Spraying control system for chemical industry place

A control system and site technology, applied in the field of spraying, can solve the problems of time-consuming, labor-intensive and material-consuming, the sprayer cannot stop spraying immediately, and the spraying amount cannot be calculated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

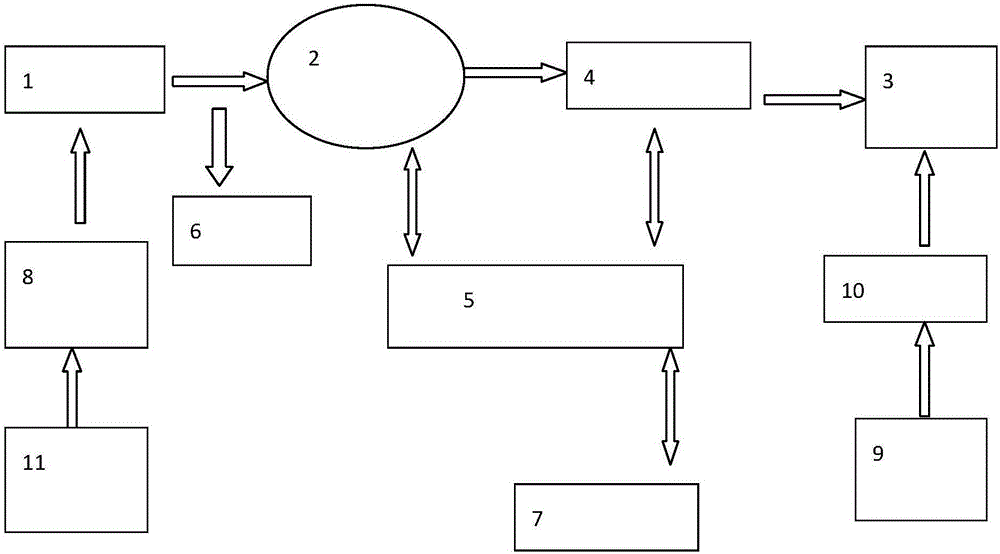

[0019] See figure 1 , the present invention has a circulating water pump 1, a flow control valve 2 and a nozzle 3; the output end of the circulating water pump 1 is connected to the input end of the flow control valve 2, and the input end of the circulating water pump 1 is connected to the water supply tank 8; the output end of the flow control valve 2 is connected to The input end of the nozzle 3; also has a dust sensor 7; the output end of the dust sensor 7 is connected with the control device 5.

[0020] There is also a conditioner 9; the conditioner 9 communicates with the front end of the water outlet of the spray head 3 through the "s" curved return pipe 10. Avoid the water in the nozzle 3 from directly flowing out to cause pollution.

[0021] One side of the water supply box 8 is provided with a medicine adding box 11 .

[0022] It also has a flow sensor 4 and a control device 5; the flow sensor 4 is connected in series between the output end of the flow control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com