Patents

Literature

69results about How to "Automatic spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

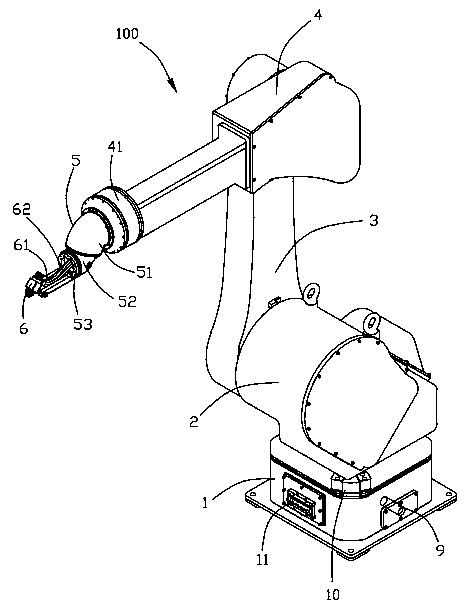

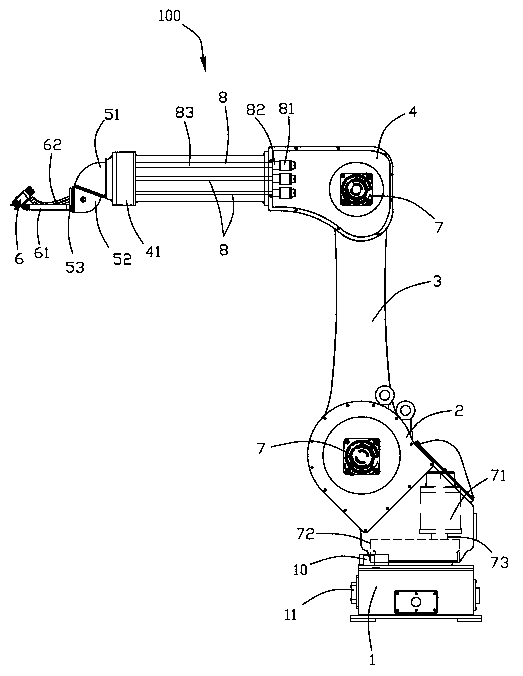

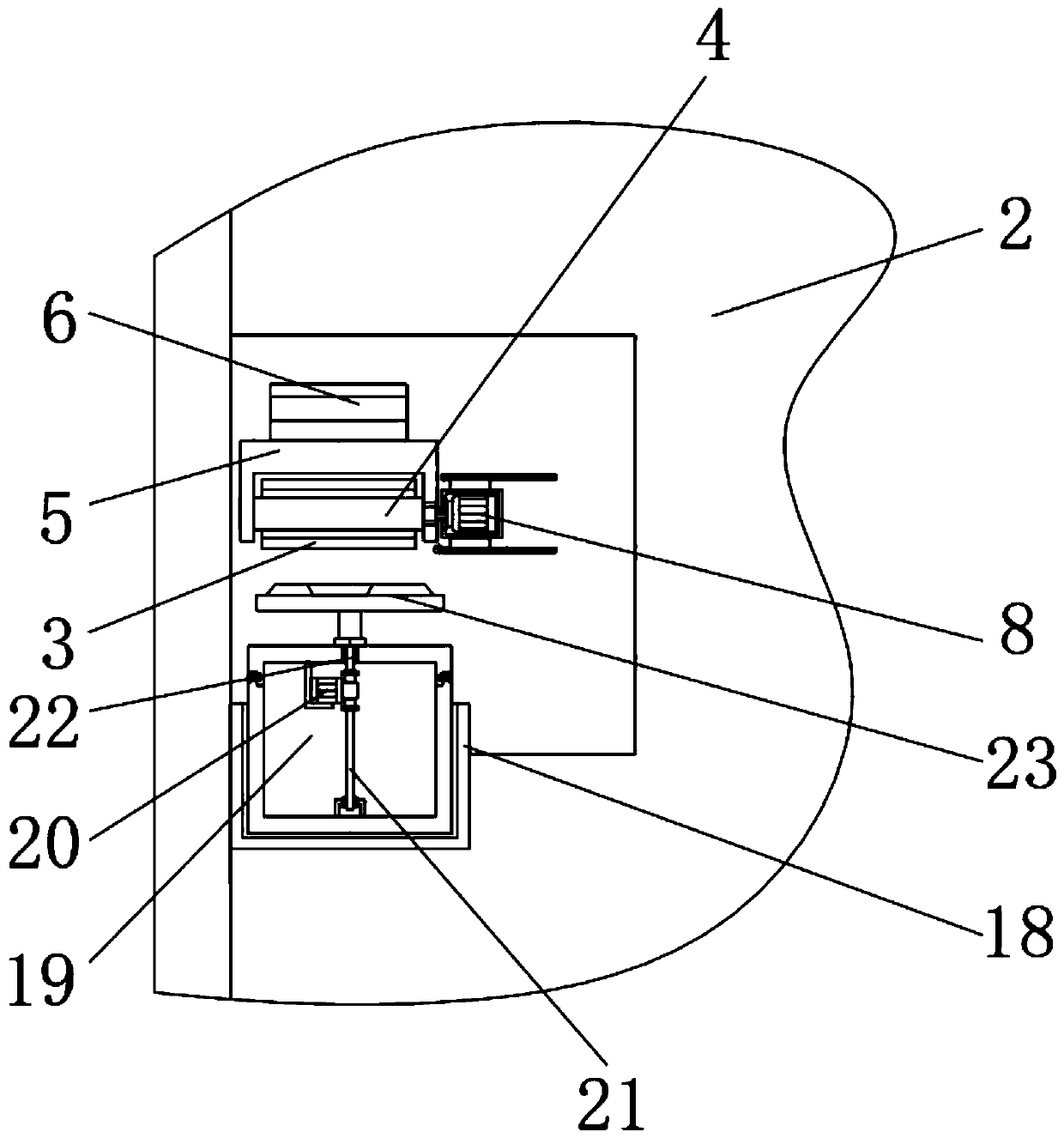

Six-freedom-degree spray coating robot

InactiveCN103538053AHigh transmission precisionImprove precision controlProgramme-controlled manipulatorJointsDrive shaftSpray coating

The invention provides a six-freedom-degree spray coating robot which comprises a base, a waist joint, a big arm joint, a small arm joint, a three-freedom-degree obliquely crossed wrist, a spray gun support, flanges, bearings, a plurality of first drive mechanisms and second drive mechanisms, wherein the waist joint is movably fixed to the base, the big arm joint is movably fixed to the waist joint, the small arm joint is movably fixed to the big arm joint, the three-freedom-degree obliquely crossed base is movably fixed to the small arm joint, the spray gun support is connected to the tail end of the three-freedom-degree obliquely crossed wrist, and the flanges and the bearings are movably connected among all the joints or between the joints and the wrist. The first drive mechanisms are used for driving the waist joint, the big arm joint and the small arm joint to work, and the second drive mechanisms are used for driving the three-freedom-degree obliquely crossed wrist to work. Each first drive mechanism comprises a first servo motor and an RV speed reducer. Each second drive mechanism comprises a second servo motor, a planetary reducer, a hollow transmission shaft and a gear pair, wherein the planetary reducer is connected with the second servo motor, the hollow transmission shaft is connected with the planetary reducer in a matched mode, and the gear pair is arranged in the three-freedom-degree obliquely crossed wrist and connected with the hollow transmission shaft.

Owner:HUAHENG WELDING

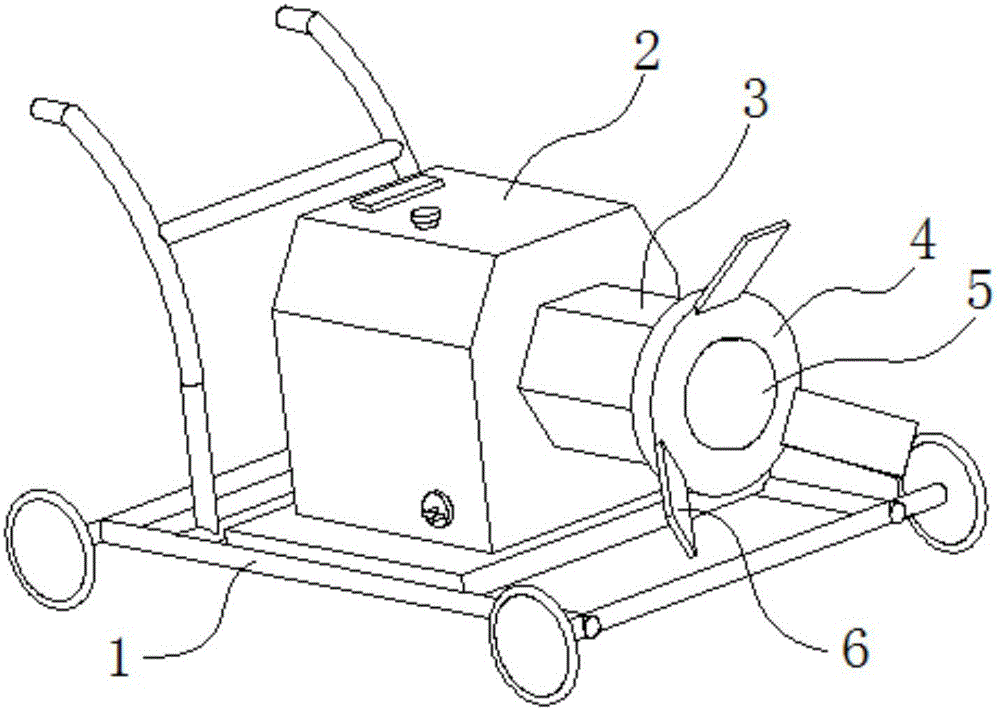

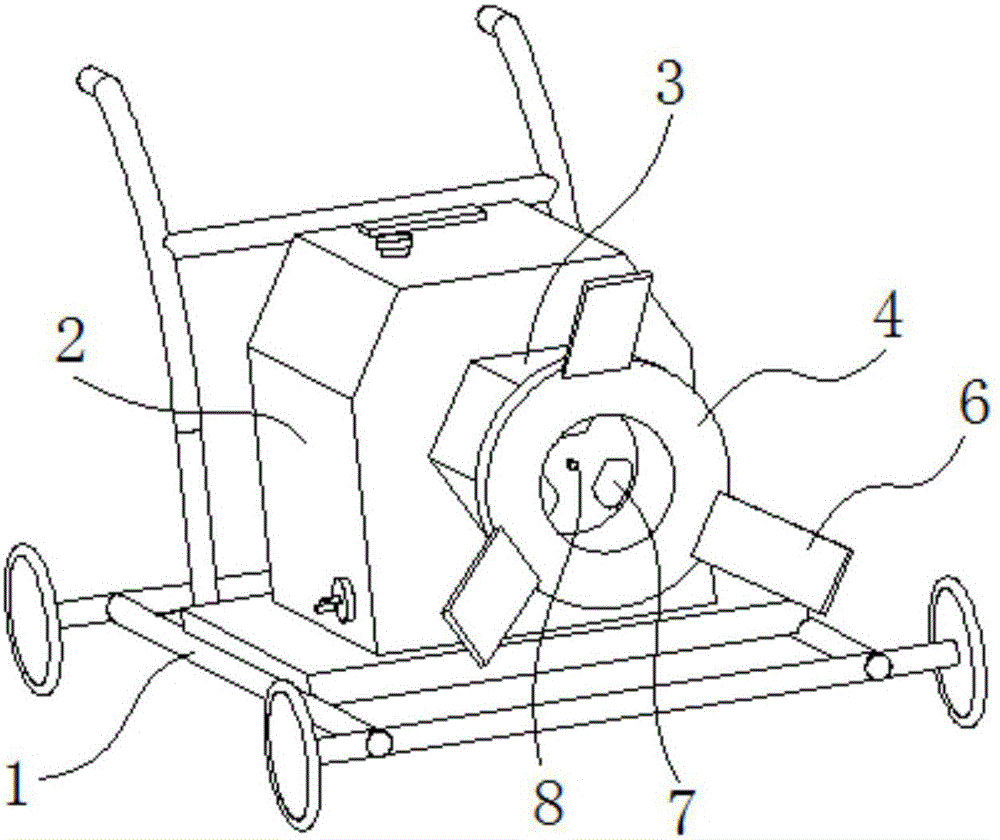

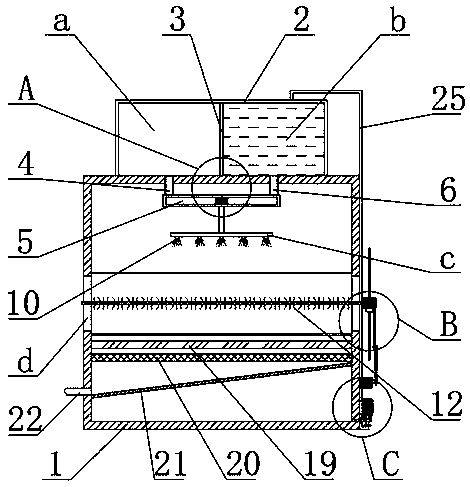

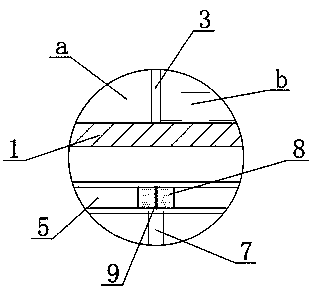

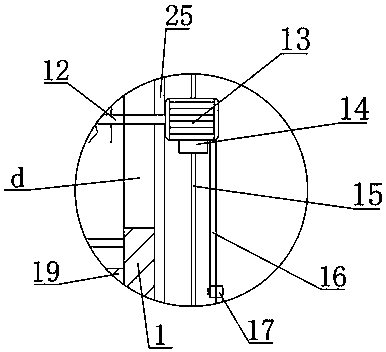

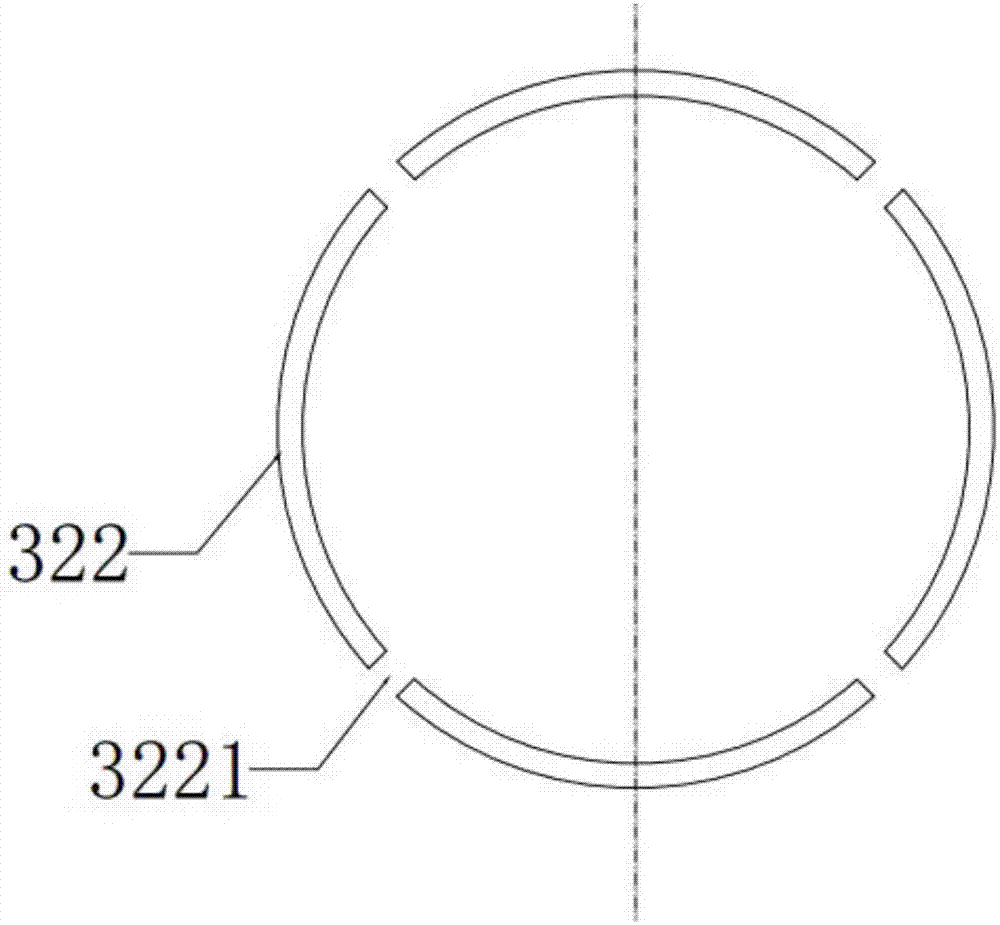

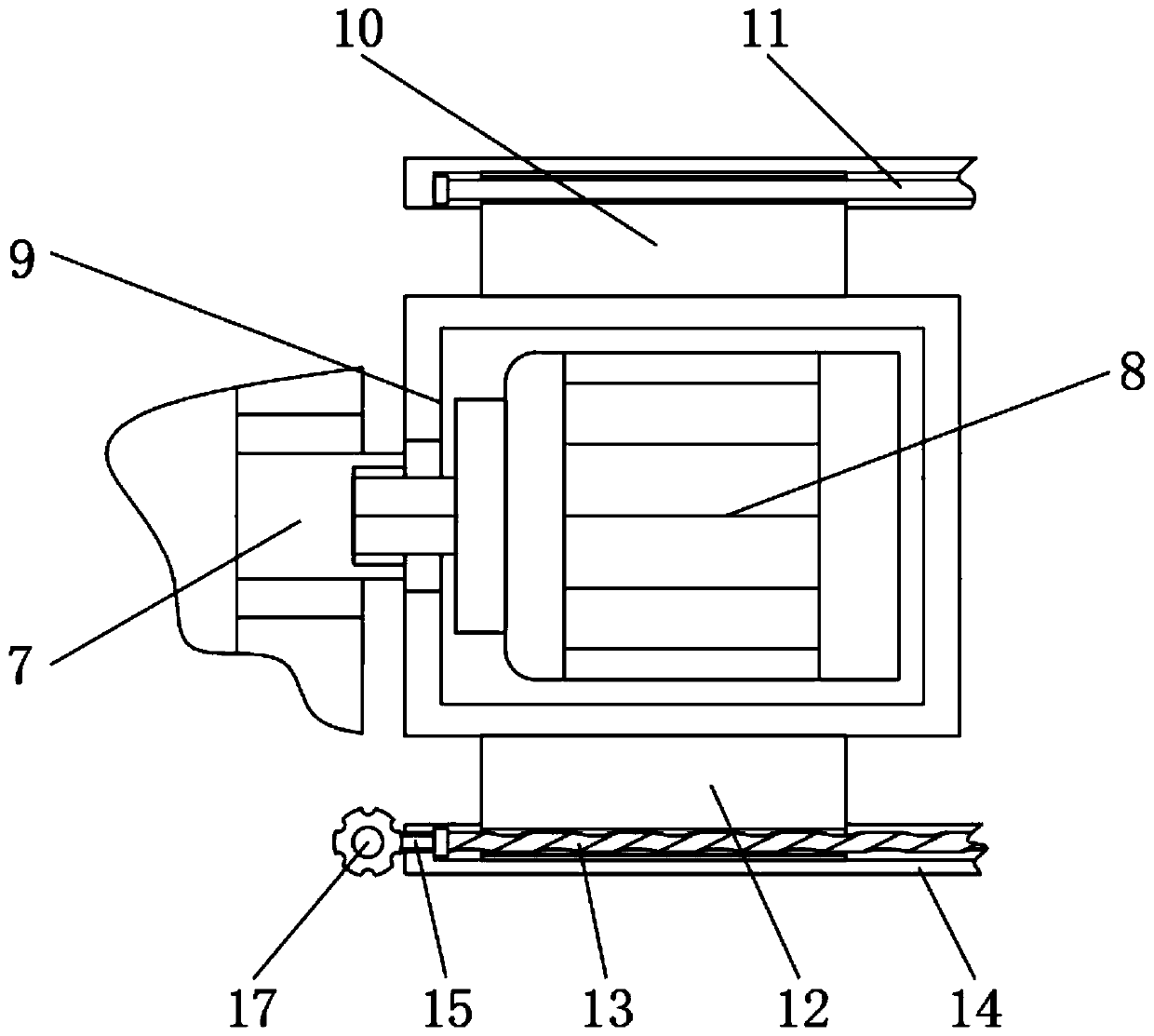

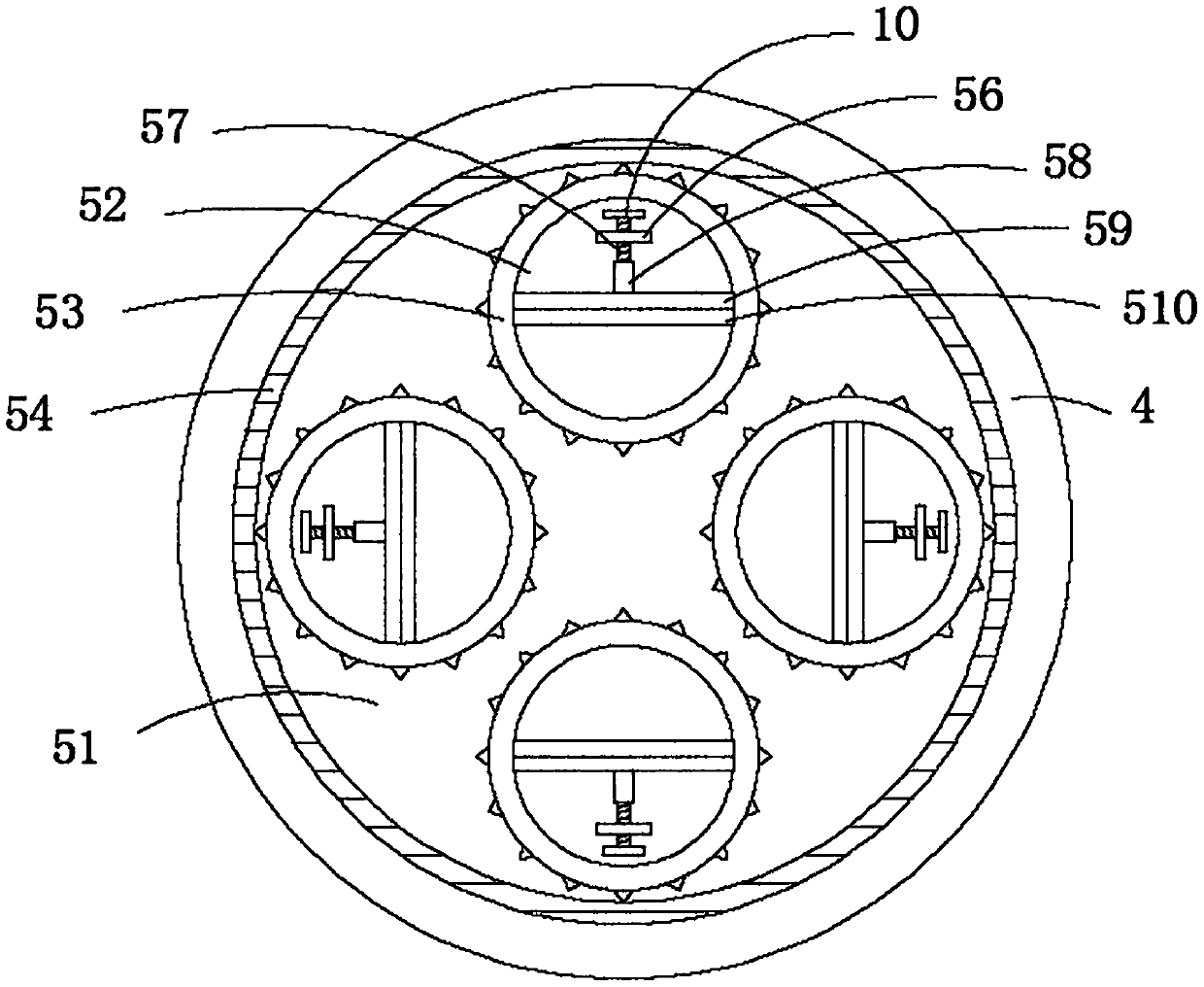

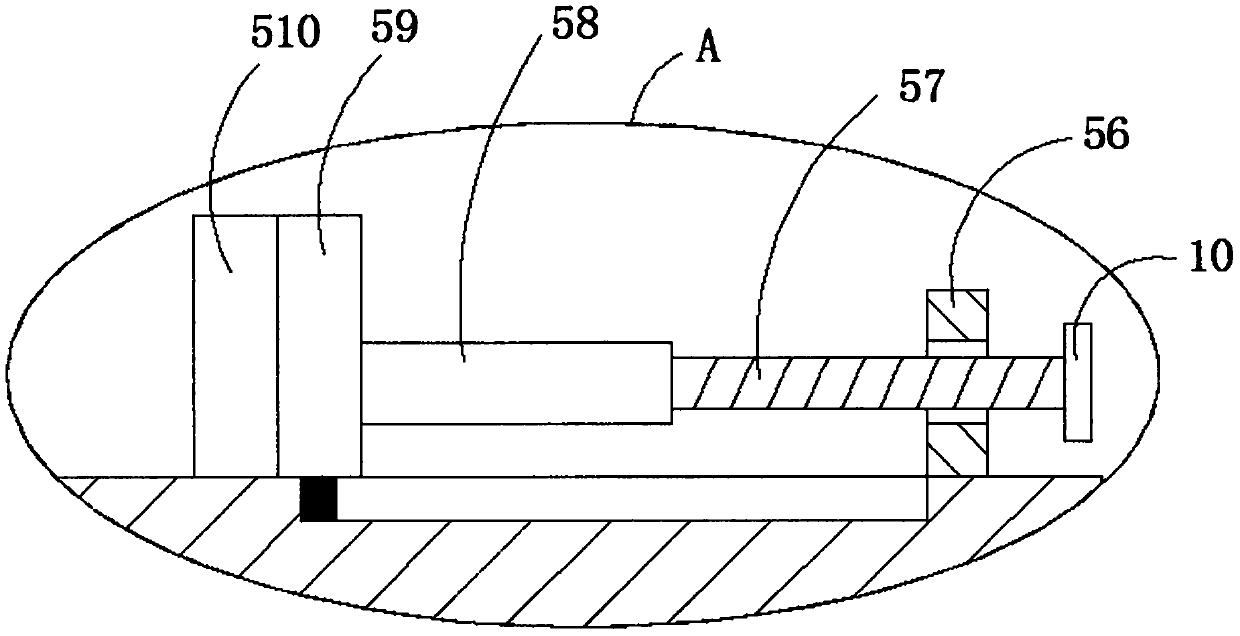

Automobile hub cleaning machine

ActiveCN105149268AImprove cleaning efficiencyImprove applicabilityCleaning apparatus for vehicle exteriorsCleaning using toolsMechanical engineering

The invention discloses an automobile hub cleaning machine. The cleaning machine comprises a trolley, a case, a machine head, a cleaning head and a cleaning door, wherein the case is arranged on the trolley; the machine head can be arranged at the front end of the case in a rotary manner and is driven by a power mechanism to rotate; the cleaning head is shaped like a ring and is arranged at the front end of the machine head; the cleaning door is used for covering an inner hole of the cleaning head; when the cleaning door covers the inner hole of the cleaning head; the front end face of the cleaning door and the front end face of the cleaning head are on the same level; besides, a fan, a solution chamber and a clear water chamber can be arranged in the case; cleaning side plates are arranged on the cleaning head. The cleaning machine can be used for automatically cleaning hubs and has high cleaning efficiency and strong applicability.

