Patents

Literature

38results about How to "Avoid labor waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

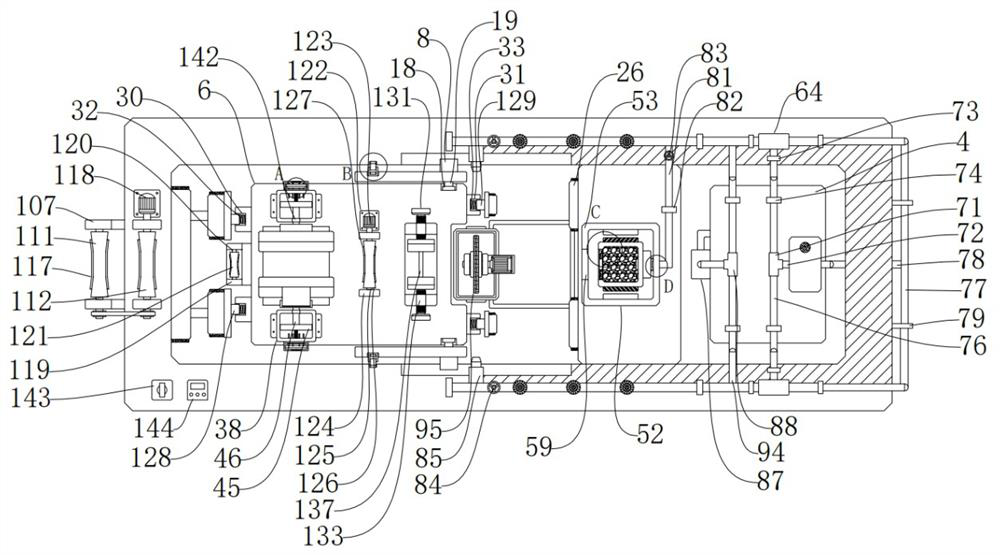

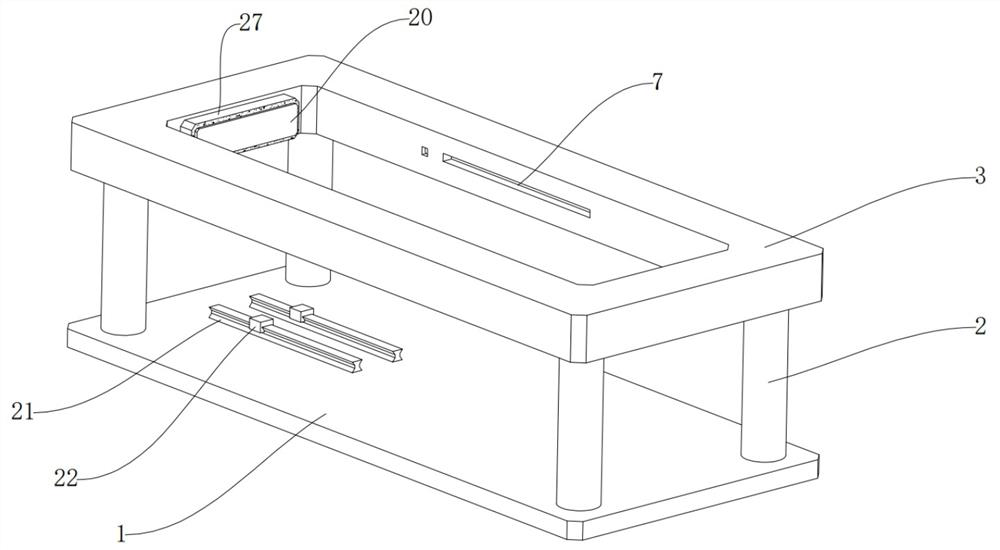

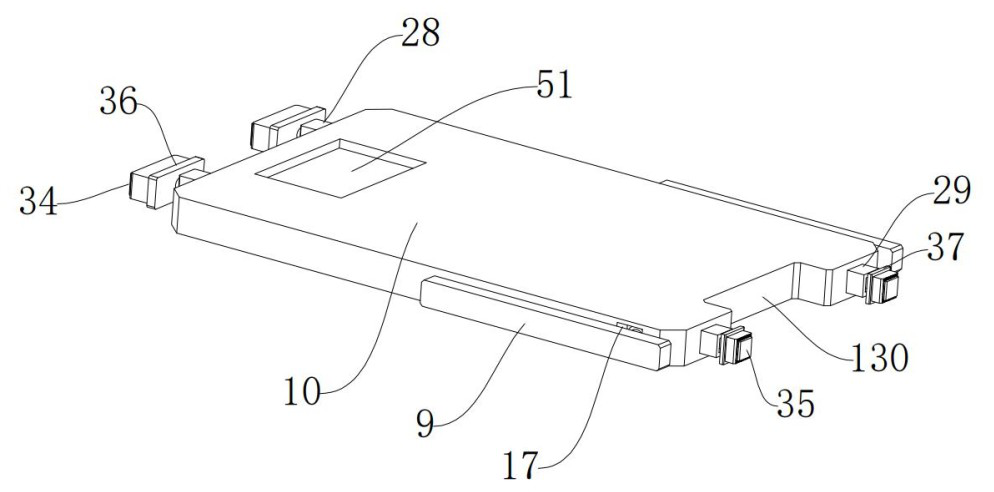

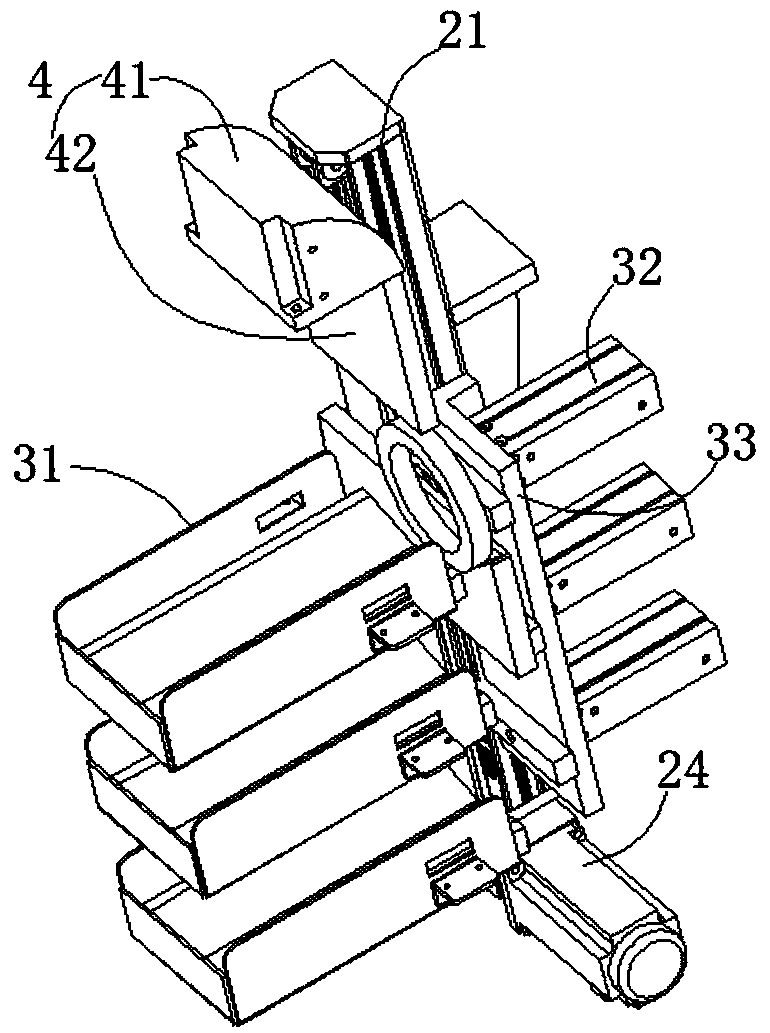

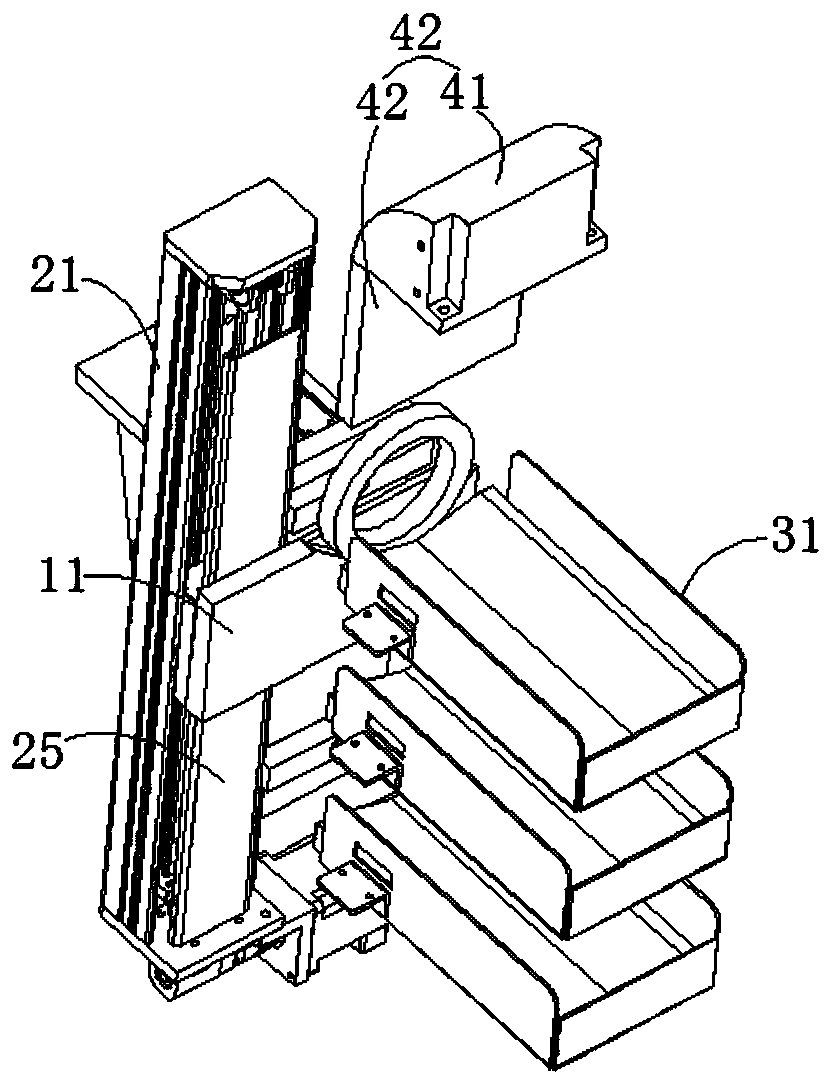

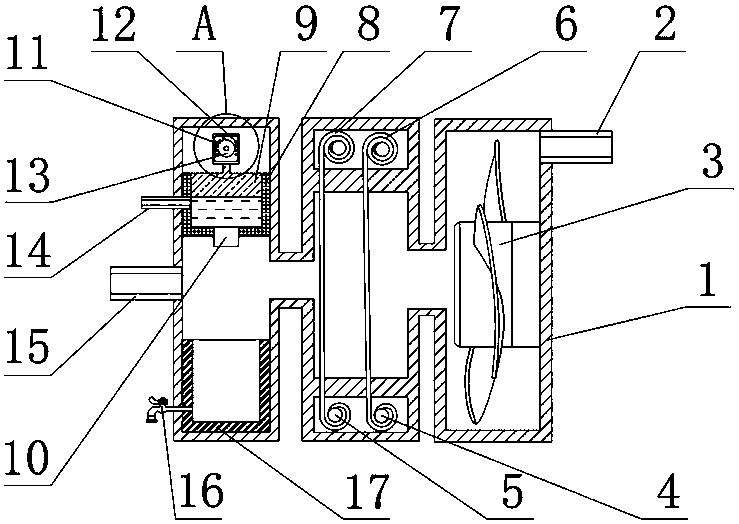

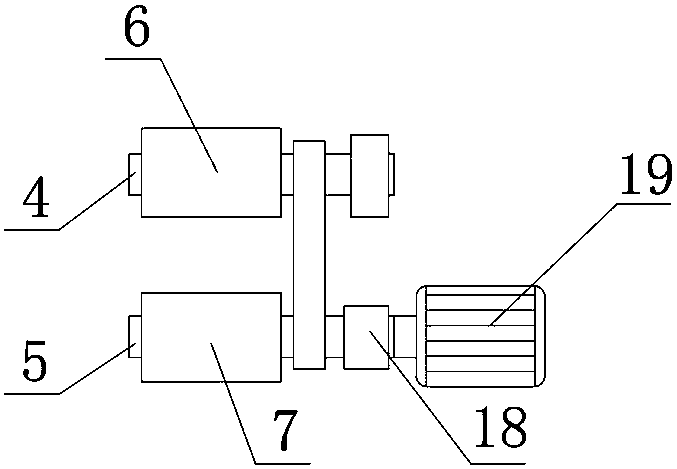

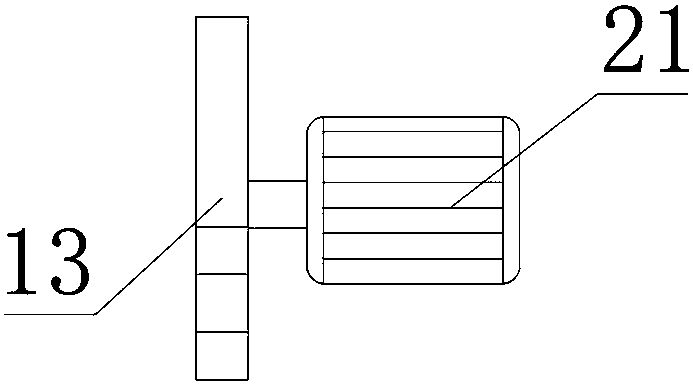

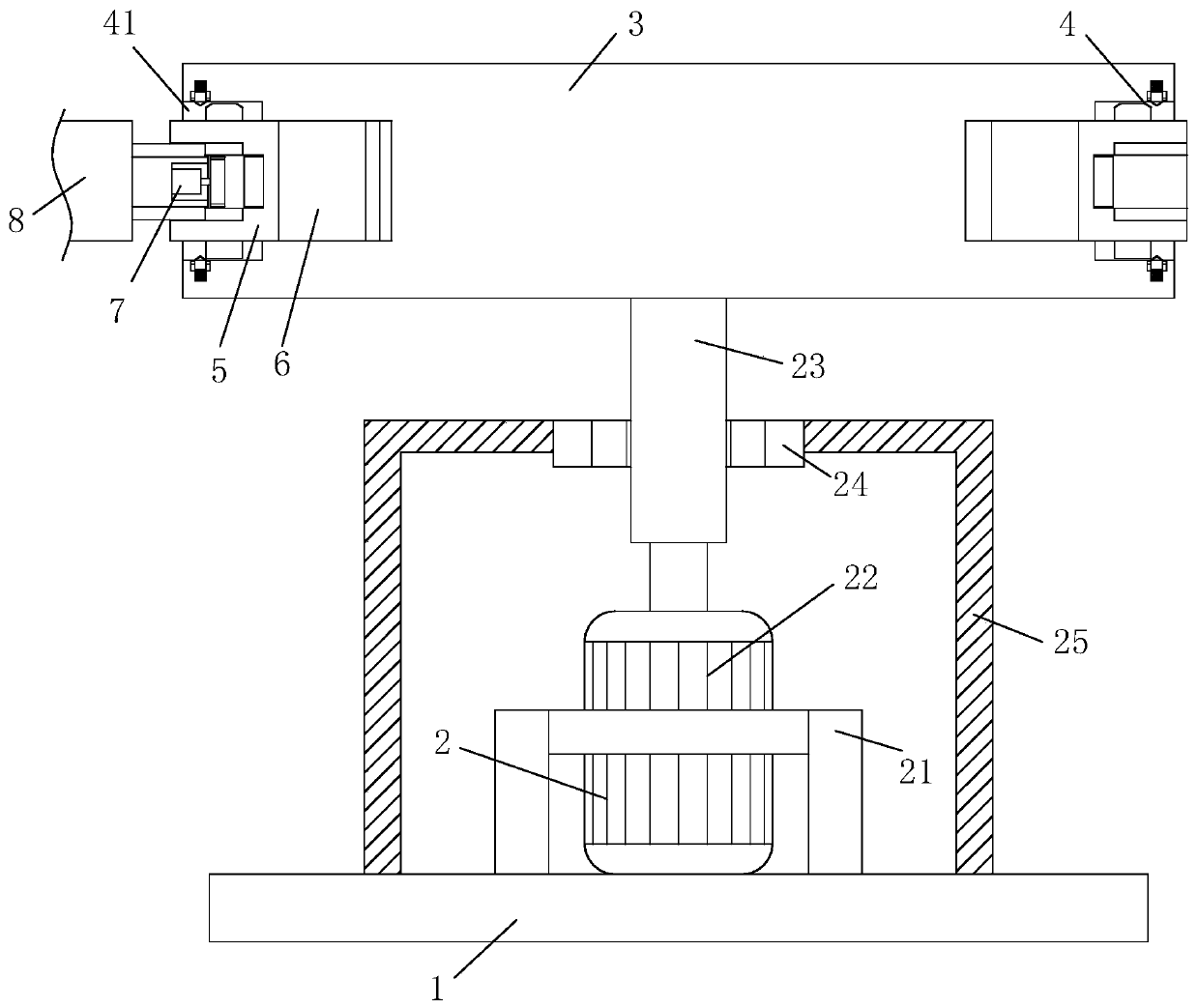

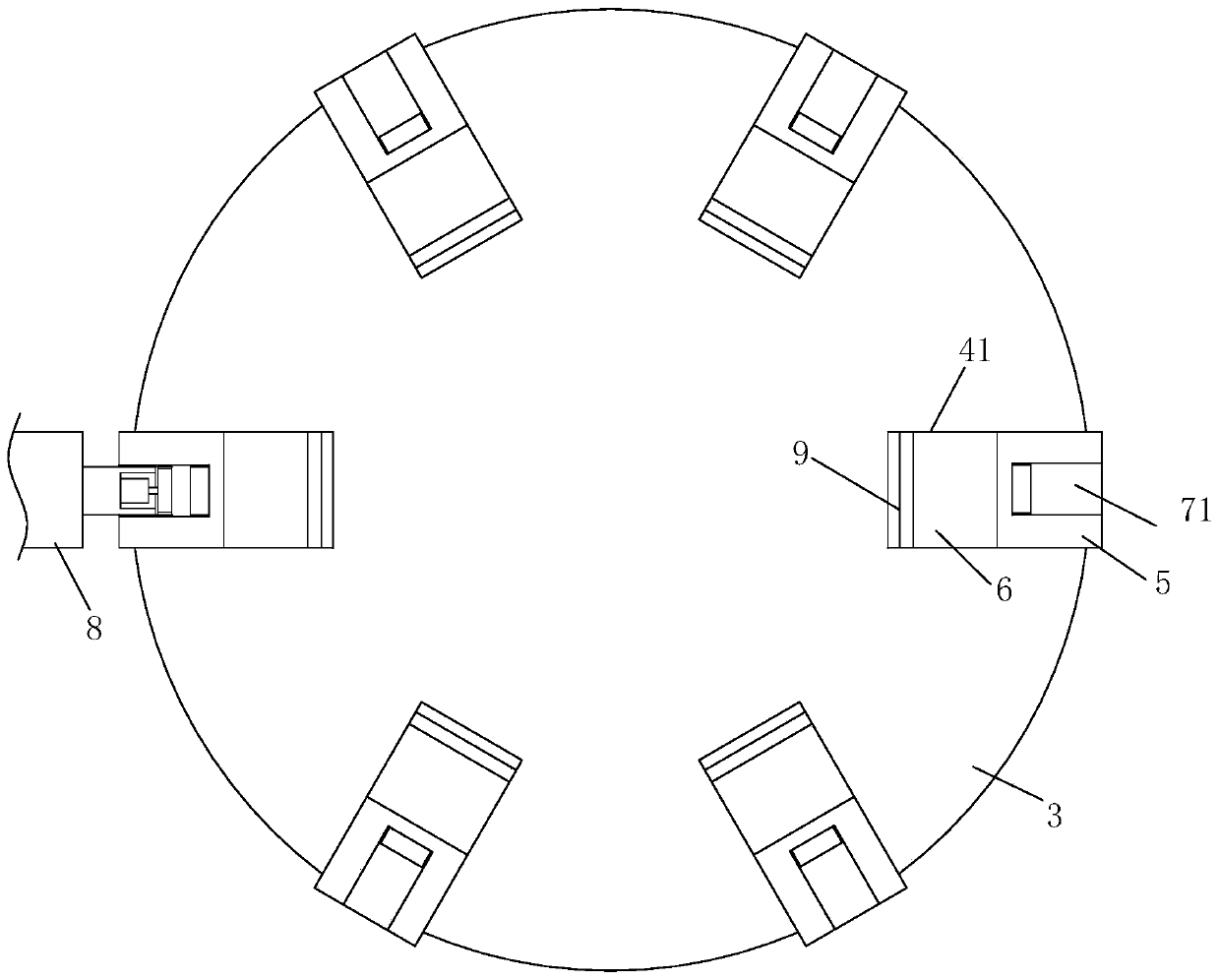

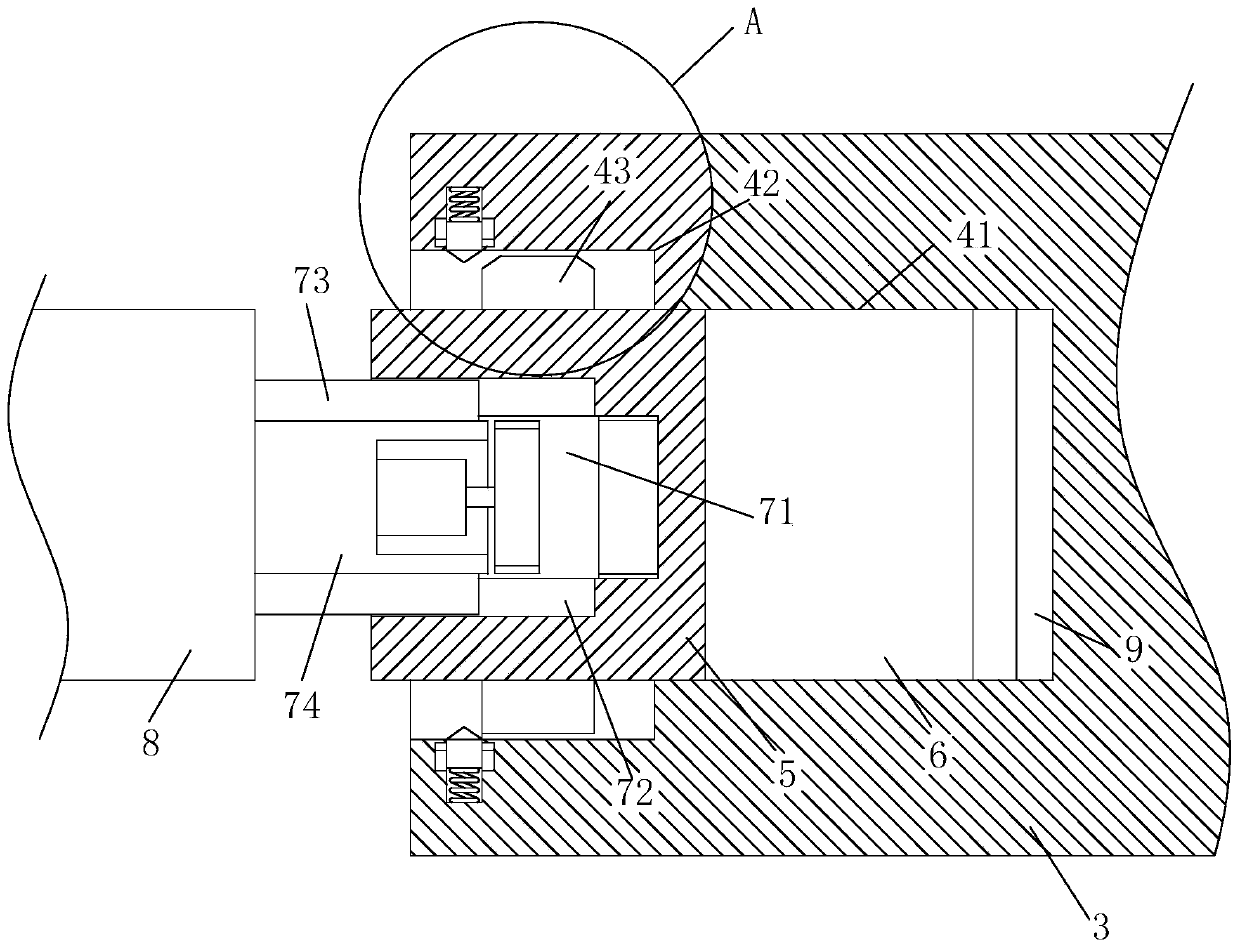

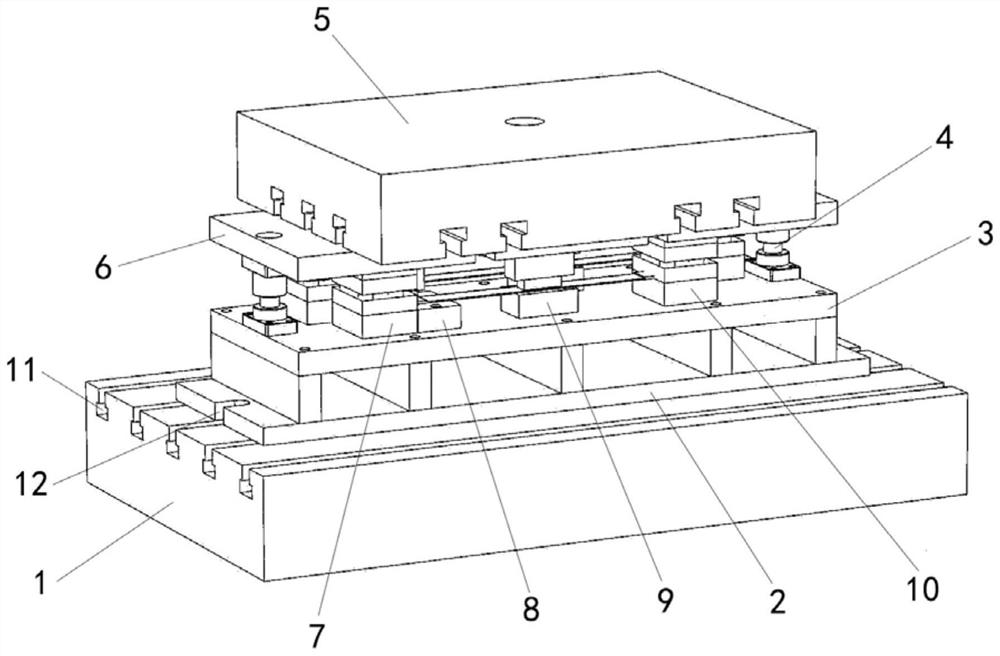

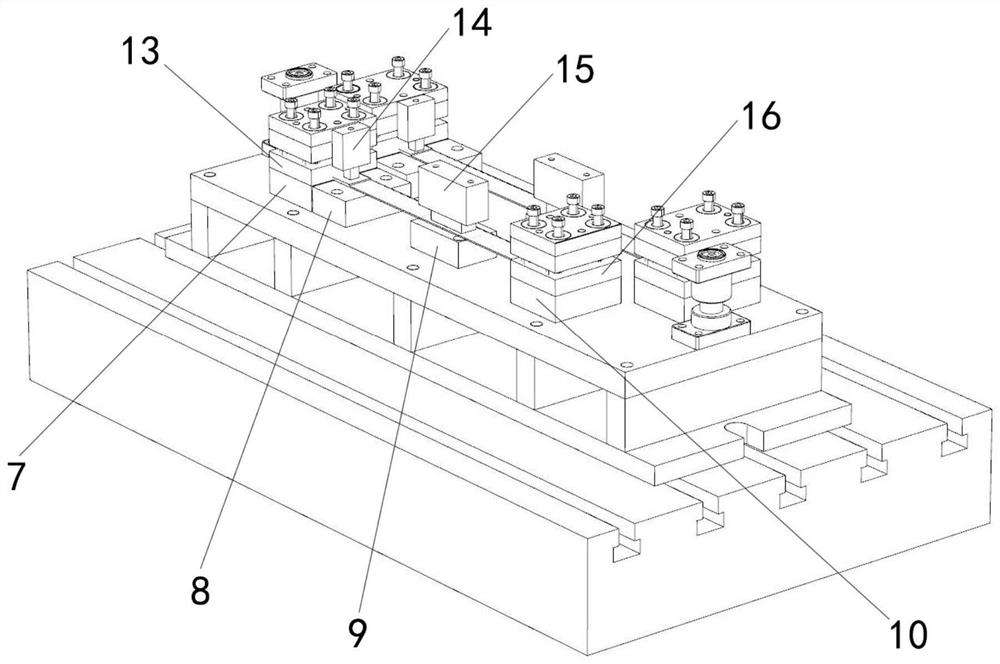

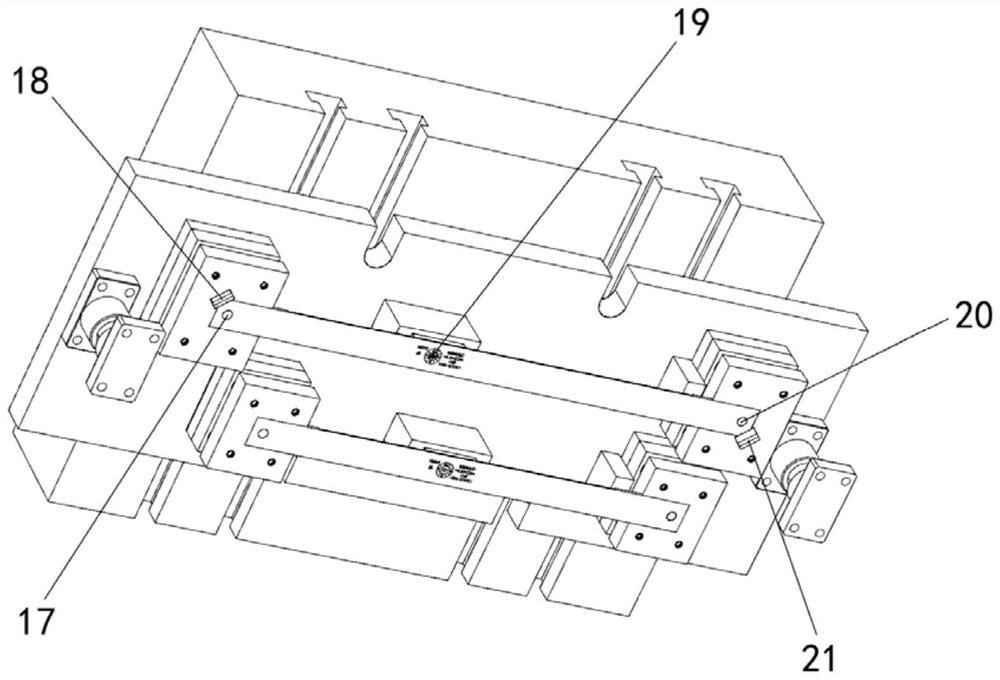

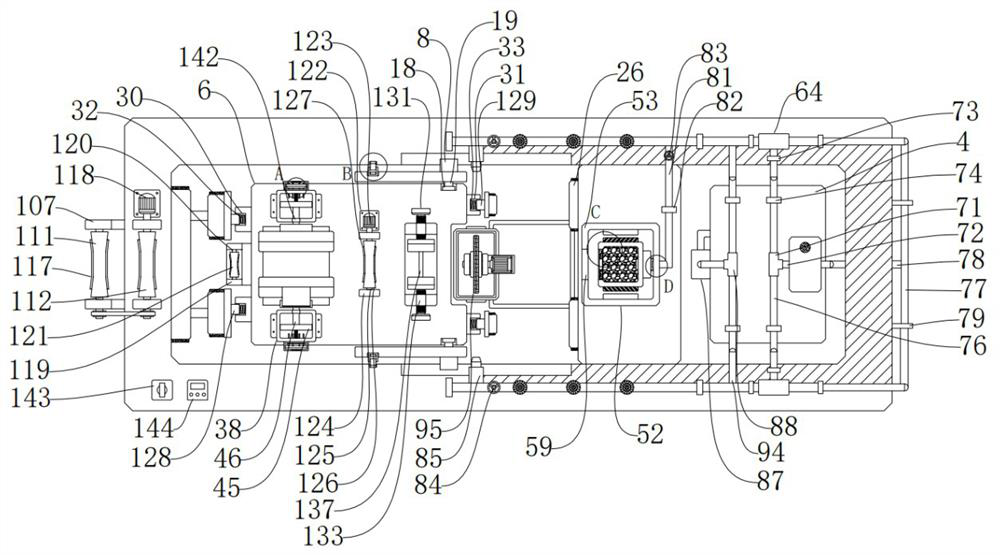

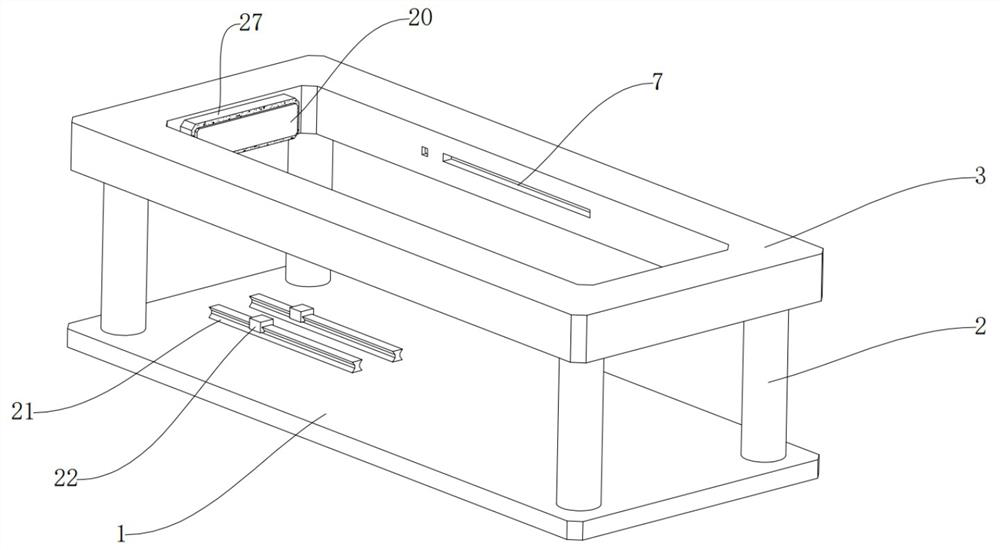

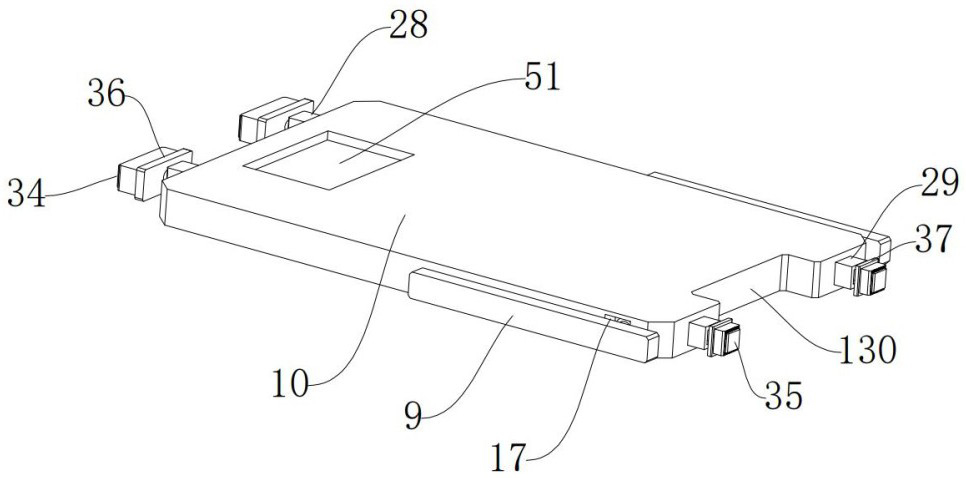

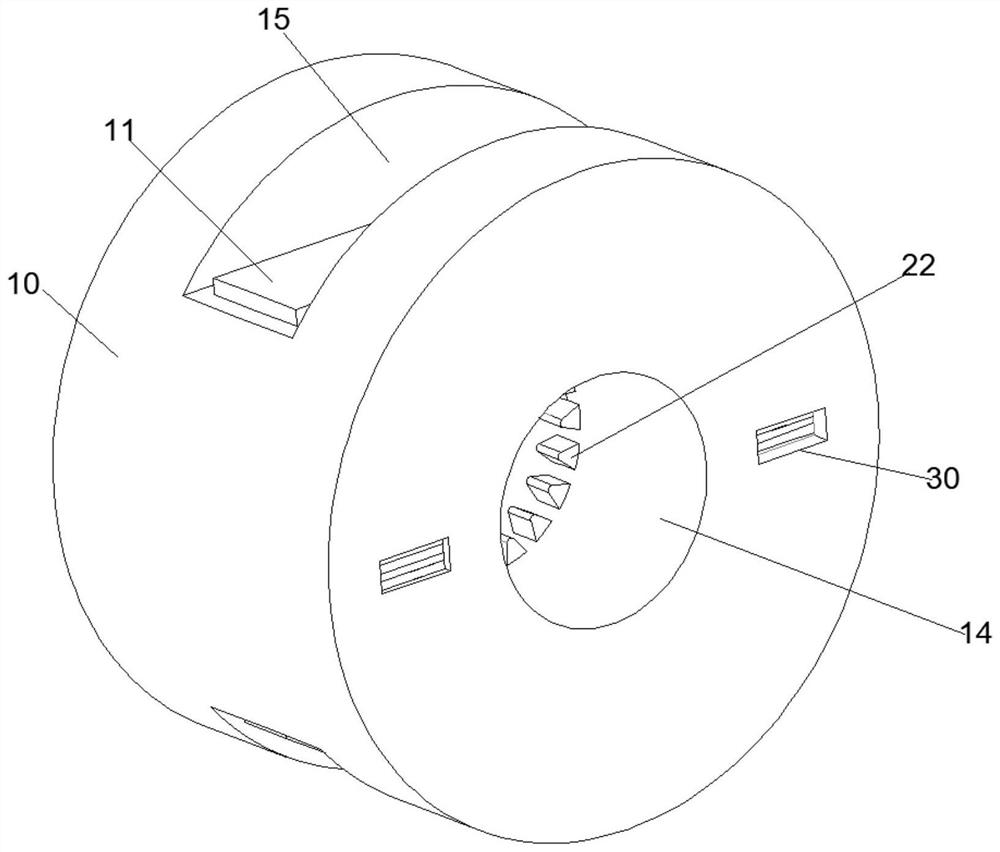

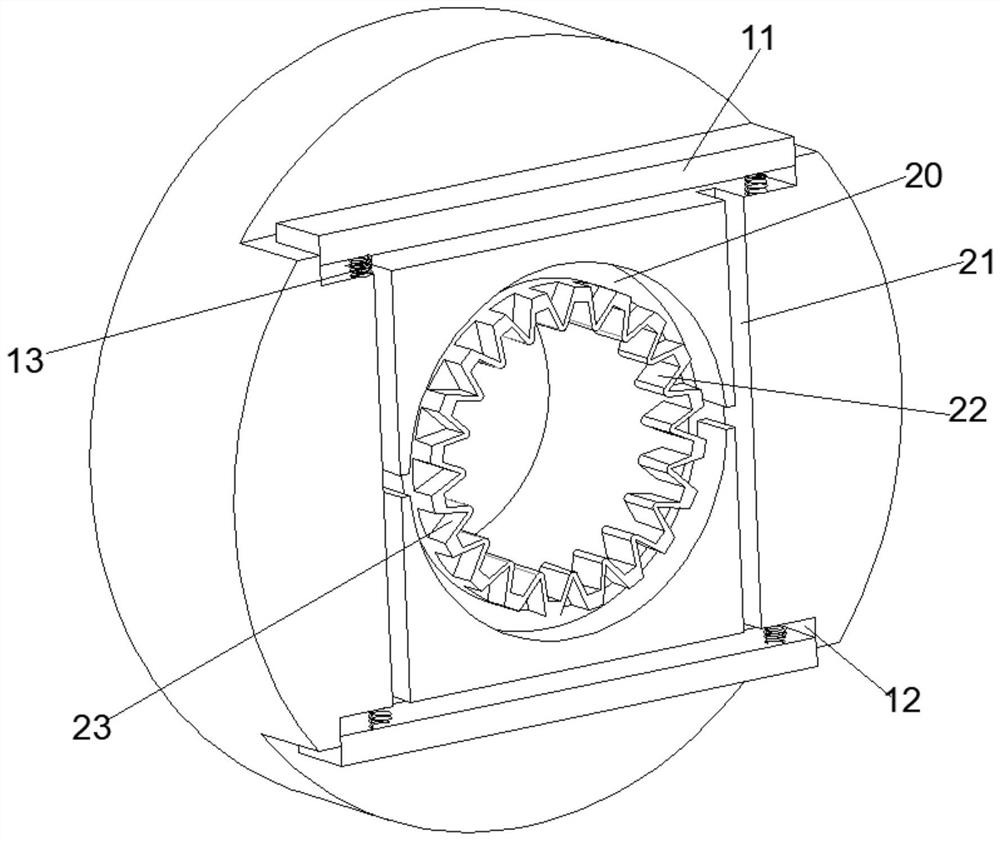

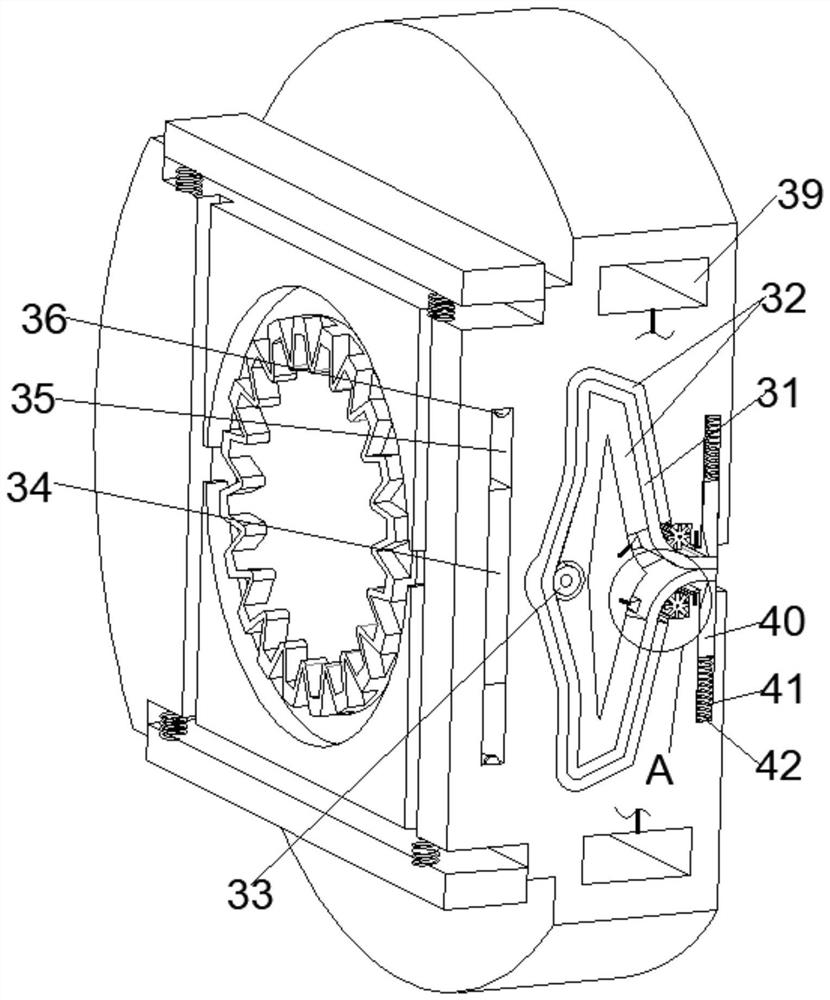

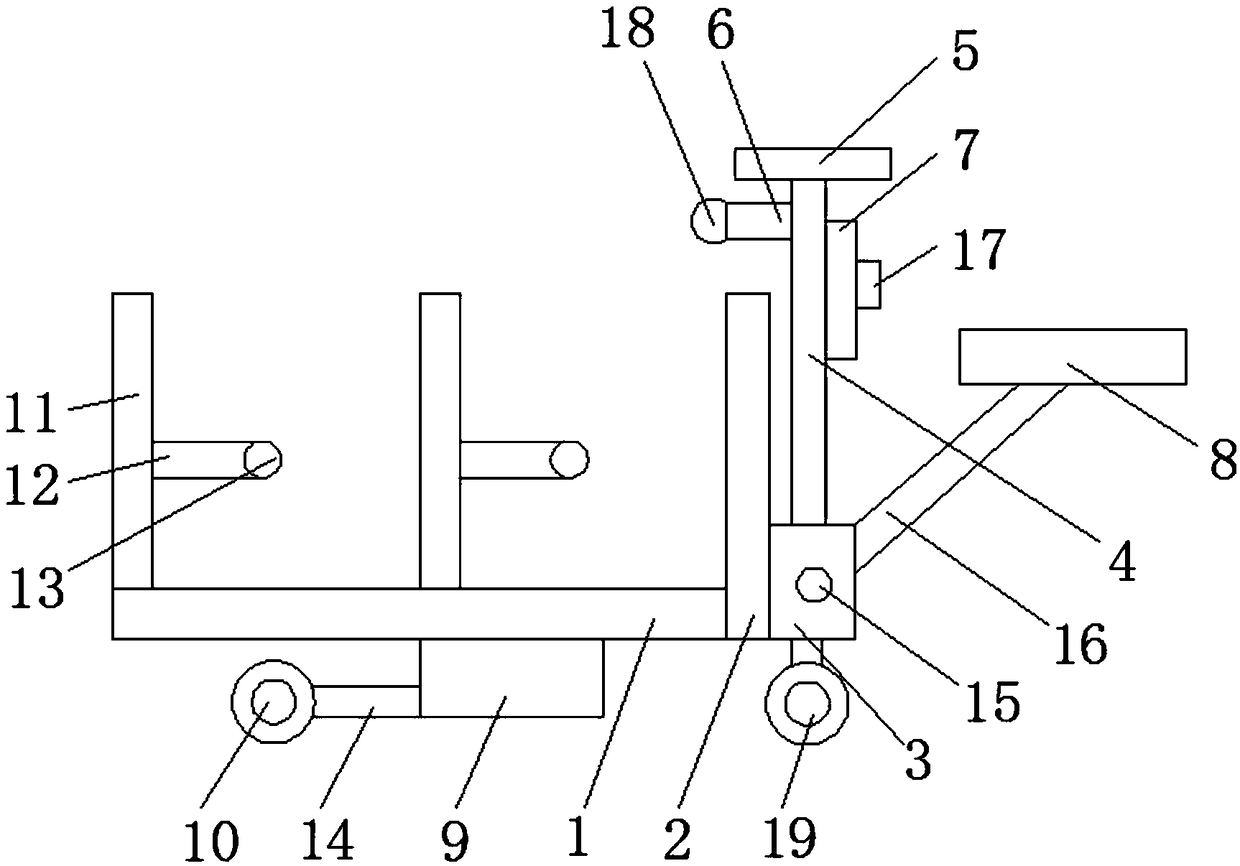

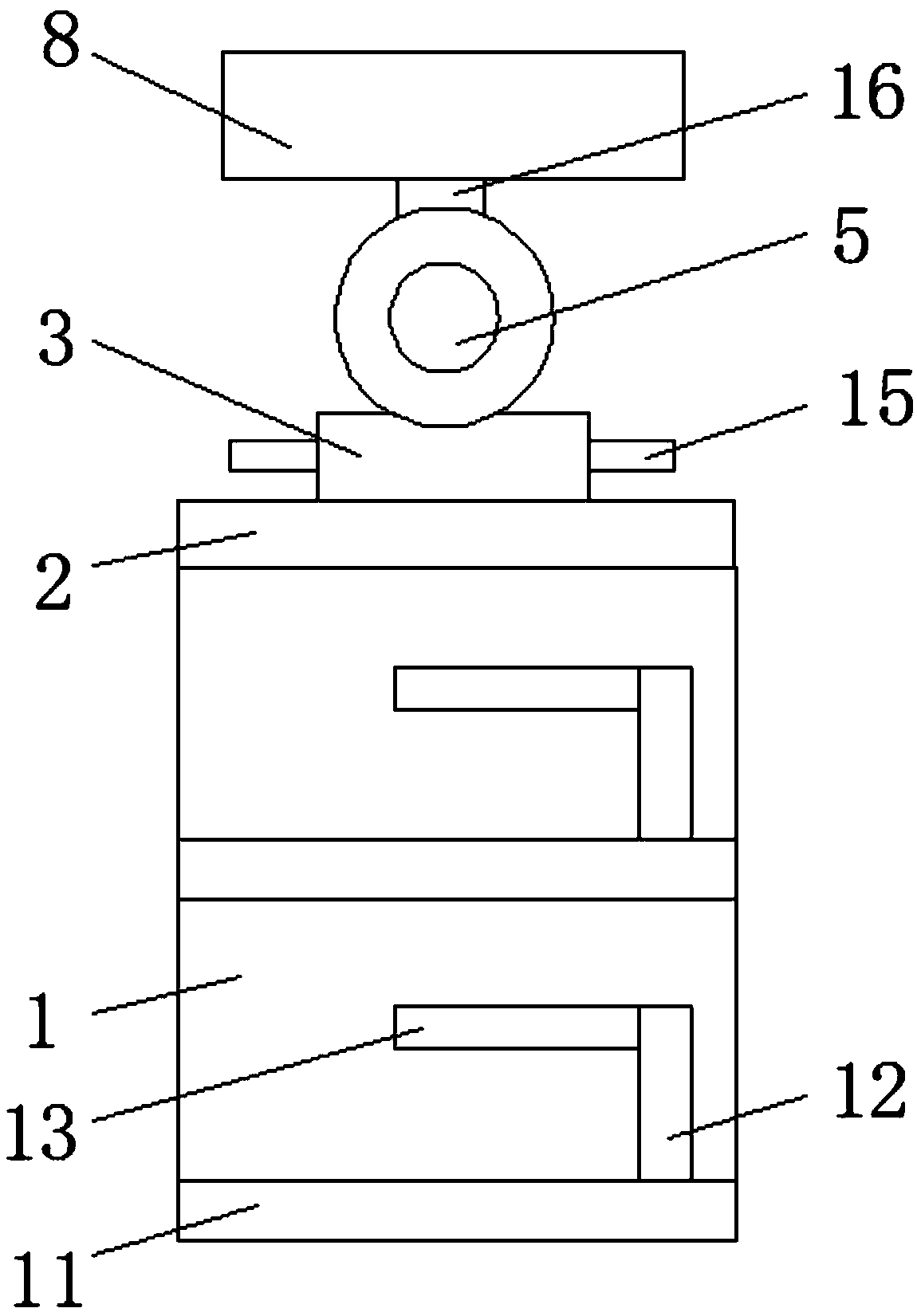

All-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of three-phase rotating structure

ActiveCN113385964AGuaranteed accuracyEasy to adjustOther manufacturing equipments/toolsMetal working apparatusStructural engineeringMachine

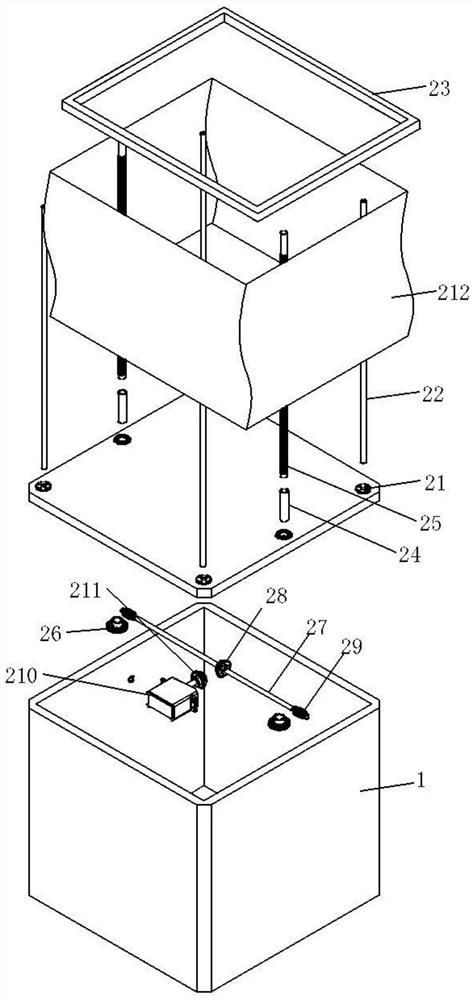

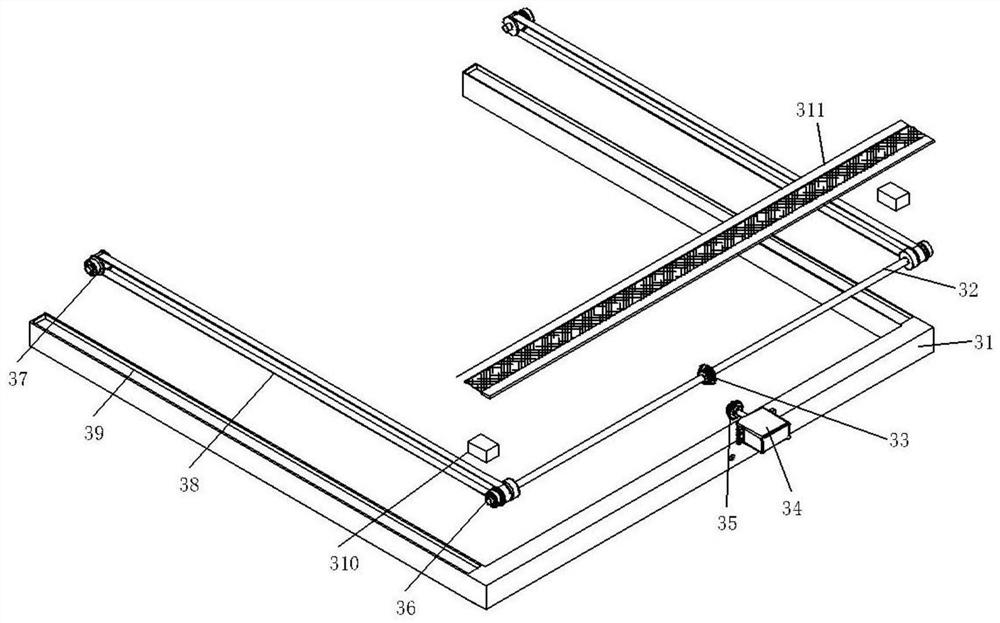

The invention discloses an all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of a three-phase rotating structure. The all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine comprises a base, a supporting column, a machining frame, a cooling water mist box, a grinding plate, a magnetic attraction type moving mechanism, an expansion type clamping mechanism, an unpowered grinding mechanism, a vortex separation type cooling mechanism, an all-dimensional atomization dustproof mechanism, a high-precision cutting device, a linkage feeding mechanism, a positioning material moving