Winding core shaft of small roll cutting machine

A technology of slitting machine and winding mandrel, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of unfavorable core size adjustment, low efficiency, etc., and achieves simple structure, convenient use and fast speed. The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

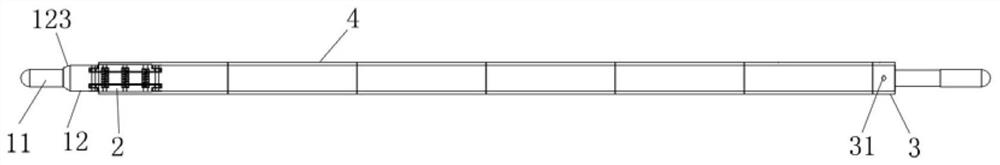

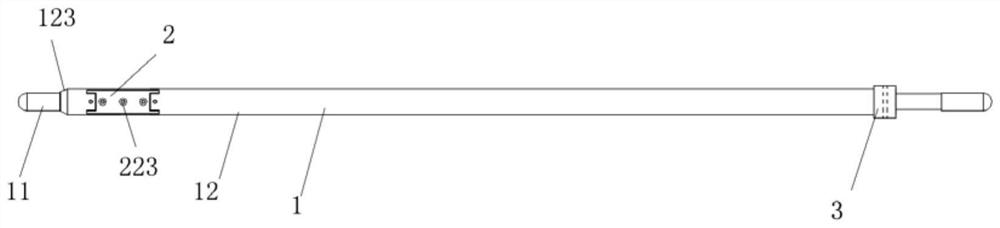

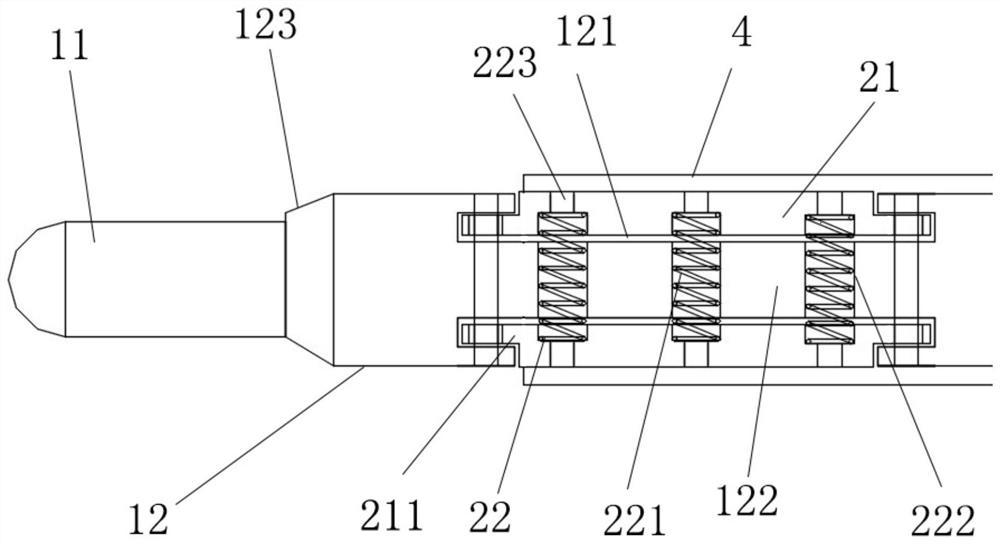

[0029] In a further embodiment of the present invention, the connection between each support section 11 and the installation section 12 is arranged as a truncated cone structure 123, and the diameter of the end of the truncated cone structure 123 near the installation section 12 is larger than that of the end of the truncated cone structure 123 near the support section 11. diameter at one end.

[0030] In a further embodiment of the present invention, the diameters of the two support sections 11 are both smaller than the diameter of the installation section 12 . Further, in order to better complete the production of small roll materials and to facilitate the assembly of the winding core 4, the diameter of the supporting section 11 is smaller than that of the installation section 12, so as to play a guiding role when the winding core 4 is loaded.

[0031]In a further embodiment of the present invention, the positioning ring 3 has a circular ring structure, the positioning ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com