Owner:GUANGXI UNIV

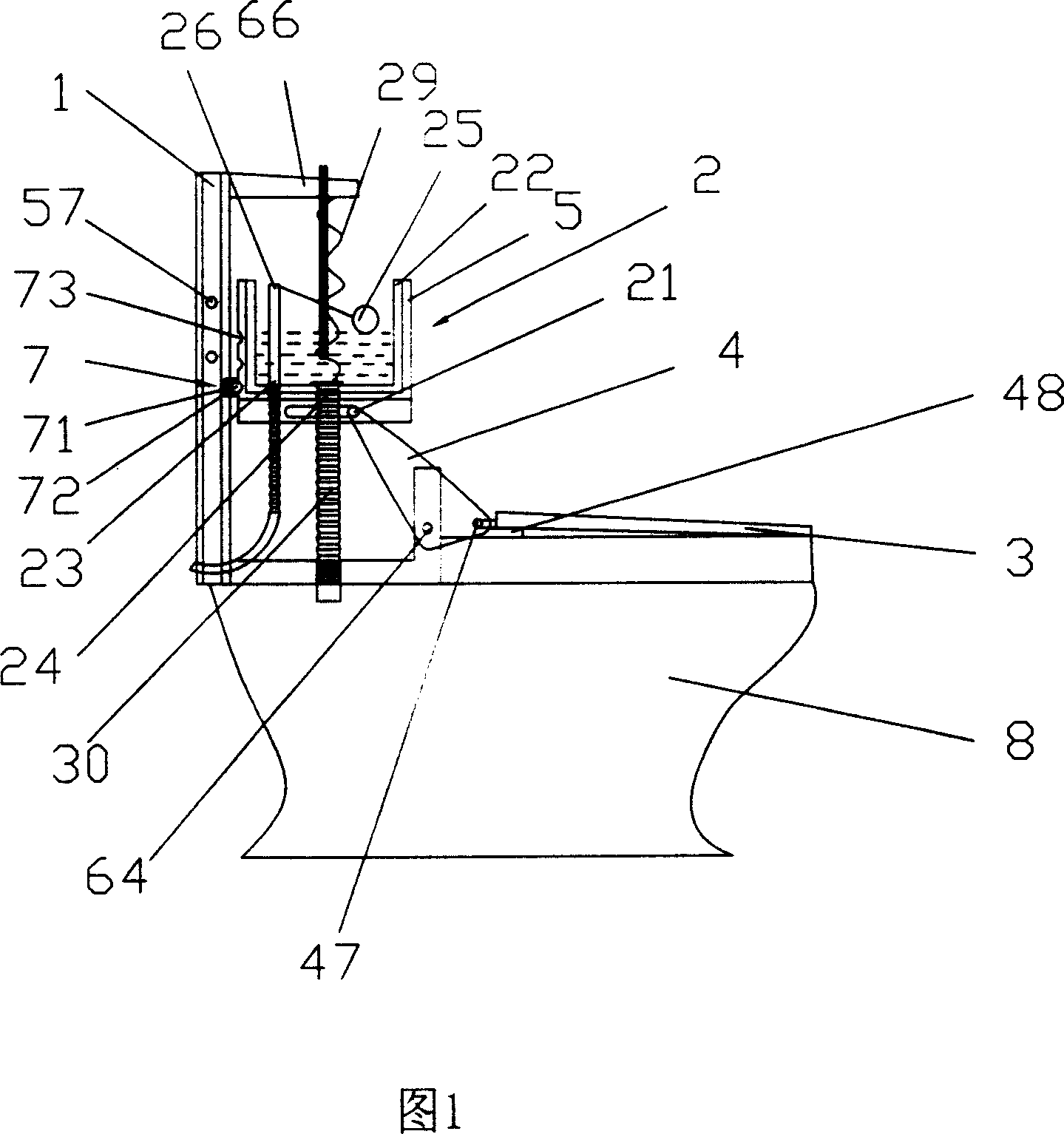

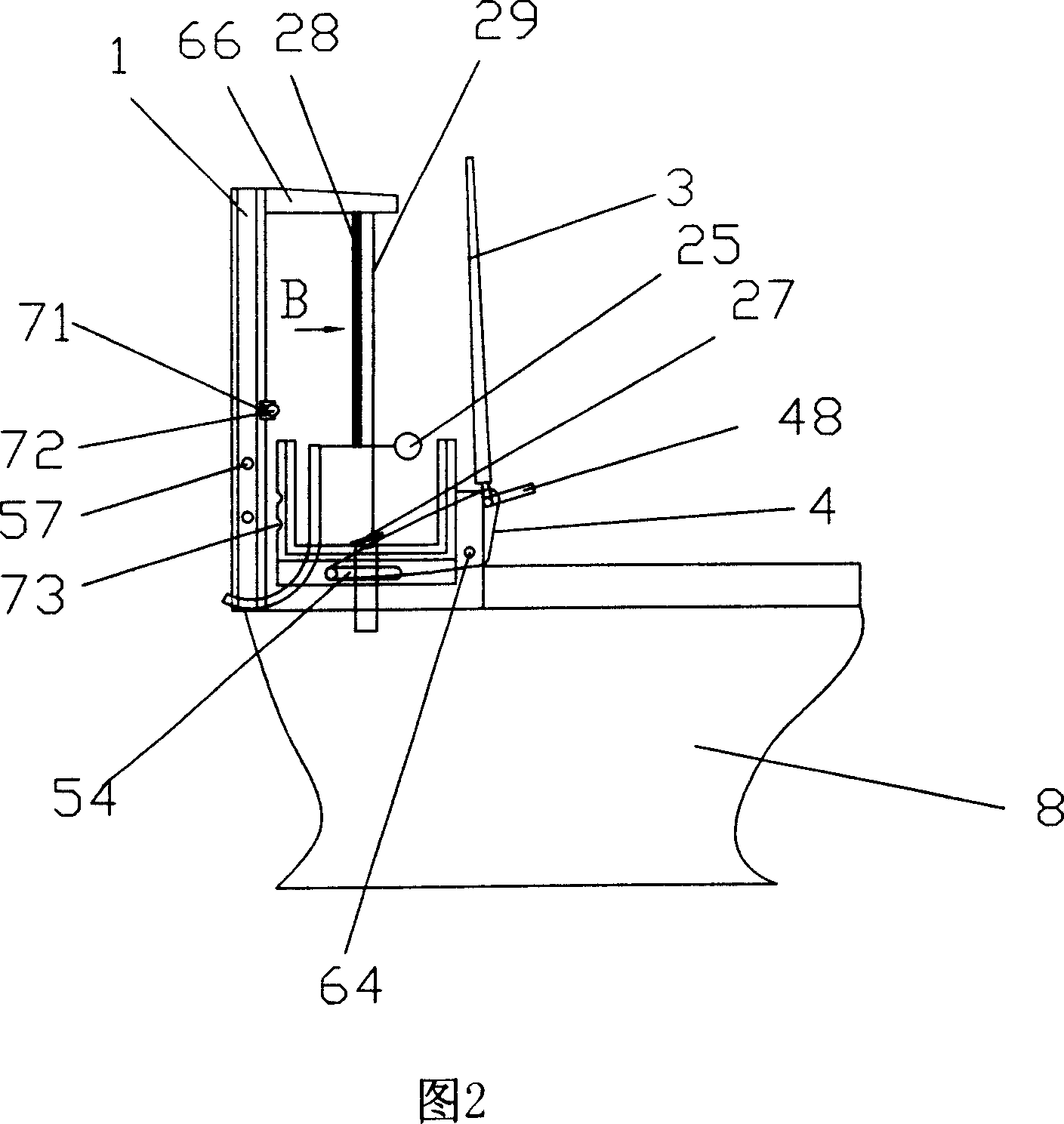

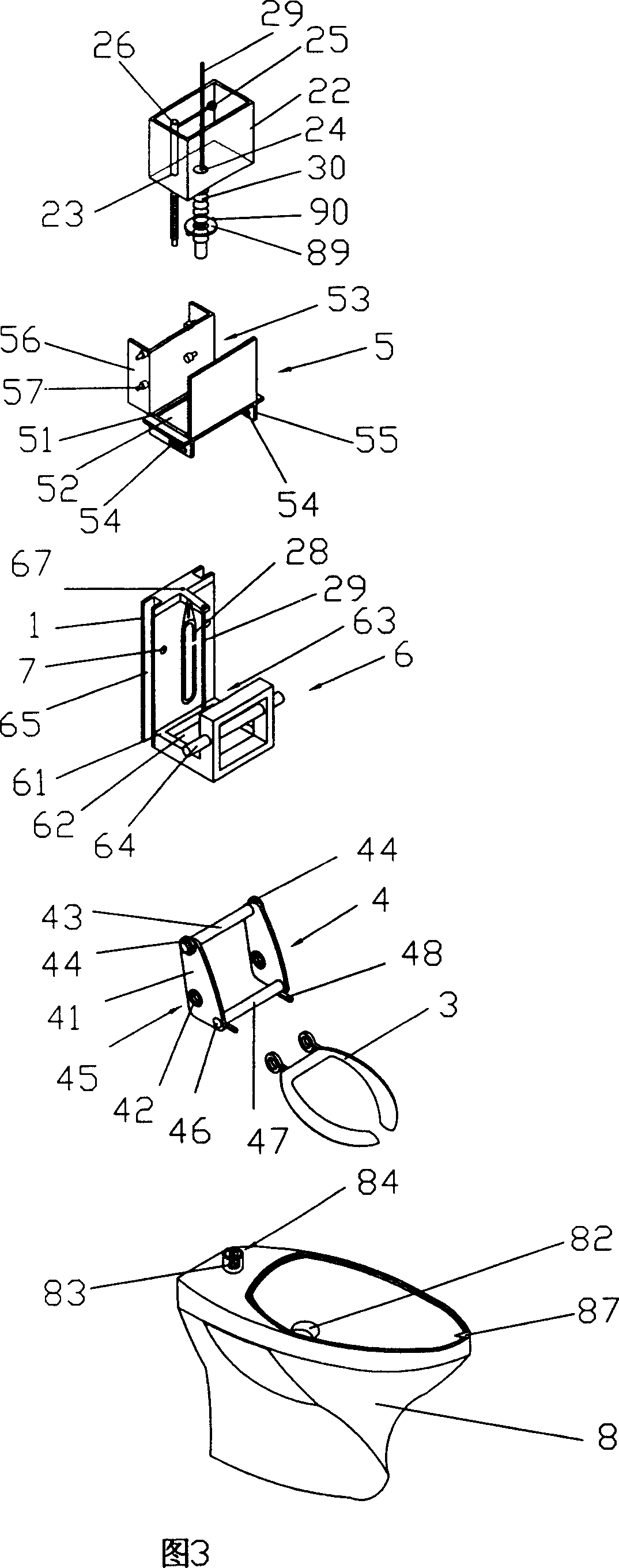

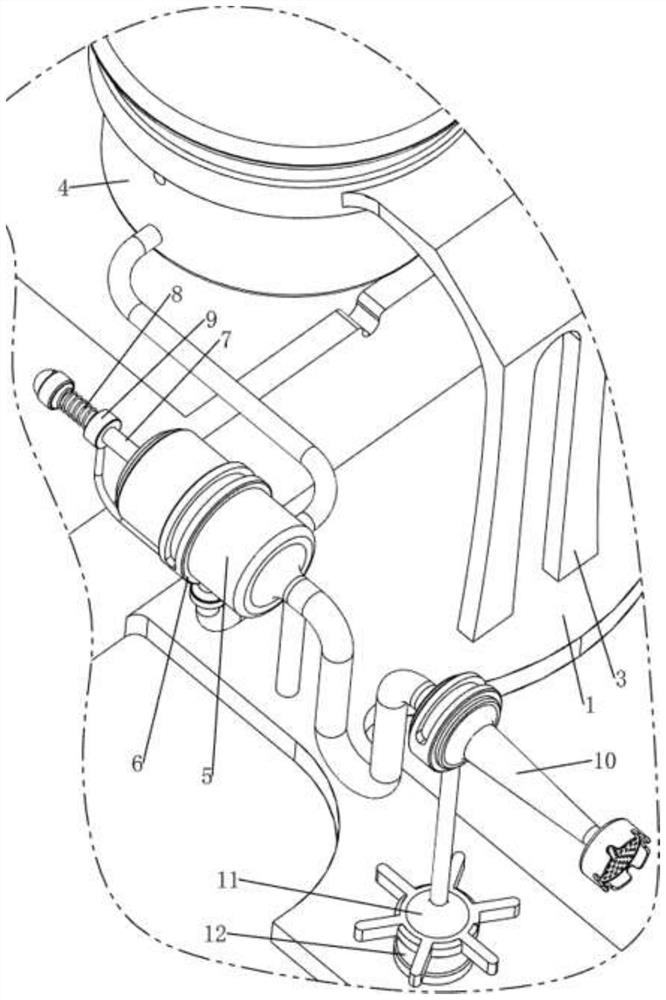

Complex functional toilet closet mechanism

InactiveCN1986986AFully automaticRealize the purpose of fully automatic toilet flushingFlushing devicesLavatory sanitoryDraining tubeInlet valve

A flushing toilet unit for the lavatory with comprehensive functions is composed of a water accumulating unit with guide track, a toilet plate, and an acting arm with one end connected with said water accumulating unit and another end linked with said toilet plate. Said water accumulating unit has a cistern with water inlet having a water inlet valve controlled by a control member, and water outlet having a water outlet valve controlled by a flexible string and a telescopic draining pipe. The toilet can be automatically flushed without electric consumption.

Owner:李名山

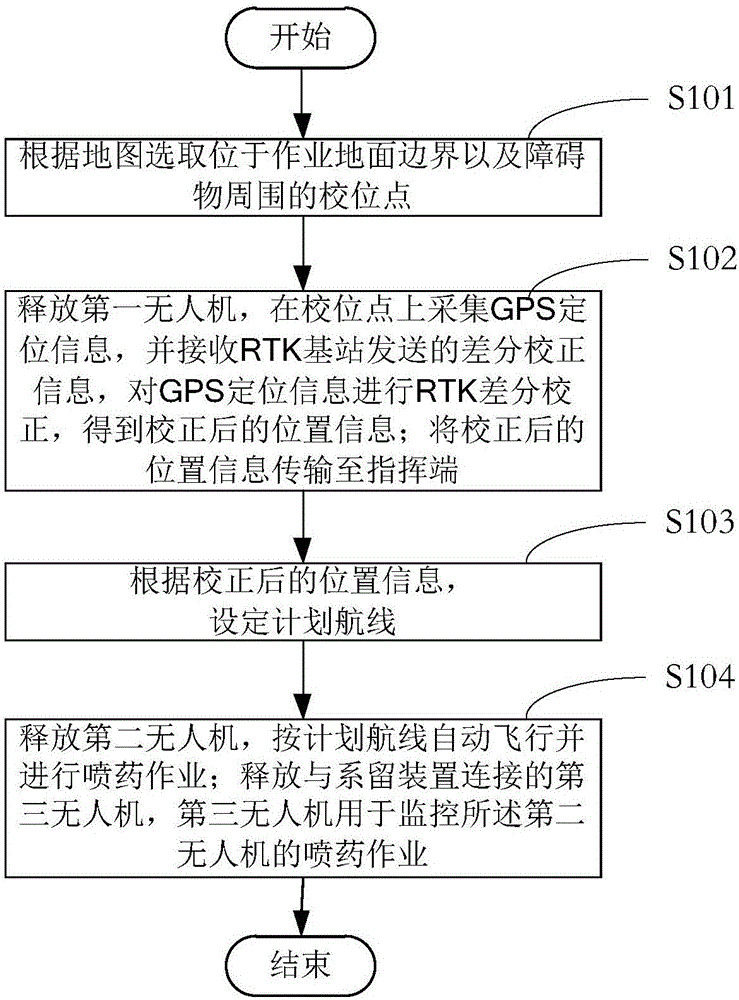

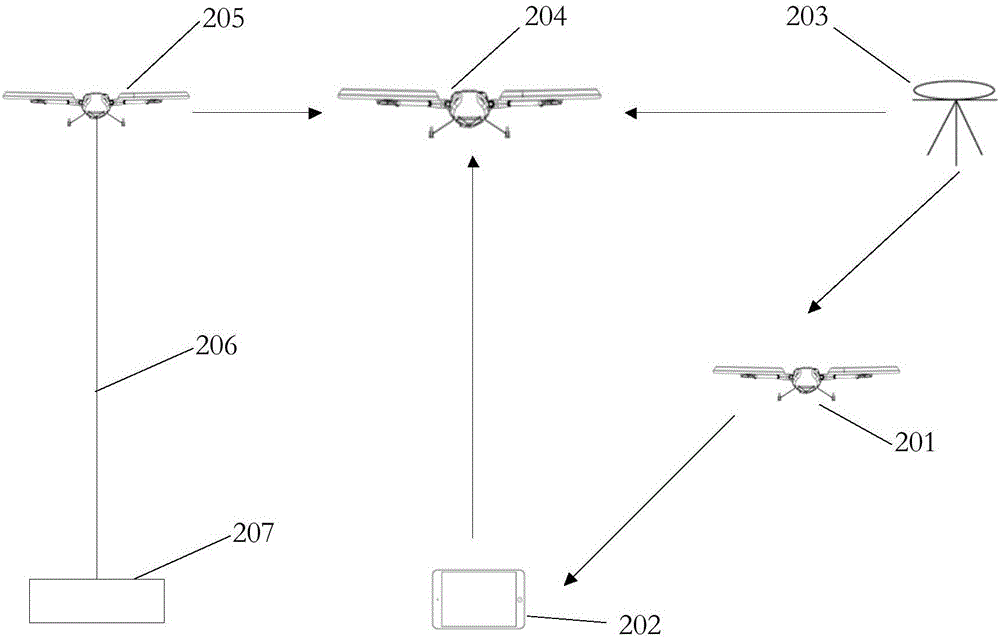

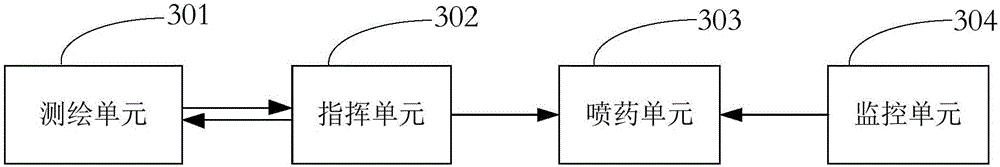

Surveying and mapping, pesticide spraying and monitoring combination work method and system of unmanned aerial vehicles

ActiveCN106843277AEnsure safetyReal-time transmissionPosition/course control in three dimensionsUncrewed vehicleDifferential correction

The invention provides a surveying and mapping, pesticide spraying and monitoring combination work method and system of unmanned aerial vehicles. The method includes the steps that according to a map, correction points located on the boundary of work ground and around obstacles are selected; the first unmanned aerial vehicle is released, GPS positioning information is collected on the correction points, differential correction information sent by an RTK base station is received, and the GPS positioning information is subjected to RTK differential correction to obtain corrected position information; the corrected position information is transmitted to a command terminal; a planned air route is set according to the corrected position information; the second unmanned aerial vehicle is released and automatically flies according to the planned air route, and pesticide spraying is conducted; the third unmanned aerial vehicle is released and connected with a mooring device, wherein the third unmanned aerial vehicle is used for monitoring pesticide spraying of the second unmanned aerial vehicle. The system is used for implementing the method and comprises a surveying and mapping unit, a command unit, a pesticide spraying unit and a monitoring unit. Large-scale automatic pesticide spraying can be achieved.

