reinforcement layer 3 is cut into certain parts by several cords. The length of the belt is superimposed sequentially, and the cord reinforcing layer 3 is horizontally arranged at the bottom of the V-shaped belt body 1; the upper part of the V-shaped belt body 1 is provided with a pulley 2. Through the change of the diameter of the pulley, the side pressure of the pulley can be used to squeeze the side of the belt; it can make the transmission V-belt have good rigidity, and can withstand huge side pressure, impact load and strong vibration, so as to realize infinitely variable speed; greatly Improve the service life of the tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com