Patents

Literature

96results about How to "Change displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

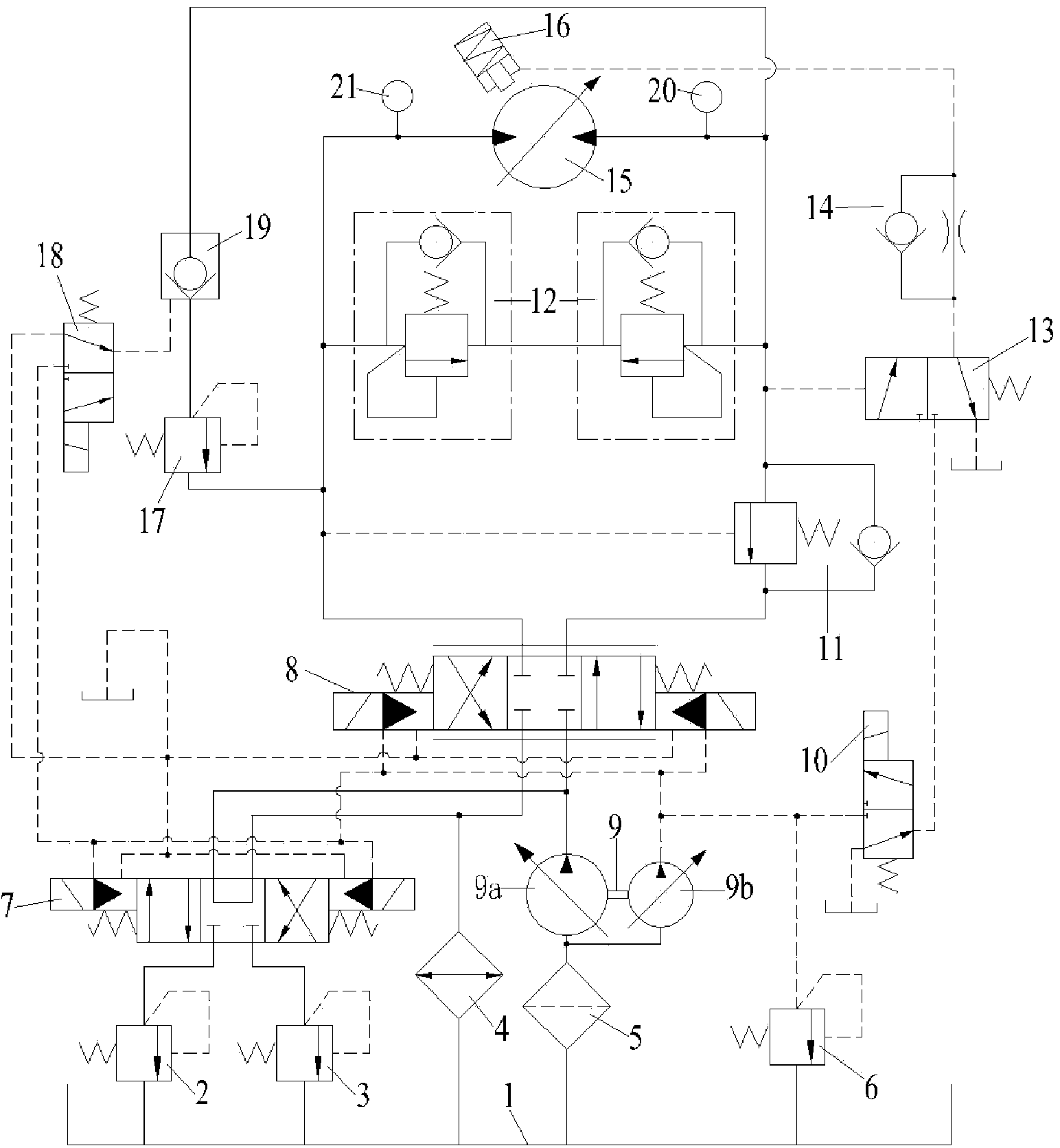

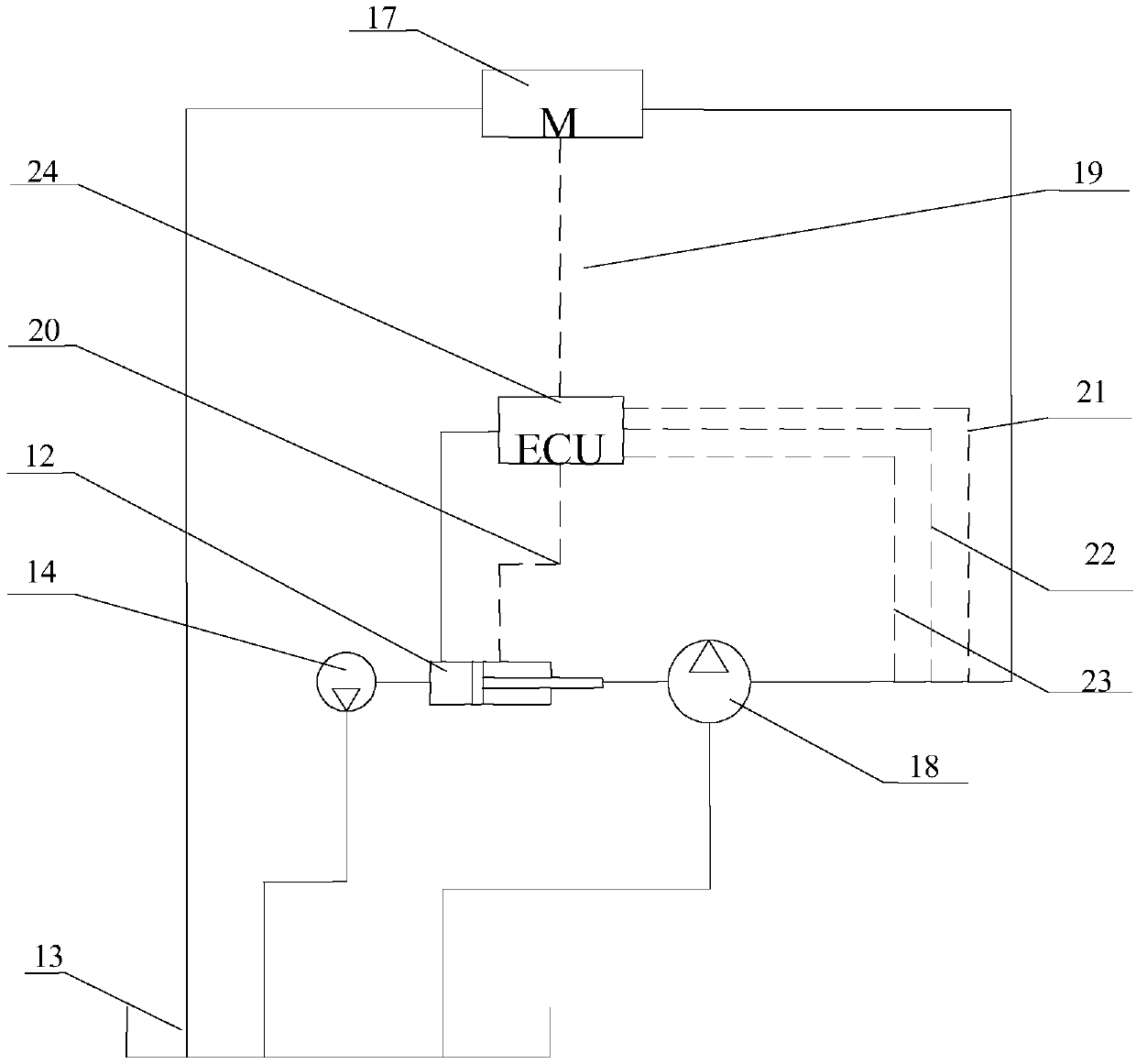

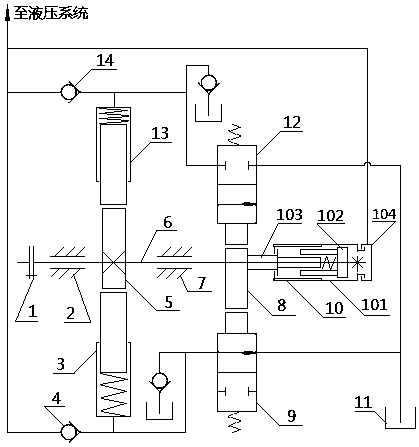

Deep-sea winch wave compensation hydraulic driving system with load adaptability

ActiveCN103922235AReduce power consumptionEffective isolationWinding mechanismsSolenoid valveCheck valve

The invention discloses a deep-sea winch wave compensation hydraulic driving system with load adaptability. The deep-sea winch wave compensation hydraulic driving system with the load adaptability comprises a main lifting loop, a brake loop and a constant tension control loop. A three-position four-way solenoid valve is adopted in the main lifting loop to select a work overflow valve, switchover of system backpressure values under different working conditions is achieved, and system power consumption is lowered effectively. An overflow valve is adopted to control the backpressure of the constant tension control loop, the inlet of a fourth overflow valve is connected with a pilot operated check valve, the pilot operated check valve is controlled through a two-position three-way solenoid valve, effective separation of the constant tension control loop and the main lifting loop when the constant tension control loop does not work can be achieved, and meanwhile, the rapidity for the constant tension control loop to be put into work is guaranteed. The driving mode of a variable displacement motor and a variable pump set is adopted, the output torque of a variable hydraulic motor is changed by changing the travel of the variable displacement mechanism of the variable hydraulic motor, namely, by changing the displacement of the variable hydraulic motor, the output power of the variable pump set is changed correspondingly according to the hydraulic power needs of the variable hydraulic motor, and the stepless regulation of the output capacity of the hydraulic winch is achieved.

Owner:DALIAN MARITIME UNIVERSITY

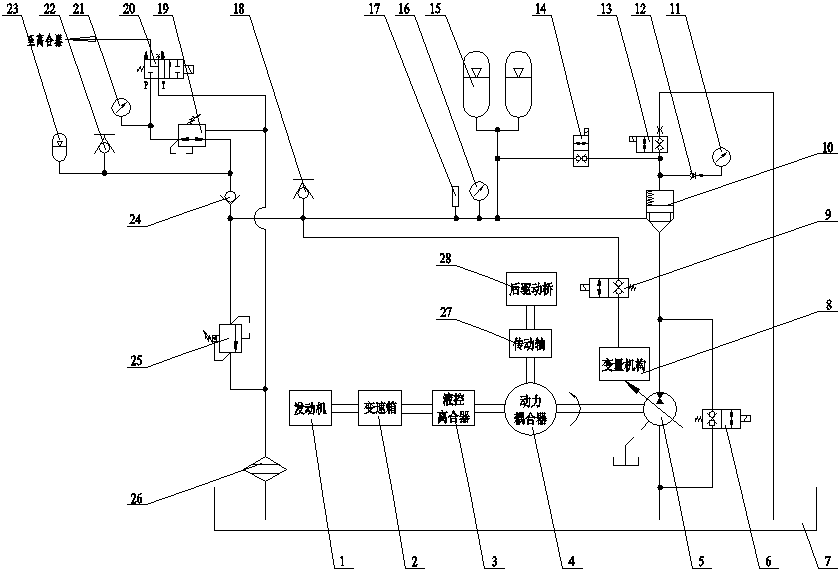

Parallel hydraulic hybrid driving system of vehicle

InactiveCN103223849ASimple structureReduce lossesGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingHigh pressureHydraulic pressure

The invention relates to a parallel hydraulic hybrid driving system of a vehicle, which comprises a mechanical transmission system and a hydraulic regenerative brake system, wherein the mechanical transmission system comprises an engine, a gearbox, a hydraulic control clutch, a power coupler, a two-way variable pump / motor, a transmission shaft and a rear driving axle; and the hydraulic regenerative brake system comprises a two-way variable pump / motor, a first stop valve, an oil tank, a variable mechanism of the two-way variable pump / motor, a plugin valve, a high pressure accumulator, a high pressure accumulator pressure gauge, a pressure sensor, a reducing valve, a two-position two-way reversing valve, an overflow valve and a filter. A charging / discharging major loop of the driving system adopts a controllable plugin valve, the plugin valve is controlled by controlling a pilot valve of the driving system, and the driving system responses rapidly. The driving system is convenient to operate and high in reliability, the power source switching is smooth, the power performances of the vehicle are improved, and the driving system has significant effects in recovering energy of the vehicle and improving fuel economy. The driving system meets the intermittent and high-power requirements and is used for the heavy vehicle requiring frequent start and parking operations.

Owner:TONGJI UNIV +1

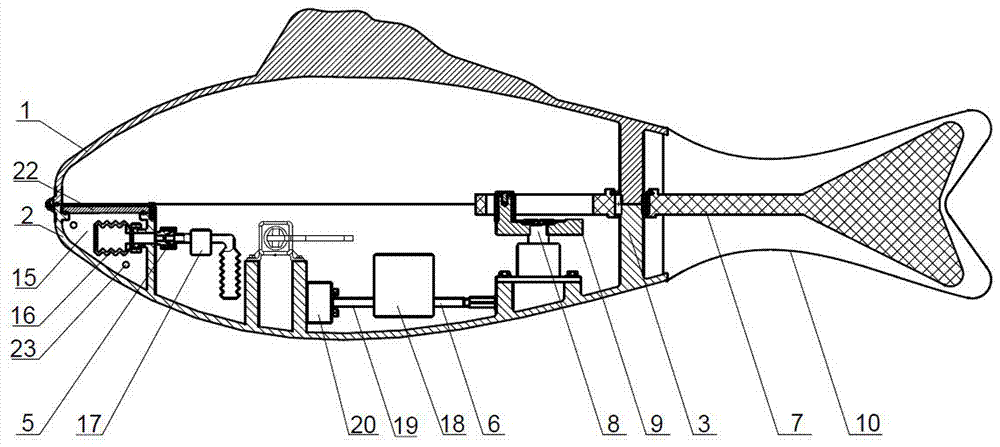

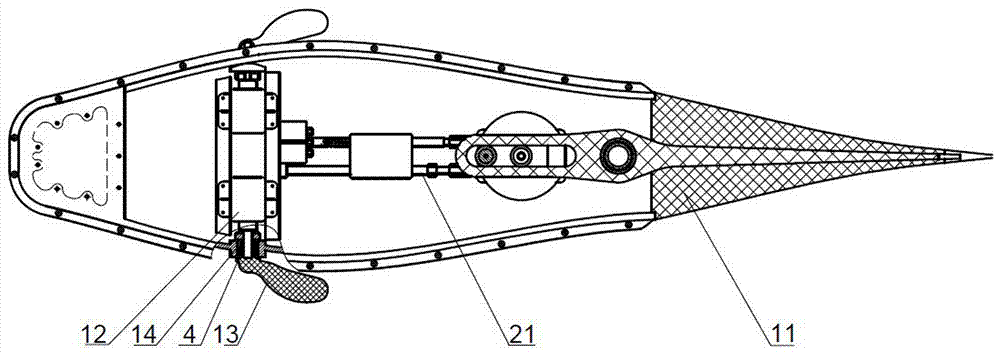

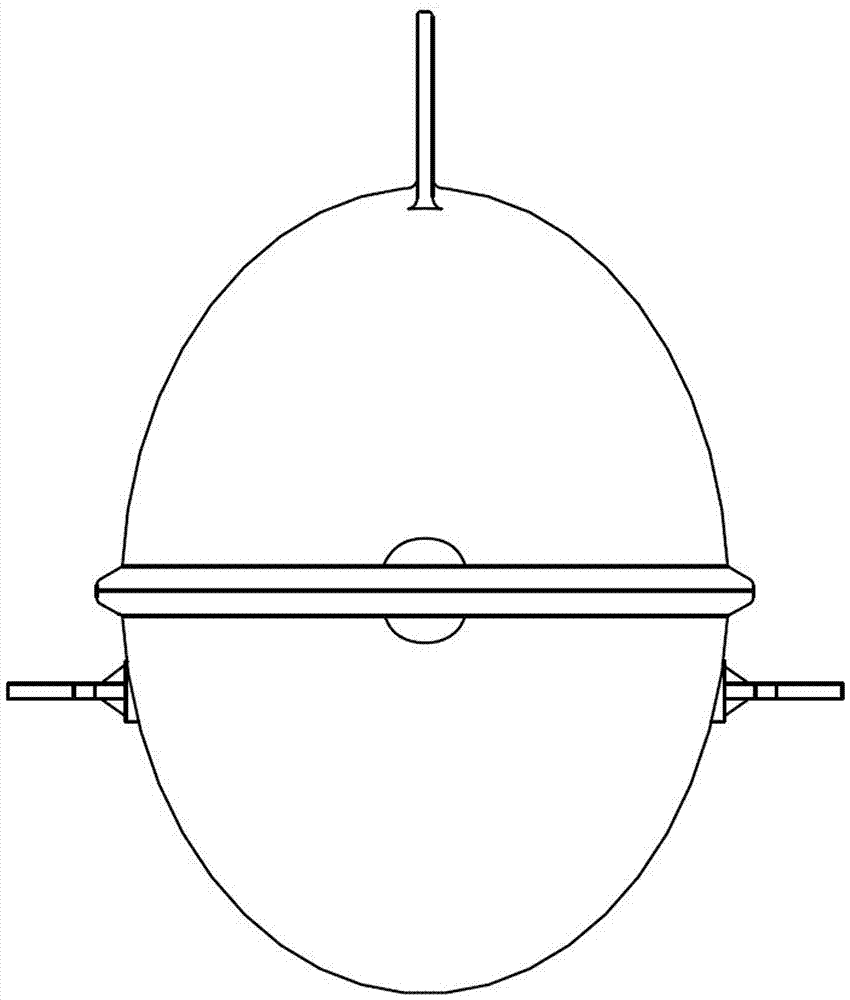

Coelacanth-imitating underwater robot

InactiveCN107310705ARealize intelligent swimmingRealize the function of automatic sinking and floatingPropulsive elements of non-rotary typeUnderwater vesselsLow noiseSimulation

A coelacanth-like underwater robot disclosed by the present invention is characterized in that it includes a fish-like cavity and a control module, a caudal fin drive module, a pectoral fin auxiliary module, a buoyancy adjustment module and a center of gravity adjustment module respectively arranged in the cavity ; wherein: the caudal fin drive module, pectoral fin auxiliary module, buoyancy adjustment module and gravity adjustment module are respectively connected with the control module, respectively control the tail fin drive module to drive the tail to bend through the pressure sensor, attitude sensor and positioning sensor of the control module, and use the curved tail to be concave-convex The pressure difference between the two sides of the liquid creates pressure to propel the robot forward. Through the above structure, the coelacanth robot of the present invention can simulate fish swimming in water, can autonomously avoid obstacles, plan routes, and realize automatic ups and downs in different water areas, thereby realizing the intelligent swimming of the robot, and its motion characteristics are relatively Compared with traditional propeller propellers, it is more efficient, quieter and stealthier.