mechanism and a positioning clamping mechanism. The invention belongs to the technical field of pipe cutting and grinding devices, and particularly provides the all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of the three-phase rotating structure, so that integration of pipe cutting, grinding and scrap iron adsorption treatment is achieved, all-around scrap collection is facilitated, self-adaptive clamping and fixing on pipes can be carried out according to different cross section shapes and sizes of the pipes through the arrangement of an expansion type clamping mechanism, and due to the arrangement of the linkage feeding mechanism, the labor intensity of workers can be reduced conveniently, and therefore the all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of the three-phase rotating structure can machine the pipes efficiently.

Owner:徐州中顺尚奕机械制造有限公司

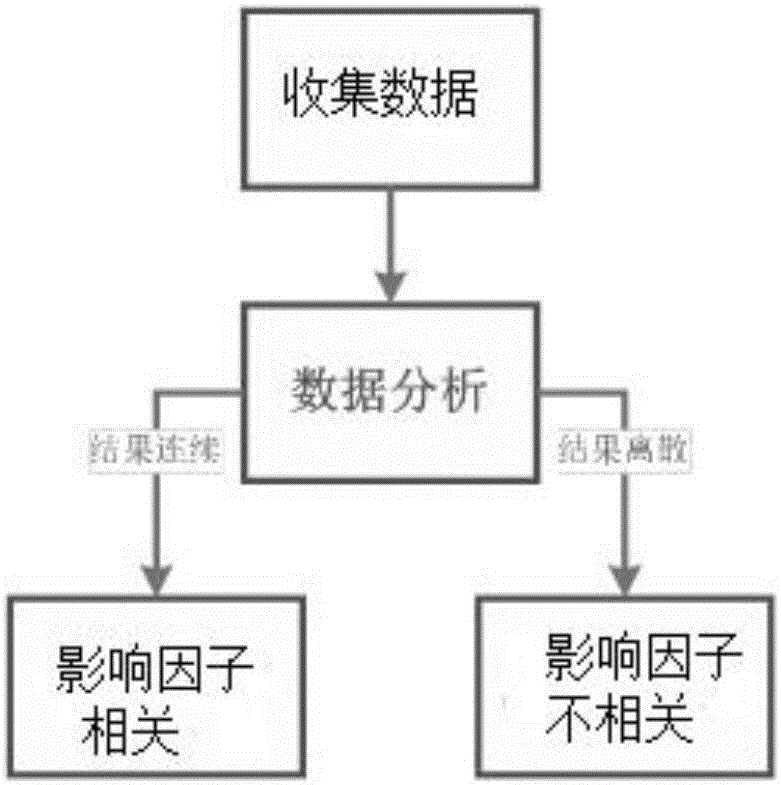

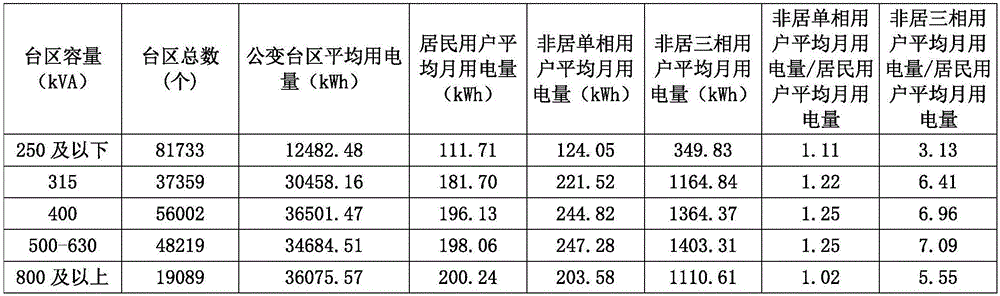

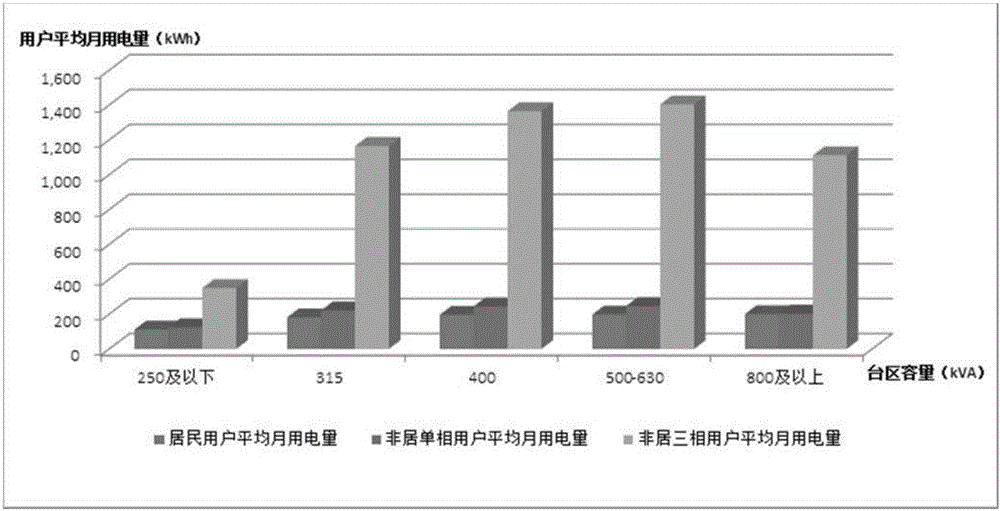

Big data analysis method based on intermittent faults

The invention discloses a big data analysis method based on intermittent faults, belonging to the technical field of electric equipment. In the prior art, the judgment of abnormal urgency mainly relies on human experience and subjective estimation to dispatch orders. This method is very unscientific and random, which leads to waste of dispatched workers and delays normal dispatched workers. Currently, there is a lack of A scientific, reasonable and accurate big data analysis solution. In the present invention, firstly, the influencing factors of abnormal urgency of collection are determined, and the influencing factors include intermittent faults. The data includes on-site collection data and work order flow data, and then performs fluctuation analysis on the electricity consumption of a large number of users. Analyze the influencing factors and establish a model, systematize, hierarchical, and simplify complex issues, provide a practical technical solution, identify and distinguish influencing factors, and include those that have an impact on the urgency into the urgency calculation model, otherwise, Not included, to avoid the waste of dispatched workers.