Owner:SANGAIR TECH

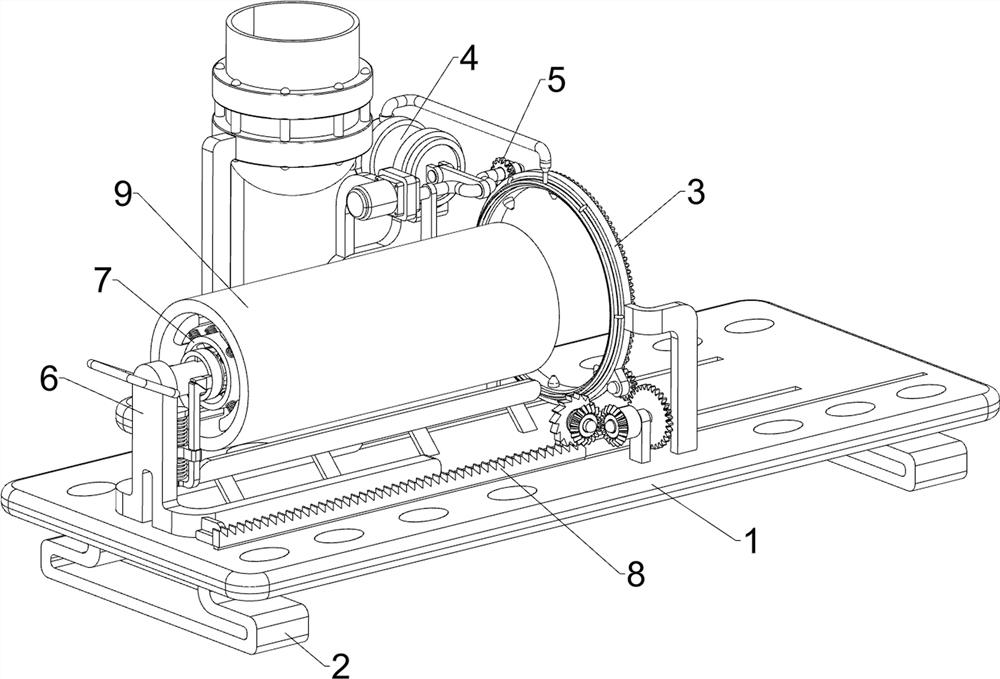

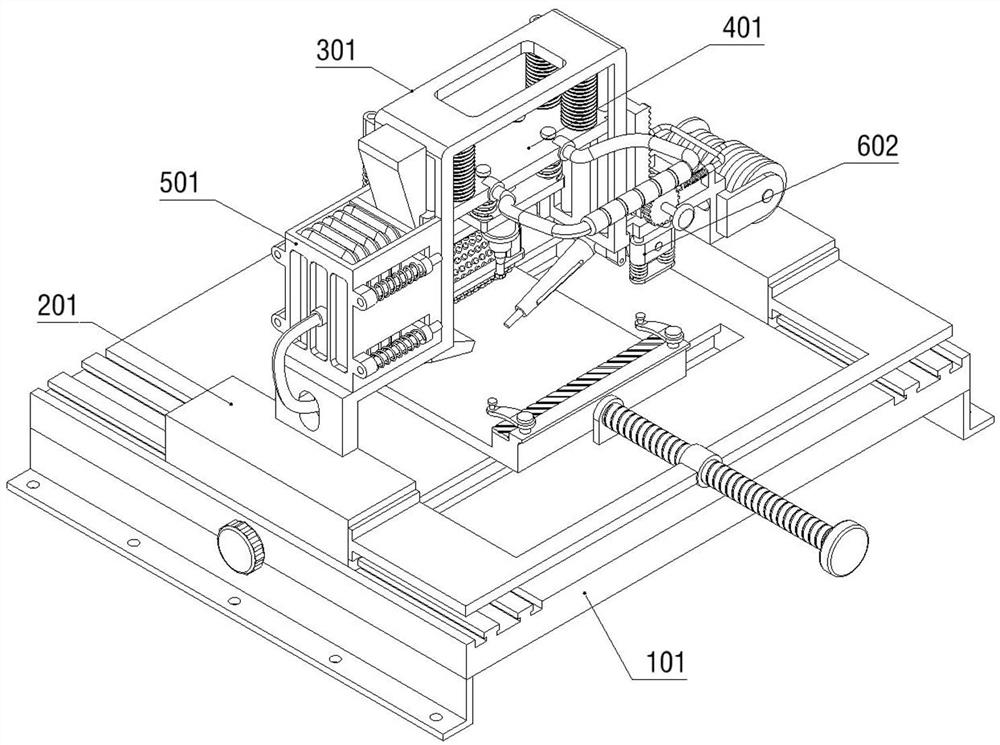

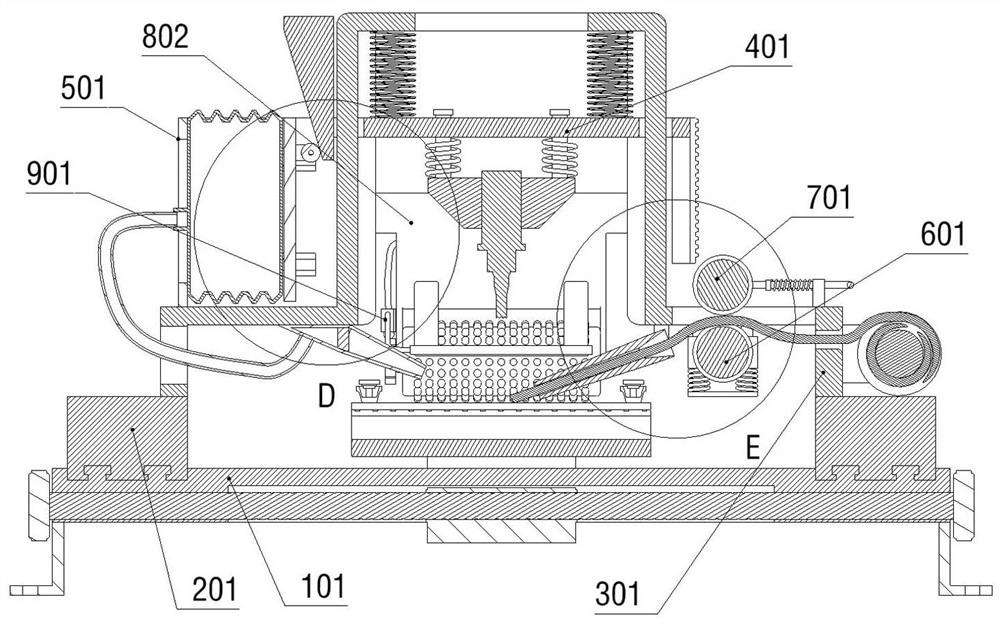

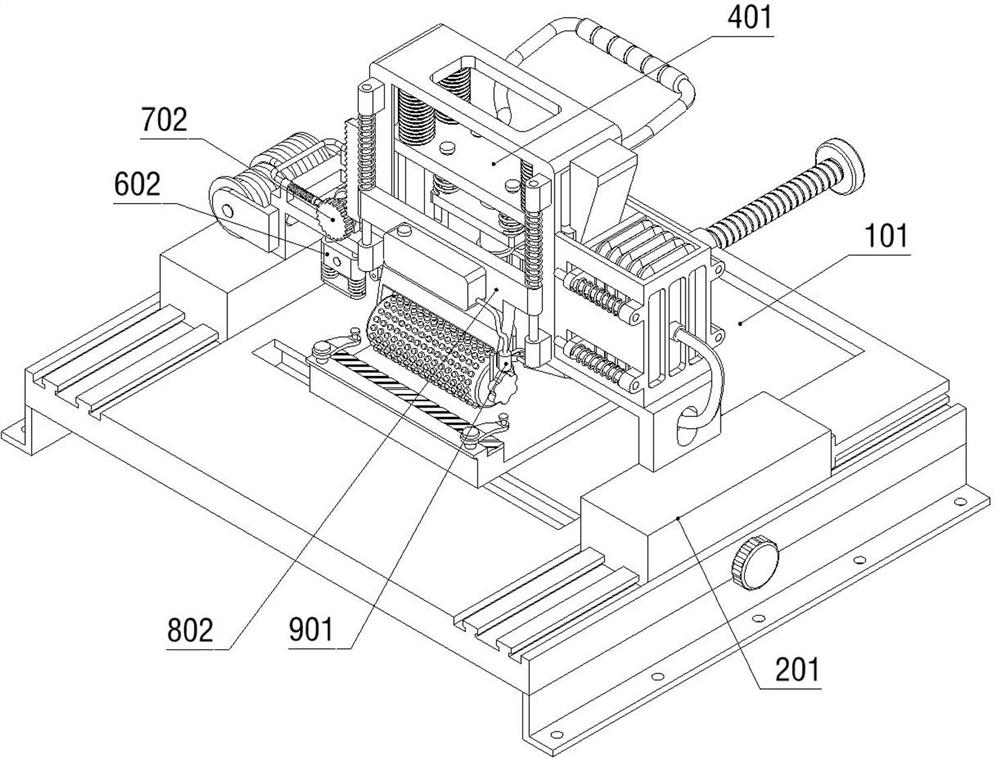

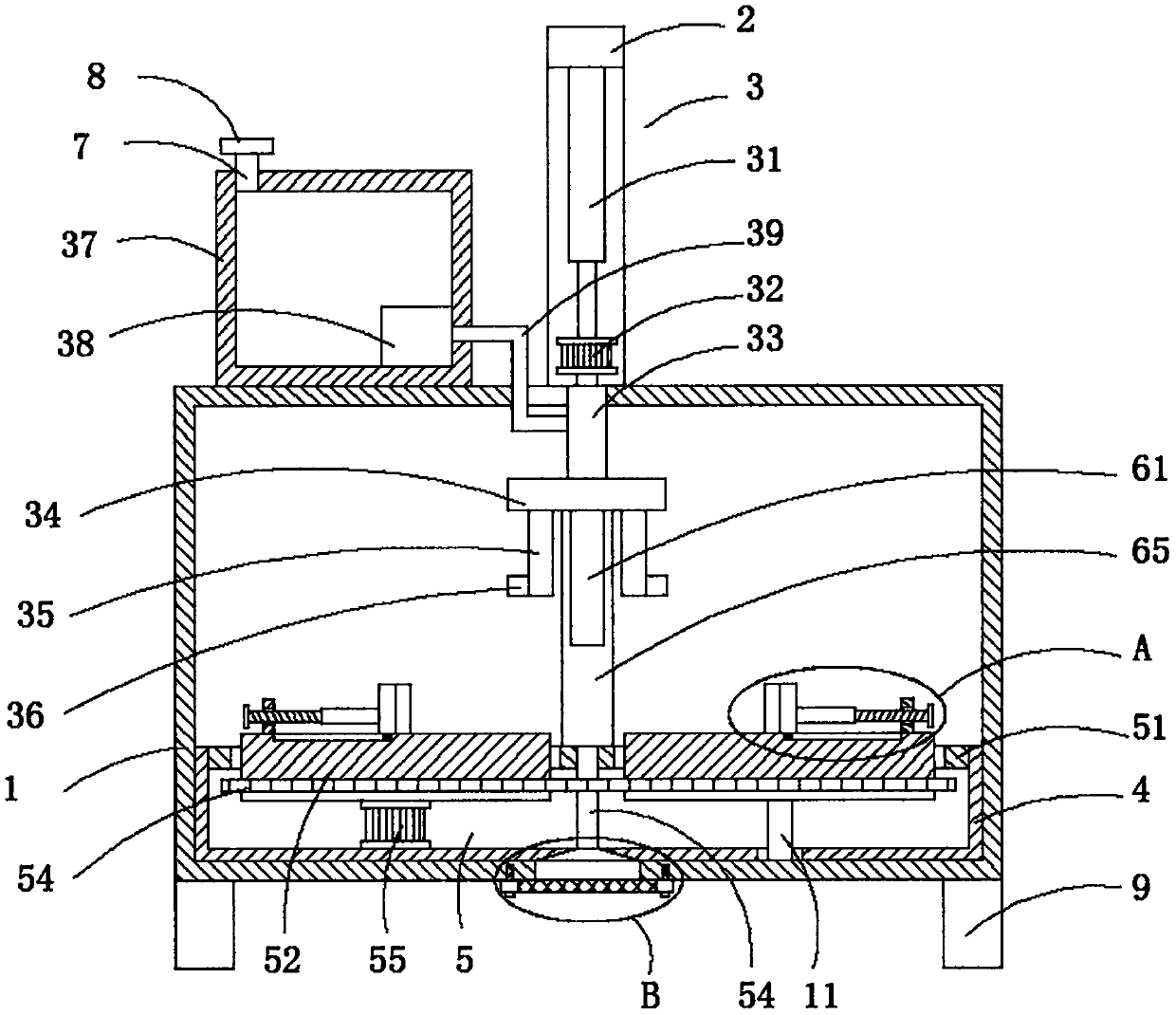

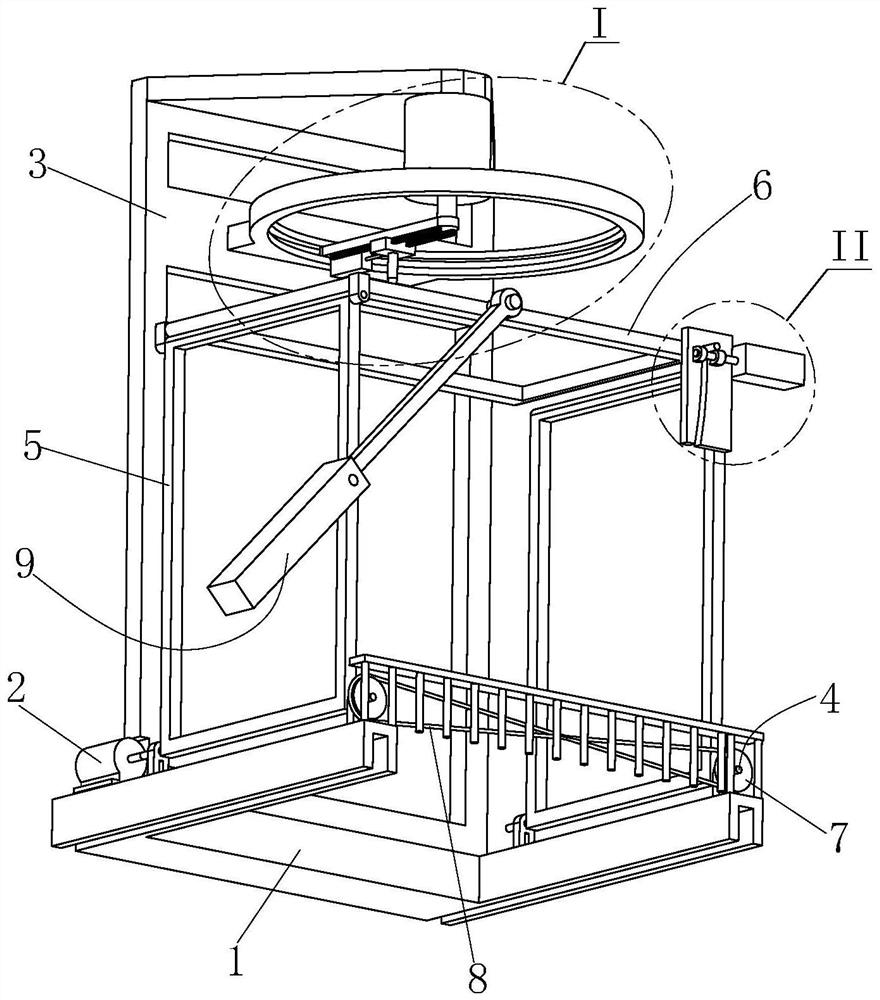

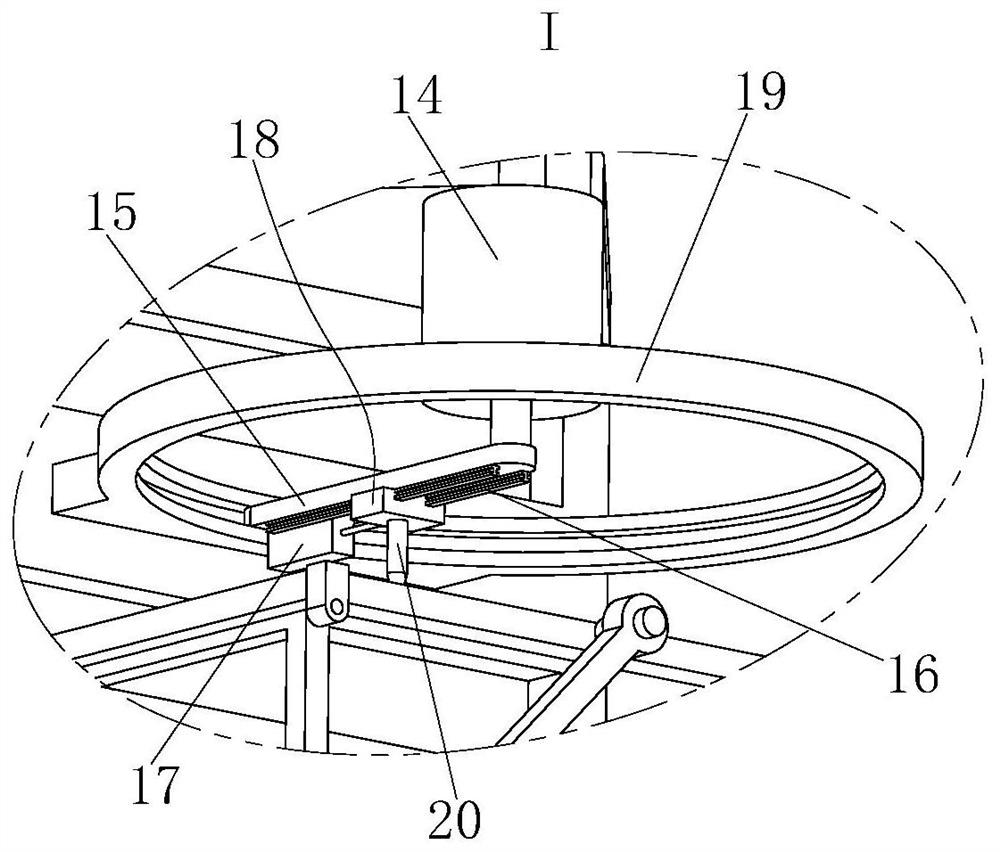

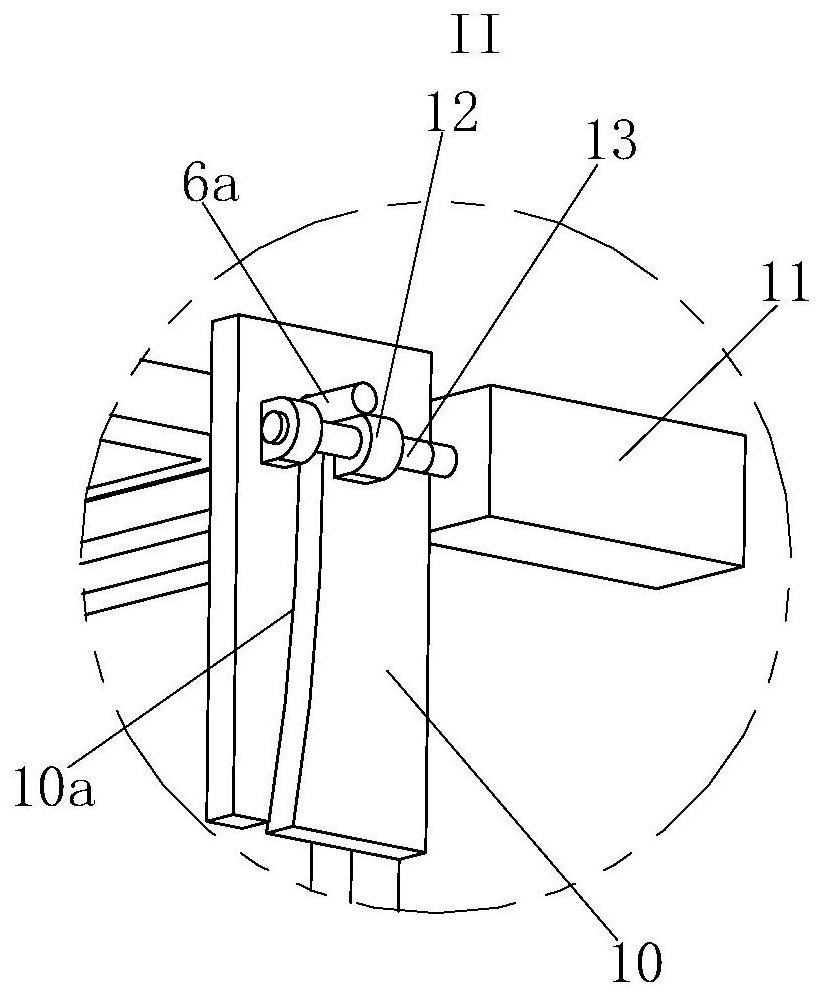

Anti-corrosion coating spraying equipment for exhaust gas emission pipeline

ActiveCN113145348AAutomatic sprayingImprove work efficiencySpraying apparatusExhaust gas emissionsExhaust fumes

The invention relates to spraying equipment, in particular to anti-corrosion coating spraying equipment for an exhaust gas emission pipeline. According to the anti-corrosion coating spraying equipment for the exhaust gas emission pipeline, anti-corrosion coating can be automatically sprayed to the outer wall of the exhaust gas emission pipeline, time and labor can be saved, and the working efficiency can be improved. The anti-corrosion coating spraying equipment for the exhaust gas emission pipeline comprises a bottom plate, a spraying mechanism, a feeding mechanism and a rotating mechanism, and supporting frames are connected to the two sides of the bottom of the bottom plate; the spraying mechanism is mounted at the top of the bottom plate; the feeding mechanism is mounted at the top of the bottom plate; and the rotating mechanism is mounted at the top of the bottom plate. Through cooperation of the spraying mechanism, the feeding mechanism and the rotating mechanism, an anti-corrosion coating can be uniformly sprayed on the outer wall of the exhaust gas emission pipeline, so that the effects that the anti-corrosion coating can be automatically sprayed on the outer wall of the exhaust gas emission pipeline, time and labor can be saved, and the working efficiency can be improved are achieved.

Owner:河北恒泰管道科技有限公司

Spraying flowerpot

InactiveCN103461021AAutomatic sprayingOvercome accuracySelf-acting watering devicesReceptacle cultivationAir pumpEngineering

The invention discloses a spraying flowerpot. The spraying flowerpot mainly comprises a flowerpot (1), a decorative sleeve (2), a tray (3) and a base (4). A water bin is formed in the base, and water is pumped into a water spraying pipe by a water pump and is sprayed to a flower from top to bottom, so that the flower can be automatically sprayed, and the defects that the best spraying time and the spraying amount cannot be accurately mastered by a person are overcome; water draining and air venting holes are formed in a flowerpot wall and a central column, and a clearance is reserved between the flowerpot wall and the decorative sleeve, so that the water drainage and the air ventilation can be improved; ozone is fed to the bottom of the water bin by an air pump through an air feeding pipe, is sprayed out of air spraying holes in the wall of an air bin and is fully mixed with the water to form ozone water, and the ozone water is pumped into the water spraying pipe by the water pump and is sprayed to the flower and the soil for sterilization, so that the flower grows healthily.

