A construction method of strip foundation

A strip foundation and construction method technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of affecting the construction progress of the project, low manual work efficiency, and slow progress of the project, so as to achieve high construction efficiency, reduce construction costs, avoid The effect of wasted labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Shandong Water Margin Hometown Tourist Distribution Center Project

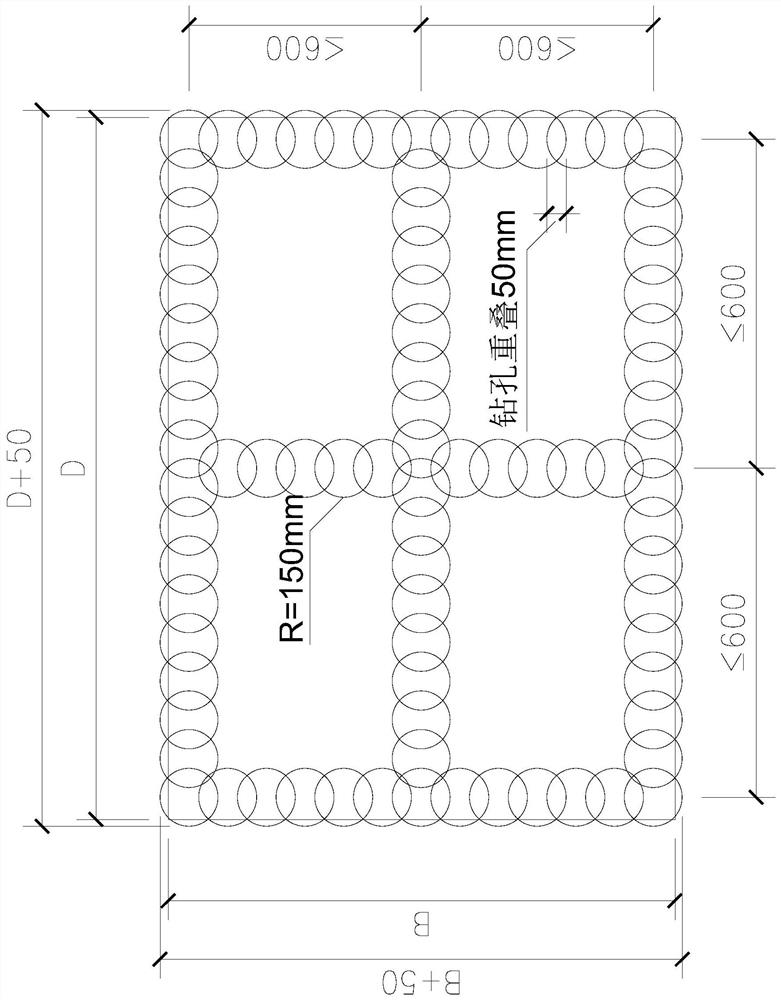

[0033] Shandong Water Margin Hometown Tourist Distribution Center project consists of three commercial areas A, B and C, poverty alleviation residential buildings, Evergrande Vocational and Technical College and Evergrande National Middle School. The total land area is about 154369.4m 2 , with a construction area of approximately 681.562 million m 2 . The number of floors in the commercial area is 2-3 floors, the height of the first floor is 4-5.4m, the height of the second floor is 4-6.7m, the building height is about 20m, the structural form is frame structure, and the foundation form is single foundation and strip foundation . The strip foundation is constructed according to the following construction methods:

[0034] 1. Site leveling

[0035] Before leveling the site, remove trees and construction waste on the ground. Use the grid to calculate the construction elevation, excavati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com