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +2

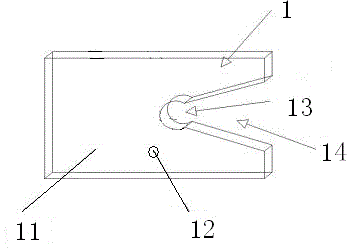

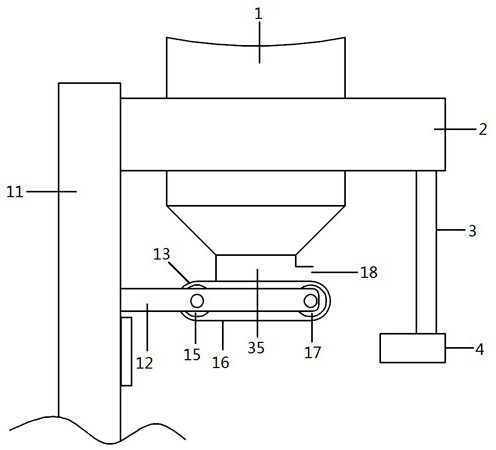

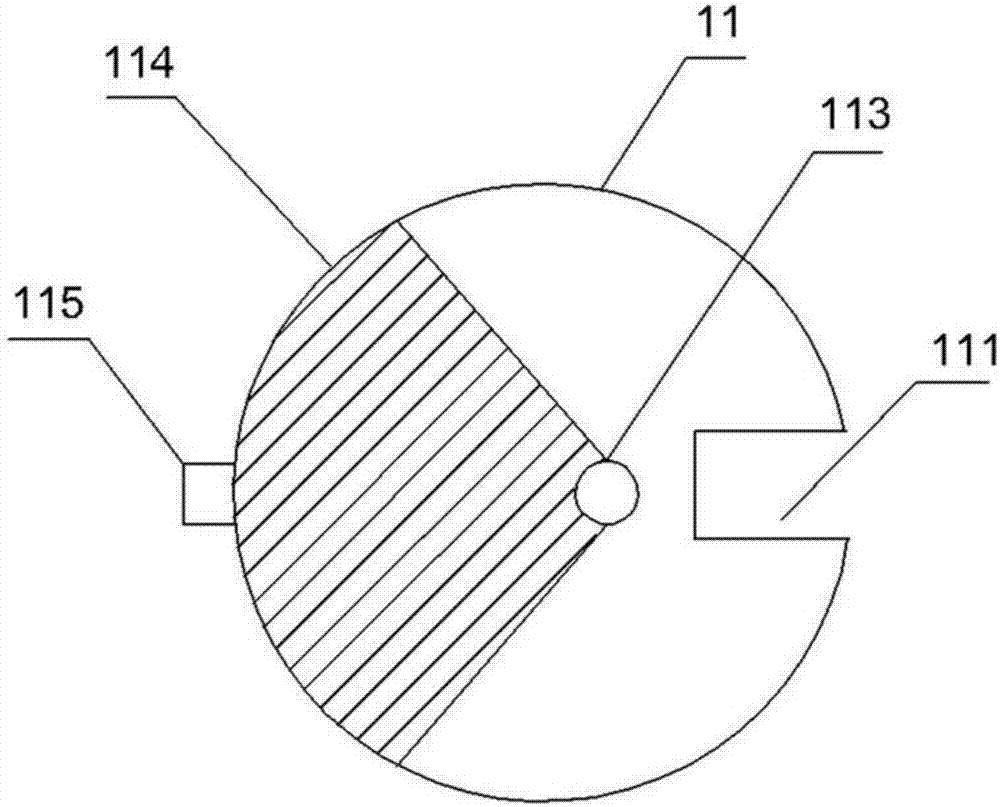

Defective product removing assembly

PendingCN109482522AReduce the number of manual emptying of the reject forehearthAvoid labor wasteSortingEngineeringManufacturing engineering

The invention provides a defective product removing assembly, and relates to the technical field of bearing processing. The defective product removing assembly comprises a defective product guiding assembly, a defective product receiving assembly, a conveying assembly and defective product storage assemblies; the defective product guiding assembly can guide the defective product in a horizontal state to a vertical state, the defective product receiving assembly is located below the defective product guiding assembly and can bear the defective product in the vertical state, and the conveying assembly is in driving connection with the defective product receiving assembly and can drive the defective product receiving assembly to move; and each defective product storage assembly comprises a driving device and a defective product channel which are arranged on the two sides of the defective product receiving assembly, and the driving device can push the defective product on the defective product receiving plate into the defective product channel. The problem that the removing assembly can not orderly arrange the unqualified products in the prior art is relieved, and the technical problemthat labor is wasted due to the fact that the material channel needs to be cleaned frequently is solved.