Owner:朱文杰

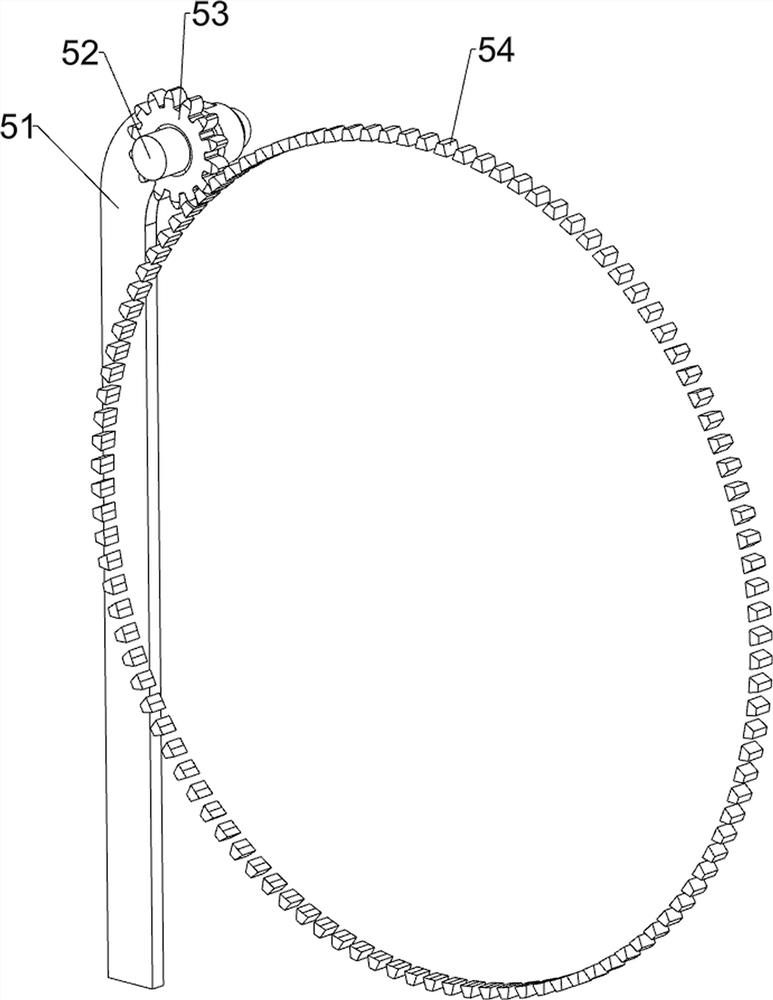

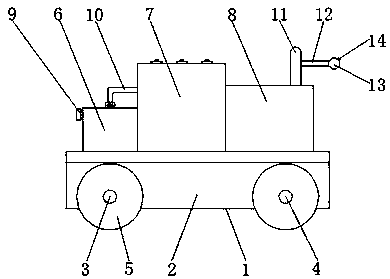

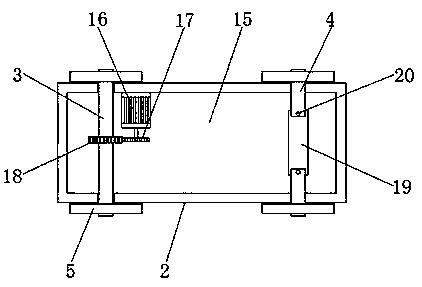

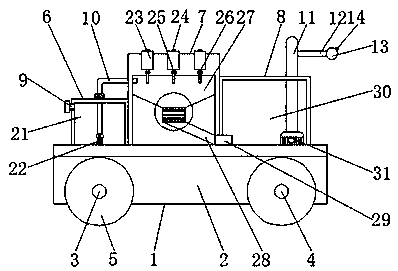

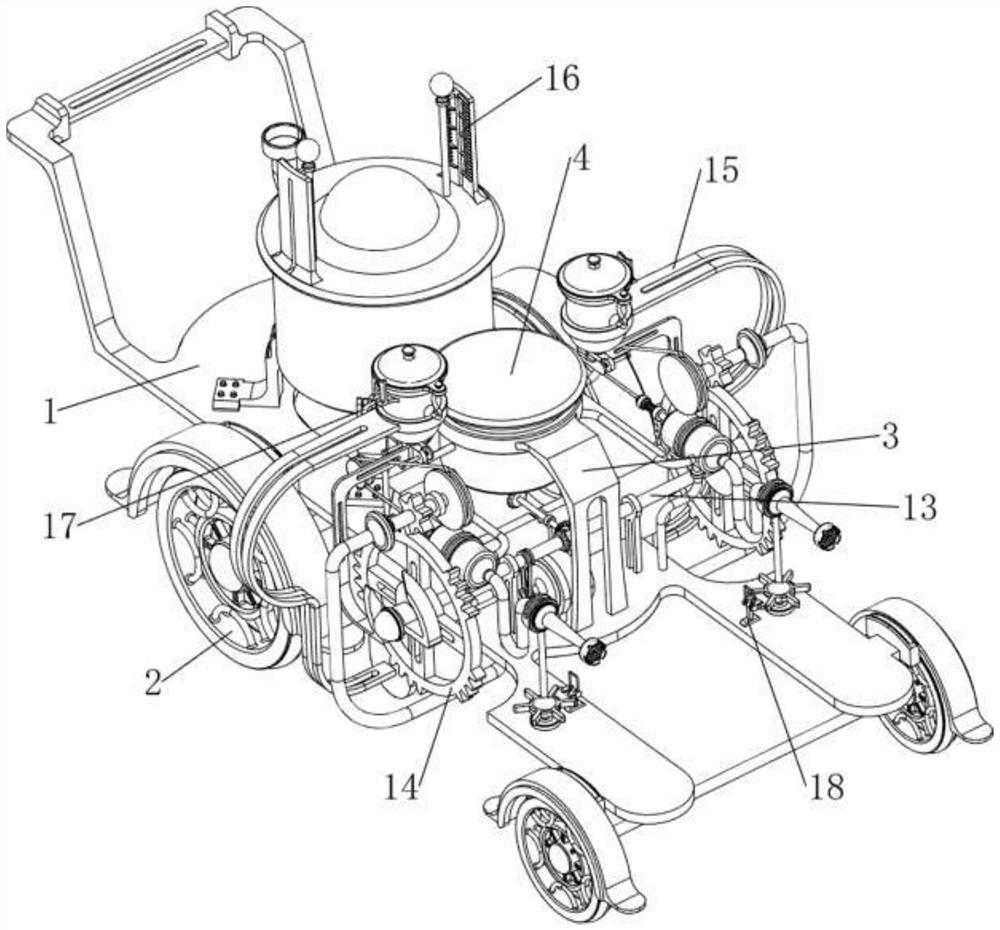

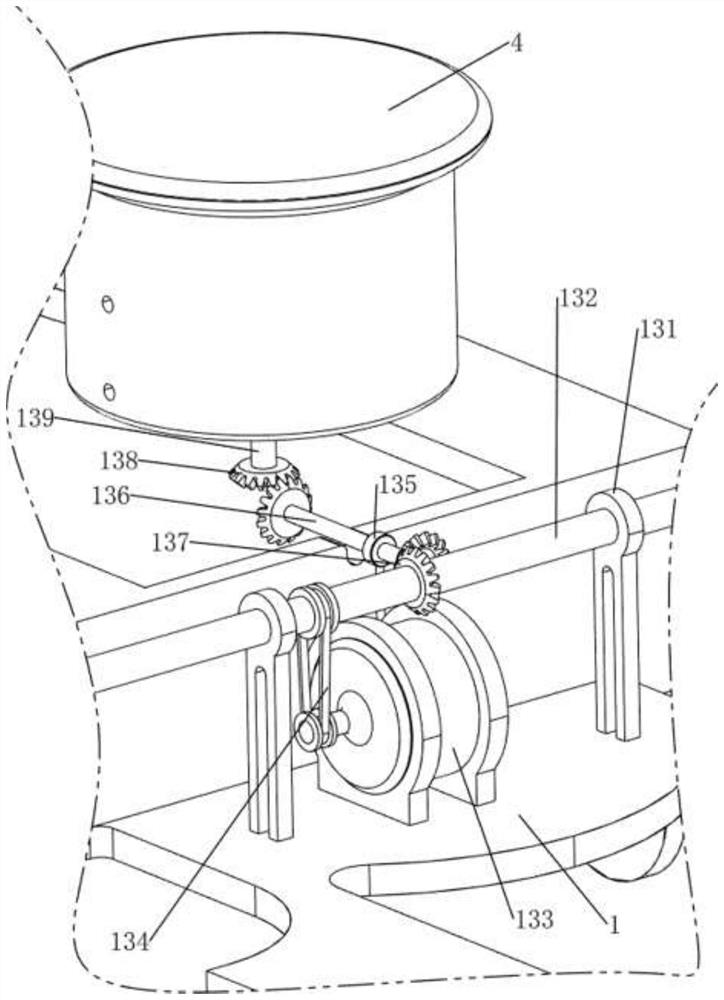

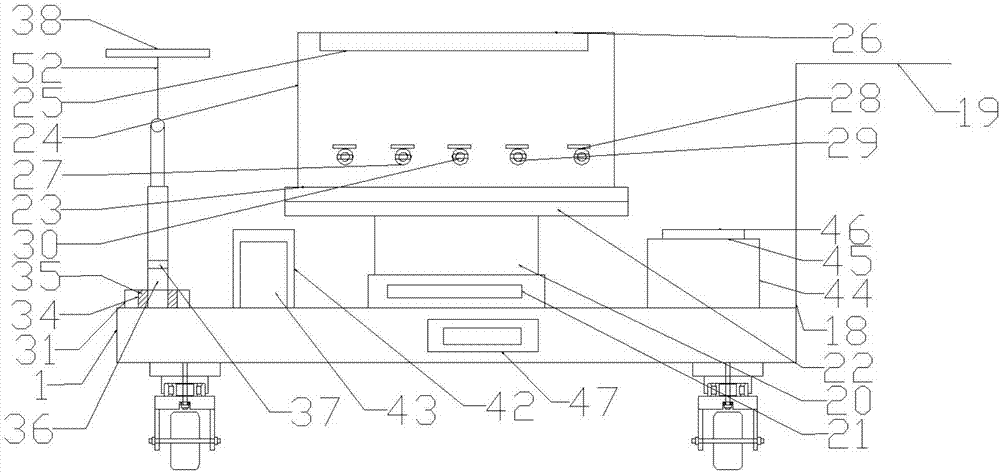

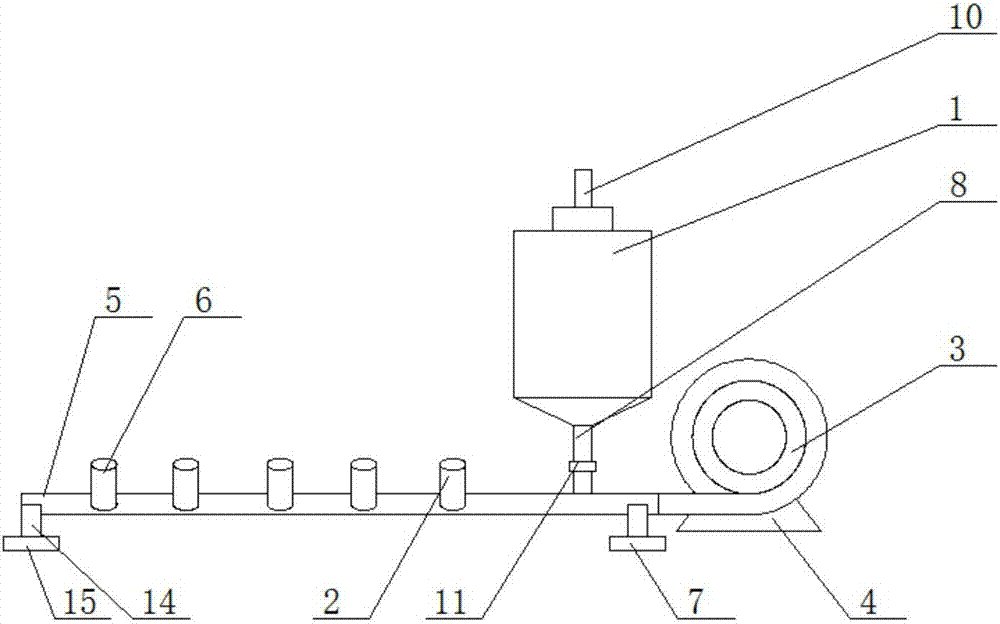

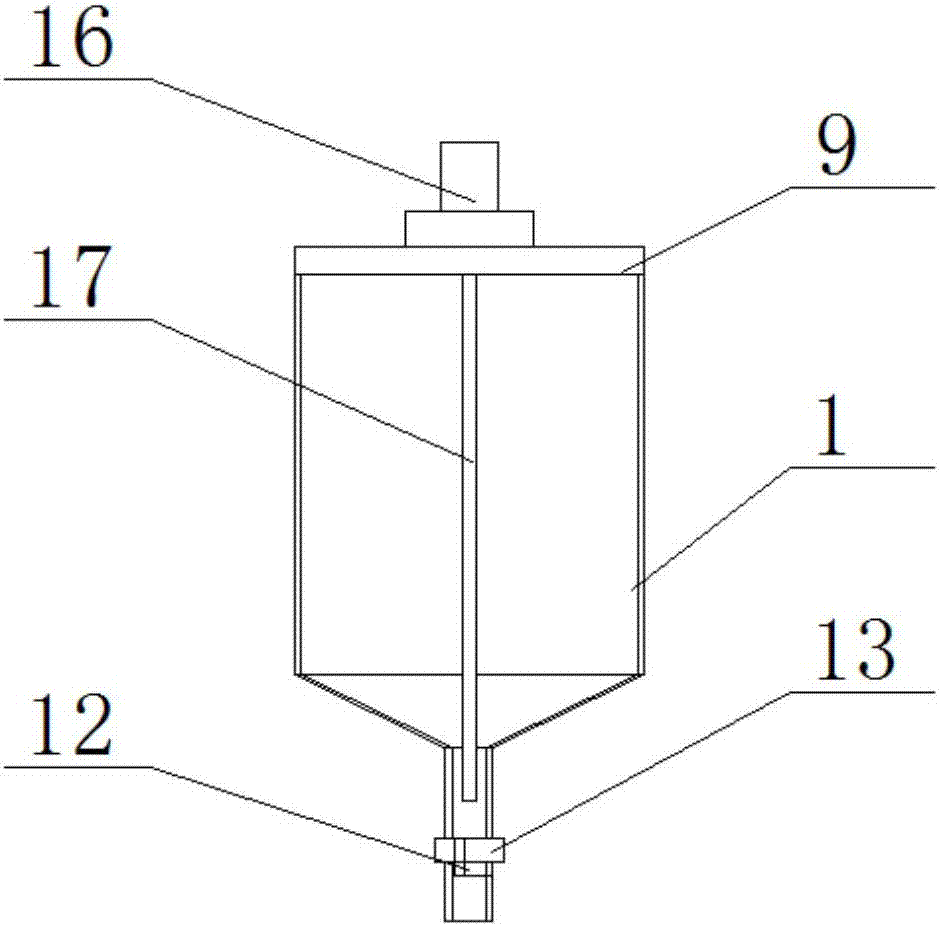

Automatic spraying equipment for agricultural pesticide

InactiveCN108617626AEasy to manufactureControl contentInsect catchers and killersMotor driveGear wheel

The invention discloses automatic spraying equipment for an agricultural pesticide. The automatic spraying equipment comprises a pesticide spraying device; the pesticide spraying device comprises a chassis; the top of the chassis is separately and fixedly connected with a water storage tank, a pesticide preparation tank and a pesticide storage tank; and the right side surface of the water storagetank is fixedly connected with the left side surface of the pesticide preparation tank. A servo motor drives a transversal gear to rotate, and the transversal gear rotates to drive a driving gear to rotate, so that it is convenient to control a rotating shaft to drive a moving wheel to rotate, and it is convenient to drive the pesticide spraying device to move; and a regulating shaft is movably connected with a connecting plate by a movable shaft, so that it is convenient for the regulating shaft to rotate, the angle of a front wheel is changed, it is convenient for the pesticide spraying device to realize the operation of making a turn and pesticide spraying treatment on a farmland, the advantage of automatic spray is achieved, and the problems of relatively low spraying efficiency and relatively high manpower consumption caused by artificial spraying required by existing pesticide spraying are solved.

Owner:秦家英

Ink recovery device for printing press

InactiveCN107718877AAutomatic sprayingImprove cleanlinessFiltration circuitsPrinting press partsEconomic benefitsEngineering

The invention relates to the technical field of printing equipment, in particular to an ink recovery device for a printing press. The ink recovery device comprises a box, wherein a sloping plate is fixedly connected in the box, slide grooves are formed in the box, a brush is glidingly connected in the slide grooves, the right end of the brush is fixedly connected with a main motor, the bottom endof the main motor is fixedly connected with a slider which is glidingly connected with a slide bar, the right end surface of the slider is rotationally connected with a first connecting rod, the otherend of the first connecting rod is rotationally connected with a second connecting rod, the other end of the second connecting rod is fixedly connected with an auxiliary motor, and the other end of the auxiliary motor is fixedly connected with the box. By means of arrangement of the sloping plate, the brush, the main motor, the slide bar and the slider, ink on the sloping plate can be cleaned, cleanness in the box is kept, the cleaned ink can be recovered, and the ink recovery device has huge economic benefit and broad market prospect and is worth popularizing and using.

Owner:张斐斐

A back-to-back mobile phone rear cover cleaning machine

ActiveCN112170386BEnhanced spot cleaning abilityRealize focused cleaningDirt cleaningCleaning using toolsEngineeringCleansing Agents

Owner:青岛海鼎通讯技术有限公司

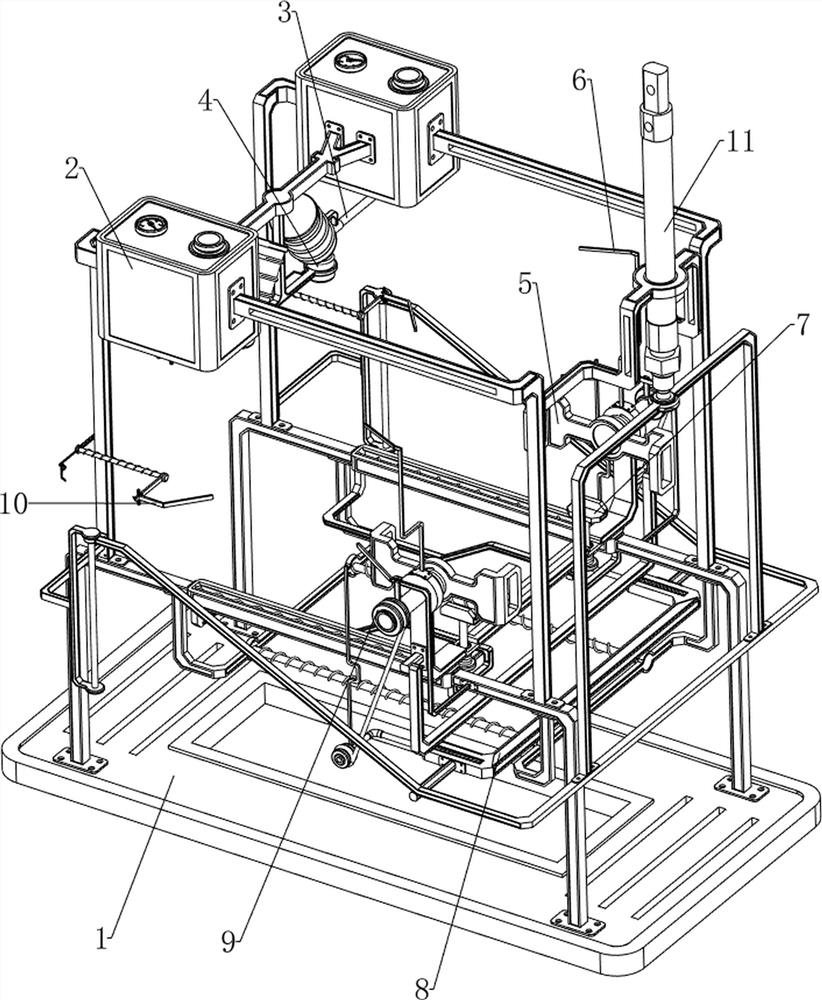

Spraying device for heat insulation layer of battery

ActiveCN113318876AReduce labor intensityAvoid falling and breakingLiquid spraying apparatusPhysicsElectrical battery

The invention relates to a spraying device for a heat insulation layer of a battery. The spraying device for the heat insulation layer of the battery comprises a supporting frame, air pressure boxes, an air pipe, a spraying head, a clamping mechanism and deflation mechanisms, wherein the upper portion of the left side of the supporting frame is connected with the two air pressure boxes, the air pressure boxes are used for pressurizing the spraying head, the bottoms of the air pressure boxes are connected with the air pipe, the air pipe is used for conveying air pressure, and the upper portion of the air pipe is connected with a storage barrel; the storage barrel communicates with the air pipe and is used for storing a spraying material, a cover is connected to the top of the storage barrel in a clamped mode, the bottom end of the air pipe is connected with the spraying head, the spraying head is used for spraying the spraying material to the surface of the battery, the clamping mechanism is arranged on the supporting frame and used for clamping the battery, and the deflation mechanisms are arranged on the air pressure boxes; and the deflation mechanisms are used for controlling conveying for the air pressure in the air pressure boxes. The clamping mechanism can clamp the battery, and the air pressure boxes and the deflation mechanisms are matched to pressurize the spraying head, so that the spraying head sprays the molten foaming material to the surface of the battery.

Owner:河南工学院

Pesticide spraying device for navel orange planting

ActiveCN113040117AAutomatic sprayingRealize the effect of deploymentClimate change adaptationSpraying apparatusNavel orangePesticide

The invention relates to a spraying device, in particular to a pesticide spraying device for navel orange planting. The invention aims to provide the pesticide spraying device for navel orange planting, which can automatically blend a pesticide and can automatically spray the pesticide. The pesticide spraying device for navel orange planting comprises an outer frame, a tire, a first fixed column, a stirring box and second fixing columns, wherein the tire is rotationally arranged on the outer frame; the first fixed column is arranged on one side of the upper part of the outer frame; the stirring box is arranged on the first fixing column; and the second fixing columns are symmetrically arranged on the side, close to the first fixing column, of the upper part of the outer frame. The pesticide spraying device for navel orange planting achieves the effects of automatically blending the pesticide and automatically spraying the pesticide; and a first pressing plate moves left and right, so that the pesticide in a pressing box is sprayed out through a mist spray head, and the effect of automatically spraying the pesticide is achieved.

Owner:金皇国(江西)农业科技有限公司

Spraying control system for chemical industry place

InactiveCN106000711AAutomatic sprayingLabor savingMovable spraying apparatusLiquid spraying apparatusChemical industryControl system

The invention relates to a spray control system for chemical industry, which has a circulating water pump, a flow control valve and a spray head; the output end of the circulating water pump is connected to the input end of the flow control valve, and the input end of the circulating water pump is connected to a water supply tank; the flow rate The output end of the control valve is connected to the input end of the nozzle; a dust sensor is also provided; the output end of the dust sensor is connected with the control device. The present invention adds a flow sensor and a control device, sets the spraying amount per mu, and the flow control valve adjusts the flow according to the set value, and calculates the ideal flow and the actual flow per minute. At the same time, the spraying amount can be adjusted according to the speed of the vehicle. When the speed of the vehicle stops, the spraying will stop.

Owner:JIANGSU JIAHUA ADVANCED MATERIALS TECH

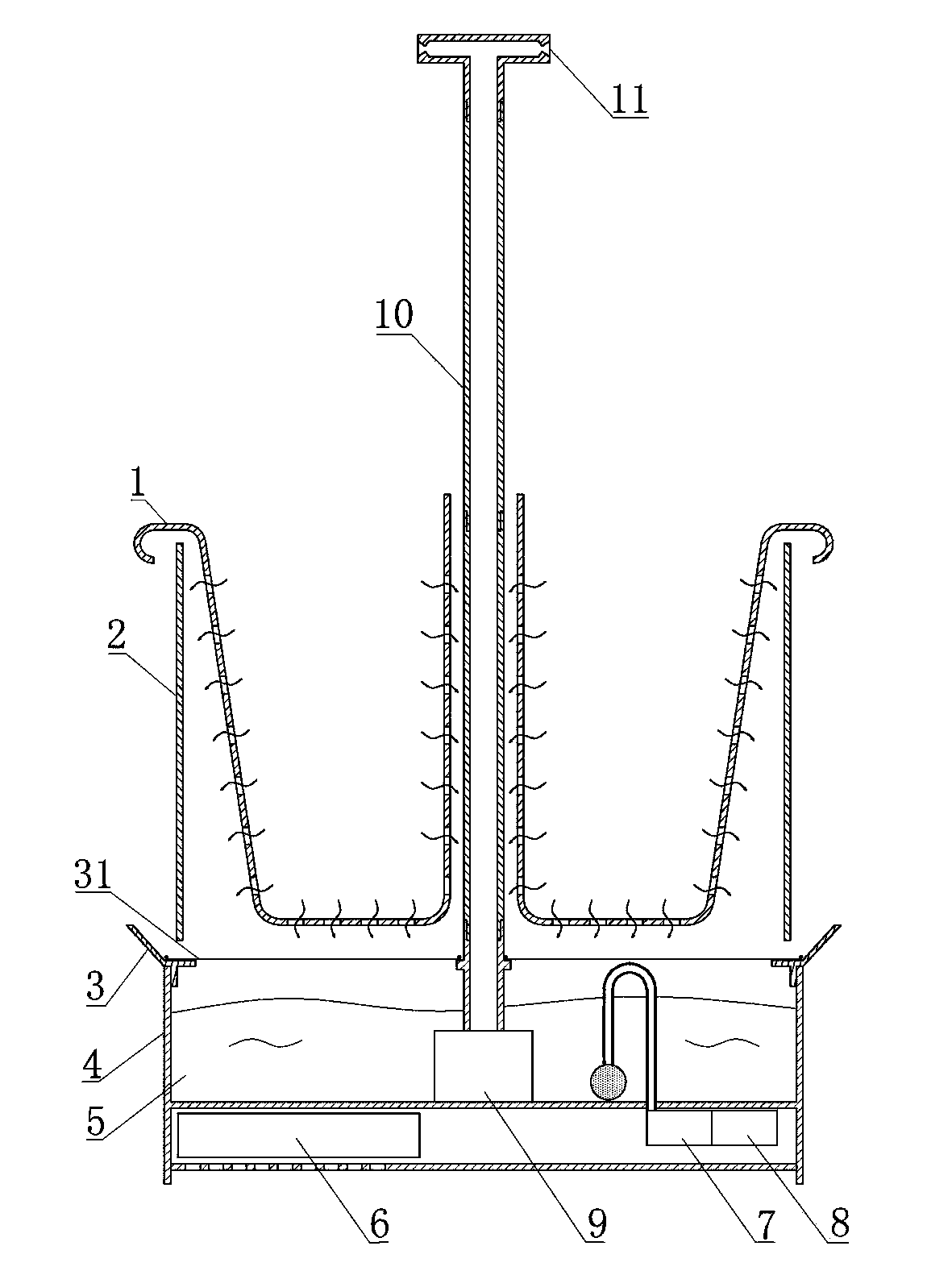

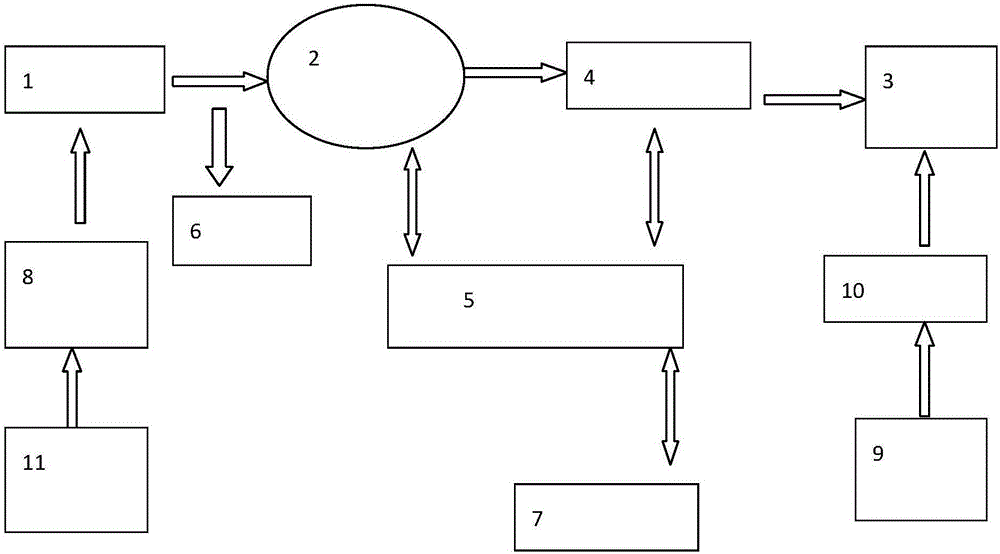

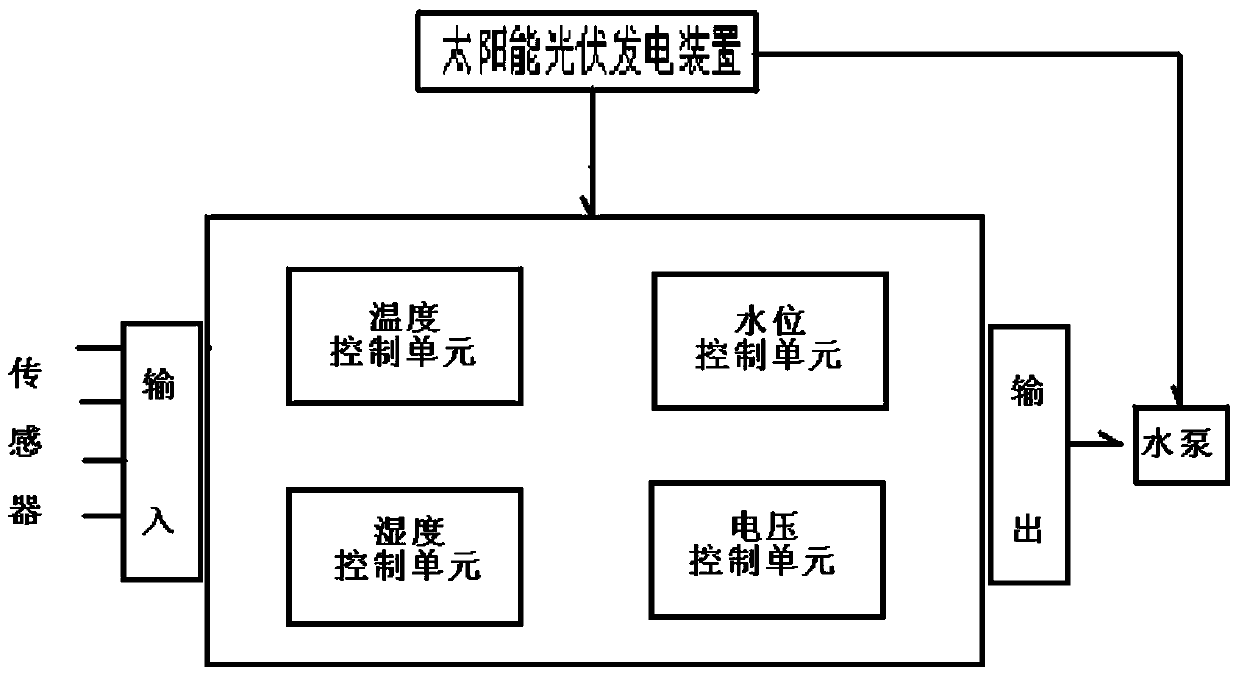

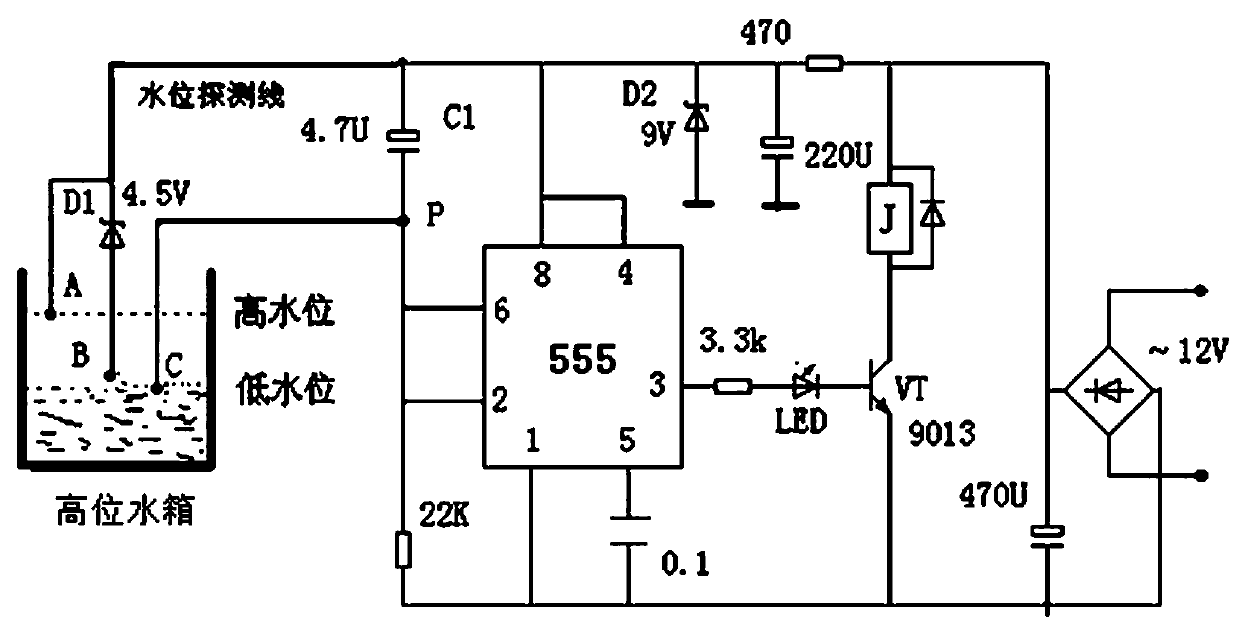

Automatic spray irrigation system for solar photovoltaic vegetable planting greenhouse

