Continuously variable transmission

A continuously variable transmission and variable displacement technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

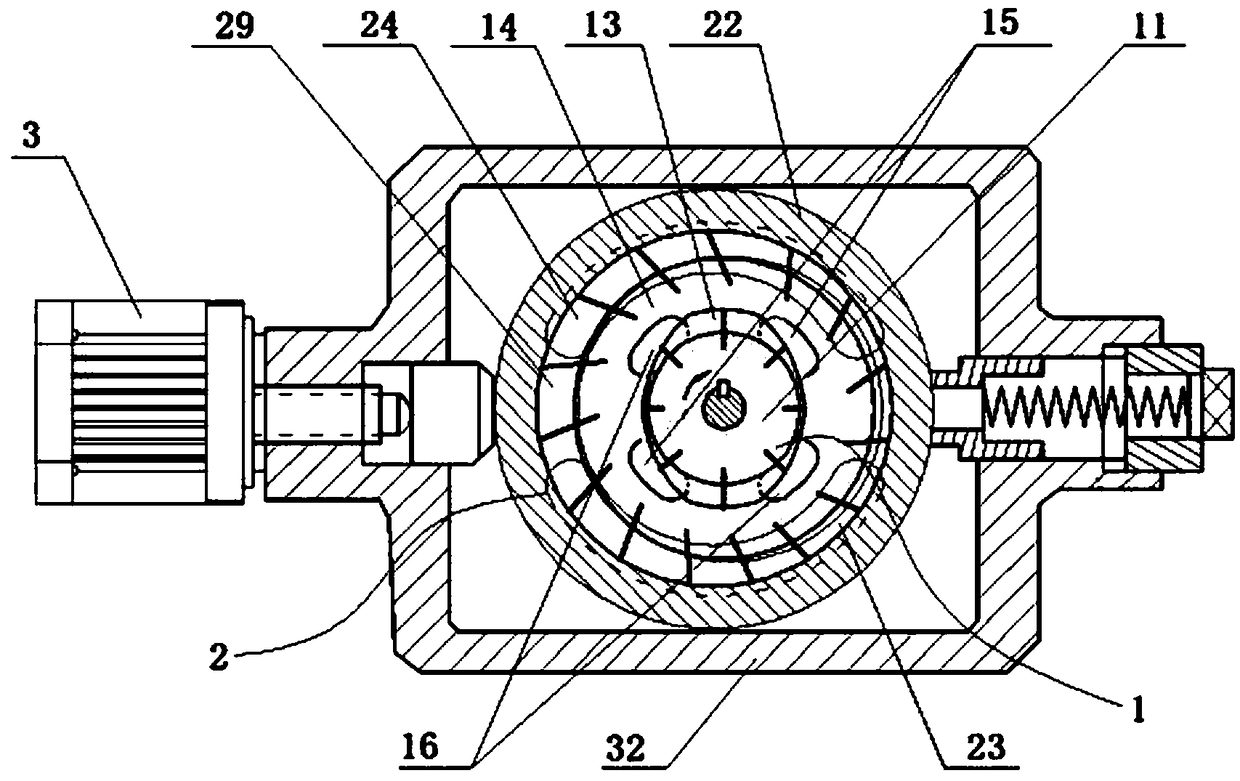

[0052] See image 3, a continuously variable transmission, including a fixed-displacement pump 1 and a variable-displacement motor 2, the fixed-displacement pump 1 is a double-vane fixed-displacement pump, the variable-displacement motor 2 is a single-vane variable-displacement motor, and the double-vane fixed The displacement pump is mainly composed of an inner rotor 11, a common rotor 14, and a cavity 13. The center of circle of the double-blade fixed-displacement pump 1 is fixed relative to the position of the housing 32; the single-blade variable displacement motor is mainly composed of the common rotor 14, The stator 22 and the cavity 29 are composed. The stator 22 of the single-vane variable displacement motor can move radially under the action of the eccentric adjustment mechanism 3, thereby changing the liquid intake volume of the single-vane variable displacement motor, that is, the displacement V2. The inner rotor 11 of the double vane fixed displacement pump is the ...