Owner:GUILIN UNIV OF ELECTRONIC TECH

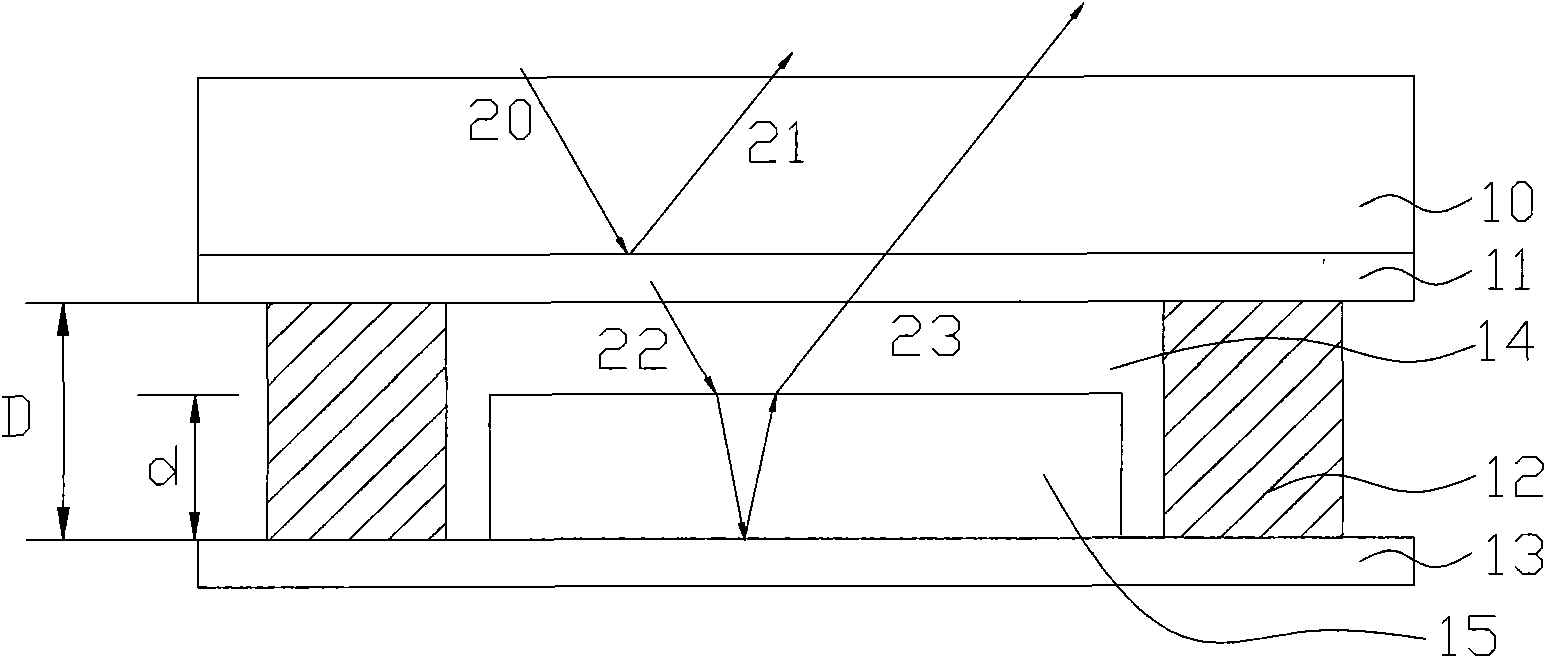

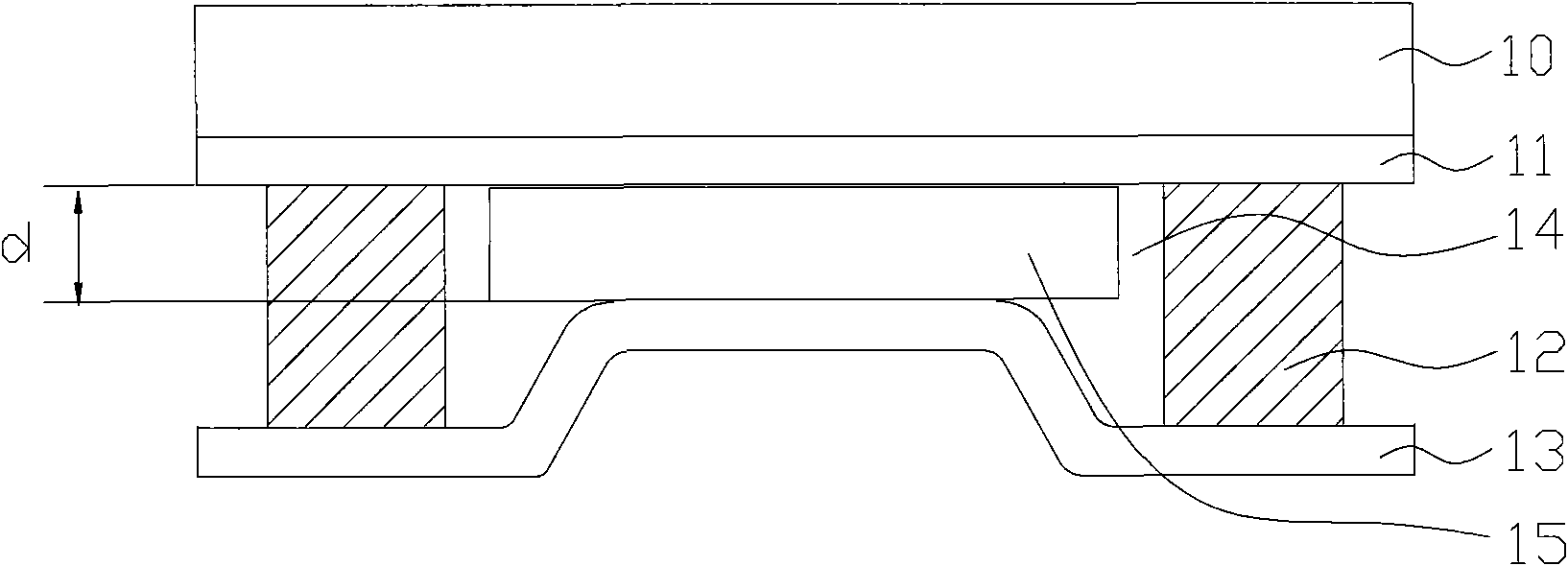

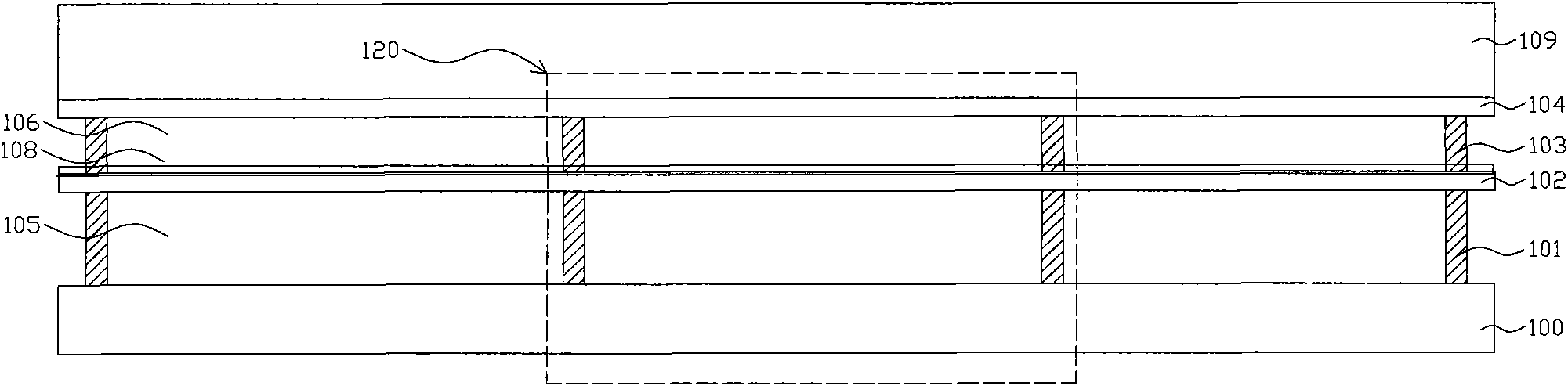

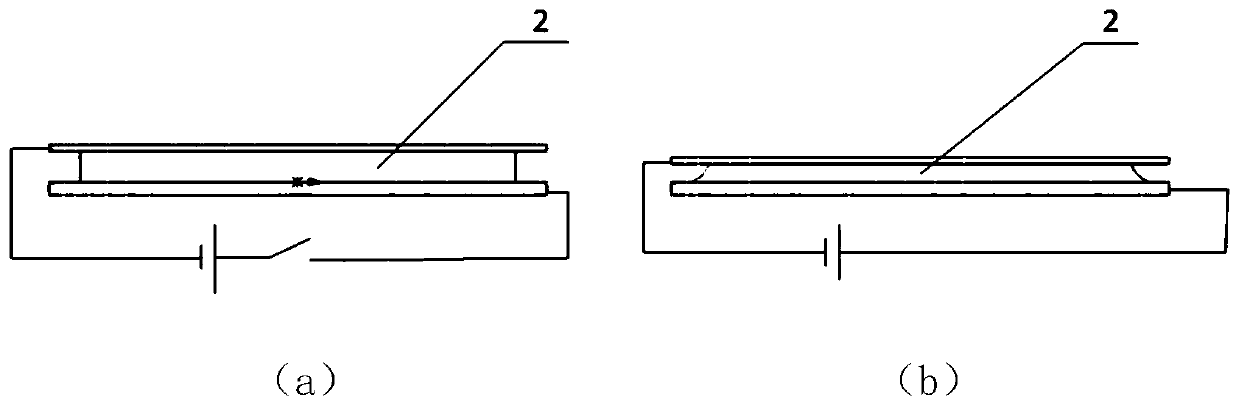

Display panel, display method, display device and color rendition method thereof

InactiveCN101872579AChange widthControl wavelengthStatic indicating devicesIdentification meansDisplay deviceTransmittance

The invention provides a display panel, which comprises a base plate. The base plate has a first reflecting layer and a second reflecting layer with specific light transmittance. The first reflecting layer comprises a reflecting unit array. Each reflecting unit comprises a reflecting plate which can continuously move along a direction perpendicular to the first reflecting layer, and a supporting beam connected with the reflecting plate and a connecting part. The invention additionally provides a display method, a display device and a color rendition method thereof. The display panel synthesizes color through time sequence color without distinguishing pixel color, the manufacturing process is only one third of the manufacturing process of a traditional display panel manufacturing method, the structure is simple and the manufacturing cost is low. The display device can compensate color drift caused by manufacturing error, the task of accurately realizing color rendition is transferred to the peripheral circuit of the display panel from the manufacturing process, and thereby the requirement on the precision of the manufacturing process is reduced.

Owner:季中

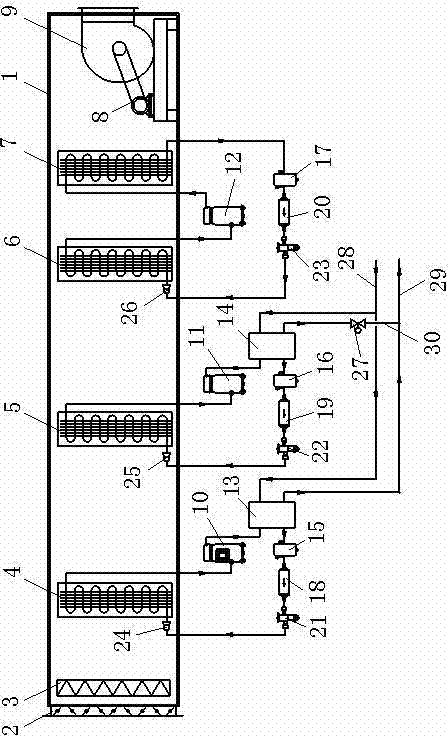

Direct evaporation type water-cooling fresh air unit

InactiveCN103940007ALarge energy adjustment rangeChange displacementLighting and heating apparatusSpace heating and ventilation detailsAir filterFresh air

The invention discloses a direct evaporation type water-cooling fresh air unit. An air inlet regulation valve (2) is arranged at one end of a fresh air processing box body (1), an air filter (3) is arranged on the inner side of the air inlet regulation valve, and a fan (9) is arranged at the other end of the fresh air processing box body (1). Three refrigerating circuits capable of operating separately or simultaneously are arranged, and the first refrigerating circuit comprises an inverter compressor (10), a first plate heat exchanger (13), a first liquid storage tank (15), a first dry filter (18), a first thermal expansion valve (21) and a first evaporator (4) which are connected through a refrigerating fluid pipe. The second refrigerating circuit comprises a first constant-speed compressor (11), a second plate heat exchanger (14), a second liquid storage tank (16), a second dry filter (19), a second thermal expansion valve (22) and a second evaporator (5) which are connected through a refrigerating fluid pipe. The third refrigerating circuit comprises a third constant-speed compressor (12), a condensing coil (7), a third liquid storage tank (17), a third dry filter (20), a third thermal expansion valve (23) and a third evaporator (6) which are connected through a refrigerating fluid pipe. The direct evaporation type water-cooling fresh air unit can operate stably under wide meteorological conditions to meet a dehumidification requirement of an air conditioning system, improve comfort of supplied air and prevent moisture condensation at an air outlet.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH +1

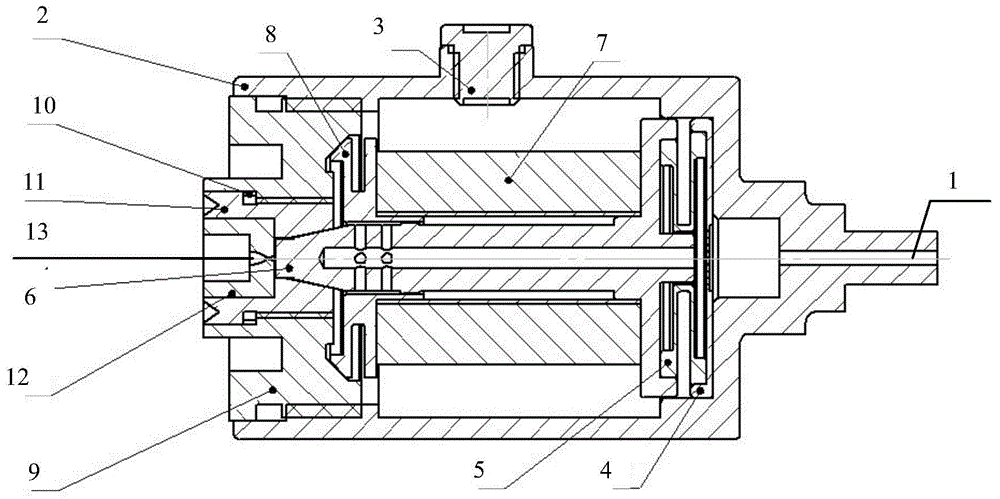

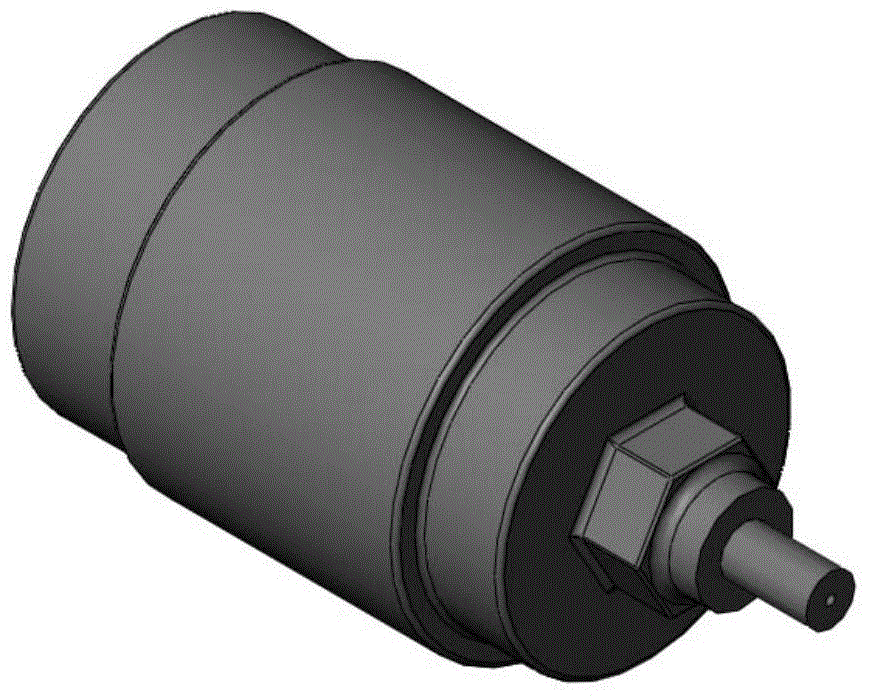

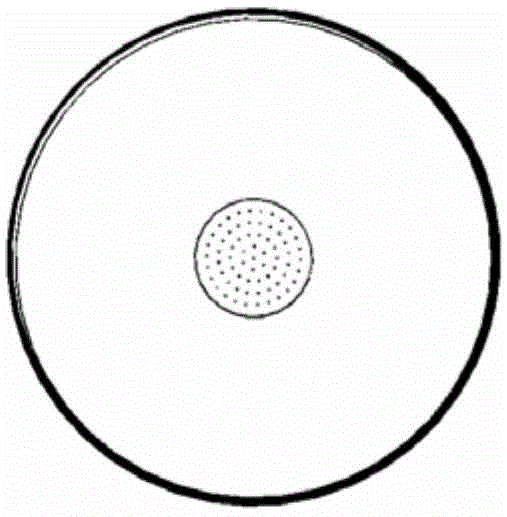

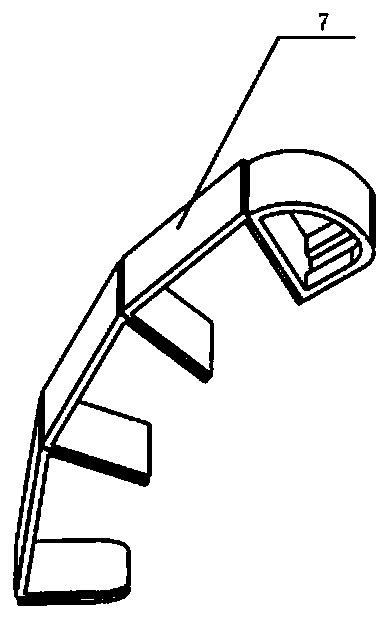

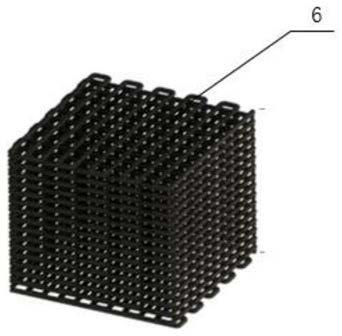

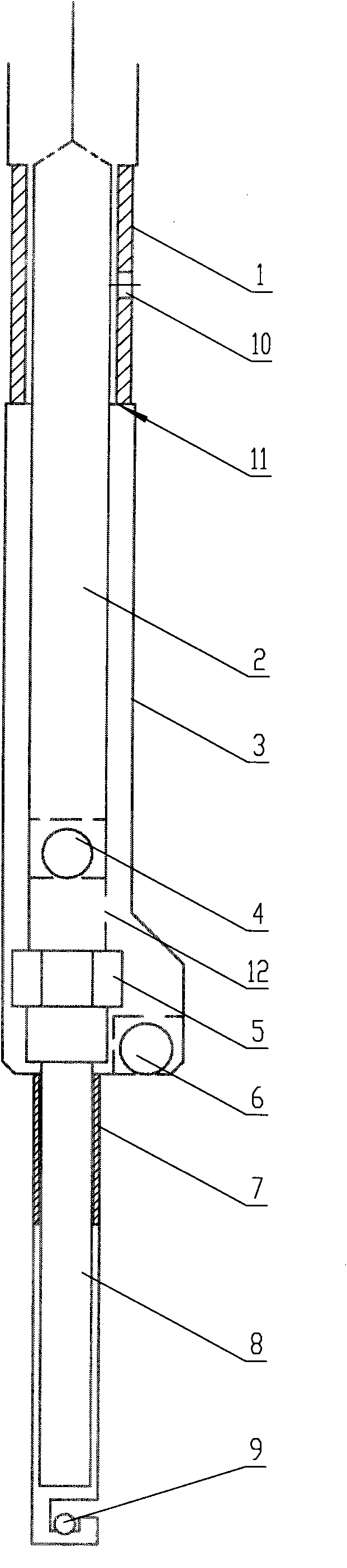

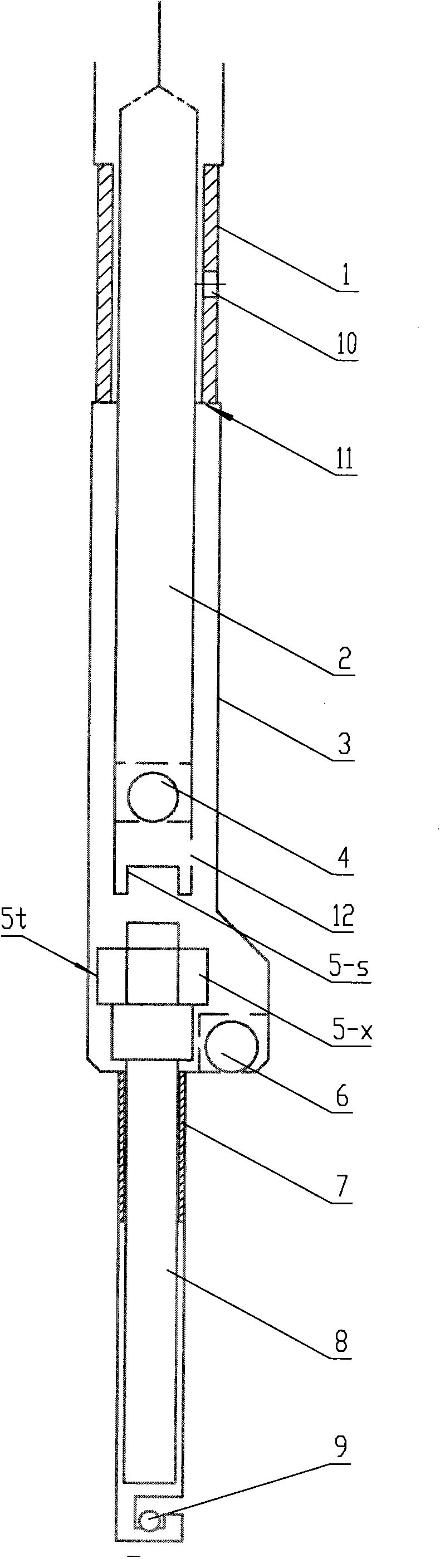

Piezoelectric micro-thruster

InactiveCN104443437AQuick responseRealize the pulse work processCosmonautic propulsion system apparatusMetallic materialsEngineering

The invention provides a piezoelectric micro-thruster comprising an air inlet (1), a housing (2), a power interface (3), a filter (4), a return spring (5), a valve core (6), a piezoelectric stack (7), a washer spring (8), a valve seat (9), a seal ring (10), an adjusting ring (11), a base (12) and a nozzle (13). In the case of power-off, the surface of the valve core (6) is tightly attached to the surface of the valve seat (9) and the surface of the adjusting ring (11), and the piezoelectric micro-thruster is off; in the case of power-on, the piezoelectric stack (7) deforms to drive the valve core (6) to move, the surface of the valve core (6) separates from the surface of the valve seat (9) and the surface of the adjusting ring (11), the piezoelectric micro-thruster is on and generates thrust. The sealing parts, such as the valve core (6), the valve seat (9) and the adjusting ring (11), are all made of metal, thus the piezoelectric micro-thruster is metal sealed. The piezoelectric micro-thruster is short in response time, continuously adjustable in thrust, low in power consumption and long service, meets the strict requirements of miniature satellites and missile precision guides for micro-thrust systems and is light in weight and small in size, and more weight and space are saved for the miniature satellites.

