Pesticide spraying device for navel orange planting

A technology for spraying devices and medicines, which can be used in spraying devices, devices for catching or killing insects, applications, etc., and can solve the problems of low efficiency of spraying pesticides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

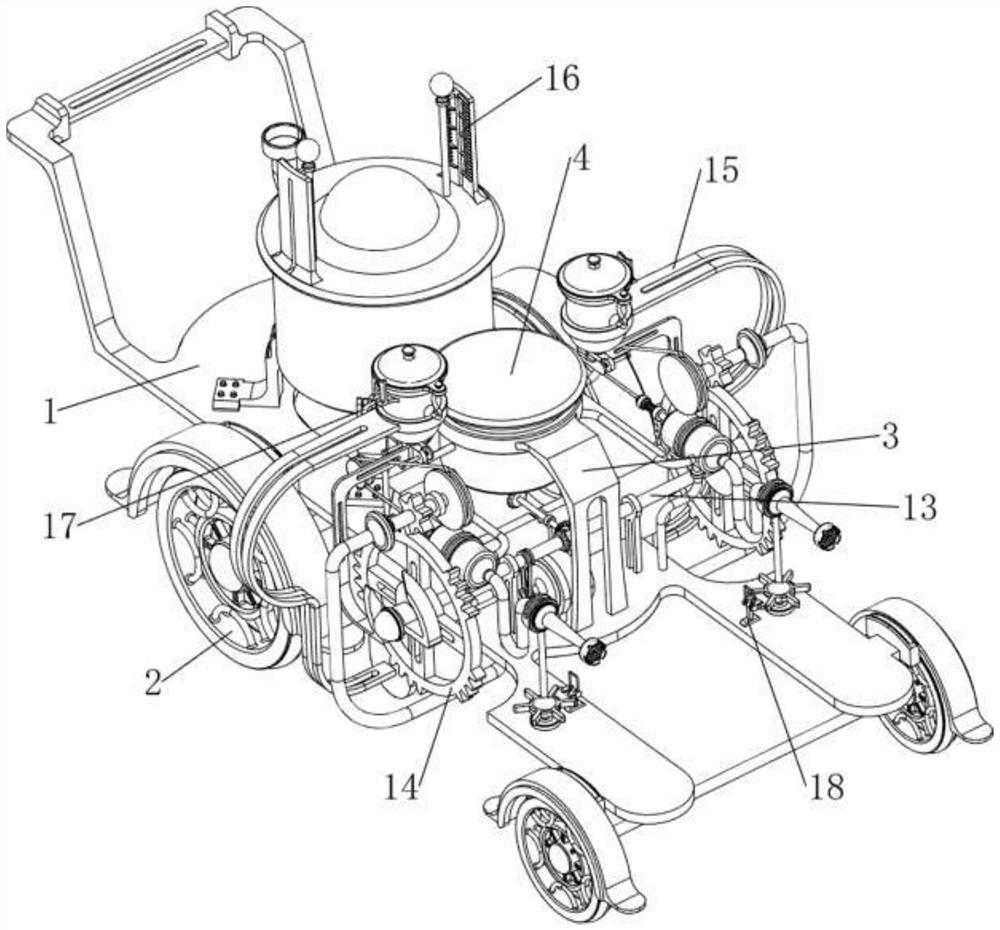

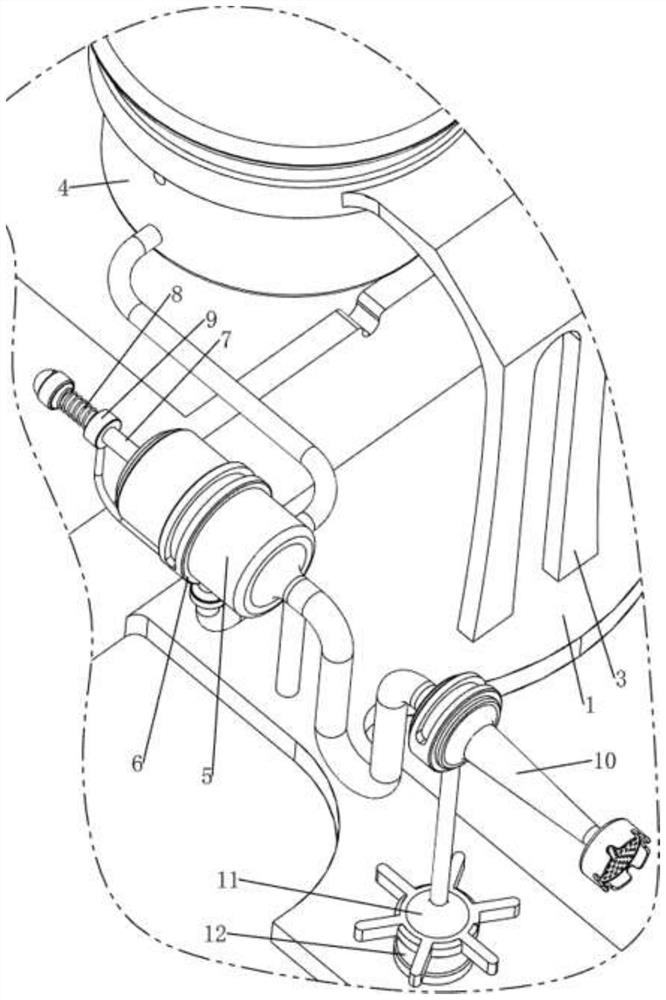

[0030] A drug spraying device for planting navel oranges, such as Figure 1-2 As shown, it includes outer frame 1, tire 2, first fixed column 3, stirring box 4, pressing box 5, second fixed column 6, first pressing plate 7, first linear spring 8, third fixed column 9, Mist nozzle 10, rotating rod 11, annular slide rail 12, stirring mechanism 13 and spraying mechanism 14, two tires 2 are rotated on the outer frame 1, and the right side of the outer frame 1 top is provided with the first fixed column 3, the second A stirring box 4 is arranged on a fixed column 3, and a second fixed column 6 is arranged symmetrically front and back on the right side of the outer frame 1, and a pressing box 5 is arranged on the second fixing column 6, and the mixing box 4 communicates with the pressing box 5, The second fixed column 6 is provided with a third fixed column 9, a first pressing plate 7 is slidably connected between the third fixed column 9 and the press box 5, and a first pressing pl...

Embodiment 2

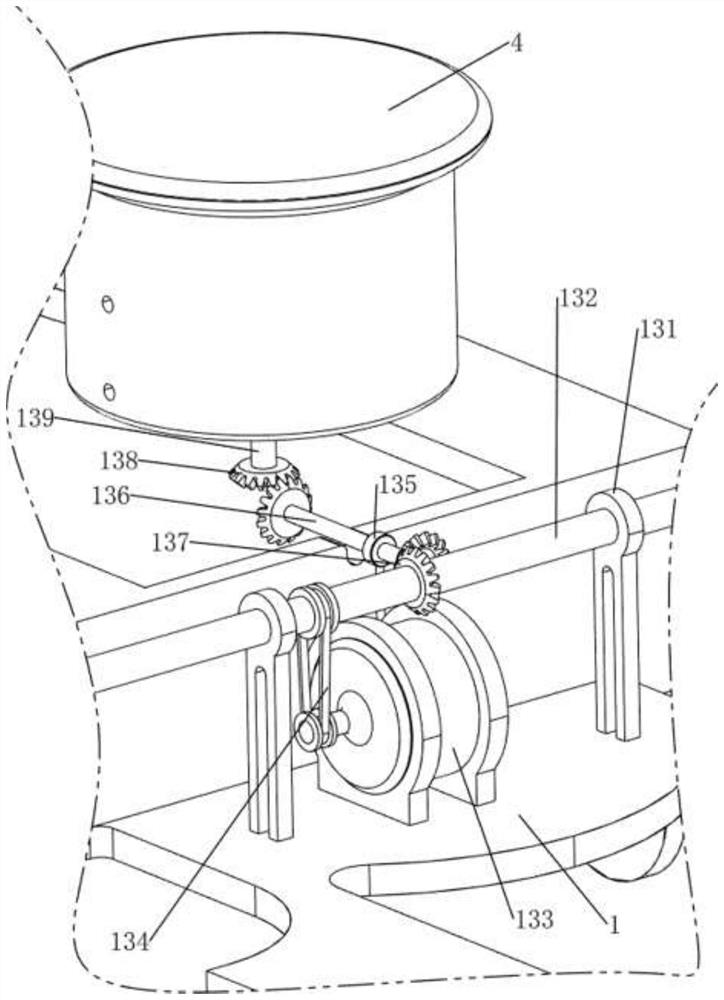

[0033] On the basis of Example 1, such as Figure 3-4As shown, the stirring mechanism 13 includes a fourth fixed column 131, a first rotating shaft 132, a motor 133, a belt 134, a fifth fixed column 135, a second rotating shaft 136, a first bevel gear set 137, a second bevel gear set 138 and