A three-phase rotating structure all-round dust-suppressing and expanding pipe clamping and processing integrated machine

A rotating structure, all-round technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of single use of cutting and grinding devices, easy to float in the air, and threaten the operator's body, so as to reduce labor costs Labor intensity, the effect of avoiding labor waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of this patent will be described in further detail below in conjunction with the specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted.

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

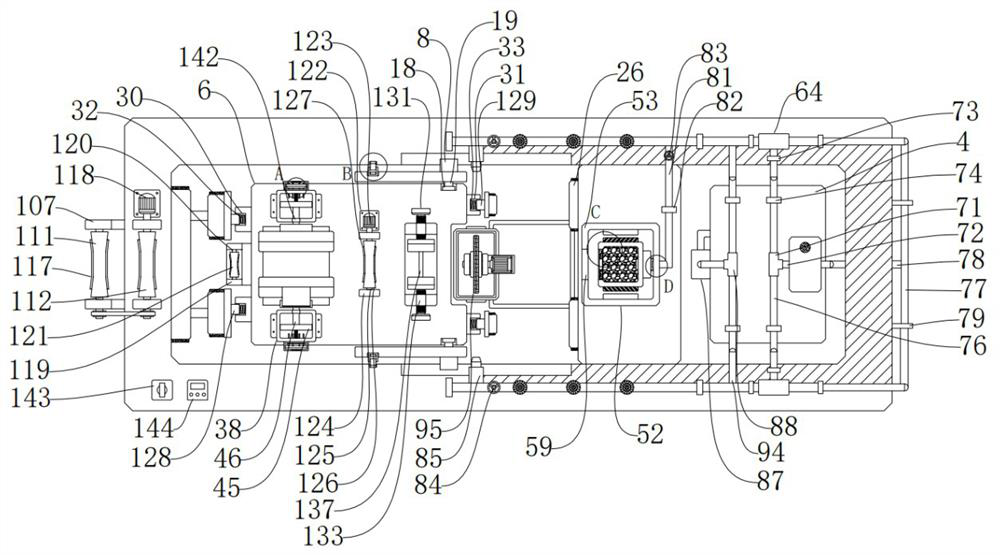

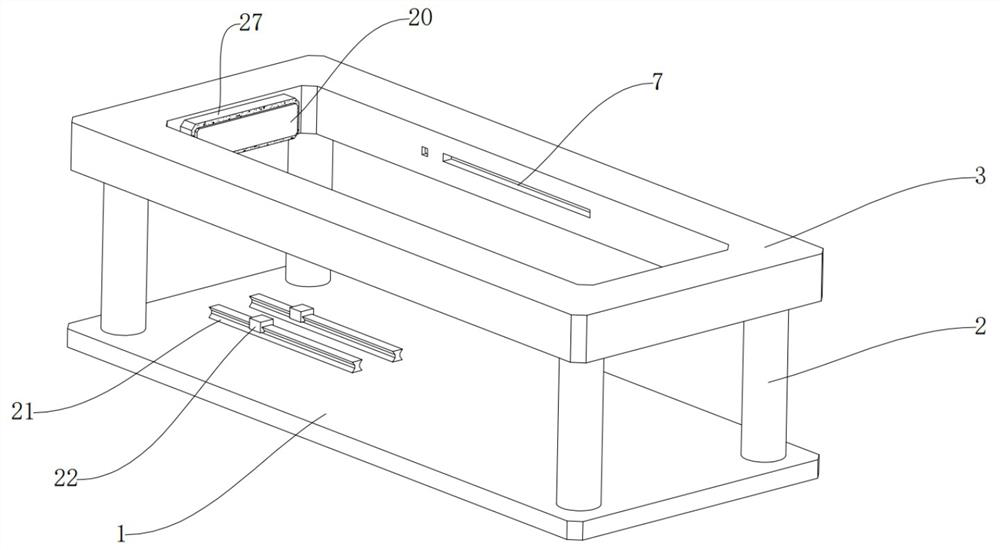

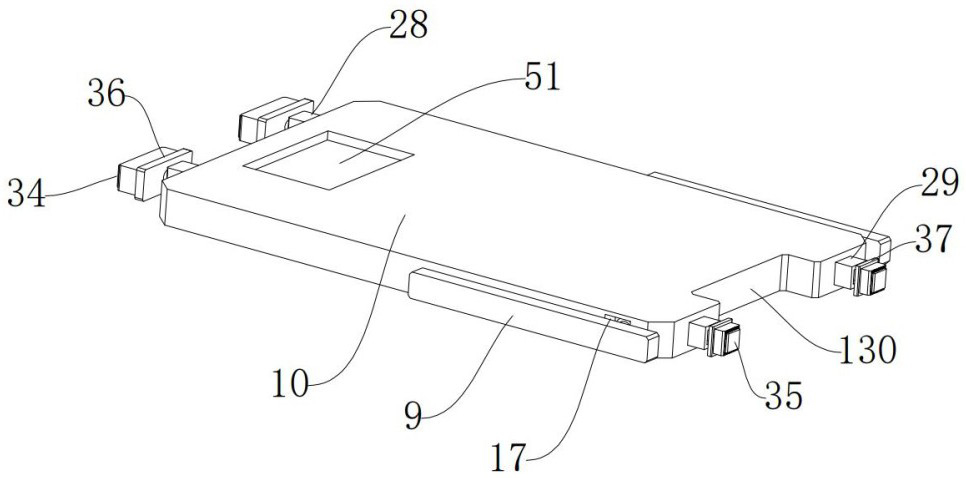

[0034] Such as Figure 1-6As shown, the present invention is a three-phase rotating structure omni-directional dust-suppressing expansion type pipe clamping and processing integrated machine, including the technical solution adopted by the present invention as follows: The present invention is a three-phase rotating structure omni-directional dust-suppressing expansion type pipe clamping Processing integrated machine, including multi-functional bearing base 1, square support column 2, self-contained slot processing frame 3, all-round dust suppression cooling water mis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com