Owner:NAT UNIV OF DEFENSE TECH

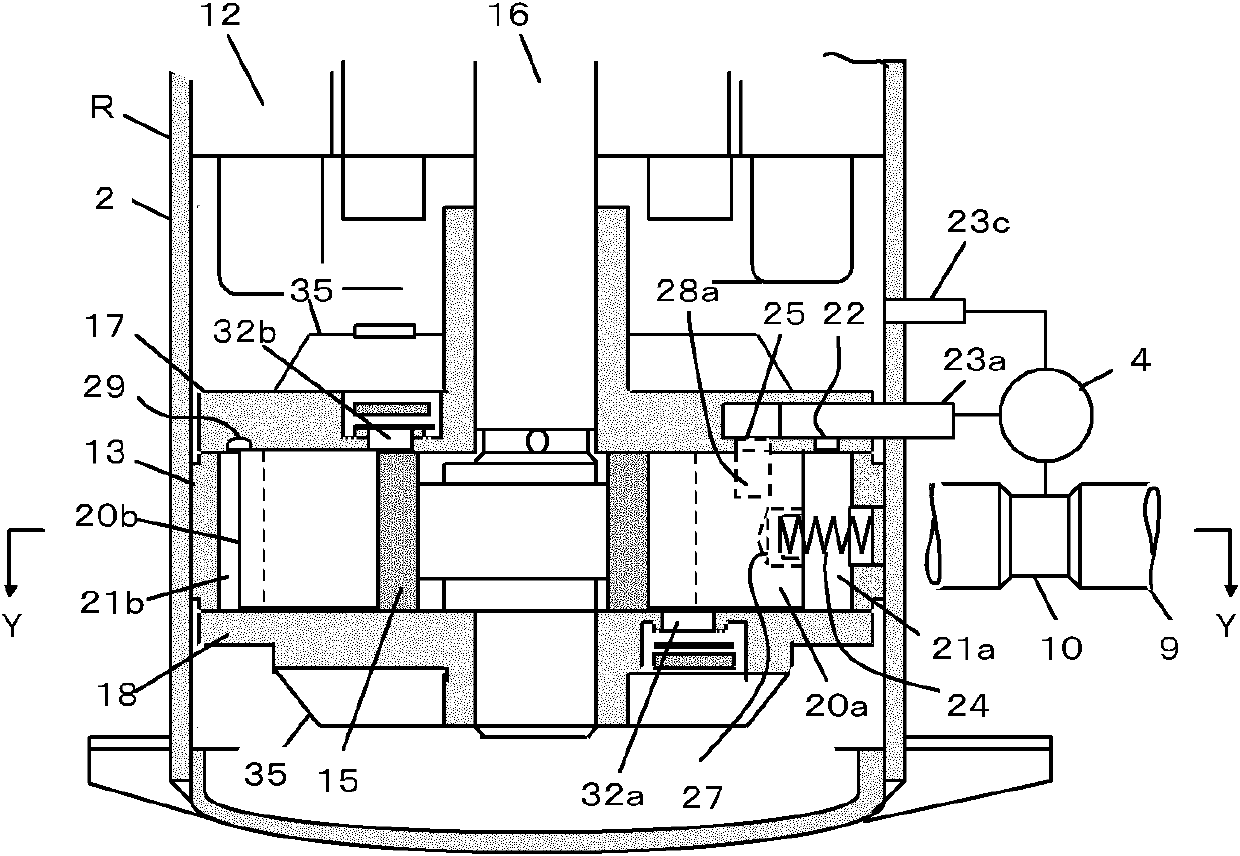

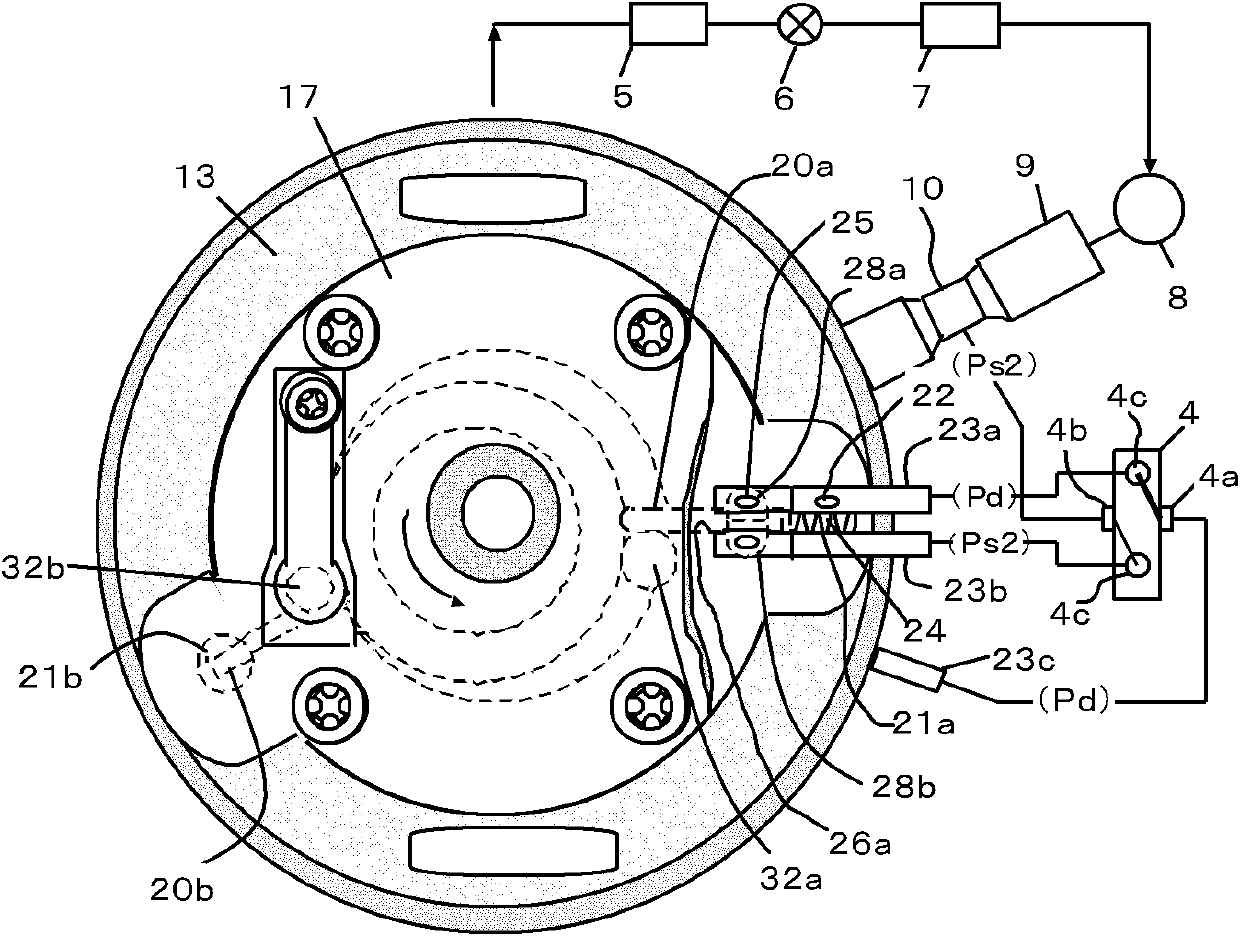

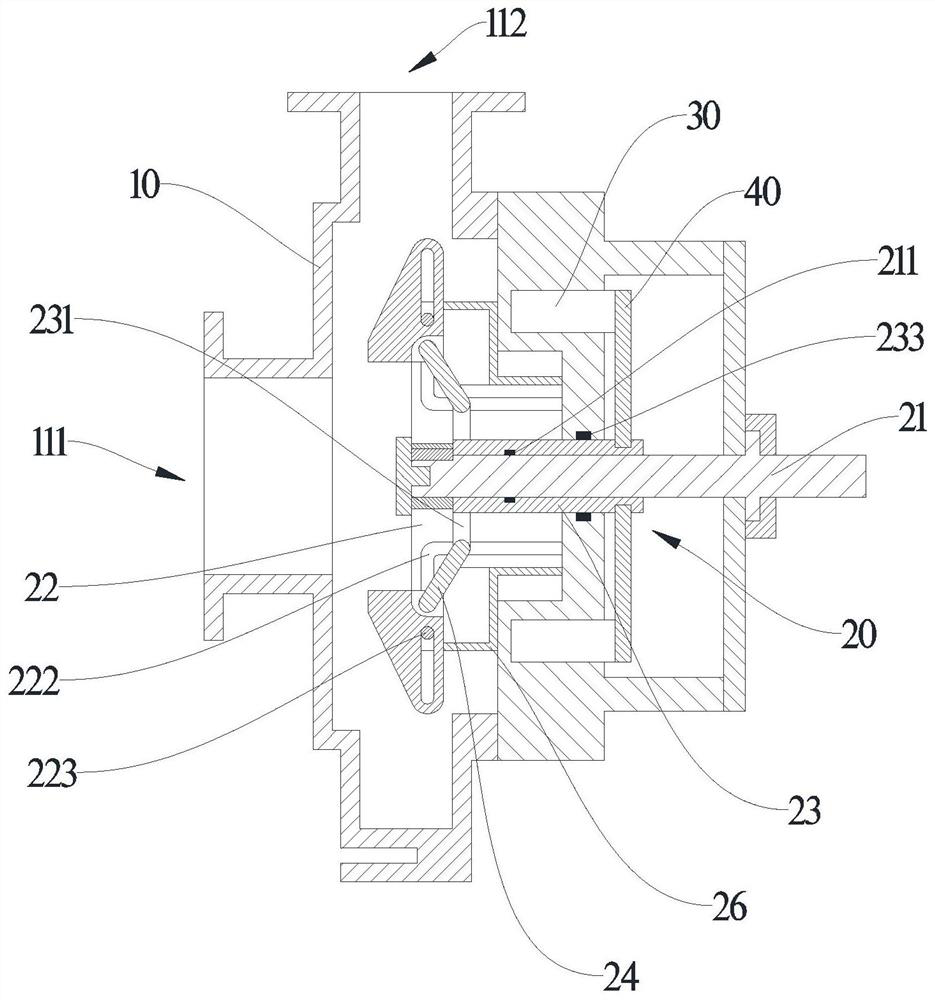

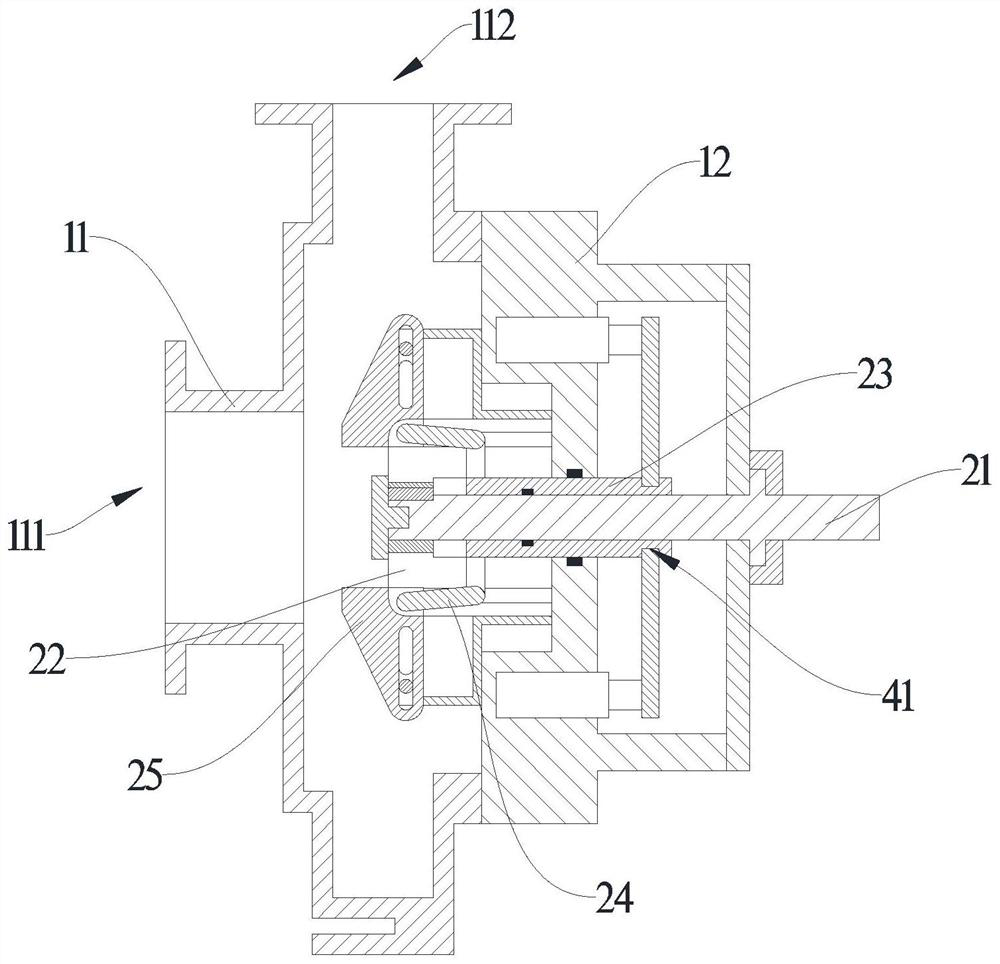

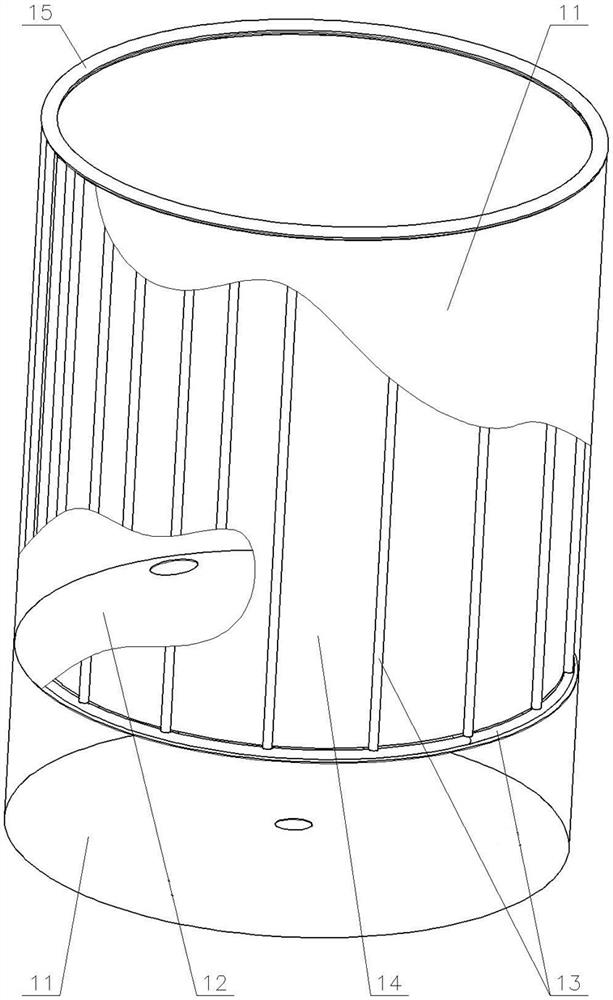

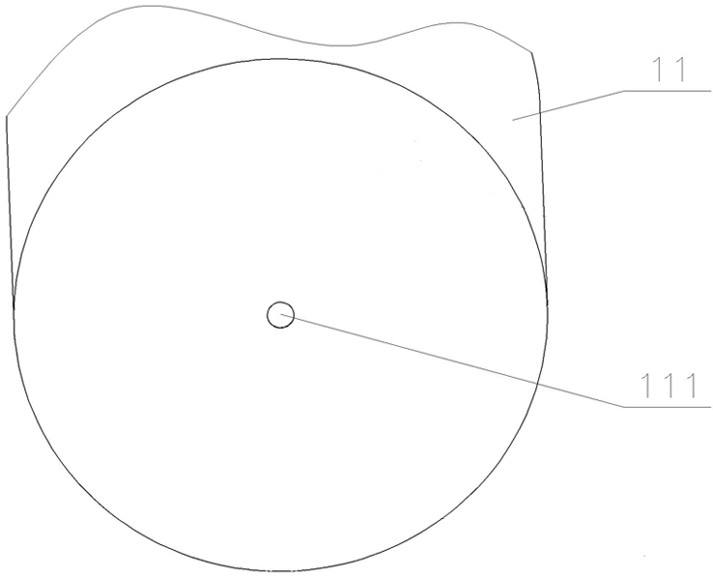

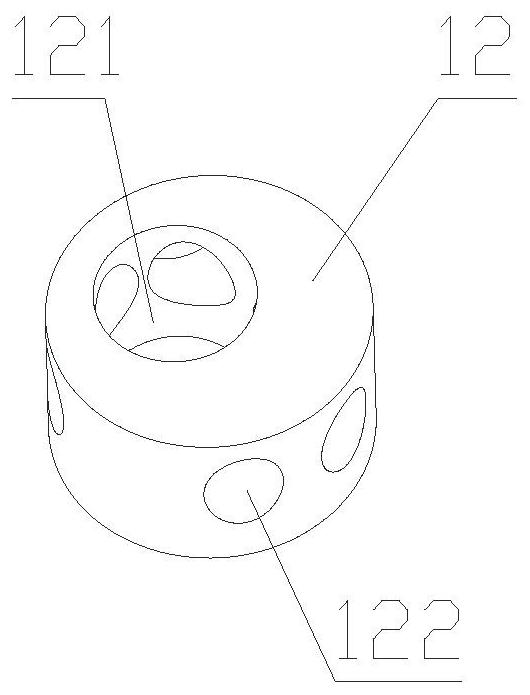

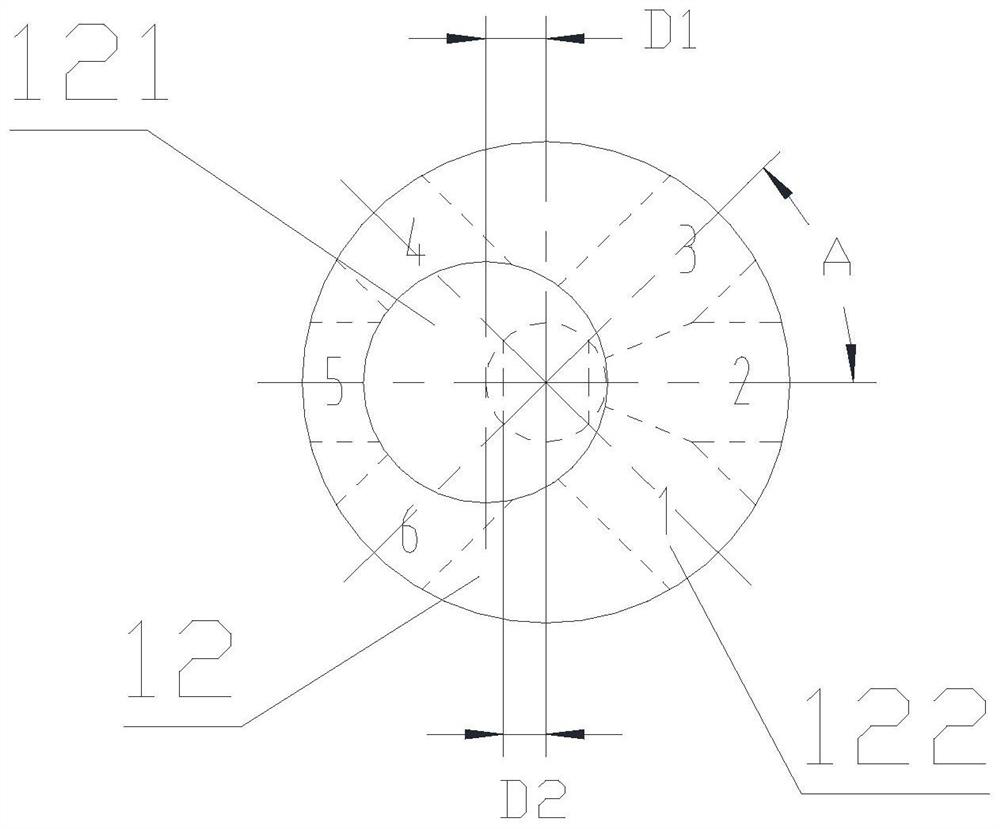

Capacity-varying rotary type compressor

ActiveCN102562594AFree optimization of the controlled stopping forceChange displacementRotary piston pumpsRotary piston liquid enginesFour-way valveEngineering

Owner:GUANGDONG MEIZHI COMPRESSOR

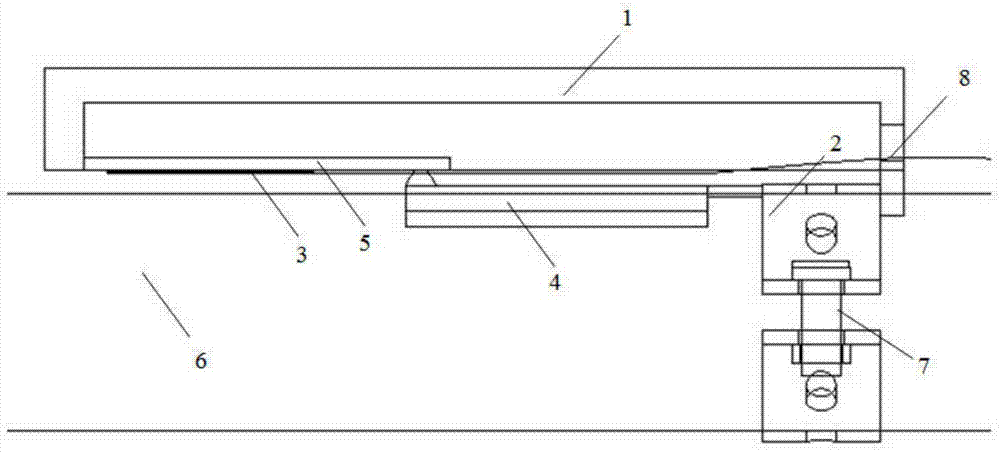

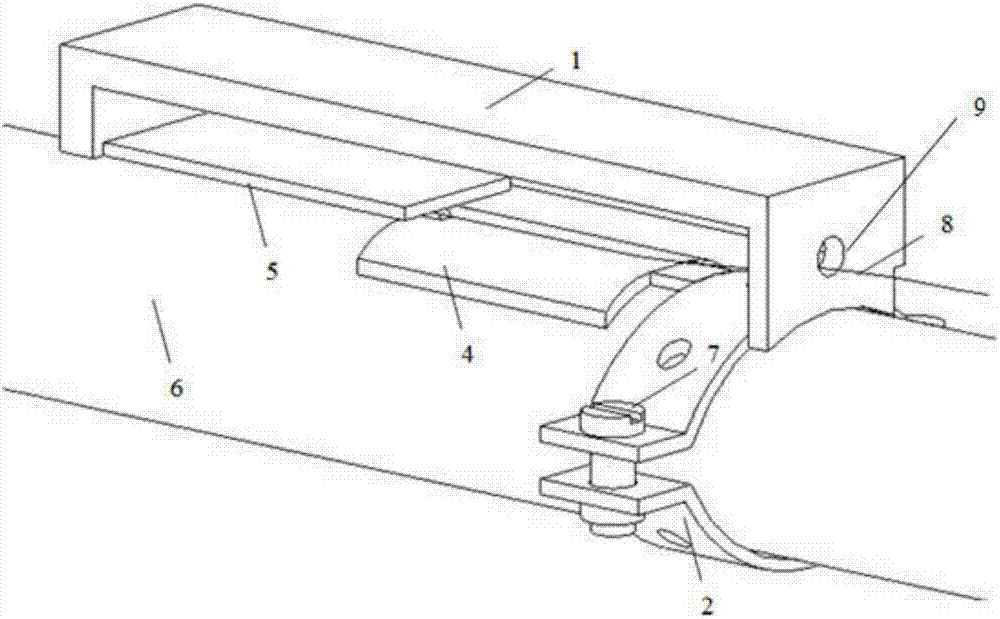

PVC gel driven flexible mechanical tongs and preparing method thereof

ActiveCN111113380AFunctionalSimple drive formProgramme-controlled manipulatorAdditive manufacturing apparatusEngineeringStructural engineering

The invention discloses PVC gel driven flexible mechanical tongs and a preparing method thereof. A multi-layer PVC driver is arranged in a flexible outer frame. A flexible sensor is arranged on the top of the flexible outer frame. The multi-layer PVC driver is formed by stacking a plurality of single-layer PVC drivers, and object grabbing is achieved through the layer number of the single-layer PVC drivers and voltage applying. The PVC gel driven flexible mechanical tongs have the grabbing function and the sensing function at the same time, and on the basis of PVC gel driving, the drive form is simple.

Owner:XI AN JIAOTONG UNIV

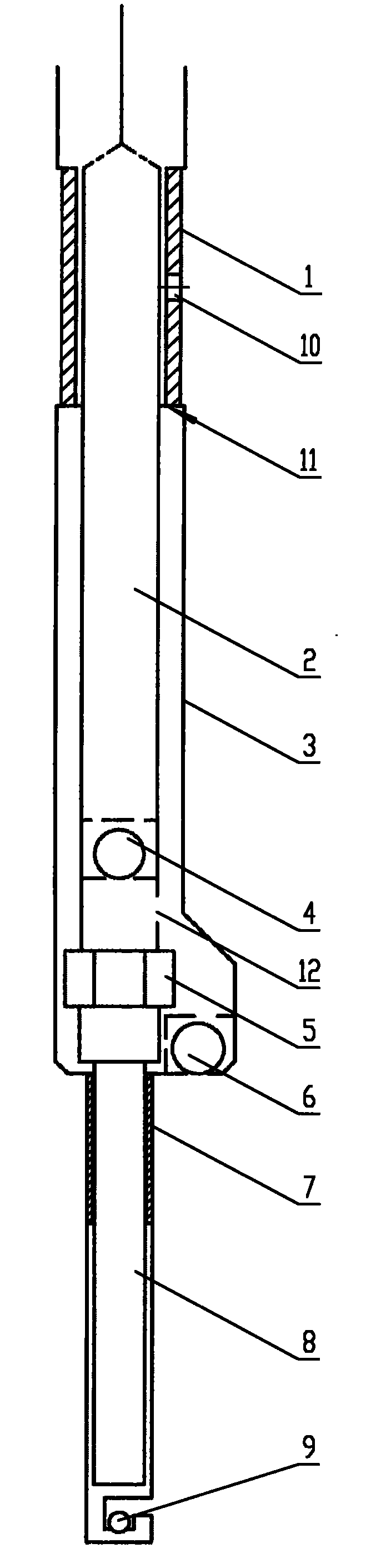

Optical fiber grating sensor for long-term real-time monitoring of the corrosion on steel bars

InactiveCN107505253ARealize full life cycle monitoringMeasurement accuracy can be adjustedWeather/light/corrosion resistanceUsing optical meansFiberGrating

The present invention discloses an optical fiber grating sensor for long-term real-time monitoring of the corrosion on steel bars. The optical fiber grating sensor comprises a protection shell, a fixation pipe buckle, an optical fiber grating, a conduction cantilever and a monitoring cantilever, wherein a protection shell is a bottomless rectangular box type structure, one side wall of the protection shell is provided with a round hole, the protection shell is fixedly connected to a steel bar through the fixation pipe buckle, the protection shell and the fixation pipe buckle form cementation connection after surface treatment, the protection shell is connected to the monitoring cantilever in a partially embedded manner, the fixation pipe buckle is connected to the conduction cantilever in a partially embedded manner, the monitoring cantilever forms pressing connection at the upper portion of the conduction cantilever, the optical fiber grating is arranged below the monitoring cantilever, and the tail fiber of the optical fiber grating passes through the upper portion of the conduction cantilever, penetrates through the round hole, and then is sleeved with an optical fiber loose sheath. According to the present invention, the optical fiber grating sensor can meet the long-term real-time monitoring of building members, and has advantages of convenient arrangement, simple structure, small size, high measurement precision, good stability, easy manufacture and processing, high sensitivity, anti-electromagnetic interference, adjustable measurement precision, good economic benefits, and good social benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

