Reliable and efficient bypass flue gas drying tower automatic spraying control system and method

A spray control and drying tower technology, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems such as the inability to automatically control the spray volume, the lack of practicality, and the mismatch between the spray water volume and the extraction volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

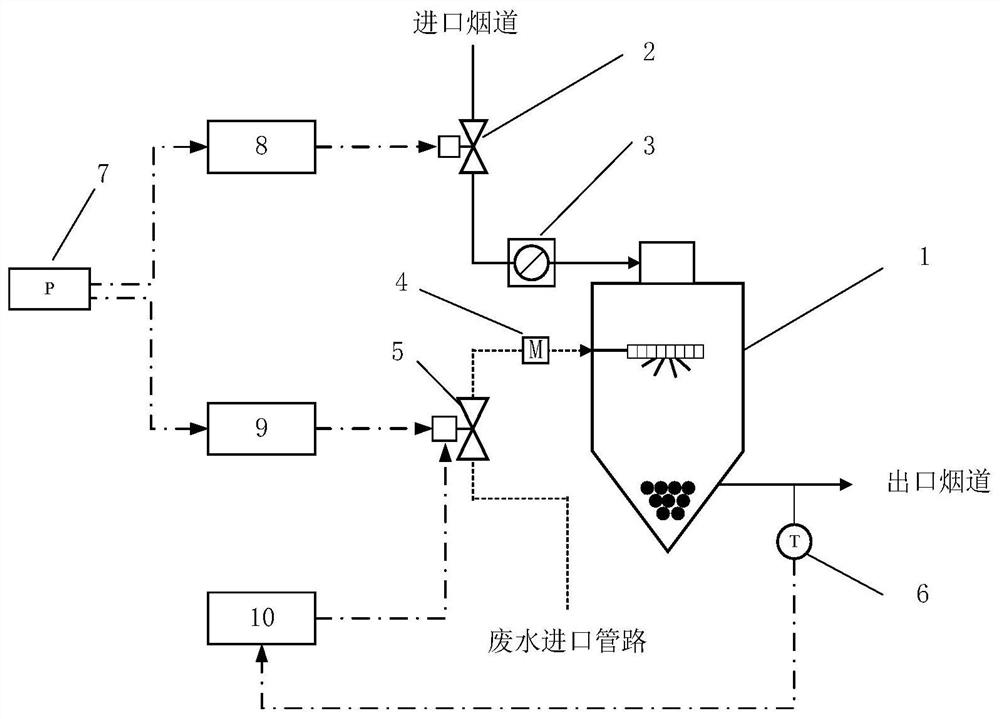

[0044] Taking the bypass flue gas drying tower 1 of a 1000MW unit in a certain power plant as an example, the reliable and efficient bypass flue gas drying tower 1 automatic spray control method of the present invention includes the following steps:

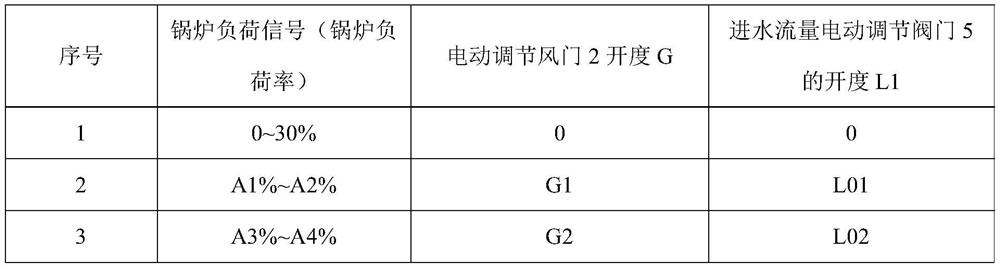

[0045] 1) The electric damper control module 8 specifies the opening G of the electric damper 2 according to the boiler load signal of the currently running unit, and adjusts the opening of the electric damper 2 according to the given opening G of the electric damper 2;

[0046]2) The control module 9 of the electric water flow regulating valve control module 9 specifies the opening L1 of the electric water flow regulating valve 5 according to the boiler load signal of the currently running unit;

[0047] Among them, the opening degree G of the electric damper 2 and the opening degree L1 of the electric water flow regulating valve 5 are determined according to Table 2.

[0048] Table 2

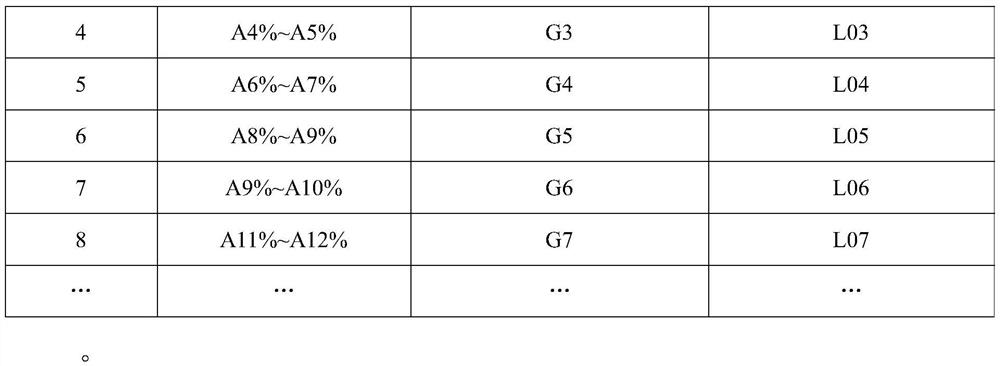

[0049]

[0050]

[0051] 3) Set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com