Owner:NINGBO ZEE AUTOMATION EQUIP

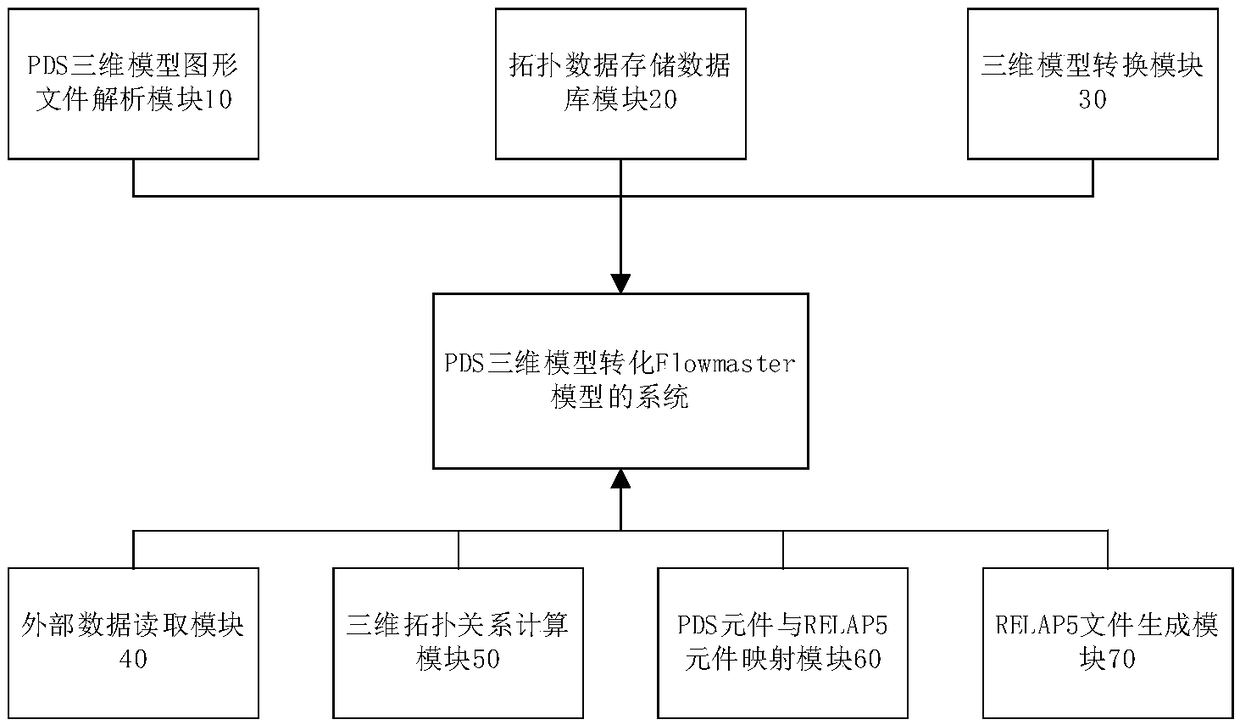

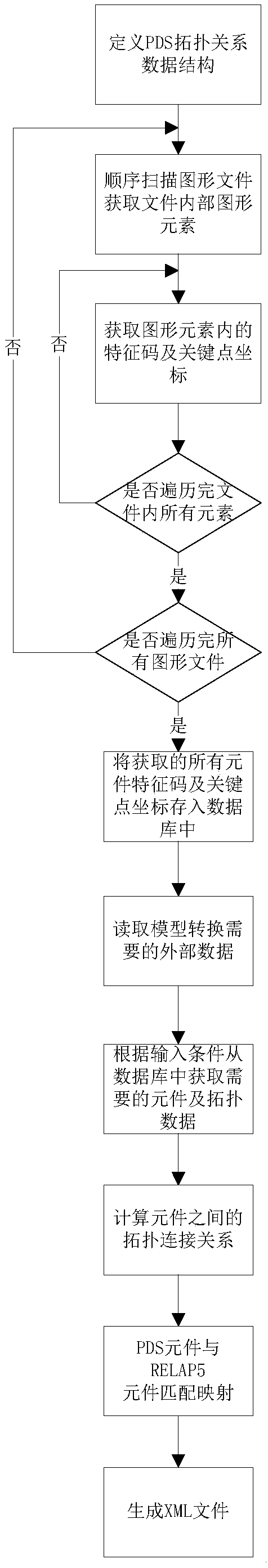

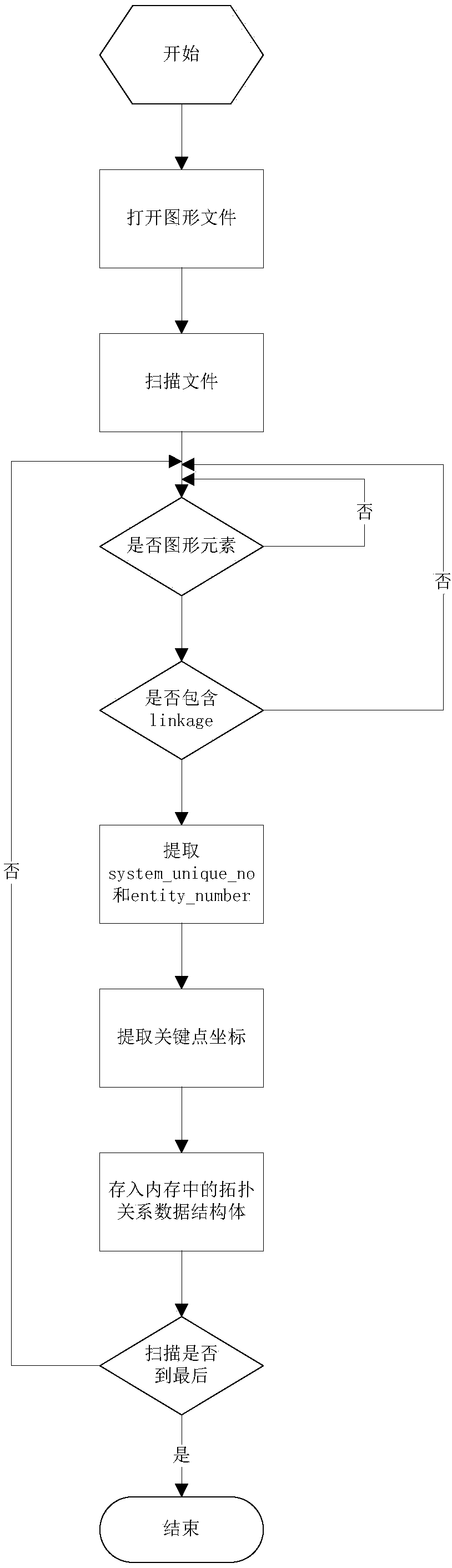

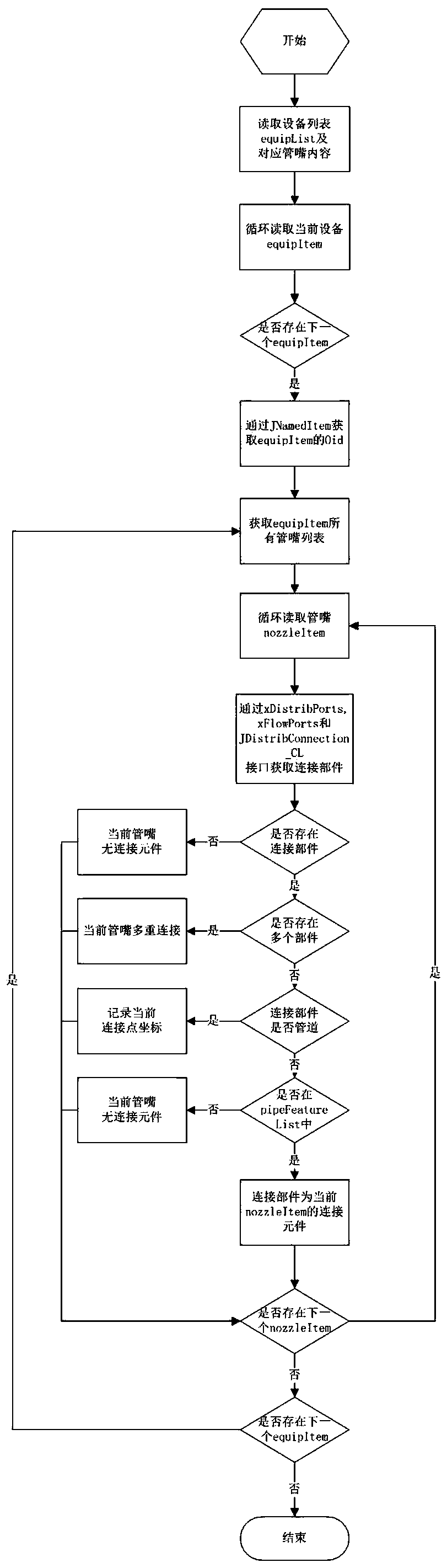

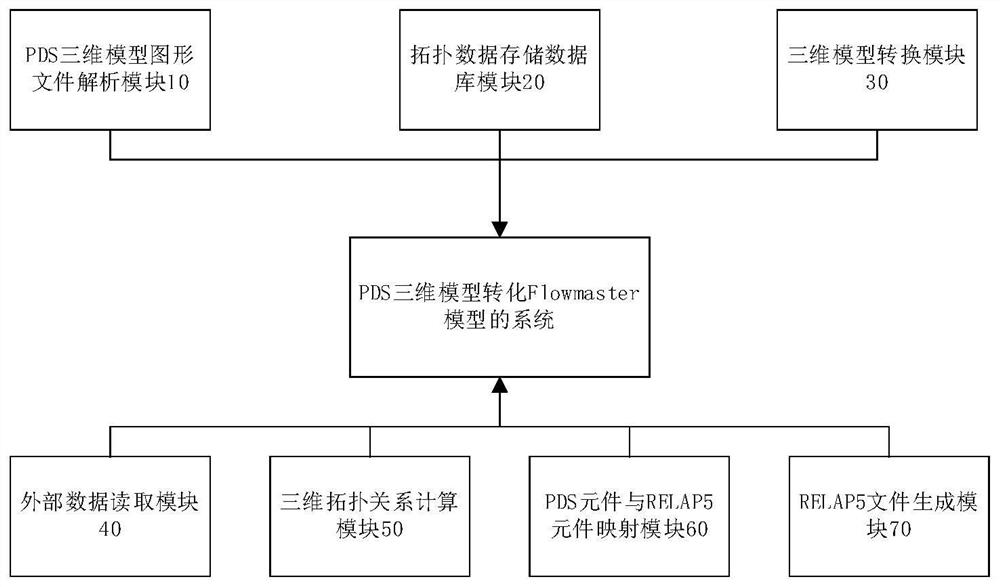

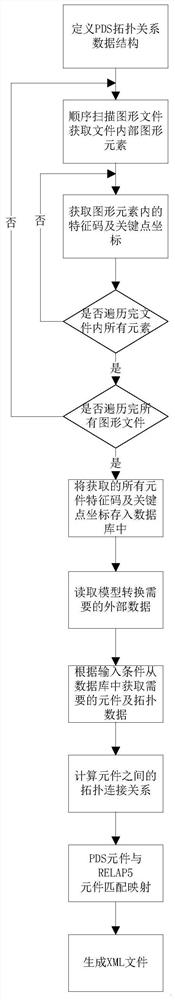

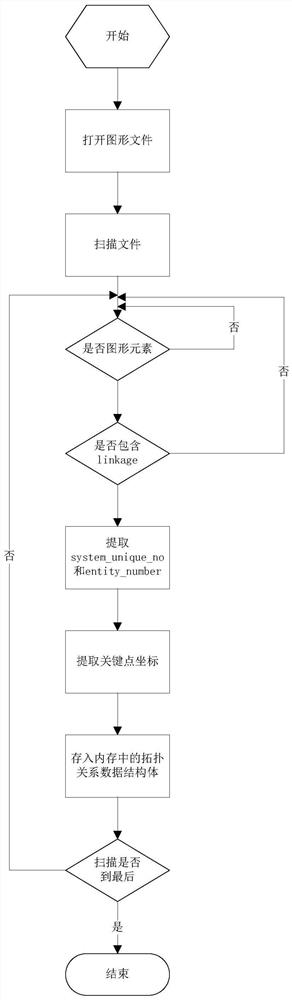

System and method for converting RELAP5 model from PDS three-dimensional model

ActiveCN109117564AAchieve conversionAvoid labor wasteDesign optimisation/simulationSpecial data processing applicationsSupporting systemFault tolerance

An object of the present invention is to disclose a system and method for converting a RELAP5 model from a PDS three-dimensional model, compared with the prior art, the PDS three-dimensional model canbe automatically converted into an XML file supported by RELAP5 software, the automatic conversion of the layout model to the mechanical analysis model is realized, the waste of labor caused by the secondary modeling is avoided, and the design efficiency and quality are greatly improved; Support system-by-system, Custom pipelines are in units, four generation modes with the model as a unit and the mechanical analysis package as a unit, flexible and easy to use, The whole process is done automatically, without human intervention, The utility model has the advantages of simple operation and high efficiency, greatly improves the utilization rate of the PDS three-dimensional model, supports the functions of equipment mapping and removing pipelines, supports the functions of removing the subsequent connection of tap points and removing small pipelines, is suitable for various application scenes, supports the threshold setting, improves the fault tolerance rate in the process of modeling the three-dimensional model, and realizes the object of the invention.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

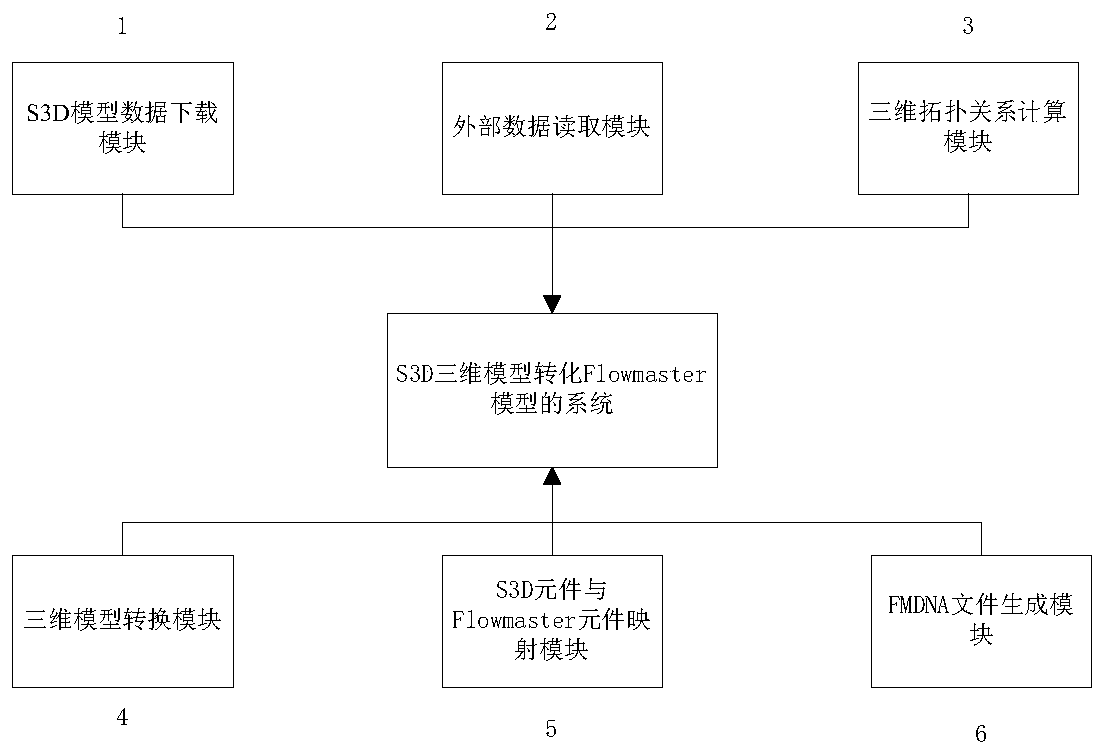

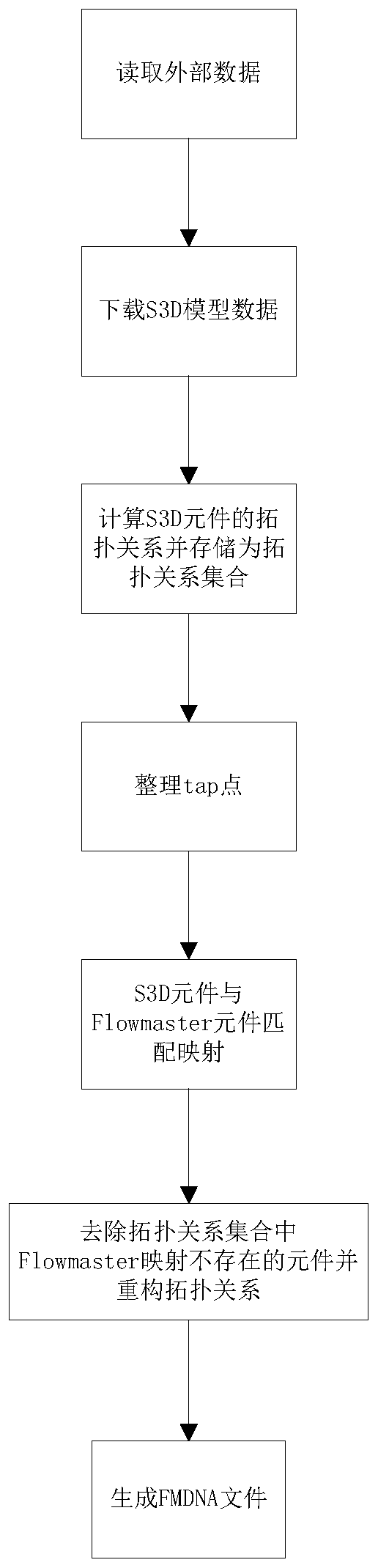

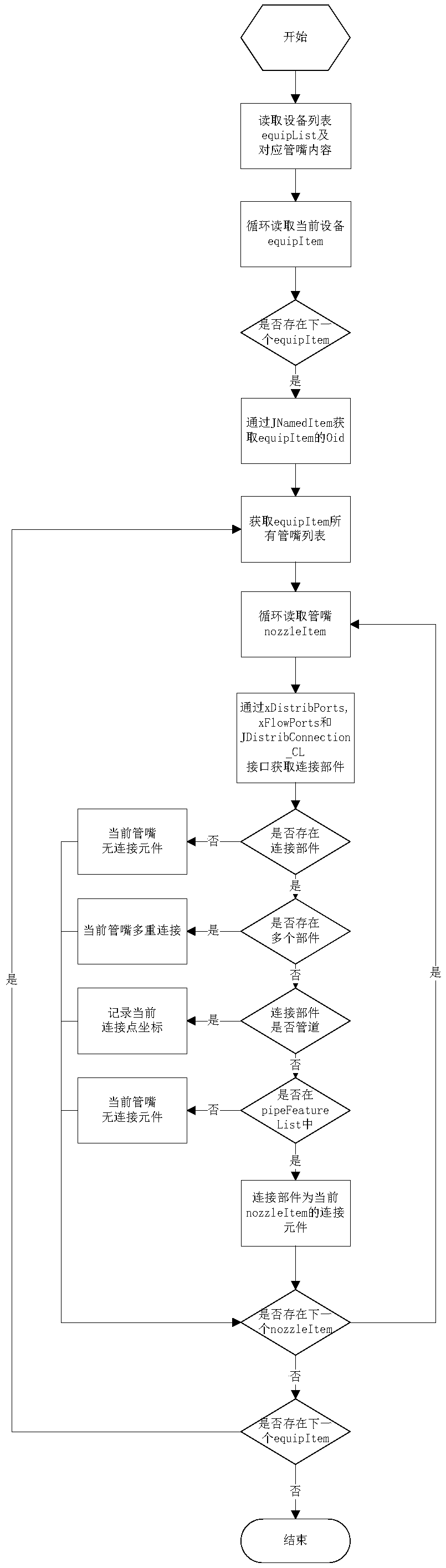

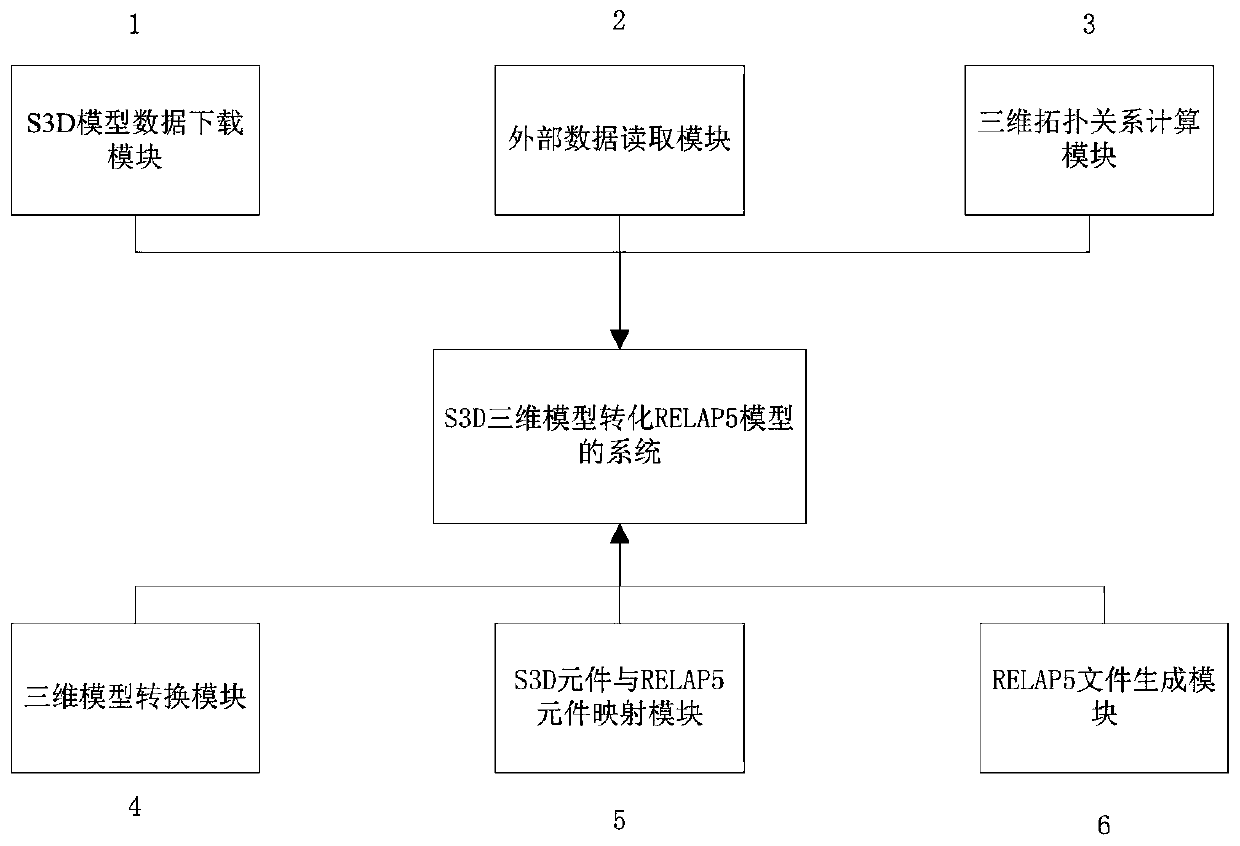

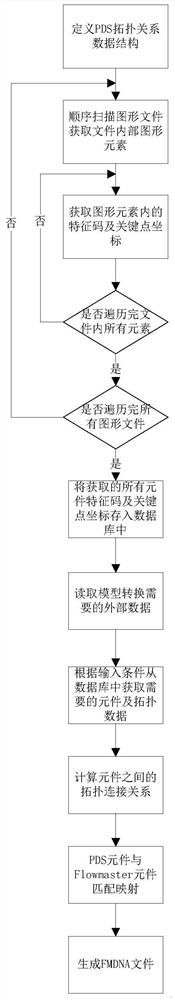

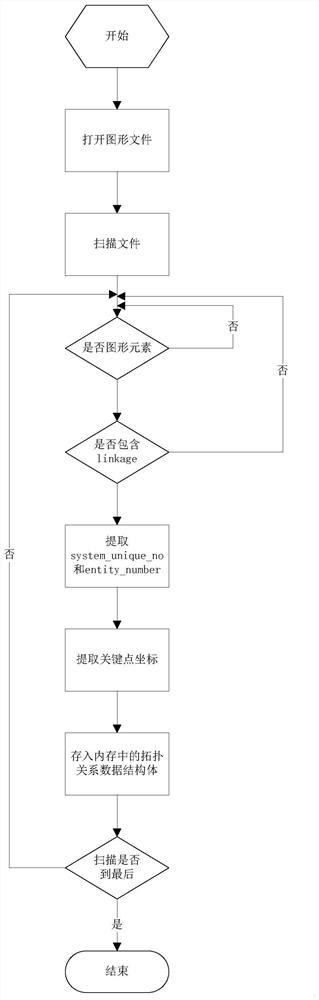

System and method for converting S3D three-dimensional model into Flowmaster model