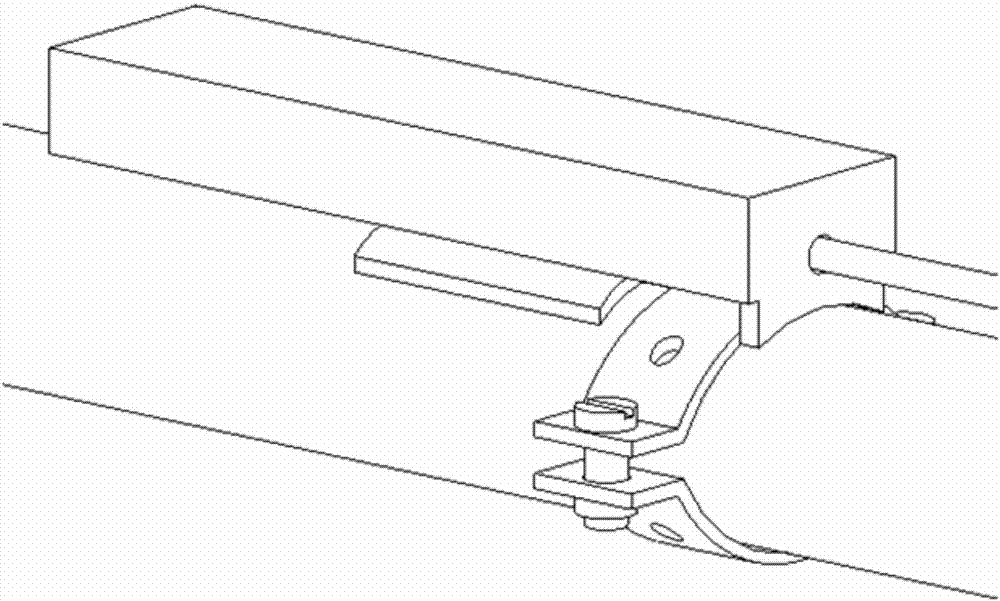

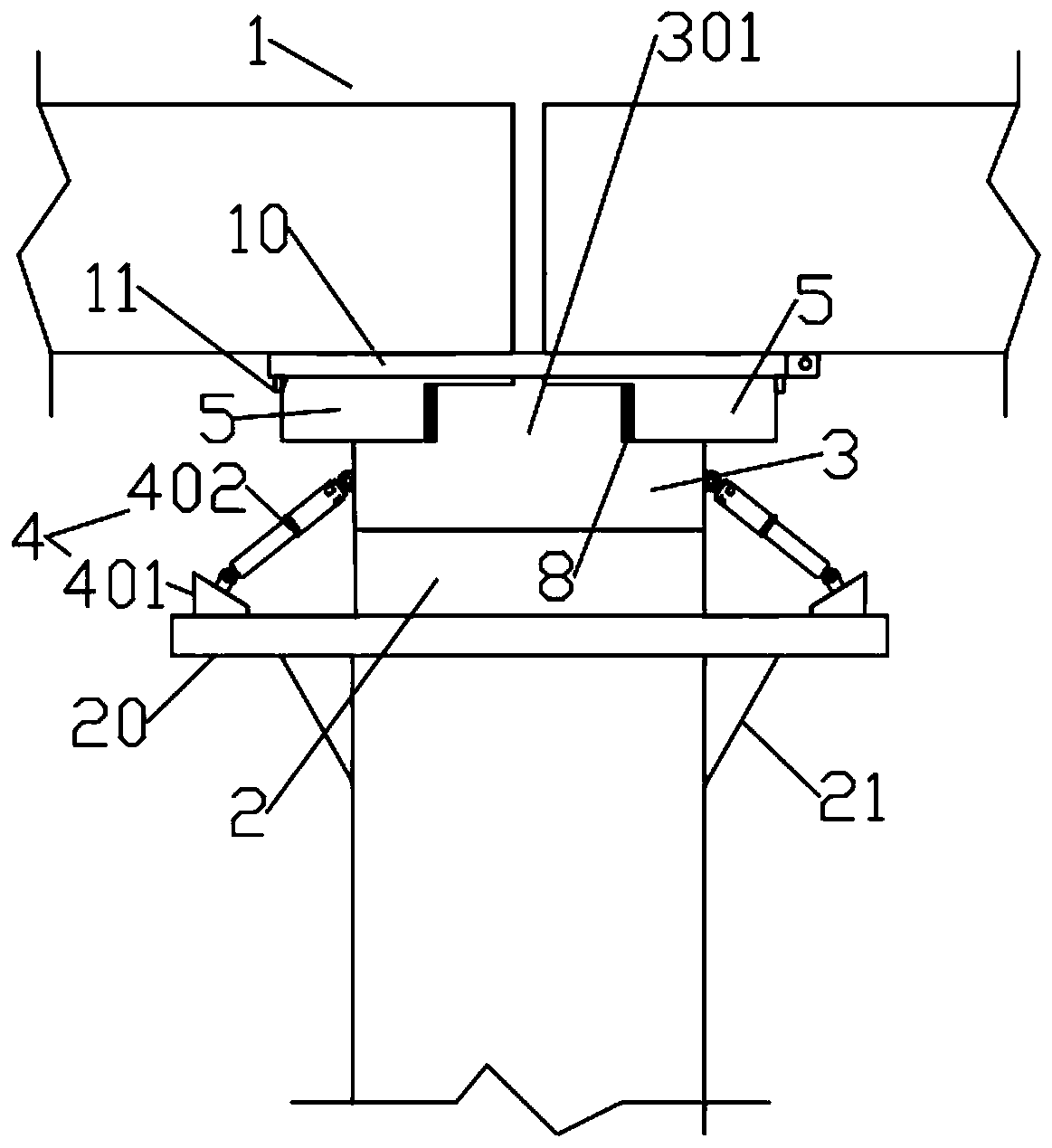

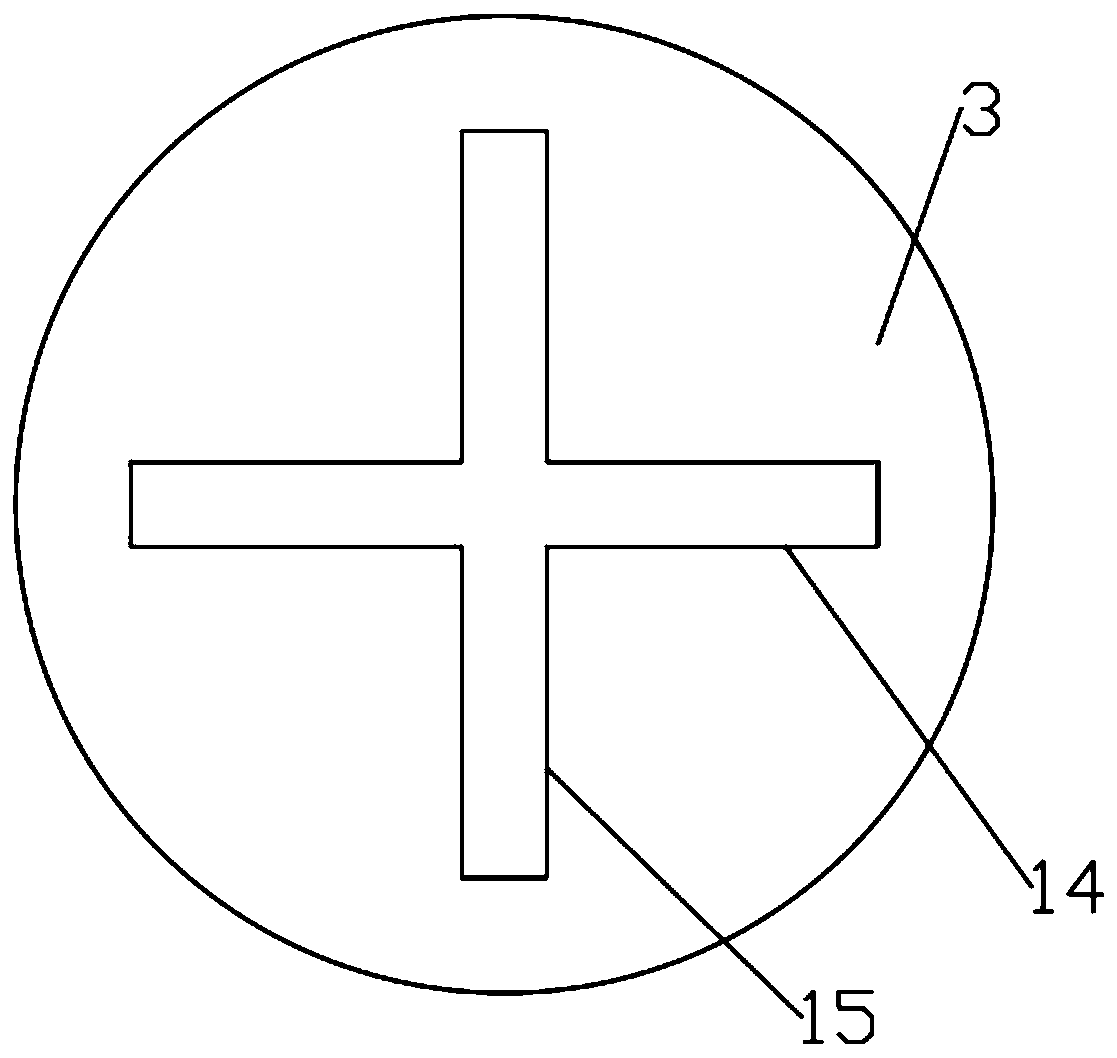

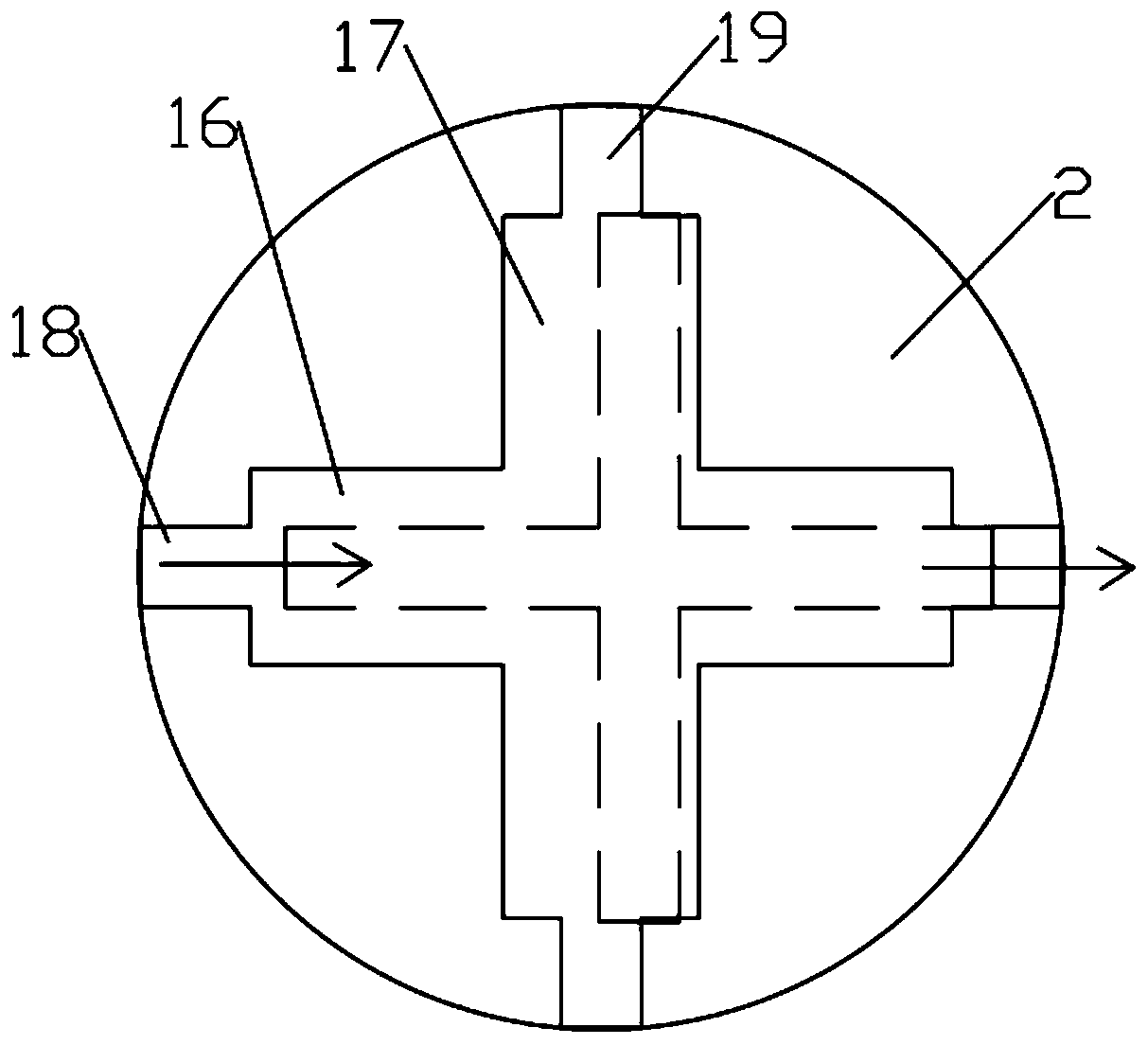

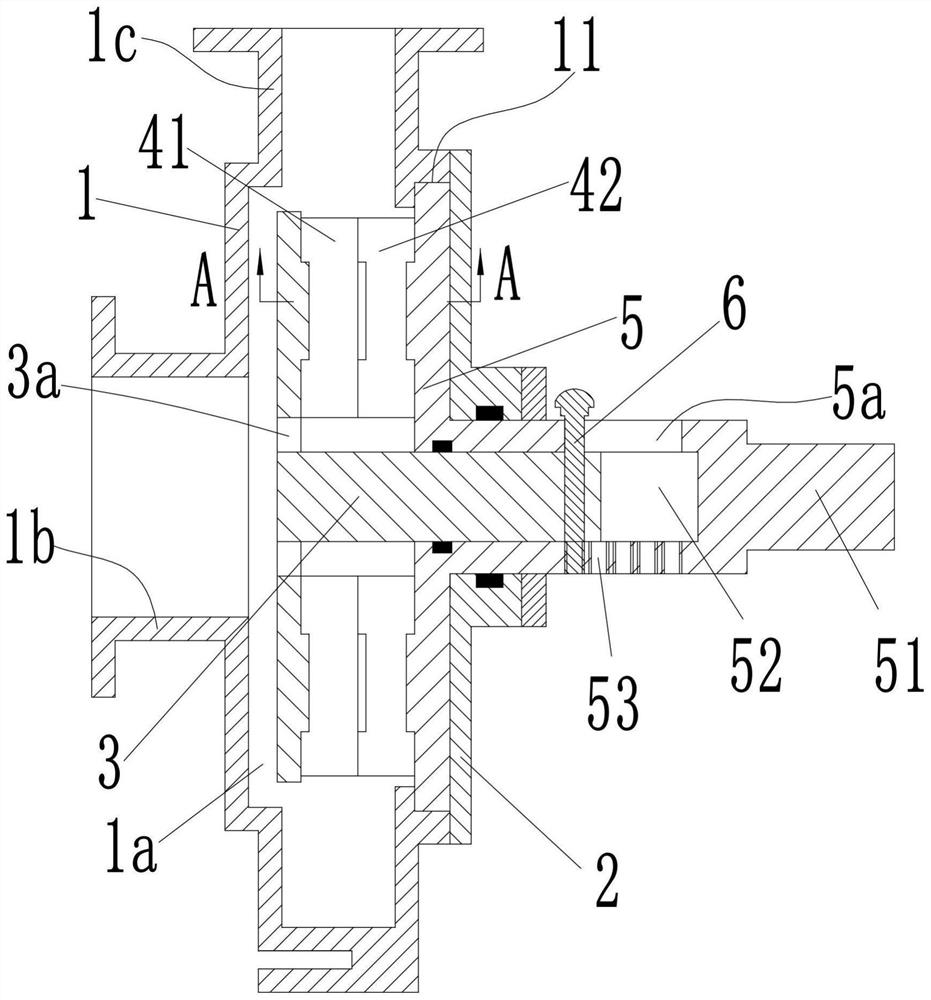

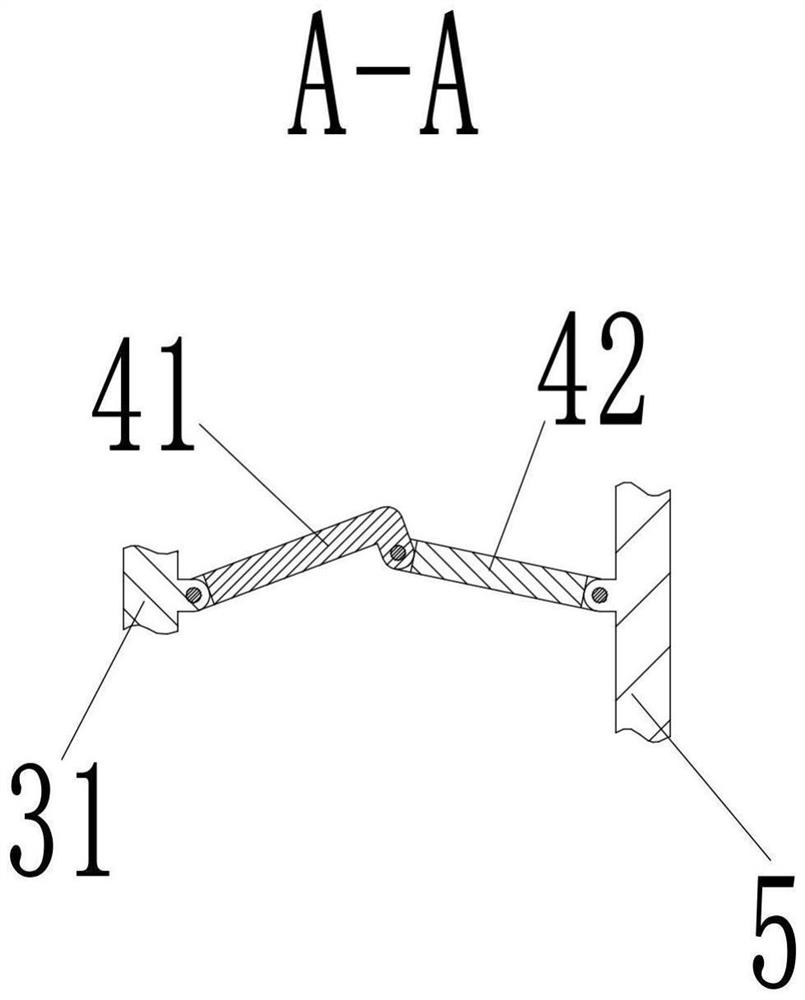

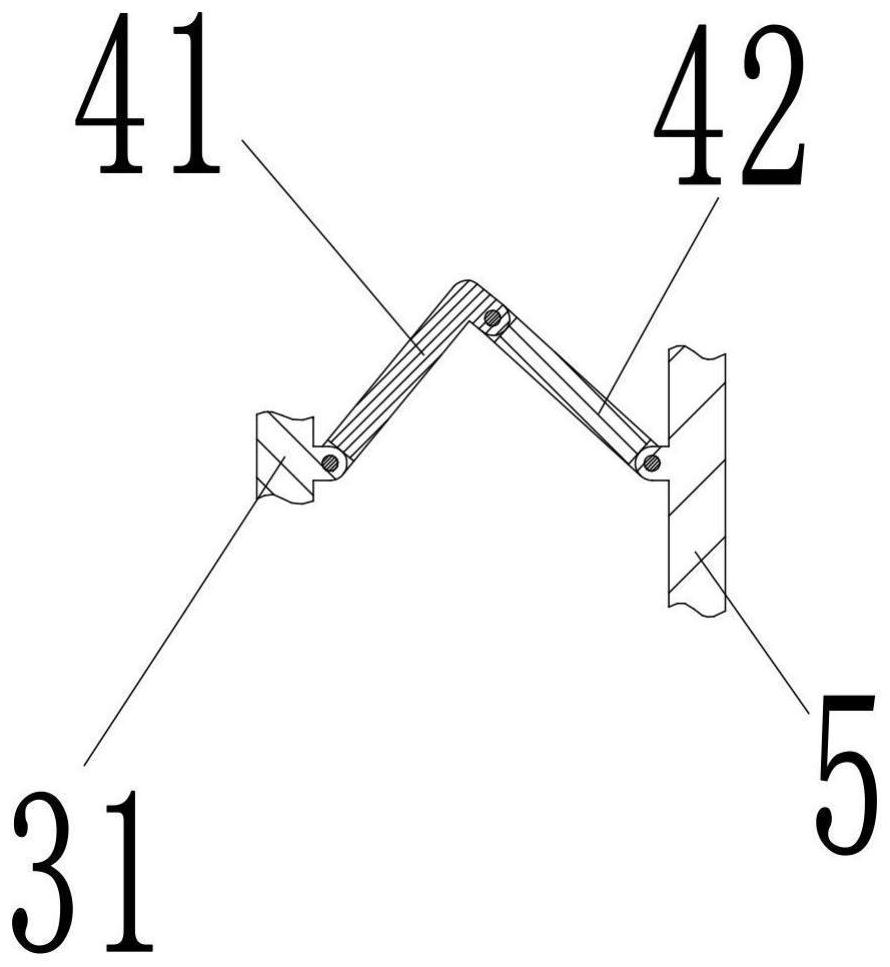

Two-direction energy dissipation beam falling prevention device

ActiveCN111455824AChange displacementPrevent falling beamsBridge structural detailsClassical mechanicsEngineering

The invention discloses a two-direction energy dissipation beam falling prevention device, and belongs to the technical field of bridges. The two-direction energy dissipation beam falling prevention device comprises a main beam and a pier used for supporting the main beam. The main beam comprise a first main beam, a second main beam, a third main beam and a fourth main beam; the first main beam and the second main beam are arranged in parallel and are positioned on one side of the pier; the third main beam and the fourth main beam are arranged in parallel and are positioned on the other side of the pier; a sliding layer is arranged between the pier and the main beam, the lower end of the sliding layer is in transverse sliding matching and longitudinal sliding matching with the pier; and amulti-direction damping structure is arranged between the sliding layer and the pier. According to the present invention, with the application of the device in the bridge construction, the energy consumption can be effectively performed on the transverse direction and the longitudinal direction of the main beam during earthquake so as to avoid the occurrence of the beam falling.

