Controllable elevated working platform

A technology for lifting and lowering workbenches and tabletops, which is applied in the direction of workbenches and manufacturing tools, can solve the problems that the workbench has no folding function, cannot provide a workbench, is unfavorable for carrying and handling, etc., so as to avoid wasting labor, improve work quality, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

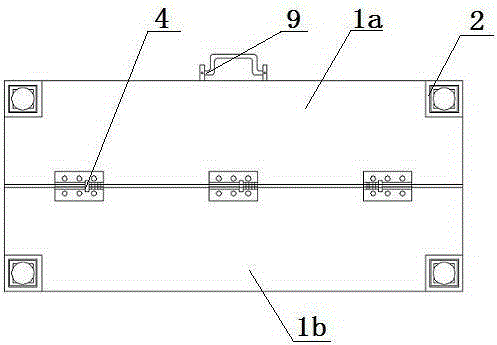

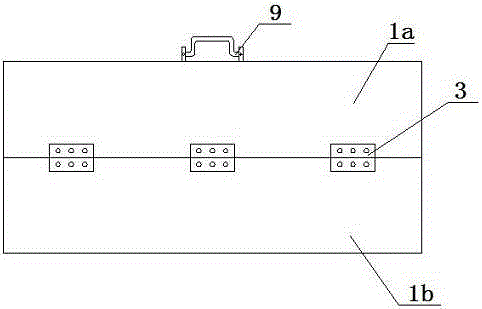

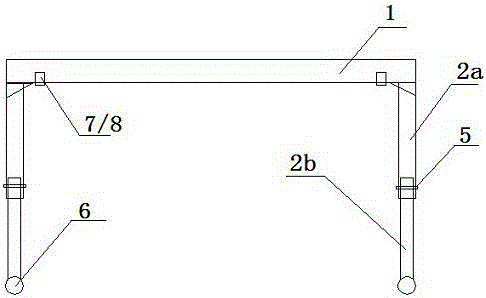

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a controllable lifting workbench includes a platform 1 and legs 2, the legs 2 are foldably installed on the bottom surface of the platform 1 through a hinge, and the platform includes a hinge 3 The hinged first deck 1a and the second deck 1b are provided with a locking mechanism 4 at the folds of the first deck 1a and the second deck 1b. repeat; such as Figure 4 As shown, the legs include a first leg 2a and a second leg 2b, the second leg 2b is telescopically inserted into the first leg 2a from bottom to top, and the first leg 2a and the second leg 2b is provided with matching slots, and positioning screws 5 are arranged in the slots, and the positioning screws 5 pass through the slots 2d on the first leg 2a and the second leg 2b successively and are fastened by nuts. To adjust the height of the legs, a scale 2c is provided on the outer peripheral wall of the slot of the first leg 2a; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com