ActiveCN110109999ASave the link of secondary modelingImprove data utilizationDatabase management systemsSpecial data processing applicationsExternal dataSimulation

The invention provides a system and method for converting an S3D three-dimensional model into a Flowmaster model. The system is characterized by comprising an external data reading module, an S3D model data downloading module, a three-dimensional topological relation calculation module, a three-dimensional model conversion module, an S3D element and Flowmaster element mapping module and an FMDNA file generation module. According to the present invention, the automatic conversion from an arrangement model to a mechanical analysis model is realized, the labor waste caused by the secondary modeling is avoided, and the design efficiency and the quality are greatly improved; two modes of generating by taking a system as a unit and generating by self-defining a pipeline list are supported, the method and the system are flexible and are easy to use, the fault-tolerant rate during the three-dimensional model modeling process is increased, the operation is simple and convenient, and the production efficiency is high.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Smoke purification device for metallurgy

InactiveCN108499297AAvoid wastingAvoid wasting timeCombination devicesGas treatmentAir filterEngineering

The invention relates to the technical field of air purification, in particular to a smoke purification device for metallurgy. The device includes a housing, a belt, a first motor and a second motor;a glass door is hinged to the front end face of the housing, an air inlet pipe is communicated with the top of the right end face of the housing, an air outlet pipe is communicated with the center ofthe left end face of the housing, a fan is fixedly connected to the right end face of the interior of the housing, a second rotating shaft is arranged at the center of the housing, a second rotating shaft is fixedly connected to the tail end of a main shaft of the first motor, a multifunctional combined air filtering net is fixedly connected to the outer side of the second rotating shaft, the upper end of the second rotating shaft is in transmission connection with the lower end of the second rotating shaft through the belt, and a first rotating shaft is arranged on the right side of the second rotating shaft. Through arrangement of the belt, the two rotating shafts can be driven to synchronously rotate by only one motor, and the structure is simplified.

Owner:桂林华冶机械制造有限公司

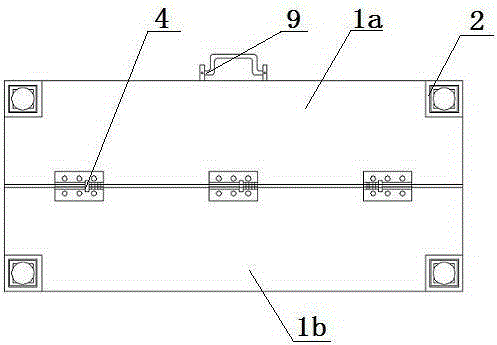

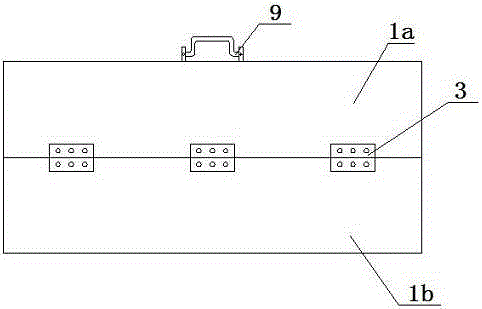

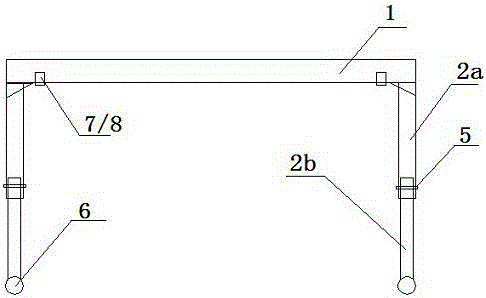

Controllable elevated working platform

The invention relates to a controllable elevated working platform which comprises a platen and supporting legs. The supporting legs are mounted on the bottom surface of the platen through hinges in a foldable mode. The platen comprises a first platen body and a second platen body which are hinged through hinges. Locking mechanisms are arranged at the folding position of the first platen body and the second platen body. Each supporting leg comprises a first supporting leg body and a second supporting leg body. Each second supporting leg body is inserted into the corresponding first supporting leg body from bottom to top in a telescopic mode. Each first supporting leg body and the corresponding second supporting leg body are provided with matched slotted holes. Positioning screws are arranged in the slotted holes. The positioning screws sequentially penetrate through the slotted holes in the first supporting leg bodies and the second supporting leg bodies and are fastened through nuts. The working platform is made of firm, light and corrosion-resistant materials and is foldable and convenient to carry, the space occupancy can be reduced greatly, the working efficiency is improved, unnecessary labor force waste is avoided, and overhaul quality is promoted.

Owner:STATE GRID CORP OF CHINA +1

Cutting tool bit

ActiveCN110977572AEasy to replaceAvoid labor wastePositioning apparatusMetal-working holdersTool bitElectric machinery

The invention relates to the field of cutting tool bits, in particular to a cutting tool bit. The cutting tool bit a base, and the upper surface of the base is fixedly connected with one end of a rotating mechanism. The other end of the rotating mechanism is fixedly connected with a turntable; and a fixing mechanism is arranged on the side edge of the rotary disc, a plurality of fixed tool apronsare fixedly clamped in the fixing mechanism, cutting tool bits are fixedly connected to the ends, located in the fixing mechanism, of the multiple fixed tool aprons, and the other ends of the fixed tool aprons are fixedly connected with a mechanical arm through a connecting mechanism. The rotating mechanism drives the turntable to rotate; further, the fixed tool aprons fixedly connected with different cutting tool bits and the mechanical arm are connected via the connecting mechanism; a motor in a connecting shaft is used for driving a wafer to rotate, then the connecting relation between a threaded barrel and a threaded face is controlled, then the cutting tool bit connected to the mechanical arm can be replaced conveniently, manual operation of operators is not needed, and waste of laborforce of the operators is avoided.

Owner:唐山友乾科技有限公司

Punching integrated punching die

PendingCN111687313AReduce workloadAvoid labor wasteShaping toolsMetal working apparatusEngineeringSteel belt

The invention discloses a punching integrated punching die. At least one set of punching modules is arranged between a base and an upper driving block. Telescopic parts are arranged at both ends of the punching module between the base and the upper driving block. The punching module comprises a first punching die, an embossing code die, an embossing arrow code die and a second punching die in sequence from left to right. The first punching die comprises a first upper punching die and a first lower punching die. The embossing code comprises an upper pressing die and a lower pressing die. The embossing arrow code die comprises an upper arrow pressing die and a lower support die. The second punching die comprises a second upper punching die and a second lower punching die. The first upper punching die, the upper pressing die, the upper arrow pressing die and the second upper punching die can be detachably installed on an upper driving block. The first lower punching die, the lower pressing die, the lower support die and the second lower punching die can be detachably installed on the base. The punching integrated punching die improves processing efficiency of steel strip and reduces personnel cost.

Owner:WUHU SHUNRONG AUTOMOBILE PARTS

Semi-automatic door lock for barn feeding sheepfold and grazing fence

InactiveCN104790783ARealize semi-automatic lockingAvoid artificial increaseWing fastenersSemi openSemi automatic

The invention provides a semi-automatic door lock for a barn feeding sheepfold and a grazing fence. The semi-automatic door lock mainly consists of a lock body, a pin and a lock cylinder, wherein the lock body adopts a semi-open cavity structure; oppositely formed axle holes are formed in the two side walls of the lock body; a V-shaped open slot is inwardly formed in the side wall of the lock body, and is opened in the opening direction of a door; a lock hole is formed in the end part of the V-shaped open slot; a rotating shaft, a handle and a baffle are arranged on the pin; the pin is connected with the lock hole in the lock body through the rotating shaft; the pin rotates in a cavity of the lock body by winding the rotating shaft; the handle stretches out from the top of the lock body; an arc-shaped notch is formed in the edge of the baffle, and is just positioned in the lock hole; when the pin is in the closing state, the arc-shaped notch blocks the opening of the lock hole. The structure realizes semi-automatic locking of a sheepfold door, a sheep house door and a fence door, and unnecessary chaos or loss of the sheep due to improper opening of the house and the fence door to cause labor increase, unnecessary labor consumption, economy loss and the like can be avoided can be avoided.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

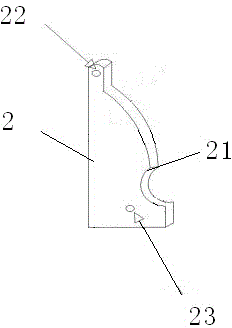

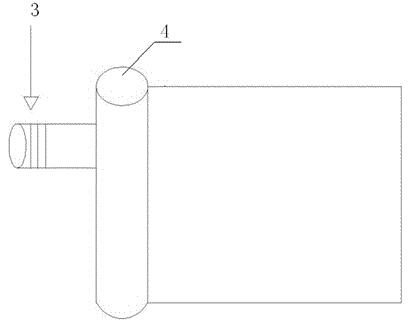

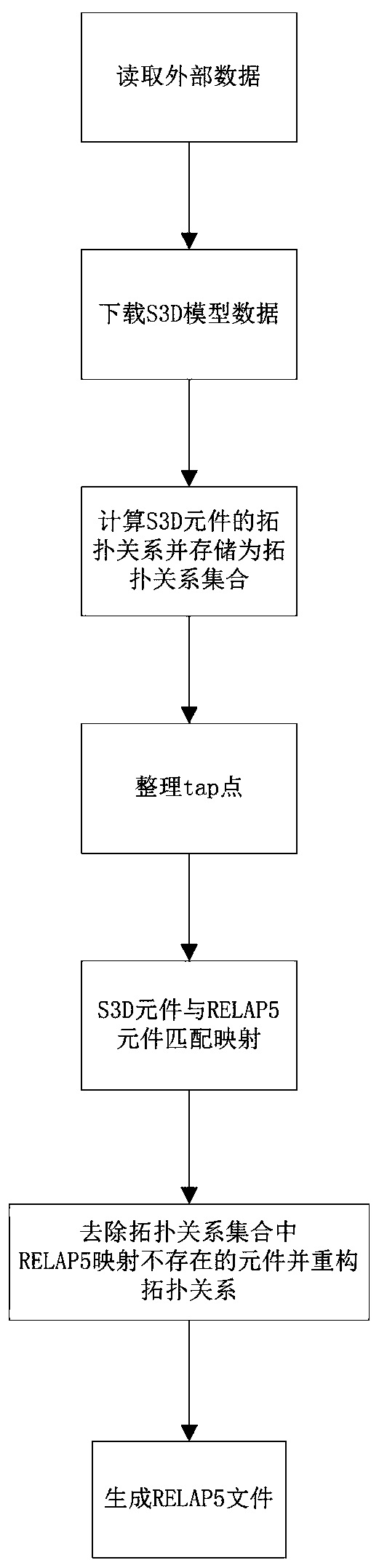

System and method of converting S3D model into RELAP5 model

PendingCN110795390AImprove fault toleranceAvoid labor wasteGeometric CADSemi-structured data mapping/conversionXMLIndustrial engineering

The invention aims to disclose a system and method of converting an S3D model into an RELAP5 model. Compared with the prior art, the system and method can automatically convert an S3D three-dimensional model into an XML file supported by RELAP5 software, realize automatic conversion from an arrangement model to a mechanical analysis model, avoid labor waste caused by secondary modeling, greatly improve the design efficiency and quality, support two modes of generation by taking a system as a unit and generation by customizing a pipeline list, and are flexible and easy to use, wherein the process is fully automatically completed without human intervention, and the operation is simple and convenient, and the production efficiency is high; the functions of equipment mapping and pipeline removal are supported; meanwhile, the functions of tap point removal, subsequent connection and small pipeline removal are supported; the method and system are suitable for various application scenes; andthreshold setting is supported, and the error-tolerant rate in the modeling process of the three-dimensional model is increased, and the purpose of the invention is achieved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

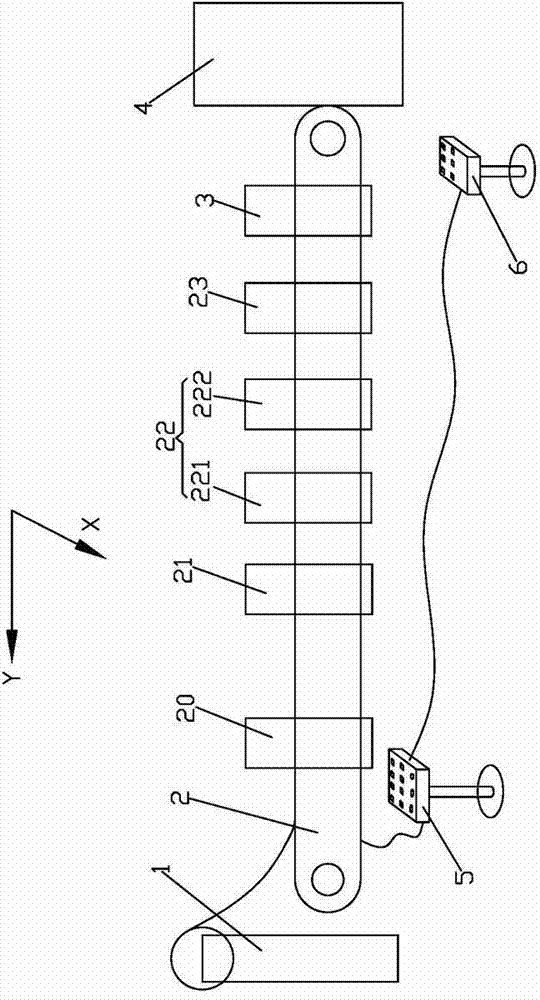

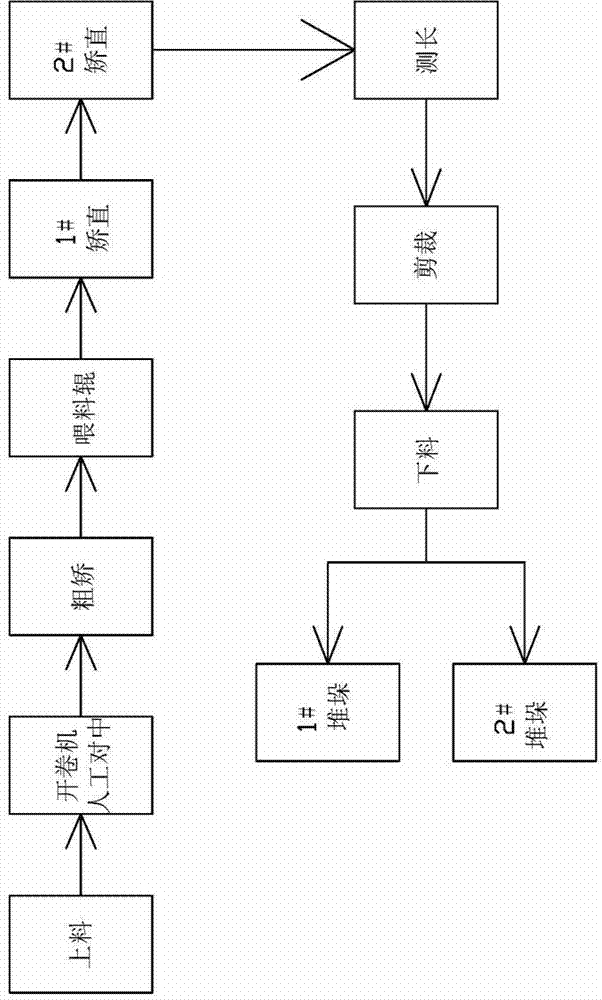

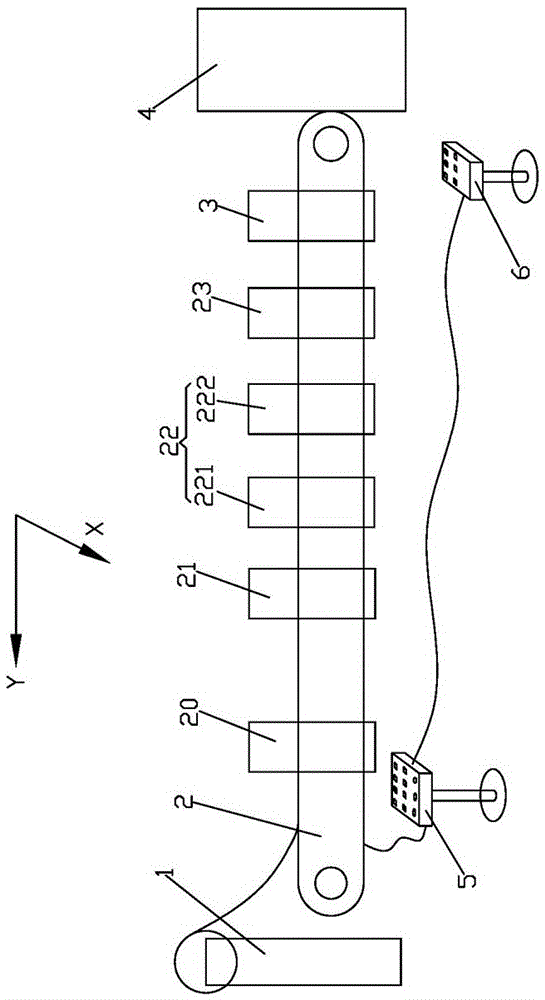

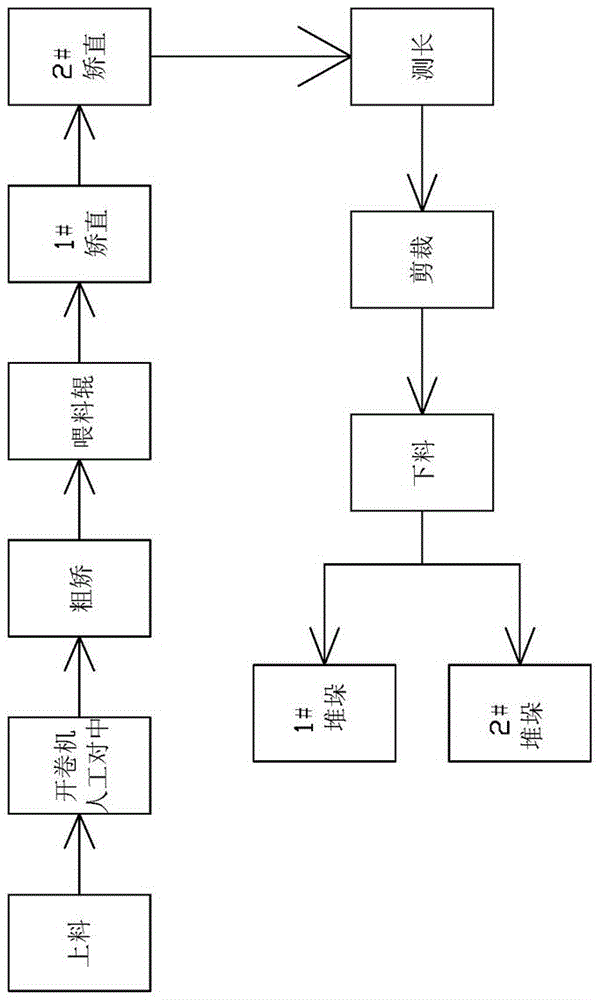

Control system used for tail of coiler to adjust central line of coiler and using method of control system

ActiveCN103753220AShorten the timeIncrease productivityOther manufacturing equipments/toolsControl systemThe Internet

The invention discloses a control system used for the tail of an uncoiler to adjust the central line of the uncoiler. The control system comprises the uncoiler, a feeding roller, a cutter, a stacker and a first control device, an auxiliary control device used for controlling left-right movement of the feeding roller is arranged on one side of the tail of the uncoiler, and the auxiliary control device is connected with the first control device and the uncoiler through a network line to form the Internet of Things. The invention further discloses a method for using the control system to adjust the central line of the uncoiler. The auxiliary control device is arranged at the tail of the uncoiler, so that after measuring whether coil stock deviates or not at the tail of the uncoiler in the process of uncoiling, a worker can directly control the feeding roller to move leftwards and rightwards on the auxiliary control device arranged at the tail of the uncoiler so as to adjust the central line of the uncoiler, and does need to run to the front portion of the uncoiler to operate the first control device, saving of time is facilitated, and production efficiency is improved.

