Patents

Literature

30results about How to "Change speed ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

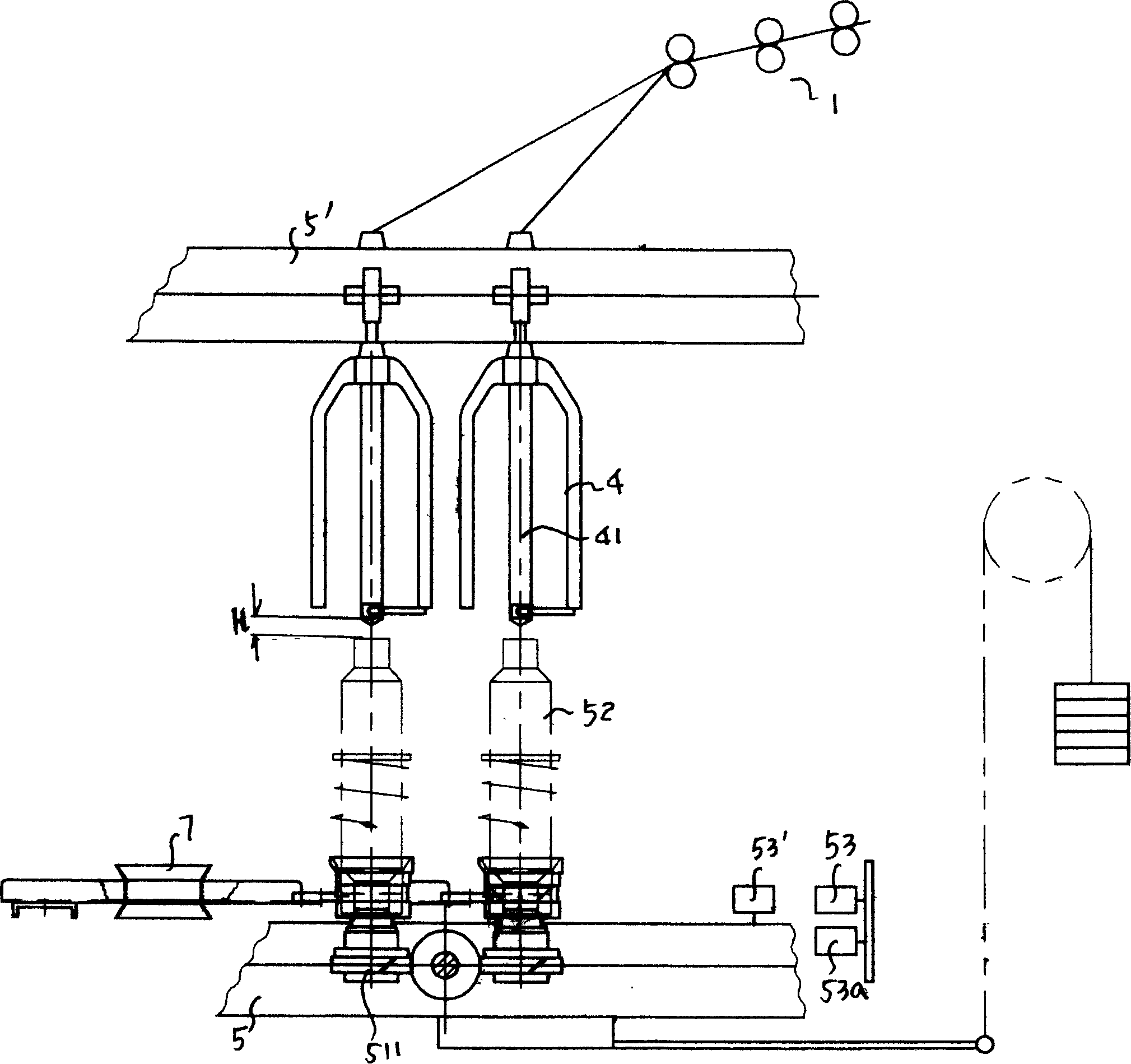

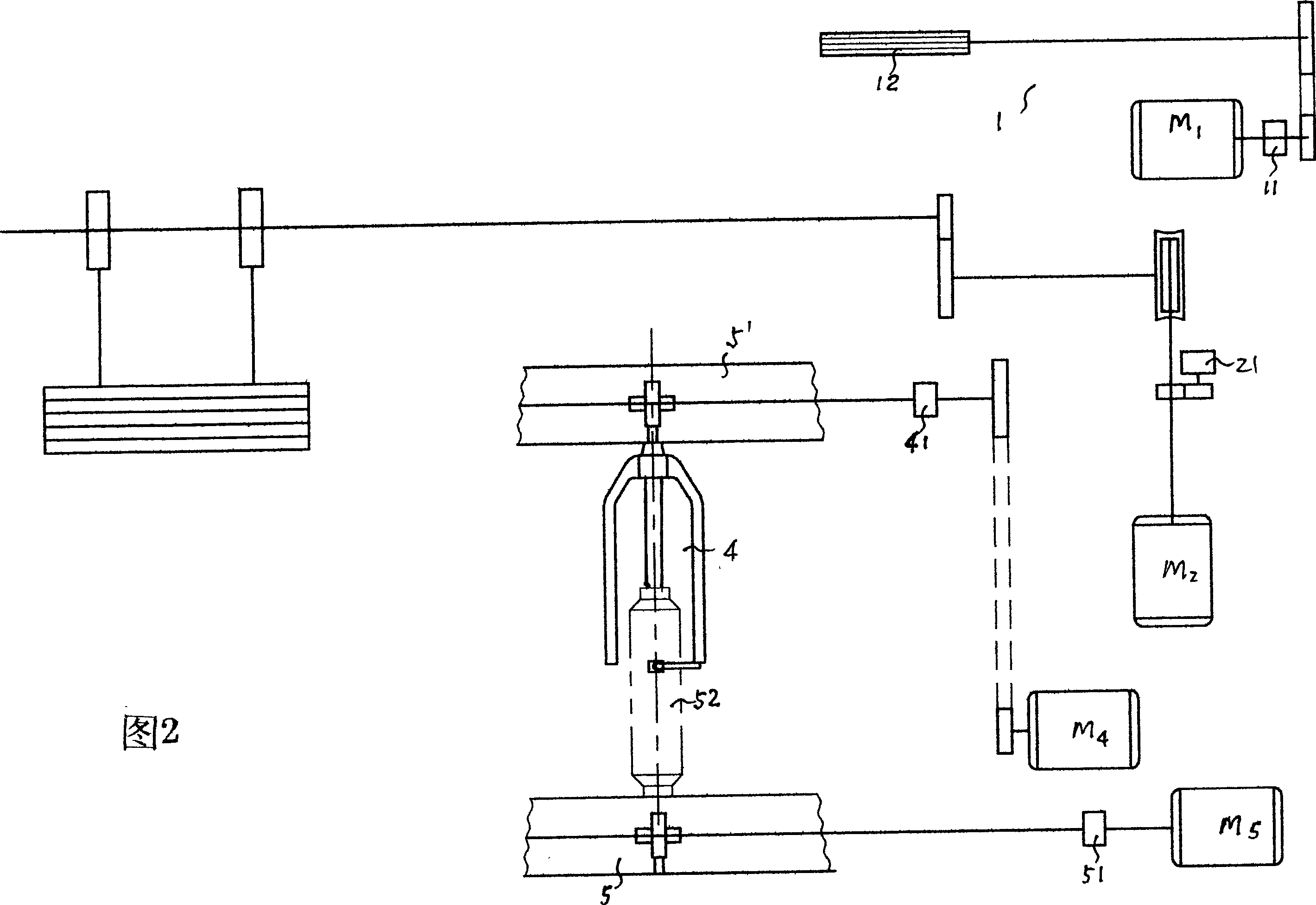

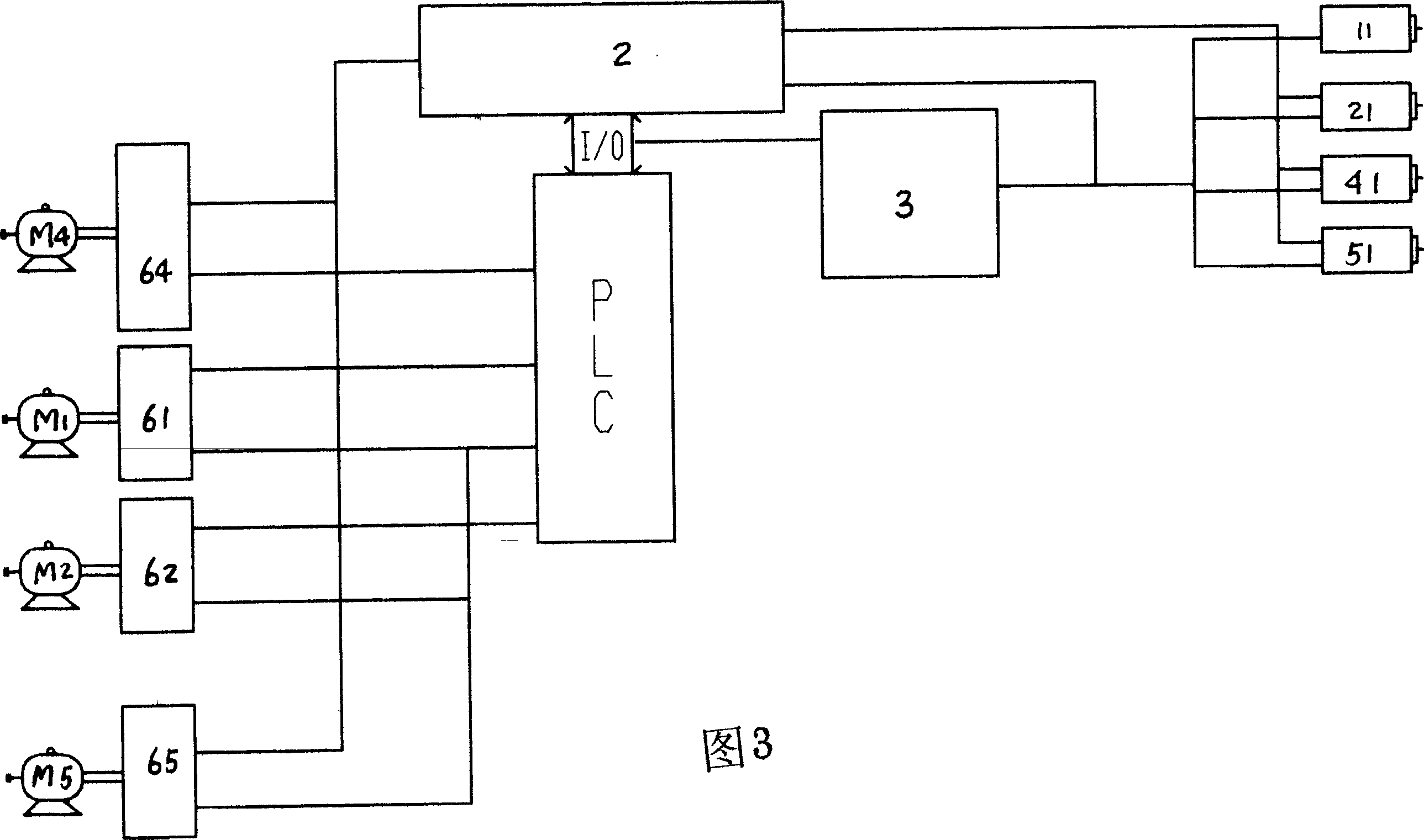

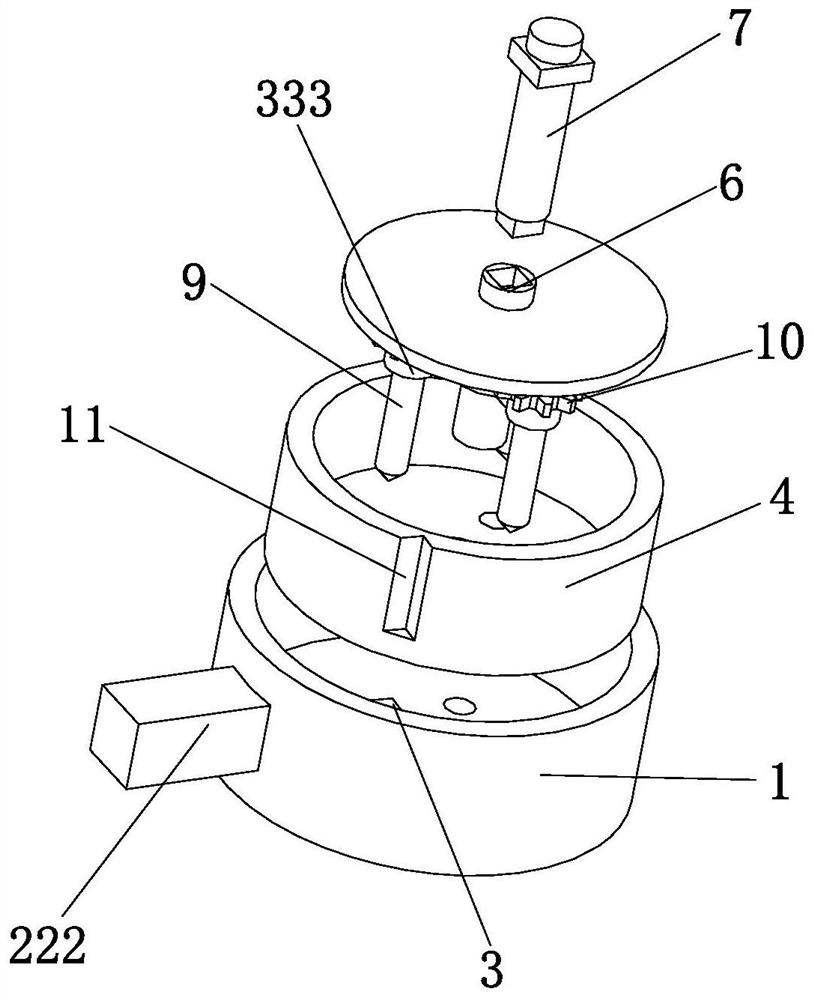

Method and device for automatic spinning repiece

InactiveCN1488798AOptimize structural configurationReduce twistPiercing arrangementsContinuous wound-up machinesYarnLow speed

