Inductance element provided with permanent magnet bias magnet and bypass magnetic core

A technology of inductive components and magnetic cores, which is applied to inductors with magnetic cores, transformer/inductor cores, etc., can solve the problems of reducing the inductance of inductive components, demagnetizing permanent magnets, and offsetting, so as to improve power density and increase Large inductance, reduce the effect of magnetic core saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings

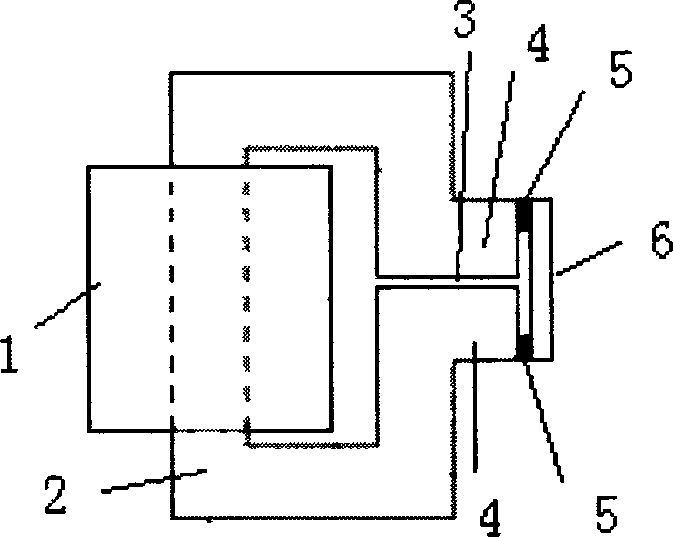

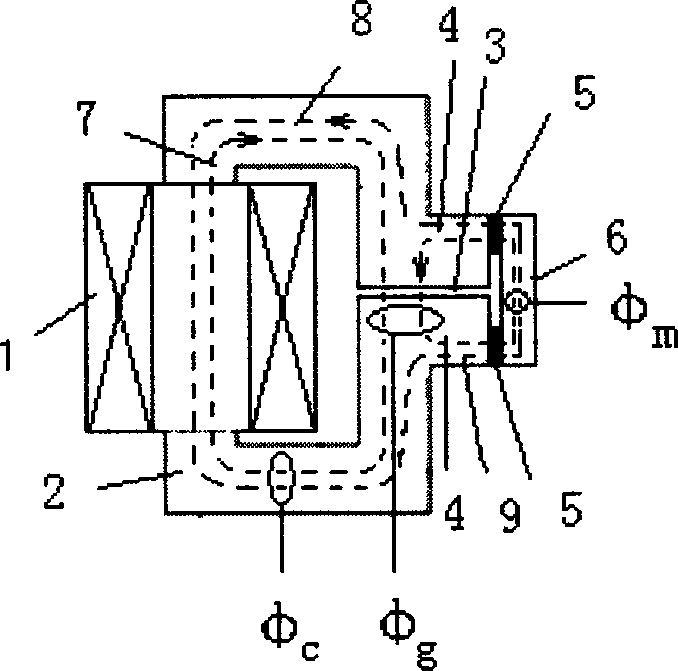

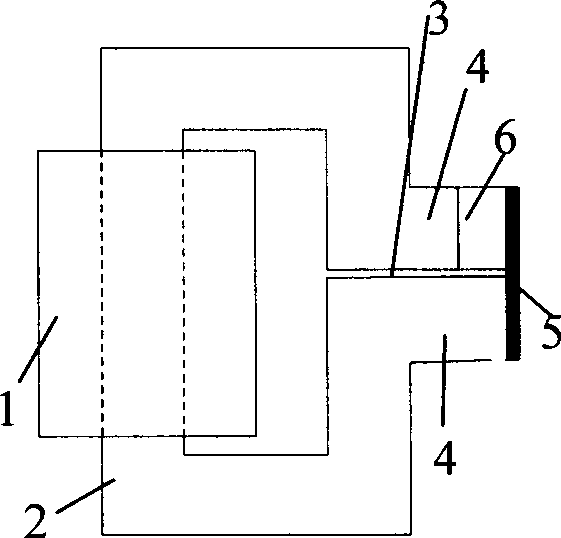

[0020] Such as figure 1 with image 3 As shown, the inductance element with permanent magnetic bias and bypass magnetic core of the present invention includes a coil 1, a magnetic core 2 with at least one air gap in the coil, and a local bypass soft magnet 4 that jointly constitutes an air gap 3. Magnetic shim 5 and permanent magnet 6.

[0021] Such as Figure 5 As shown, in addition to the coil 1, the magnetic core 2 with at least one air gap in the coil, the local bypass soft magnetic body 4 forming the air gap 3, the soft magnetic spacer 5 and the permanent magnet 6, the embodiment 3 is also added to avoid A plastic spacer 10 directly in contact with the air-gap magnetic core and the permanent magnet.

[0022] The magnetic flux generated by the permanent magnet is superimposed on the magnetic flux generated in the magnetic core when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com