Six-freedom-degree spray coating robot

A technology of spraying robot and degree of freedom, which is applied in the direction of manipulators, spraying devices, program-controlled manipulators, etc., can solve the problems of small working space, low spraying quality, low paint utilization rate, etc., and achieve high spraying freedom, high spraying quality, The effect of a large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

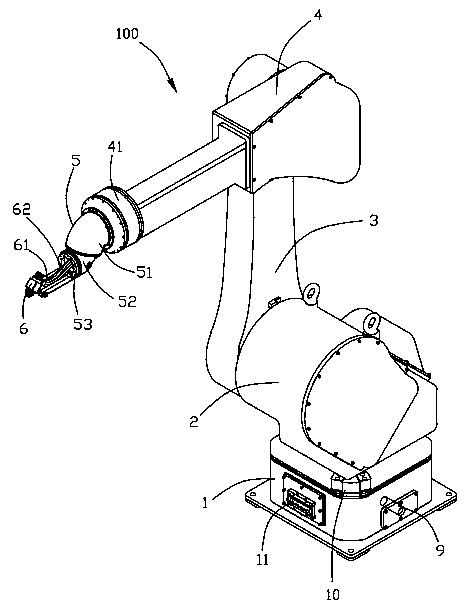

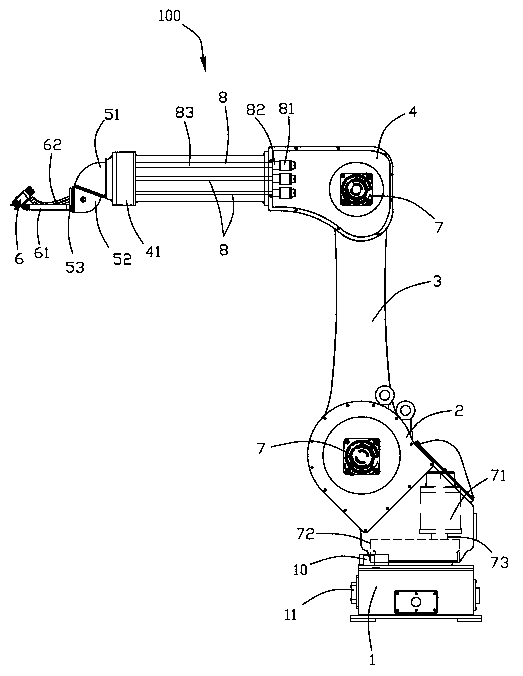

[0017] Please refer to figure 1 and figure 2 Shown is a preferred implementation of the six-degree-of-freedom painting robot 100 of the present invention. The six-degree-of-freedom spraying robot 100 includes a base 1, a waist joint 2 movably fixed on the base 1, a big arm joint 3 movably fixed on the lumbar joint 2, a forearm joint 4 movably fixed on the big arm joint 3, The three-degree-of-freedom oblique wrist 5 that is movably fixed on the forearm joint 4, the spray gun bracket 6 connected to the end of the three-degree-of-freedom oblique wrist 5, is movably connected between each joint 2, 3, 4 or joints 2, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com