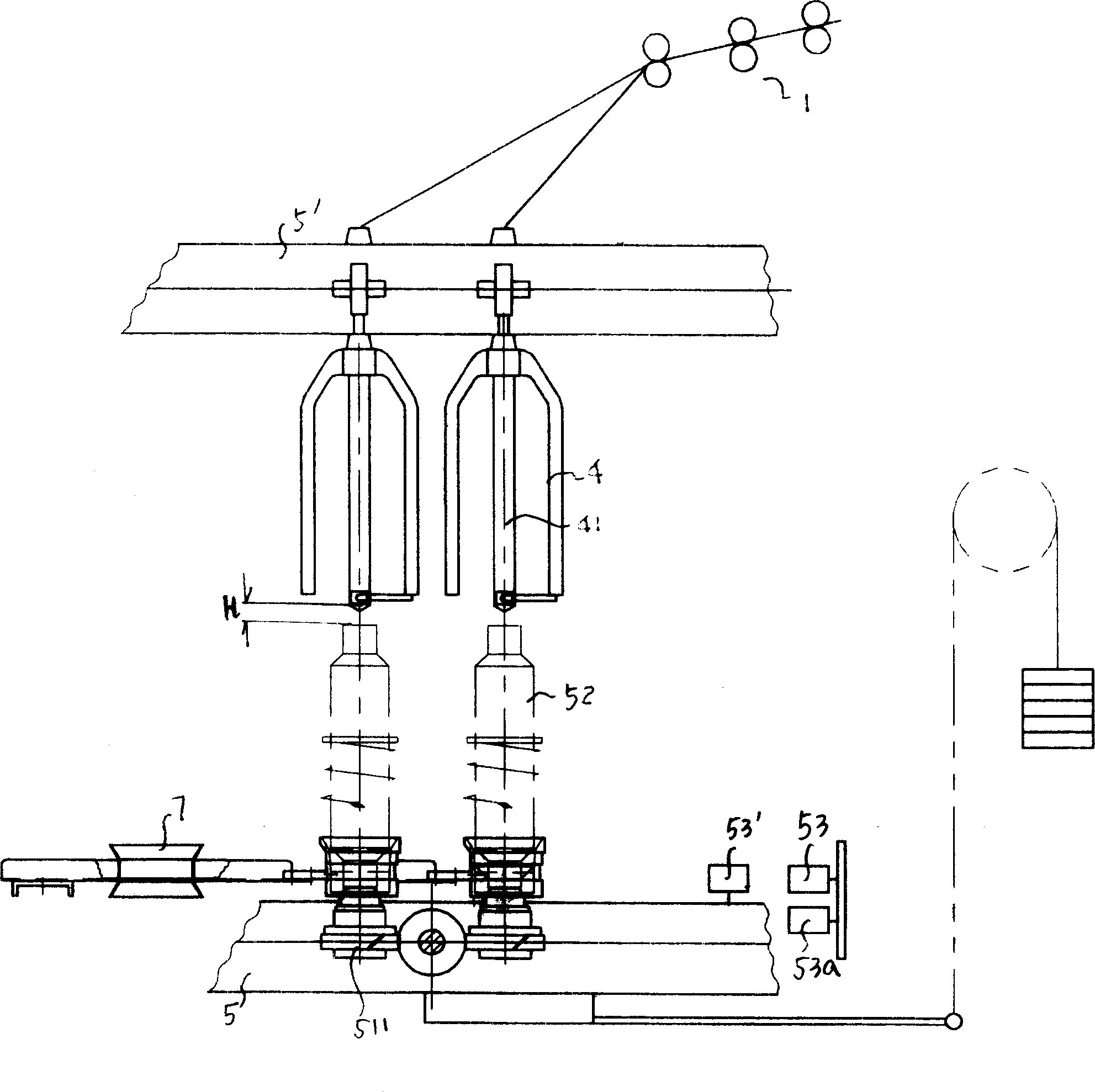

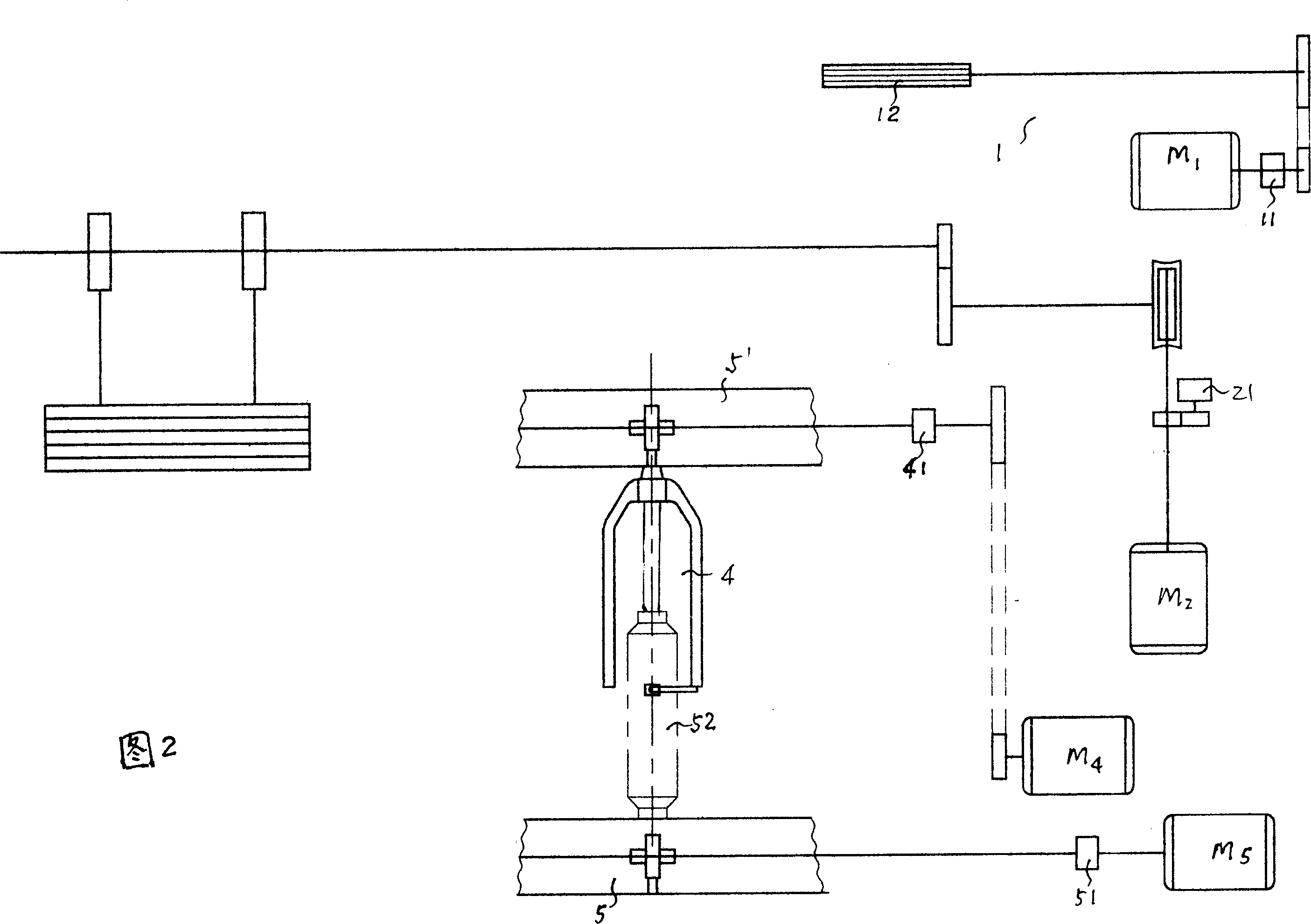

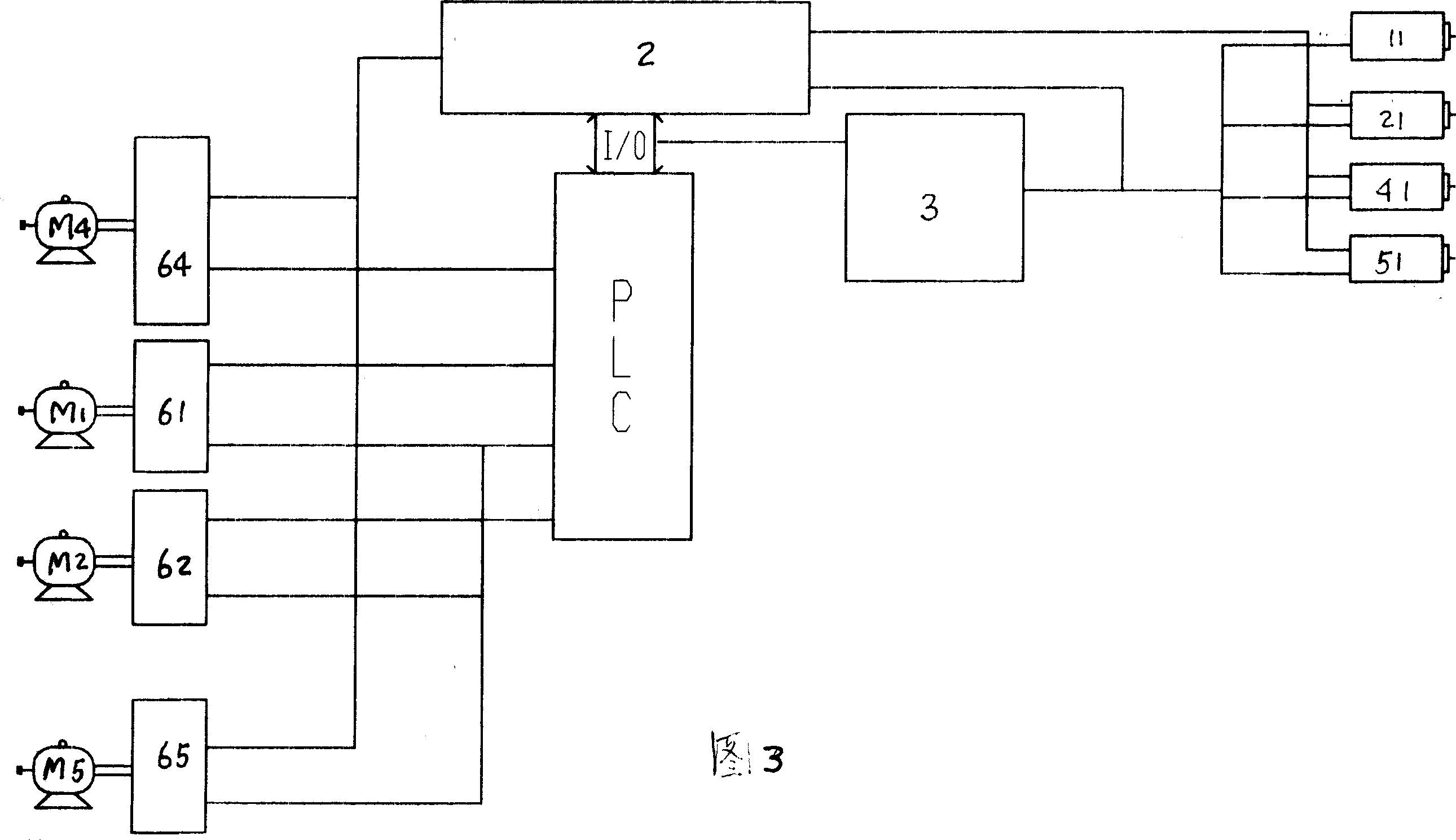

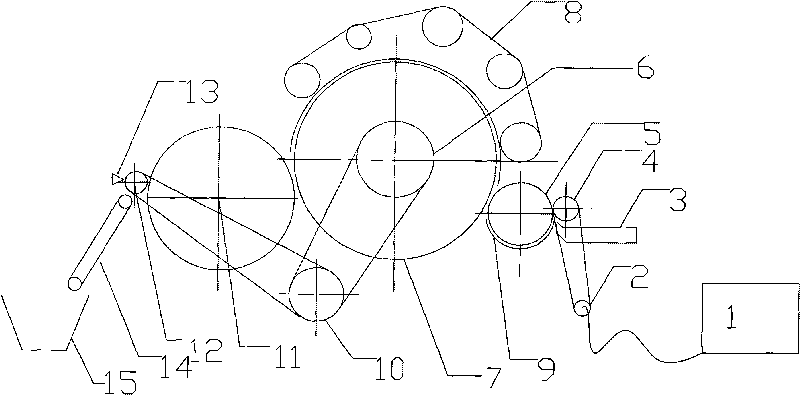

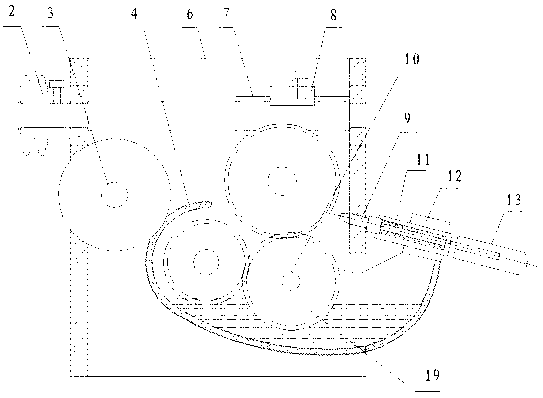

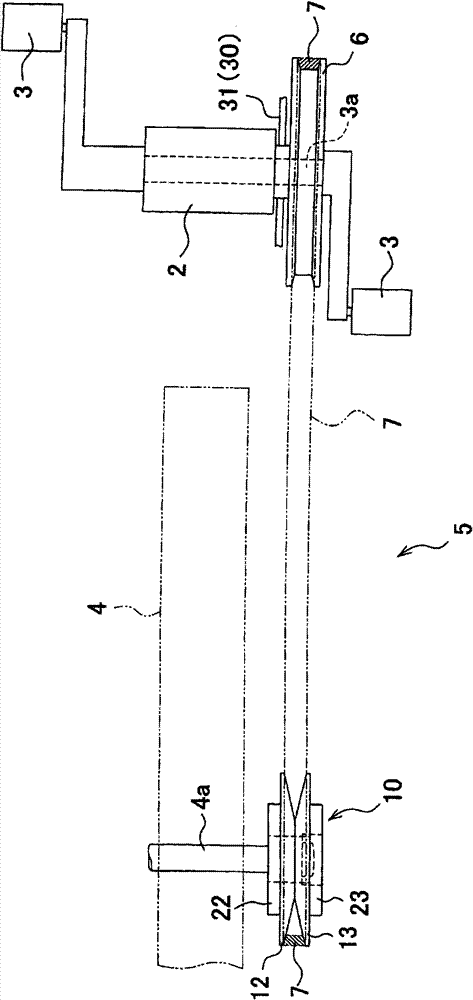

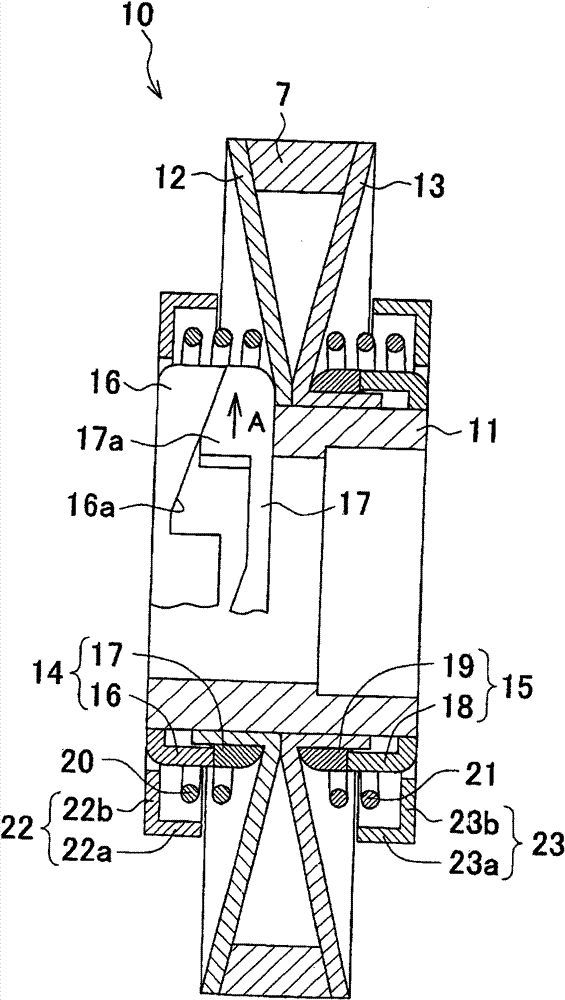

The present invention relates to an automatic spinning new end forming method and its equipment. The roving machine utilizes the coder positioned at the drafting portion position to detect the full-yarn length when the bobbin can be fulled, and makes the roving machine spin to a certain length in low speed, after the roving is spun to a certain length, makes the roving machine operate in low speed, at the moment makes the spindle rail stop lifting movement and makes the yarn be in said height position, winds 2-3 turns of halching and makes the spindle rail be quickly lowered to form large thread pitch wind so as to make the roving do not take-off in its transportation process; changes the speed ratio of flywer and roller so as to reduce roving twist, and obtain undertwisted roving, and when the ultralowering of spindle rail is made to place, the yarn is stretch-broken to produce fuzzy fibre whose length can be suitable for secondary automatic spinning new end formation.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

Production device of fiber color points and spinning method of color point yarns

The invention provides a production device of fiber color points and a spinning method of color point yarns, and improves the common cotton spinning machinery, i.e. adding a cotton feeding system on various carding machines, simultaneously being dispensed with a cotton stripping device, installing a stripping and conveying device, configuring all the technological parameters (e.g. transmission rate, cutting die, doffer space and the like) of the carding machines, and being reformed into a device capable of producing various fiber color points. The spinning method utilizes the production device, selects the kind and the dosage of an adhesive suitable for the fiber to produce color points with different size specifications, different tightness and extensive color change according to different fiber types during the production process of the color points.

Owner:广东广纺检测技术股份有限公司

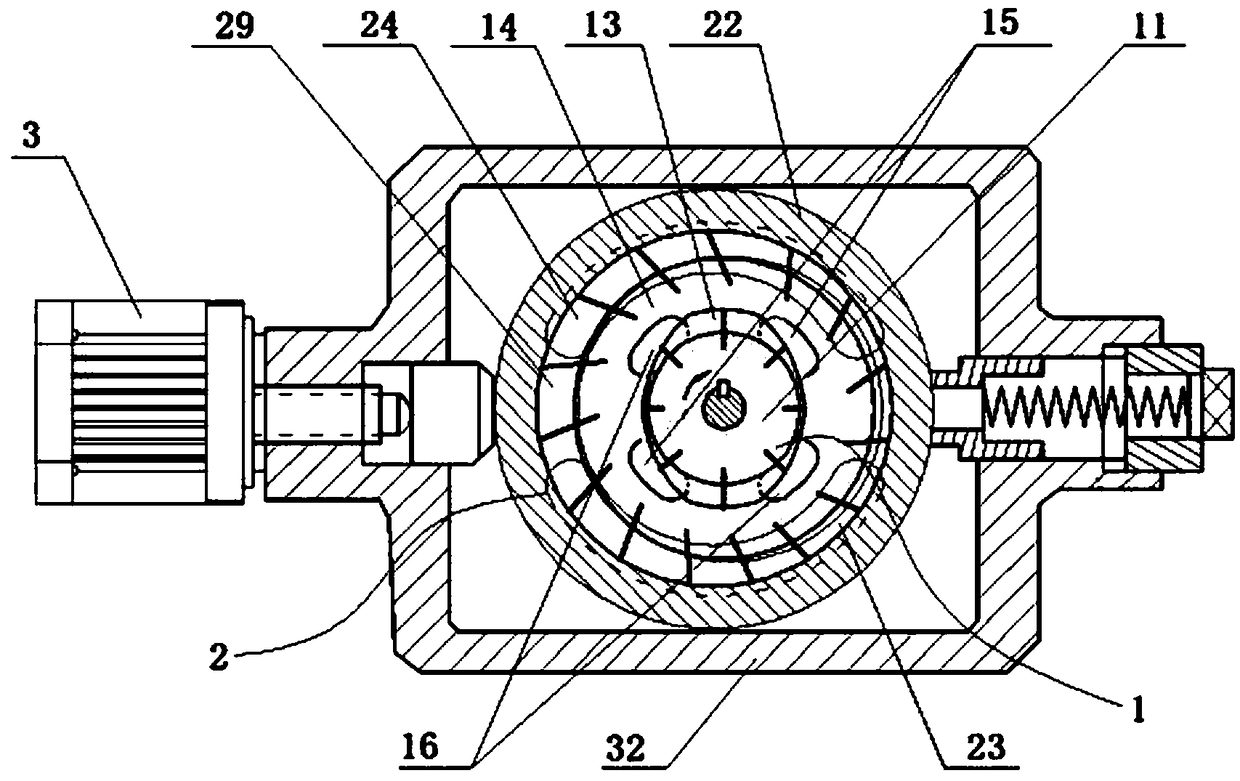

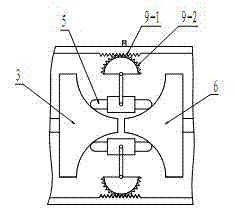

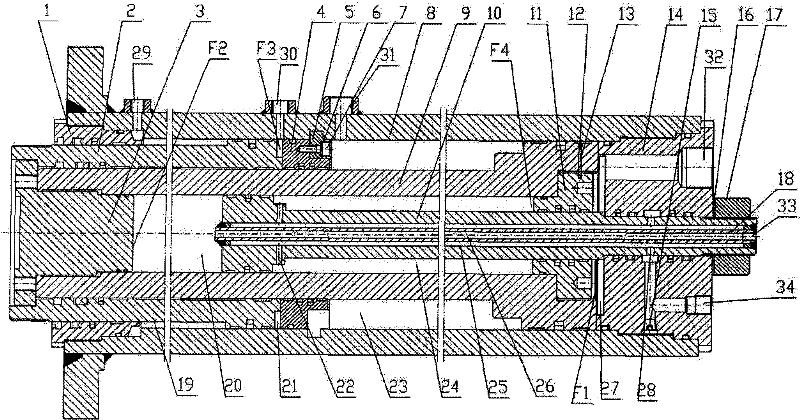

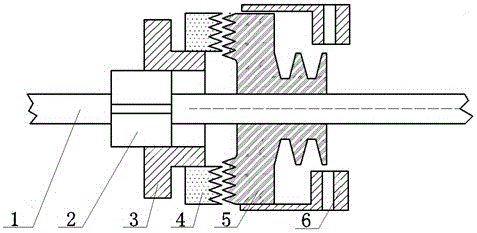

Multi-functional integrated type hydraulic cylinder

ActiveCN101893017AImprove matchLarge speed differenceFluid-pressure actuatorsHydraulic cylinderMaster cylinder

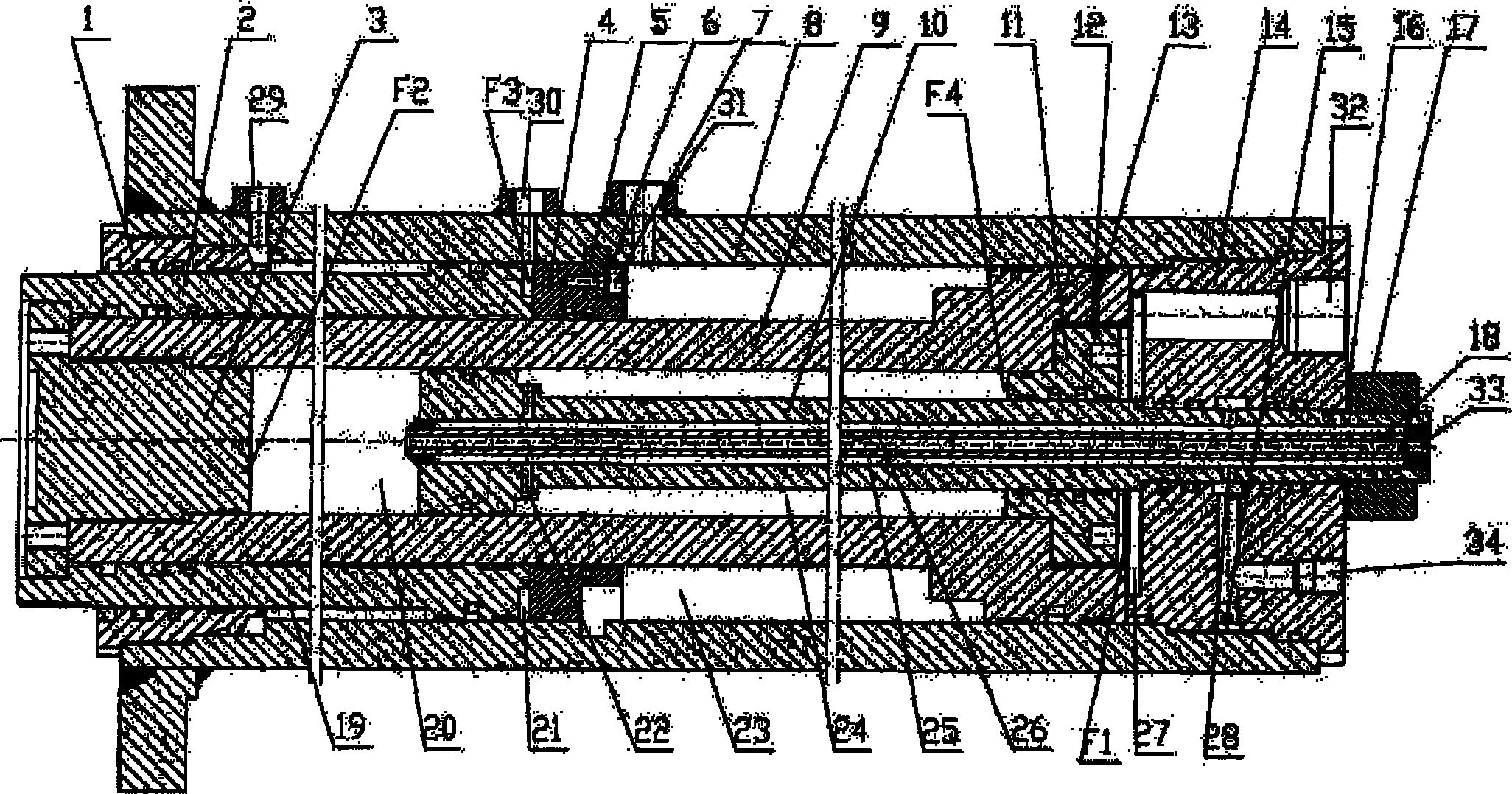

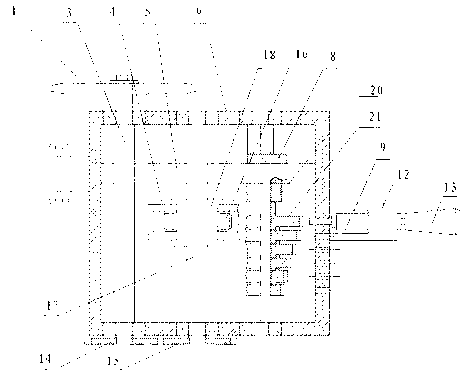

The invention discloses a multi-functional integrated type hydraulic cylinder. The multi-functional integrated type hydraulic cylinder comprises a main cylinder barrel, a main cylinder cover, a barrel-shaped main cylinder piston rod, a rapid cylinder guide sleeve, an isolating ring, a three-section card key and a main cylinder guide sleeve and is characterized in that: a first oil port, a second oil port and a third oil port are formed on the main cylinder barrel; a fourth oil port and a sixth oil port are formed on the main cylinder cover; a positioning cylinder guide sleeve is matched with the inner wall of the left end part of the main cylinder barrel; the inner wall of the positioning cylinder guide sleeve is matched with the outer wall of the main cylinder guide sleeve; the left end part of a barrel-shaped rapid cylinder piston rod is matched with the inner wall of the barrel-shaped main cylinder piston rod; the right end of the barrel-shaped rapid cylinder piston rod is connected with a locknut in a matching way; a rapid cylinder head is connected with the inner wall of the left end part of the barrel-shaped main cylinder piston rod in a matching way; a low-pressure oil inlet pipe is fixedly connected in the barrel-shaped rapid cylinder piston rod; and the right end of the low-pressure oil inlet pipe is a fifth oil port. The multi-functional integrated type hydraulic cylinder has the advantages of compact structure, high circulating operation speed, high working pressure, large thrust force of a working condition, high power density and convenient installation.

Owner:泸州众大科技液压件有限公司

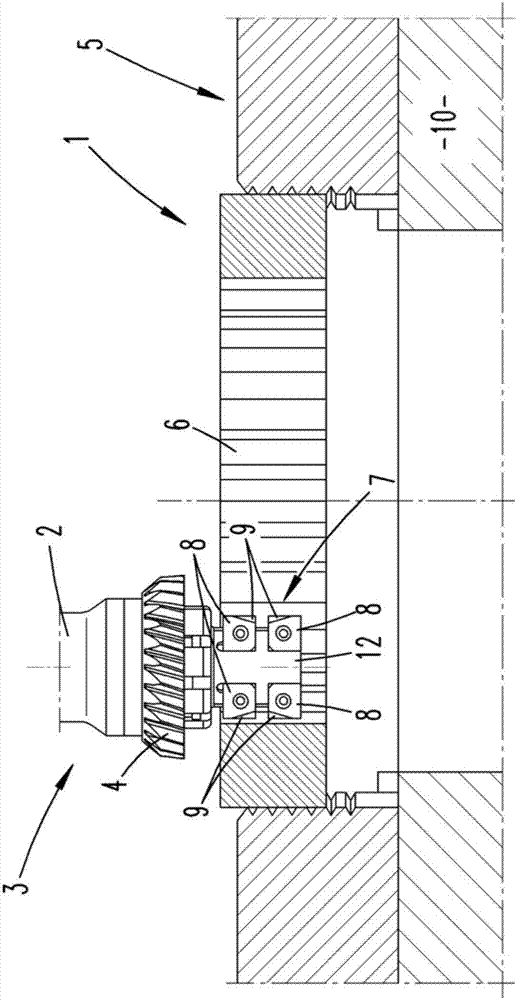

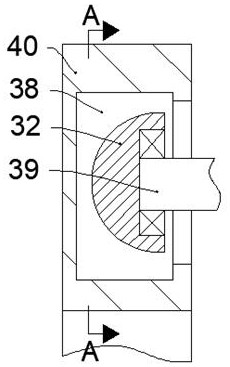

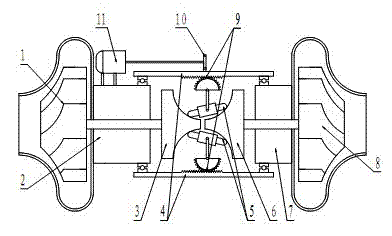

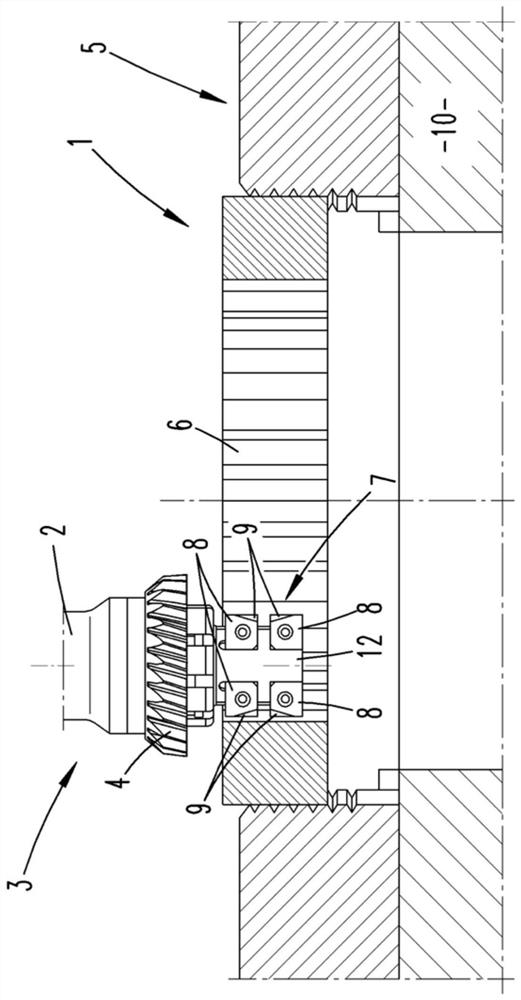

Lathe sliding box

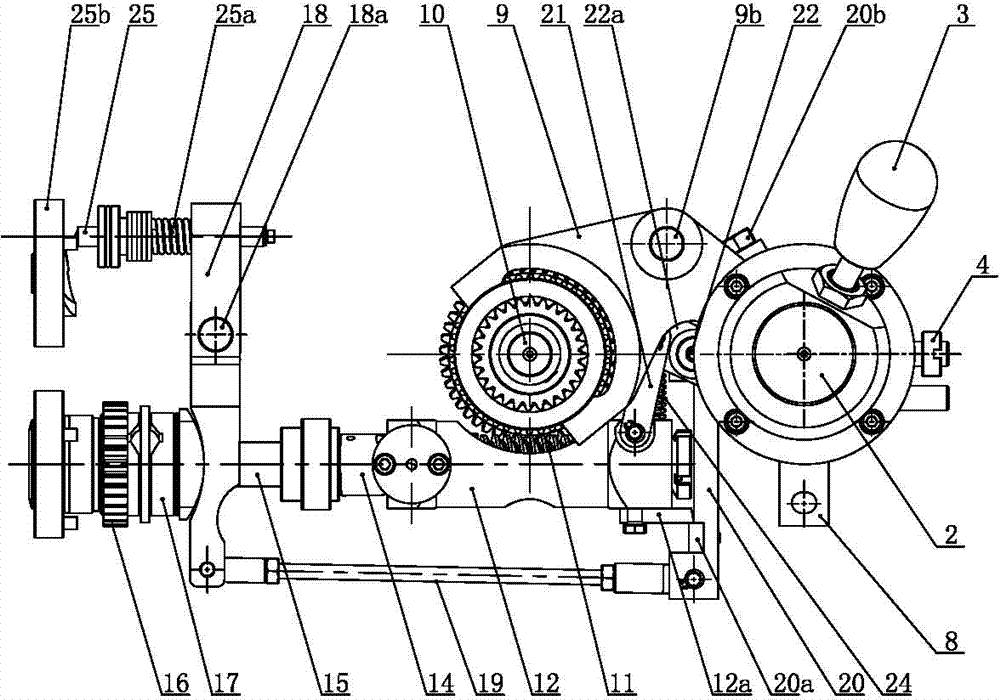

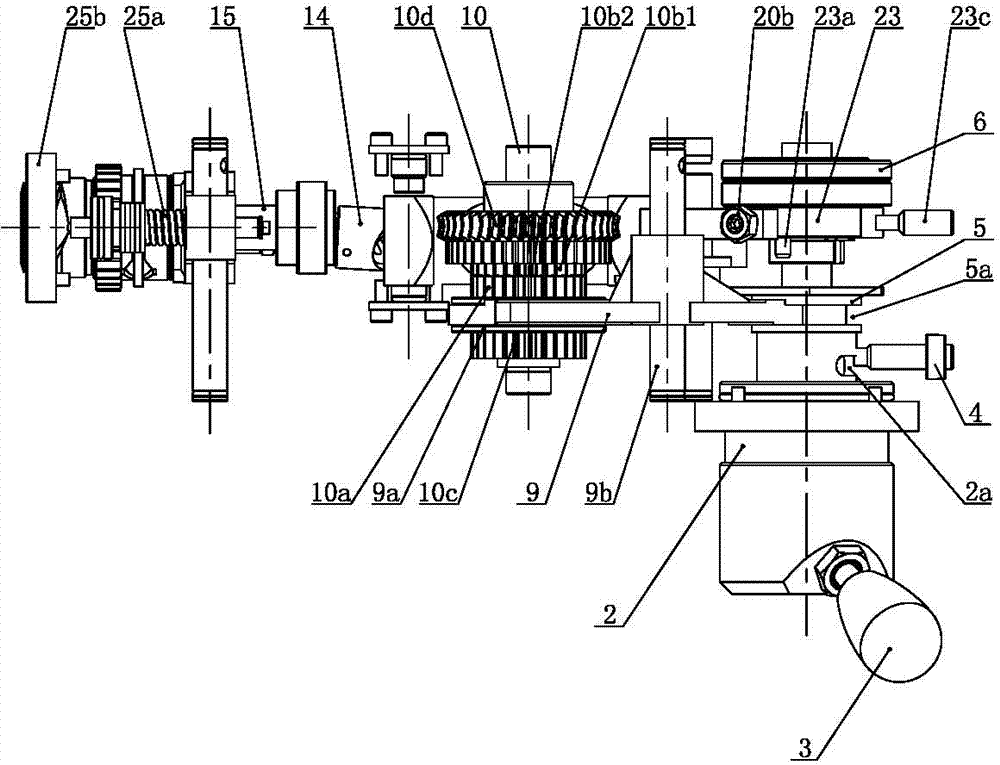

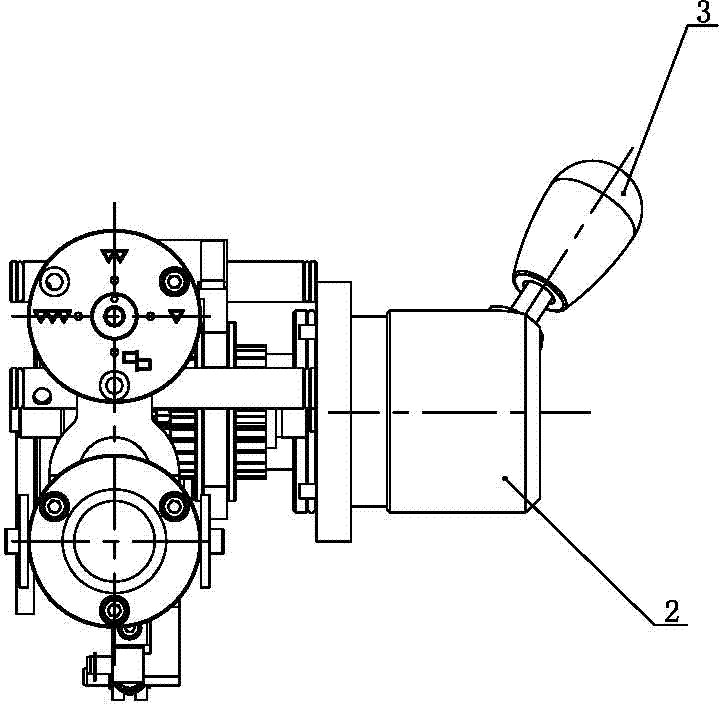

ActiveCN104259492AAchieve interlockAvoid displacementFeeding apparatusLarge fixed membersGear wheelEngineering

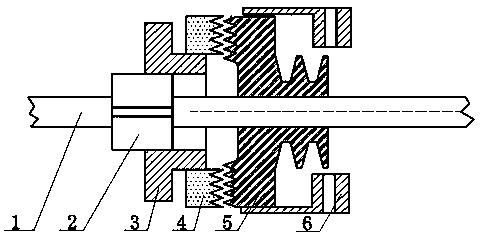

The invention relates to a lathe sliding box; a transverse knife feeding gear and a longitudinal knife feeding gear are installed on front and rear sides of a middle gear on a wheel shaft; the middle gear, the transverse knife feeding gear and the longitudinal knife feeding gear are respectively engaged with an annular gear; a control handle shaft is parallel to the wheel shaft; a handle capable of driving the control handle shaft to rotate or slide forwards and backwards is installed on the control handle shaft; the annular gear is rotationally connected to one end of a sliding link rod, and the middle part of the sliding link rod is installed on a sliding link rod shaft that is parallel to the control handle shaft; a sliding link rod driving plate is fixedly installed on the control handle shaft and provided with a sliding link rod slot extending along the circumference, and the other end of the sliding link rod is inserted into the sliding link rod slot. A concave arc cam is installed on the control handle shaft, the rear end face of the concave arc cam is provided with a concave arc groove in which a link rod pin is inserted, and the outer end of the link rod pin is hinged to the upper end of a half nuts control link rod. According to the sliding box, interlocking of the transverse knife feeding gear, the longitudinal knife feeding gear and the half nuts is achieved by the control handle.