PendingCN107912192AReduce energy consumptionSimple structureCalcareous fertilisersBio-organic fraction processingElectric power transmissionEngineering

The invention relates to a spray irrigation system using solar energy, in particular to an automatic spray irrigation system for a solar photovoltaic vegetable planting greenhouse. The automatic sprayirrigation system for the solar photovoltaic vegetable planting greenhouse comprises an automatic spray irrigation controller, a solar photovoltaic power generation device, a filtering tank, an underwater well, a high-position water tank and a greenhouse body, wherein the filtering tank is connected with the high-position water tank through a pipe and a water pump; a sprayer is arranged above a planting bed in the greenhouse body, and is connected with the high-position water tank through a water tube and a water spraying pump; water in the filtering tank is provided by a septic tank and theunderwater well; the filtering tank is connected with the underwater well through a pipe and a make-up pump; and the automatic spray irrigation controller controls electric power transmission of the solar photovoltaic power generation device and water replenishment, water pumping and spraying of the whole system. The automatic spray irrigation system for the solar photovoltaic vegetable planting greenhouse is low in energy consumption, simple in structure, convenient to mount, high in degree of intelligence, simple to operate and low in cost; and by the solar energy, water spraying, fertilizerapplication and pesticide spraying for plants in the greenhouse can be realized automatically.

Owner:武宣县科学技术情报研究所

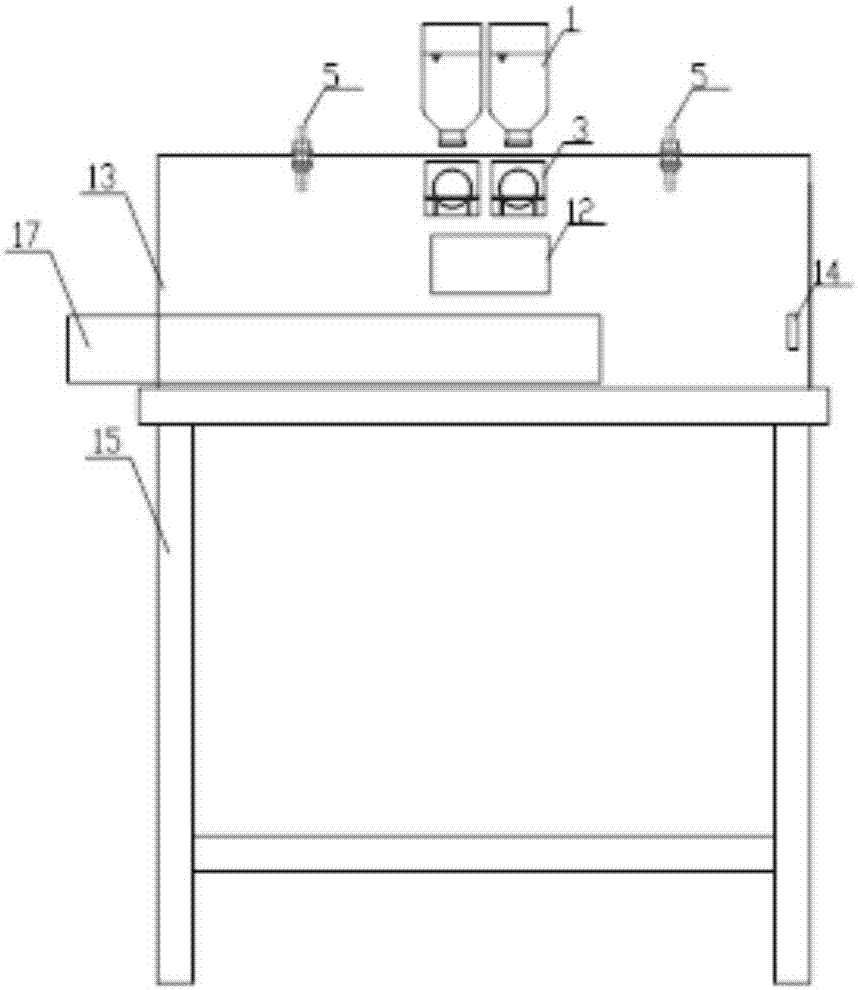

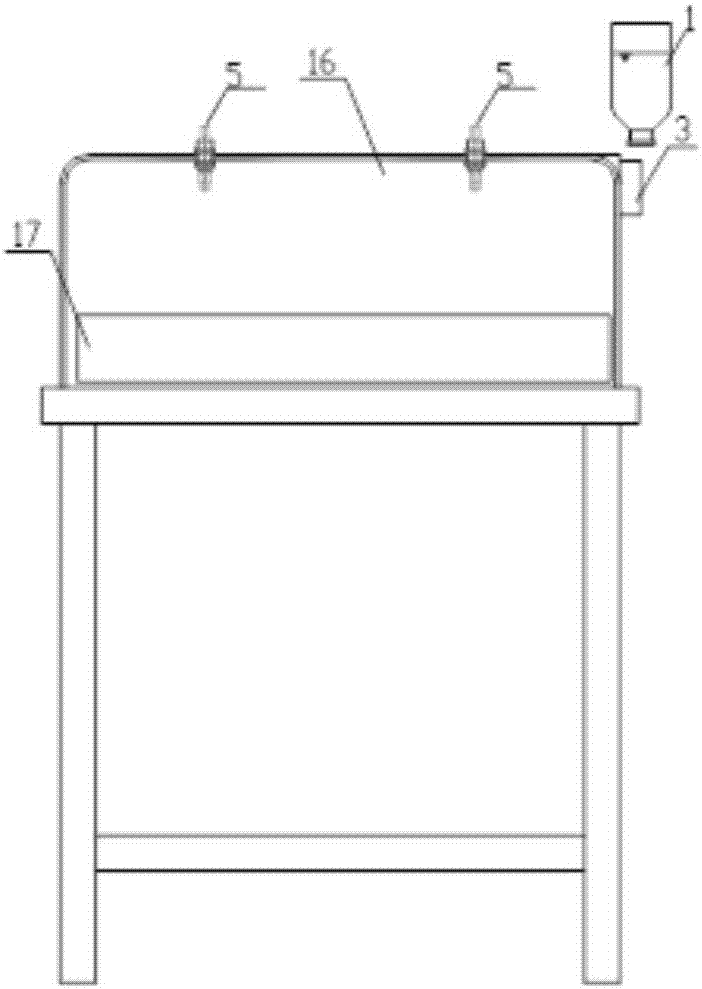

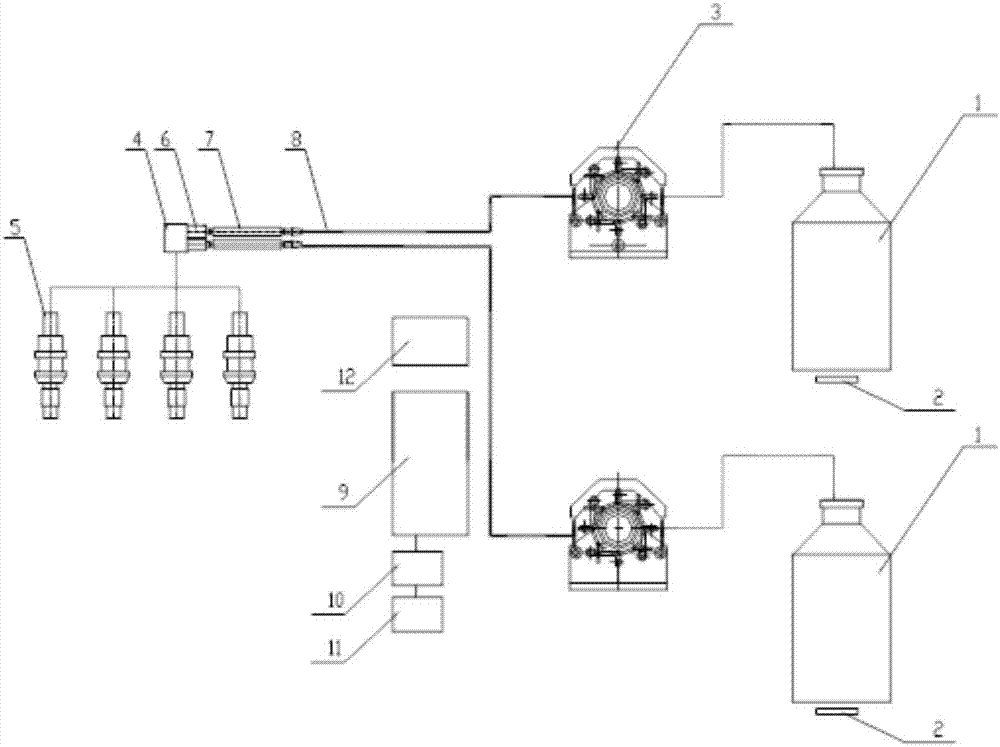

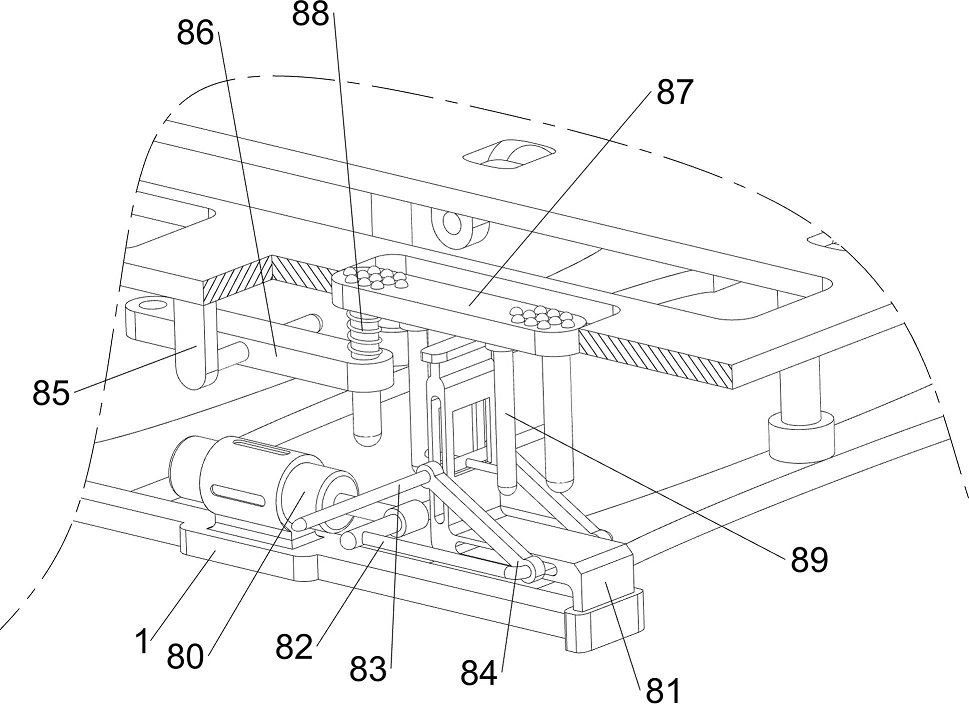

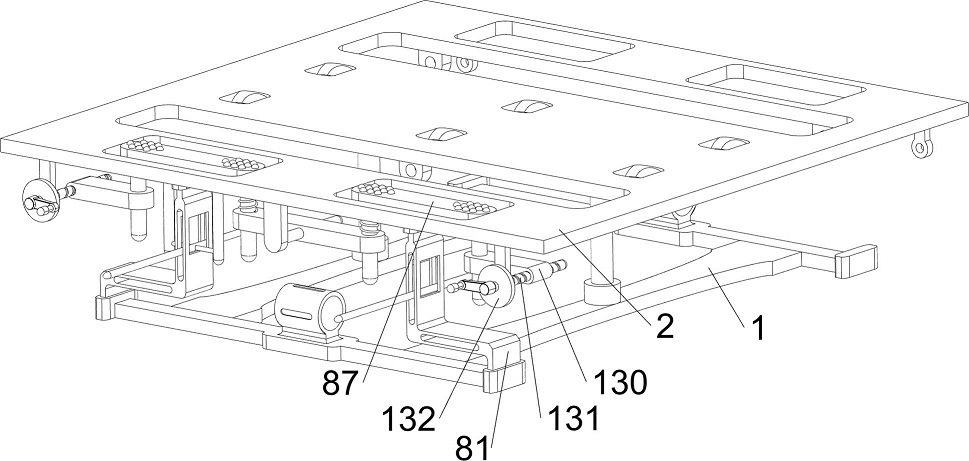

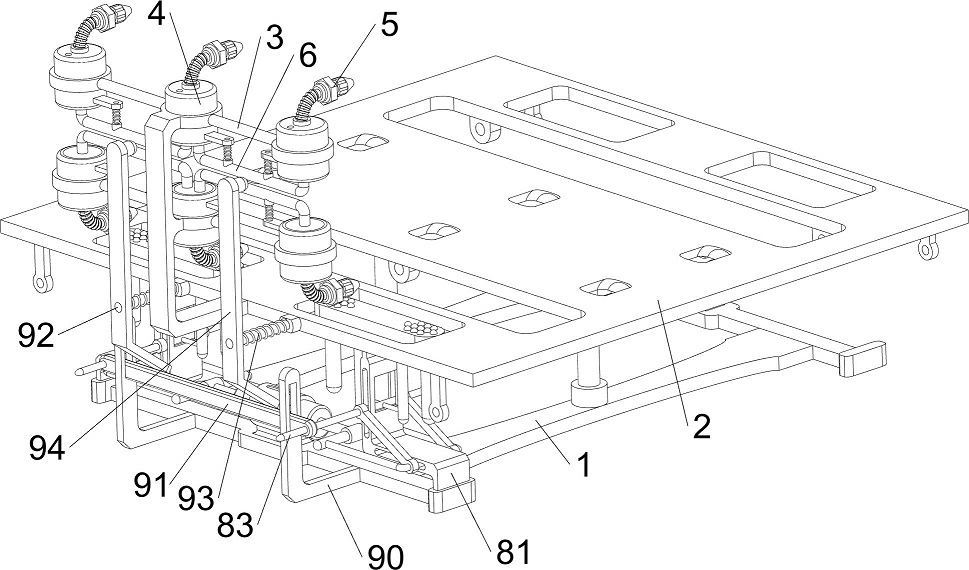

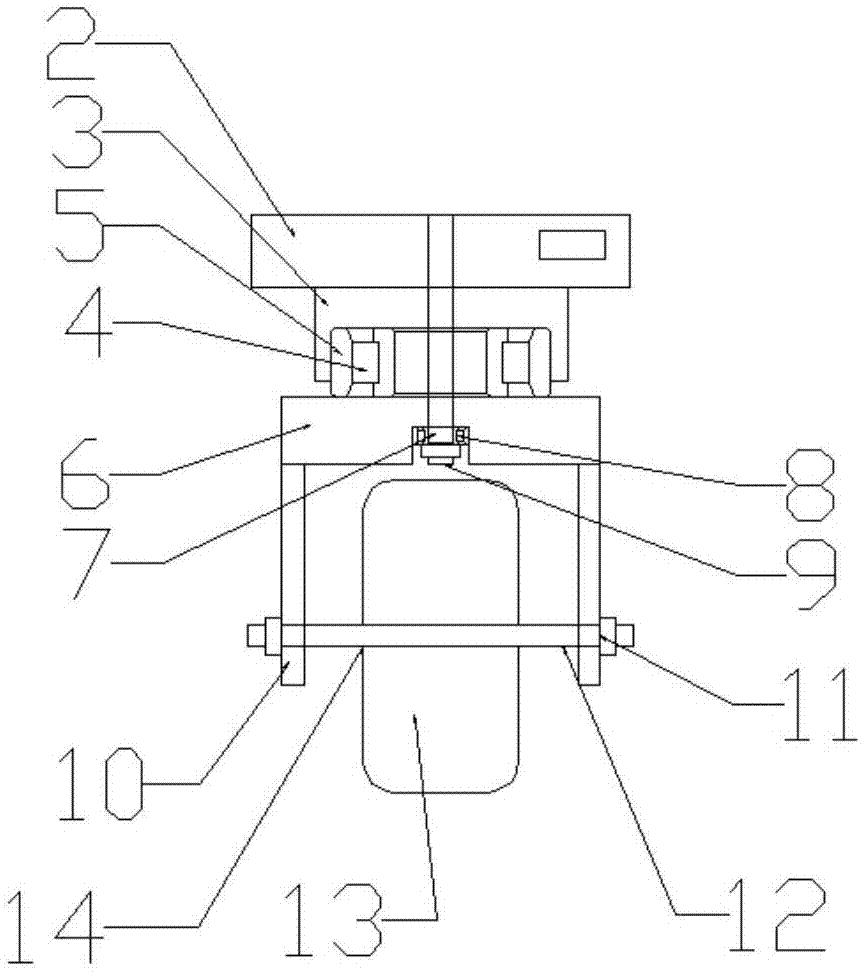

Bench-type automatic spraying device for chick immunity

InactiveCN107007375AReasonable designNovel structureVeterinary instrumentsPeristaltic pumpMechanical equipment

The invention belongs to the technical field of mechanical equipment, and discloses a bench-type automatic spraying device for chick immunity. The device comprises an atomization cover, a weighing device, a chick placing square plate and vaccine bottles, wherein atomization nozzles, peristaltic pumps and a display touch screen are fixedly arranged on the top of the atomization cover; an inlet corresponding to the chick placing square plate is formed in one end of the atomization cover, and a position switch corresponding to the inlet is arranged at the other end of the atomization cover; a control box is arranged inside the atomization cover, and a controller, a battery, a battery charger, an infusion tube, a check valve and a mixing cavity are arranged inside the control box. The bench-type automatic spraying device for chick immunity is reasonable in design and novel in structure; automation and intelligentization of chick vaccine injection can be achieved, which fills the gaps in international and domestic technology; the device is suitable for wide popularization.

