Rotor type external combustion engine air cylinder and rotor type external combustion engine

An external combustion engine, rotor type technology, applied in the direction of machine/engine, hot gas variable capacity engine device, mechanical equipment, etc., to achieve the effect of improving work efficiency, high power output, and improving the ability of expansion to do work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

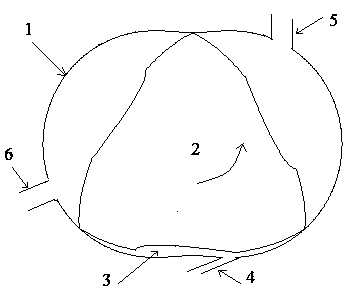

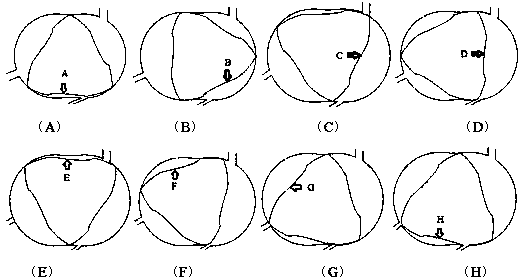

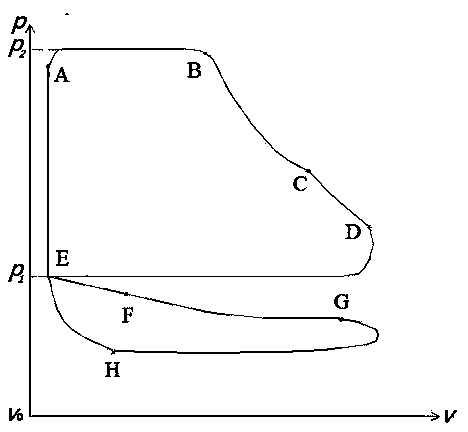

[0034] Such as figure 1 , figure 2 as well as Figure 5 As shown, a cylinder of a rotor-type external combustion engine includes a cylinder block 1, on which an intake pipe 4 and an exhaust pipe are arranged, and the inside of the cylinder block 1 also includes a triangular rotor 2; the triangular rotor 2 is in contact with the inner wall of the cylinder; The rotor 2 and the cylinder 1 form a working room 3, which is a dynamic airtight space; there are two exhaust pipes, including the primary exhaust pipe 5 and the secondary exhaust pipe 6; the inlet pressure of the intake pipe 4 is 10MPa ; The diameter of the air inlet pipe 4 is 40mm. In addition, the nozzle of the intake pipe 4 is located at the position where the short axis of the cylinder block 1 rotates 20° counterclockwise, and the angle formed by the center line of the intake pipe 4 and the long axis of the cylinder block is 25°. The included angle formed by the 5 nozzles of the primary exhaust pipe and the short a...

Embodiment 2

[0037] Same as embodiment 1, the difference is that the air inlet pressure is 25MPa, the diameter is 50mm, and the mouth of the air intake pipe 4 is located directly below the cylinder block, that is, at the short axis, and the clamp formed by the center line of the air intake pipe 4 and the long axis of the cylinder body Angle is 10. The angle formed by the 5 nozzles of the primary exhaust pipe and the short axis of the cylinder is 30; the angle formed by the 6 nozzles of the secondary exhaust pipe and the long axis of the cylinder is also 30.

Embodiment 3

[0039] Same as embodiment 1, the difference is that the air inlet pressure is 50MPa, the diameter is 60mm and the mouth of the air inlet pipe 4 is located at the position where the short axis of the cylinder rotates 45 degrees counterclockwise, and the centerline of the air inlet pipe 4 and the long axis of the cylinder form the The included angle is 40°. The angle formed by the 5 nozzles of the primary exhaust pipe and the short axis of the cylinder body is 45°; the angle formed by the 6 nozzles of the secondary exhaust pipe and the long axis of the cylinder body is also 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com