Owner:YANGZHOU SUPER MASCH TOOL CO LTD

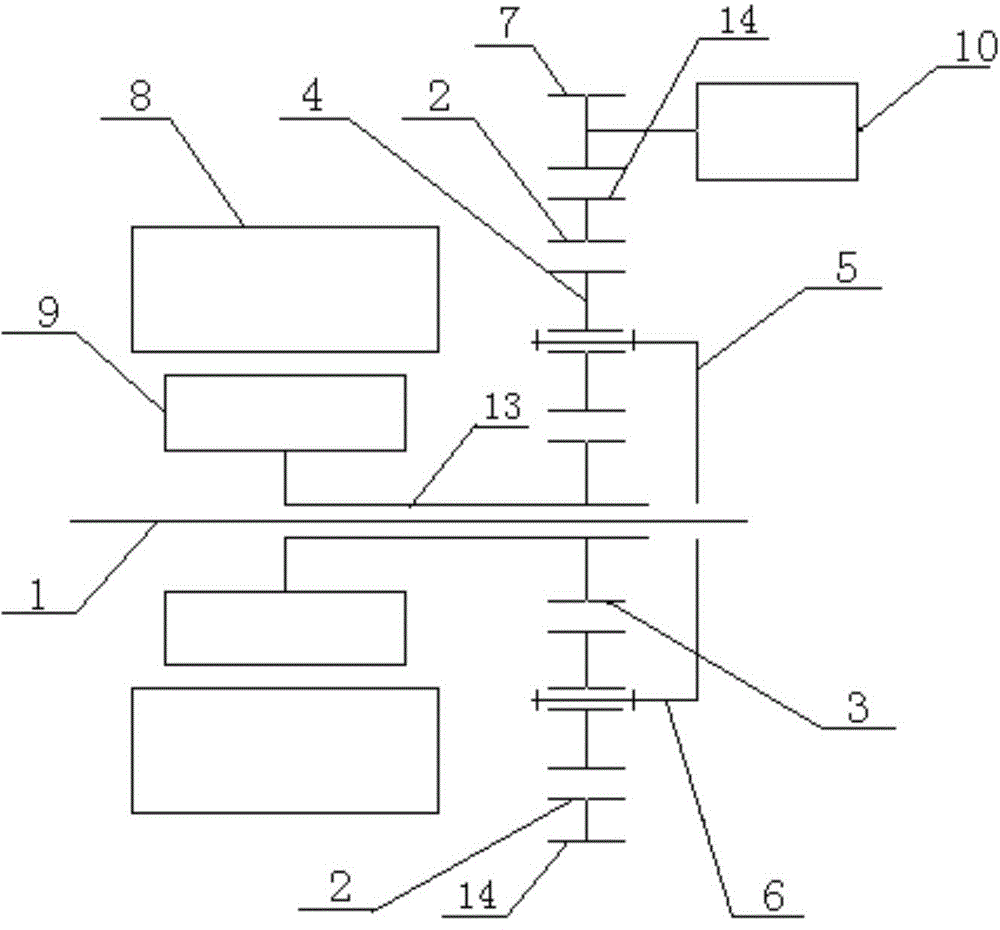

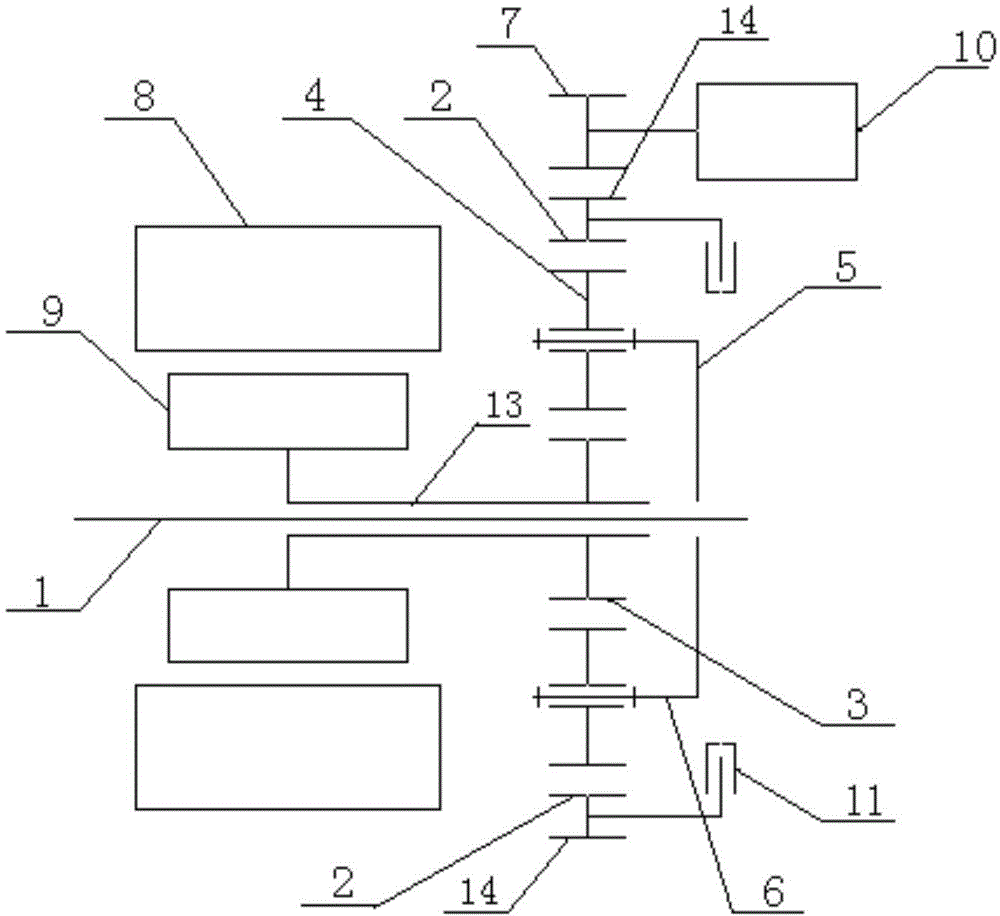

Planetary reduction stepless variable speed coupling box of new energy automobile

InactiveCN104595465AGood transmission effectImprove climbing abilityGearboxesToothed gearingsDrive wheelNew energy

The invention relates to a planetary reduction stepless variable speed coupling box of a new energy automobile. The planetary reduction stepless variable speed coupling box comprises a main drive loop formed by motors, planetary reduction mechanisms and a differential mechanism, wherein the motors are connected with sun wheels of the planetary reduction mechanisms through rotor frames to be used as power input, and planet carriers of the planetary reduction mechanisms are connected with the differential mechanism to be used as power output drive wheels. The planetary reduction stepless variable speed coupling box of the new energy automobile further comprises an auxiliary drive device for driving inner gear rings of the planetary reduction mechanisms to rotate. Compared with the prior art, the main drive loop can carry out gear switching of different speed ratios on a planet gearbox according to the working conditions of the inner gear rings, and therefore the whole gear shifting process is continuous, stable and free of impact force, so that stepless variable speed of the automobile in climbing, heavy-load starting, common-load driving at the moderate speed and light-load driving at high speed can be achieved.