Owner:青岛澳德思瑞智能免疫技术有限公司

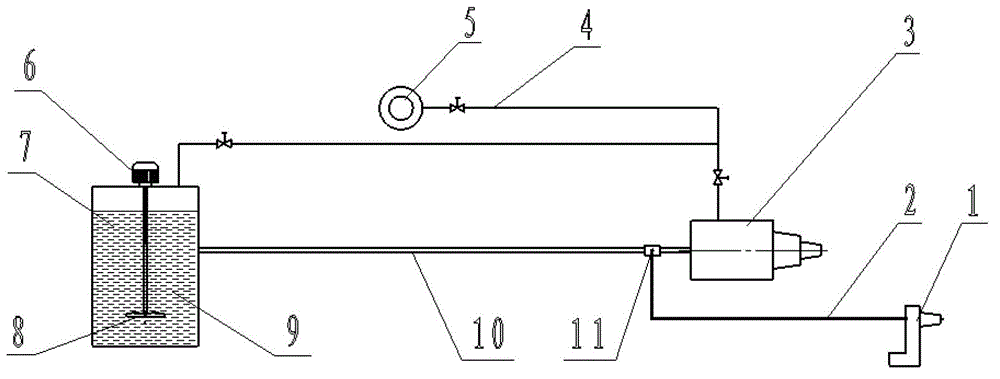

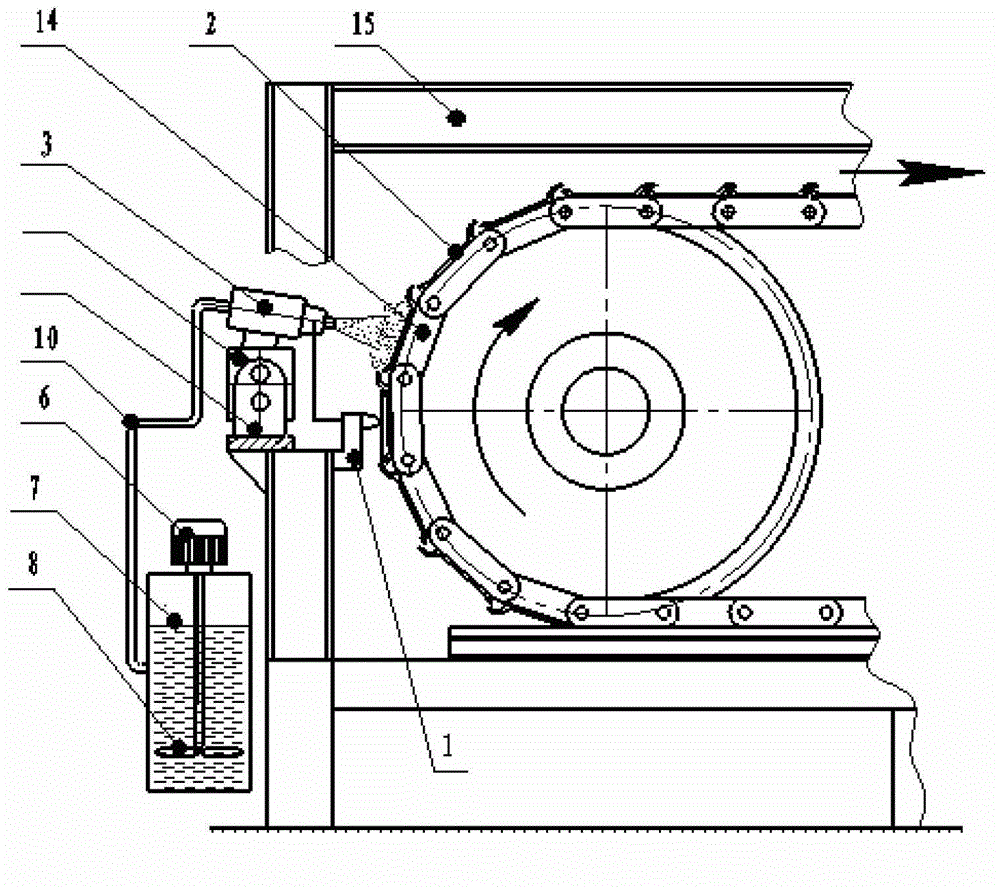

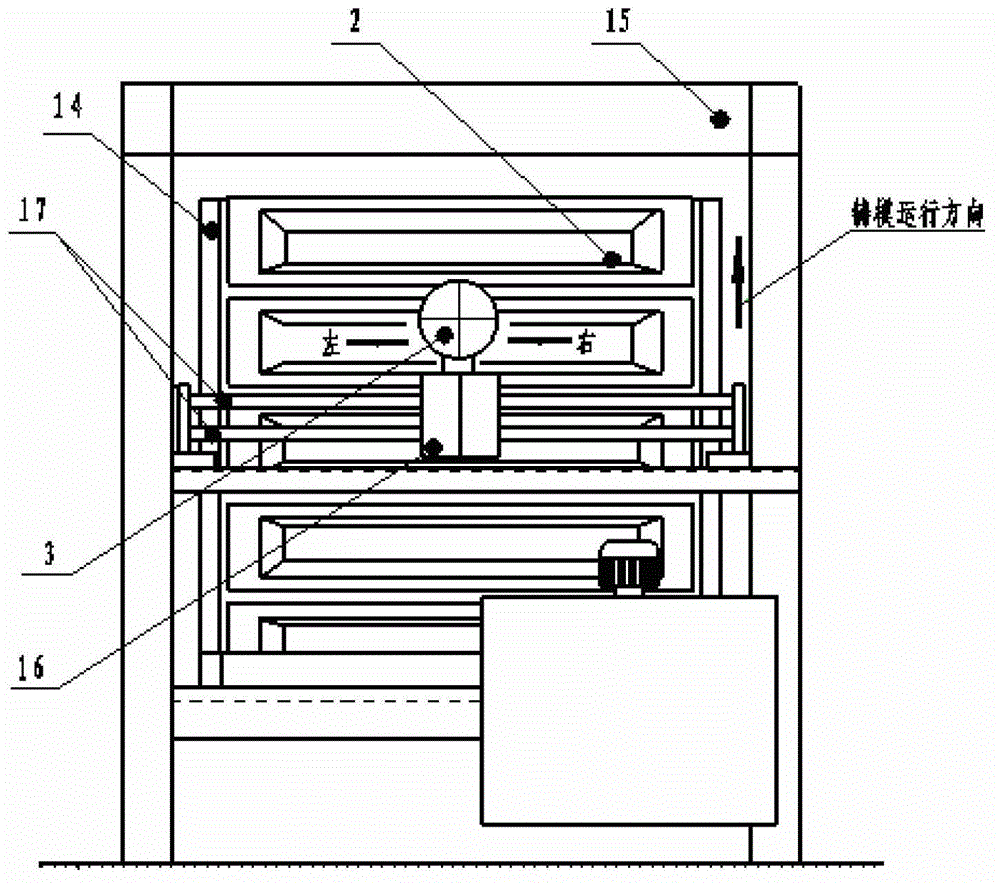

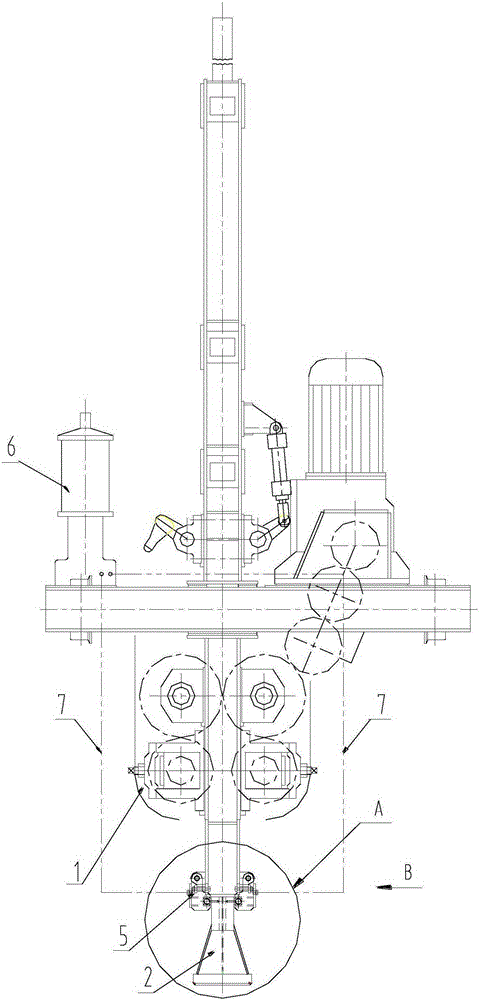

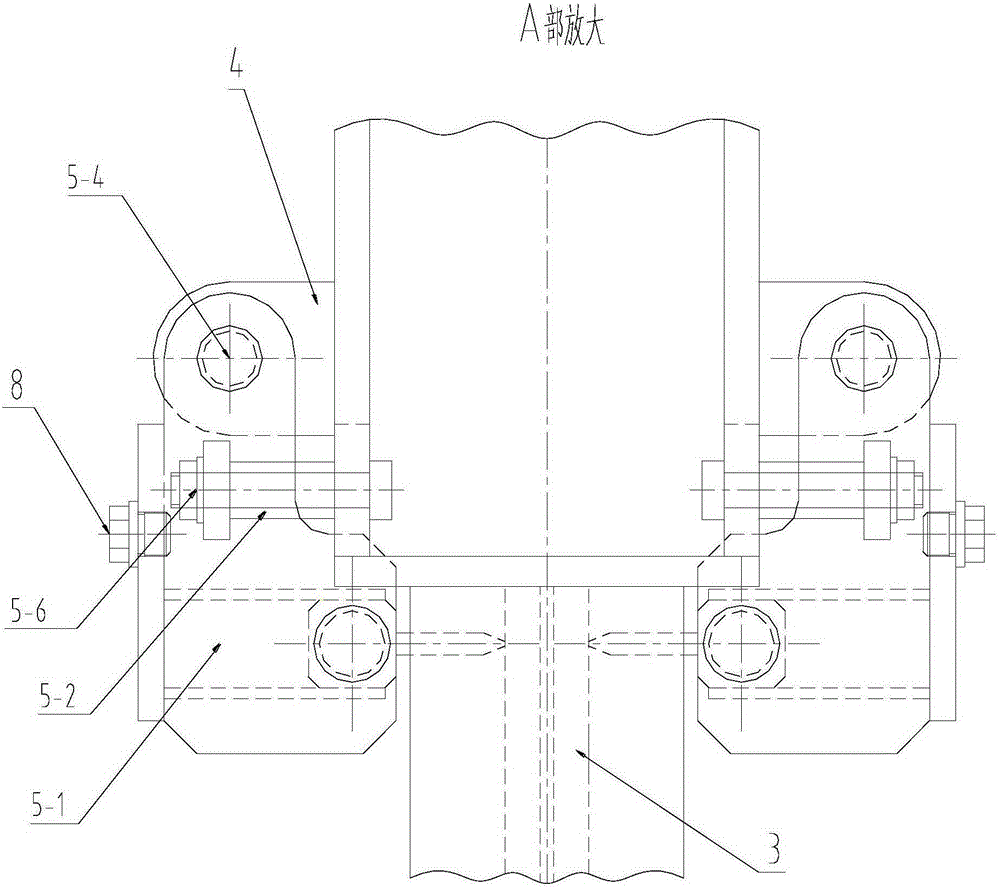

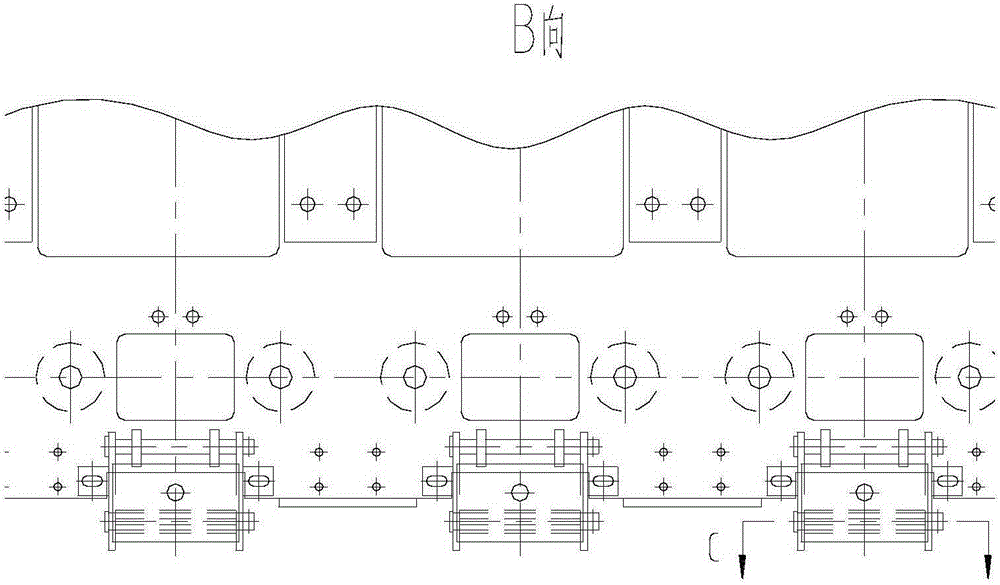

Release agent automatically spraying device of common aluminum ingot casting machine

The invention relates to a common aluminum continuously casting and producing device suitable for an electrolytic aluminum liquid, and in particular relates to a release agent automatically spraying device of a common aluminum ingot casting machine suitable for 20kg of ingot, comprising a rack rear beam and a mold casting chain wheel, wherein a spray gun is fixed on the rack rear beam; a material box for storing the release agent provided with a mixing impeller driven by a drive motor is arranged on the lower part of the spray gun; the material storing box is connected with the spray gun by a feeding air pipe; an electromagnetic switch which is connected with an electric signal generator arranged at the lateral part of the mold casting chain wheel by an electric signal transmission line, is arranged on the feeding air pipe; and the spray gun is connected with a pressure air pipe, which is connected with a pressure air source. The release agent automatically spraying device of the common aluminum ingot casting machine disclosed by the invention is unique in structure, safe and reliable, and is capable of realizing precision spraying control of release agent, raising cost management and improving working efficiency.

Owner:QINGTONGXIA ALUMINUM GRP

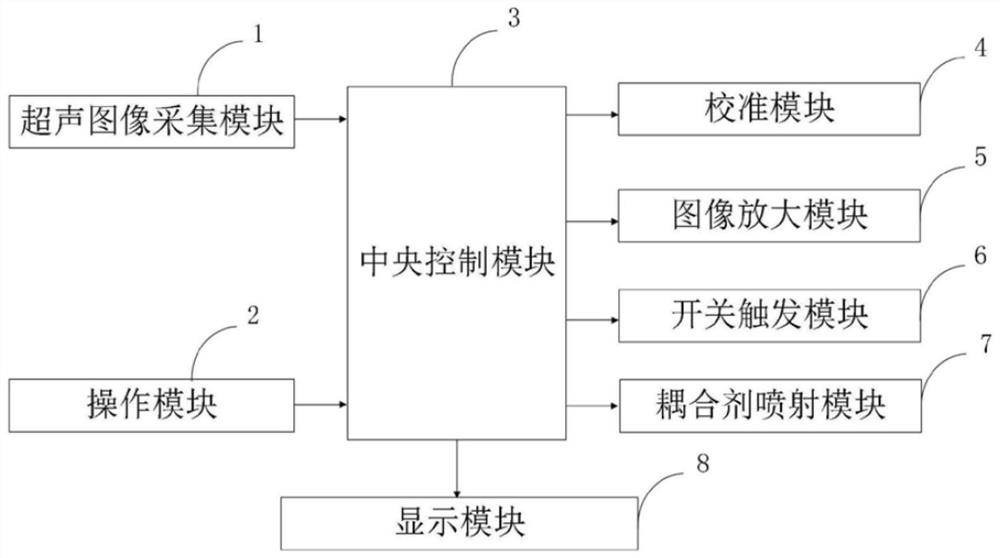

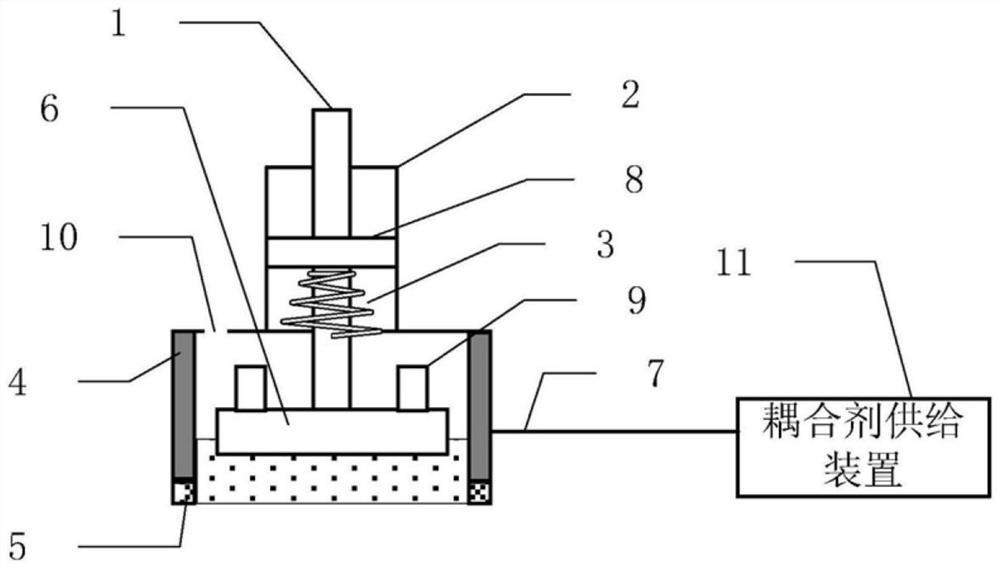

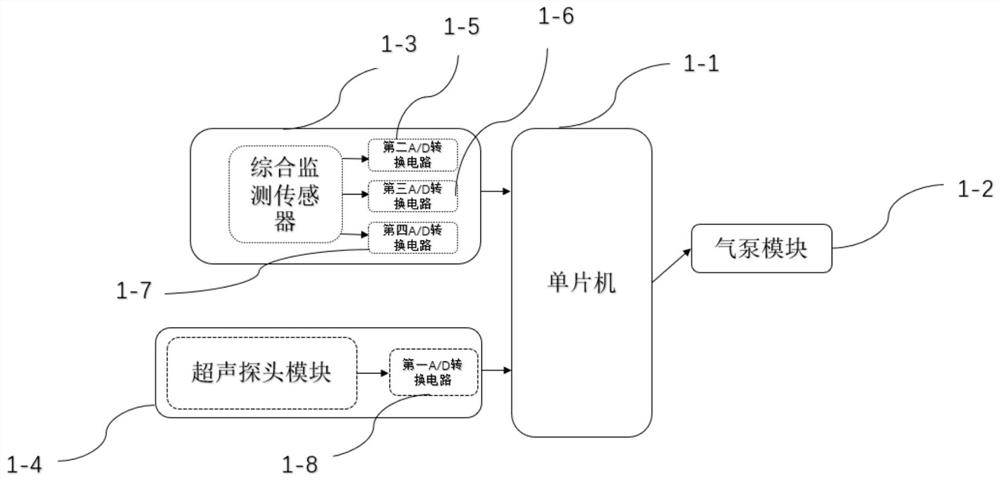

Device capable of automatically smearing coupling agent on ultrasonic probe

InactiveCN112807020AReal-time monitoring of body temperatureReal-time monitoring of moisture contentOrgan movement/changes detectionMedical applicatorsAir pumpSingle chip

The invention provides a device capable of automatically smearing a coupling agent on an ultrasonic probe. The device capable of automatically smearing the coupling agent comprises an ultrasonic probe module, a comprehensive monitoring sensor, a single chip microcomputer, an air pump module and a nozzle, wherein the ultrasonic probe module, the comprehensive monitoring sensor and the air pump module are all connected with the single chip microcomputer. and the air pump module is connected with the nozzle through a hose. By monitoring different patients in real time and automatically and comprehensively judging the amount required for spraying the coupling agent, the workload of doctors can be reduced, and the working efficiency is improved.

Owner:赵晓辉

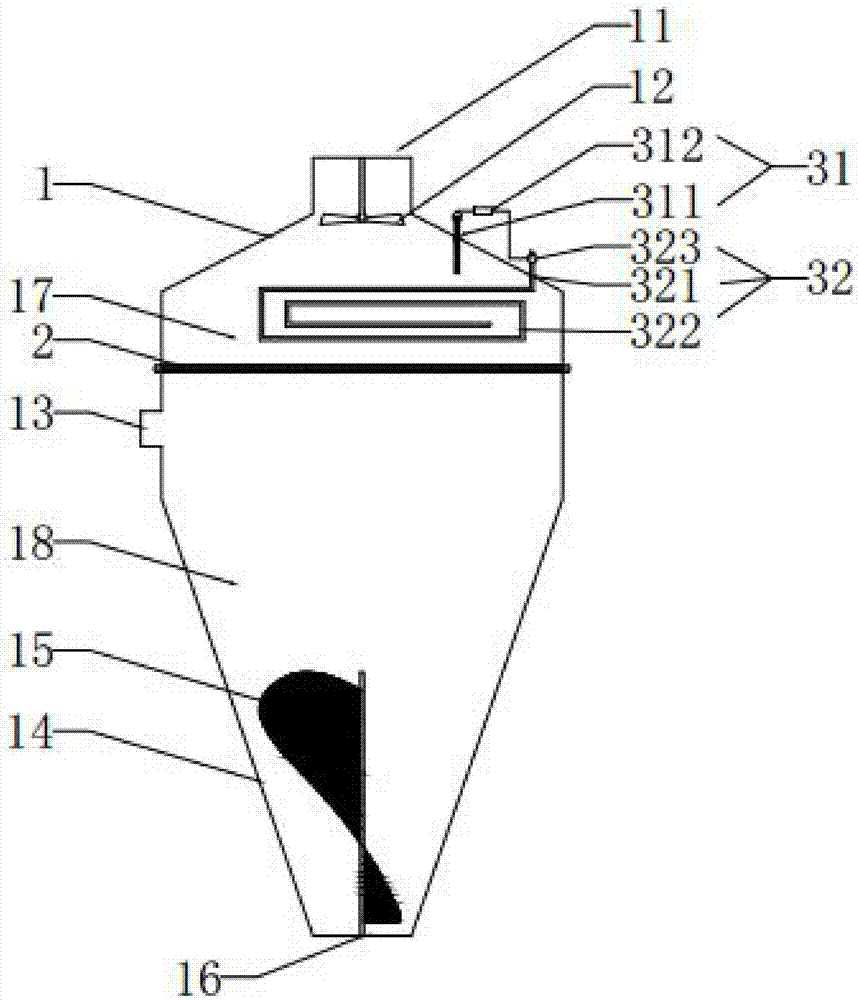

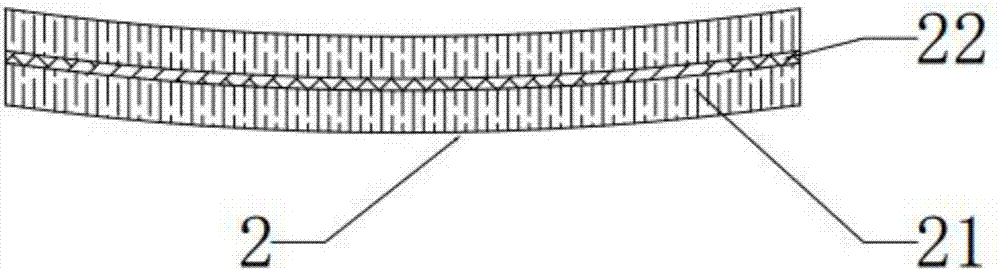

Industrial ceramic dust removing device

ActiveCN107051046AReduce dust removal costsAdjust the degree of opening and closingCombination devicesDispersed particle filtrationContinuous operationProduct gas

The invention discloses an industrial ceramic dust removing device, which comprises a tank body, a filtering mechanism and a pneumatic spraying mechanism. The filtering mechanism is arranged in an inner chamber of the tank body, and divides the inner chamber of the tank body into a first cavity and a second cavity. The pneumatic spraying device comprises a pneumatic component and a spraying component. Specifically, the pneumatic component comprises a pressure gauge and a controller; the spraying component comprises a water inlet, a spray pipe and a quick shut-off valve. According to the industrial ceramic dust removing device provided by the invention, the filtering mechanism an tank body inner wall surface are in seal connection, no gap exists, and the dust removing efficiency is high. Through linkage of the pneumatic component and the spraying component, dust or glaze on the filtering mechanism can be cleared automatically to realize continuous operation, the equipment utilization rate is high, and the production capacity is large. The opening degree of the quick shut-off valve is controlled in real time according to the deposition degree of dust or glaze on the filtering mechanism, thus saving spraying liquid and reducing the dust removing cost. The industrial ceramic dust removing device is especially suitable for the circumstance of uneven concentration of dust or glaze in dusty gas of different periods.

