Release agent automatically spraying device of common aluminum ingot casting machine

A technology of automatic spraying and release agent, applied in casting and molding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing personnel positions, safety accidents, failure to overcome, etc., to improve cost control management, improve work efficiency, Improve the effectiveness of cost management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

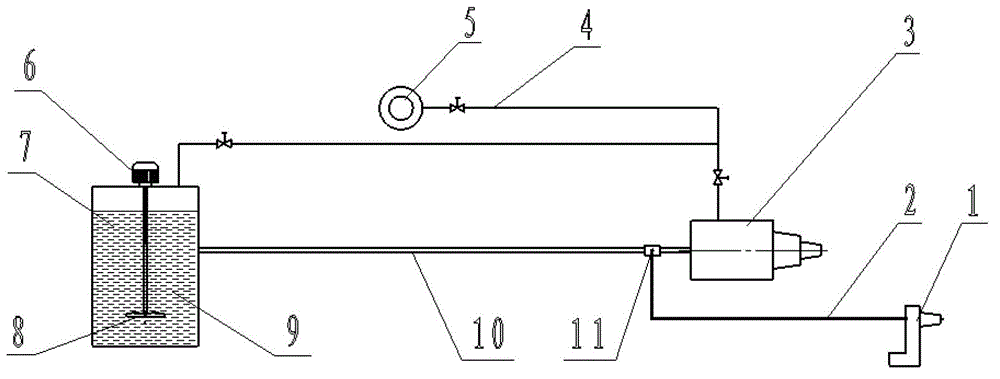

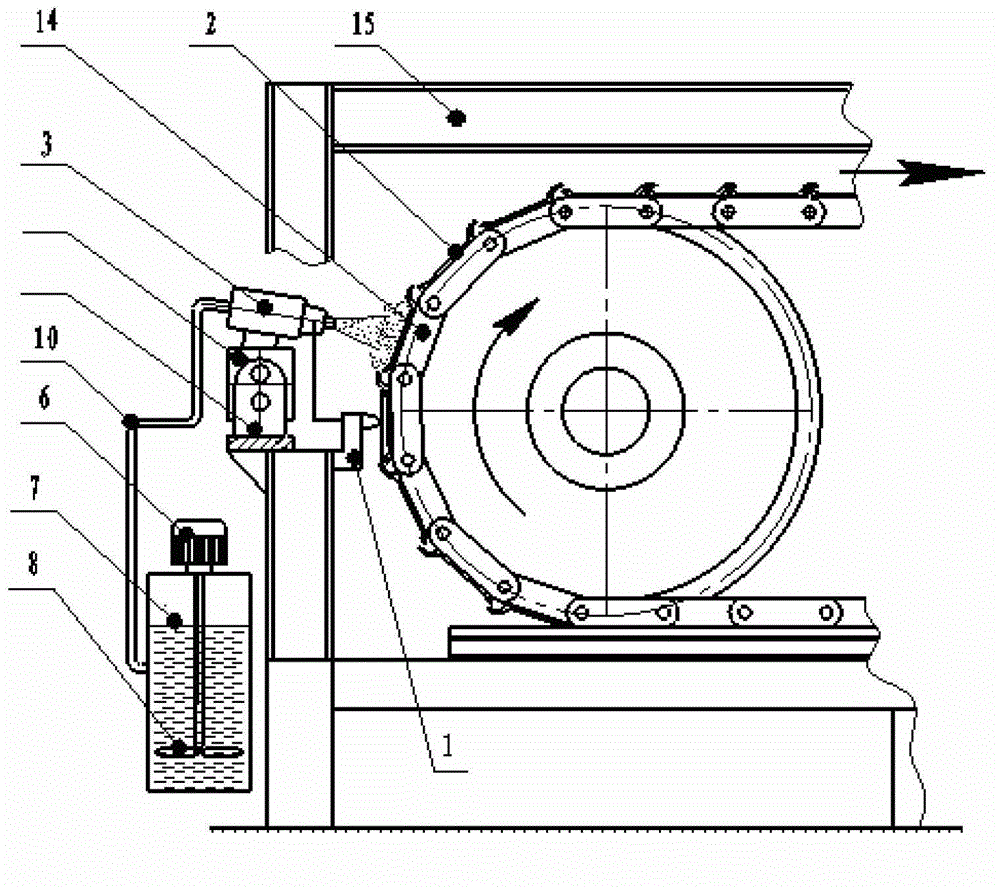

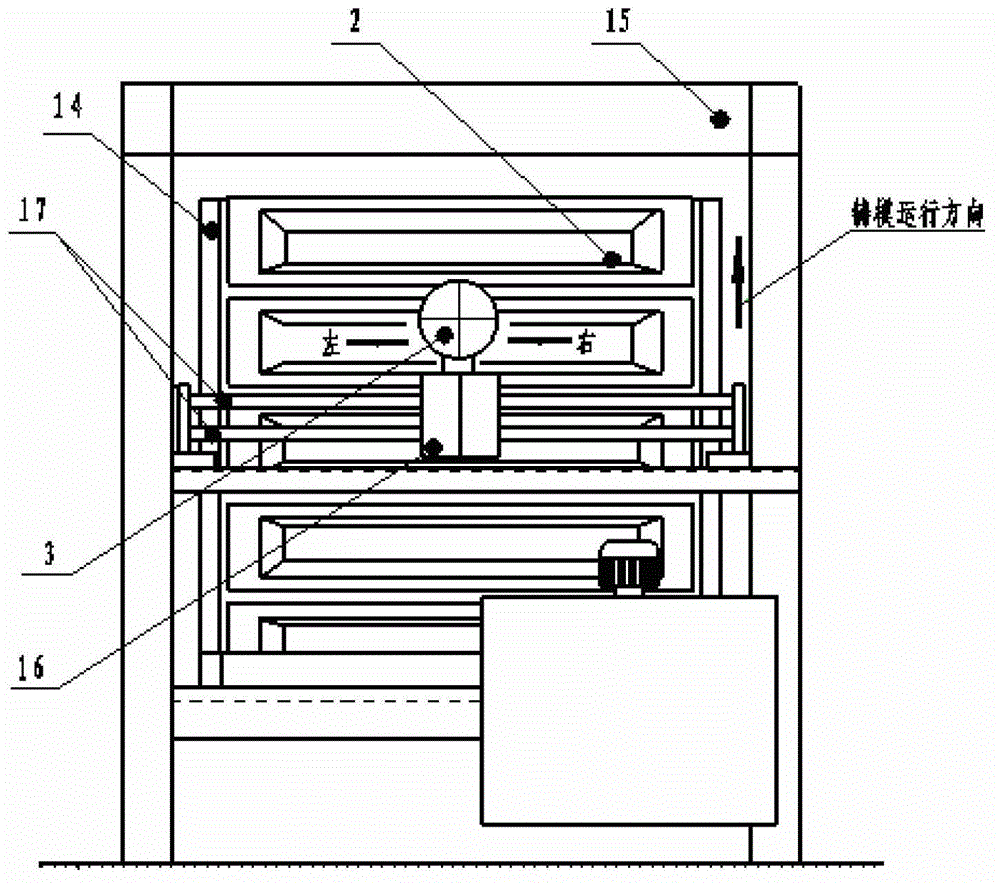

[0015] A common aluminum ingot casting machine release agent automatic spraying device, it includes a frame back beam 15 and a mold sprocket 14, such as figure 1 , 2 Shown in and 3: a spray gun 3 is fixed on the frame back beam 15, and a spray gun 3 bottom is connected with a feed box 7 that is equipped with a stirring impeller 8 driven by a drive motor 6 to store a release agent. The material air pipe 10 is connected with the spray gun 3, and the electromagnetic switch 11 is installed on the material air pipe 10, and the electromagnetic switch 11 is connected with the electric signal generator 1 installed on the side of the mold sprocket 14 through the electric signal transmission line 2, and the spray gun 3 is connected with a pressure The air duct 4 and the pressure air duct 4 are connected with the pressure air source 5 .

[0016] The spray gun 3 is supported by a support 16 on the frame back beam 15, and the slide bar 17 that can slide left and right is connected in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com