Owner:佛山宝钢不锈钢贸易有限公司

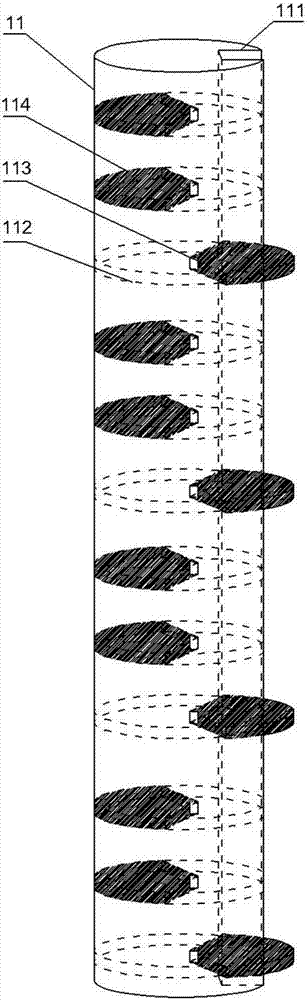

Semi-dry stored grass airing device for modern agriculture

InactiveCN112240686AIncrease the turning areaDry evenlyGrass dryingDrying chambers/containersAgricultural scienceThunderstorm

The invention discloses a semi-dry stored grass airing device for modern agriculture. The device comprises a box body, a lifting mechanism, a shielding mechanism, an electric hydraulic rod, a turningmechanism and a controller; the lifting mechanism is arranged in an inner cavity of the box body; the shielding mechanism is mounted at the top end of the lifting mechanism; the electric hydraulic rodis arranged in the center of the top end of the rear side of the box body in the up-down direction; the turning mechanism is arranged at the top end of the electric hydraulic rod in the left-right direction; and the controller is arranged on the front side of the top end of the box body and electrically connected with the electric hydraulic rod. According to the semi-dry stored grass airing device for modern agriculture, aired fresh grass can be shielded in thunderstorm weather, workers do not need to transfer the grass into a room, time and labor are saved, the grass can be automatically turned over up and down in the airing process to guarantee uniform airing, the workers do not need to manually and frequently turn over the aired grass, operation is simple, and labor waste is avoided.

Owner:薛刚

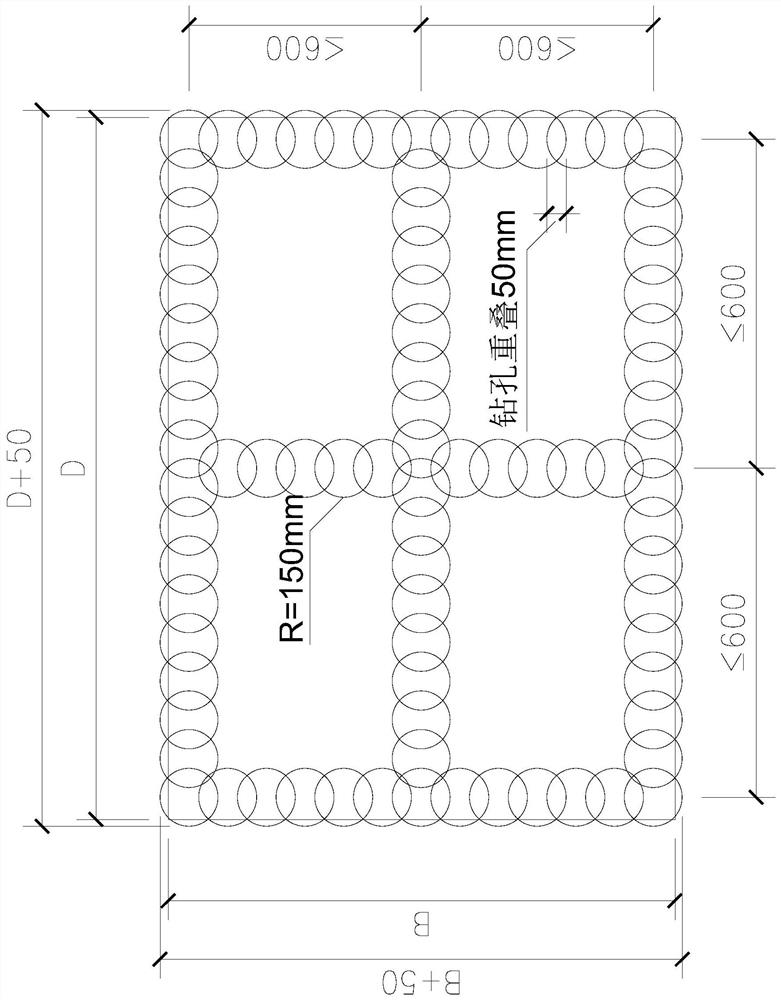

A construction method of strip foundation

ActiveCN110565671BImprove construction efficiencyImprove efficiencyFoundation engineeringArchitectural engineeringEngineering

The invention relates to a construction method of a strip foundation. The construction method comprises the following steps of (1) removing sundries from a construction area; (2) spreading lime so asto form rectangular frames corresponding to each pile position according to a design drawing, wherein the shape enclosed by the rectangular frames adapts to the profile of the strip foundation; (3) calculating the construction capacity of earthwork according to the design drawing, and calculating the number of incoming machinery; (4) digging holes at intervals in the length direction of the rectangular frames corresponding to the center of the width of the rectangular frames in the step (2), wherein a drill of a pile machine is vertical downwards during hole digging, the diameter of each holeis larger than the width of the rectangular frames by 50 mm, and the overlapped distance between adjacent holes is larger than or equal to 50 mm, so that a rectangular closed slot is obtained; (5) digging empty earthwork in the closed slot in the step (4) by using an excavator after the holes are dug so as to obtain a foundation trench, correcting the level and coordinates of the foundation trench, removing capping mass of the foundation trench, and manually flattening; and (6) pouring a cushion of the foundation trench so as to obtain the strip foundation.

Owner:CHONGQING ZHONGKE CONSTR GROUP

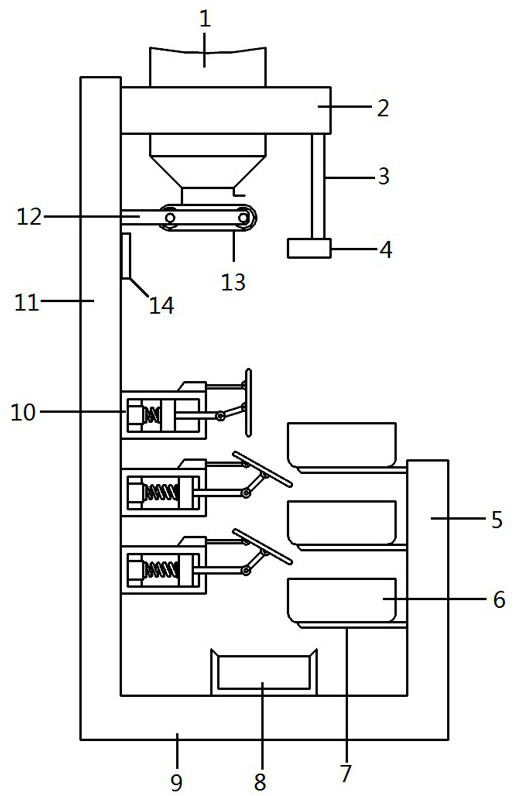

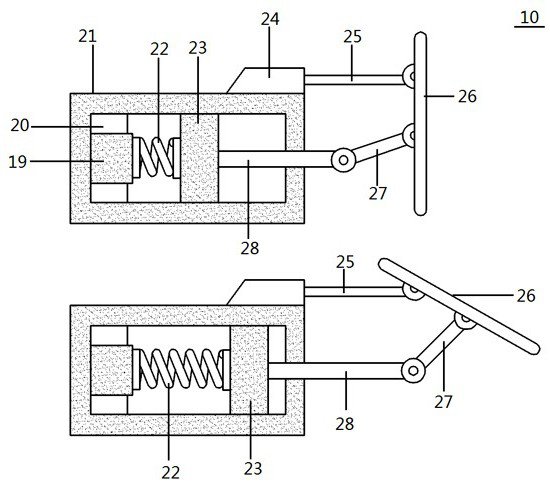

Button sorting device for garment manufacturing

The invention discloses a button sorting device used for garment manufacturing. The button sorting device comprises a conical hopper, a recognition device, a bottom plate, a discharging device and a plurality of direction-changing devices. By means of the button sorting device, large-bath buttons can be automatically classified, the phenomenon of labor wasting caused by manual sorting is avoided,during using, the buttons fall off uniquely and uniformly by means of the discharging device and are fast detected by the recognition device, permanent magnets are driven to move in an electromagneticcoil attraction mode, springs achieve damping and buffering purposes as well as fast storing elastic potential energy so as to be ready for bouncing operation next time, the rotating mode of guide plates fast responds, the interval time is short, the button separation speed can be increased, furthermore, the equipment cost is low, the abrasion resistance effect is good, and the button sorting device is suitable for wide application and popularization.

Owner:浙江铠悦新材料科技股份有限公司

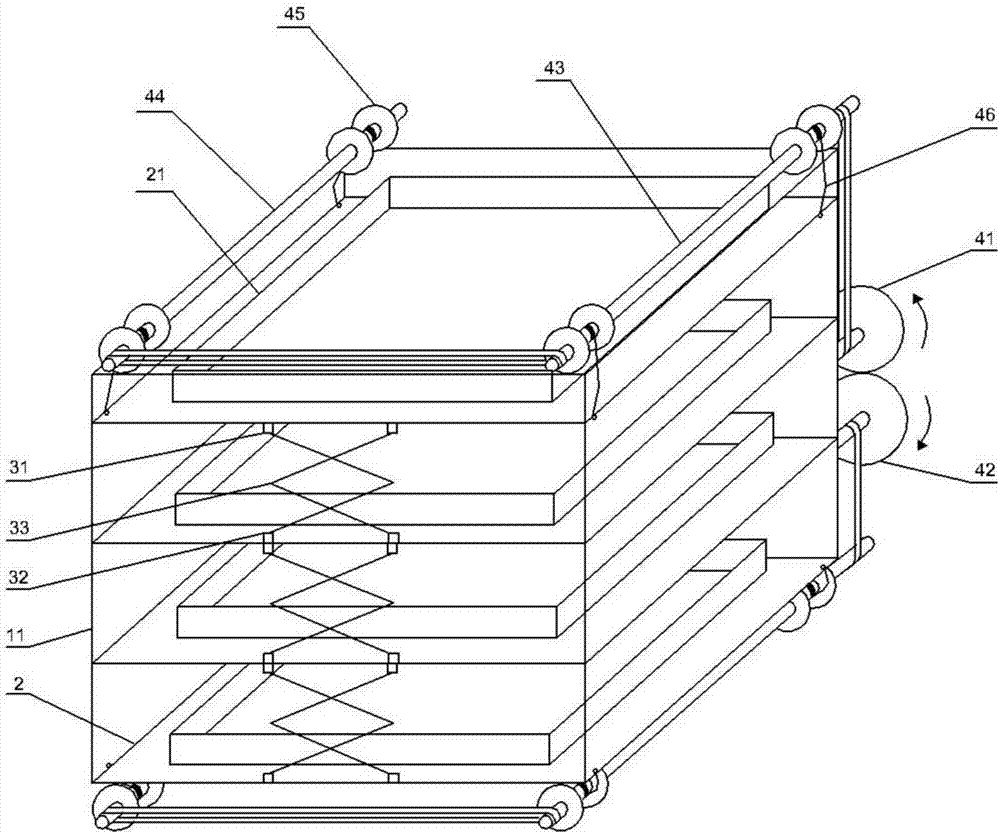

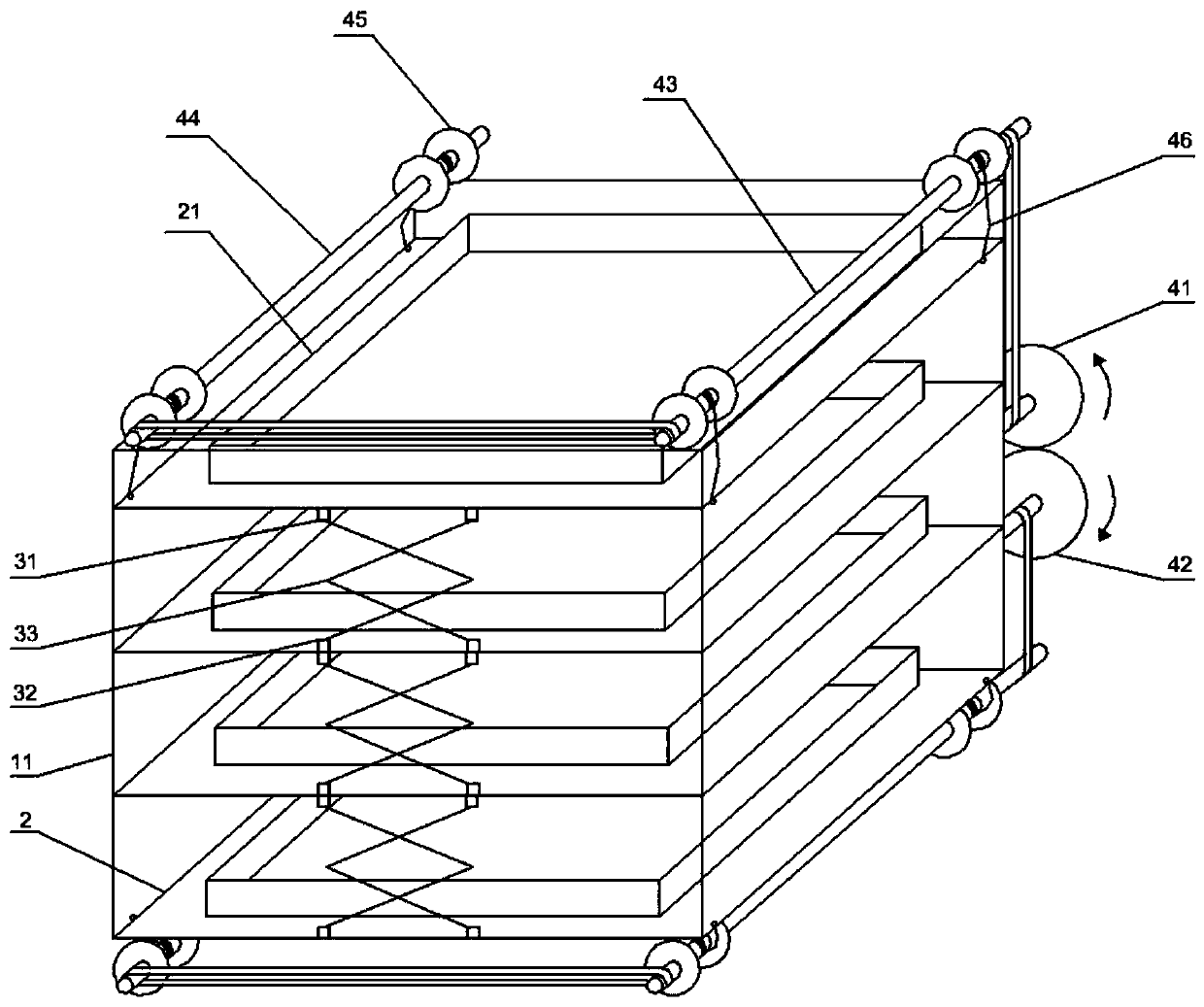

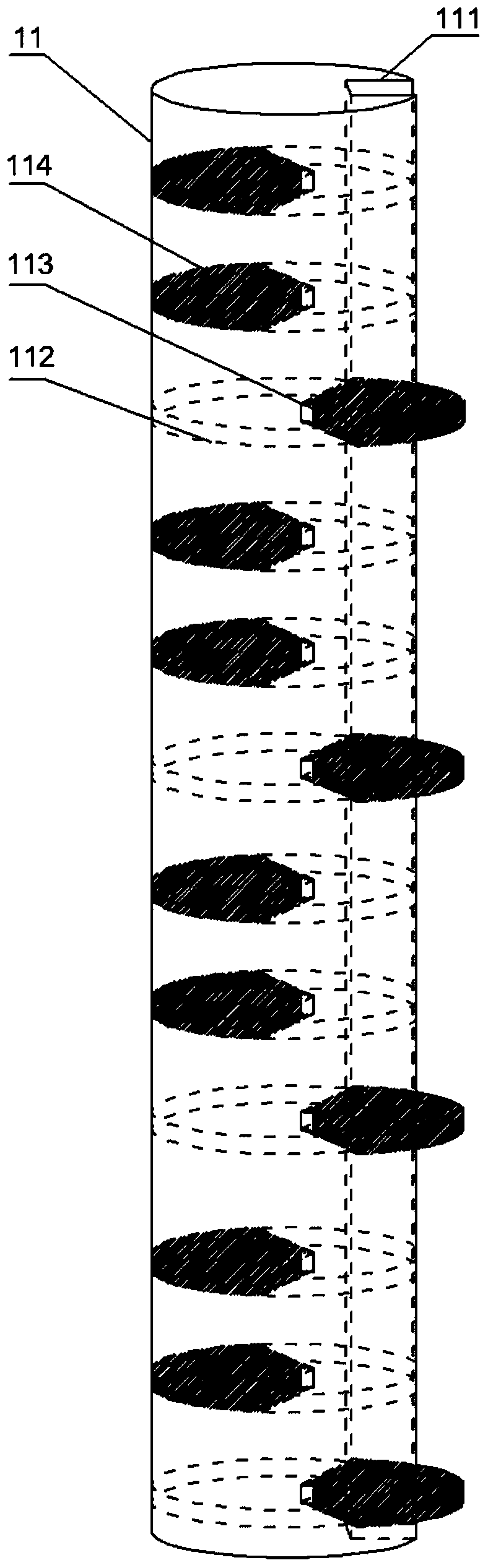

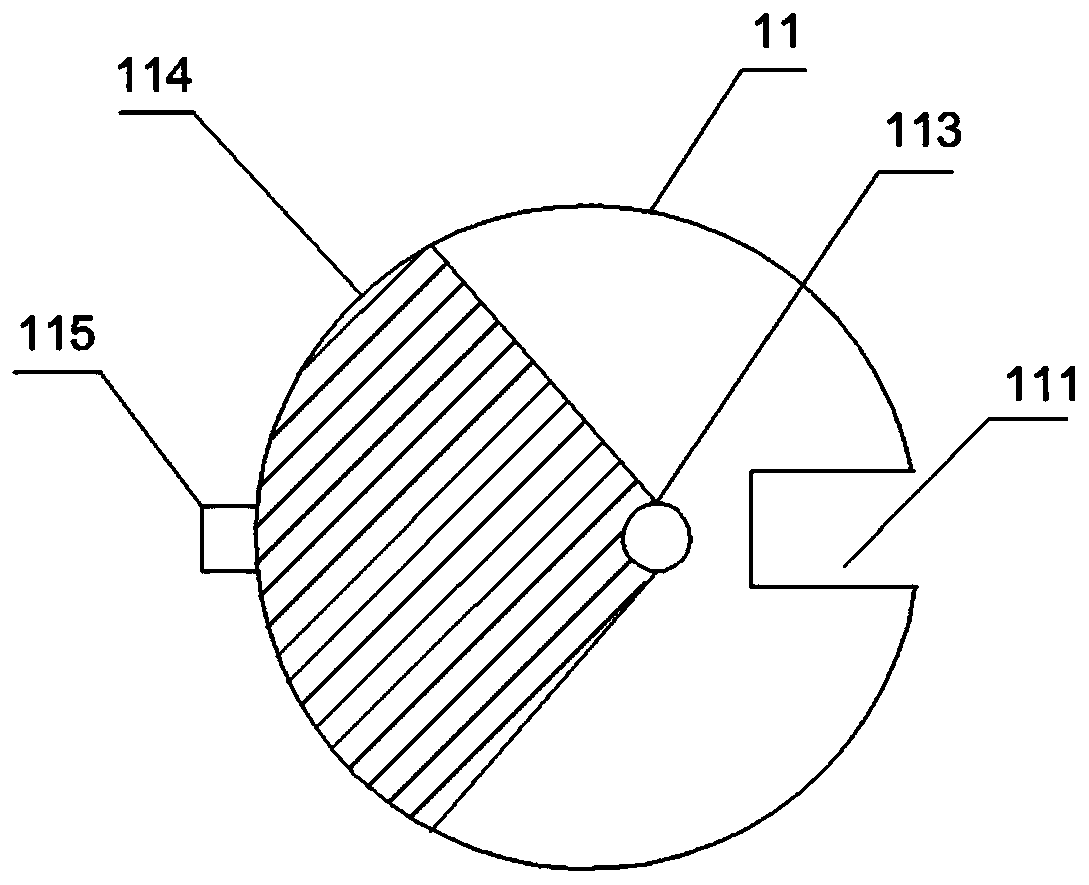

Gear-driven sericulture device

ActiveCN107494463APromote growth and developmentQuality improvementAnimal husbandryGear driveSericulture

The invention discloses a gear-driven sericulture device which comprises a support frame body, a plurality of silkworm cocoon tray layers, a lifting mechanism and a hoisting mechanism, wherein a space for accommodating a silkworm cocoon lattice cluster is formed in each silkworm cocoon tray layer; the lifting mechanism comprises a plurality of pairs of lifting components, each lifting component comprises a pair of upper positioning blocks, a pair of lower positioning blocks and a pair of V-shaped hinged frames; the hoisting mechanism comprises a gear pair and a pair of hoisting components, the gear pair comprises a first gear and a second gear which are mutually meshed, and each hoisting component comprises a drive rod and a driven rod parallel to a group of opposite sides of each silkworm cocoon tray layer. The gear-driven sericulture device disclosed by the invention can reach an equivalent height and is high in space utilization rate; and operation personnel can finish operation on the ground, so that both time and labor are saved, and therefore, the practical value is high.