Owner:JINGDEZHEN CERAMIC INSTITUTE

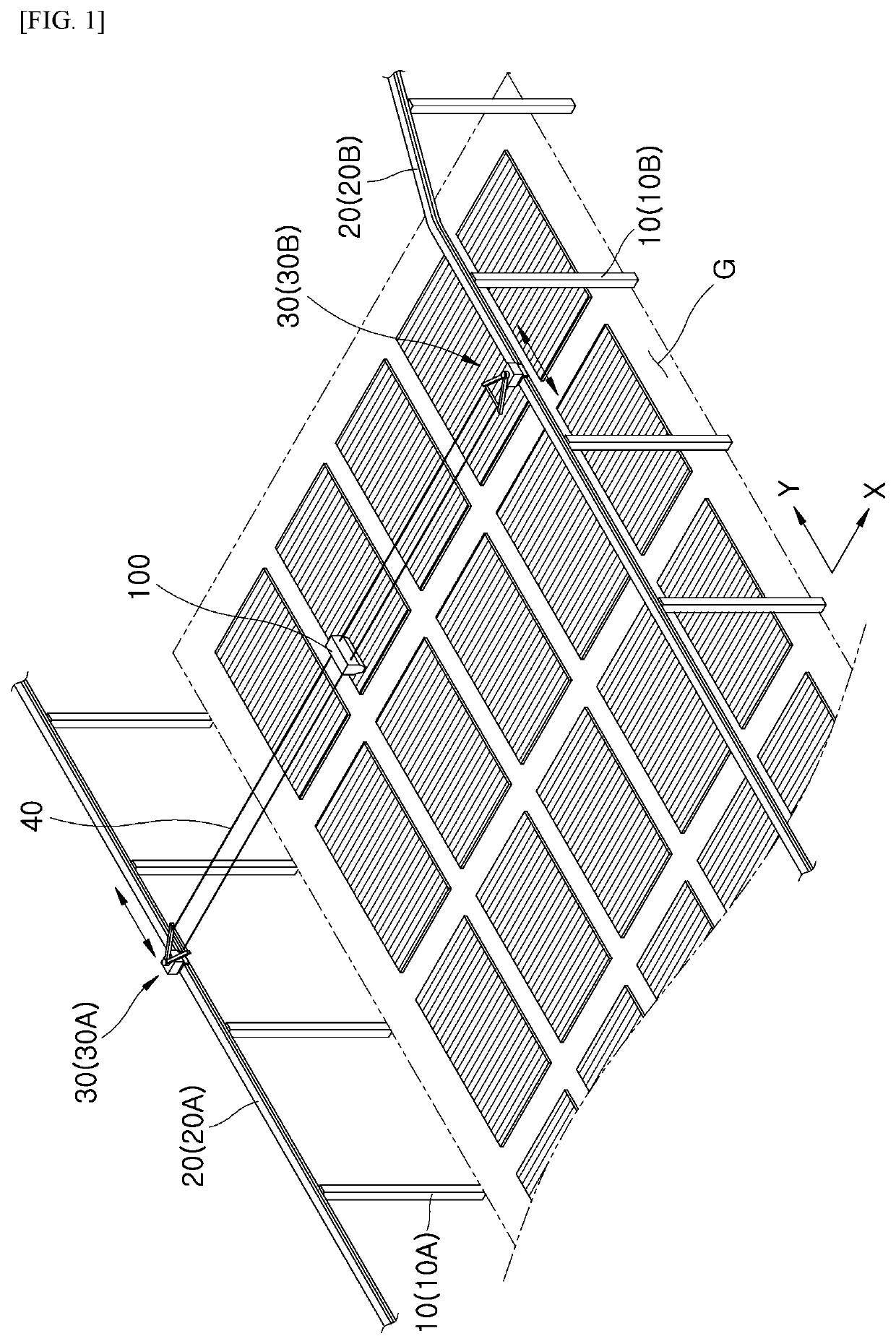

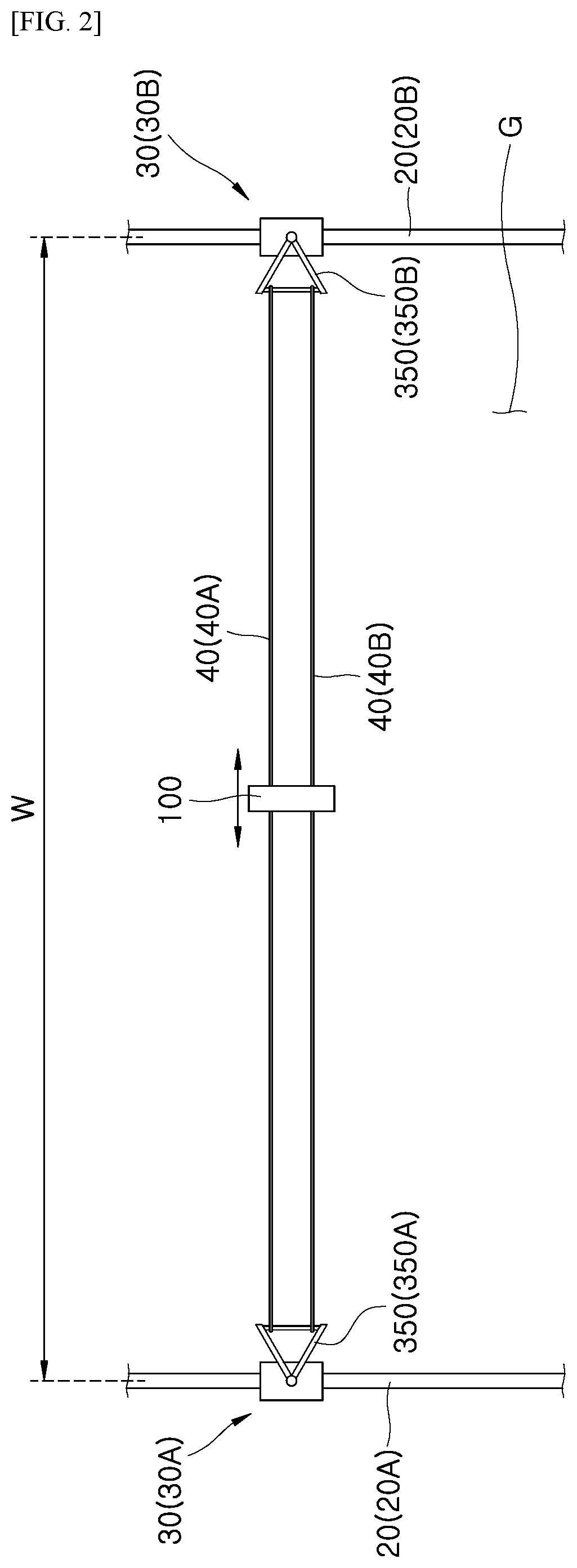

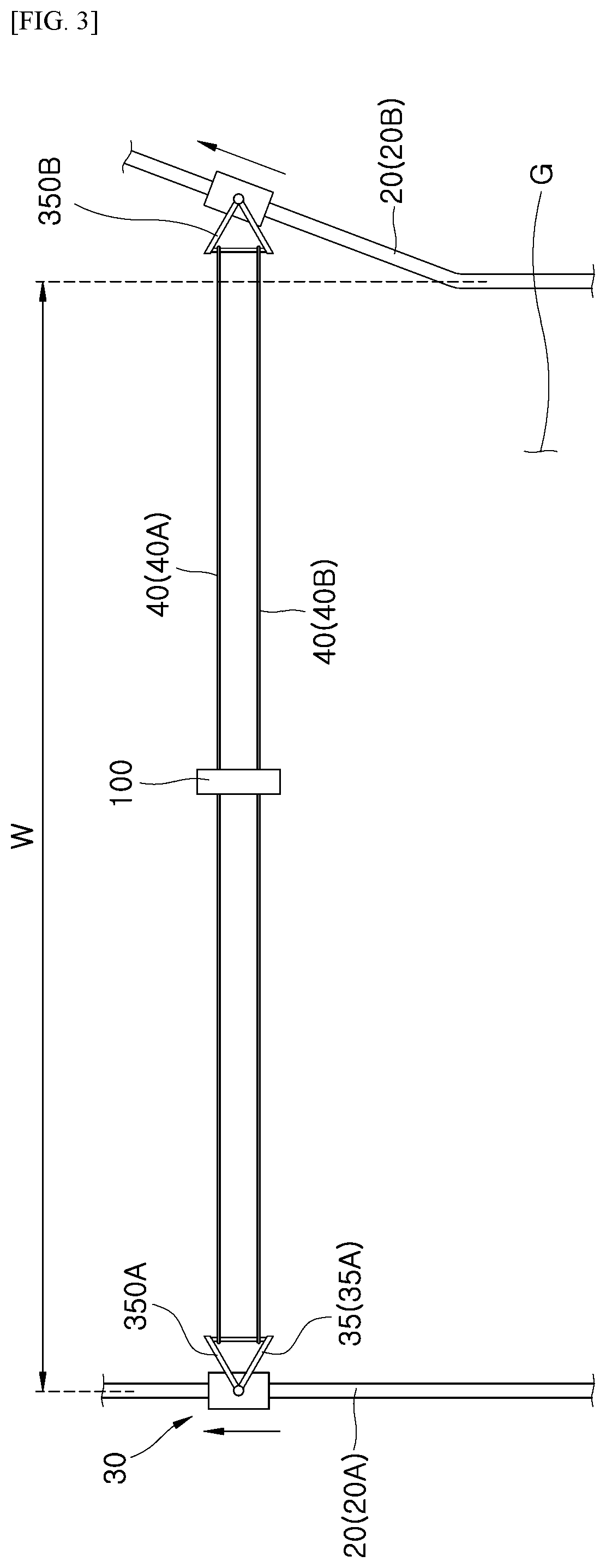

Automatic agricultural equipment and automatic moving system

ActiveUS20200337290A1Automatic sprayingSpraying apparatusAgricultural undercarriagesAgricultural scienceAgricultural engineering

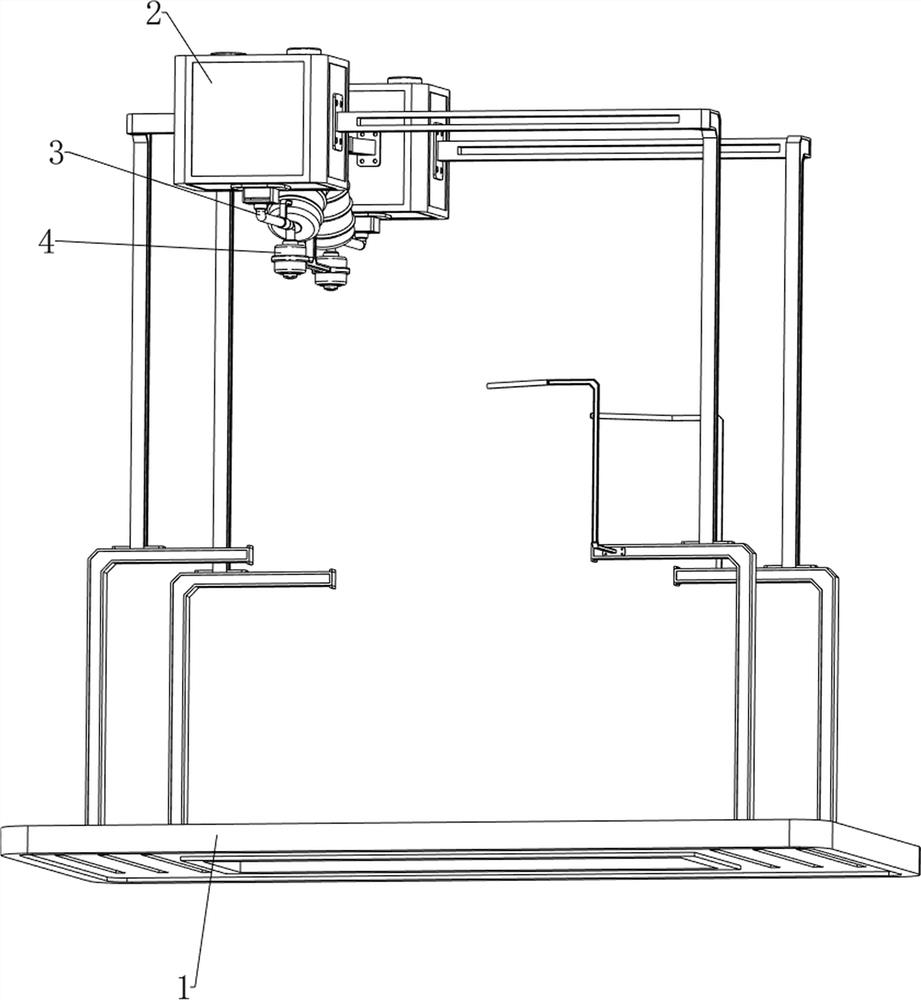

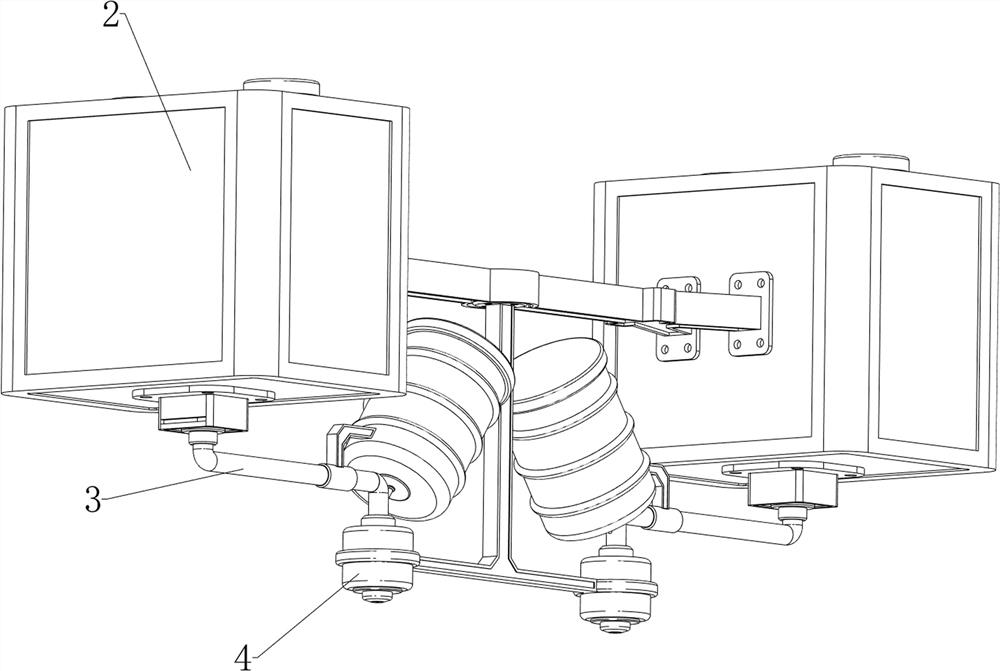

An automatic agricultural machine according to the present invention includes: a fixed base disposed on farmland; a first-direction movement guide part installed on the fixed base so as to be spaced apart from the farmland; a first-direction movement trolley configured to travel on the first-direction movement guide part; and an automatic spraying device configured to travel on a second-direction movement guide part connected to the first-direction movement trolley, wherein traveling control of the first-direction movement trolley and winding control of the second-direction movement guide part are performed on the basis of at least any one of the trigonometric function principle and the Pythagorean theorem.

Owner:KANG MYOUNG SOO

Building template surface spraying device

PendingCN114749308AAutomatic sprayingEvenly paintedSpraying apparatusClassical mechanicsSupport plane

Owner:王大超

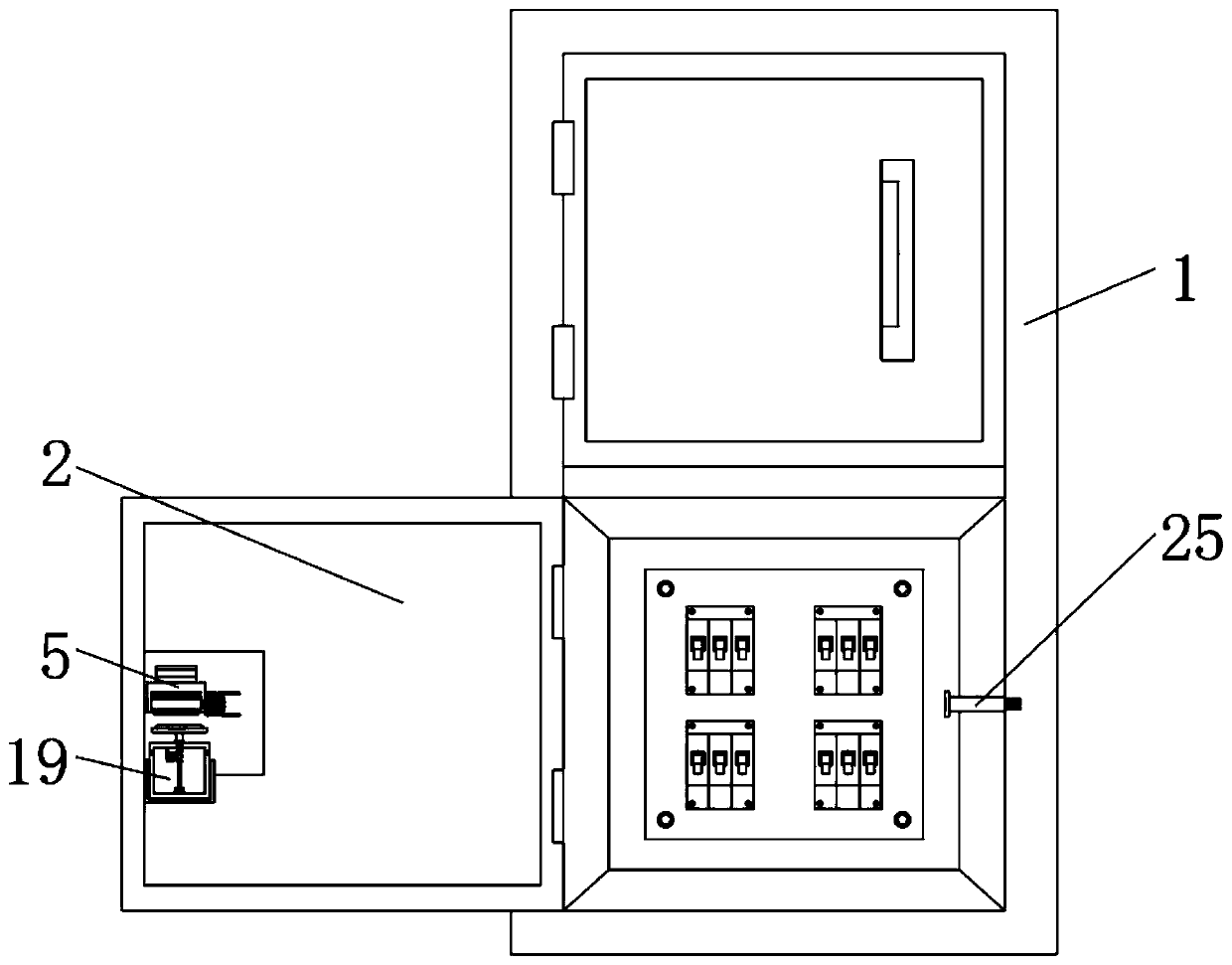

Locking structure for low-voltage switch cabinet

InactiveCN111478199AAutomatic sprayingRealize the mergerNon-mechanical controlsSubstation/switching arrangement casingsEngineeringOil can

The invention relates to the technical field of low-voltage switch cabinets. The invention further discloses a locking structure for the low-voltage switch cabinet, and solves the problem that the locking structure of the low-voltage switchgear currently on the market is partially damaged, due to the inability to disassemble the relevant parts, the locking mechanism cannot be used normally, and the lubricating oil cannot be applied when the low-voltage switchgear is in a closed state. The locking structure comprises a cabinet body, a sealing door is mounted on the surface of the cabinet body,a retention pipe is fixed to the surface of the sealing door, a movable rod is installed in an inner cavity of the retention pipe, a support is installed at one end of the movable rod, a clamping block is fixed to the top of the support, an assembling rod is installed at the other end of the movable rod, a motor is installed at one end of the assembling rod, a protection box is installed outside the motor, and a first movable plate is fixed to the top of the protection box. The locking structure has the advantages that after being locally damaged, the locking structure can be detached and replaced, the locking mechanism can be continuously used, and lubricating oil can be automatically sprayed when the locking structure is in a closed state.

Owner:江苏海潮电气科技有限公司

Mini-type medical device disinfector

The invention discloses a mini-type medical device disinfector, which comprises a disinfecting truck bottom plate; four sides at the lower part of the disinfecting truck bottom plate are provided withuniversal wheel devices; a hand pushing device is arranged on the side surface of one side of the disinfecting truck bottom plate; a flexible device is arranged in the middle of the upper part of thedisinfecting truck bottom plate, a disinfecting box device is arranged on the flexible device; left and right ends of the disinfecting truck bottom plate are provided with sweeping devices; an audible device is arranged between the disinfecting box device and the sweeping device, and the back part of the disinfecting box device is provided with a duster cloth placing device. The mini-type medicaldevice disinfector has the beneficial effects of being simple in structure and strong in practicability.

Owner:李志慧

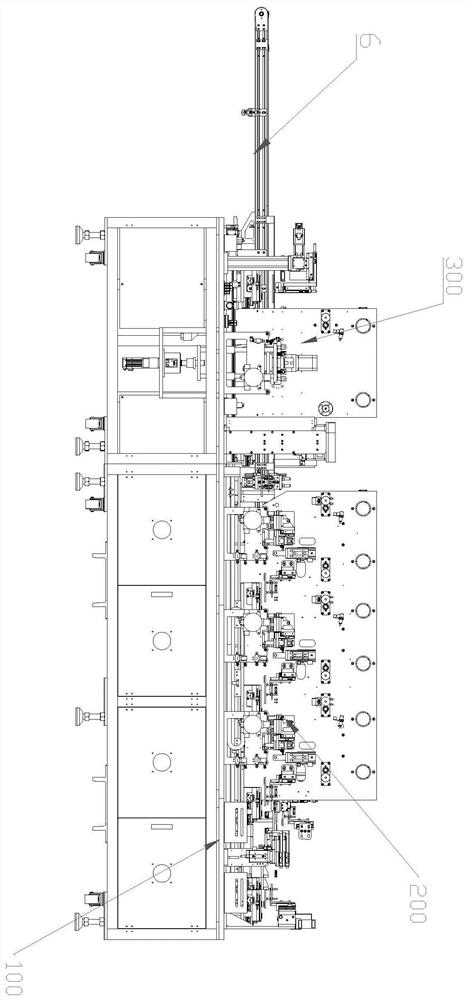

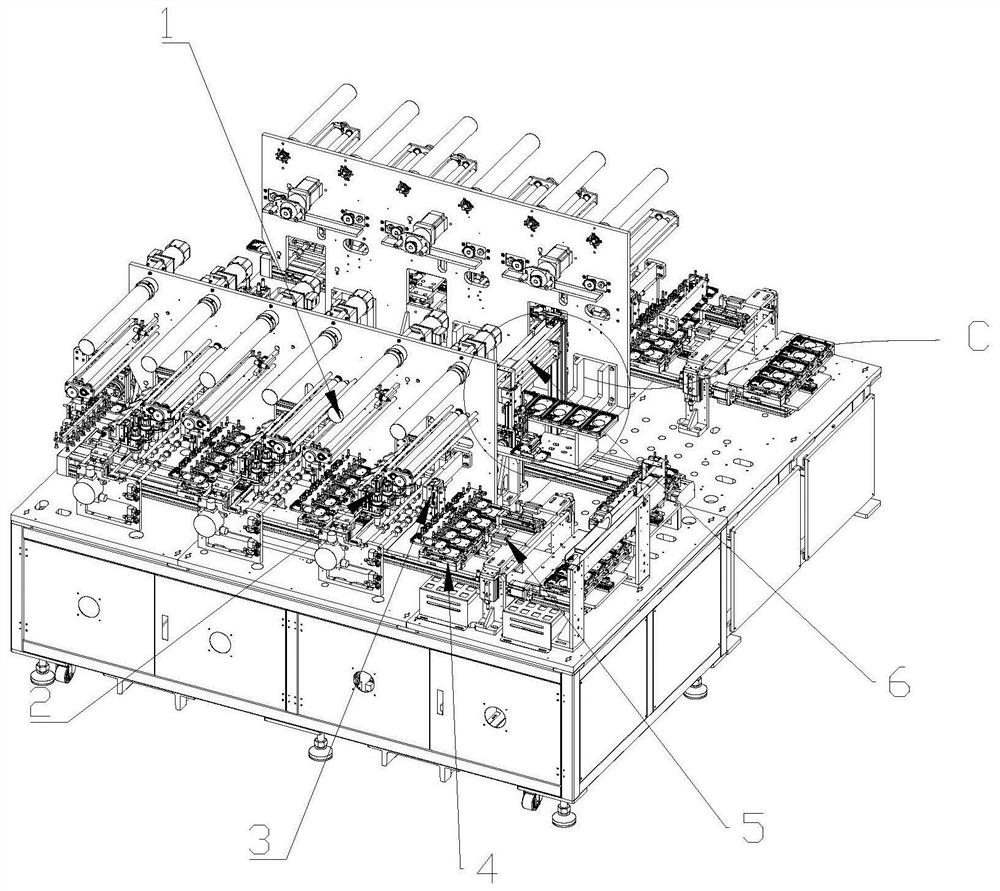

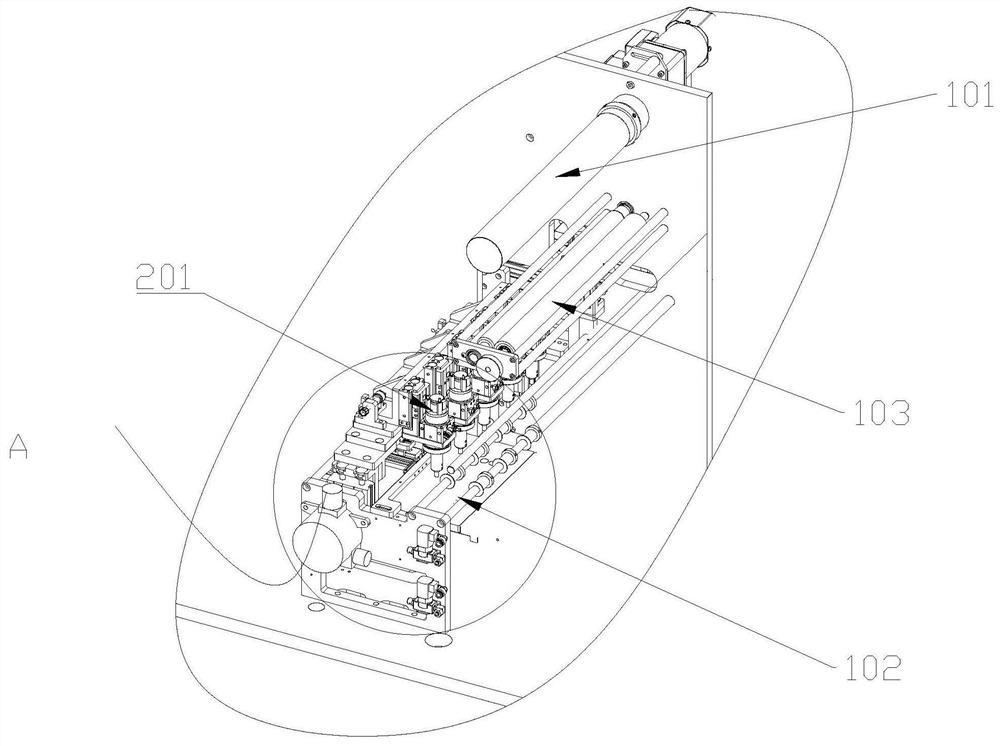

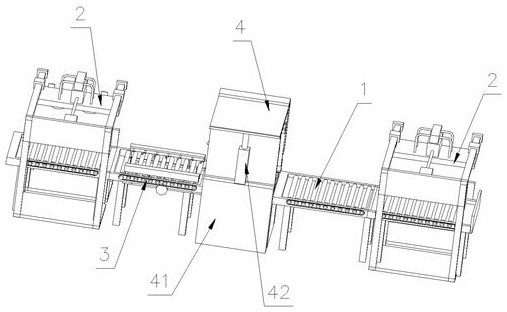

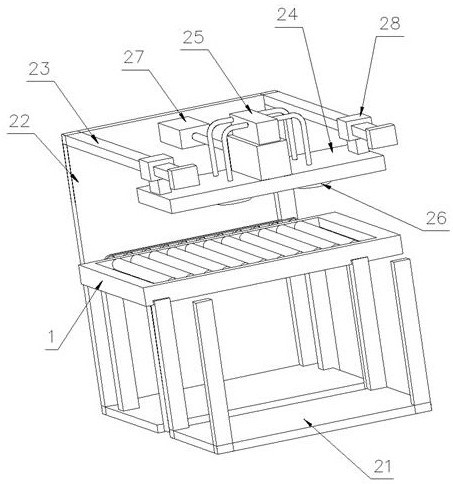

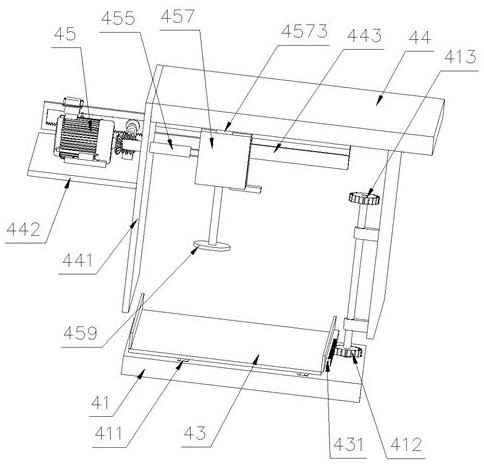

Plate spraying system

PendingCN113426598AHigh degree of automationEasy loadingLiquid spraying apparatusElectric machineryEngineering

The invention discloses a plate spraying system, which comprises a conveying belt and is characterized in that a feeding device is arranged at one end of the conveying belt, and a material frame is arranged on one side of the feeding device; a guide frame is arranged on one side of the feeding device, the guide frame is arranged on the conveying belt, a spraying device is arranged on one side of the guide frame, and the feeding device is arranged on one side of the spraying device; the spraying device comprises a rack, and a bottom plate is arranged on the upper side of the rack; a top plate is arranged on the upper side of the rack, and a cylinder II is arranged on the lower side of the top plate; and side plates are arranged on the two sides of the top plate, a mounting base is arranged on one sides of the side plates, a motor is arranged on the upper side of the mounting base, a transmission pipe shaft and a transmission shaft are arranged on one side of the motor, a gear IV is arranged at one end of the transmission shaft, a gear V is arranged on one side of the gear IV, and a spray head is arranged on the lower side of the gear V. According to the plate spraying system provided by the invention, plate spraying is automatically completed, generated chippings are collected, spraying is comprehensive, and the integration degree is high.

