Control system used for tail of coiler to adjust central line of coiler and using method of control system

A technology of control system and uncoiler, which is applied in the field of control system, can solve problems such as unfavorable enterprise development, waste of labor force, and long time spent, so as to achieve the effect of enhancing social competitiveness, avoiding labor waste, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

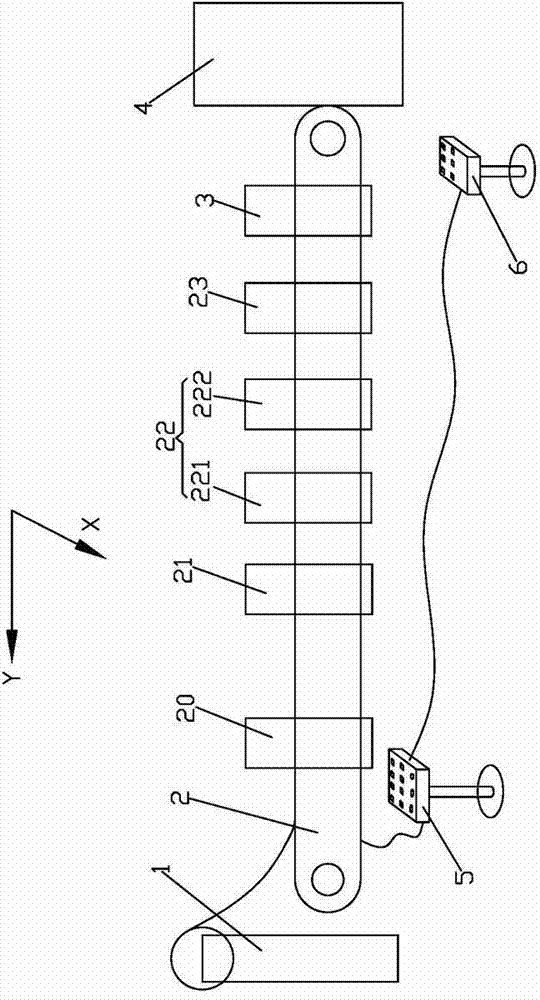

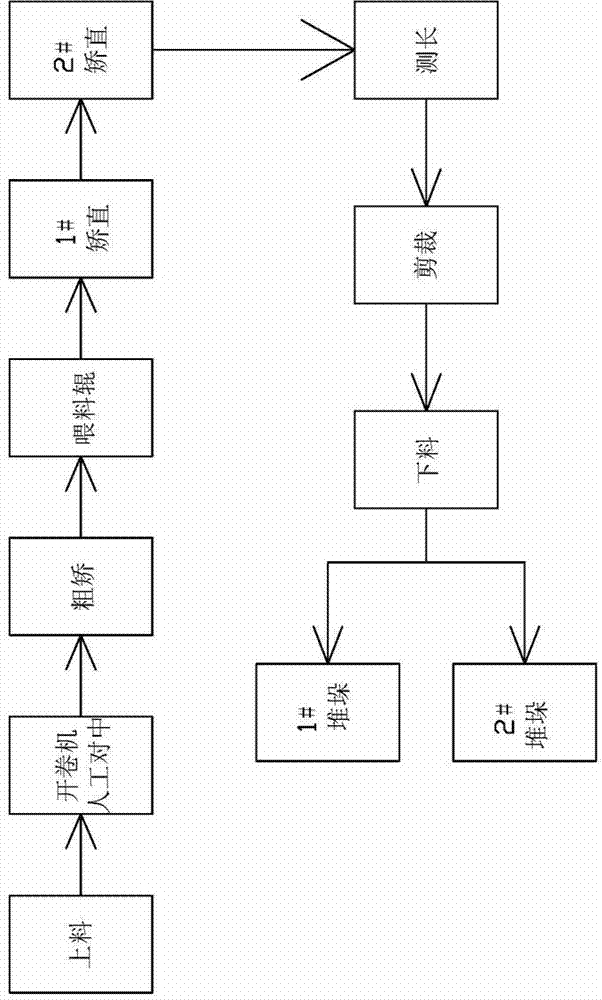

[0018] refer to figure 1 ,figure 2( figure 1 The direction shown by the middle arrow Y indicates the front direction of the uncoiler, and the arrow X indicates the left direction of the uncoiler), which is used to adjust the centerline control system at the tail of the uncoiler, including the uncoiler 2 and the movable installation on the uncoiler 2 The front end and the feeding roller 1 that can move left and right along the direction perpendicular to the axis of the uncoiler, here as a preferred embodiment of the present invention, the feeding roller 1 is driven by a hydraulic motor to move left and right, and the uncoiler 2 The tail is provided with a cutter 3 for cutting the flattened coils, and one side behind the cutter 3 is provided with a stacker 4 for stacking the trimmed coils, and the uncoiler 2 One side of the front part is provided with a first control device 5 for controlling the left and right movement of the feeding roller 1, preferably, the first control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com