Owner:CHONGQING JIAOTONG UNIVERSITY

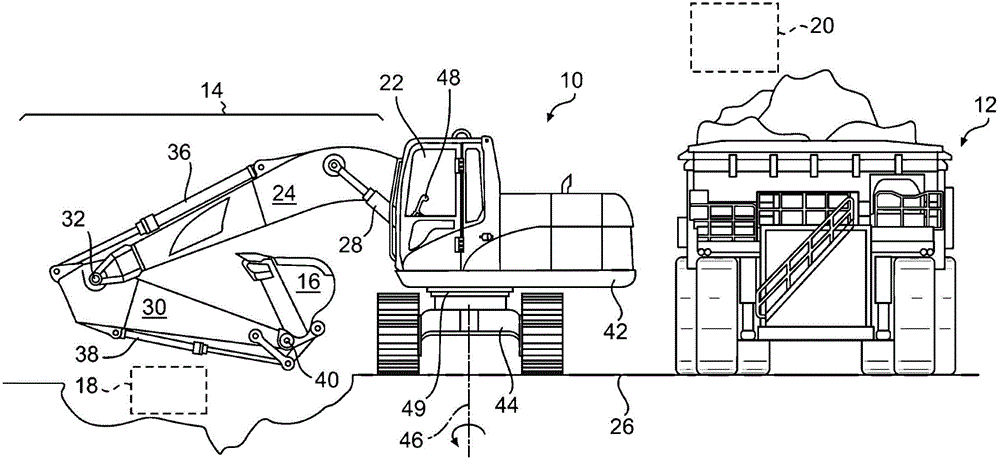

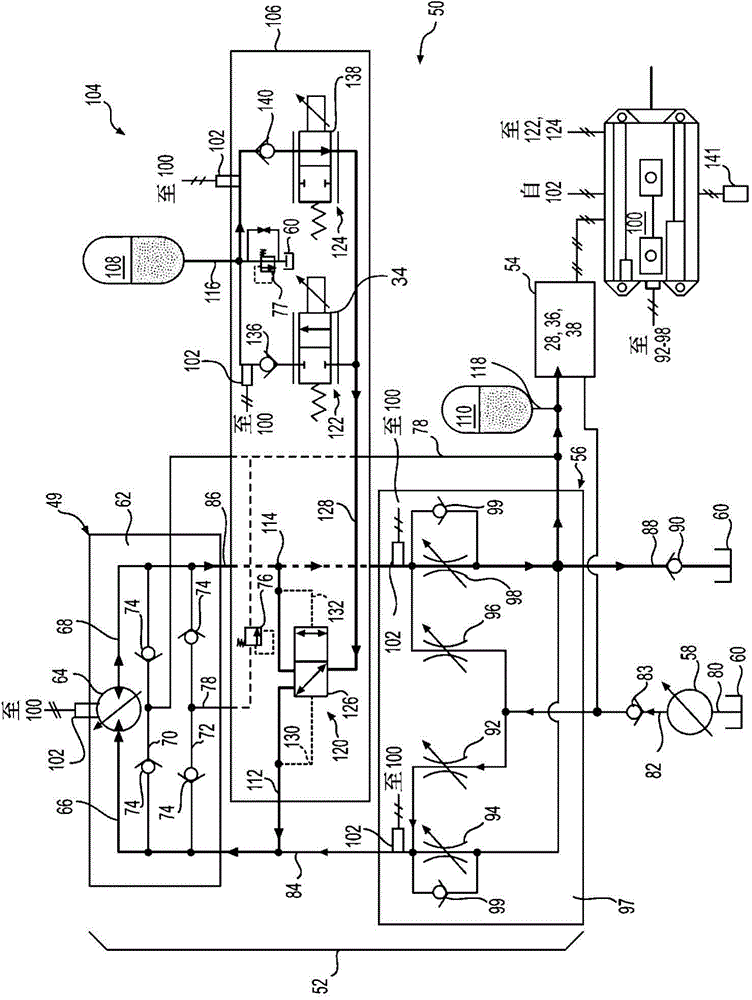

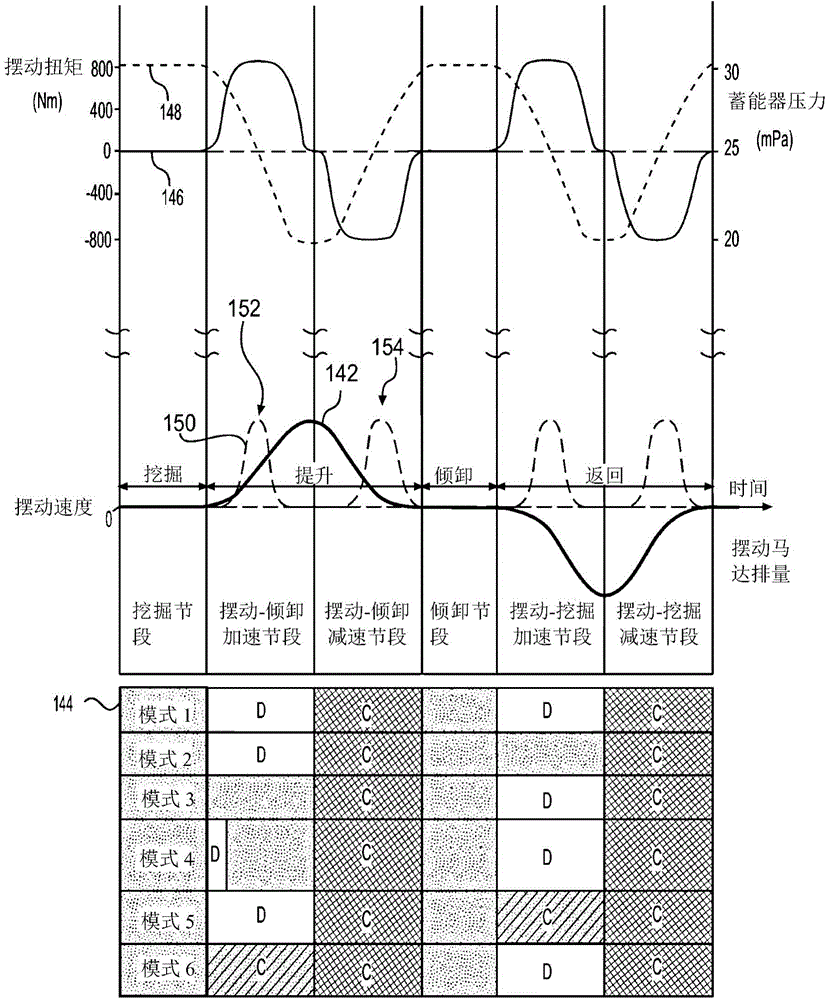

Hydraulic control system

InactiveCN104603372AChange displacementServomotor componentsAccumulator installationsControl systemControl theory

A hydraulic control system includes an implement movable to perform an excavation cycle having a plurality of segments, a variable displacement motor configured to swing the implement at a desired speed during the excavation cycle, and a pump configured to pressurize fluid directed to drive the motor. The system further includes an accumulator configured to selectively receive fluid discharged from the motor via a charge valve, and to discharge fluid to the motor via a discharge valve. The system includes a selector valve fluidly connected to the charge valve and the discharge valve. The system also includes a controller configured to vary displacement of the motor, resulting in the desired speed.

Owner:CATERPILLAR INC

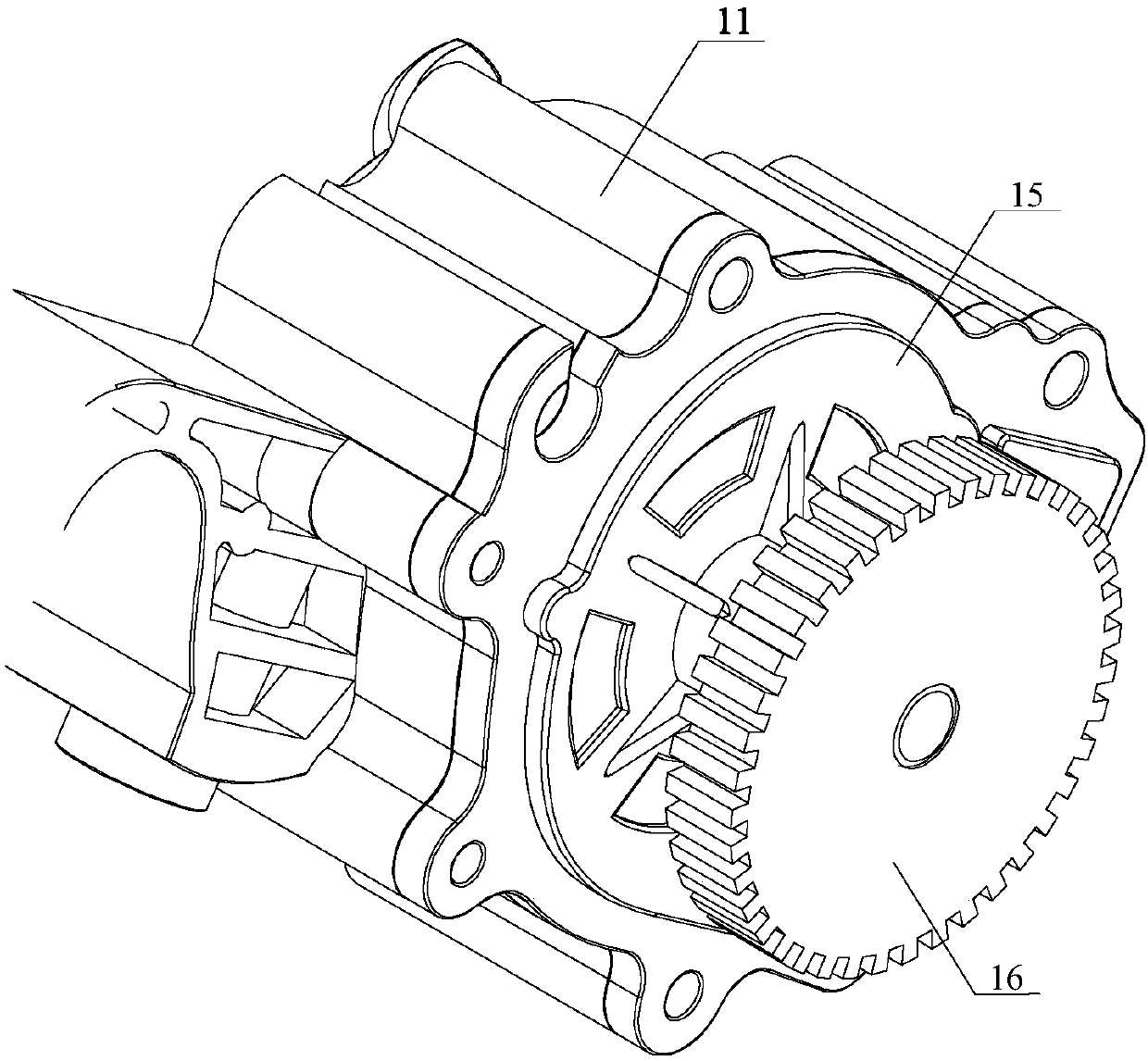

Energy-saving water pump for automobile engine

ActiveCN111622982AImprove fuel economyImprove energy consumption and emissionsCoolant flow controlPump componentsPower performanceImpeller

The invention relates to an energy-saving water pump for an automobile engine. The energy-saving water pump comprises a pump body with an inlet and an outlet. The energy-saving water pump for the automobile engine further comprises an impeller assembly. The impeller assembly comprises a rotating shaft, a rotating table, a sliding shaft, a connecting piece and blades. The energy-saving water pump has the advantages that the height and length of the portions, extending out of the rotating table, of the blades can be controlled through an electric pole, and therefore the displacement of the waterpump can be changed; when the blades completely retract, the blades are in a completely-non-working state, and therefore when the engine is in cold start or warm-up, an impeller can stop working, thetemperature of the engine can be rapidly increased, the fuel economy of the engine is improved, energy consumption and emission of the engine can be improved, and the power performance and fuel economy of an automobile can be improved.

Owner:浙江启达汽车部件有限公司

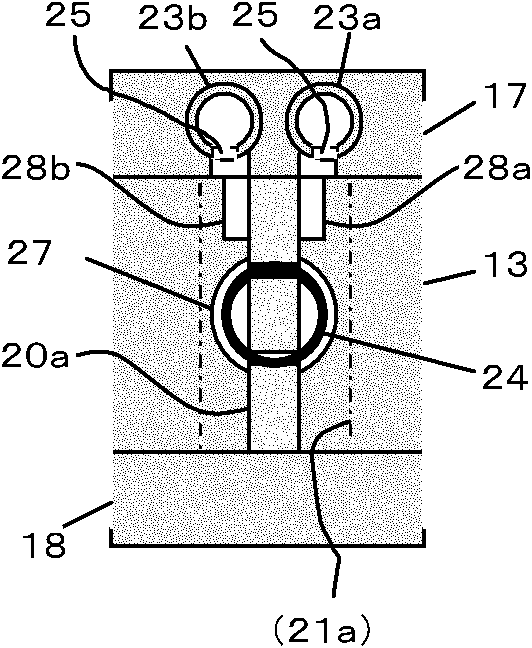

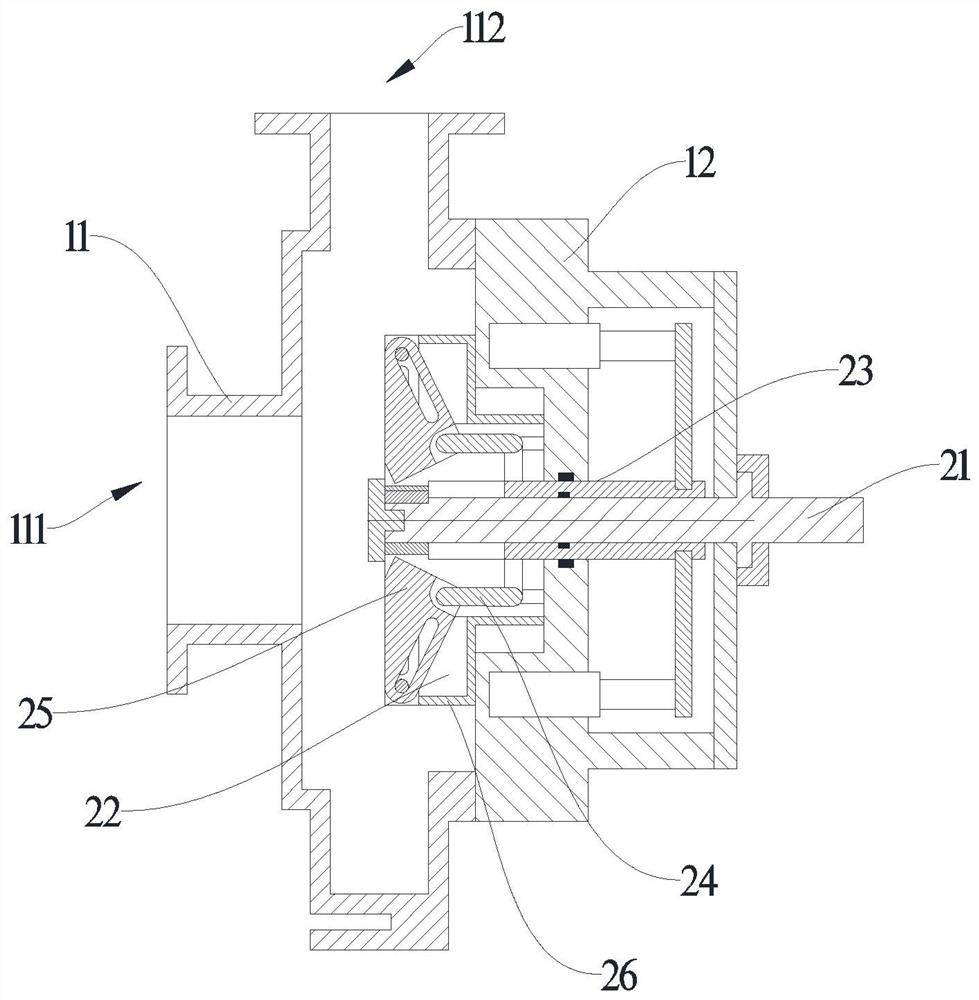

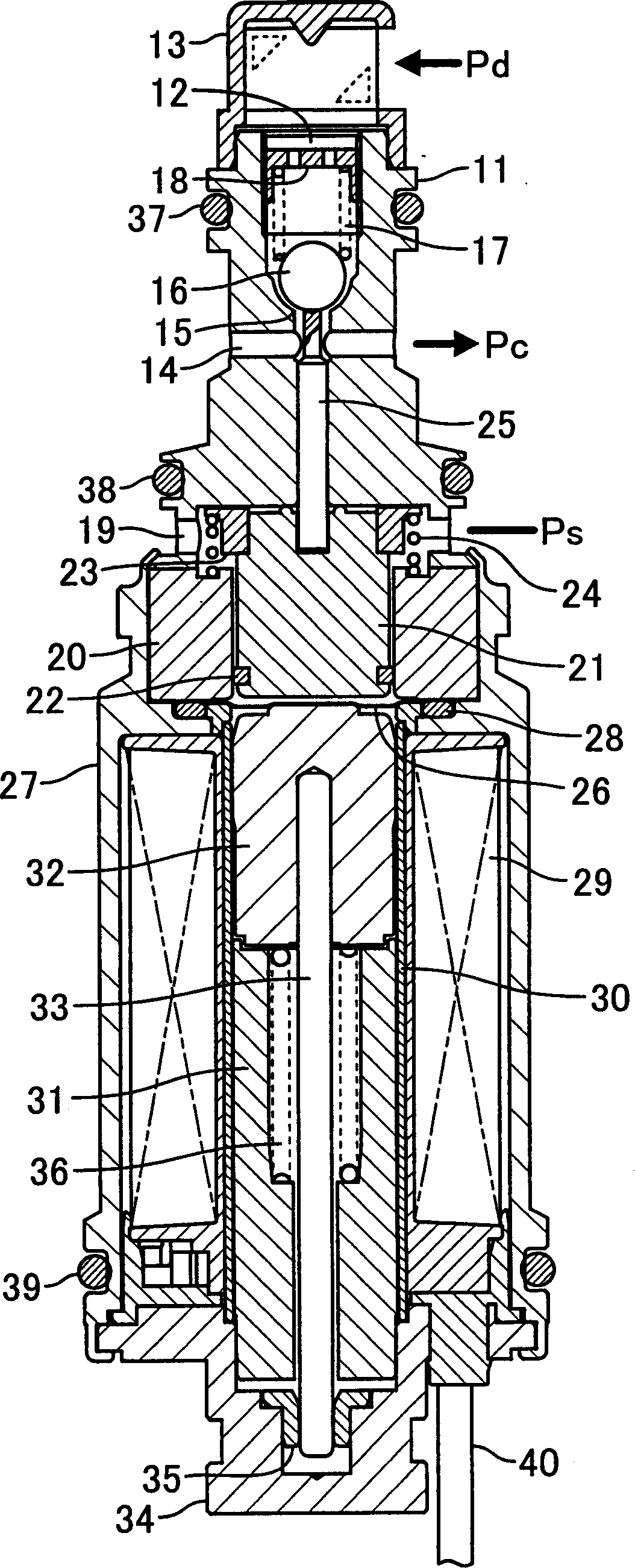

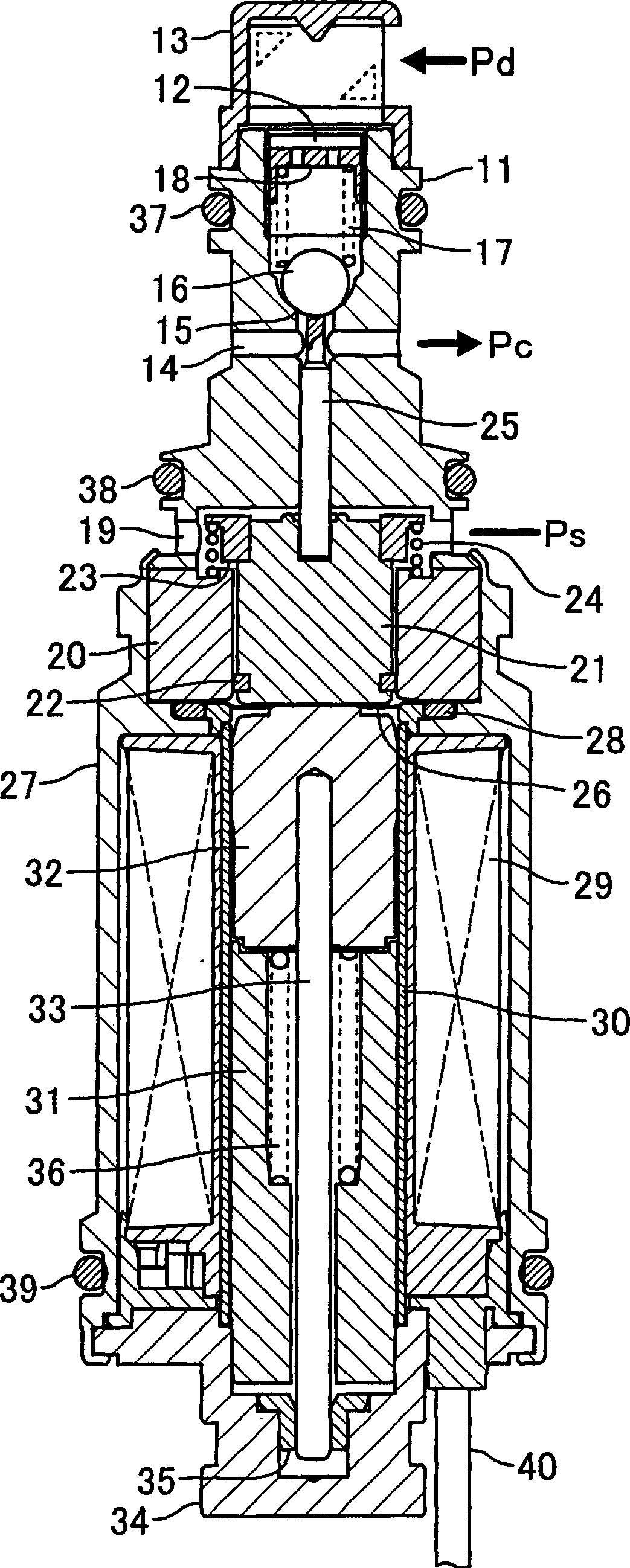

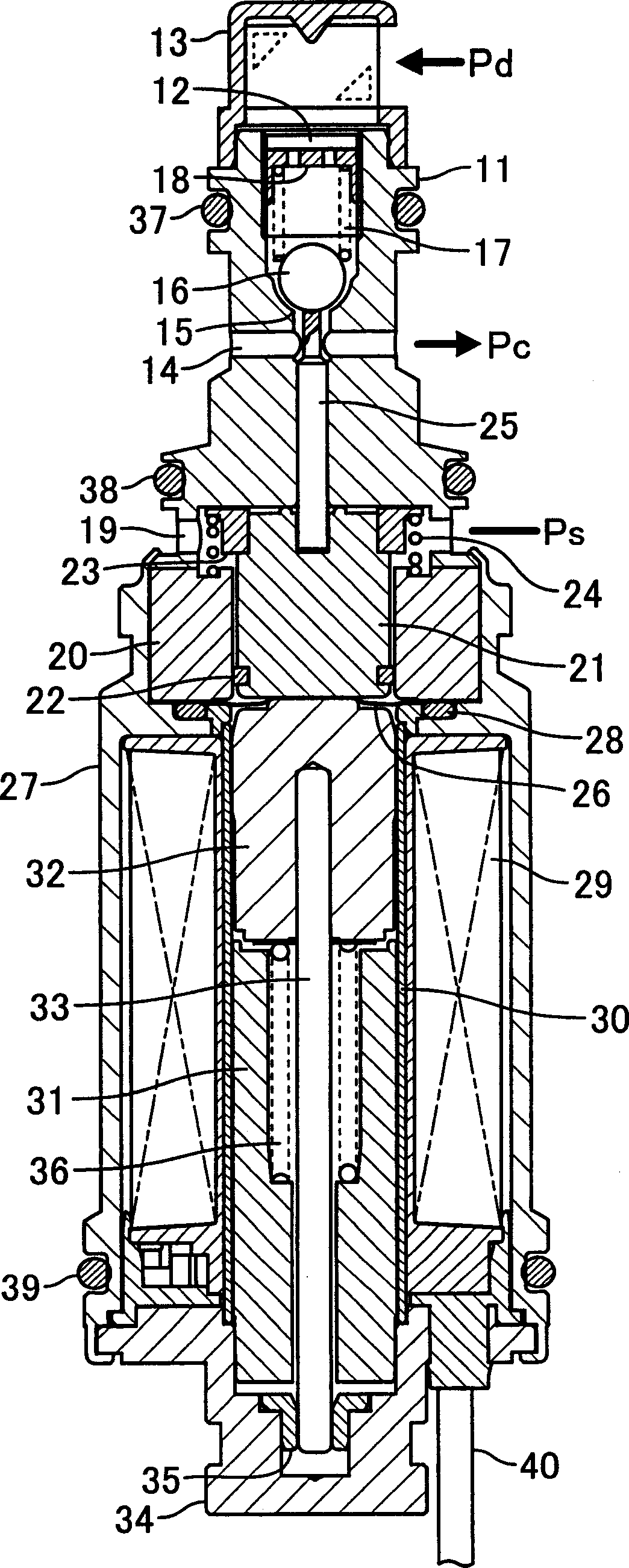

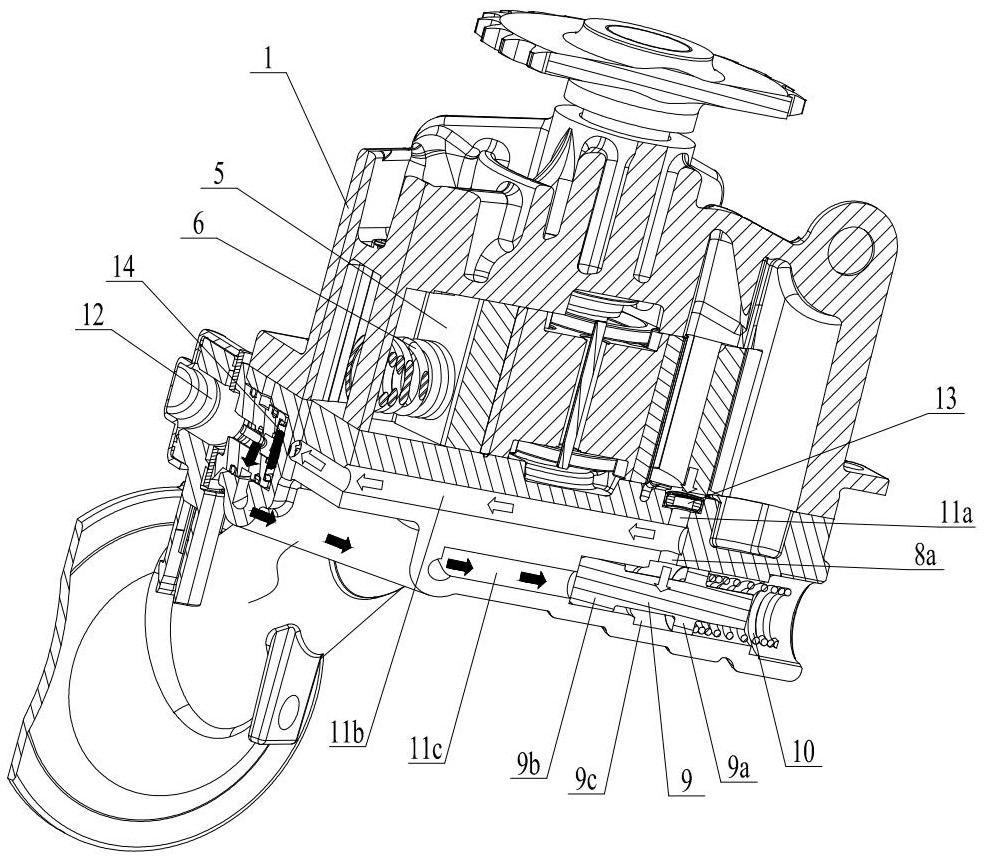

Control valve of variable capacitance compressor

InactiveCN1497179AChange displacementPositive displacement pump componentsPump controlCapacitanceEngineering

The object of the present invention is to provide a control valve for a variable displacement compressor, which is capable of controlling the variable displacement compressor to the minimum capacity without using an electromagnetic clutch, and can be constructed without accommodating a solenoid in a pressure chamber. A plunger of a solenoid is formed by a first plunger and a second plunger, and a diaphragm is disposed between them, for sensing suction pressure Ps, such that the first plunger controls a valve element via a shaft, with component elements of the solenoid except for the first plunger being disposed on a side of the diaphragm where the atmospheric pressure is received. Further, when the solenoid is not energized, the high suction pressure Ps urges the second plunger toward the core via the diaphragm, and a spring causes the first plunger to urge the valve element to the fully open position, which enables the variable displacement compressor to be controlled to the minimum capacity.

