Plate spraying system

A technology of sheet metal and spraying device, applied in the field of sheet metal processing, can solve the problems of incomplete and uneven spraying of sheet metal, and achieve the effect of high degree of automation and convenient feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

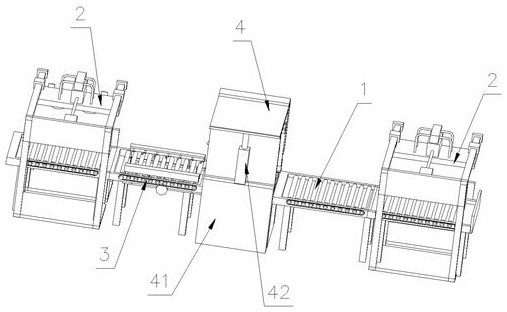

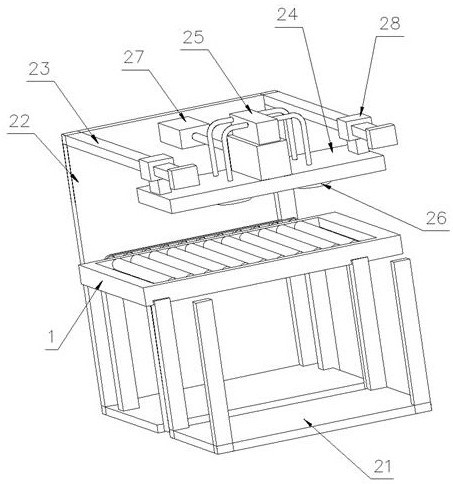

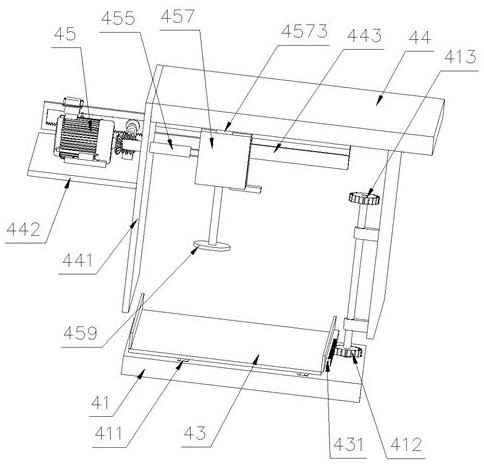

[0023] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-7 , to further specifically describe the technical solution of the present invention.

[0024] A plate spraying system, comprising a conveyor belt 1, one end of the conveyor belt 1 is provided with a feeding device 2, and one side of the feeding device 2 is provided with a material rack 21; one side of the feeding device 2 is provided with a guide frame 3, and the guide frame 3 is arranged on On the conveyor belt 1, a spraying device 4 is provided on one side of the guide frame 3, and a feeding device 2 is provided on one side of the spraying device 4. Perform positioning, move to the spraying device 4, and automatically spray, after the spraying is completed, place it on the material rack 21 through the feeding device 2;

[0025] Described spraying device 4 comprises frame 41, and described frame 41 is provided with chute 411, and described frame 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com