Owner:NANJING ZHIQIAO AGRI CO LTD

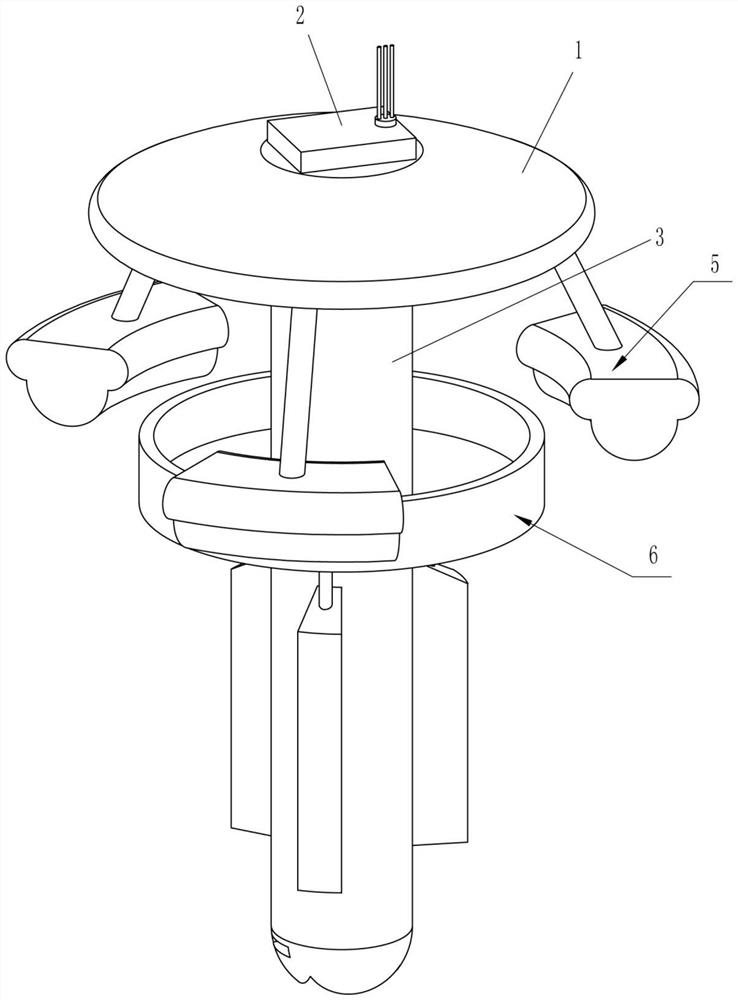

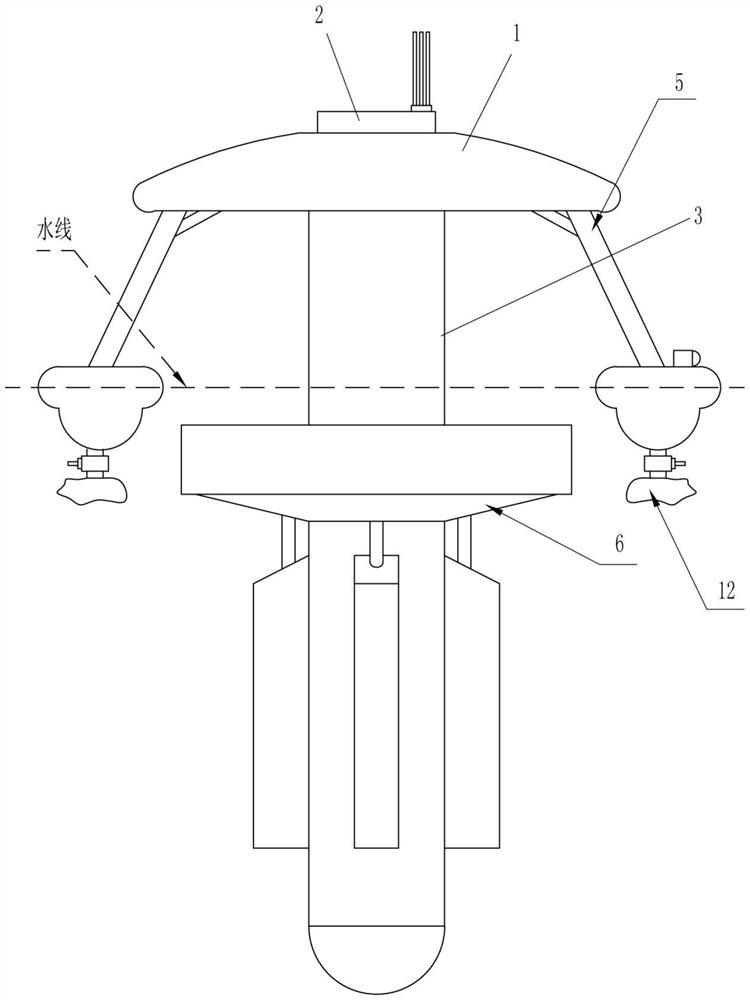

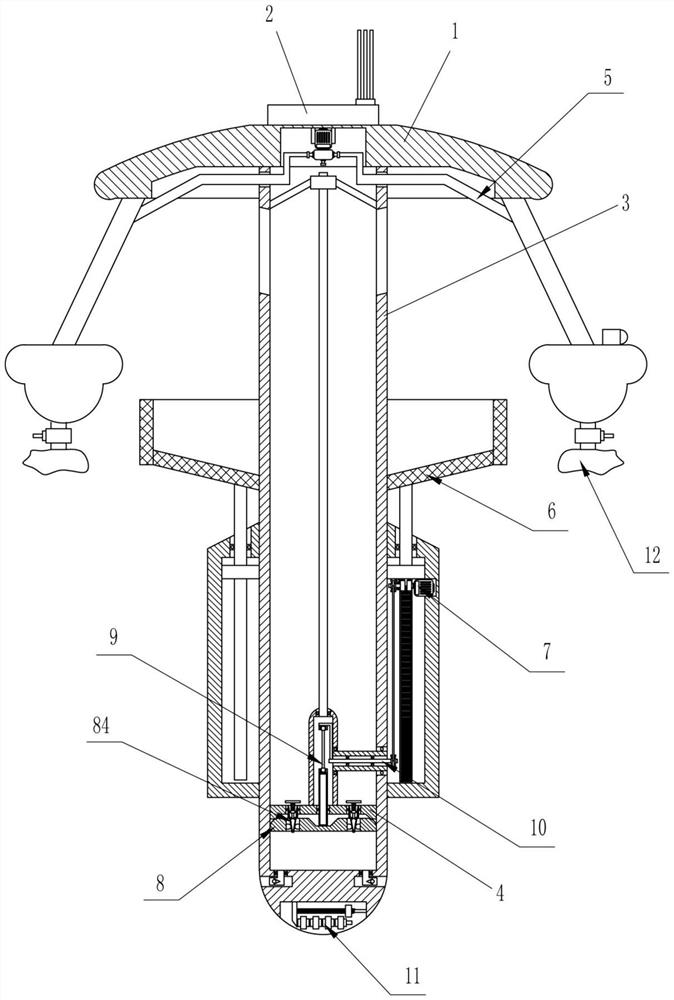

Intelligent ocean service platform

ActiveCN113699955AAutomatic collectionAvoid labor waste,Water cleaningWaterborne vesselsRefuse collectionWireless control

The invention discloses an intelligent ocean service platform which comprises a mounting table. The mounting table is characterized in that a floating assembly, a filtering assembly, a driving assembly, a drainage assembly, a reciprocating assembly and a linkage assembly are arranged on the mounting table, wherein a power source and a wireless controller are fixedly connected to one side of the mounting table, a containing pipe is fixedly connected to the other side of the mounting table, the containing pipe is of a structure with an opening in the side close to the mounting table, a water outlet disc is fixedly connected to the side, away from the mounting table, in the containing pipe, and the water outlet disc is of a structure with a water outlet. Through cooperation of the floating assembly, the filtering assembly, the driving assembly, the drainage assembly, the reciprocating assembly, the linkage assembly, a counterweight assembly and a float adding assembly, marine garbage can be automatically treated, the marine environment cannot be further polluted, the cost can be reduced, and garbage collection can be automatically carried out along with ocean currents.

Owner:海南环球海洋服务有限公司

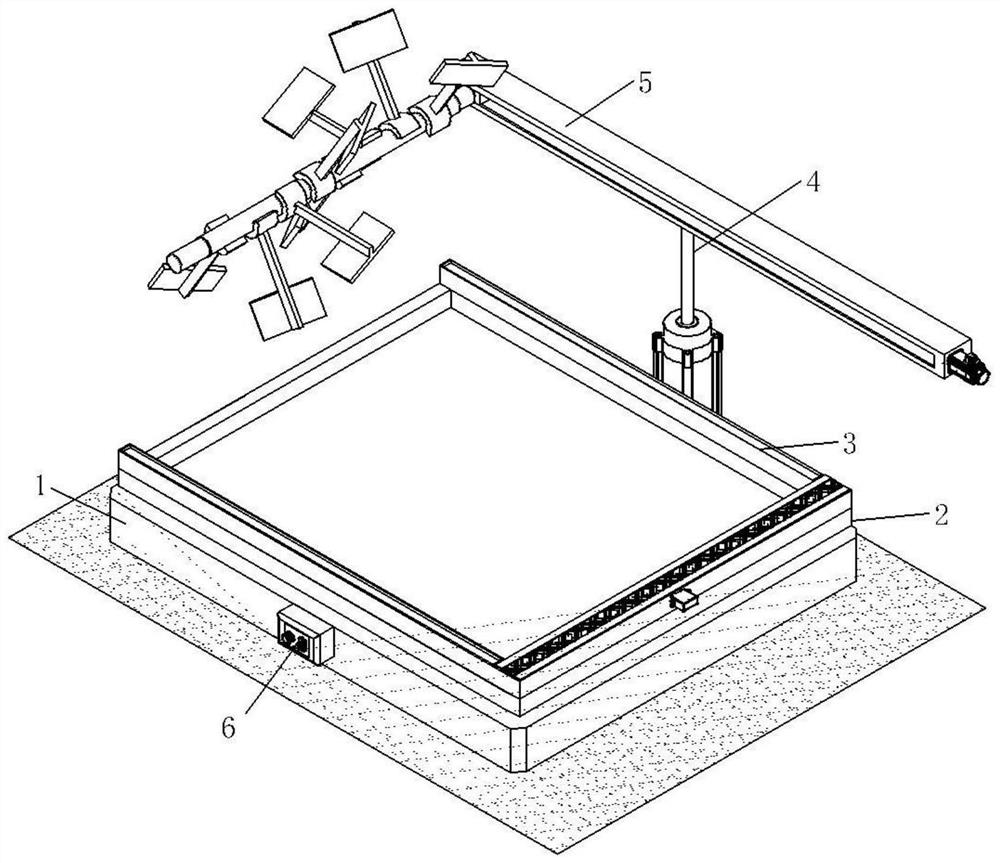

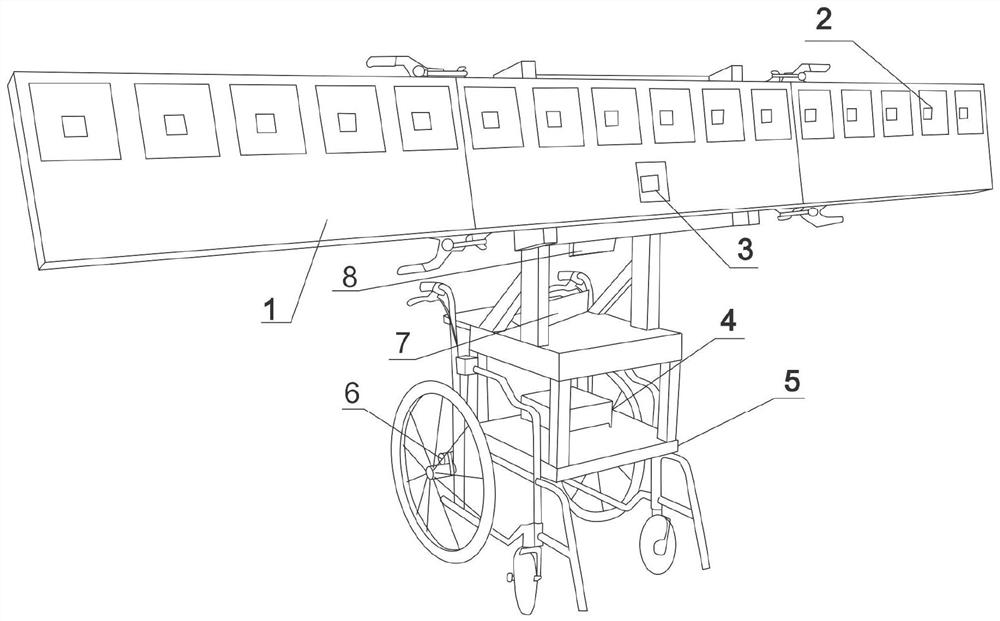

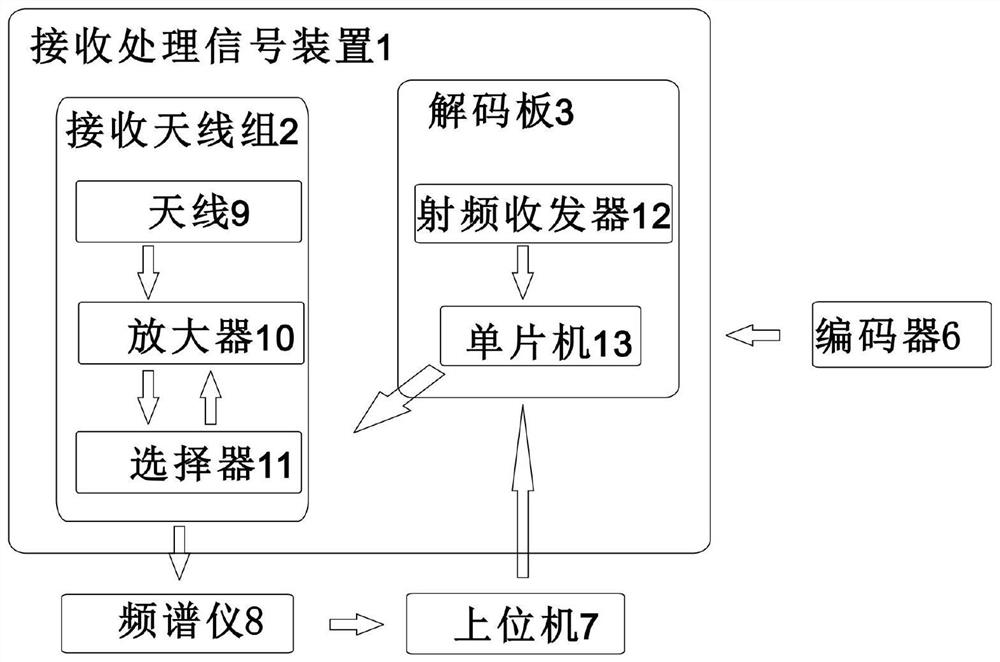

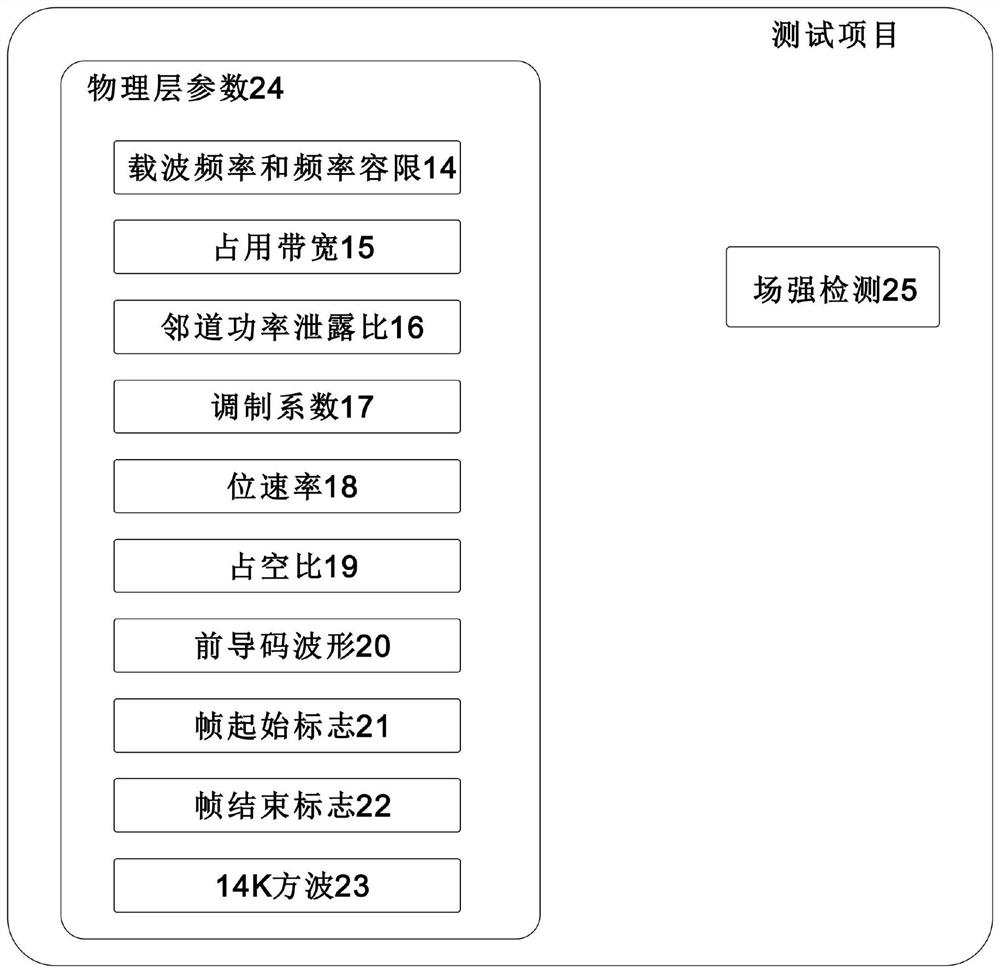

Equipment for detecting physical characteristics of highway RSU antenna

PendingCN113092881AAvoid labor wasteImprove work efficiencyAntenna radiation diagramsTelecommunicationsComputer software

The invention discloses equipment for detecting physical characteristics of a highway RSU antenna. The detection equipment comprises a receiving antenna device, a frequency spectrograph, an encoder, a power supply and an upper computer. RSU signals are received through the signal receiving and analyzing device, physical characteristics of an RSU antenna are analyzed through the frequency spectrograph, and physical parameters are further analyzed, processed and displayed through upper computer software. The wireless signal field intensity distribution data in the lane is quantitatively analyzed according to the condition fed back by the detection equipment, and the abnormal state that the field signal intensity is too weak and the signal coverage is too small is found and assisted to solve.

Owner:TRANSCEND COMM BEIJING

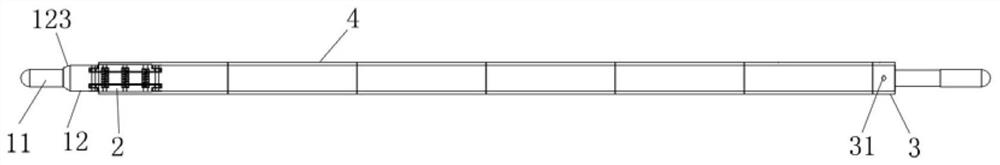

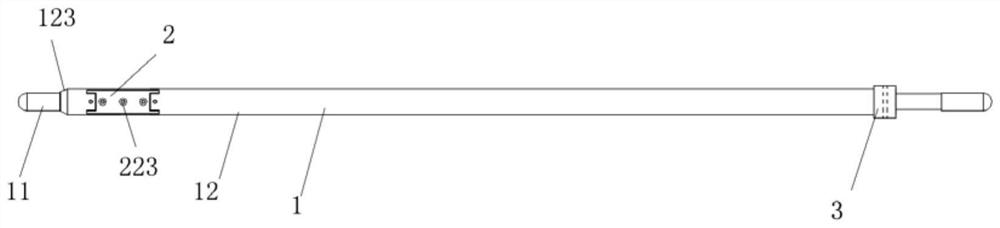

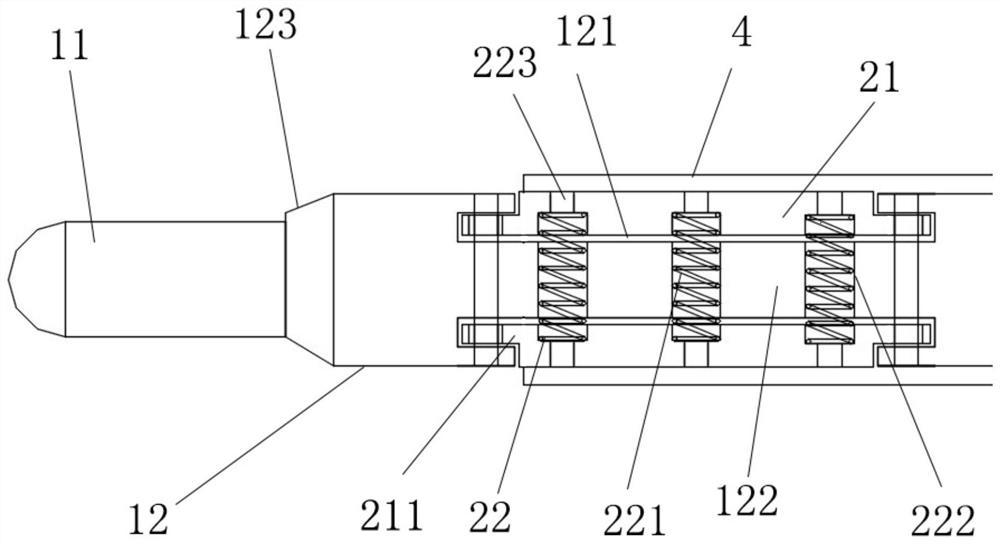

Winding core shaft of small roll cutting machine

PendingCN111908222AIncrease productivitySimple structureWebs handlingStructural engineeringMechanical engineering

The invention discloses a winding core shaft of a small roll cutting machine. The winding core shaft comprises a main mandrel body, a telescopic jacking piece, a positioning ring and a plurality of winding cores; the main mandrel body is of a rod-shaped structure; the positioning ring is fixedly installed at one end of the main mandrel body; the telescopic jacking piece is fixedly installed at theother end of the main mandrel body; the plurality of winding cores are sequentially arranged on the main mandrel body in a sleeving manner, one winding core close to one end of the main winding corebody abuts against the positioning ring, and one winding core close to the other end of the main winding core body is clamped on the telescopic jacking piece; and the telescopic jacking piece is arranged in a pressing and telescopic manner in the radial direction of the main mandrel body. Through application of the winding core shaft, rapid winding core pre-assembling work can be conducted, and rapid disassembling can also be conducted, so that the production efficiency of small roll materials such as paper rolls is greatly improved, and waste of labor force is avoided.