Stirring bar 139, outer frame 1 upper right side is provided with the 4th fixed column 131 symmetrically front and rear, the 4th fixed column 131 is provided with the first rotating shaft 132 in rotation, and outer frame 1 upper right side is provided with motor 133, and motor 133 A belt 134 is connected by a pulley between the output shaft of the output shaft and the first rotating shaft 132, the upper right side of the outer frame 1 is provided with a fifth fixed post 135, the fifth fixed post 135 is rotatably provided with a second rotating shaft 136, and the first rotating shaft 132 A first bevel gear set 137 is connected with the second rotating shaft 136 , and a stirring rod 139 is r...

Embodiment 3

[0038] On the basis of Example 2, such as Figure 5-10 As shown, it also includes a blanking mechanism 15, and the blanking mechanism 15 includes a seventh fixed column 151, a first wedge block 152, a second wedge block 153, a storage box 154, a cover 155, a hose 156, a second Pressing plate 157, the second linear spring 158 and the third pressing plate 159, outer frame 1 intermediate position is provided with the seventh fixed post 151 symmetrically front and back, the seventh fixed post 151 is all provided with material storage box 154, on the material storage box 154 all Rotary type is provided with cover 155, first rotating shaft 132 front and rear sides are all provided with first wedge block 152, is communicated with flexible pipe 156 between mixing box 4 and material storage box 154, is all provided with second on the material storage box 154. Pressing plate 157, the second pressing plate 157 is provided with the third pressing plate 159 slidingly, the third pressing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com