Stepless speed change automatic feeding device for centerless grinder

A technology of stepless speed change and automatic feeding, which is applied in the direction of grinding feed movement, grinding machine tool parts, grinding/polishing equipment, etc., to achieve reliable and balanced feeding, no need for demagnetization, and the effect of solving human efficiency problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

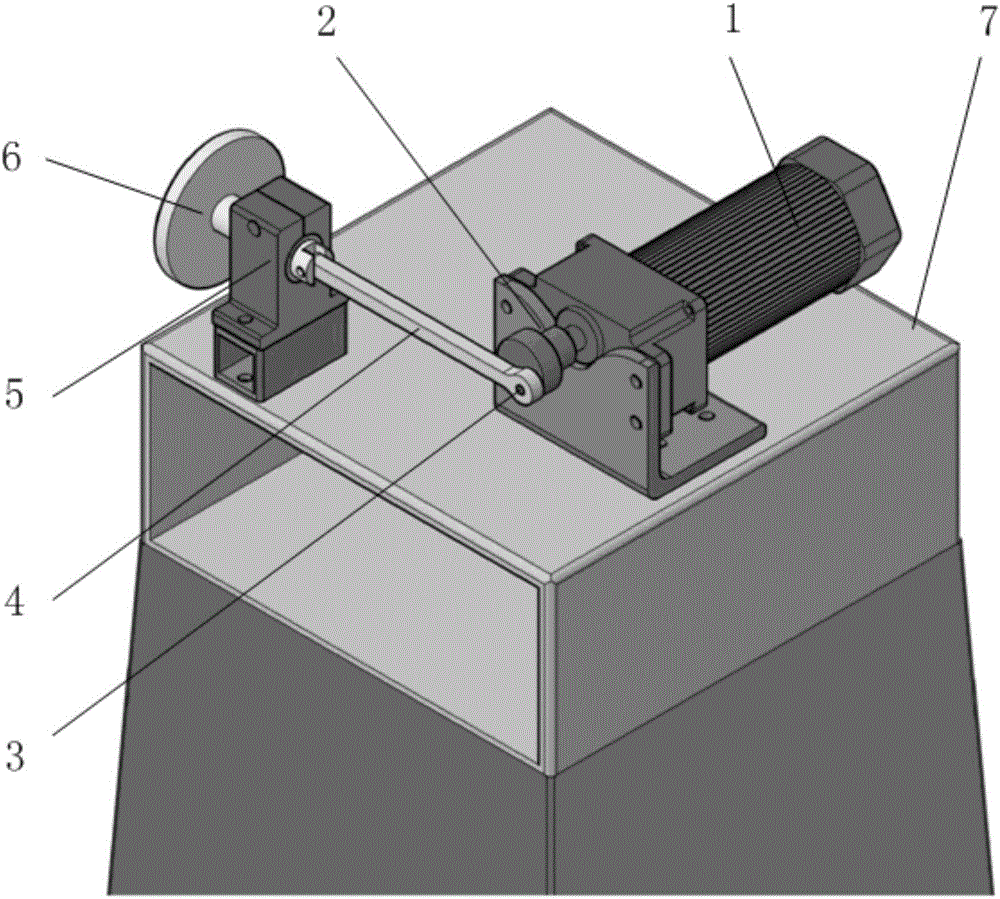

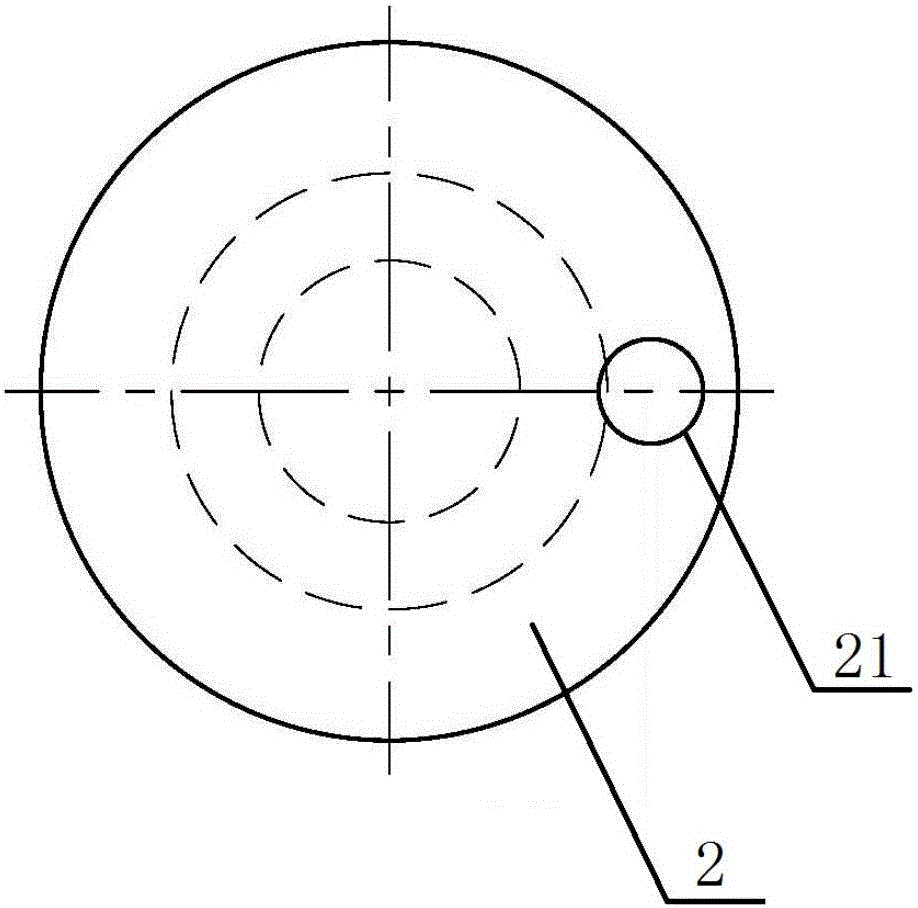

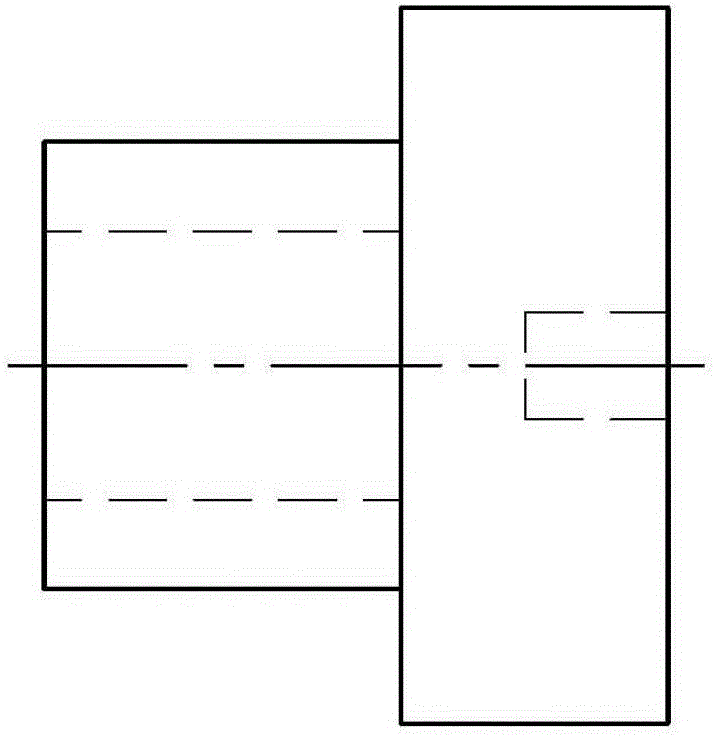

[0019] refer to Figure 1 ~ Figure 3 As shown, the stepless speed-variable automatic feeding device for the centerless mill of the present invention includes a servo motor 1, an eccentric runner 2, a connecting rod 4, a linear guide rail 5, a stripping head 6 and a base 7, and the servo motor 1 is installed on On the base 7, the eccentric runner 2 is connected with the output shaft of the servo motor 1, and one end of the connecting rod 4 is connected with the eccentric hole 21 of the eccentric runner 2 with a bolt 3 through the eccentric hole, and the other end is erected on the linear guide rail 5 and connected with the The material return head 6 is connected.

[0020] The eccentric runner 2 and the output shaft of the servo motor 1 are fastened and connected by bolts and keys.

[0021] The eccentric distance of the eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com