Owner:TGK

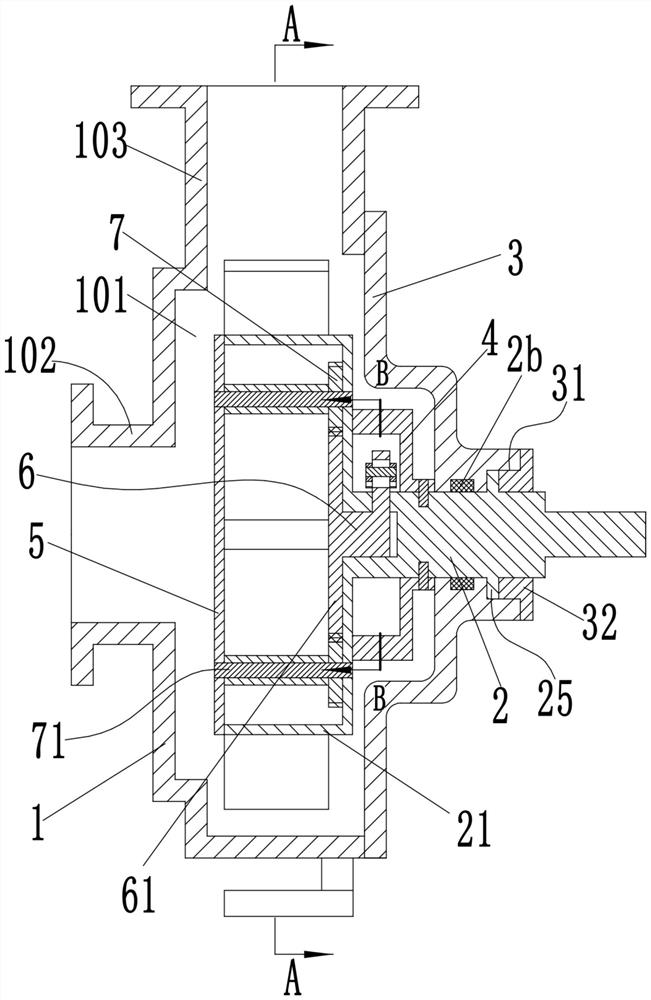

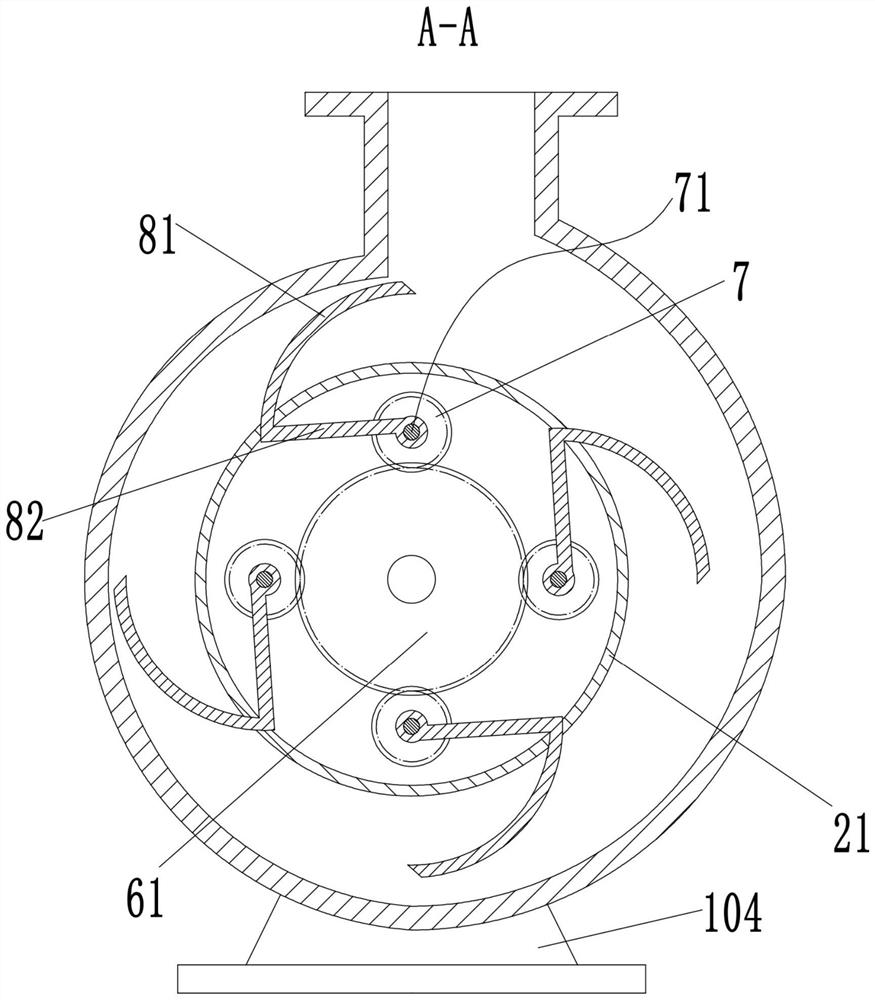

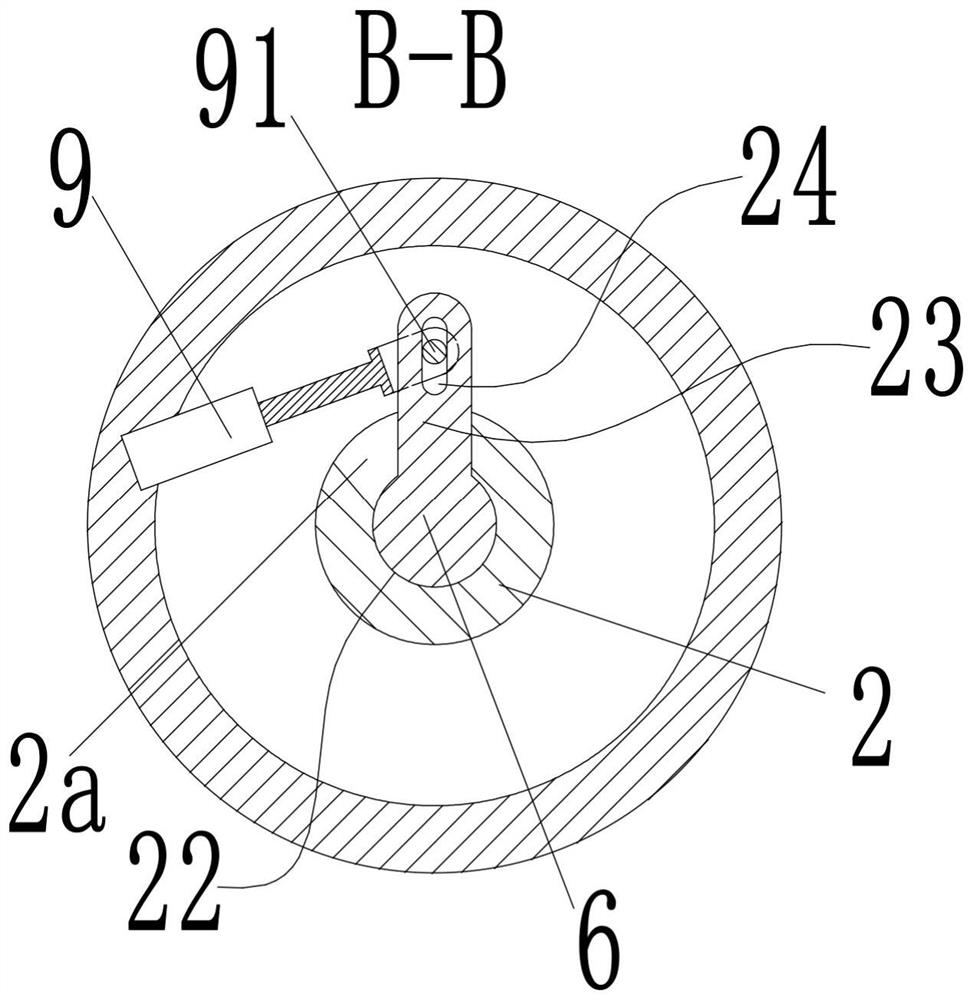

Centrifugal water pump

ActiveCN111648965AChange angleChange displacementPump componentsPump controlMechanical engineeringPhysics

The invention discloses a centrifugal water pump. The centrifugal water pump comprises a pump body, a pump cavity is formed in the pump body, a pump cover is fixedly installed at an opening in the right end of the pump cavity, a power shaft is rotationally connected into the pump cover, and a first wheel disc is arranged at one end of the power shaft; a water inlet pipeline and a water outlet pipeline are arranged on the side surface of the pump body; a sliding groove is formed in the power shaft, a protruding shaft is connected into the sliding groove in a sliding mode, and a second wheel disc is arranged at the left end of the protruding shaft; a plurality of first blades are hinged to the first wheel disc; a plurality of second blades are hinged to the second wheel disc; the first blades and the second blades are hinged to each other; when the protruding shaft slides leftwards, the first blades and the second blades are unfolded, the displacement of the centrifugal water pump is increased, and when the protruding shaft slides rightwards, the first blades and the second blades are folded, and the displacement of the centrifugal water pump is reduced; and the power shaft is provided with a push rod assembly for controlling the protruding shaft to slide left and right. The centrifugal water pump is simple in structure, and the displacement can be adjusted.

Owner:安徽凯润泵阀科技有限公司

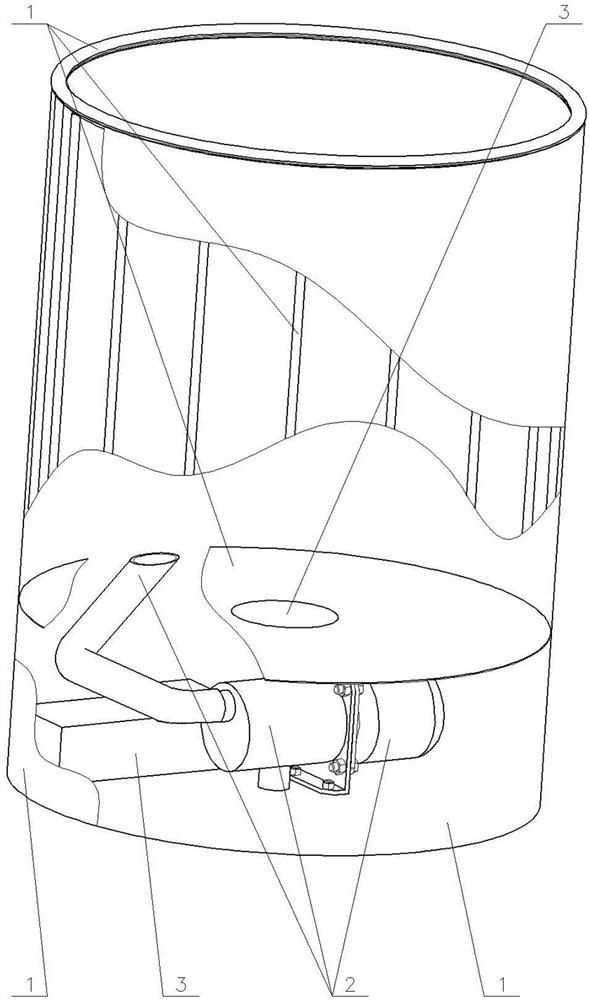

Water surface garbage collector

InactiveCN113322916AChange displacementEasy to inhaleWater cleaningStationary filtering element filtersRefuse collectorBarrel

The invention provides a water surface garbage collector. The water surface garbage collector is characterized in that one end of a barrel body of a collecting barrel is open, the other end of the barrel body is closed, a water outlet is formed in the barrel bottom, a partition plate is arranged at the end, close to the barrel bottom, in the barrel body, a water suction opening is formed in the partition plate, and the outer diameter of two ring rods of a filtering screen frame is smaller than the inner diameter of a cylinder part of the barrel body by 5mm + / -2mm; the maximum distance between the outer side arc surfaces is equal to the distance between the plate surface of the partition plate and the open end of the barrel body, a filtering screen provided with a plurality of small holes and the filtering screen frame are arranged in the barrel body, and the open end of the filtering screen frame is located at the open end of the barrel body; a flow guiding cover is clamped at the opening ends of the barrel body and the filtering screen frame, and the open end of the filtering screen is clamped between the open ends of the barrel body and the filtering screen frame; a power input shaft of a water pump installed at the bottom of the barrel body is connected with an adjustable-speed motor, a water outlet of the water pump is hermetically connected with the water outlet, a water inlet of the water pump is hermetically connected with the water suction opening of the partition plate through a water suction pipe, and a controller and a storage battery of a control system are installed at the bottom of the barrel body. The water surface garbage collector is high in cleaning efficiency and low in labor intensity.

Owner:石明霞

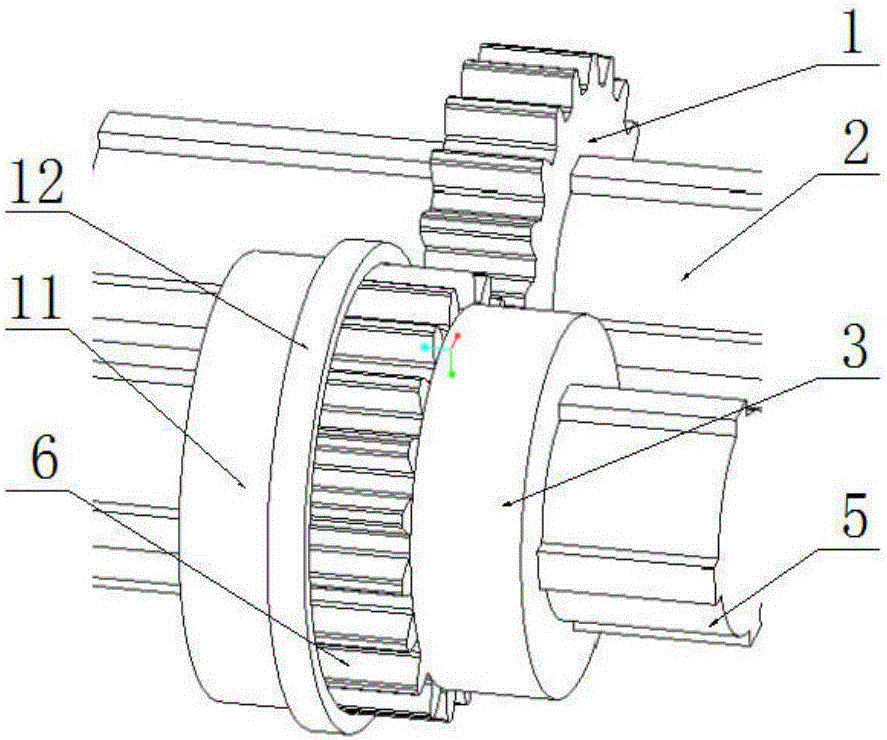

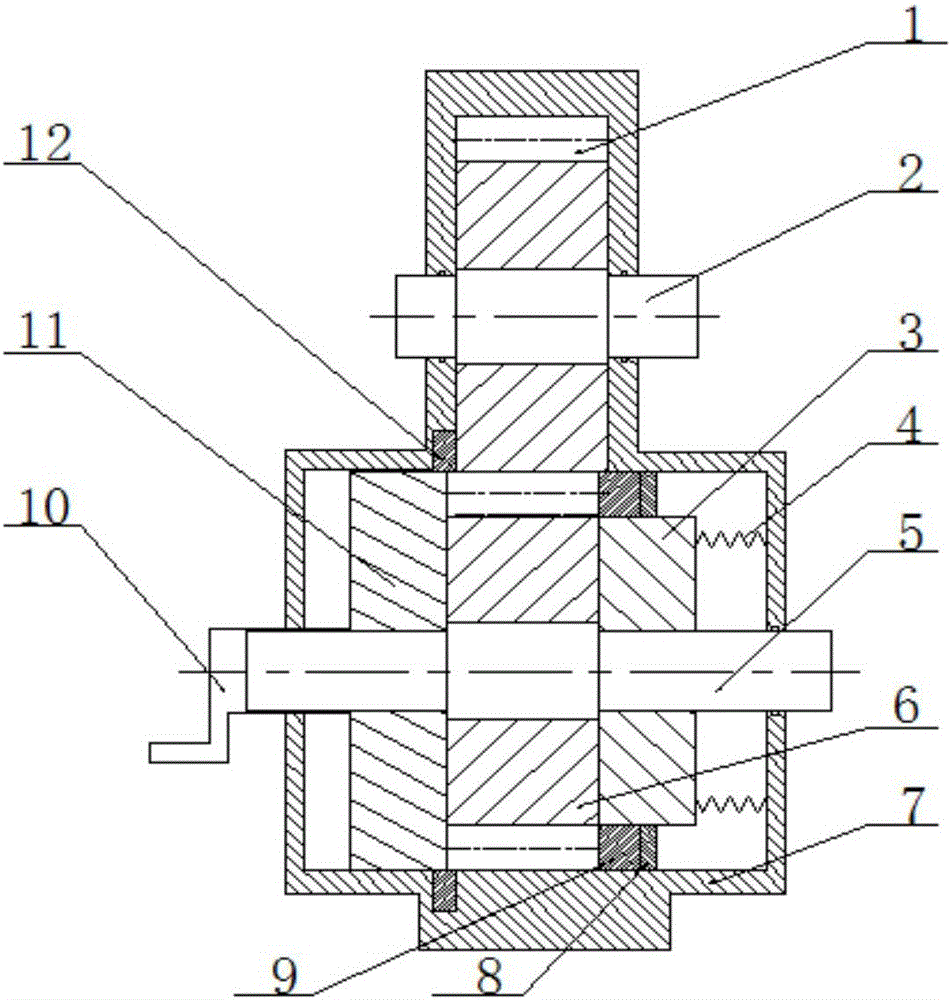

Manual-adjusted variable gear pump

InactiveCN106704175AChange displacementChange flow sizeRotary piston pumpsRotary piston liquid enginesGear pumpDrive shaft

The invention provides a manual-adjusted variable gear pump. The manual-adjusted variable gear pump comprises a pump body (7), a driving gear (1), a driven gear (6), an adjusting stopper (11), a gear ring (12), a return stopper (3), a return spring (4), a driving shaft (2), a driven shaft (5), an adjusting handle (10), a tooth-shaped slide block (9) and a baffle plate (8); the driving shaft (2) cannot axially move; and the driven gear (6), the adjusting stopper (11) and the return stopper (3) are all mounted on the driven shaft (5), and can move along the driven shaft (5). The adjusting handle (10) is shaken to enable the adjusting stopper (11) to push the driven gear (6), the return stopper (3) and the tooth-shaped slide block (9) to axially move, so that the engagement width of the driving gear (1) and the driven gear (6) can be changed, and the manual displacement adjustment of the gear pump is realized. A displacement adjusting device is simple in structure and convenient to operate, and can change the displacement of the gear pump in real time according to working conditions.