Owner:廉廉机电科技发展(上海)有限公司

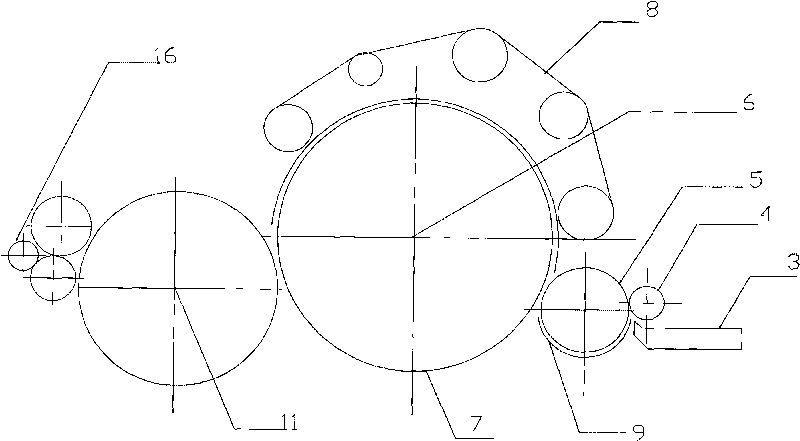

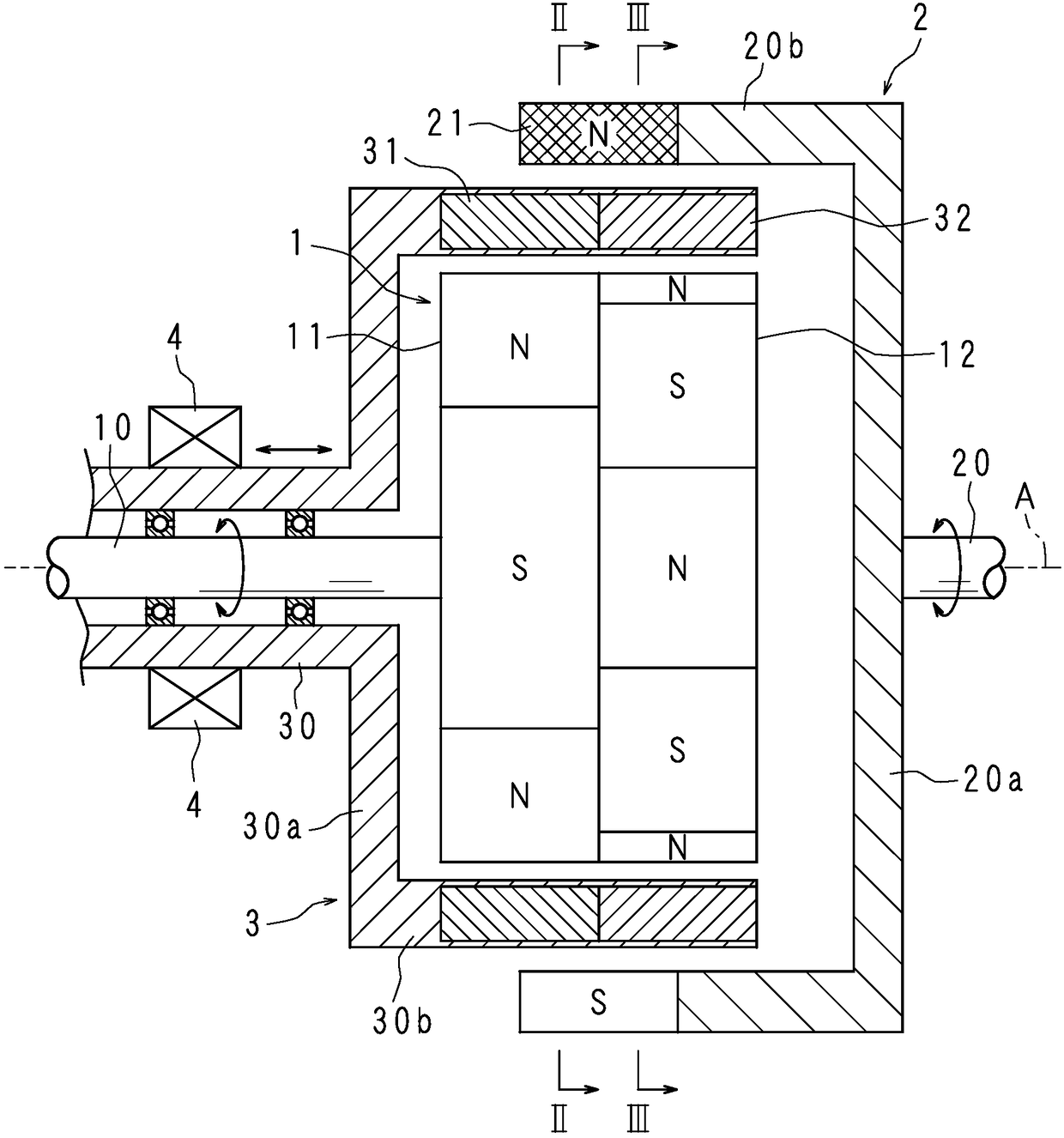

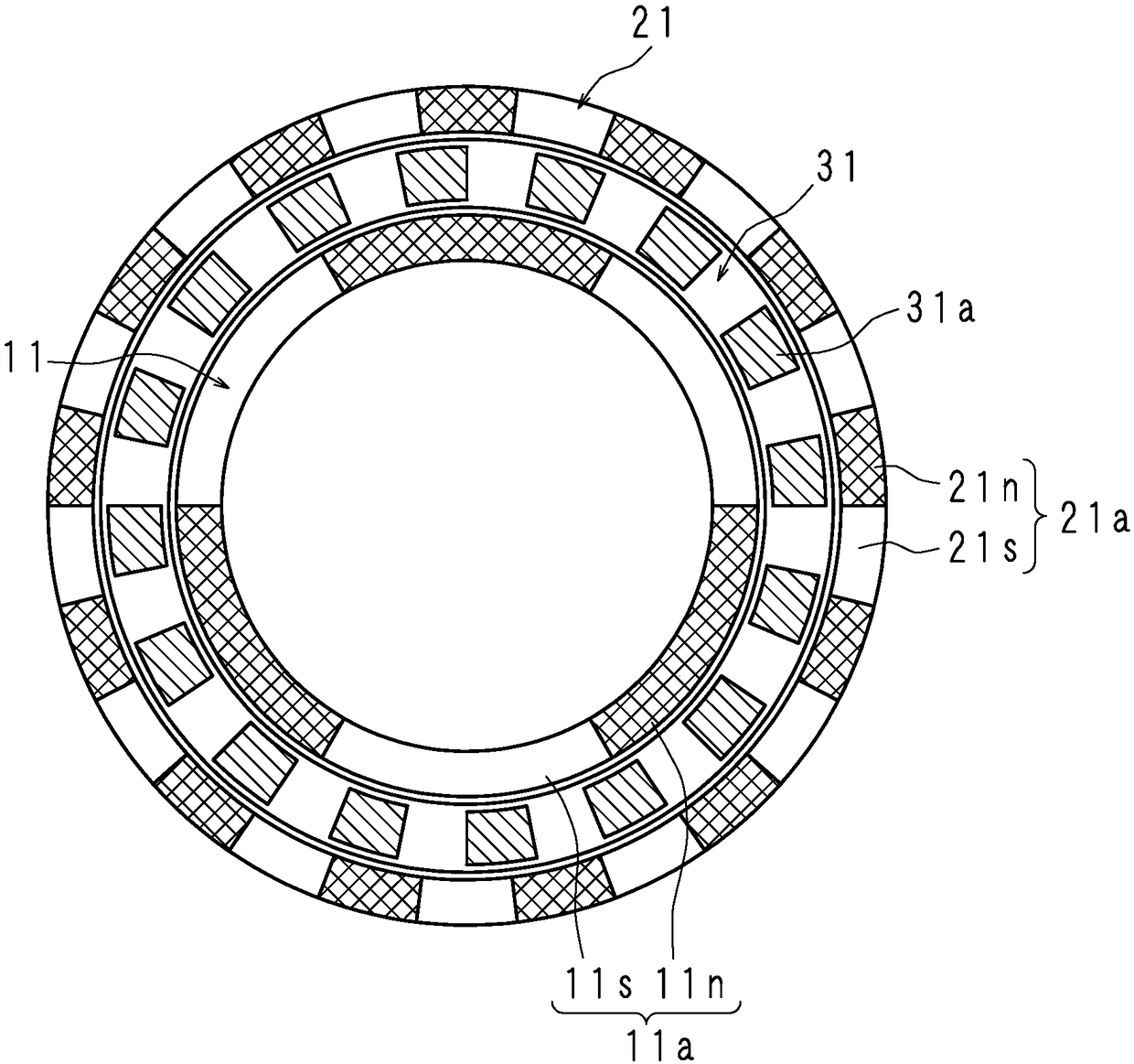

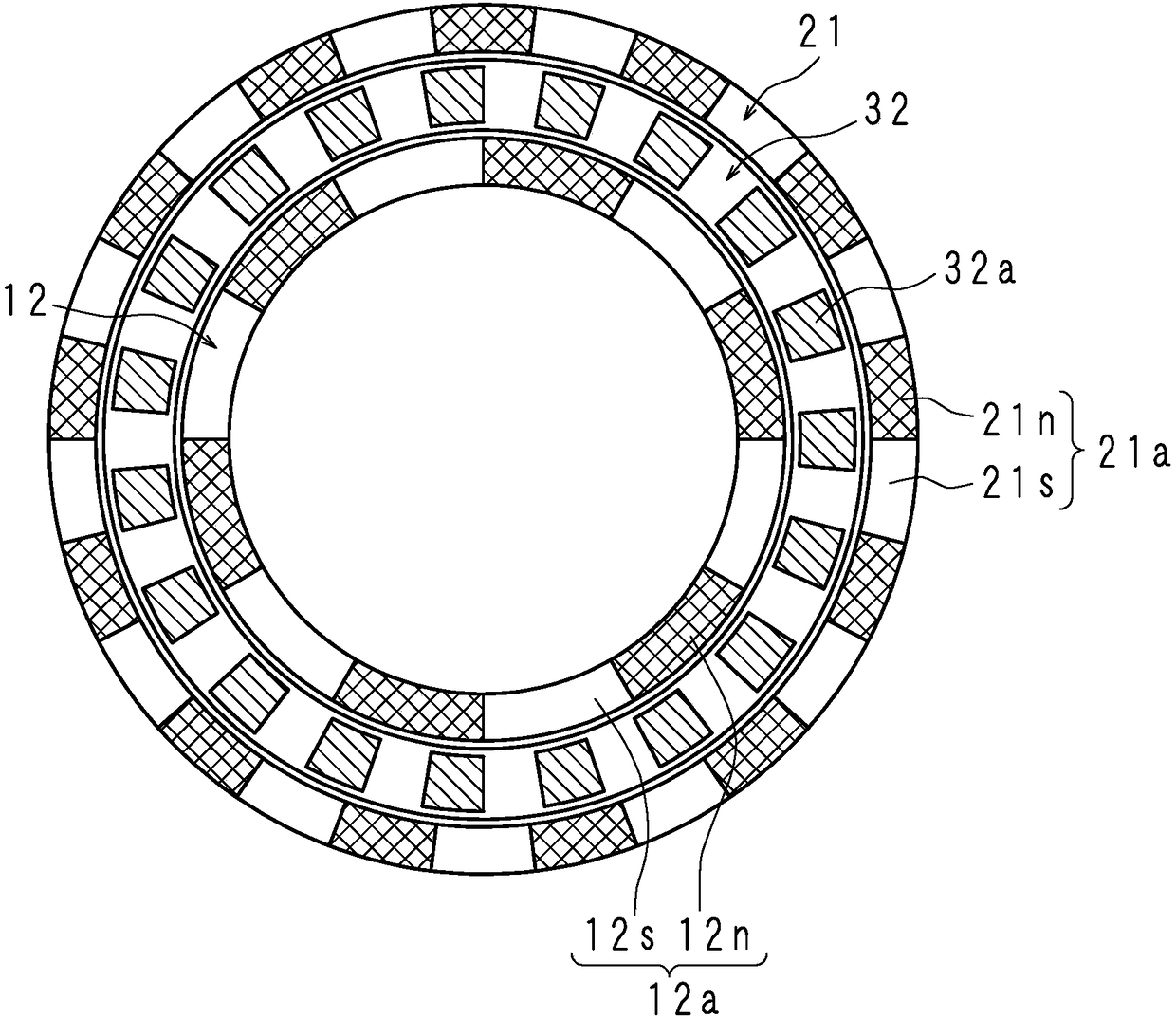

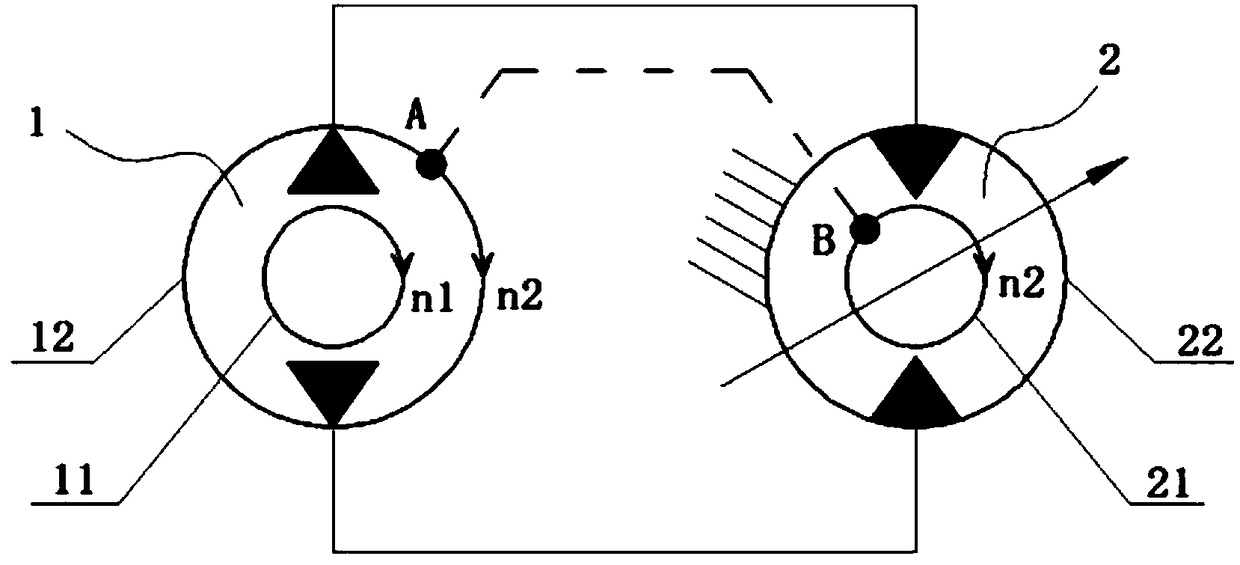

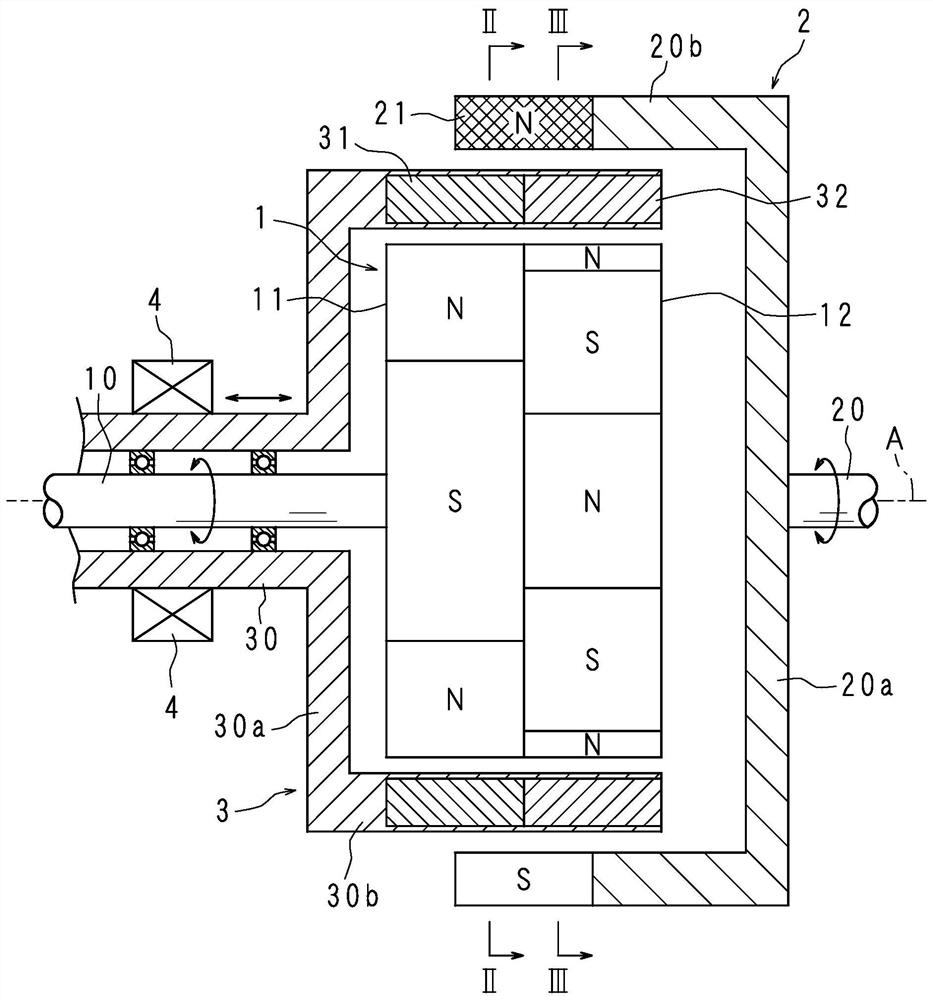

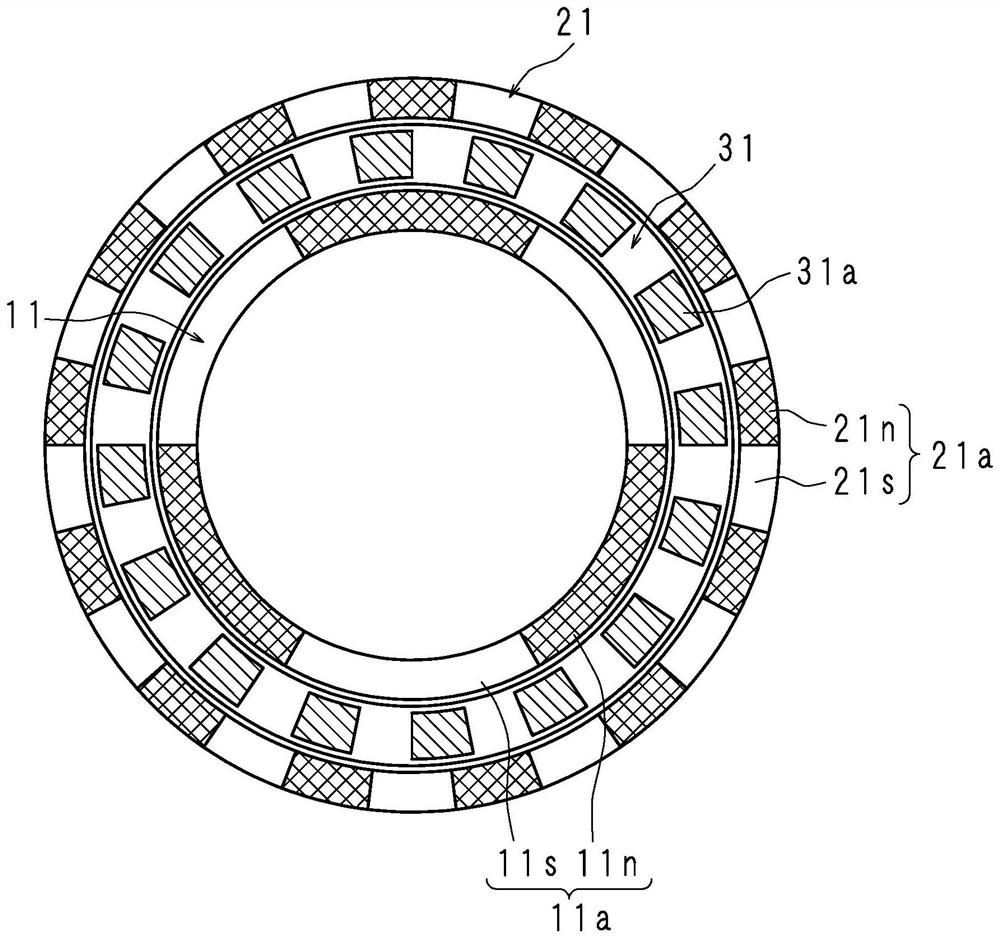

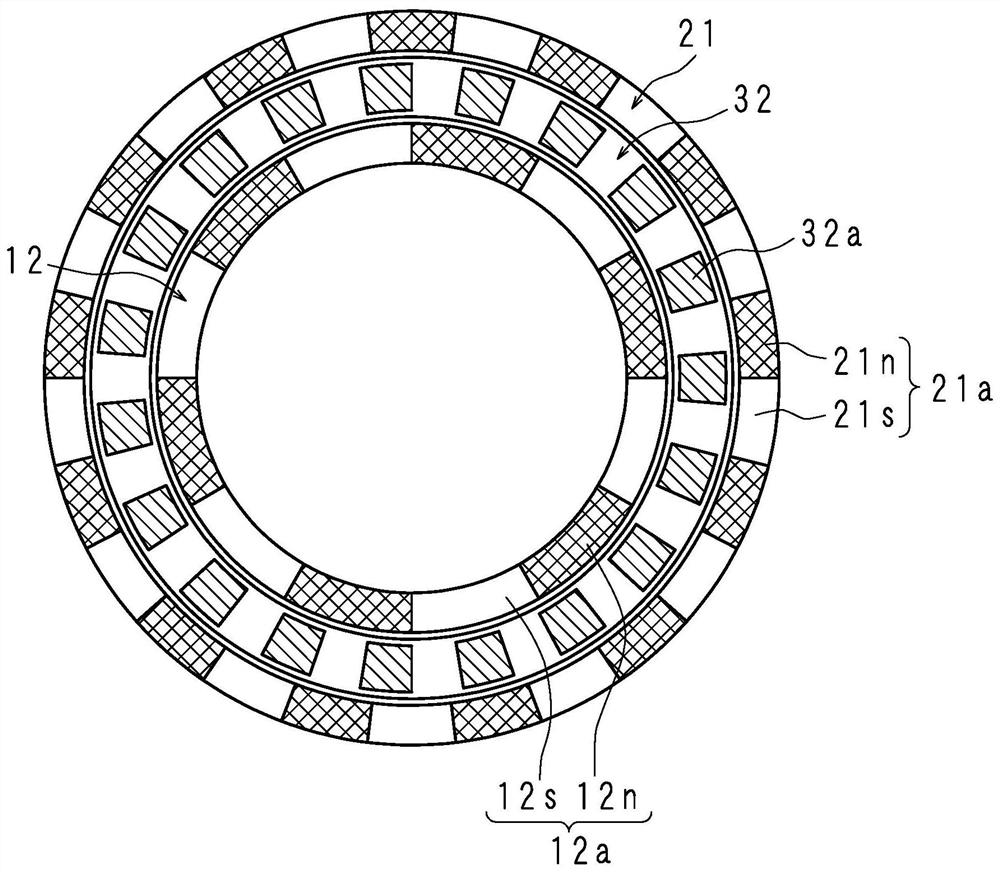

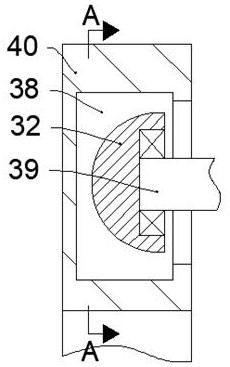

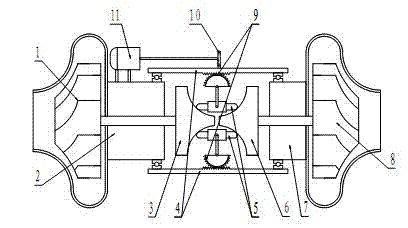

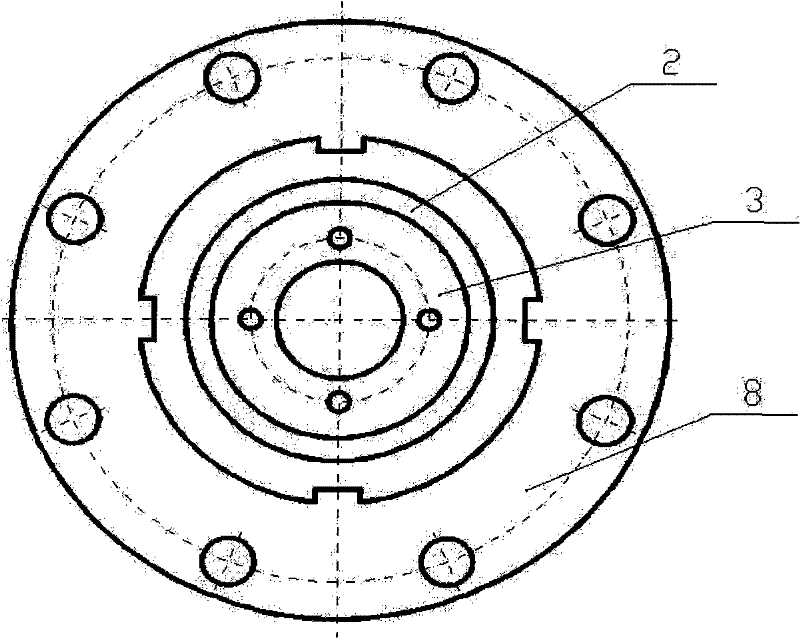

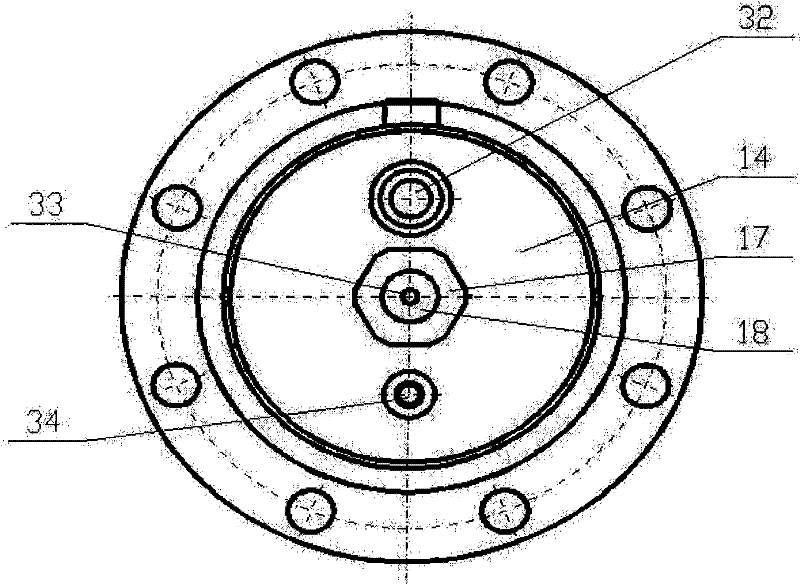

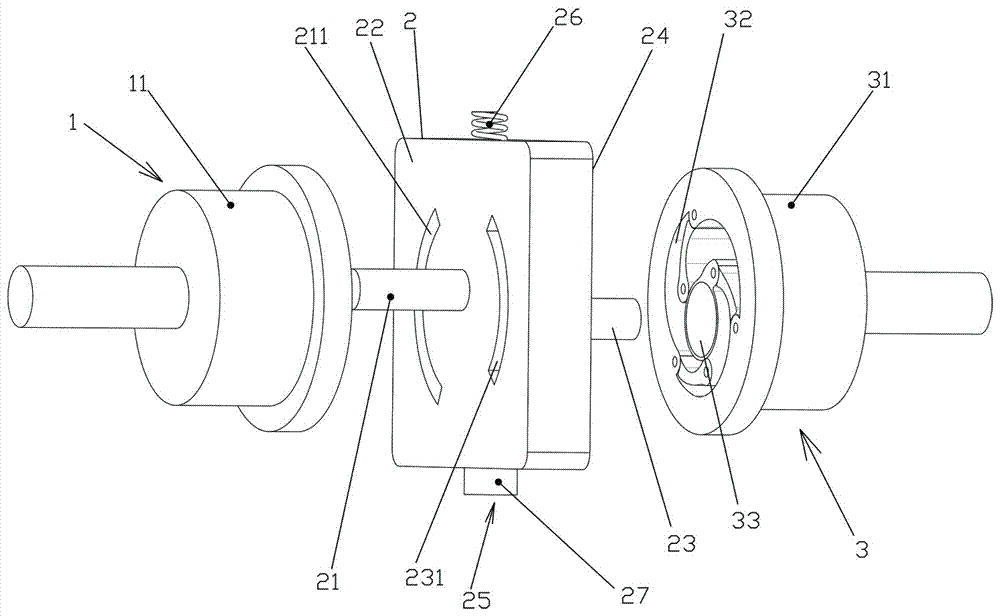

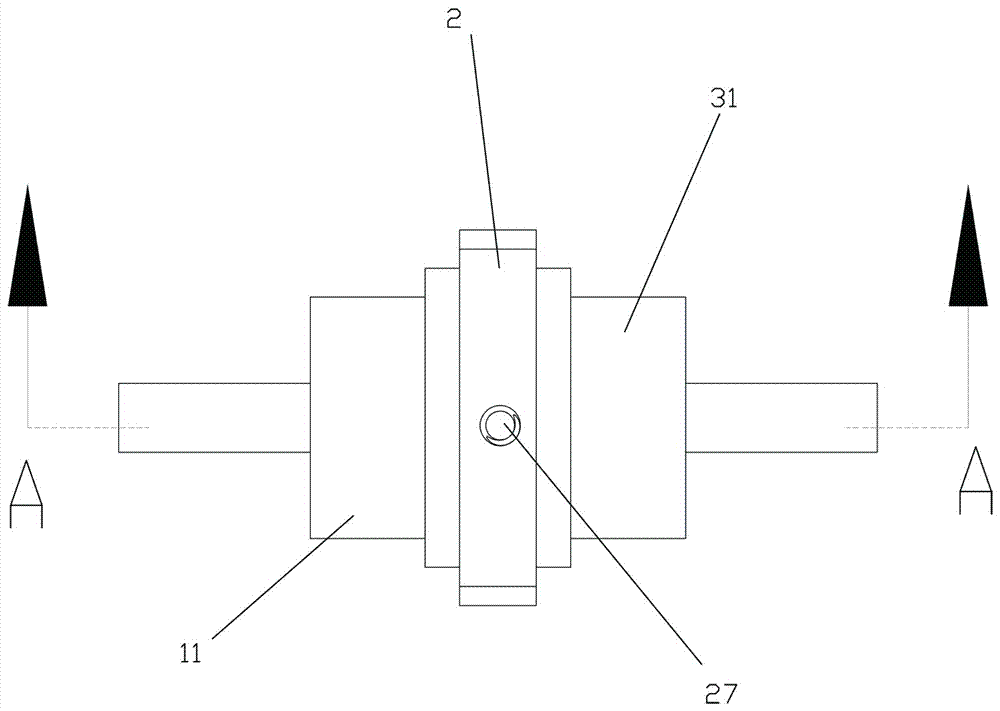

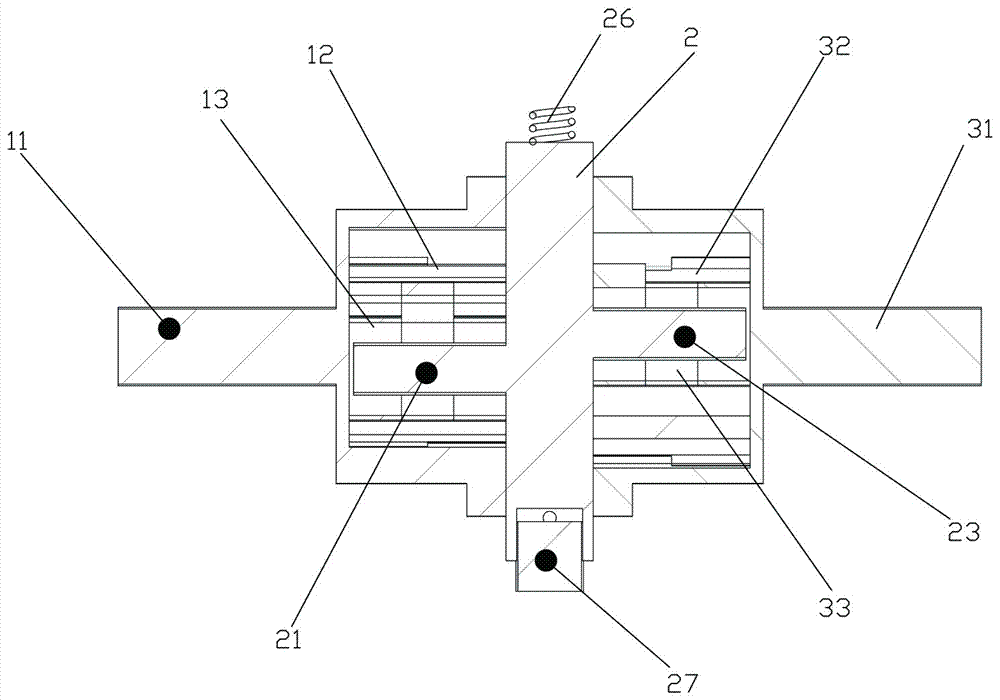

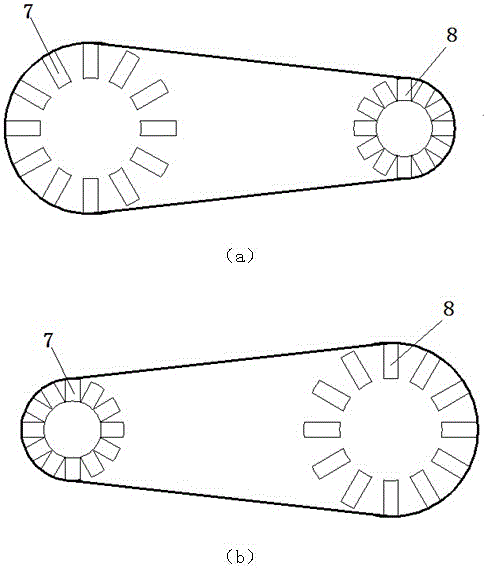

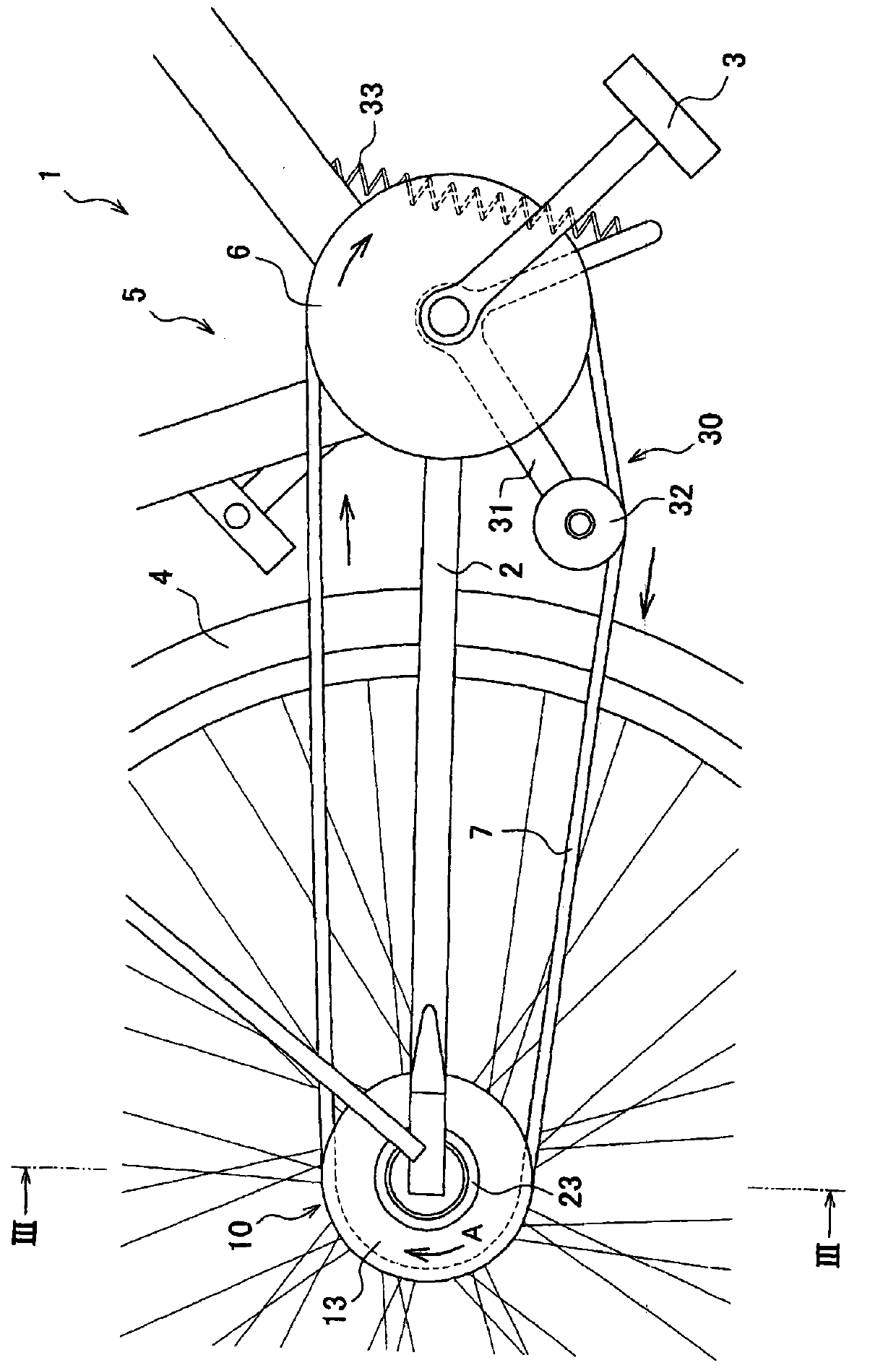

Magnetic transmission

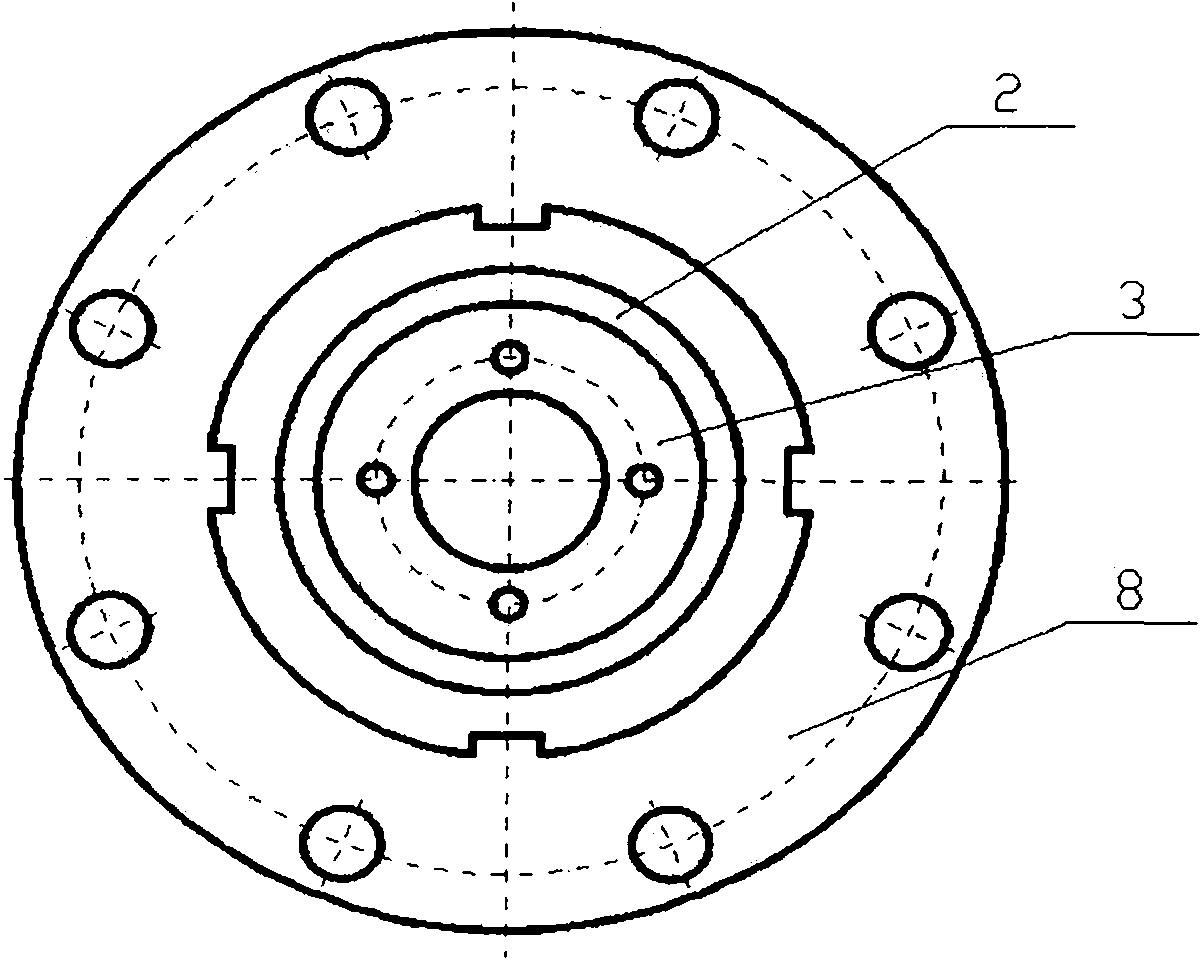

A magnetic transmission is provided with an inner rotor (1), an outer rotor (2), and a magnetic field-modulating stator (3) disposed coaxially between the inner rotor (1) and the outer rotor (2). Theinner rotor (1) is provided with a first magnet row (11) and a second magnet row (12) that are disposed in parallel in the direction of the central axis (A) and disposed at different pitches along thecircumferential direction. The outer rotor (2) is provided with a magnet row that is disposed along the circumferential direction. The magnetic field-modulating stator (3) is provided with a first magnetic body row (31) and a second magnetic body row (32) that oppose the first magnet row (11) and the second magnet row (12), respectively. Moreover, by moving the inner rotor (1) and the magnetic field-modulating stator (3) in the direction of the central axis (A) while maintaining the opposing relationship between the first magnetic body row (31) and the second magnetic body row (32) and the first magnet row (11) and the second magnet row (12), the position of opposition between the outer rotor (2) and the first magnet row (11) and second magnet row (12) is varied continuously.

