Locking structure for low-voltage switch cabinet

A low-voltage switchgear and cabinet technology, applied in the field of low-voltage switchgear, can solve the problems of inability to carry out lubricating oil, smear work, and inability to disassemble related parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

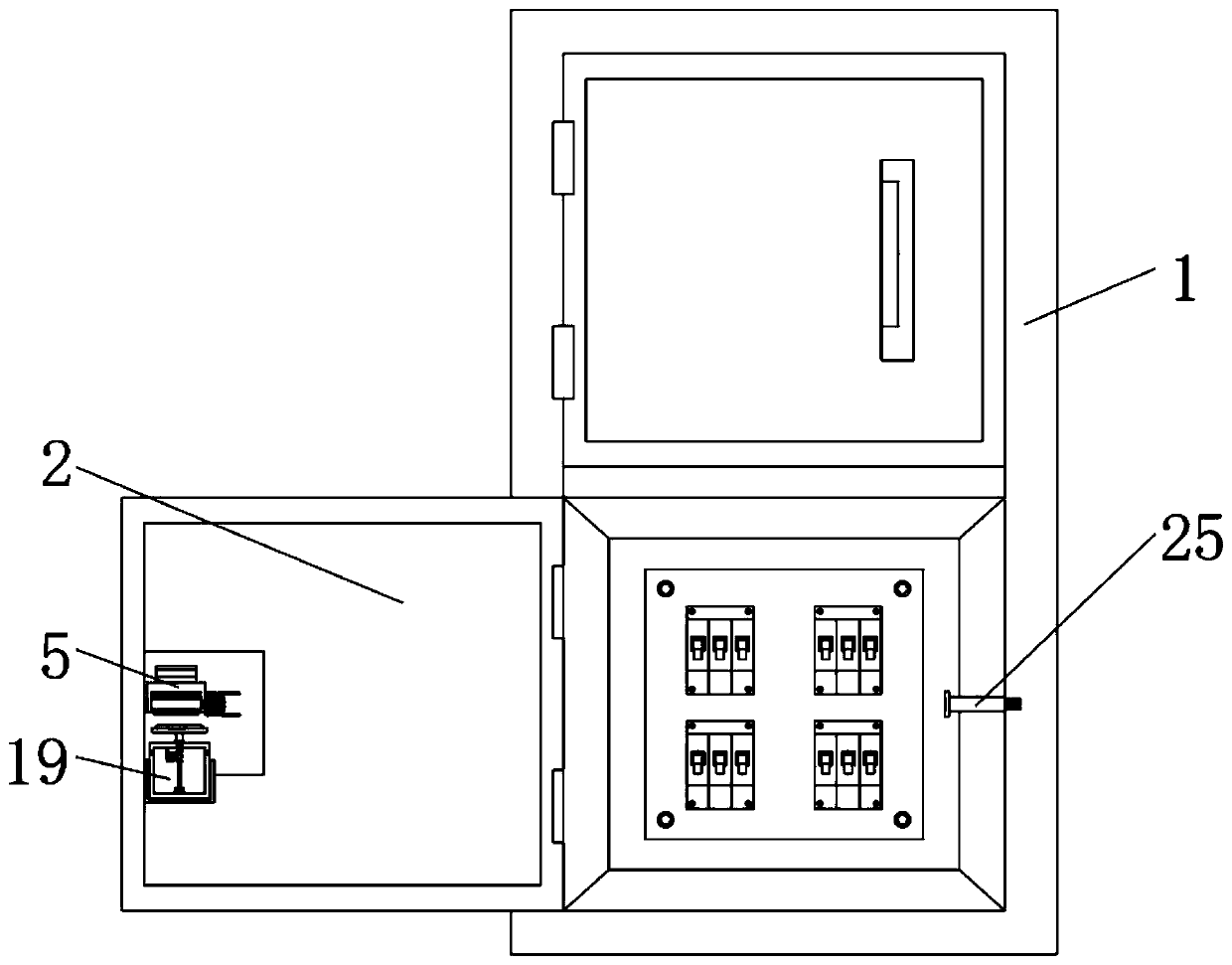

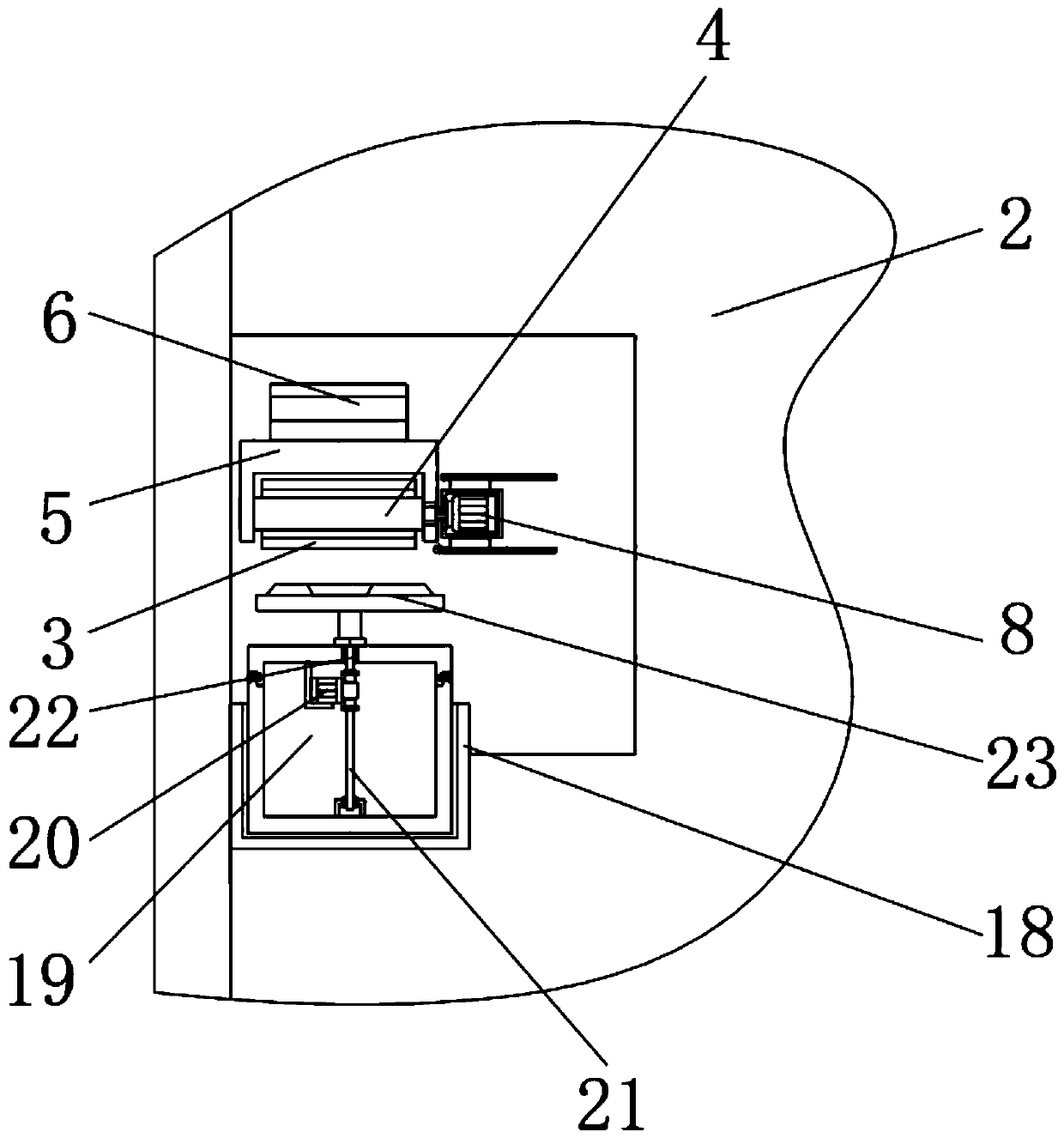

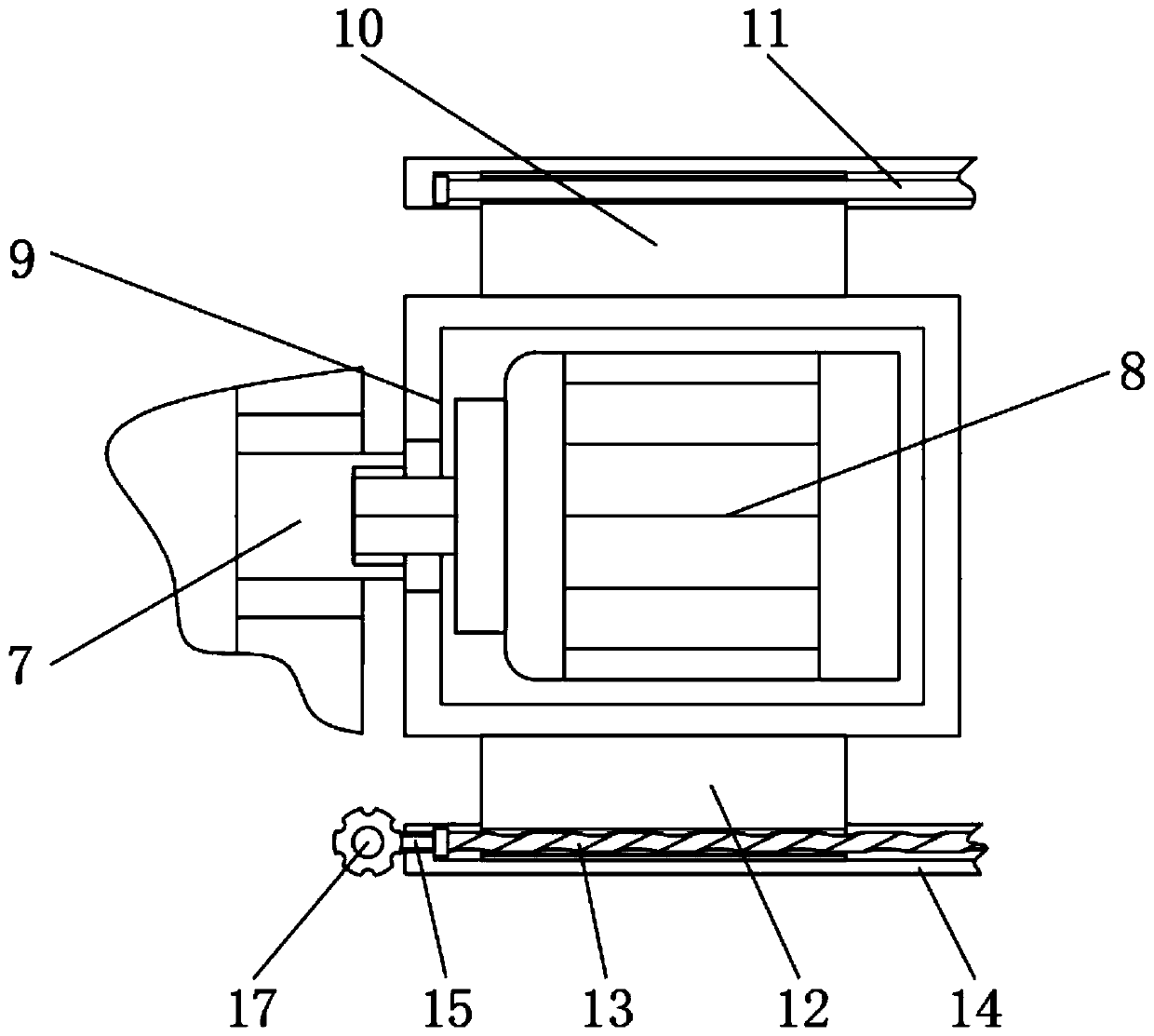

[0022] Embodiment one, by Figure 1-4 Given, the present invention comprises a cabinet body 1, a closed door 2 is installed on the surface of the cabinet body 1, a retaining pipe 3 is fixed on the surface of the closed door 2, and a movable rod 4 is installed in the inner chamber of the retaining pipe 3, and the movable rod 4 