Owner:CHANGZHOU UNIV

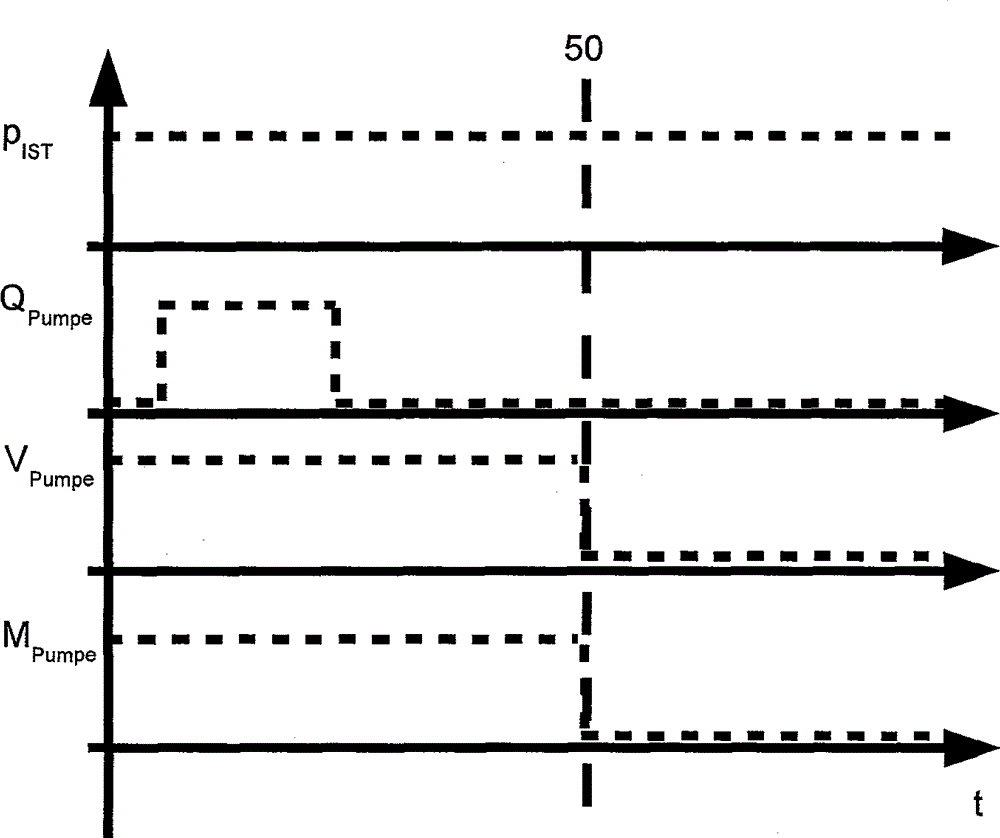

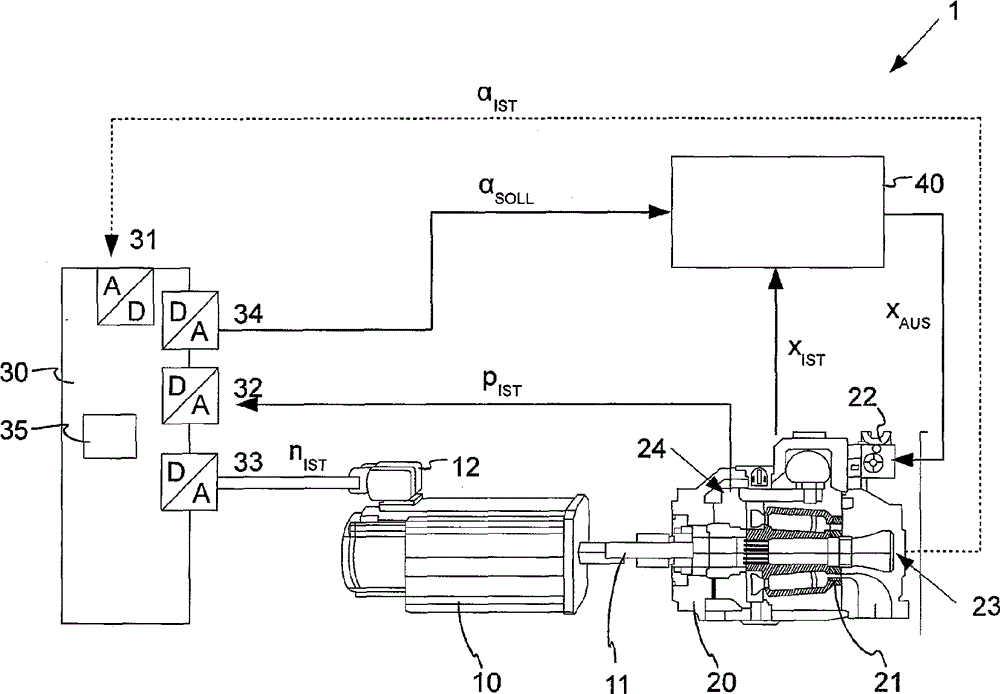

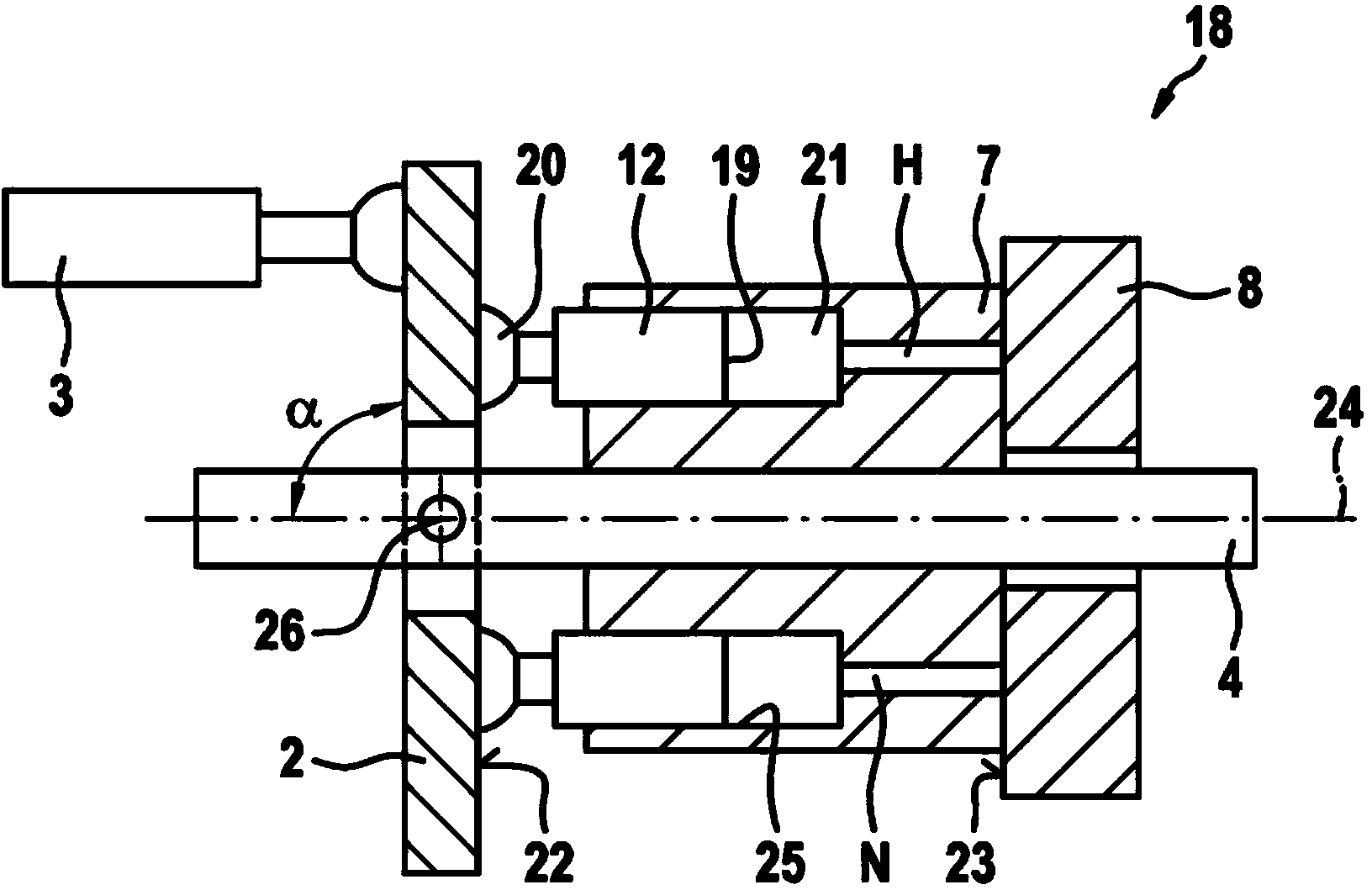

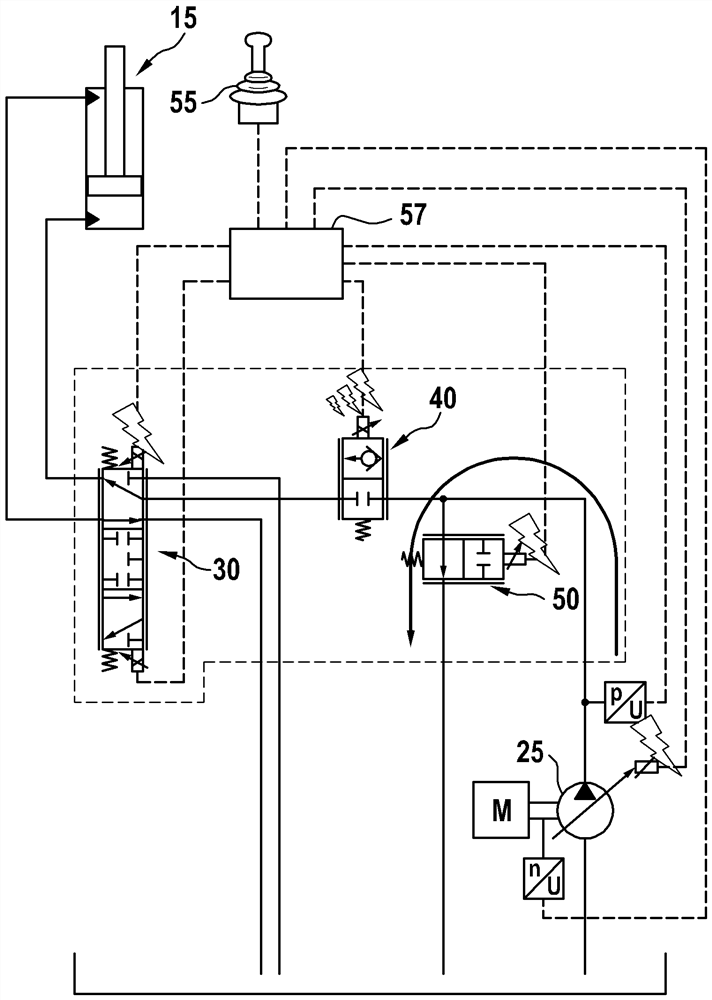

Use of a motor-driven speed-variable hydraulic pump as a hydrostatic transmission

ActiveCN104100508AChange displacementReduce speedPump parameterPump controlHydraulic cylinderMotor drive

Provided are an adjusting device (30) and an adjusting method for adjusting a motor (10) driven hydraulic pump (20). The adjusting device (30) comprises an adjusting mechanism (35) for adjusting the speed (n) and the stroke volume (VH) of the hydraulic pump (20) for regulating the pressure of the hydraulic pump (20) or the force control or position control of a hydraulic cylinder. Here, the stroke volume (Vh) of the hydraulic pump (20) is either stationary by adjusting the angle ([alpha]) of the hydraulic pump (20) or dynamically adjusted by dynamically adjusting the swivel angle ([alpha]) of the hydraulic pump (20) and the speed (n) of the motor (10) in normal operation. The unit consisting of the hydraulic pump (20), the motor (10) and the drive controller or adjusting device (30) is thereby used as an electro-hydraulic transmission for optimizing the system efficiency.

Owner:ROBERT BOSCH GMBH

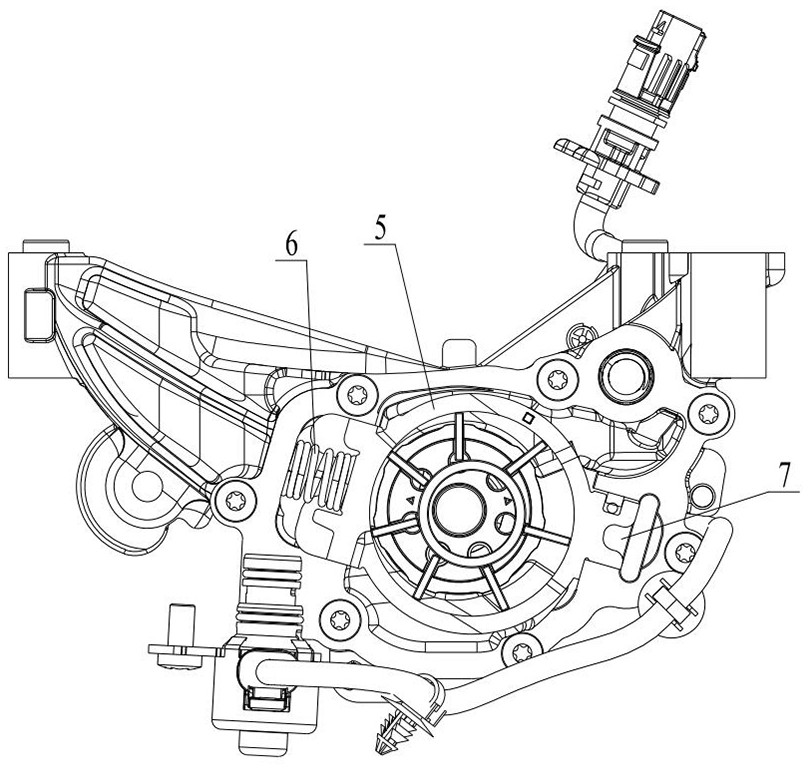

Centrifugal water pump

ActiveCN111810440AChange displacementControl displacementPump componentsPump controlGear wheelEngineering

The invention discloses a centrifugal water pump comprising a pump body. A pump cavity is arranged in the pump body. The opening of the right end of the pump cavity is fixedly provided with a pump cover. A power shaft with the left end extending into the pump cavity is rotationally connected into the pump cover. The side face of the pump body is provided with a water inlet pipe and a water outletpipeline. The left end of the power shaft is provided with a wheel shell. The portion, at the left end of the power shaft, in the wheel shell is provided with a shaft hole. A shaft rod is rotationallyconnected into the shaft hole. The left end of the shaft rod is provided with a toothed disk located in the wheel shell. The opening of the left end of the wheel shell is fixedly provided with a cover plate. Multiple rotating shafts are rotationally connected between the cover plate and the right end of the wheel shell. Each rotating shaft is fixedly provided with a gear. Each rotating shaft is fixedly provided with a connecting plate. Each connecting plate is provided with an arc blade. The side face of the wheel shell is provided with sliding grooves allowing the arc blades to extend therein. An adjusting assembly used for driving the shaft rod to rotate is arranged in the pump cavity. The centrifugal water pump is simple in structure, and the displacement can be adjusted.

Owner:SHANGHAI LIANCHENG GRP SUZHOU

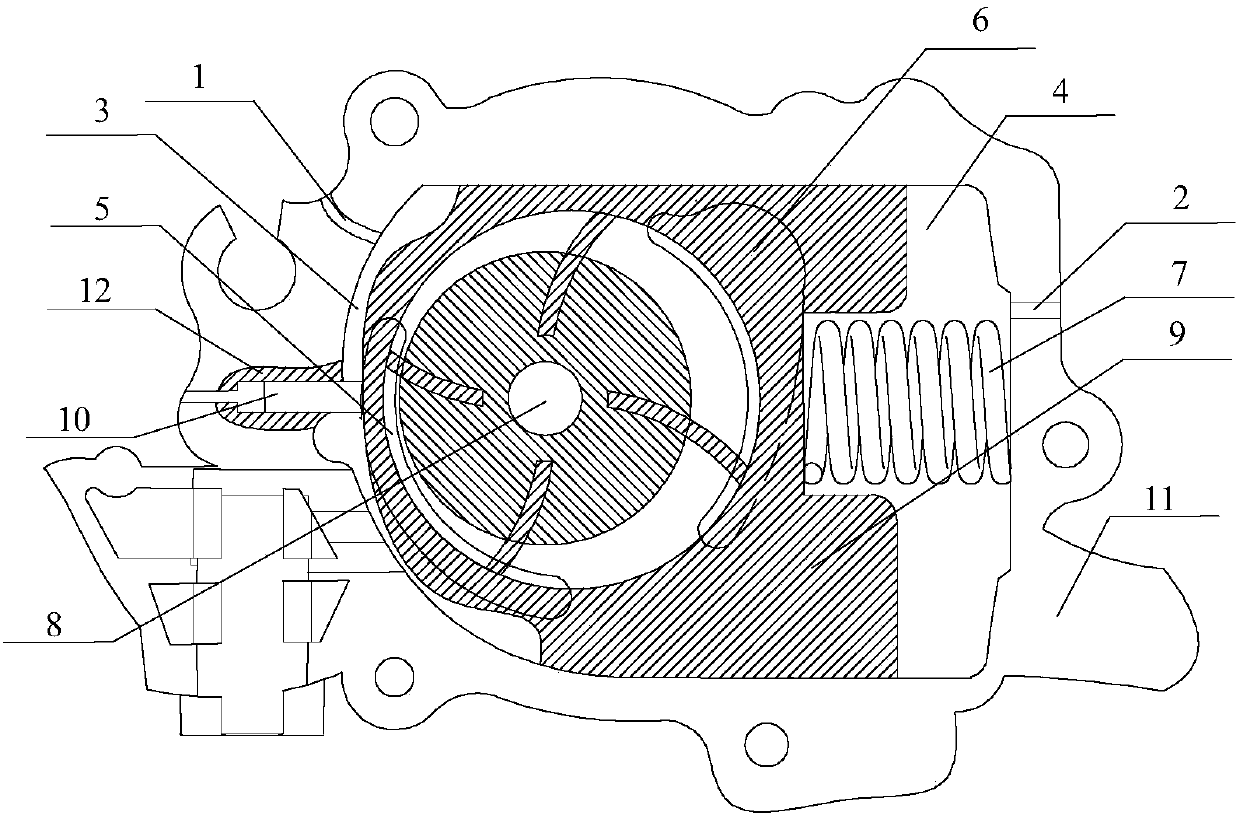

Stepless adjusting type variable displacement oil pump

InactiveCN107725135AChange displacementGood oil flowLubricating pumpsMachines/enginesSpool valveControl system

The invention discloses a stepless adjusting type variable displacement oil pump. The stepless adjusting type variable displacement oil pump comprises an engine body and a case arranged on the enginebody. A slide valve is slidably arranged in the engine body. The eccentricity of the oil pump is changed along with sliding of the slide valve. A hydraulic driving device comprises a piston cavity formed in the engine body in a penetrating mode and a piston slidably sleeved with the piston cavity. A flow control system is connected with the engine body and the piston. All real-time flow parametersin the engine body are sequentially fed back to the flow control system. The flow control system controls the hydraulic driving device to drive the piston to move and drive the slide valve to move, so that the displacement of the oil pump is controlled. According to the stepless adjusting type variable displacement oil pump, by controlling the piston to move, the slide valve is driven to move, thus, the eccentricity of the oil pump is changed, then, the displacement of the oil pump is changed, in the oil flow adjusting process, the rotation speed of an engine is considered, the influence of the oil temperature is also considered, and the effect that the optimal oil flow is achieved at any temperature under any rotation speed of an engine lubricating system is ensured.

Owner:JILIN UNIV

Displacement variable oil-well pump

InactiveCN101846062AReliable changeExtend the production cyclePositive displacement pump componentsFlexible member pumpsOil wellLower body

The invention relates to a displacement variable oil-well pump. A pump cylinder, a connecting pipe, an oil inlet valve and a small pump are sequentially connected; a large plunger, an oil outlet valve and an uncoupling device are sequentially connected, an oil inlet is arranged between the oil outlet valve and an upper body of the uncoupling device, the diameter of the upper body of the uncoupling device is less than the internal diameter of the large pump cylinder, the inner diameter of the connecting pipe is more than that of the large pump cylinder to ensure that the joint of the lower part of the large pump cylinder and the upper part of the connecting pipe generates a releasing ledge, and the upper body of the uncoupling device and the lower body of the uncoupling device can be separated at the releasing ledge. Due to the combination of the large cylinder and the connecting pipe, a releasing ledge of the uncoupling device is formed, and the displacement of the oil-well pump can be changed by adopting the common uncoupling device; because the outer diameter of the lower body of the common uncoupling device is more than the internal diameter of the releasing ledge, only the uncoupling device is released after lifted to the releasing ledge, and the uncoupling device can be released as long as being lifted to the releasing ledge. The invention can be used for reliably changing the displacement and prolonging the oil well production period, and has remarkable economic benefit.

Owner:苗在朝

Movable booster type pump outlet control two-stage variable oil pump

ActiveCN112324534AChange displacementTwo-stage displacement precise controlMachines/enginesPressure lubrication with lubrication pumpEngineeringCylinder block

The invention discloses a movable booster type pump outlet control two-stage variable oil pump, and relates to the technical field of oil pumps. The movable booster type pump outlet control two-stagevariable oil pump comprises a pump body, a pump cover, a pump shaft, a rotor, a sliding block and a spring; a feedback cavity is arranged in the pump body; a control valve is arranged on the pump cover; a plunger is arranged in a valve hole of the control valve; a control valve spring is abutted between the plunger and the rear end of the valve hole; a convex ring is arranged on the circumferential surface of the middle of the plunger; a plug is arranged at the front end of the plunger; an oil inlet and an oil outlet are formed in the side wall of the control valve; the oil inlet communicateswith a pump outlet and located in the front side of the convex ring; a control valve normally-open cavity communicating with the pump outlet is formed between the convex ring and the plug; the oil outlet communicates with the feedback cavity, and is located in the rear side of the convex ring; the pump cover is provided with an oil channel communicating with the pump outlet and an inlet in the front end of the control valve hole; and an electromagnetic valve is arranged in the oil channel. Two-stage variables are achieved through the internal oil duct of the oil pump and the electromagnetic valve, and a feedback oil hole does not need to be designed in an engine cylinder body, so that the structure of the engine cylinder body is greatly simplified.

Owner:HUNAN OIL PUMP

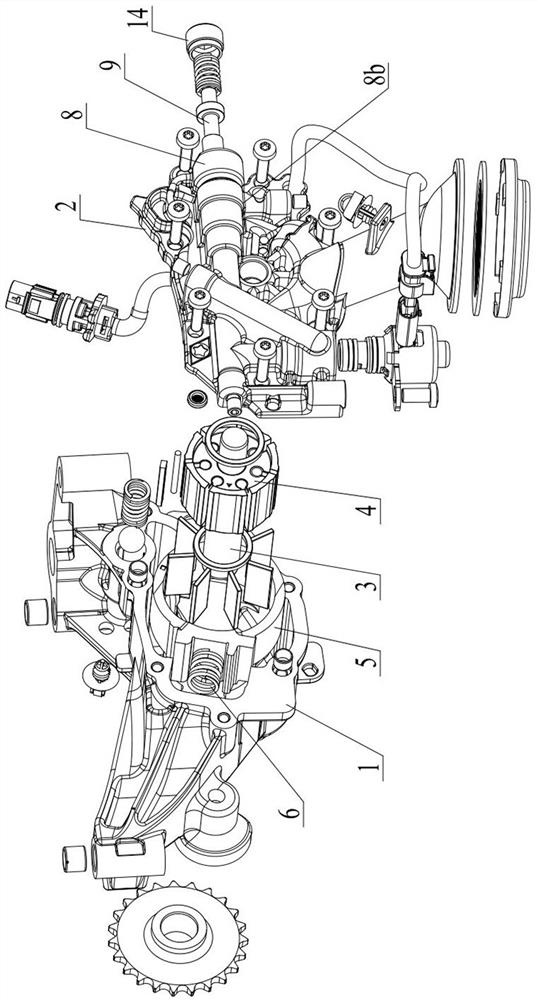

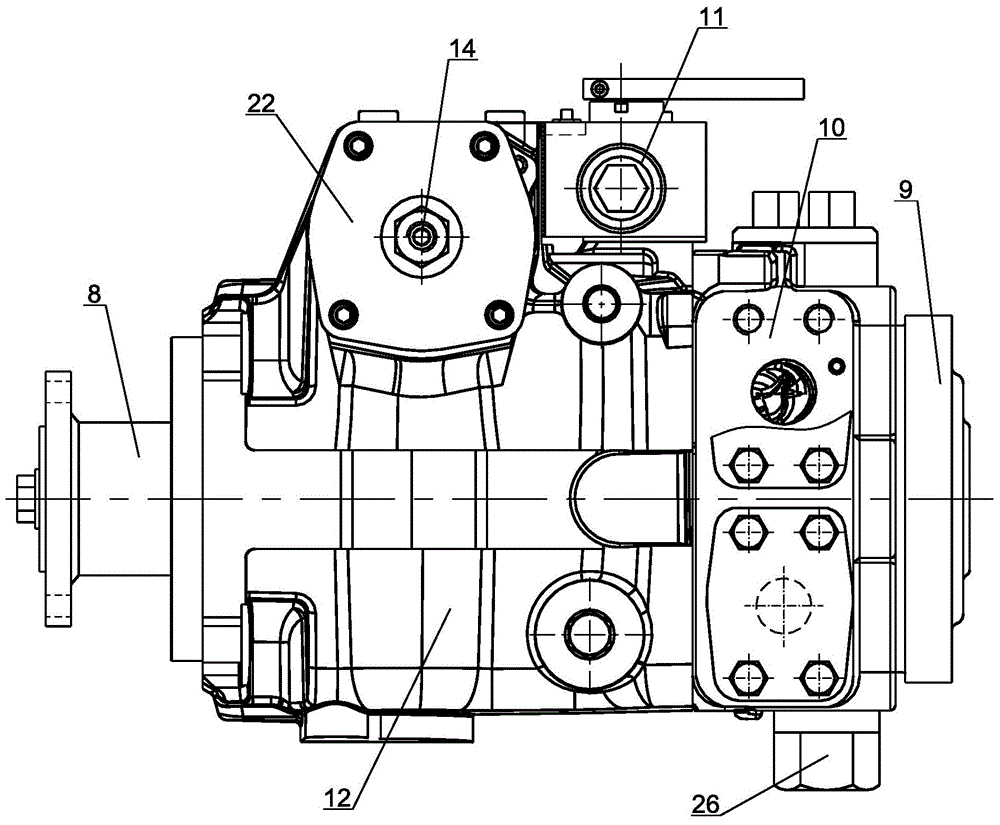

Servo control variable piston pump and control method thereof

InactiveCN104533741ASimple and fast operationPlay a lubricating rolePositive displacement pump componentsPositive-displacement liquid enginesBall bearingSystem requirements

A servo control variable piston pump comprises a shell. A valve body is installed at the lower end of the shell. An oil supplementary pump is installed on the valve body in a fastened mode. A transmission flange is installed at the upper end of a driving shaft. The middle of the driving shaft is installed inside the shell through a ball bearing in a supported mode. The lower end of the driving shaft is installed inside a sliding bearing. The sliding bearing is installed inside the valve body. A bottom crescent bearing and a top crescent bearing for installation of a swash plate are arranged on the shell. A piston assembly is pressed on the swash plate through a pressure plate. An oil distribution disc is installed on the valve body. A cylinder body is pressed on the oil distribution disc. A variable cylinder body is installed inside the shell. A center shaft penetrates through the variable cylinder body. A reset assembly is arranged at the right end of an inner cavity of the variable cylinder body. A sliding block is arranged on one side of the reset assembly so that the swash plate can be prevented from being inclined. A servo control valve is installed on the shell. The displacement can be changed in real time by controlling the servo control valve, so that the operating difficulty is effectively lowered, and the various system requirements are met; in addition, a safety control device is further arranged on the valve body and used for overload protection during oil pumping.