Owner:HITACHI METALS LTD

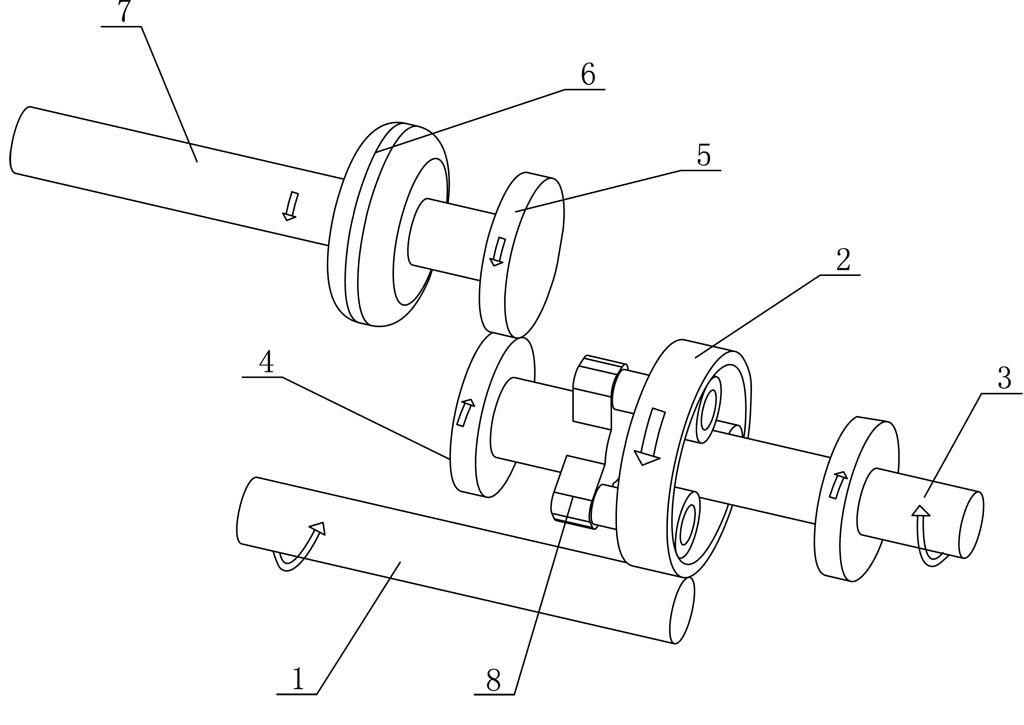

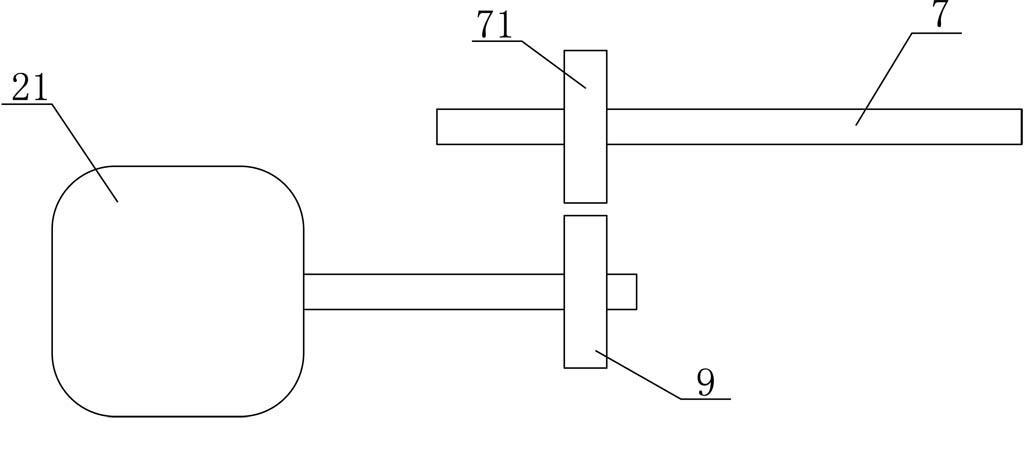

Stepless speed change structure for planetary gears

InactiveCN102537238AChange speed ratioRealize infinitely variable speedToothed gearingsGearing detailsControl powerGear wheel

The invention discloses a stepless speed change structure for planetary gears, which has the advantages of high torque bearing capability, no slipping, simple structure, less parts, low manufacture and maintenance costs, superior long service life and wide speed change range, and can be applied to heavy-duty vehicles, large-scale vehicles and mini-type vehicles. Based on the structural characteristics of the planetary gears, the stepless speed change of power input and output speeds is realized when the revolution ratio between a gear ring and a sun gear is changed by changing the rotational speed of a planetary gear rack. The stepless speed change structure comprises the gear ring, the planetary gear rack and the sun gear, wherein the gear ring is connected with the power input shaft of a vehicle engine; the sun gear is connected with the power output shaft; the planetary gears are mounted on the planetary gear rack and are connected with a power adjusting control device capable of changing the speeds of the planetary gears; and the power adjusting control device comprises a control power input shaft and a control gear arranged at one end of the control power input shaft.

Owner:宏万兵

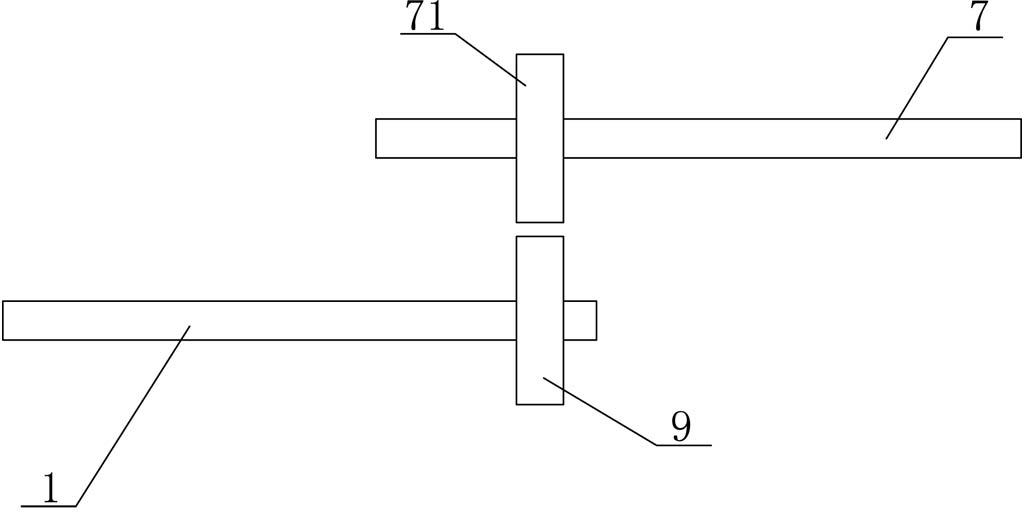

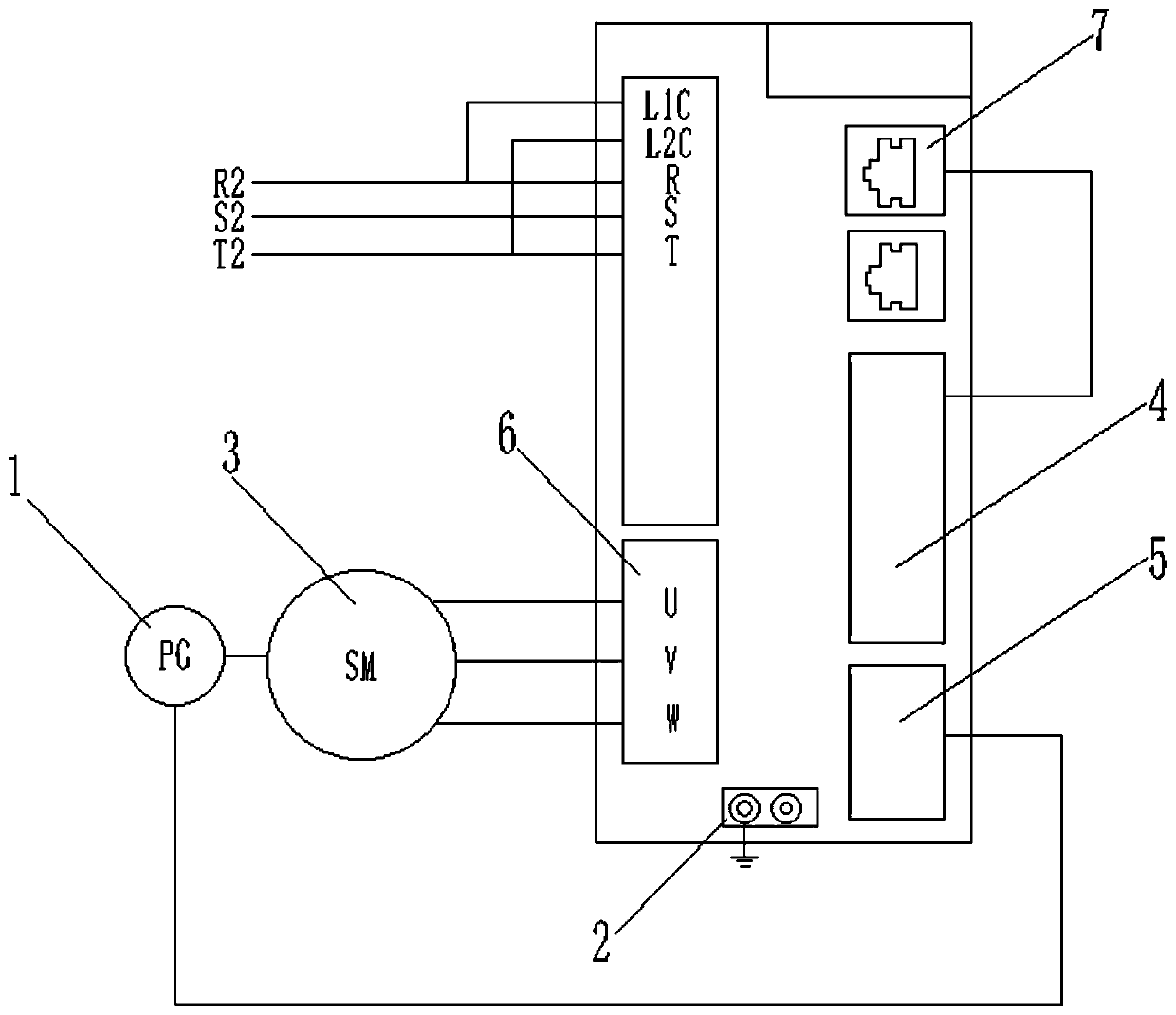

Stranding machine with frequency division lay control function

PendingCN110060823AChange the pulse amountChange speed ratioCable/conductor manufactureElectric machineWinch

Disclosed is a stranding machine with a frequency division lay control function. The stranding machine comprises a driving winch variable-frequency controller, a traction wheel motor and a winch driving motor; and the length of a real-time stranded wire is calculated through the rotating speed of the main motor and the rotating speed of the winch, the pulse quantity of the traction wheel is changed, and the electronic gear ratio of the driver is controlled to control the speed ratio of the traction wheel motor to the winch driving motor, so that the speed ratio of the traction wheel and the winch is changed so as to achieve the purpose of controlling the lay.

Owner:GUANGZHOU HONGHUI ELECTRICIAN & MACHINERY

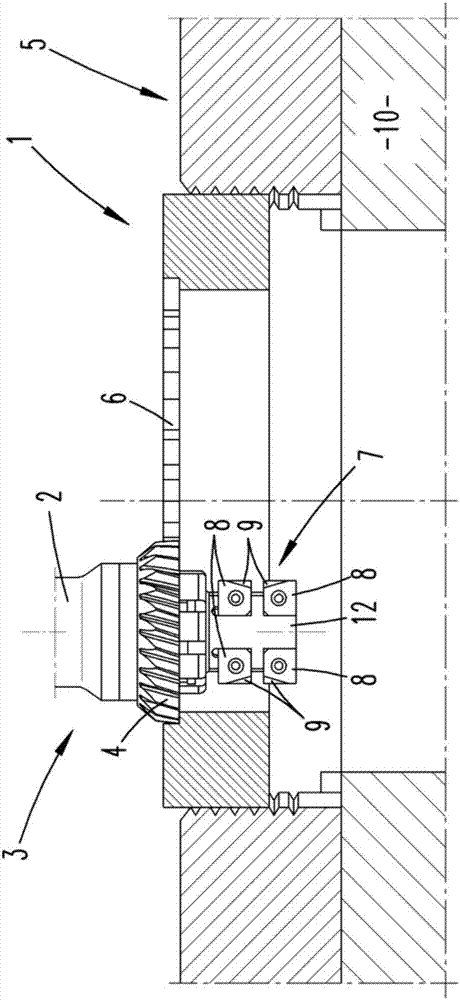

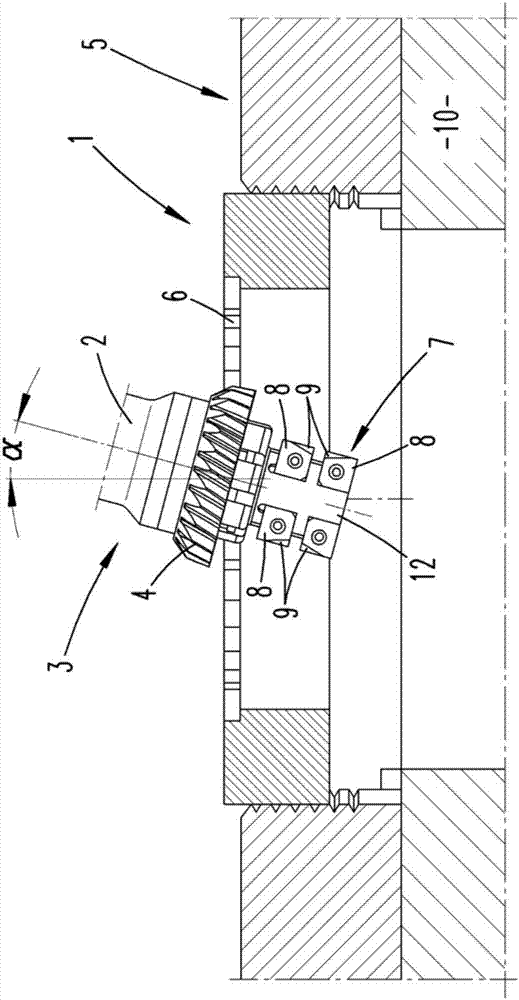

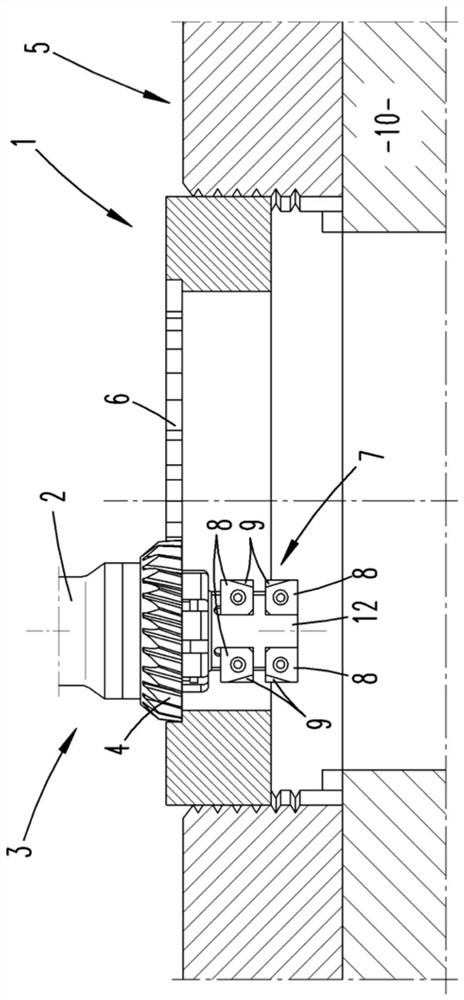

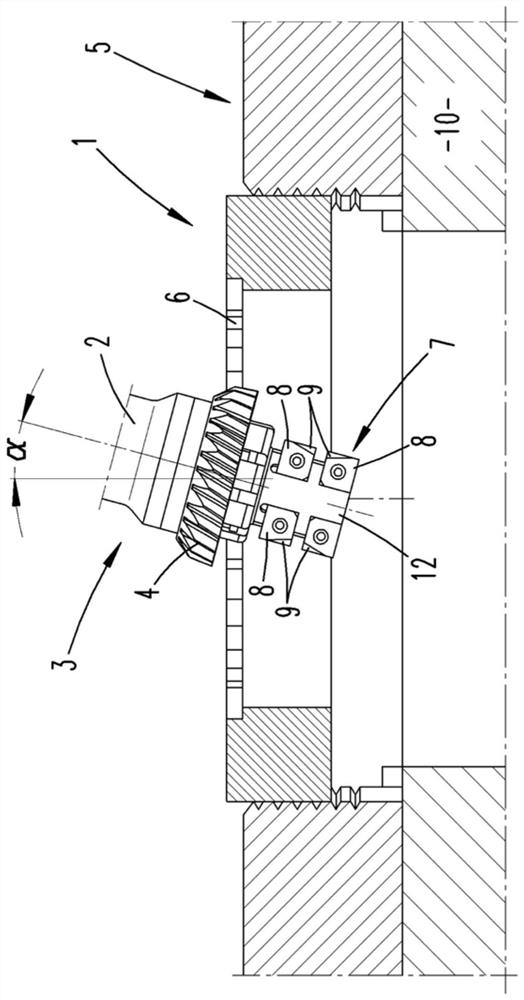

Tooth-forming method having tooth finishing, and combination tool therefor

ActiveCN107530803AChange speed ratioGear teeth manufacturing toolsGear-cutting machinesGear wheelEngineering

The invention relates to a method for producing gears, wherein in a first step a set of teeth (6) is formed by means of a skiving wheel (4) rotationally driven by a tool spindle (2) in a workpiece gear (1) rotationally driven synchronously thereto by a workpiece spindle (5), wherein the workpiece spindle (5) and the tool spindle (2) are at an axis intersection angle ([Alpha]) to each other and theadvancement occurs in the tooth-flank extension direction, and wherein in a second step at least some teeth of the set of teeth (6) are machined by means of a tooth-machining tool (7). A combined tool is used, in the case of which the tooth-machining tool (7) and the skiving wheel (4) are fixedly connected to each other. Between the two steps, the combined tool (3) remains connected to the tool spindle (2) and the workpiece gear (1) remains connected to the workpiece spindle (5). Between the two steps, merely the relative position of the tool spindle (2) in relation to the workpiece spindle (5) and the rotational speed ratio of the two spindles (2, 5) are changed.

