Wire anti-drop welding device for electronic component processing

A technology of electronic components and welding devices, which is applied in welding equipment, metal processing, auxiliary devices, etc., can solve the problems of inability to realize auxiliary floating cleaning and smoke filtration, affect the health of welders' respiratory tract, and inconvenience welding positioning operations, so as to avoid hand-holding Unstable welding, easy to squeeze the butt wire, and avoid impurities affecting the welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

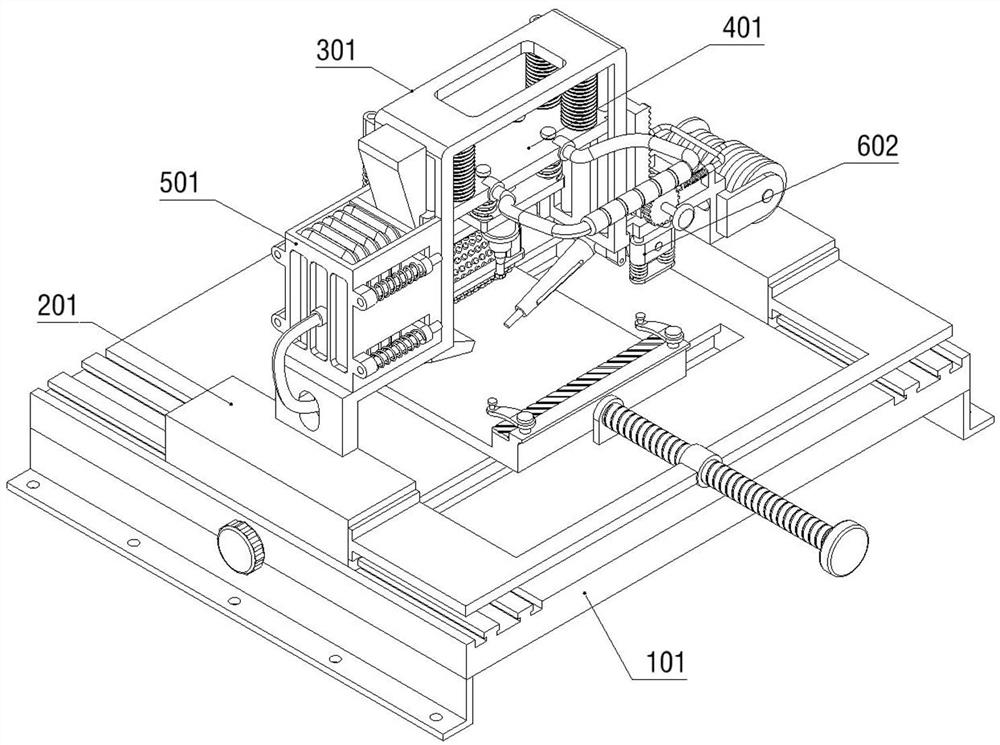

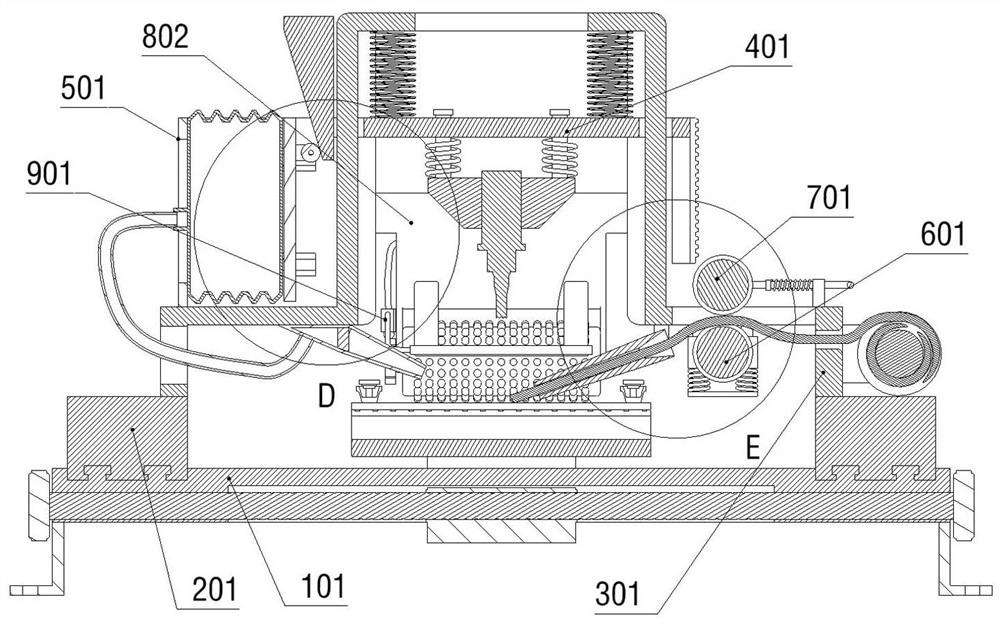

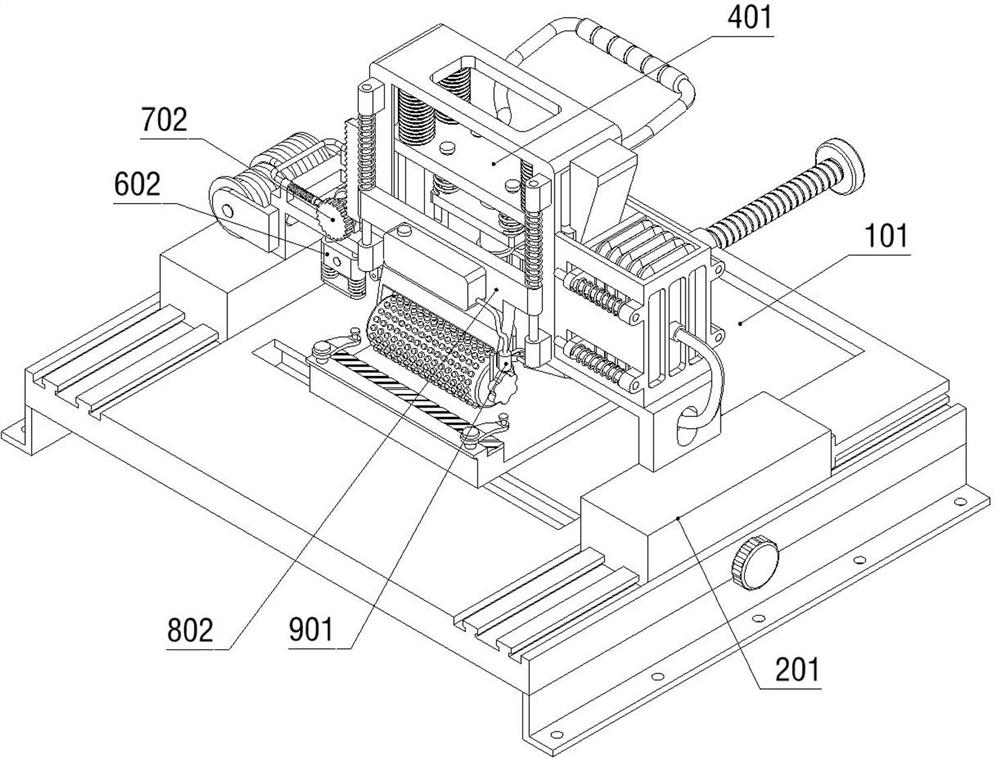

[0045] Example: please refer to Figure 1 to Figure 18 :

[0046] The present invention provides an anti-separation welding device for wires used for processing electronic components, which includes an installation support part 1: a drive propulsion device 2 is slidably connected to the installation support part 1; the drive propulsion device 2 is fixedly connected with a tin wire guide part 3; A welding device 4 is slidably connected to the tin wire guide part 3; a cooling smoking part 5 is fixedly connected to the side of the tin wire guide part 3; The solder feeding part 7; the tin wire guide part 3 is fixedly connected with a floating cleaning part 8; the floating cleaning part 8 is installed with a squeezing spray part 9; The sides are respectively fixedly connected with installation feet 1011; drive screw 102, which is rotatably connected to the installation push plate 101; both ends of the drive screw 102 pass through the installation push plate 101 and are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com