Automatic gear shifting method of hydraulic transmission system

A technology of hydraulic transmission and automatic transmission, which is applied in the direction of transmission, fluid transmission, transmission control, etc., and can solve the problems of frequent shifting, difficulty in determining the timing of shifting, and rising cost of the transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

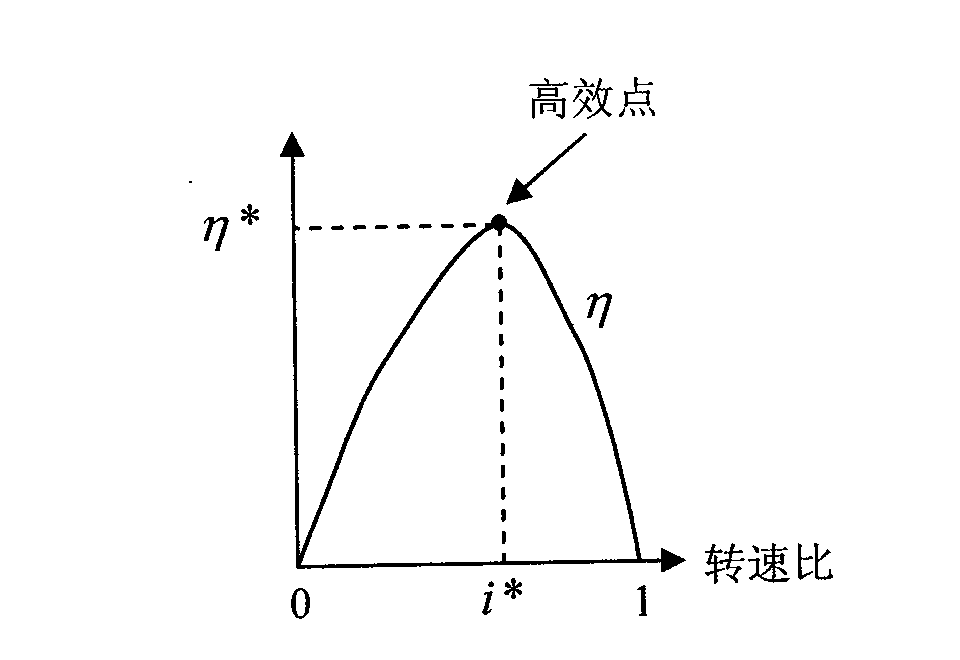

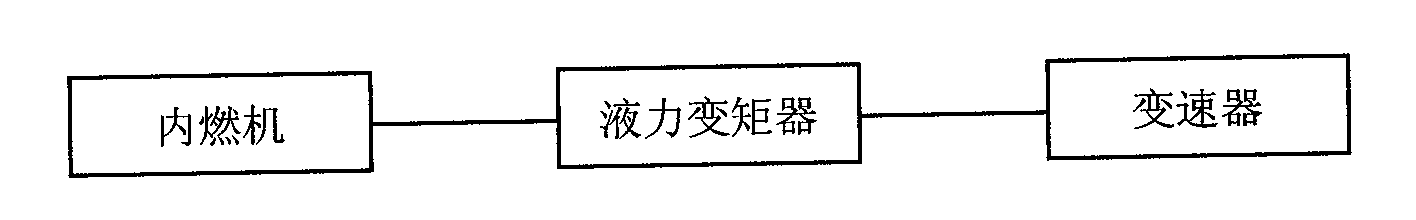

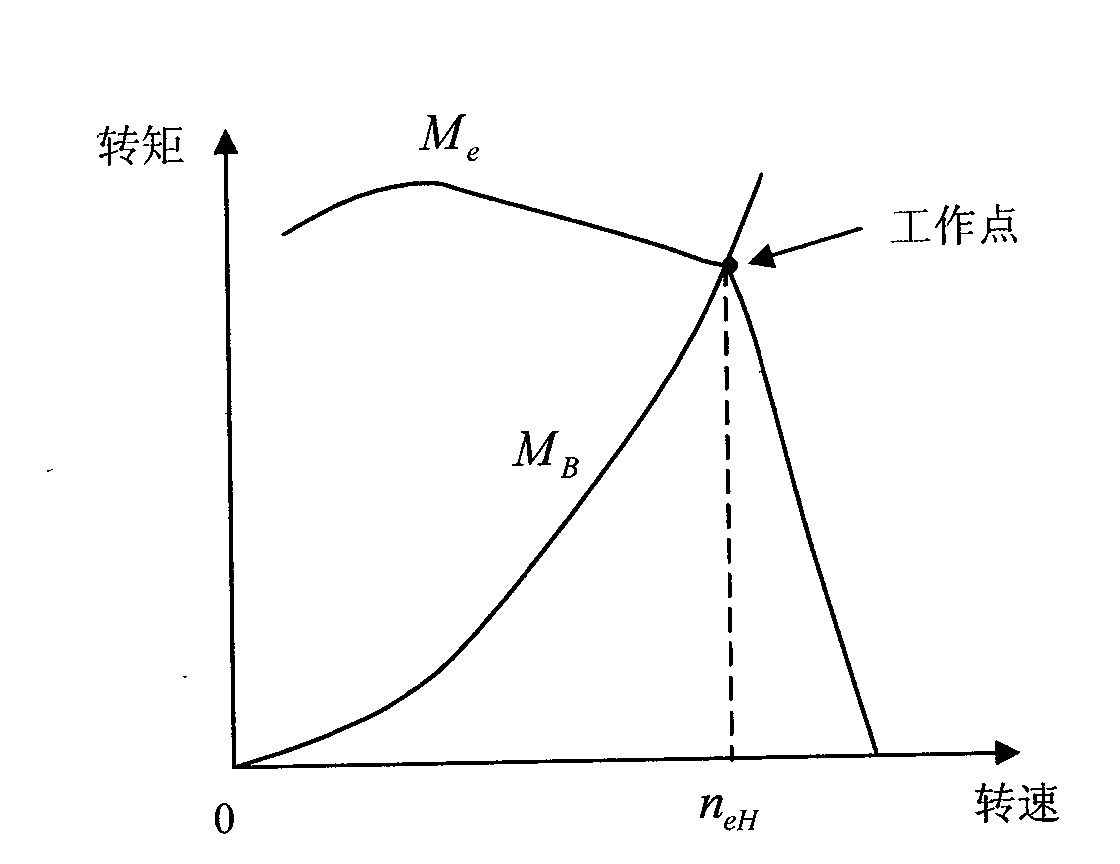

[0014] The technical route adopted by the present invention is as follows Figure 5 As shown, a magnetic powder clutch is added between the internal combustion engine and the transmission, and the magnetic powder clutch is connected in parallel with the torque converter. The electronic control unit detects the status of each part of the transmission system and takes corresponding control measures in order to make the hydraulic torque converter work at an efficient point.

[0015] The magnetic powder clutch is mainly composed of the active part, the driven part, the magnetic powder and the excitation coil. The magnetic powder is filled in the working gap between the driving part and the driven part. When the excitation coil is energized, a magnetic field is generated between the driving part and the driven part. Under the action of the magnetic field, the magnetic powder is connected in a chain shape along the magnetic flux direction to form a magnetic powder chain. Torque can be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com