Owner:PROFILATOR

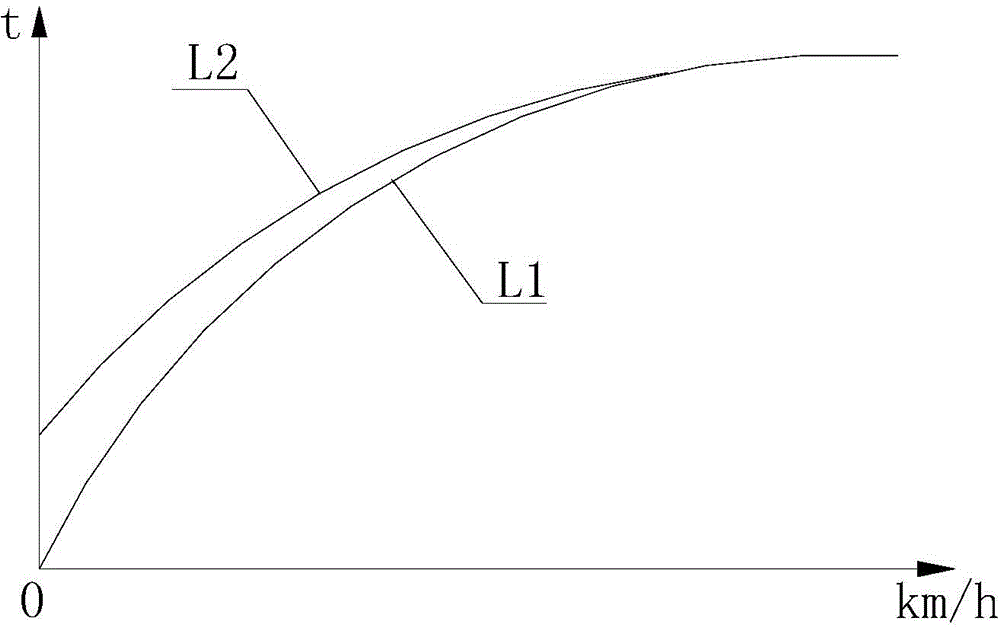

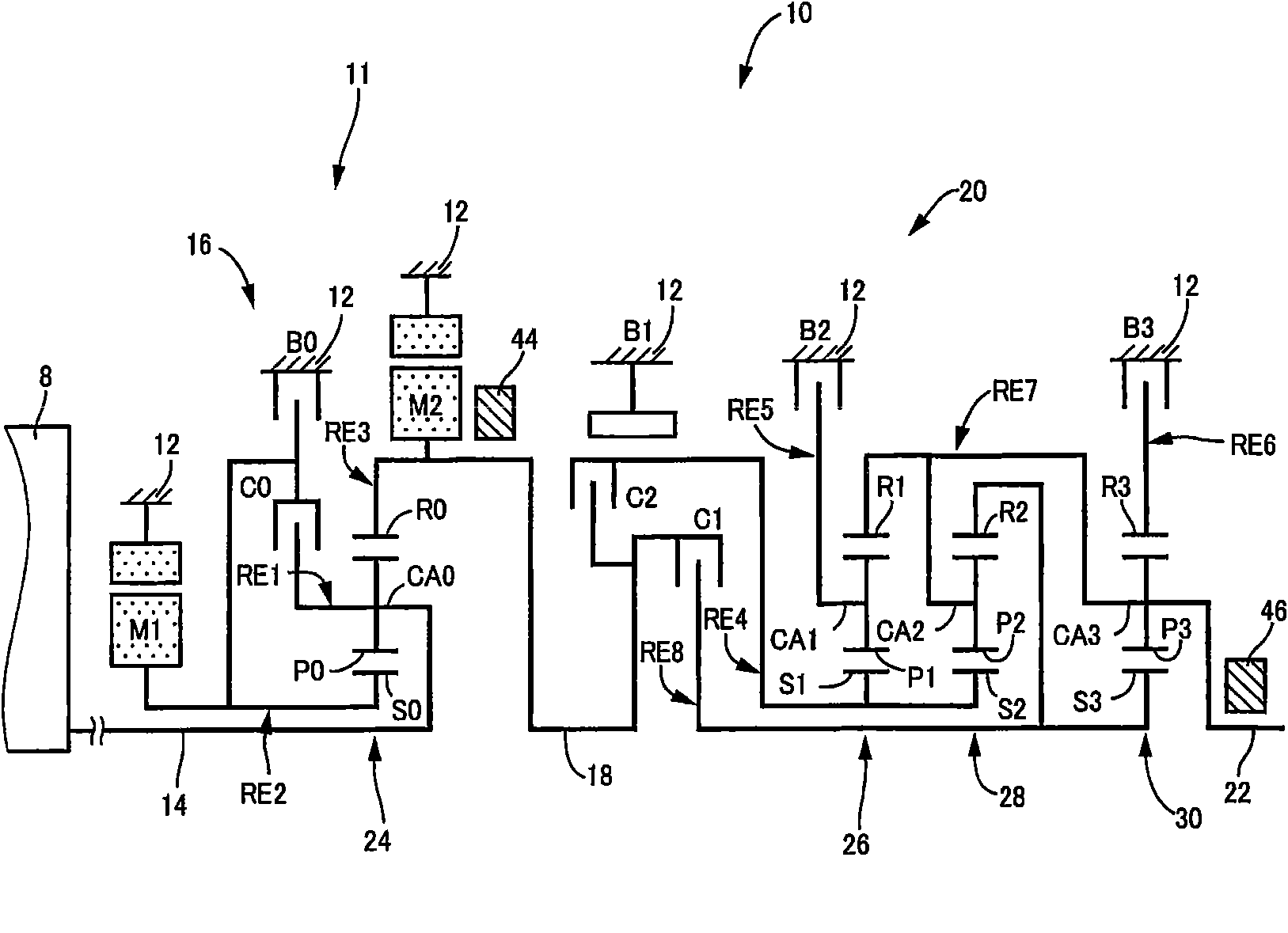

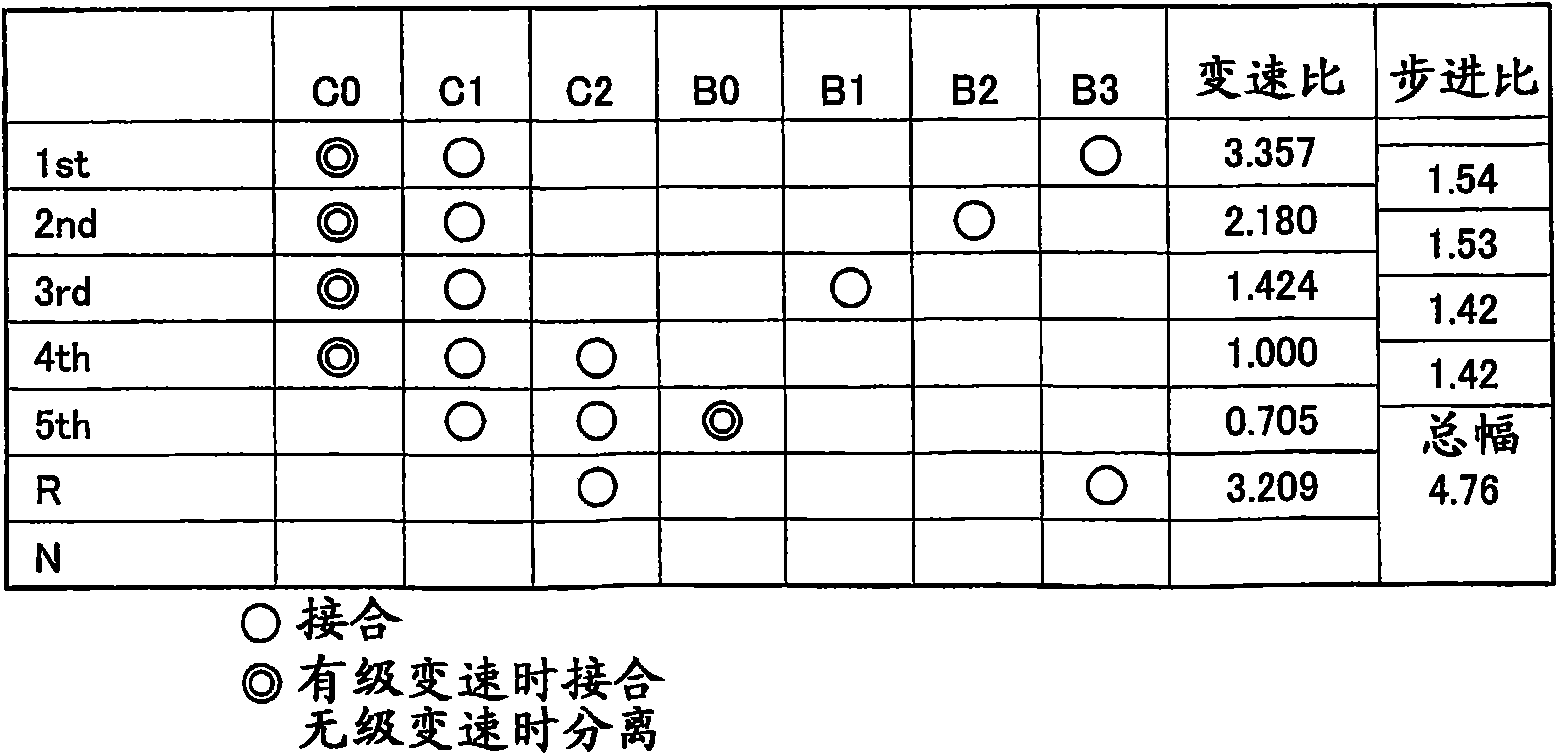

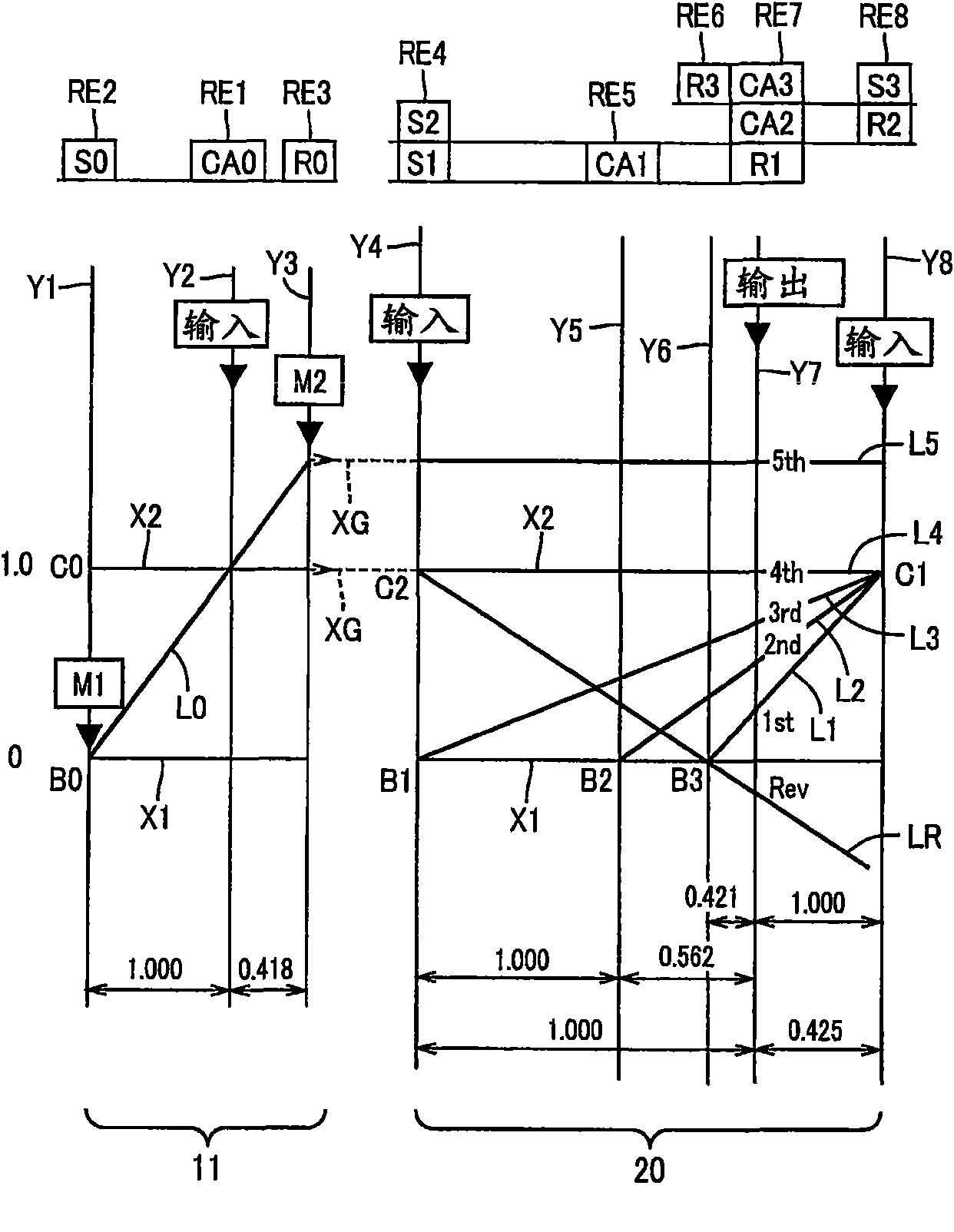

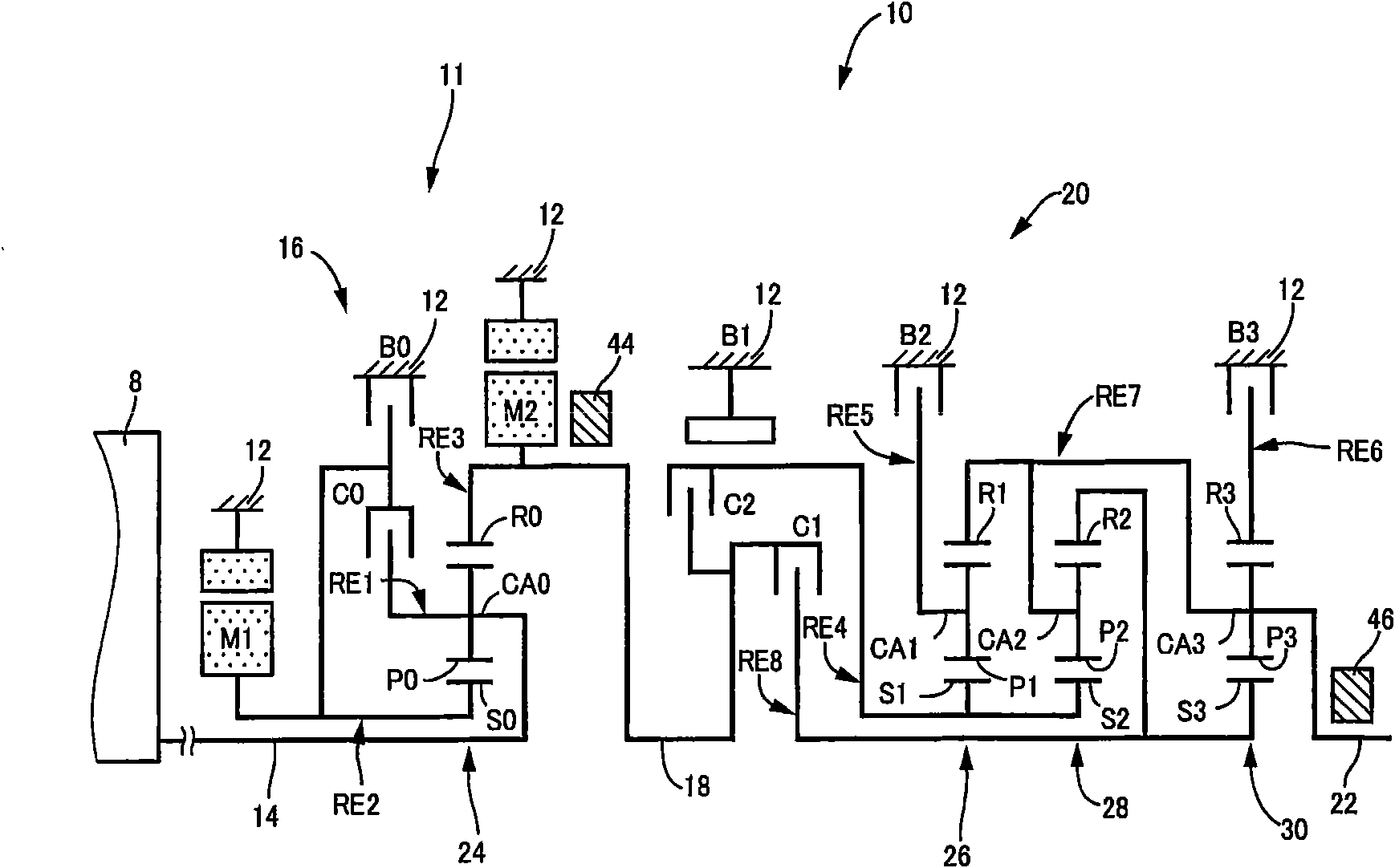

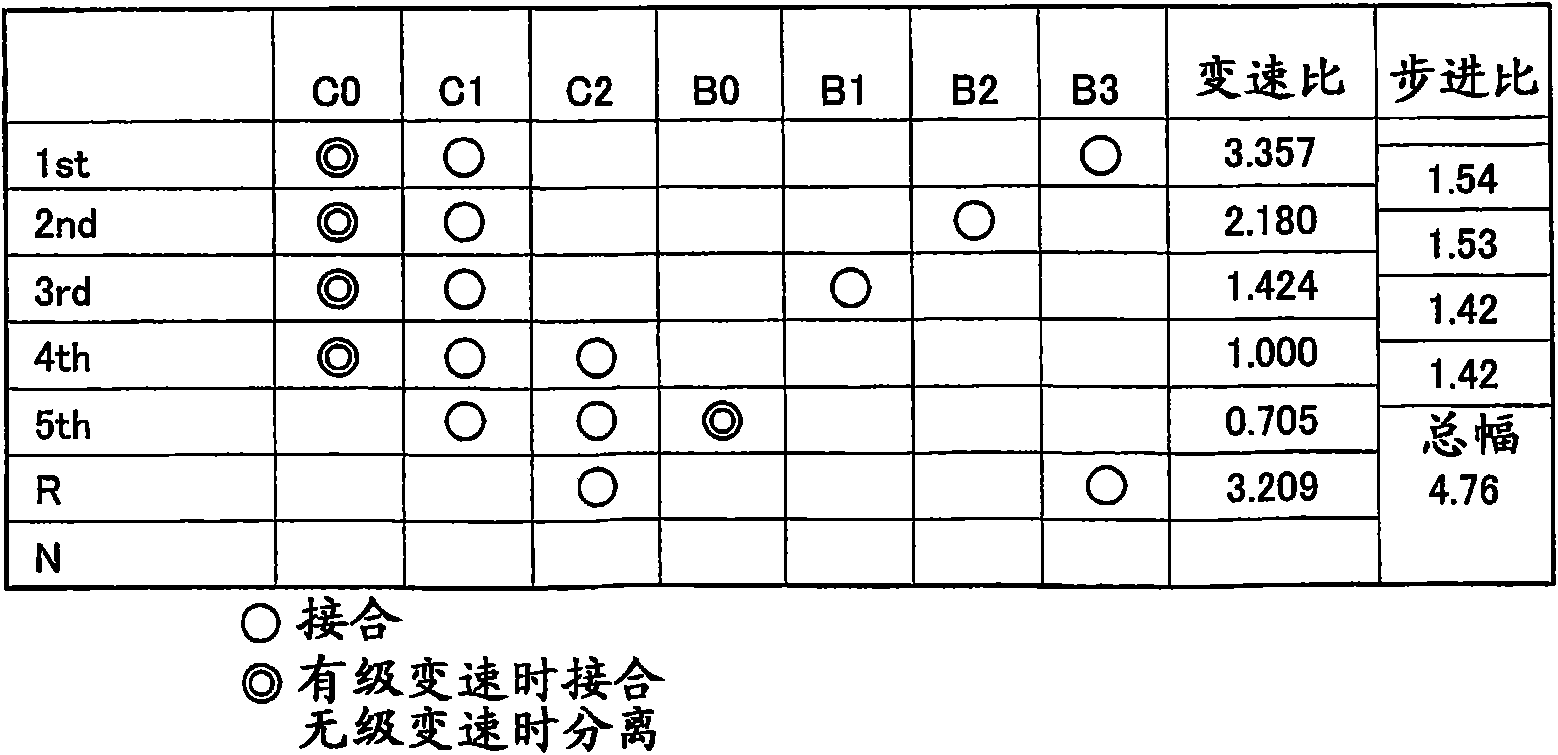

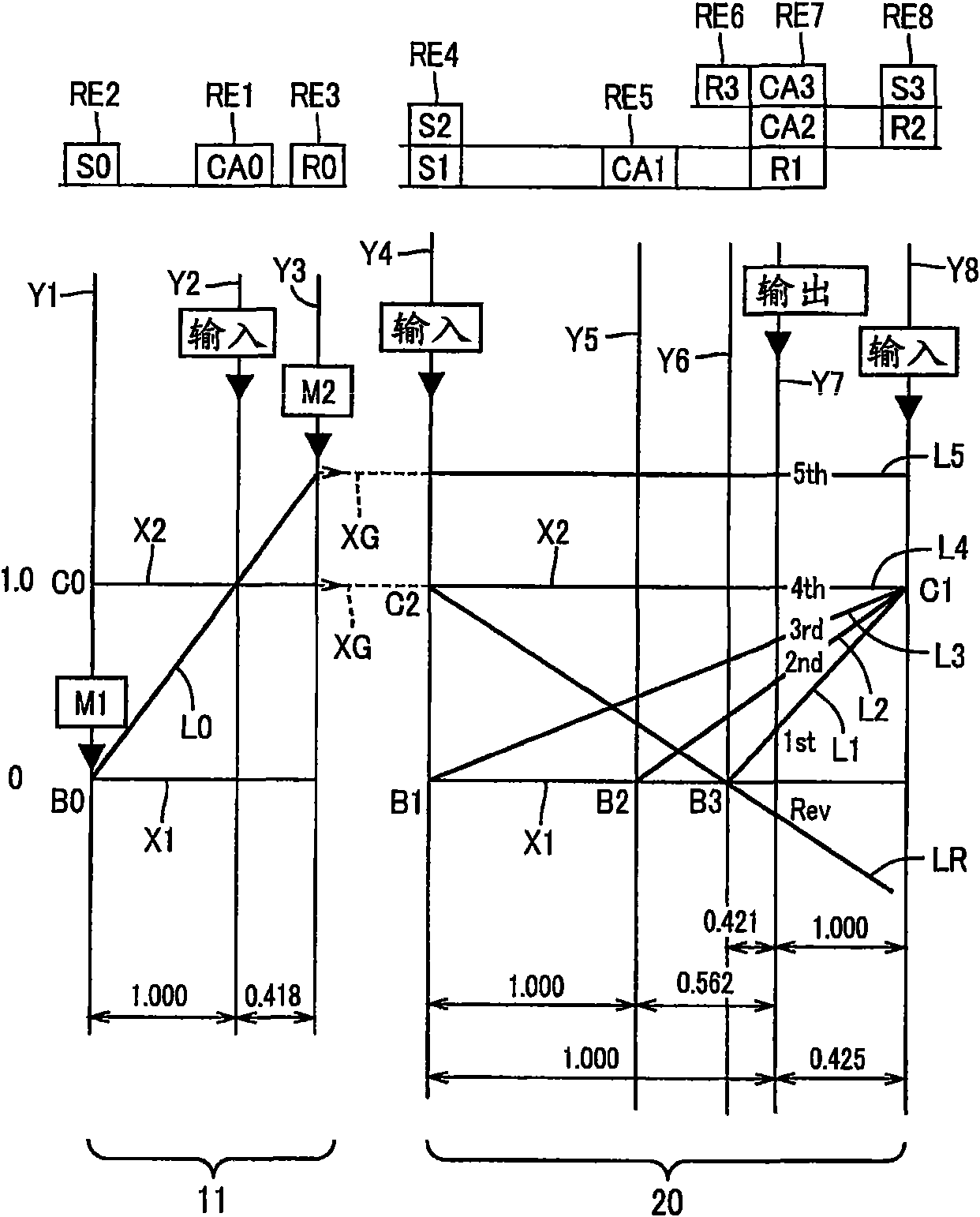

Control device for vehicular power transmitting apparatus

ActiveCN101668671AExcellent economical performanceImprove economyHybrid vehiclesInternal combustion piston enginesBoundary valuesExternal combustion engine

A control device is disclosed which can obtain increased fuel economy performance depending on a kind of fuel in a vehicle having an internal combustion engine and an electric motor when the kind of fuel supplied to the internal combustion engine is altered. A determining vehicle speed (V 1 ) and determining output torque (T 1 ), representing a boundary value with which a step-variable control region and a continuously variable control region of a shifting mechanism ( 10 ) are demarcated, are altered such that the higher the mixing ratio of ethanol, the lower will be the determining vehicle speed (V 1 ) and determining output torque (T 1 ). Therefore, the determination is made whether to operate a first electric motor (M 1 ) depending on the mixing ratio of ethanol, making it possible to obtain increased fuel economy performance in line with the mixing ratio of ethanol.

Owner:TOYOTA JIDOSHA KK

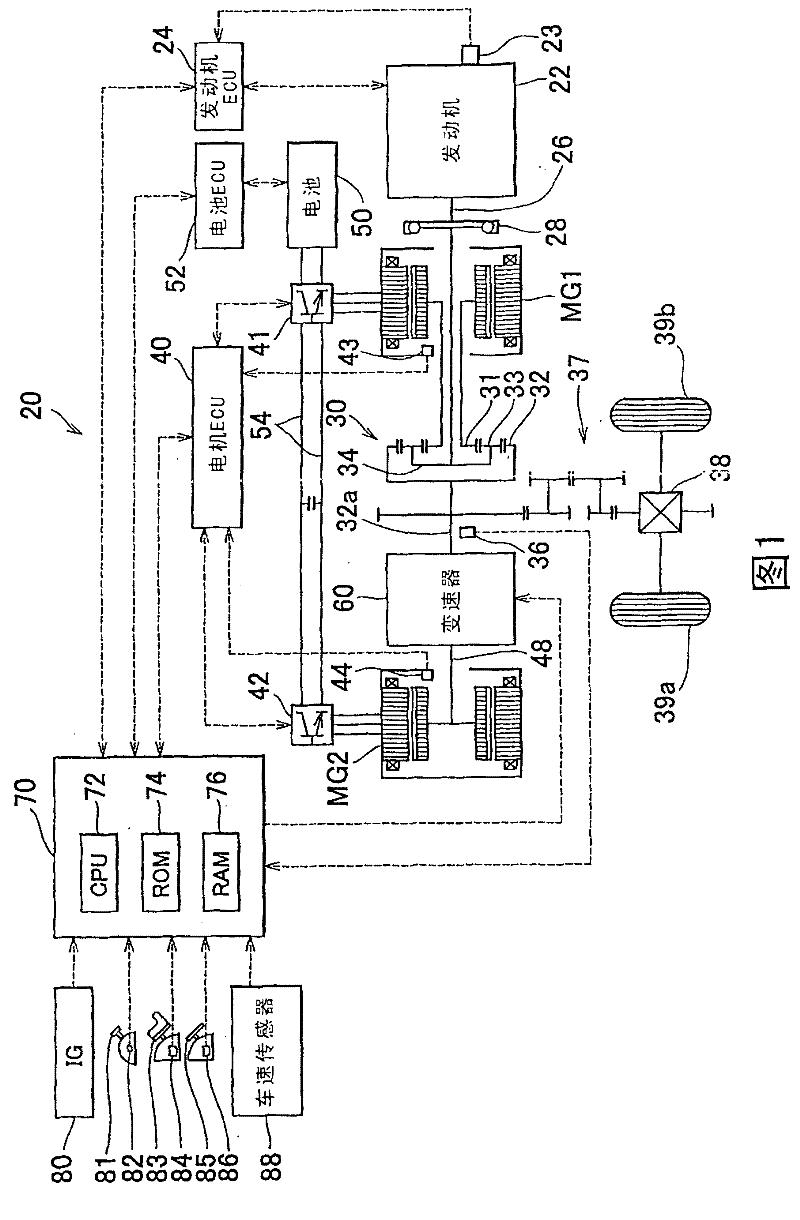

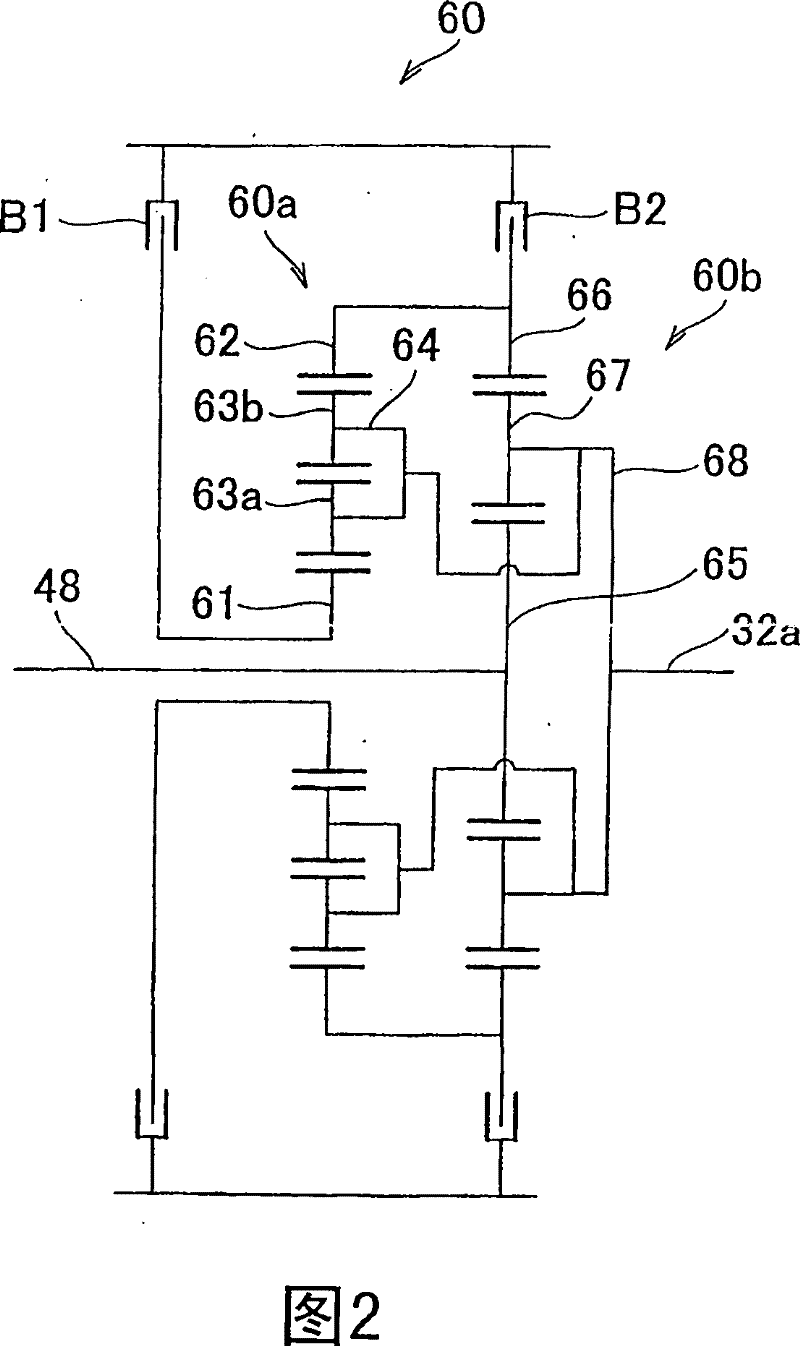

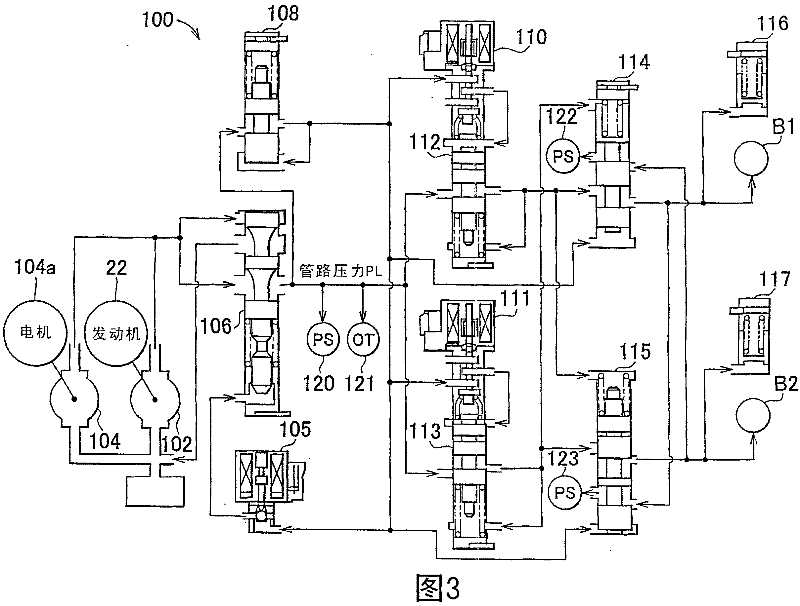

Power output apparatus, vehicle including power output apparatus, and control unit and method for power output apparatus

InactiveCN101346252BSuppress undesired changesChange speed ratioHybrid vehiclesGearing controlPower splitElectric machine

Owner:TOYOTA JIDOSHA KK +1

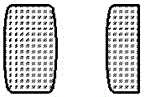

Chuck type stepless speed changing mechanism

InactiveCN104033551AChange speed ratioTo achieve the purpose of continuously variable speedGearingGear vibration/noise dampingTooth spacePulley

The invention relates to a chuck type stepless speed changing mechanism which comprises a driving belt pulley and a driven belt pulley. Each belt pulley comprises a rotary shaft, a rear mounting base end cover, a front mounting base end cover, spiral discs and chuck plates, each rear mounting base end cover is arranged at one end of the corresponding rotary shaft, and each front mounting base end cover is arranged at the other end of the corresponding rotary shaft. The chuck type stepless speed changing mechanism is characterized in that the spiral discs are arranged on the rear mounting base end covers, positioning tooth spaces which can be meshed with spiral tooth spaces of the spiral discs are arranged on the inner side surfaces of the chuck plates, belt wheels are arranged at the tail ends of the chuck plates, a plurality of belt clamp grooves are spliced with one another to form each belt wheel and are arranged around the axis of the corresponding rotary shaft, and the chuck plates are mounted on plate grooves of the front mounting base end covers, are fixed by the aid of fixing grooves and only can move along the radius directions of the belt wheels. The chuck type stepless speed changing mechanism has the advantages that only the radiuses of wheel discs of the two belt pulleys need to be adjusted, so that a speed regulating ratio of the mechanism can be changed, and speeds can be regulated under the condition that the belt pulleys are not changed; the chuck type stepless speed changing mechanism is flexible in regulating range, and speed regulating tasks under different working conditions can be implemented.

Owner:SHANGHAI INST OF TECH

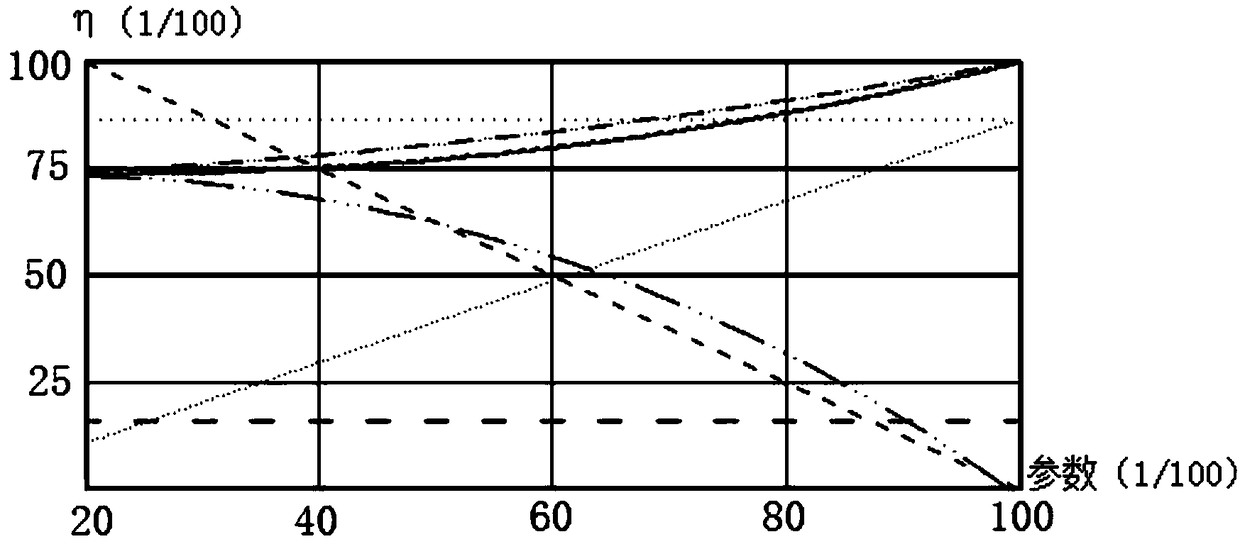

Continuously variable transmission

InactiveCN108730469AWith continuously variable speedWide range of speed ratioFluid gearingsHigh pressureVariable displacement pump

The invention discloses a continuously variable transmission. The continuously variable transmission comprises a pump and a motor, the pump is a constant displacement pump or a variable displacement pump, the motor is a fixed displacement motor or a variable displacement motor, and at least one of the pump and the motor is a variable displacement structure; and a high-pressure input port of the motor communicates with a high-pressure output port of the pump, a low-pressure input port of the pump communicates with a low-pressure output port of the motor, an inner rotor of the pump is power input, an outer rotor of the pump is power output, and the outer rotor of the pump and an inner rotor of the motor are of a rigid connection structure or a rigid integrated structure. According to the continuously variable transmission, due to the fact that the rotating torque borne by the outer rotor of the pump and the output torque of the motor are output in an overlapping mode, the system efficiency and the output rotating speed are greatly improved, when the rotating torque required by the load is close to the rotating torque of the inner rotor of the pump, the output rotating speed of the continuously variable transmission is close to the input rotating speed, and the efficiency of the continuously variable transmission is close to 100%.

