Anti-corrosion coating spraying equipment for exhaust gas emission pipeline

A technology for spraying equipment and exhaust gas emission, which is applied in the direction of spraying device to achieve the effect of good spraying work, preventing shaking and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

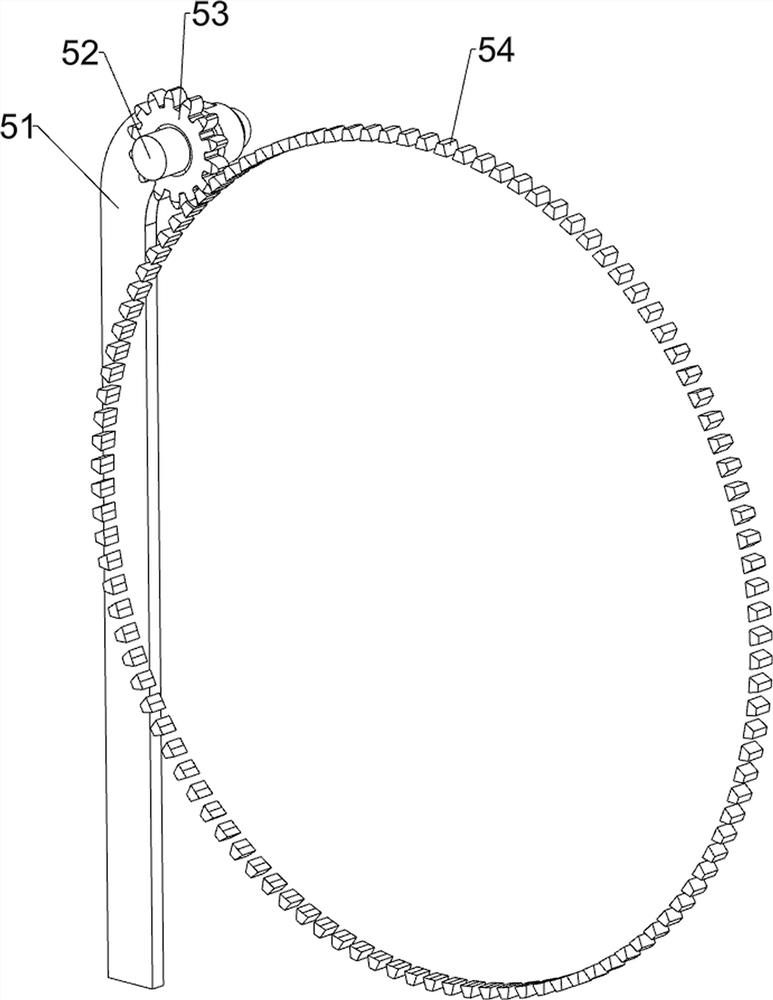

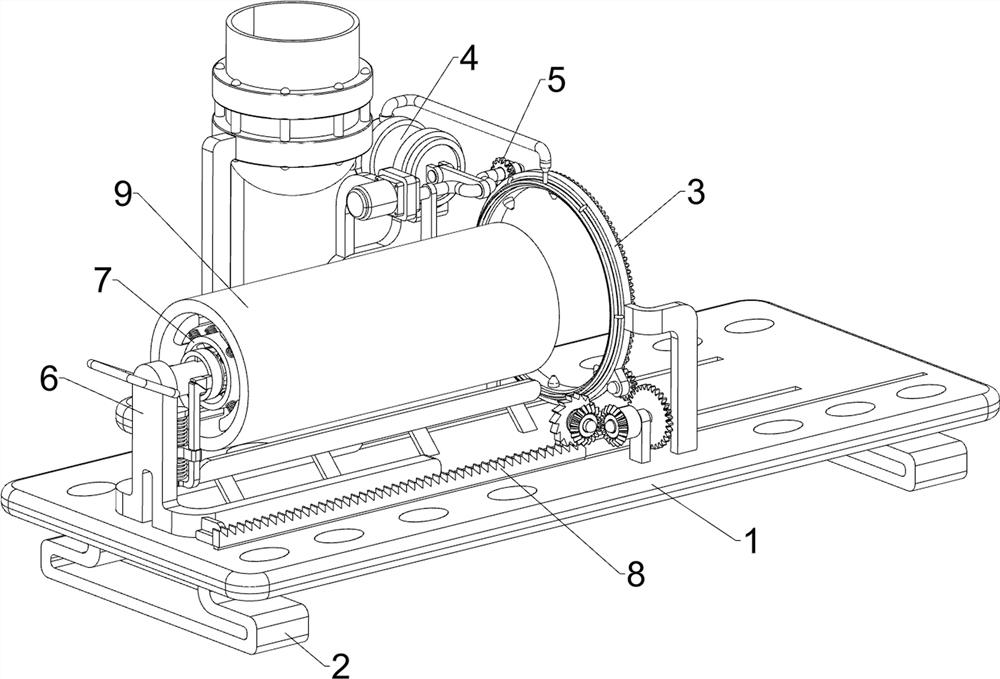

[0029] An anti-corrosion paint spraying equipment for exhaust gas discharge pipes, such as Figure 1-4 As shown, it includes a base plate 1, a support frame 2, a spraying mechanism 3, a feeding mechanism 4 and a rotating mechanism 5, the left and right sides of the bottom of the base plate 1 are connected with a support frame 2, and the base plate 1 is respectively equipped with a spraying mechanism 3, a supply mechanism Feeding mechanism 4 and rotating mechanism 5.