Owner:山东中亿木业有限公司

Wire anti-drop welding device for electronic component processing

InactiveCN114654036AImprove welding precisionImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusDust controlEngineering

The invention provides a wire anti-falling welding device for electronic component machining, and relates to the technical field of electronic component machining, the wire anti-falling welding device comprises a mounting supporting part, and the mounting supporting part is slidably connected with a driving propelling device; a tin wire guide part is fixedly connected to the driving and propelling device; a welding device is connected to the tin wire guide part in a sliding manner; the side surface of the tin wire guide part is fixedly connected with a cooling smoke-absorbing part; the bottom of the tin wire guide part is fixedly connected with a clamping device; the tin wire guide part is rotationally connected with a soldering tin feeding part; a floating cleaning part is fixedly connected to the tin wire guide part, so that extrusion welding is achieved, the fitting degree is improved, falling is prevented, tin wires can be automatically pushed in a floating mode, and meanwhile dust removal and smoke collection can be assisted; the problems that an existing electronic component welding device cannot assist in automatic propelling soldering tin, welding efficiency is low, floating cleaning and smoke filtering cannot be assisted, sawtooth pressure welding is assisted through a method, and welding flexibility is poor are solved.

Owner:NANTONG SANXI ELECTRONICS CO LTD

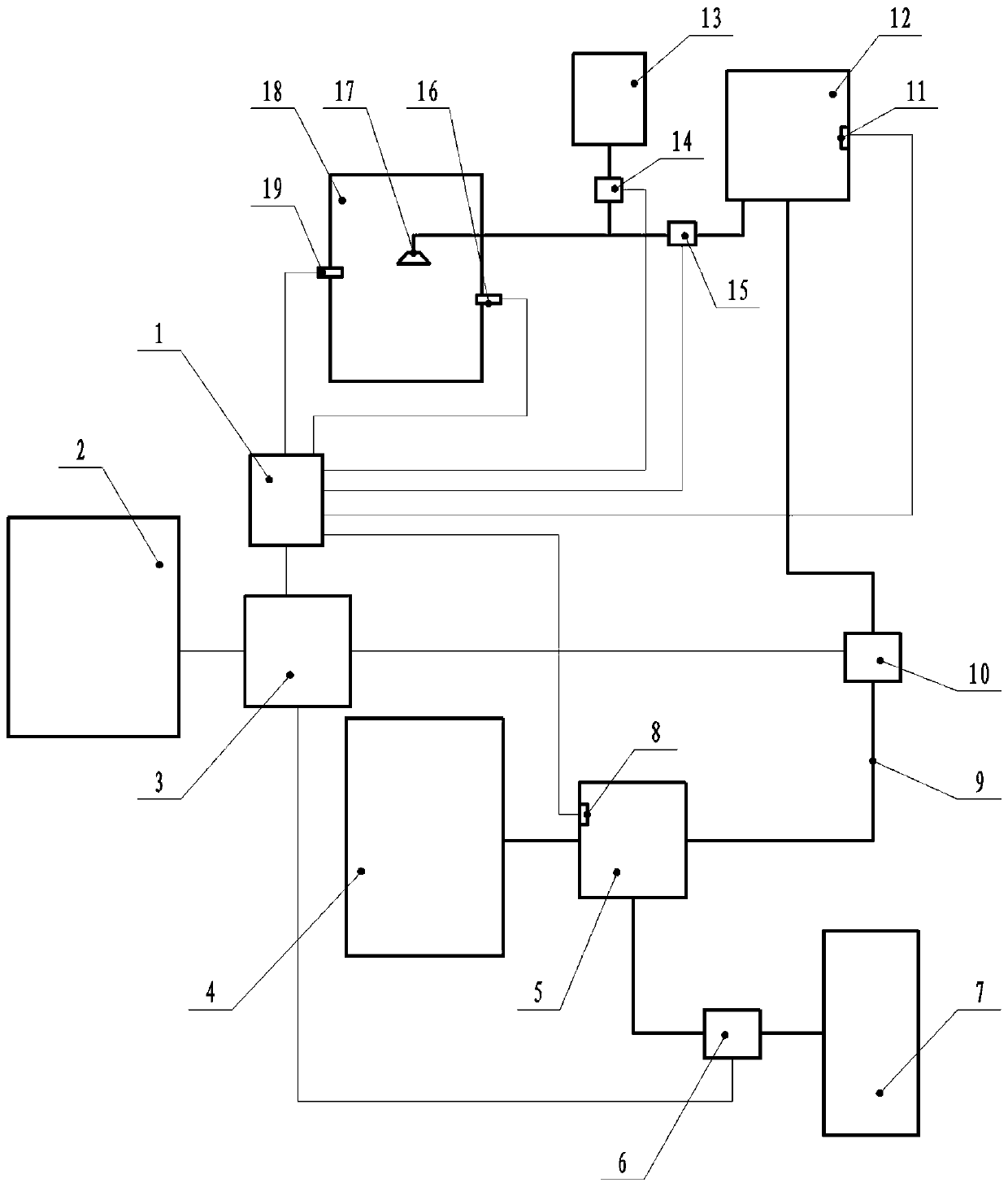

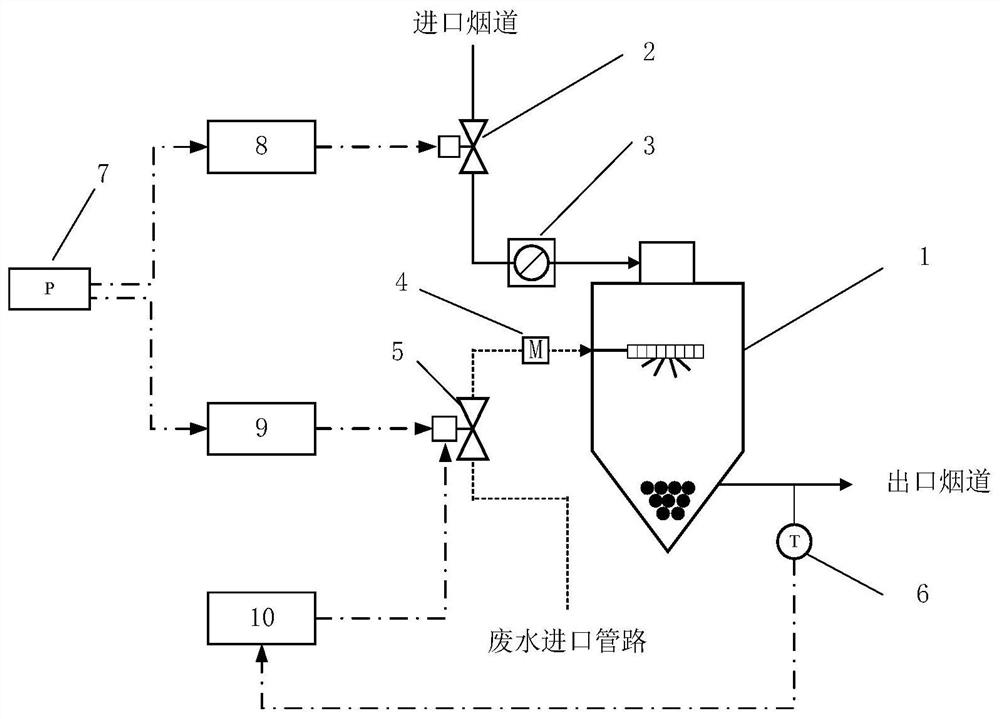

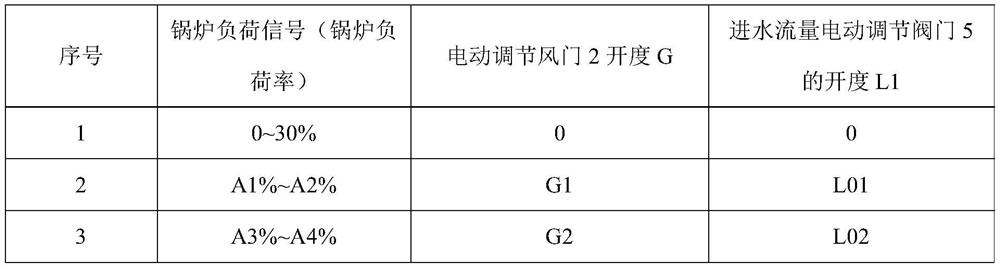

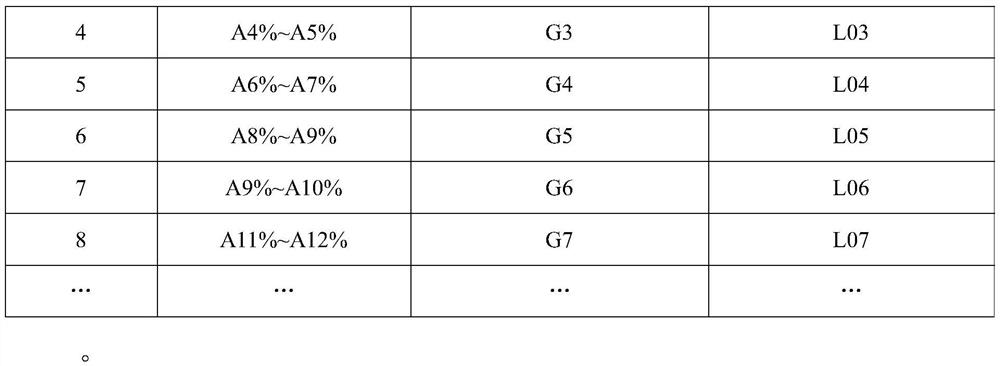

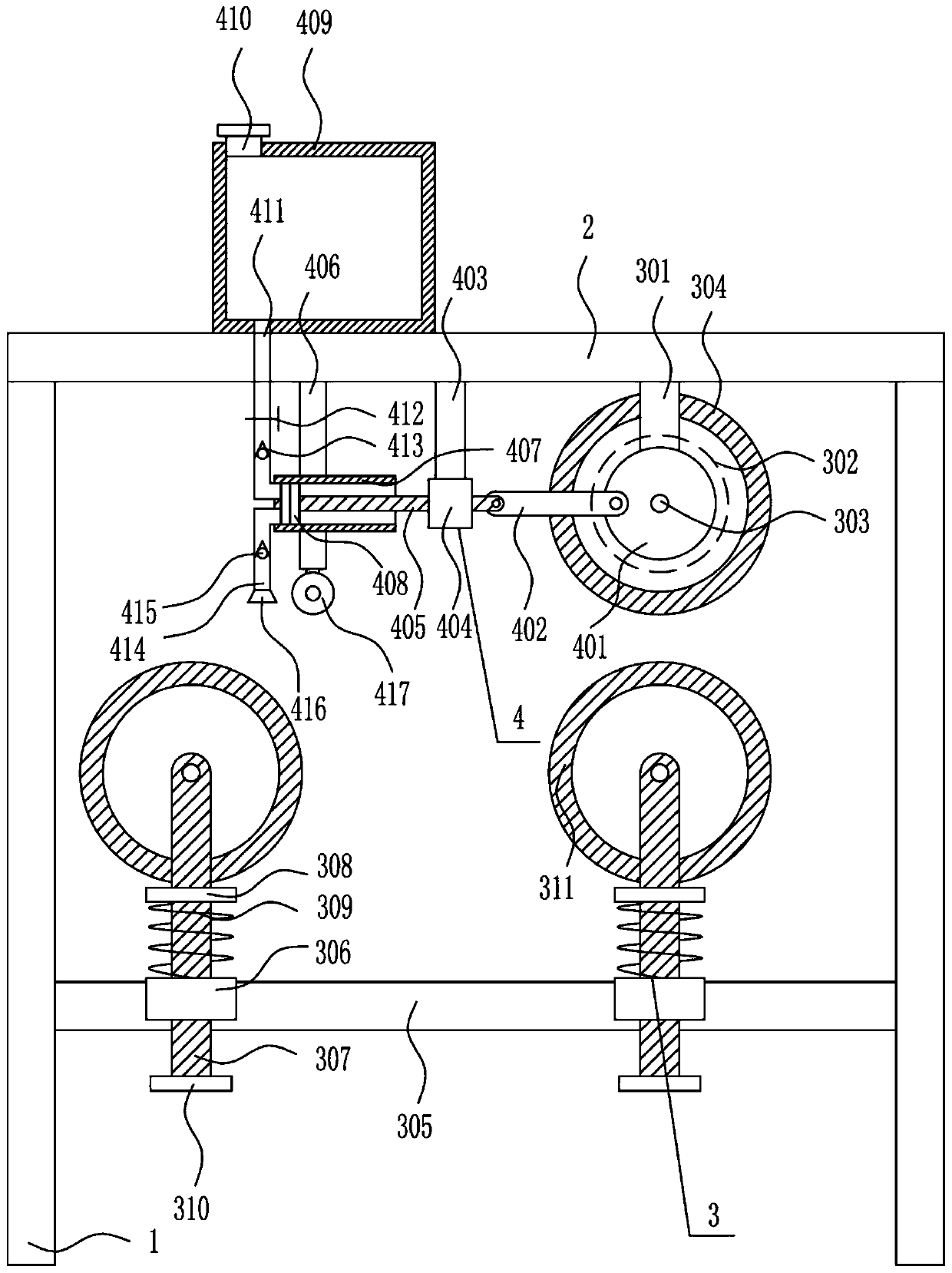

Reliable and efficient bypass flue gas drying tower automatic spraying control system and method

PendingCN112370933AAutomatic sprayingAutomatic spray controlGas treatmentDispersed particle separationAutomatic controlFeedback control

The invention discloses a reliable and efficient bypass flue gas drying tower automatic spraying control system and method. The system comprises an inlet flue, a bypass flue gas drying tower, an outlet flue, a waste water inlet pipeline, a boiler load signal input end, an electric adjusting air door control module, a water inlet flow electric adjusting valve control module and a water inlet flow electric adjusting valve feedback control module. According to the system and the method, automatic control on spraying of the bypass flue gas drying tower is realized, meanwhile, the reliability and the accuracy are higher.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

A device for applying glue to wooden boards at intervals

ActiveCN108284046BAutomatic sprayingSpray evenlyLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

Owner:浙江范优奇家具制造有限公司

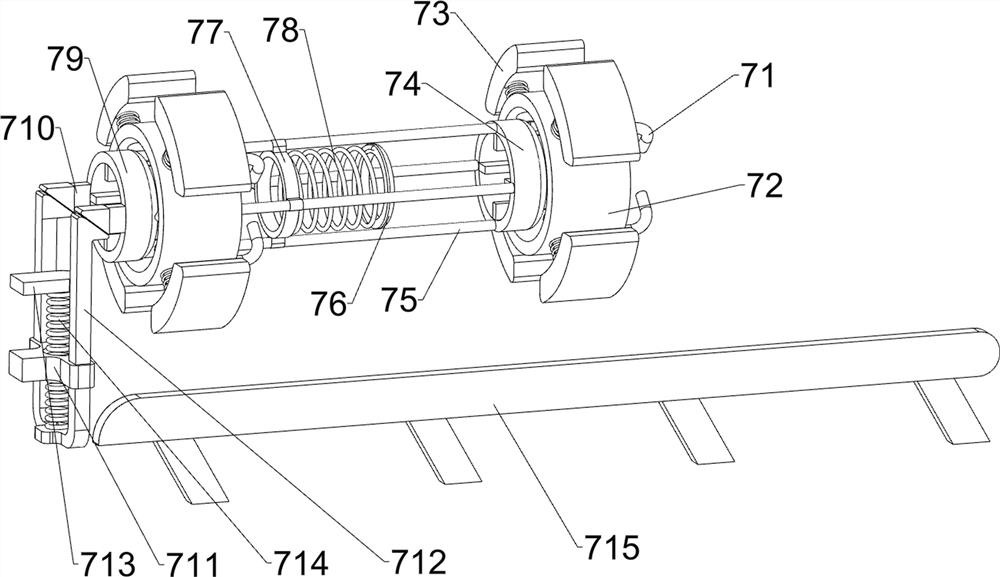

Tamping hammer friction plate sweeper

ActiveCN105349159AAutomatic sprayingEasy to cleanOven incrustations prevention/removalSpray nozzleEngineering

The invention discloses a tamping hammer friction plate sweeper, and belongs to the field of tamping machines of tamping coke ovens. The tamping hammer friction plate sweeper is used for solving problems of the prior art that time and energy are wasted by manual cleaning of attachments on friction plates, and potential safety hazard is caused. The tamping hammer friction plate sweeper comprises a tamping hammer driven by a tamping machine, friction plates arranged on the two sides of the tamping hammer, and sweepers which are arranged on the tamping machine one the two sides of the friction plates, and are installed via connecting plates; each sweeper comprises a support, a spring, and a scraper, wherein the support is connected with a corresponding connecting plate via a No. I pin shaft, the scraper is connected with the support via a No. II pin shaft, the spring is arranged between the support and the tamping machine, and is connected via bolts; the tamping machine is provided with a pump station filled with acetone, and is connected with nozzles arranged on the sweepers via pipelines. The tamping hammer friction plate sweeper is used for tamping machines, and is reasonable in structure design, and excellent in attachment cleaning effect, and installation, adjusting, and maintenance are convenient.

Owner:TAIYUAN HEAVY IND

Vehicle body spraying device for electro-tricycle production

InactiveCN110152929AImprove spraying efficiencyEasy to sprayPretreated surfacesCoatingsAutomotive engineering

The invention relates to the technical field of spraying equipment and discloses a vehicle body spraying device for electro-tricycle production. The vehicle body spraying device comprises a box. An L-shaped supporting frame is fixedly connected to the top of the box. The lower surface of the horizontal part of the L-shaped supporting frame is fixedly connected with a spraying mechanism. The innerwall of the bottom of the box is fixedly connected with a fixed box. The top of the fixed box is provided with an opening. A turnover mechanism is fixedly connected to the opening. The spraying mechanism comprises an electric push rod fixedly connected with the lower surface of the horizontal part of the L-shaped supporting frame. The bottom of the electric push rod is fixedly connected with a first rotating motor. The output end of the first rotating motor is fixedly connected with a first delivery pipe. The vehicle body spraying device for electro-tricycle production can conveniently and simultaneously conduct spraying on multiple vehicle body parts, can automatically turn over the vehicle body parts to conduct spraying, improves the spraying efficiency and can dry the sprayed vehicle body parts conveniently.

Owner:徐州玉伟机械设备有限公司

Device for heavy-metal-polluted soil control

InactiveCN107138514AAvoid blockingGuaranteed uniformityContaminated soil reclamationGastric tube feedingContaminated soils

The invention discloses a device for treating heavy metal polluted soil, which includes a hopper and a feeding device, and the feeding device includes a fan, a fixing seat, a feeding pipe, a discharge pipe, a supporting seat, a connecting pipe, a top cover, a stirring device and Closing device, the bottom of the fan is fixed with a fixed seat, the output shaft of the fan is connected to one end of the feeding pipe, the other end of the feeding pipe is sealed, and a plurality of discharge pipes are equidistantly arranged on the feeding pipe, Therefore, both ends of the feeding pipe are fixed with support bases, the hopper is fixed on the end of the feeding pipe close to the fan through the connecting pipe, the top of the hopper is fixed with a top cover, and a stirring device is fixed on the top cover. For the device for the treatment of heavy metal polluted soil, a motor is fixed on the upper end of the top cover. The rotation of the motor can drive the rotating shaft to rotate, and then the improving agent can be stirred through the rotating shaft, so as to prevent the improving agent from clogging when feeding and ensure the feeding. Uniformity.

Owner:CHENGDU YIRUIXIN TECH CO LTD

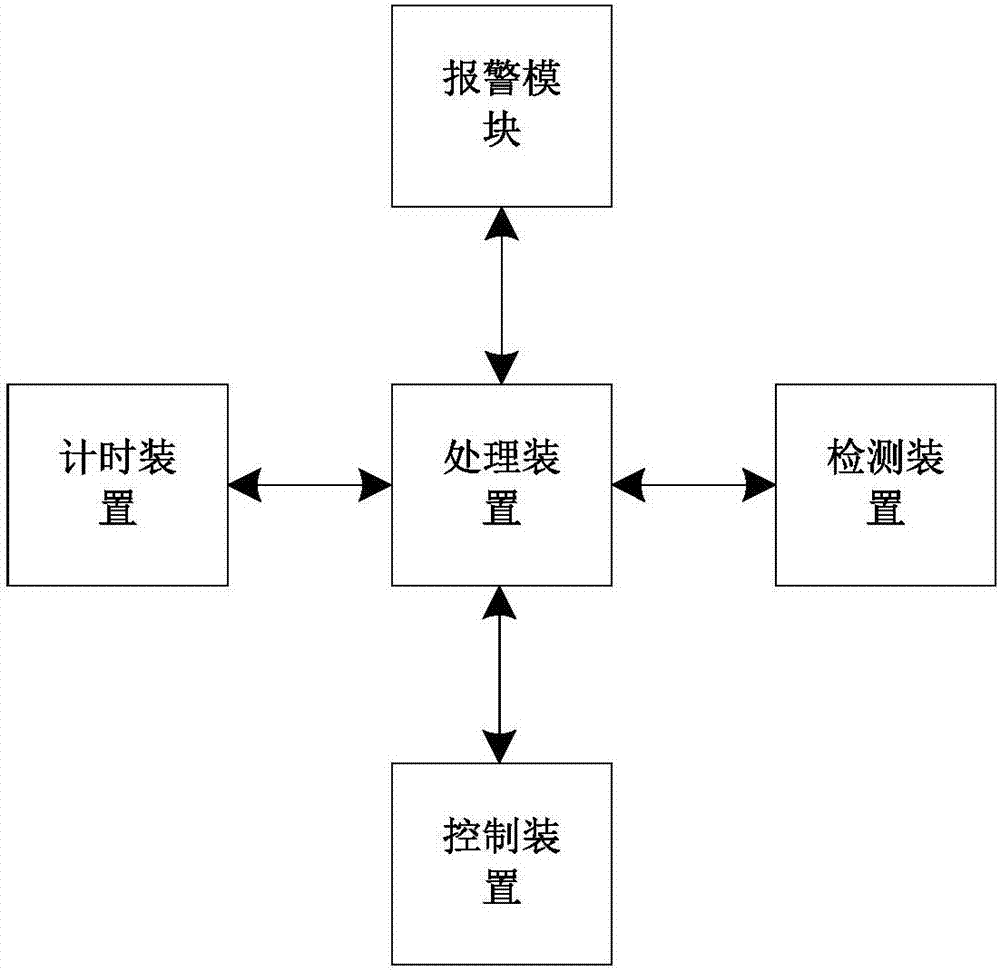

Pesticide spraying device capable of traveling automatically

InactiveCN107306923AAutomatic sprayingSpray on timeInsect catchers and killersImaging processingComputer engineering

The invention provides a pesticide spraying device capable of traveling automatically. The device comprises a pesticide box, traveling wheels are arranged at the bottom of the pesticide box, a control box is arranged on the side face of the pesticide box, and a timing device, a detection device, a processing device and a control device are arranged in the control box; the timing device is used for timekeeping according to the set spraying time, and when the spraying time is up, a start signal is sent to the processing device; the processing device is started according to the start signal and sends a detection signal to the detection device; the detection device continuously acquires image information of a monitoring area according to the detection signal, and sends the image information to the processing device; the processing device processes the image information according to a preset image processing algorithm, so that traveling control information is obtained, and a traveling instruction is sent to the control device; the control device controls the traveling wheels to move according to the traveling instruction. According to the pesticide spraying device, a grower can be assisted in automatically spraying pesticide on time, the labor cost is reduced, and the time and the labor are saved.

Owner:广西英伟科技有限公司

Rain shelter for maintaining chrysanthemum in cultivation period

InactiveCN113141945AFull lightAutomatic sprayingPlant protective coveringsInsect catchers and killersElectric machineryEngineering

The invention relates to a rain shelter for maintaining chrysanthemum in the cultivation period. The rain shelter comprises a side linkage frame, a first motor and an outer hanging bracket, wherein the first motor and the outer hanging bracket are both installed on the side linkage frame; a pesticide spraying device is mounted on the outer hanging bracket; two lower rotating shafts are mounted on the side linkage frame through bearing seats; any one of the two lower rotating shafts is connected with the first motor; each lower rotating shaft is connected with a side shed frame; and in the two side shed frames, a ceiling frame is hinged to the upper portion of the side shed frame located on the left side, and a locking assembly is mounted on the upper portion of the side shed frame located on the right side. The rain shelter is convenient to use, not only can protect the chrysanthemum from rain, but also can automatically remove the shielding of the ceiling frame and the side shed frames, the chrysanthemum can be fully illuminated, and an insecticide can be automatically sprayed to the chrysanthemum, so that the effect of ensuring the healthy growth of the chrysanthemum is achieved.

Owner:安徽海舜生态农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com