Owner:HEFEI CHUANGYUAN VEHICLE CONTROL TECH

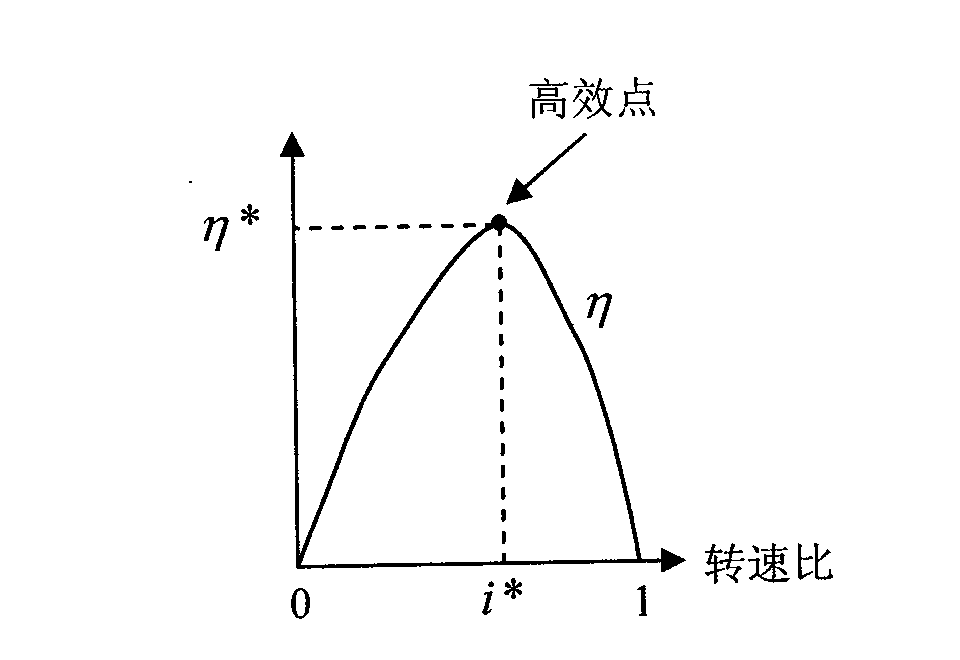

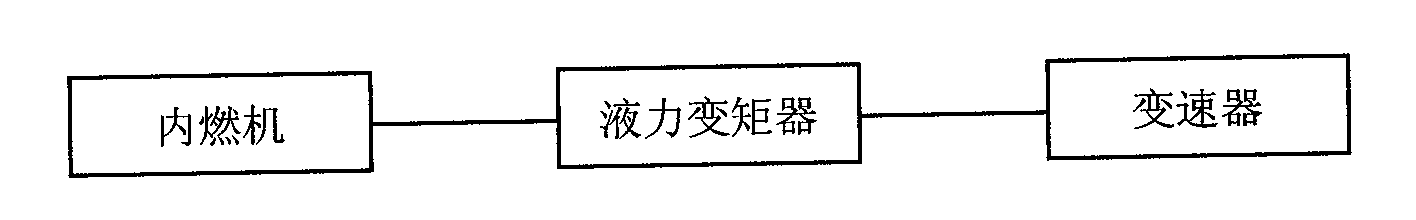

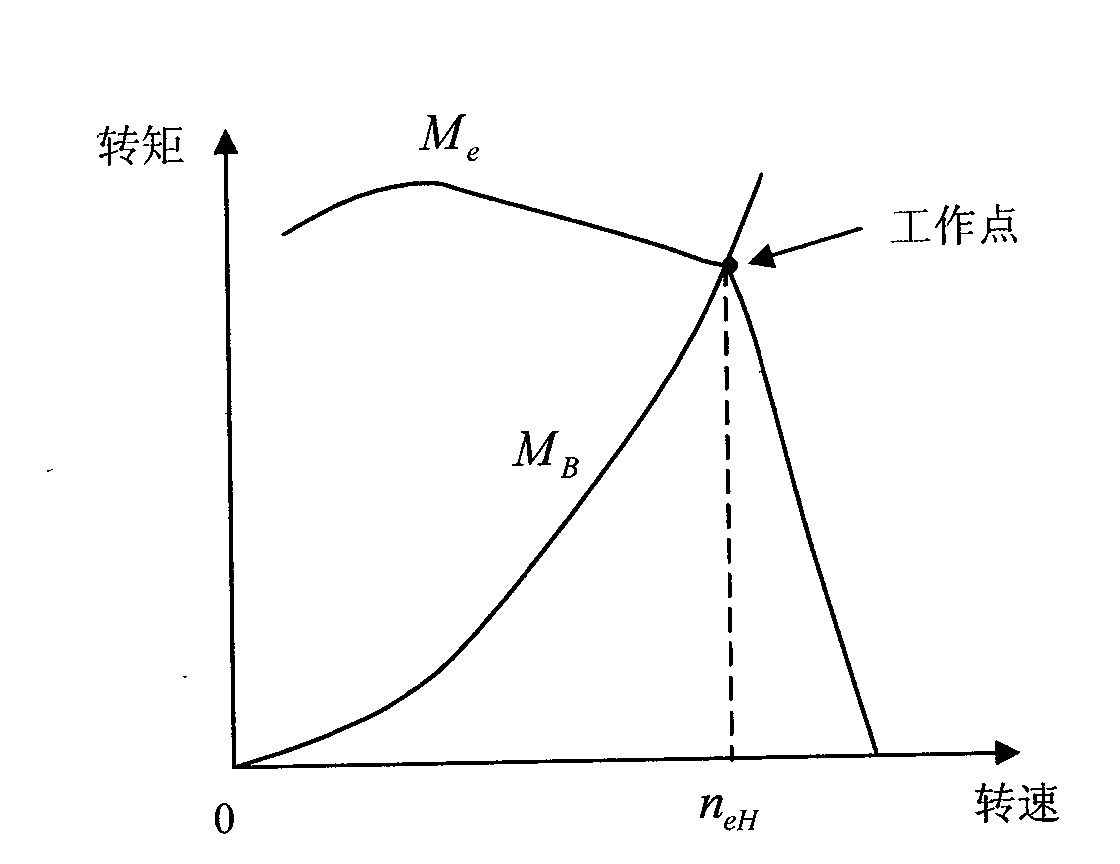

Automatic gear shifting method of hydraulic transmission system

InactiveCN101576156AChange speed ratioImprove transmission efficiencyGearing controlFluid gearingsMagnetic powderMagnetic particle clutch

The invention provides an automatic gear shifting method of a hydraulic transmission system, aiming at solving the problem that the efficiency of the hydraulic transmission system changes with loads. A combination mode of step regulation and stepless regulation is adopted, wherein the step regulation plays the role of crude regulation, and the stepless regulation plays the role of fine regulation. A mechanical transmission is adopted for crude regulation, and a magnetic powder clutch or a device with similar function is adopted for fine regulation. By a certain algorithm, a hydrotransmitter can be caused to work at a high-efficiency point, thereby achieving the purposes of improving efficiency and saving energy.

Owner:SICHUAN UNIV

Method and device for automatic spinning repiece

InactiveCN1285782COptimize structural configurationReduce twistPiercing arrangementsContinuous wound-up machinesYarnBobbin

A method and device for automatic spinning yarn spinning. The roving frame detects the length of the full yarn when the bobbin is about to be full through the encoder at the drafting part, so that the roving frame spins at a low speed to a certain length. When the roving reaches a certain length Finally, let the roving frame run at a low speed. At this time, the dragon tendon stops the lifting movement so that the yarn is at this height, and wraps the body yarn 2-3 times, and then the dragon tendon is quickly lowered to form a large pitch winding, so that the roving is in the transportation of the roving. No yarn falling off during the process; change the speed ratio of the flyer and the roller to reduce the twist of the roving, and obtain a low-twist roving at the end of the roving that is about 20% lower than the normal twist. Its length is adapted to the second automatic spinning head, and the pile is more adherent; by setting a special width of pile on the bobbin, the hairiness at the broken end of the yarn can be better attached to the bobbin, The invention has the advantages of simple structure, ingenious method, good spinning effect and easy industrial realization.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

Magnetic gearbox

ActiveCN108291625BChange speed ratioDynamo-electric brakes/clutchesGearingCondensed matter physicsMaterials science

A magnetic transmission is provided with: an inner rotor; an outer rotor; and a magnetic-field-modulating stator disposed coaxially between the inner rotor and the outer rotor. The inner rotor is provided with a first magnet array and a second magnet array arranged in the direction of the central axis and disposed at different pitches along the circumferential direction. The outer rotor is provided with a magnet array disposed along the circumferential direction. The magnetic-field-modulating stator is provided with a first magnetic body array and a second magnetic body array opposing the first magnet array and the second magnet array, respectively. Further, by moving the inner rotor and the magnetic-field-modulating stator in the direction of the central axis while holding the opposing relationship between the first magnetic body array and the second magnetic body array, and the first magnet array and the second magnet array, the position where the outer rotor, and the first magnet array and the second magnet array oppose each other is changed continuously.

Owner:HITACHI METALS LTD

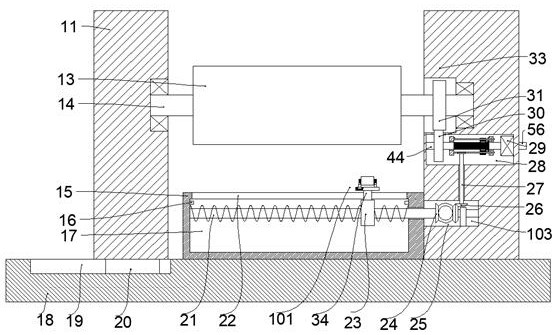

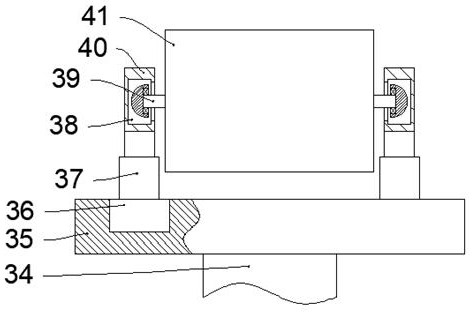

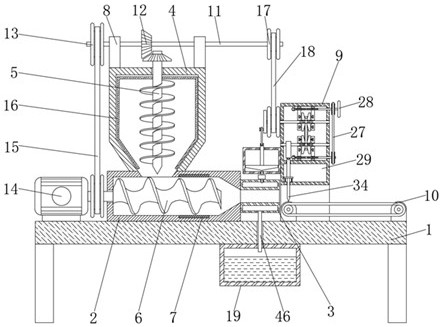

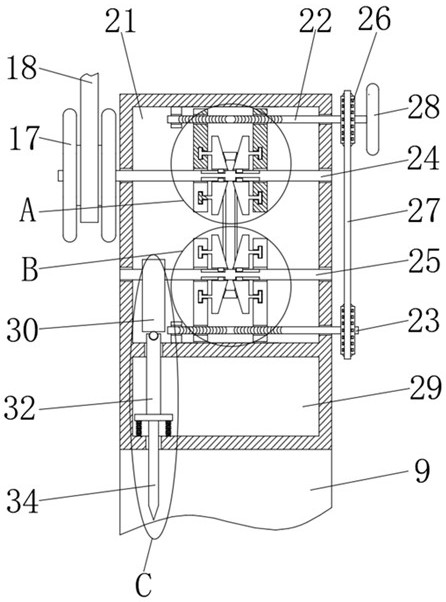

An intelligent glass fiber reinforced plastic automatic production machine

The invention discloses an intelligent automatic production machine for glass fiber reinforced plastics, which comprises a base, a first slideway is provided through the top surface of the base, a mover is arranged in the first slideway, and the mover is fixed on the top surface of the base. There is a left body; the present invention is simple in structure and easy to use. It utilizes gear transmission to complete the automatic production of FRP laying work. The layer paste materials are all the same to improve the process performance of the product. The invention also has a slidable matching block, which can be controlled by the control rod to change the movable distance of the matching block, thereby changing the rotation speed of the main shaft and the threaded shaft. Ratio, to achieve the purpose of changing the number of layers of pasted materials for each laying, it can be changed according to user needs, and the diversity of products can be improved.

Owner:南通盛瑞复合材料有限公司

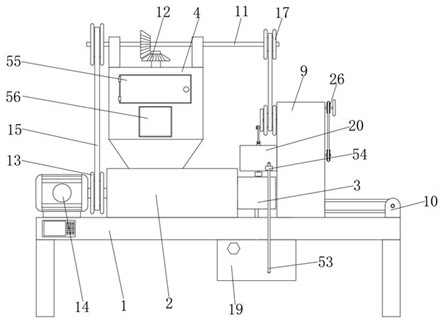

Intelligent glass fiber reinforced plastic automatic production machine

The invention discloses an intelligent glass fiber reinforced plastic automatic production machine. The machine comprises a base, a first sliding way is arranged in the top face of the base in a penetrating manner, a mover is arranged in the first sliding way, and a left machine body is fixedly arranged on the mover. The intelligent glass fiber reinforced plastic automatic production machine is simple in structure and convenient to use, automatic production of glass fiber reinforced plastic paste spreading work is completed through gear transmission, and compared with existing common hand molding in China, the machine has the advantages that the mechanical degree is higher, the production efficiency is higher, it can be guaranteed that paste spreading materials of all layers are the same,and the process performance of products is improved. The machine is provided with a sliding matching block, the matching block can be controlled through a control rod, the movable distance of the matching block is changed, and therefore the rotating speed ratio of a main shaft to a threaded shaft is changed, the purpose of changing the number of layers of materials spread with the paste every timeis achieved, self-changing can be conducted according to user requirements, and product diversity is improved.

Owner:南通盛瑞复合材料有限公司

Multi-shift speed change gear box for sectional warping machine

InactiveCN102242436BChange speed ratioEasy to adjustOther manufacturing equipments/toolsTextiles and paperEngineeringSprocket

The invention discloses a multi-shift speed change gear box for a sectional warping machine, and the multi-shift speed change gear box comprises an input shaft, a middle shaft, a speed change gear shaft and an output shaft, wherein an input chain wheel is arranged on the input shaft; selective gears which are engaged with each other are mounted on the input shaft and the middle shaft; a semi-closed bracket is sleeved on the middle shaft; a moveable gear mounted on the middle shaft is positioned inside the bracket, is locally exposed and is engaged with a speed change gear mounted on the speedchange gear shaft; steering gears which are mutually engaged and steered are mounted on the speed change gear shaft and the output shaft; and lastly power is outputted from a power chain wheel on theoutput shaft. The multi-shift speed change gear box for the sectional warping machine can be used for realizing the rough adjustment and fine adjustment of a measured value and realizing the high-precision transmission.

Owner:SHAOXING QUNFANG MACHINERY

Split-type supercharger for a turbocharged engine

ActiveCN103016140BChange speed ratioChange gear functionInternal combustion piston enginesGearingEngine efficiencyGas compressor

The invention relates to a split supercharger of a turbo supercharged engine and is used for realizing the matching of the air inlet pressure of the engine and the work condition of the engine. The split supercharger consists of an air compressor, a turbine and an intermediate body and is characterized in that the intermediate body is in a split structure and comprises an air compressor end intermediate body, a turbine end intermediate body, an intermediate body casing, a rolling wheel turntable type stepless speed changer and a driving motor, the air compressor end intermediate body and the turbine end intermediate body are connected through the intermediate body casing, the intermediate body casing is connected with the driving motor through a gear engaging mechanism, and the rolling wheel turntable type stepless speed changer is arranged in an inner cavity of the intermediate body casing. The split supercharger has the advantages that the structure is simple, the manufacture cost is low, the work noise is low, the split supercharger can be matched with different work conditions of the engine, the efficiency of the engine is improved, and the NVH (noise, vibration and harshness) performance of the engine is improved.

Owner:GREAT WALL MOTOR CO LTD

A pressure forming device for carbon production

ActiveCN113524772BRealize the function of cutting offCut length adjustmentMetal working apparatusShaping pressDrive wheelDrive shaft

The invention discloses a pressure forming device for carbon production, which relates to the technical field of carbon production, and comprises a base, a first transmission belt, a second transmission belt, a gear belt, and a metal transmission belt. A raw material transmission box is arranged on the top of the base. The side of the raw material transmission box is fixedly connected with a pressure forming box. The pressure forming device for carbon production, when the driving shaft rotates, drives the driving wheel to follow the driving shaft to rotate through the transmission of the first transmission groove and the first transmission block, and also through the transmission between the driving wheel, the metal transmission belt and the driven wheel Drive the driven wheel to rotate, drive the driven shaft to rotate through the transmission between the second transmission groove and the second transmission block, use the driven shaft to drive the cam to rotate, squeeze the pressing column through the rotation of the cam to move the pressing column and the cutting knife downward At the same time, the spring pushes the cutting knife and the pressing column to move upwards, realizing the function of cutting off the pressurized carbon rod.

Owner:南通市康斯达碳制品有限公司

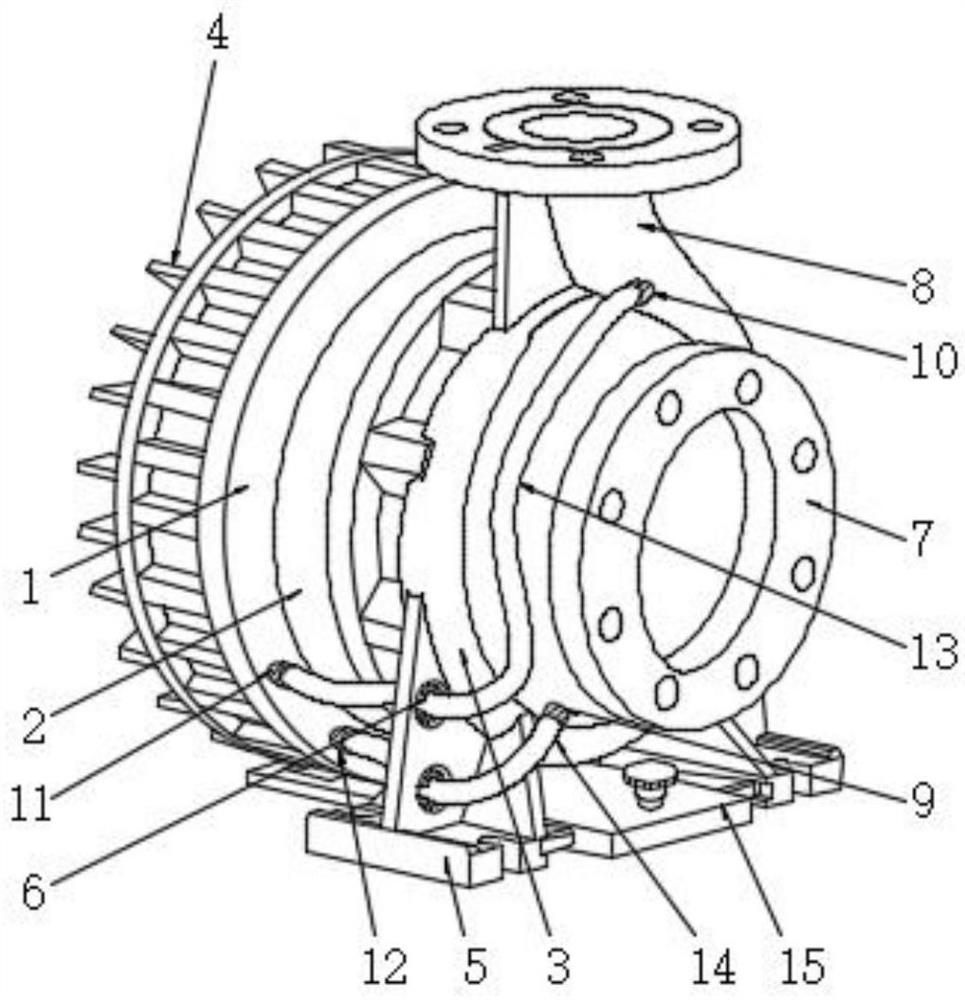

A gear variable speed disc water pump

ActiveCN112128116BShorten the lengthImprove the use environmentPump componentsPump controlImpellerGear wheel

The invention discloses a gear-variable disc water pump, which relates to the technical field of water pumps and comprises a disc motor and an impeller box. A gear box is fixedly connected between the disc motor and the impeller box. The connecting shaft of the disc motor One end is fixedly connected to the input end of the gear box, the output end of the gear box runs through the impeller box, and the output end of the gear box box is fixedly connected to the impeller, the two sides of the impeller box are welded with support plates, one side Two sets of holders are fixedly connected to the inside of the support plate, and a cooling plate is embedded and connected to the rear surface of the disc motor. The water pump in the present invention uses a disc motor as the driving component, thereby reducing the overall length of the water pump and reducing the demand for the installation site of the water pump. At the same time, the present invention adds a gear box between the driving component and the impeller of the existing water pump, which can Changing the speed ratio between the disc motor and the impeller can facilitate the staff to adjust the speed of the impeller.

Owner:ANHUI JINWAN PUMP TECH CO LTD

Control device for vehicular power transmitting apparatus

ActiveCN101668671BExcellent economical performanceImprove economyHybrid vehiclesInternal combustion piston enginesExternal combustion engineBoundary values

A control device is disclosed which can obtain increased fuel economy performance depending on a kind of fuel in a vehicle having an internal combustion engine and an electric motor when the kind of fuel supplied to the internal combustion engine is altered. A determining vehicle speed (V1) and determining output torque (T1), representing a boundary value with which a step-variable control region and a continuously variable control region of a shifting mechanism (10) are demarcated, are altered such that the higher the mixing ratio of ethanol, the lower will be the determining vehicle speed (V1) and determining output torque (T1). Therefore, the determination is made whether to operate a first electric motor (M1) depending on the mixing ratio of ethanol, making it possible to obtain increased fuel economy performance in line with the mixing ratio of ethanol.

Owner:TOYOTA JIDOSHA KK

Multi-functional integrated type hydraulic cylinder

ActiveCN101893017BImprove matchLarge speed differenceFluid-pressure actuatorsHydraulic cylinderCylinder head

The invention discloses a multi-functional integrated type hydraulic cylinder. The multi-functional integrated type hydraulic cylinder comprises a main cylinder barrel, a main cylinder cover, a barrel-shaped main cylinder piston rod, a rapid cylinder guide sleeve, an isolating ring, a three-section card key and a main cylinder guide sleeve and is characterized in that: a first oil port, a second oil port and a third oil port are formed on the main cylinder barrel; a fourth oil port and a sixth oil port are formed on the main cylinder cover; a positioning cylinder guide sleeve is matched with the inner wall of the left end part of the main cylinder barrel; the inner wall of the positioning cylinder guide sleeve is matched with the outer wall of the main cylinder guide sleeve; the left end part of a barrel-shaped rapid cylinder piston rod is matched with the inner wall of the barrel-shaped main cylinder piston rod; the right end of the barrel-shaped rapid cylinder piston rod is connected with a locknut in a matching way; a rapid cylinder head is connected with the inner wall of the left end part of the barrel-shaped main cylinder piston rod in a matching way; a low-pressure oil inlet pipe is fixedly connected in the barrel-shaped rapid cylinder piston rod; and the right end of the low-pressure oil inlet pipe is a fifth oil port. The multi-functional integrated type hydraulic cylinder has the advantages of compact structure, high circulating operation speed, high working pressure, large thrust force of a working condition, high power density and convenient installation.

Owner:泸州众大科技液压件有限公司

Gear making method for tooth finishing and its combination tool

ActiveCN107530803BChange speed ratioGear teeth manufacturing toolsGear-cutting machinesGear wheelGear tooth

Owner:PROFILATOR

Stepless hydrodynamic transmission device

InactiveCN107269797AChange speed ratioRealize power lossFluid gearingsDisplacement controlEngineering

A stepless hydraulic transmission device, including a front-stage eccentric movable vane pump, a movable seat, a secondary eccentric movable vane pump, and a displacement control device; the front-stage eccentric movable vane pump is movably arranged on one side of the movable seat, The secondary eccentric movable vane pump is arranged on the opposite side of the movable seat; the pre-stage eccentric movable vane pump includes the first rotor of the pre-stage, several movable vanes of the pre-stage, the second rotor of the pre-stage connected with the movable vanes of the pre-stage one by one and The front-stage eccentric part; the secondary eccentric movable vane pump includes the secondary first rotor, several secondary movable vanes, the secondary second rotor and the secondary eccentric part connected to the secondary movable vanes one by one; the front-stage eccentric part It is installed on the movable seat; there is a displacement control device on the movable seat, and the displacement control device controls the rotation or translational movement of the movable seat, thereby changing the eccentric distance between the front-stage eccentric member and the front-stage first rotor. The transmission device has the advantages of large transmission torque, which can not only increase the output torque, but also increase the output speed, and can also transmit high-efficiency torque transmission under the condition that the output shaft speed exceeds the input shaft.