[0030] The spraying mechanism 3 includes a fixed ring frame 31, the first connecting rod 32, a hollow fixed ring 33, a feed joint 34 and a spray frame 35, the right side of the bottom plate 1 top is connected with a fixed ring frame 31, and the left side of the fixed ring frame 31 A plurality of first connecting rods 32 are evenly spaced along the circumferential direction, and a hollow fixing ring 33 is connected between the tail ends of the plurality of first connecting rods 32, and the top of the hollow fixing...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 and Figure 5 As shown, it also includes a placement frame assembly 6, the placement frame assembly 6 includes a mounting frame 61, a slider 62, a placement bar 63 and a handle 64, two sliders 62 are slidably connected to the top of the bottom plate 1, and the slider 62 is located at the second The front side of the two fixed mounts 44, the tops of the two slide blocks 62 are connected with a mounting frame 61, the mounting frame 61 top is connected with a placement bar 63, and the mounting frame 61 top is connected with a handle 64, and the handle 64 is positioned on the left side of the placement bar 63. side.

[0036] The pipe 9 can be set on the placement rod 63, so that there is no need to manually hold the pipe 9 for spraying, push the handle 64 to the right so that the installation frame 61 moves to the right, and the installation frame 61 moves to the right to drive the placement rod 63 to move to the right. Place ba...

Embodiment 3

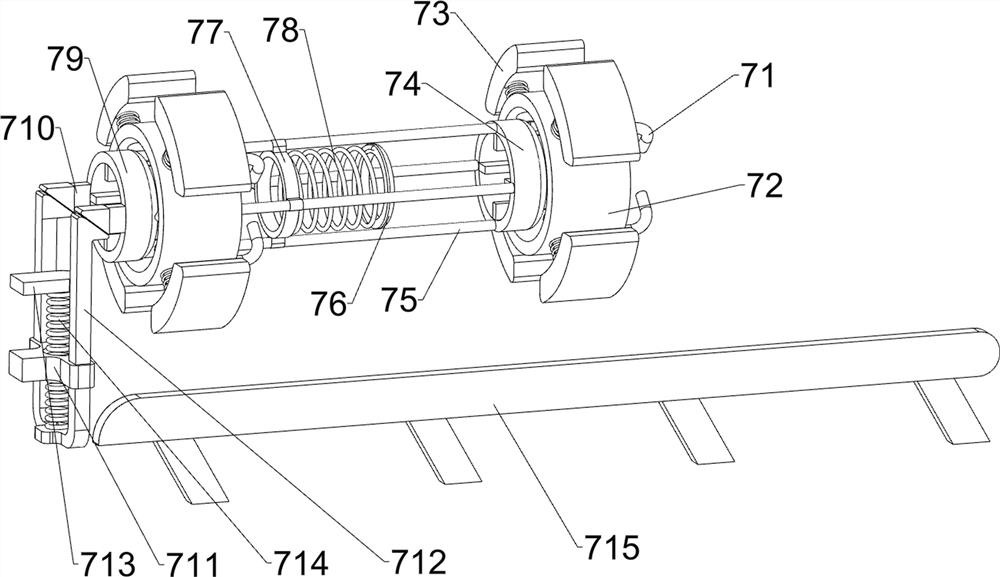

[0038] On the basis of Example 2, such as figure 1 and Figure 6 As shown, it also includes a limit mechanism 7, and the limit mechanism 7 includes a second connecting rod 71, a mounting ring 72, an elastic clamp block 73, a first push ring frame 74, a third connecting rod 75, a limit ring 76, a connection Ring 77, the first spring 78, the second push ring frame 79, fixed wedge block 710, guide block 711, sliding wedge block frame 712, first fixed plate 713, second spring 714 and top plate frame 715, place bar 63 outer walls A plurality of second connecting rods 71 are connected to the left and right sides, and a mounting ring 72 is connected between the second connecting rods 71 on the same side, and a plurality of elastic clips 73 are connected to the mounting ring 72 in a sliding manner evenly spaced along the circumferential direction. , the right side of the outer wall of the placement rod 63 is slidably connected with a first push ring frame 74, and the left side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com