Owner:SHANGHAI GUANGPING PRINTING EQUIP

A system and method for converting a pds three-dimensional model into a relap5 model

ActiveCN109117564BAchieve conversionAvoid labor wasteGeometric CADDesign optimisation/simulationFault toleranceXML

The purpose of the present invention is to disclose a system and method for converting a PDS three-dimensional model into a RELAP5 model. Compared with the prior art, the PDS three-dimensional model can be automatically converted into an XML file supported by RELAP5 software, and the conversion of the layout model to the mechanical analysis model is realized. Automatic conversion avoids labor waste caused by secondary modeling, greatly improving design efficiency and quality; supports four generation modes with system as the unit, custom pipeline as the unit, model as the unit and mechanical analysis package as the unit, flexible Easy to use, the whole process is fully automatic, without human intervention, easy to operate, high efficiency, greatly improving the utilization rate of the PDS 3D model, supporting equipment mapping and removing pipeline functions, supporting removing tap point follow-up connections and removing small pipe functions, It is applicable to various application scenarios, supports threshold setting, improves the fault tolerance rate in the modeling process of the three-dimensional model, and realizes the object of the present invention.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

A three-phase rotating structure all-round dust-suppressing and expanding pipe clamping and processing integrated machine

ActiveCN113385964BGuaranteed accuracyEasy to adjustOther manufacturing equipments/toolsMetal working apparatusEngineeringPipe

Owner:徐州中顺尚奕机械制造有限公司

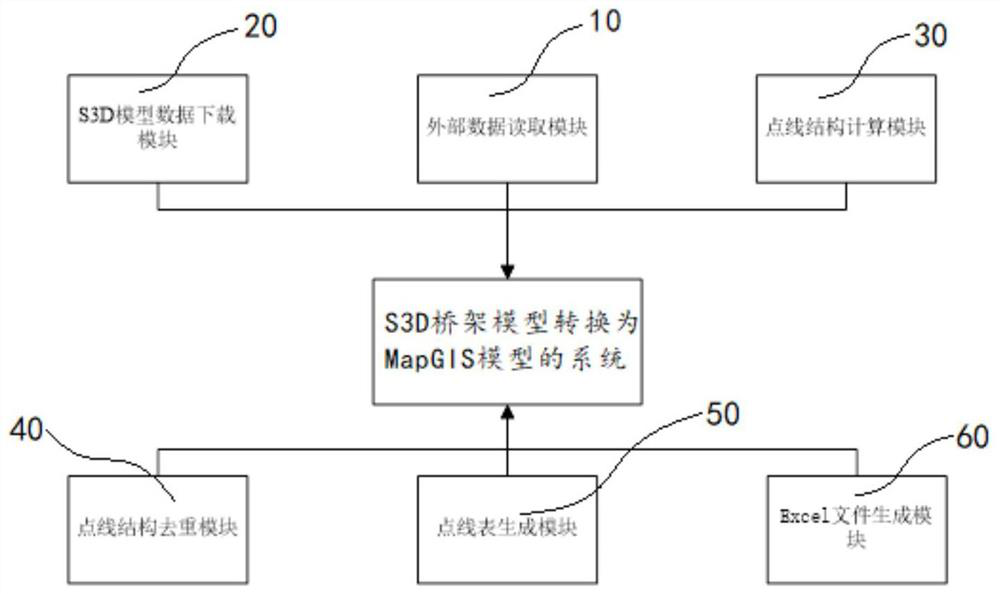

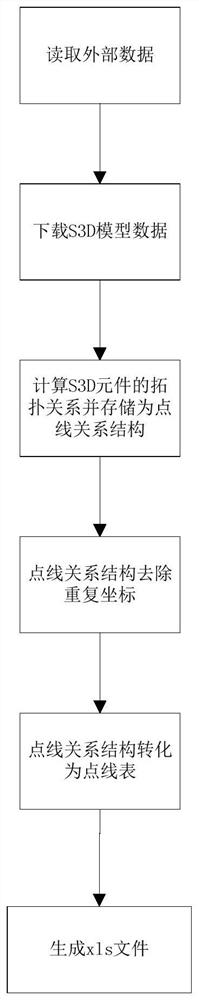

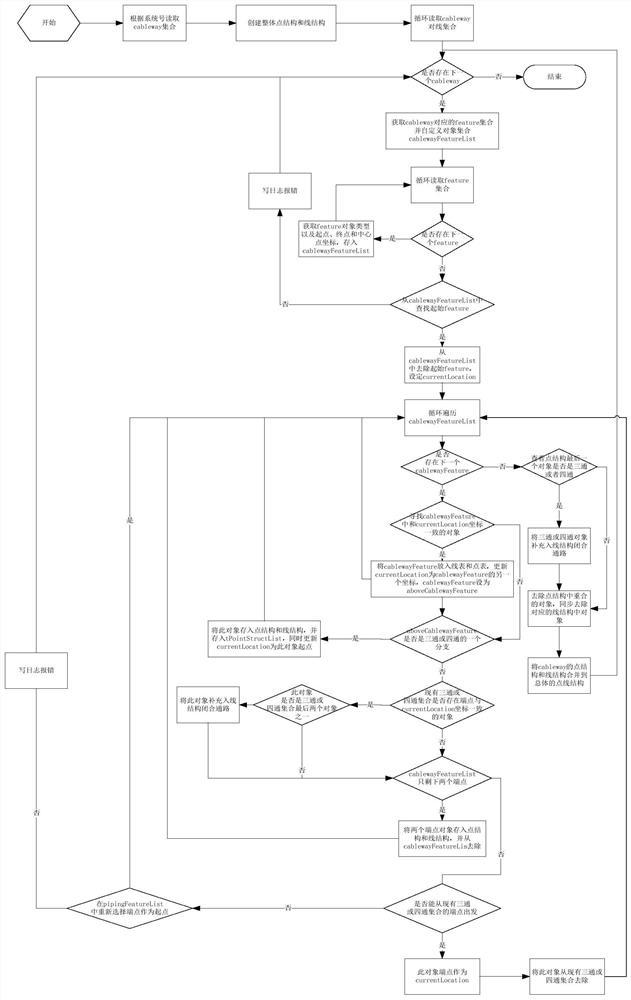

System and method for converting S3D bridge model into MapGIS model

PendingCN112948911AAvoid labor wasteImprove design efficiencyGeometric CADGeographical information databasesModelSimGeographic information system

The invention aims to disclose a system and a method for converting an S3D bridge model into a MapGIS model, and compared with the prior art, the system and the method can automatically convert the S3D bridge model into an Excel file which is supported to be imported by MapGIS software, realize automatic conversion from an arrangement model to a geographic information system model, avoid labor waste caused by secondary modeling, and greatly improve the design efficiency and quality; two modes of generating by taking a system as a unit and generating in a whole plant are supported, the invention is flexible and easy to use, the whole process is fully automatically completed, human intervention is not needed, operation is easy and convenient, the production efficiency is high, a log query function is provided, analysis and calculation of other pipelines can still be completed under the condition that a single bridge goes wrong, robustness is high, and the purpose of the invention is achieved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

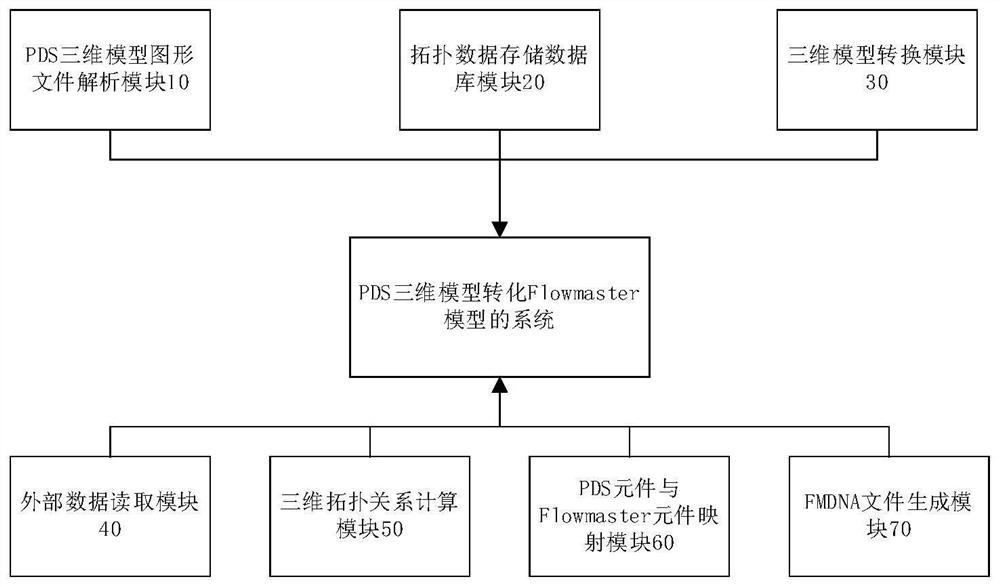

A system and method for converting pds three-dimensional data into a flowmaster model

ActiveCN109272571BAvoid labor wasteImprove design efficiency3D modellingData transformationAlgorithm

An object of the present invention is to disclose a system and method for converting PDS three-dimensional data into a Flowmaster model, in accordance with that prior art, to the invention automatically converts PDS 3D models into FMDNA files supported by Flowmaster software, the automatic conversion of the layout model to the mechanical analysis model is realized, the waste of labor caused by thesecondary modeling is avoided, the design efficiency and quality are greatly improved, and the utilization ratio of the PDS three-dimensional model is greatly improved. The whole process is completedautomatically without human intervention, and the operation is simple, flexible and easy to use, and the efficiency is high. At the same time, the topology data of the three-dimensional model is stored in the external database, As the interface between the PDS software and other software is provide with the data guarantee, the device mapping and the pipeline removal function are supported, the tap point subsequent connection removal function and the small pipeline removal function are supported, the PDS software is suitable for various application scenes, the threshold setting is support, thefault tolerance rate in the three-dimensional model modeling process is improved, and the purpose of the invention is realized.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

Integrated machining process for metal workpieces

The invention relates to the technical field of metal workpieces, in particular to an integrated machining process for metal workpieces. The integrated machining process comprises the following stepsof stamping treatment, pretreatment, thermal treatment, workpiece coarse grinding, workpiece fine grinding, aftertreatment and workpiece detection. A full-length grinding machine is adopted, comparedwith the mode that one metal workpiece is machined on two devices in sequence, the full-length grinding machine can improve the former machining mode at a time, the workpieces are prevented from beingmachined on multiple devices, time is saved, the work progress is accelerated, and waste of labor force is avoided; moreover, stamped workpieces are heated before being ground, and therefore the full-length grinding machine can conveniently grind the stamped workpieces, and grinding efficiency is improved.

Owner:重庆羿业气门有限公司

Production process of novel environment-friendly plastic building template

InactiveCN113232338AReduce measurement errorLow granulation costFlat articlesWeather resistanceArchitectural engineering

The invention discloses a production process of a novel environment-friendly plastic building template. The production process comprises the steps of preparation of an A-layer material, preparation of a B-layer material, preparation of a C-layer material, die pressing, cooling shaping, die cutting and finished product conveying, wherein the preparation of the A-layer material, the preparation of the B-layer material and the preparation of the C-layer material respectively comprise material mixing, feeding and mixing modification; and the specific steps are as follows: S1, the preparation of the A-layer material: a, material mixing: feeding a recycled crushed material, PP1, PP2 and an auxiliary agent mixture to a material storage barrel through a vacuum material suction system according to a formula ratio, discharging materials to a material mixing bin according to the formula ratio through a weighing mixer, carrying out mixing and stirring at a high speed in the material mixing bin to form an A-layer mixture, and then discharging the A-layer mixture to a main machine material storage barrel. The production process of the novel environment-friendly plastic building template has the main beneficial effects that the matching accuracy is high, the labor waste is avoided, the cost is saved, the working efficiency is high, the wear resistance, the temperature resistance, the weather resistance and the chemical resistance are achieved, and energy conservation, environmental protection and emission reduction are achieved.

Owner:福建塑鑫旺新能源有限公司

Control system for adjusting the center line of the tail of the uncoiler and its application method

ActiveCN103753220BShorten the timeIncrease productivityOther manufacturing equipments/toolsControl systemEngineering

The invention discloses a control system used for the tail of an uncoiler to adjust the central line of the uncoiler. The control system comprises the uncoiler, a feeding roller, a cutter, a stacker and a first control device, an auxiliary control device used for controlling left-right movement of the feeding roller is arranged on one side of the tail of the uncoiler, and the auxiliary control device is connected with the first control device and the uncoiler through a network line to form the Internet of Things. The invention further discloses a method for using the control system to adjust the central line of the uncoiler. The auxiliary control device is arranged at the tail of the uncoiler, so that after measuring whether coil stock deviates or not at the tail of the uncoiler in the process of uncoiling, a worker can directly control the feeding roller to move leftwards and rightwards on the auxiliary control device arranged at the tail of the uncoiler so as to adjust the central line of the uncoiler, and does need to run to the front portion of the uncoiler to operate the first control device, saving of time is facilitated, and production efficiency is improved.

Owner:佛山宝钢不锈钢贸易有限公司

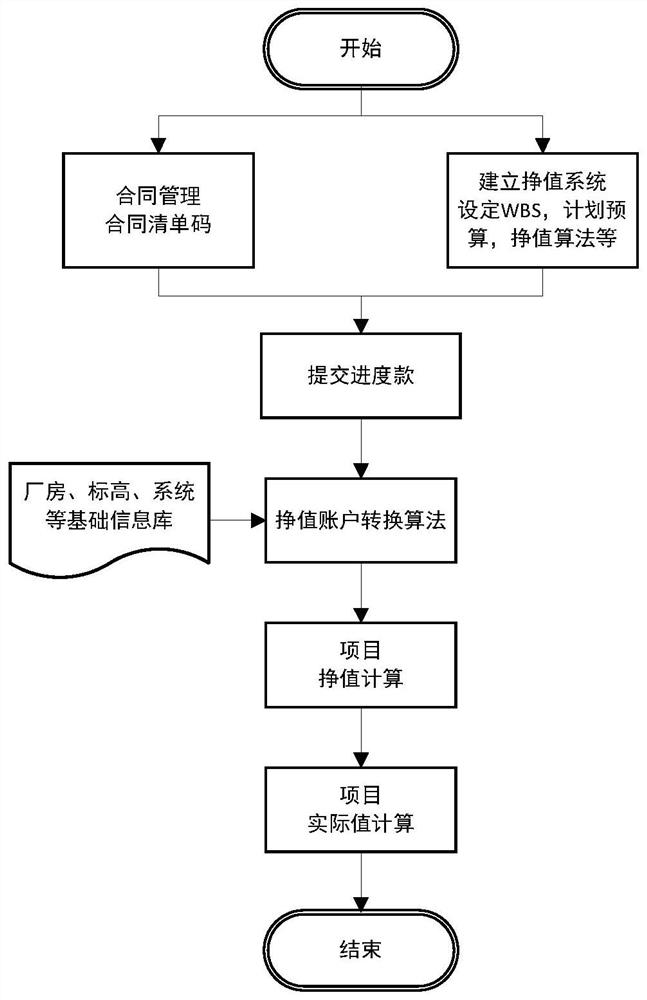

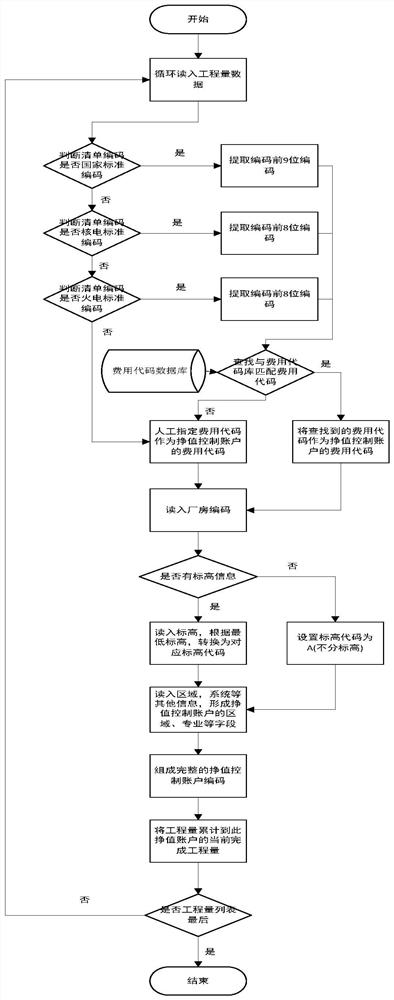

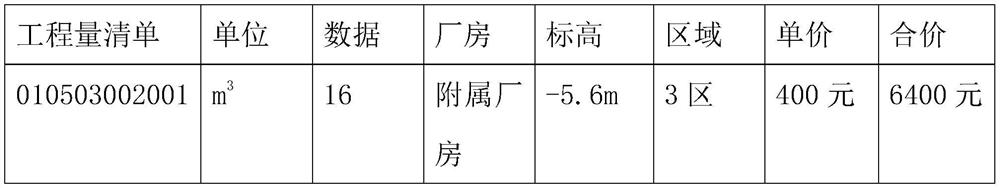

Method for converting progress fund data into earned value system data

PendingCN113570217AAvoid labor wasteImprove efficiencyDigital data information retrievalResourcesData transformationProject manager

The invention belongs to the field of conversion processing methods of model data formats, and particularly discloses a method for converting progress fund data into earned value system data, which comprises the following steps: establishing a project earned value system: establishing a WBS structure and setting a control account according to actual selection; initializing a contract list; submitting progress money; performing automatic switching; calculating a earned value; and calculating an actual value: according to the earned value control account corresponding to the engineering quantity list code, assigning the audited amount to each earned value account to obtain the actual value of the earned value system. According to the invention, automatic conversion is realized, labor waste caused by manual conversion is avoided, the efficiency and quality are greatly improved, the project cost management level can be greatly improved, the working efficiency of project managers is improved, and effective connection and cooperation of management teams are promoted.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Emergency intubation fixing device for unconscious patient

InactiveCN114849001AImprove stabilityPrevent Tongue Biting SituationsTracheal tubesChemicalsPhysical medicine and rehabilitationApparatus instruments

The invention discloses an emergency intubation fixing device for unconscious patients, and belongs to the field of medical instruments. An emergency intubation fixing device for unconscious patients comprises a supporting shell, an occlusion cavity, an occlusion limiting part, a storage cavity and an elastic pressing strip. The supporting shell is cylindrical, an axial through center inserting hole is formed in the axis position of the supporting shell, limiting elastic protrusions are arranged in the center inserting hole in a surrounding mode, meshing cavities which are symmetrically arranged relative to the center inserting hole are formed in the outer side curved surface of the supporting shell, the meshing limiting parts are arranged in the meshing cavities, and the containing cavity is formed in the supporting shell. The storage cavity is provided with an opening in any circular side plane of the supporting shell, and the elastic pressing strip is arranged in the storage cavity in a sliding mode. The oral cavity of a patient is supported through the supporting shell, the situation that teeth bite the tongue when the patient is in an unconscious state is prevented, and meanwhile the stability of the patient when the teeth of the patient bite the supporting shell can be improved by putting the teeth of the patient into the bite cavity.

Owner:QUZHOU UNIV +2

Textile fabric transporting device

The invention discloses a textile fabric transporting device comprising a supporting plate. A baffle is fixedly connected to the outer wall of one side of the supporting plate. A connecting block is fixedly connected to the outer wall of the side, away from the supporting plate, of the baffle. A steering rod is rotationally connected to the inner surface of the connecting block and perpendicularlypenetrates through the interior of the connecting block. A steering wheel is fixedly connected to the upper end of the steering rod. An illuminating lamp is fixedly connected to the outer wall of theside, close to the baffle, of the steering rod. A control panel is fixedly connected to the outer wall of the side, away from the illuminating lamp, of the steering rod. A seat plate is fixedly connected to the outer wall of the side, away from the baffle, of the connecting block. The textile fabric transporting device is simple in structure, it can be ensured that people observe the situation ofcloth roll fabric in the transporting device at every moment, the purpose that the device is electrically driven can be achieved, waste of labor force due to manual pushing and pulling is avoided, the cloth roll fabric can be effectively fixed, rolling of the cloth roll fabric is prevented, and the safety in the transporting process of the cloth roll fabric is ensured.

Owner:XIANGSHUI ZHONGXING TEXTILE CO LTD

Gear transmission sericulture device

ActiveCN107494463BPromote growth and developmentQuality improvementAnimal husbandryGear driveGear wheel

The invention discloses a gear-driven sericulture device which comprises a support frame body, a plurality of silkworm cocoon tray layers, a lifting mechanism and a hoisting mechanism, wherein a space for accommodating a silkworm cocoon lattice cluster is formed in each silkworm cocoon tray layer; the lifting mechanism comprises a plurality of pairs of lifting components, each lifting component comprises a pair of upper positioning blocks, a pair of lower positioning blocks and a pair of V-shaped hinged frames; the hoisting mechanism comprises a gear pair and a pair of hoisting components, the gear pair comprises a first gear and a second gear which are mutually meshed, and each hoisting component comprises a drive rod and a driven rod parallel to a group of opposite sides of each silkworm cocoon tray layer. The gear-driven sericulture device disclosed by the invention can reach an equivalent height and is high in space utilization rate; and operation personnel can finish operation on the ground, so that both time and labor are saved, and therefore, the practical value is high.

Owner:NANJING ZHIQIAO AGRI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com