Embodiment 2

[0056] See Figure 4 and Figure 5 , a continuously variable transmission, including a fixed-displacement pump 1 and a variable-displacement motor 2, the fixed-displacement pump 1 is a double-vane quantitative liquid pump, the variable-displacement motor 2 is a single-acting variable-vane motor, and the double-vane quantitative liquid pump and the single-acting variable vane motor is an axial layout structure, 3 is the eccentric adjustment mechanism, 18 is the low-pressure inlet of the double-vane quantitative liquid pump, 19 is the high-pressure outlet of the double-vane quantitative liquid pump, 25 is the high-pressure liquid input port of the motor, 26 12 is the outer rotor of the double vane quantitative liquid pump, 21 is the inner rotor of the single-acting variable vane motor, 27 is the spline sleeve connecting the motor and the pump, and 17 is the spline connecting the pump and the motor Shaft, 37 is a high-pressure rotary sealing ring, 38 is a high-pressure channel o...

Embodiment 3

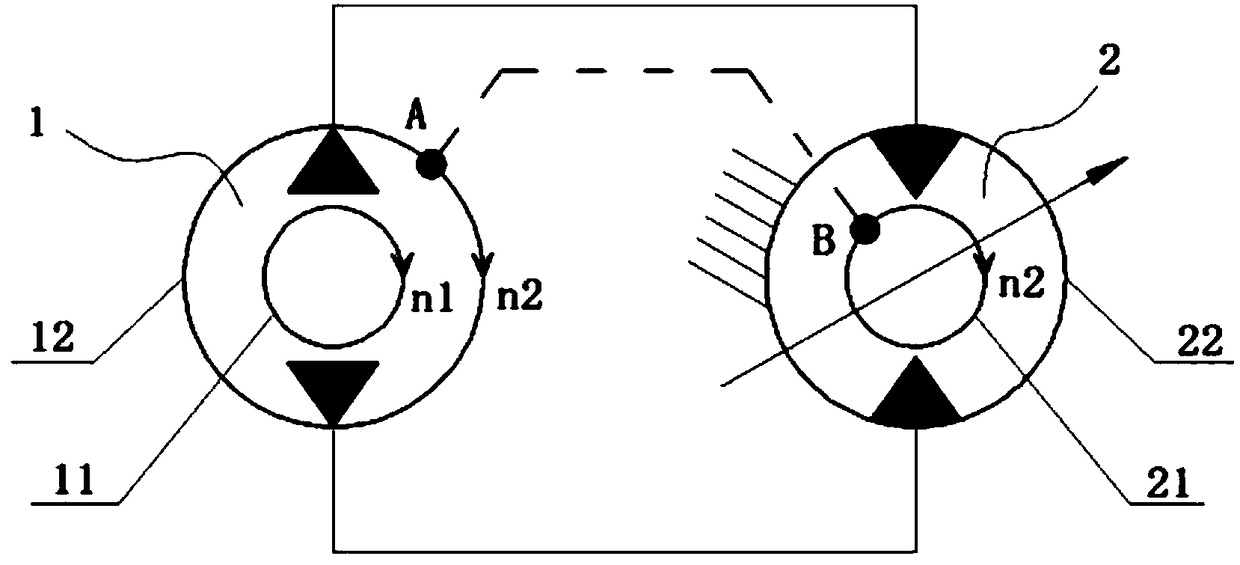

[0060] See Image 6 , a continuously variable transmission, including a variable displacement pump 5 and a variable displacement motor 2, the outer rotor (point A) of the variable displacement pump 5 is rigidly connected with the inner rotor (point B) of the variable displacement motor 2, 51 is The inner rotor of the variable displacement pump, 52 is the outer rotor of the variable displacement pump, 21 is the inner rotor of the variable displacement motor, 22 is the stator of the variable displacement motor, the stator 22 of the variable displacement motor is connected with the casing, and the The power input is added to the inner rotor 51 of the variable displacement pump 5, and the outer rotor 52 of the variable displacement pump 5 outputs power.

[0061] The power direction of the inner rotor 51 of the variable displacement pump is set to be clockwise, and the direction of the force of the high pressure oil input by the variable displacement motor 2 acting on the inner rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com