Building template surface spraying device

A technology of surface spraying and building formwork, applied in the direction of spraying device, etc., can solve problems such as inconvenience of use, and achieve the effect of reducing spraying waste, reducing covering spraying, and preventing leaving gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

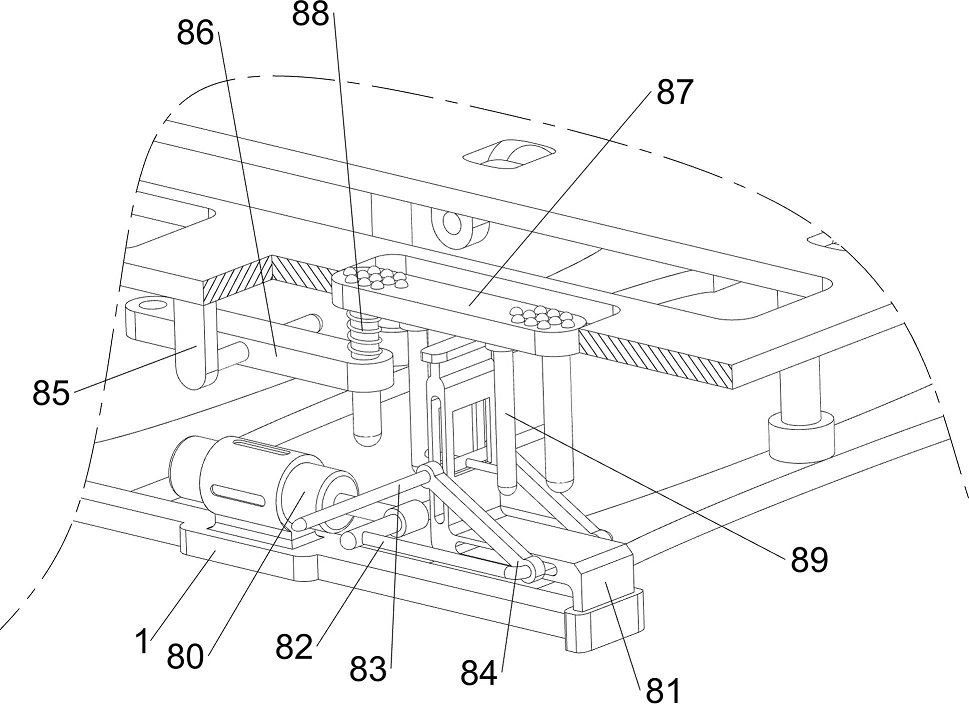

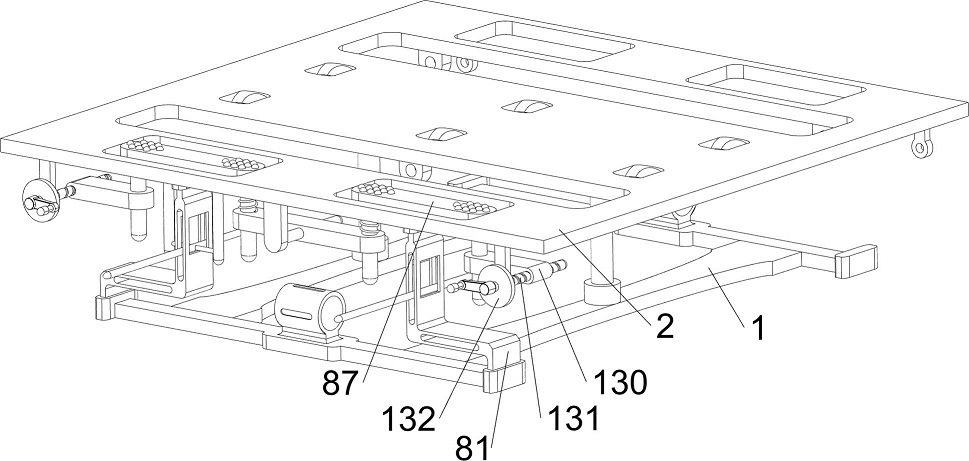

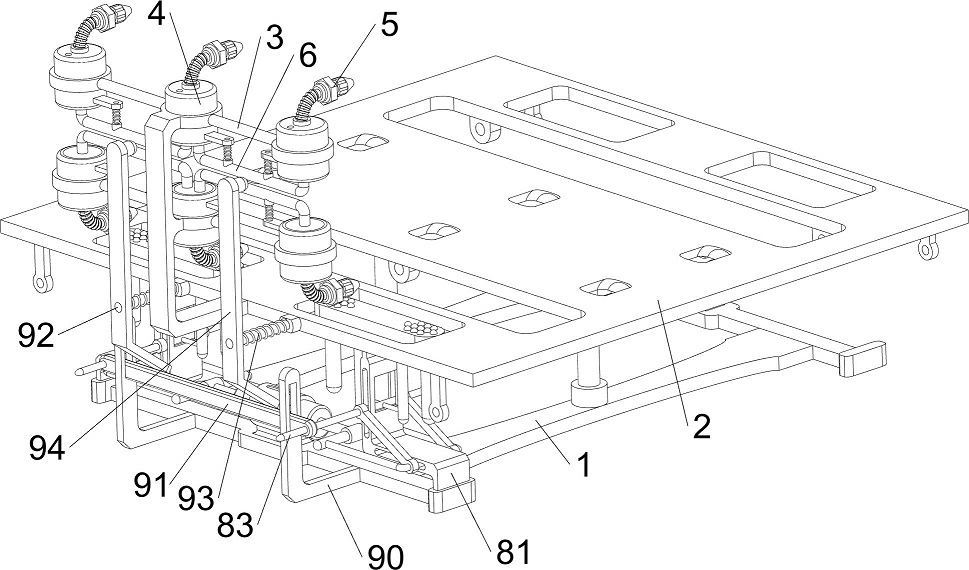

[0081] A construction formwork surface spraying device, such as Figure 1-Figure 7 As shown, it includes a base 1, a support plate 2, a support frame 3, a spraying tank 4, a stretching nozzle 5, a moving push rod 6, a first return spring 7, a jacking mechanism 8 and a spraying mechanism 9. The top of the base 1 is provided with There is a support plate 2, which is used to place the formwork. The support plate 2 is provided with a support frame 3 on the front and rear sides. The upper and lower sides of the two support frames 3 are evenly spaced with three spraying cans 4. There are twelve spraying cans 4, which are used for To store the paint, the twelve spraying cans 4 are provided with sliding plugs for injecting an appropriate amount of paint into the spraying cans 4, and the tops of the six spraying cans 4 above are all slidingly provided with stretching nozzles 5, The six spraying cans 4 below are also slidably provided with six stretching nozzles 5. The stretching nozzle...

Embodiment 2

[0086] On the basis of Example 1, as figure 1 , figure 2 , Figure 8 and Figure 9As shown, it also includes a moving mechanism 10. The moving mechanism 10 includes a first support rod 100, a first electric sliding rail 101, a second electric sliding rail 102, a first electric sliding block 103, a third connecting rod 104 and a second electric sliding rail 102. The electric slider 105, the front and rear sides of the support plate 2 are symmetrically provided with first support rods 100, the tops of the four first support rods 100 are all installed with first electric slide rails 101, and the tops of the four first electric slide rails 101 are A second electric slide rail 102 is provided, the lower part of the inner side of the four first electric slide rails 101 is slidably provided with a first electric slider 103, and the upper part of the inner side of the four second electric slide rails 102 is slidably provided with a second electric slide rail 103. Electric sliders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com