One end is equipped with support 5, and the top of support 5 is fixed with clamp block 6, and the other end of movable bar 4 is equipped with assembly bar 7, and one end of assembly bar 7 is equipped with motor 8, and the exterior of motor 8 is equipped with protective box 9, and protection The top of the box 9 is fixed with a first moving plate 10, the top of the first moving plate 10 is equipped with a sliding rod 11, the bottom of the protective box 9 is equipped with a second moving plate 12, and the bottom of the second moving plate 12 is screwed with an adjusting rod 13. A fixed rod block 14 is installed on the outside of the adjusting rod 13, and a...

Embodiment 2

[0023] Embodiment 2, on the basis of Embodiment 1, the surface of the closed door 2 is equipped with a dust-proof pad, and the shape of the closed door 2 is a square. Through the setting of the closed door 2, the dust-proof pad is used to prevent the oil from spraying. Sputtering occurs, causing the lubricating oil to contaminate the inside of the cabinet 1 .

Embodiment 3

[0024] Embodiment three, on the basis of embodiment one, one end of the shaping rod 25 is fixed with a threaded rod, and one end of the threaded rod on the shaping rod 25 is threadedly connected with the side of the cabinet body 1 inner cavity, and through the setting of the shaping rod 25, the It utilizes the threaded rod to facilitate the installation work of the shaping rod 25, and facilitates the replacement work after it is damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com