Owner:汤斌

Chuck type continuously variable transmission mechanism

InactiveCN104033551BChange speed ratioTo achieve the purpose of continuously variable speedGearingGear vibration/noise dampingTooth spacePulley

Owner:SHANGHAI INST OF TECH

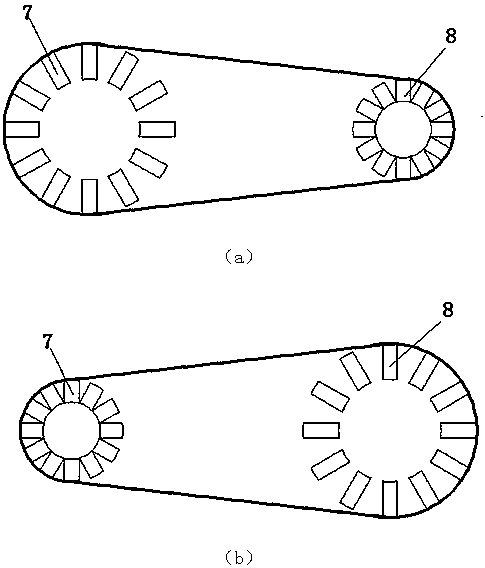

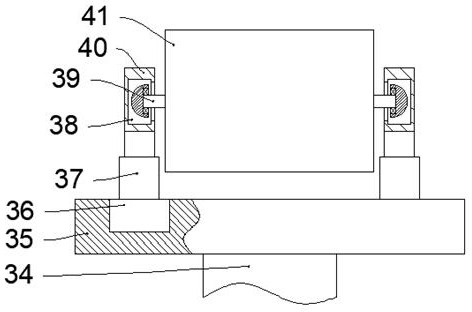

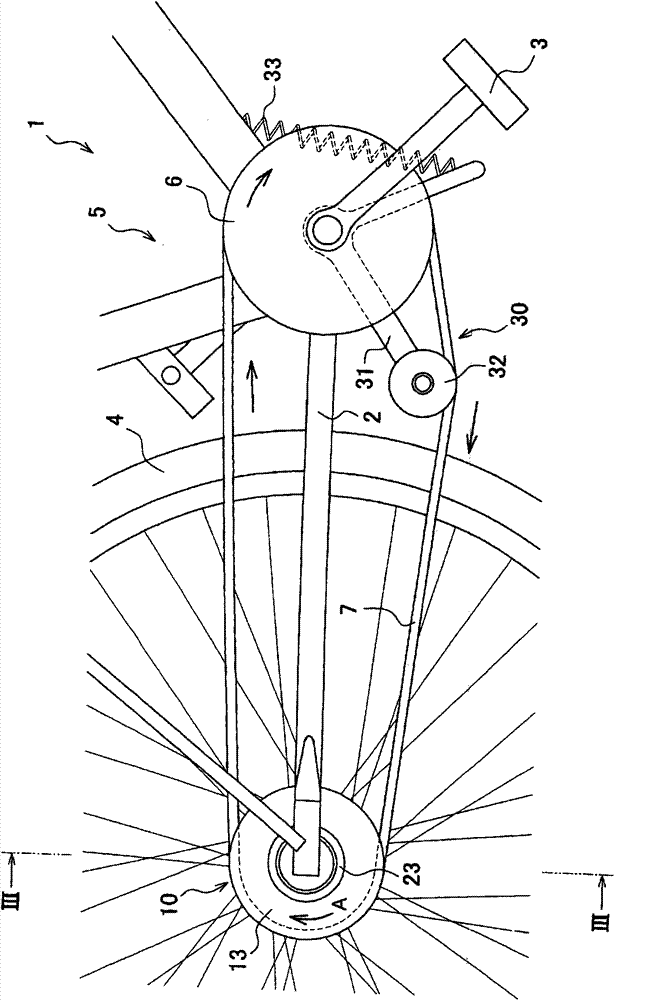

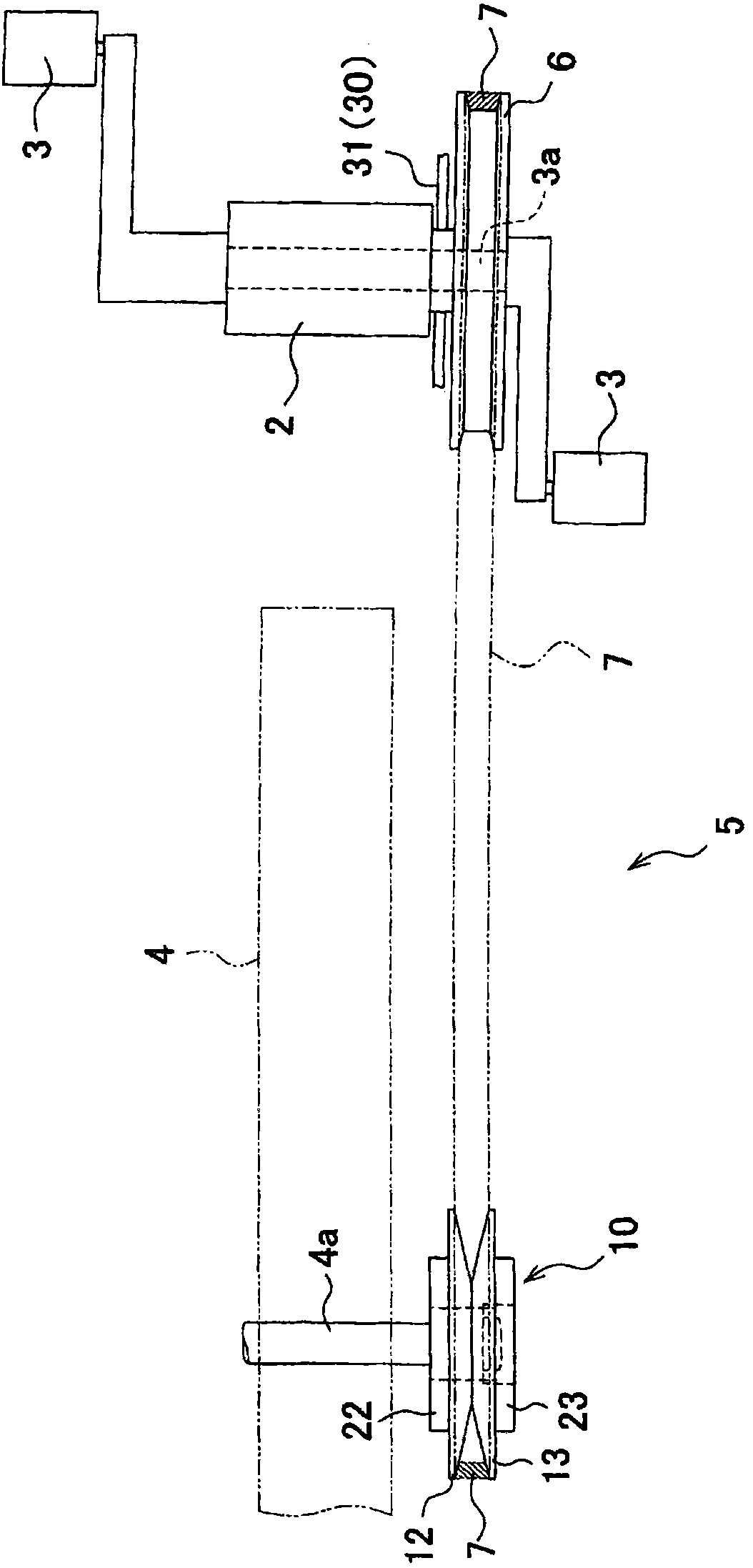

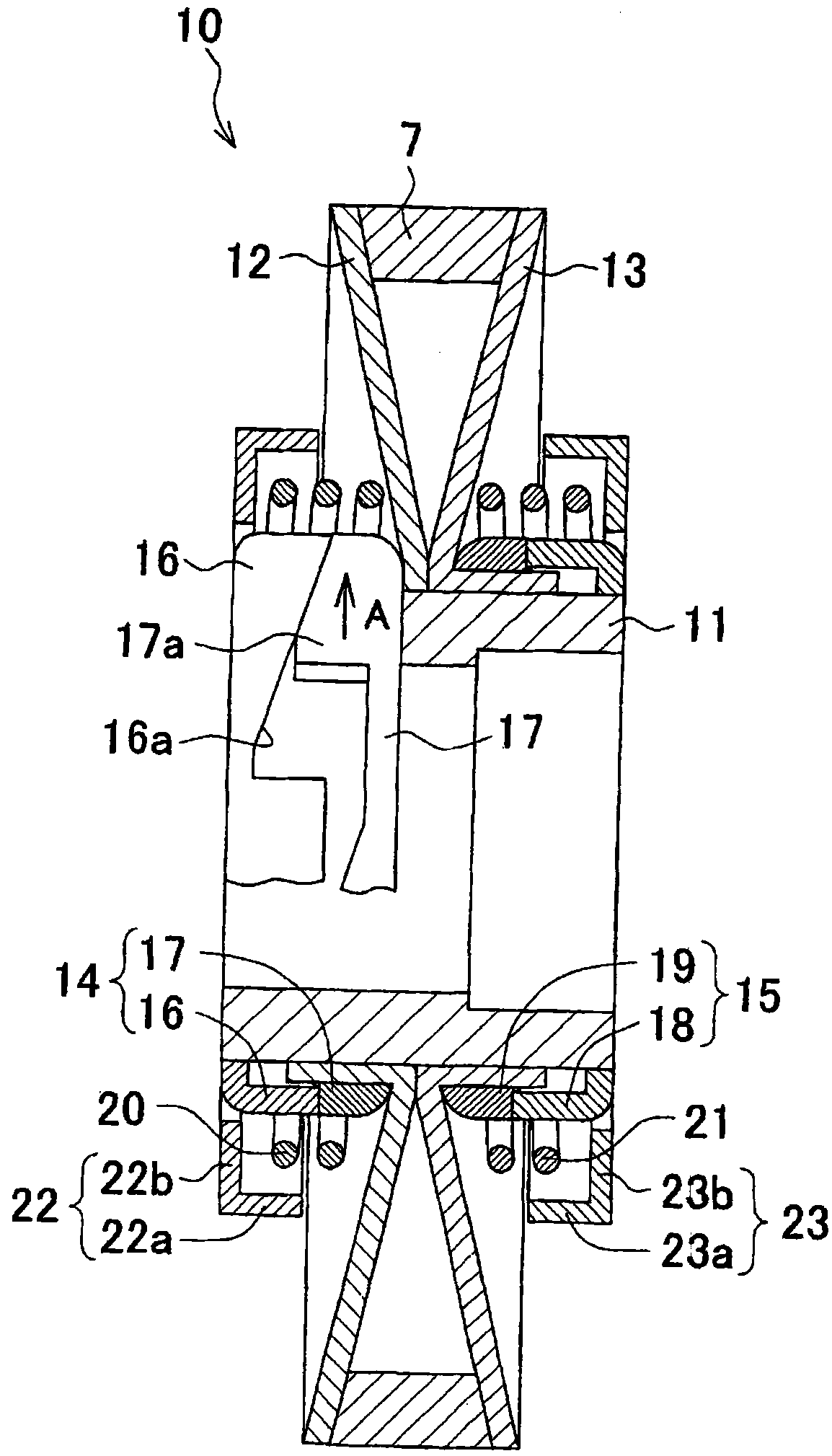

Variable speed pulley and bicycle driving device with the same

Owner:MITSUBOSHI BELTING LTD

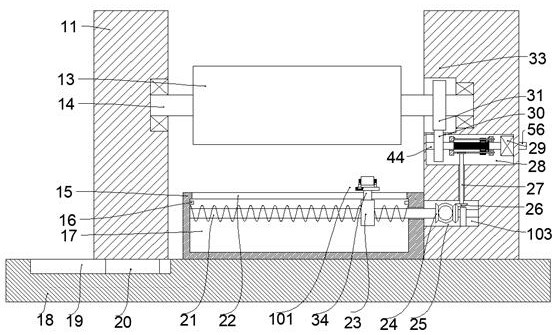

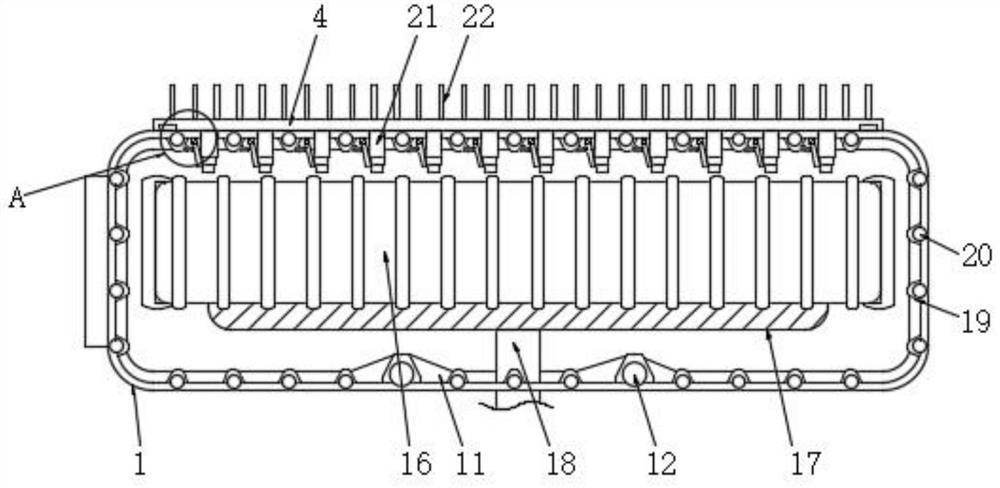

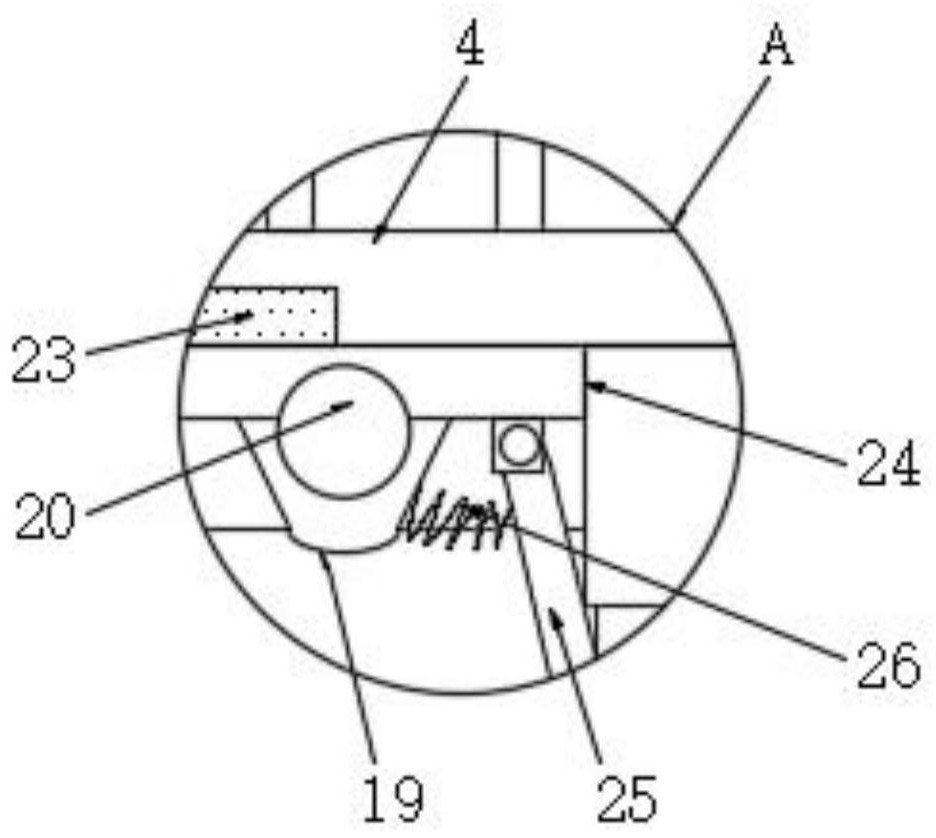

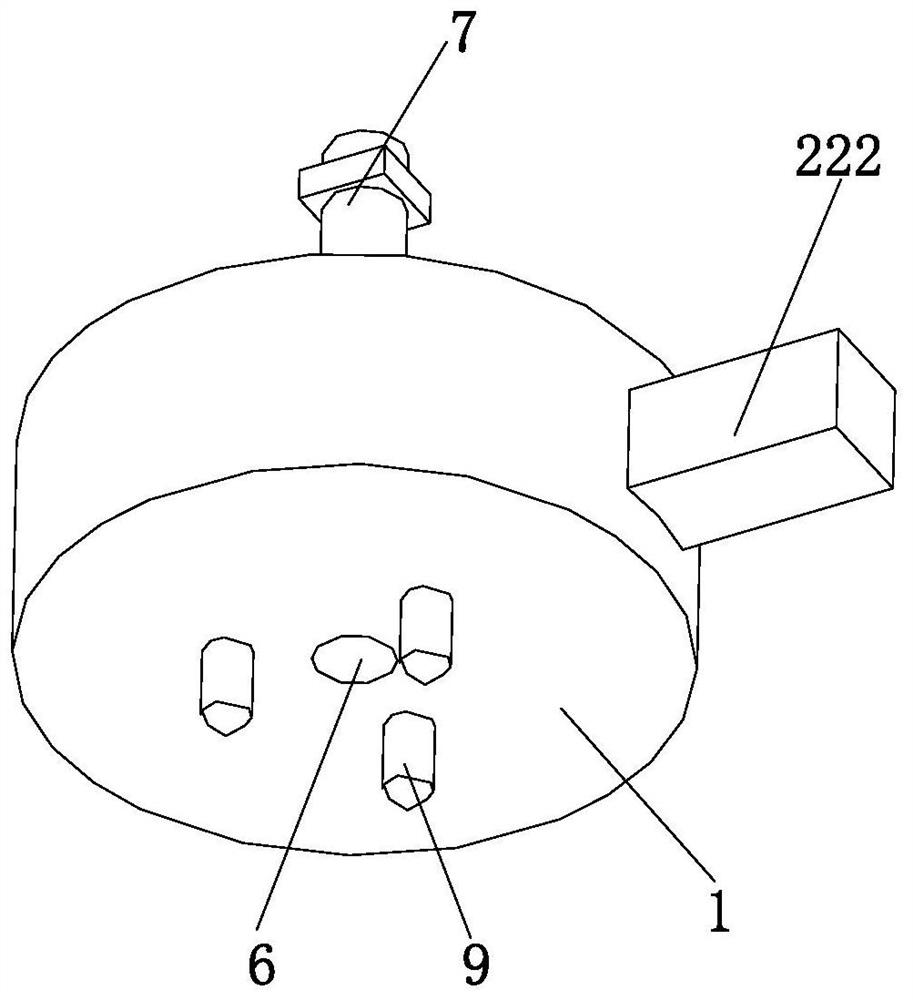

Patella replacement integrated drilling device

The invention discloses a patella replacement integrated drilling device and belongs to the technical field of medical instruments, the patella replacement integrated drilling device comprises a guider, a holding rod, a drilling assembly and a power connecting rod, the holding rod is arranged on the guider and fixedly connected with the guider, the drilling assembly is arranged on the guider and rotationally matched with the guider, and the power connecting rod is detachably connected with the drilling assembly. According to the patella replacement integrated drilling device, a first gear drives three second gears to rotate, and the three second gears drive three drilling heads to rotate, so that the patella is drilled and does not need to be drilled for three times, and drilling is faster and more stable.

Owner:THE FIRST MEDICAL CENT CHINESE PLA GENERAL HOSPITAL

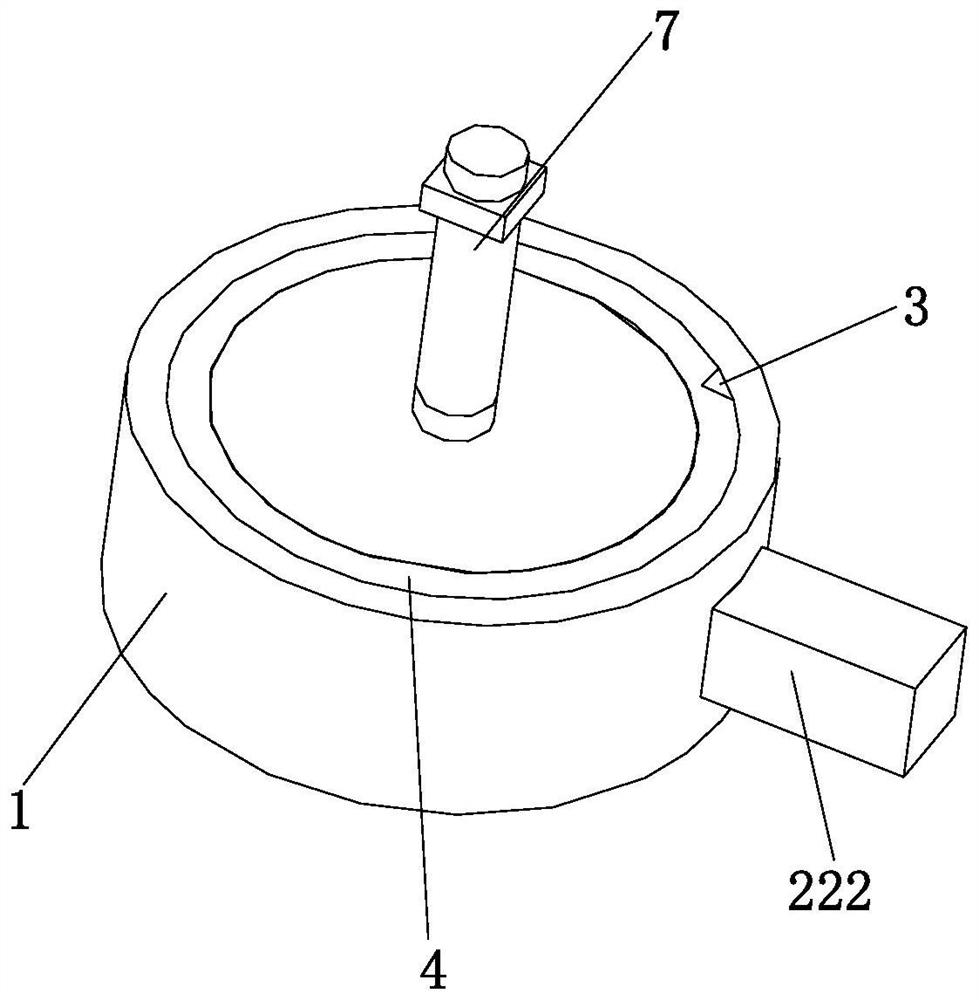

Variable speed pulley and bicycle driving device with the same

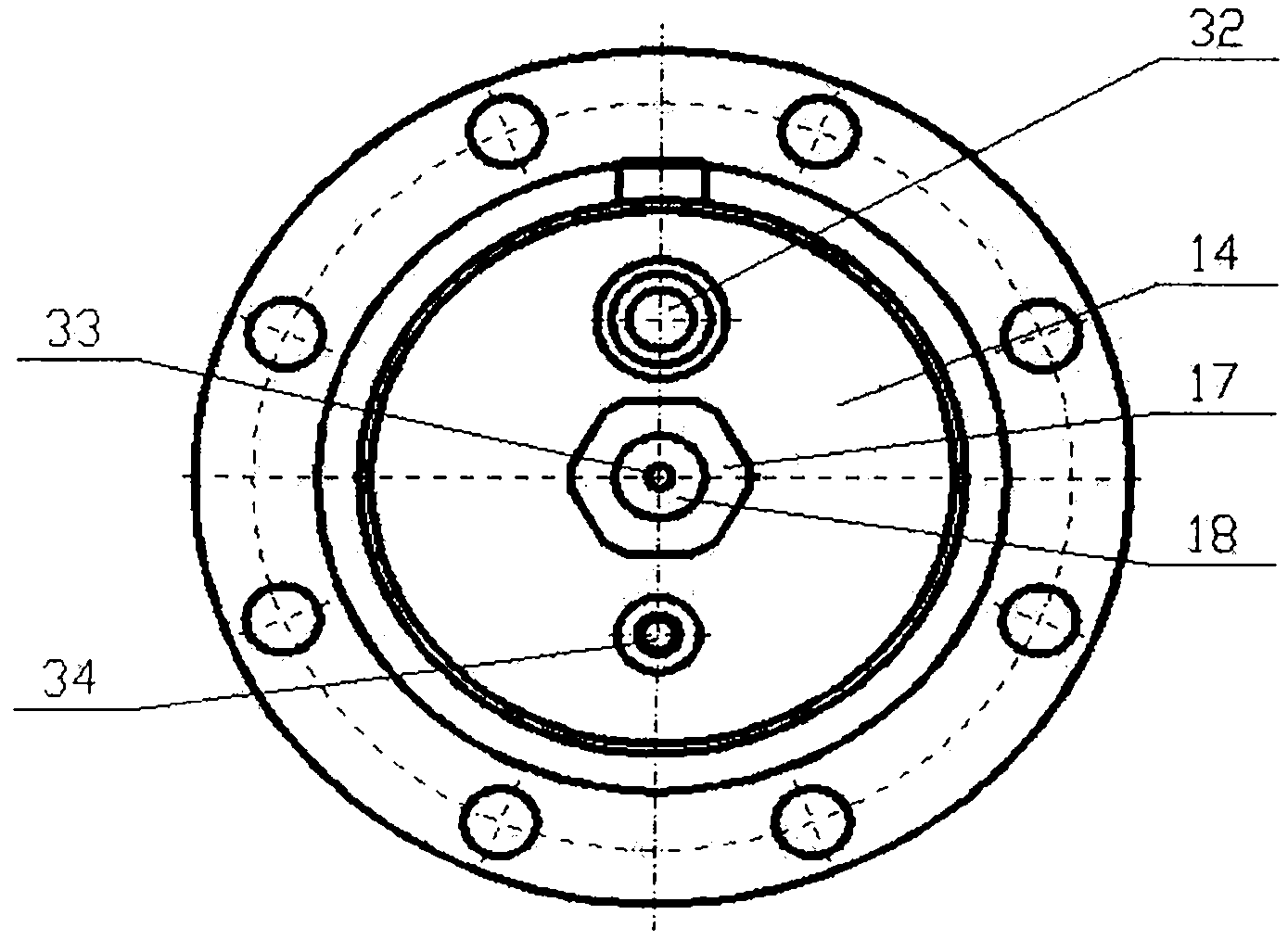

The present invention provides a variable speed pulley which can cause smooth change of separation distance of two pulley pieces and a bicycle driving device with the same. The variable speed pulley (10) is provided with the following components: a cylindrical hub (11) connected with a rotating a rotating shaft, two pulley sheets (12,13), two torque cams (14,15), and two force applying devices (20,21). The two pulley sheets are respectively equipped on the outer peripheral part of the hub. A V groove for keeping a wheel belt with a V-shaped section is formed between two opposite surfaces of the pulley sheets. Two torque cams are respectively set on the two cam sheets. Each torque cam is composed of two torque cam sheets (16,17(18,19)) which can movably fasten in a spiral direction and are respectively fixed on the hub and the pulley sheets (12(13)). The force applying devices are respectively provided on the two pulley sheets (12,13) and apply force to the pulley sheets (12,13) in a direction of separating the two pulley sheets.

Owner:MITSUBOSHI BELTING LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com