Owner:南京萨伯工业设计研究院有限公司

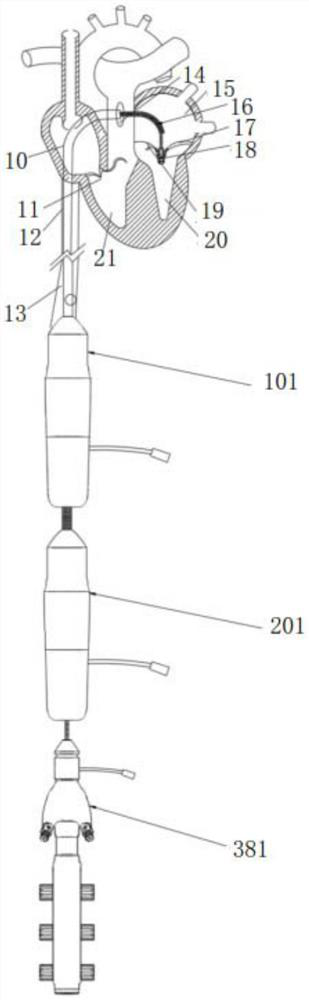

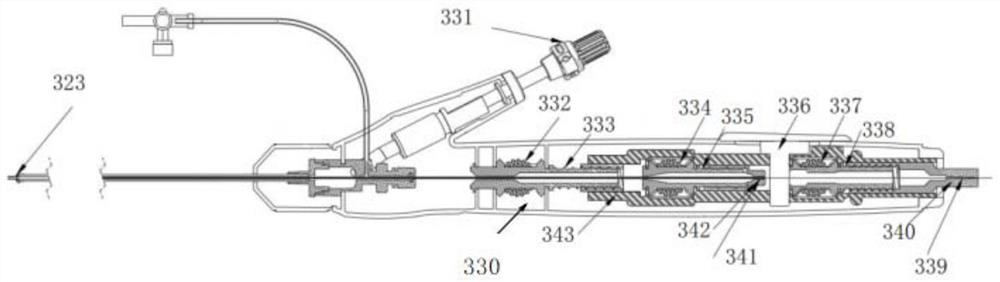

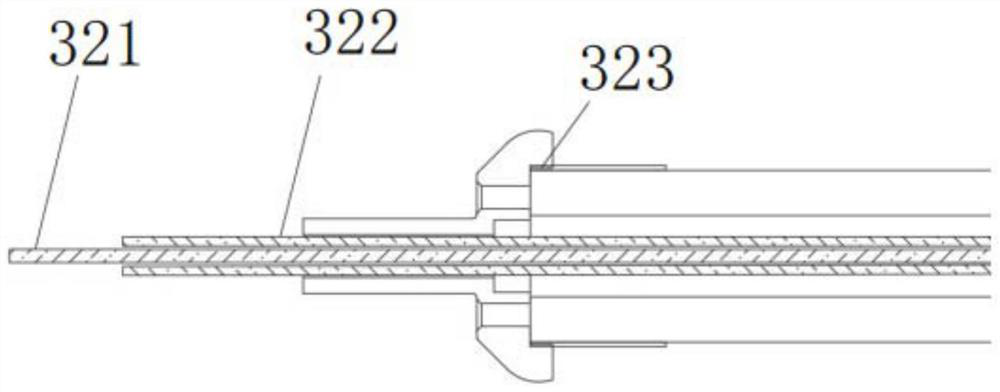

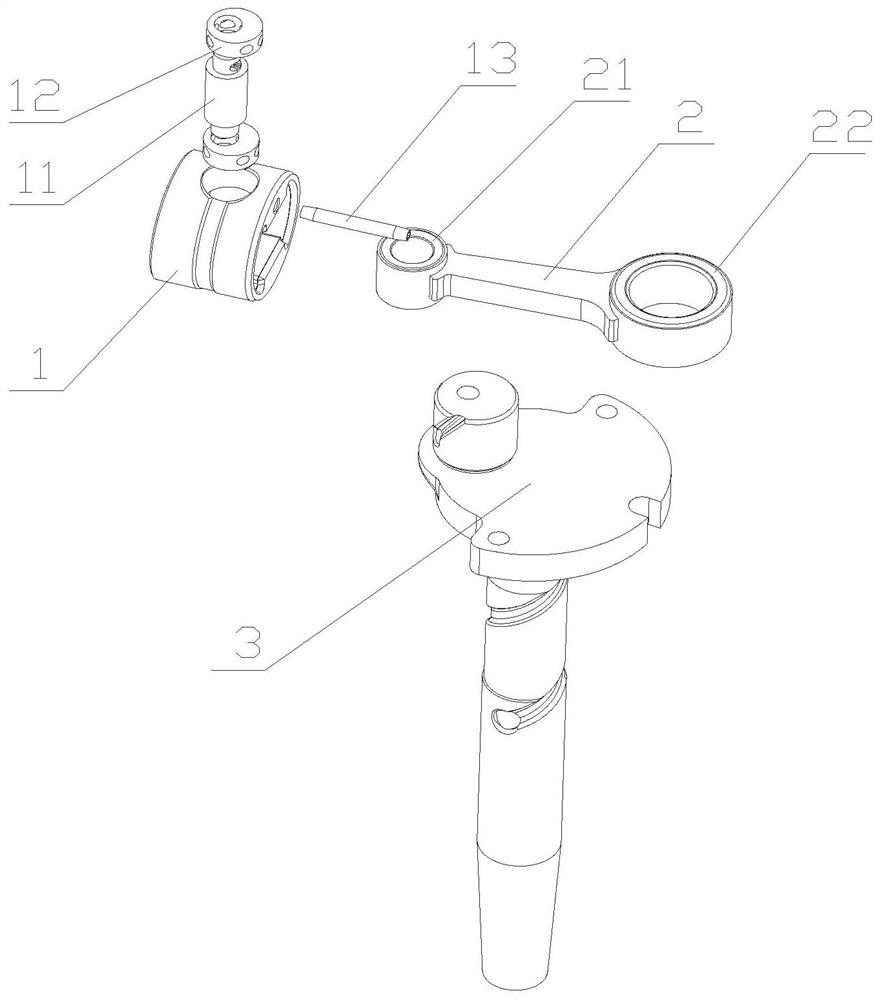

Medical device implantation unit

The invention discloses a medical device implantation unit which comprises a state control module used for adjusting the position of a moving element so as to control the working state of a medical device; the stay wire control module is used for pulling a stay wire to adjust the angle of an upper clamping piece of the medical instrument; the stay wire control module comprises an integrated stay wire element, and the integrated stay wire element comprises a sheath tube and a stay wire tube; wherein the stay wire tube extends out of the end portion of the sheath tube and extends along the axis of the sheath tube, the sheath tube and the stay wire tube are integrally formed, an inner hole of the stay wire tube is axially communicated with a first inner hole of the sheath tube, and the stay wire is arranged in the inner hole in a penetrating mode. According to the invention, an integrated stay wire element design scheme is adopted, i.e., the sheath tube and the stay wire tube are integrally manufactured, so that a gap caused by a fixed connection process between the sheath tube and the stay wire tube is effectively avoided, the problem of leakage of gas in an emptying process is finally avoided, air in an instrument can be efficiently and conveniently exhausted, the risk of gas embolism is eliminated, and the safety of the instrument is improved. And the gas discharge speed is accelerated.

Owner:SHANGHAI HUIHE HEALTHCARE TECH CO LTD

Vertical shaft hanging scaffold stabilizing device

InactiveCN101660417AChange displacementWon't scratchLoad-engaging elementsShaft liningEngineeringCycle time

The invention relates to a vertical shaft hanging scaffold stabilizing device, belonging to a pit shaft construction hanging scaffold of a vertical shaft. The scaffold stabilizing device comprises a base plate, support seats, a connecting rod, an adjuster and a rubber wheel. The base plate is provided with two support seats, wherein one support seat is connected with the connecting rod, the adjuster is arranged between the connecting rod and the other support seat, and the connecting rod is connected with the rubber wheel. An upper-layer scaffold and a lower-layer scaffold of the hanging scaffold are respectively provided with four scaffold stabilizing devices. When in work, the solid rubber wheel and the scaffold stabilizing devices tightly support the shaft wall, so the hanging scaffoldcannot shake in the annular space. The vertical shaft hanging scaffold stabilizing device has the advantages that: firstly, the device can be repeatedly used has simples processing and convenient installation and use, saves processing materials and the capital and is free from manual operation and control on the hanging scaffold when the hanging scaffold is lifted; secondly, the device can not only stabilize the hanging scaffold, but also can be used for adjusting the gap between a hanging bucket and a horn so as to ensure that the hanging bucket has enough safe distance in the running process; and thirdly, the device creates the conditions for quick construction of the vertical shaft, saves labor force and physical resource, is safe and reliable and shortens the circulation time.

Owner:CHINA COAL NO 5 CONSTR

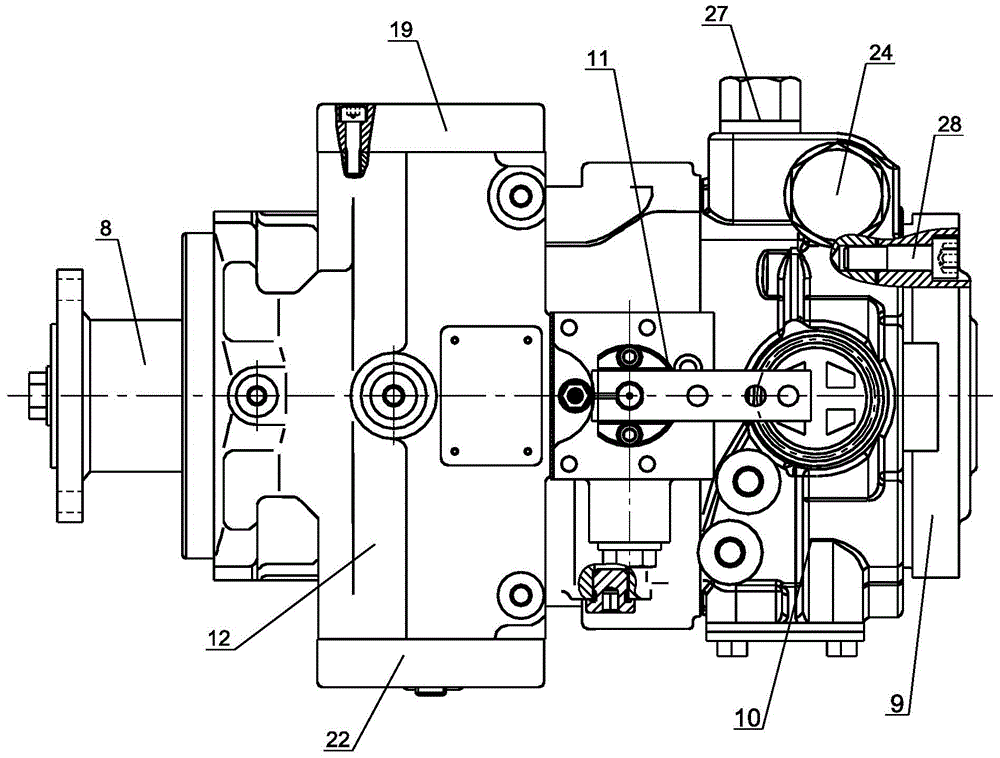

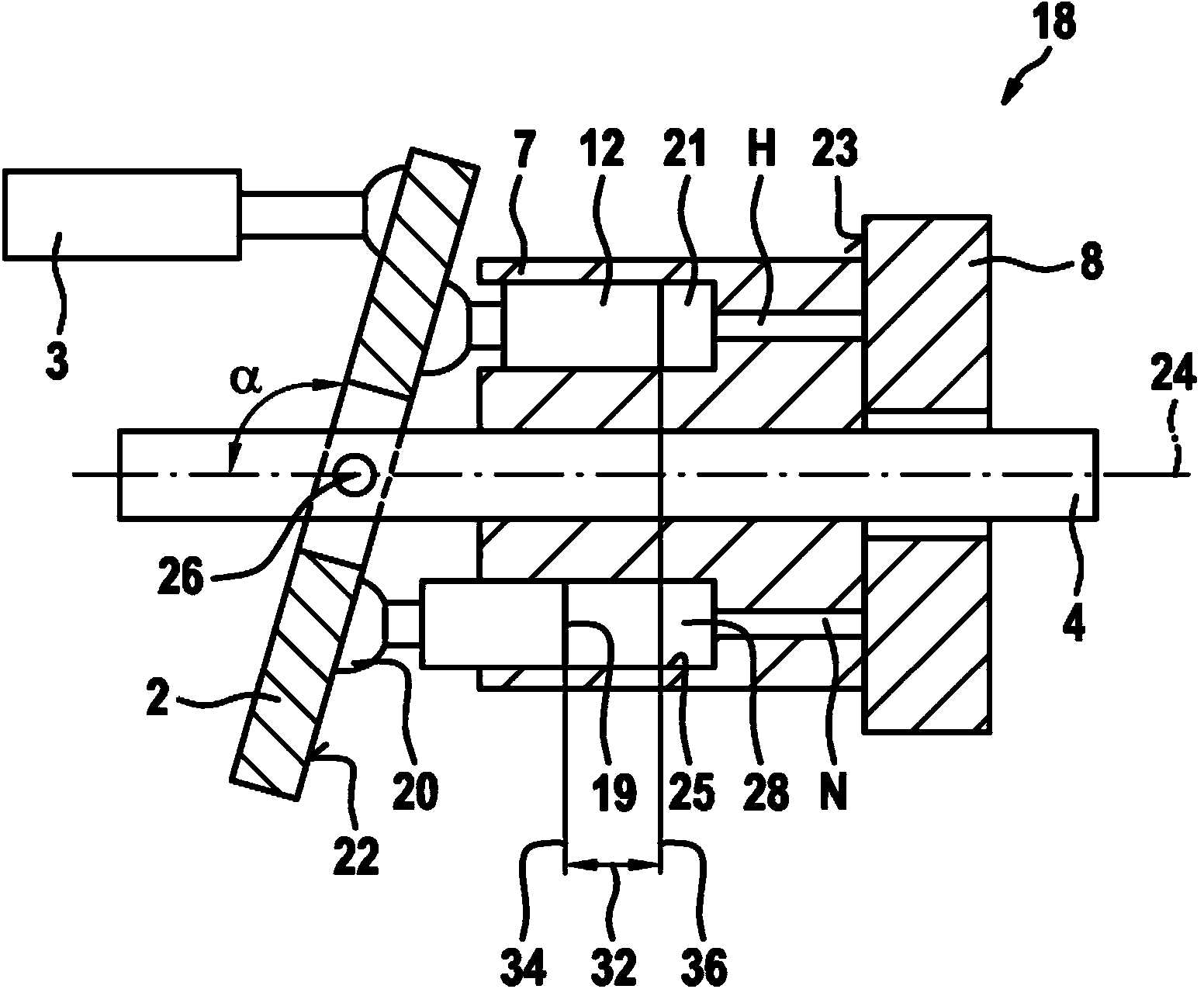

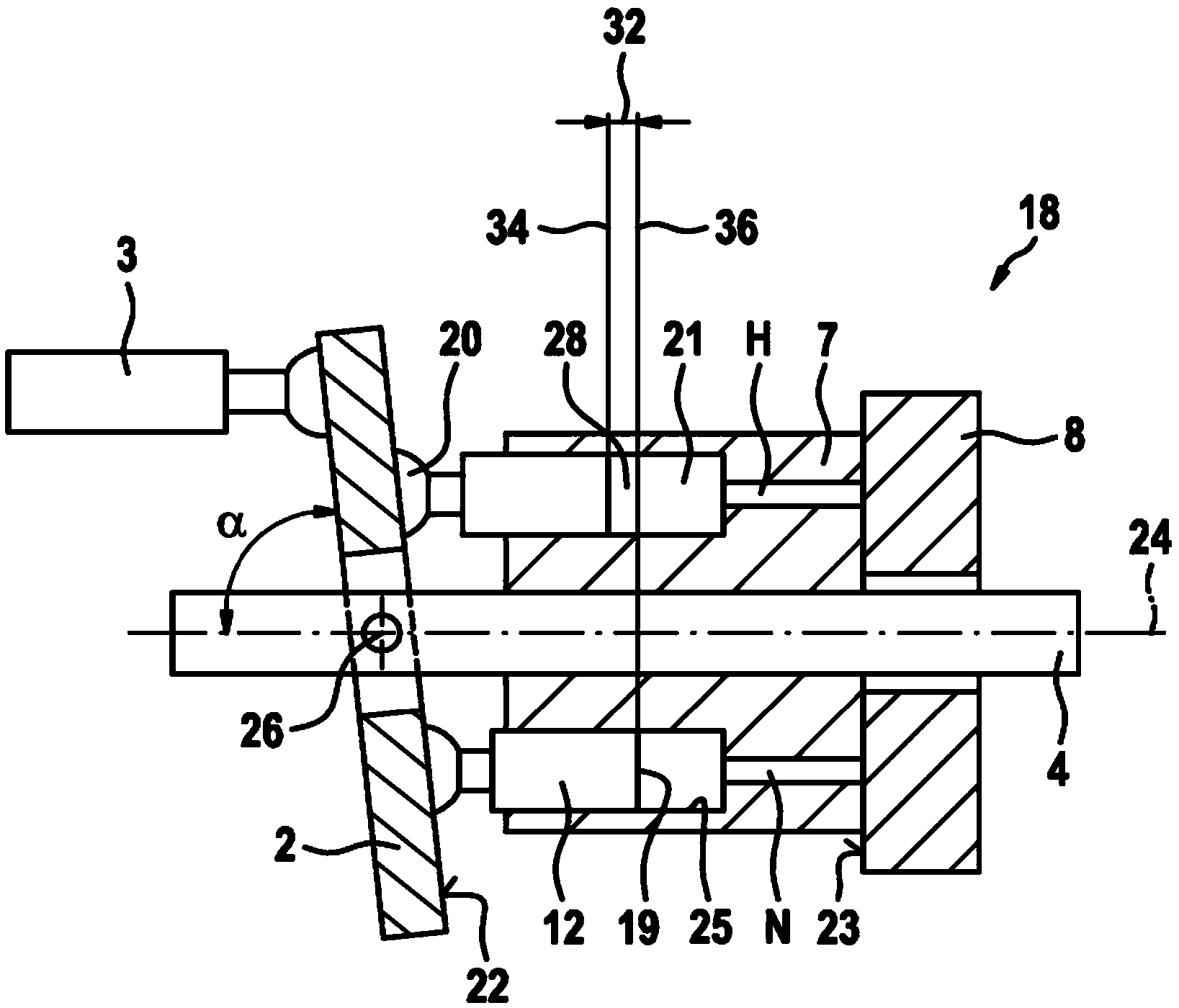

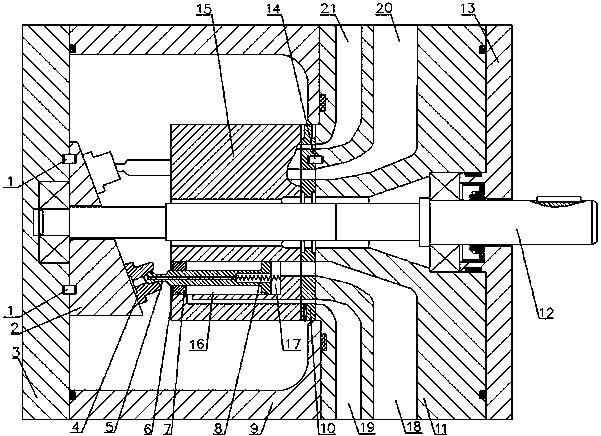

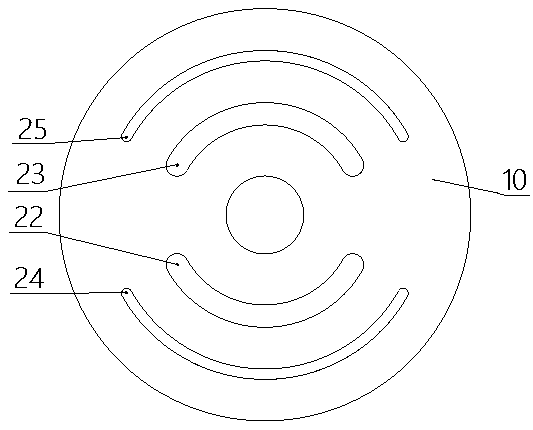

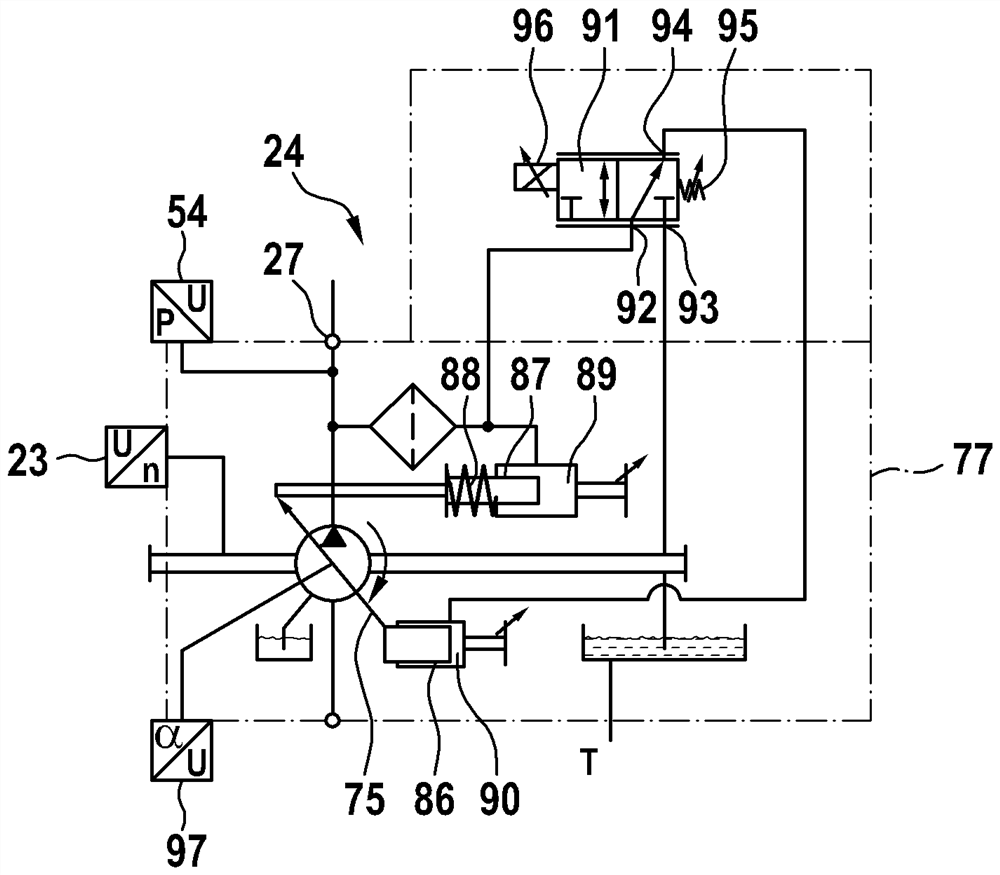

Axial piston machine with variable displacement volume, and hydraulic drivetrain having an axial piston machine

InactiveCN103998779AChange displacementChange torquePositive-displacement liquid enginesMulti-cylinder pumpsDrivetrainEngineering

The invention relates to an axial piston machine (18), with a housing (1), for pump and / or motor operation with a variably adjustable displacement volume, having a pivot cradle (2) which can be pivoted by a first adjustment device (3) within an angle range predefined by the first adjustment device (3) and which has at least one surface (22), and having a piston drum (7) which is arranged rotationally fixedly on an axis (24) and which has pistons (12, 120) arranged in the piston drum (7), wherein the pistons (12, 120) bear against the surface (22) of the pivot cradle (2) in such a way that pressure forces can be transmitted between the pistons (12, 120) and the pivot cradle (2). The axial piston machine (18) according to the invention furthermore has a second adjustment device (9, 16) which is movable in such a way that the displacement volume of the axial piston machine (18) can be varied in addition to the displacement volume variably adjustable by means of the first adjustment device (3).

Owner:ROBERT BOSCH GMBH

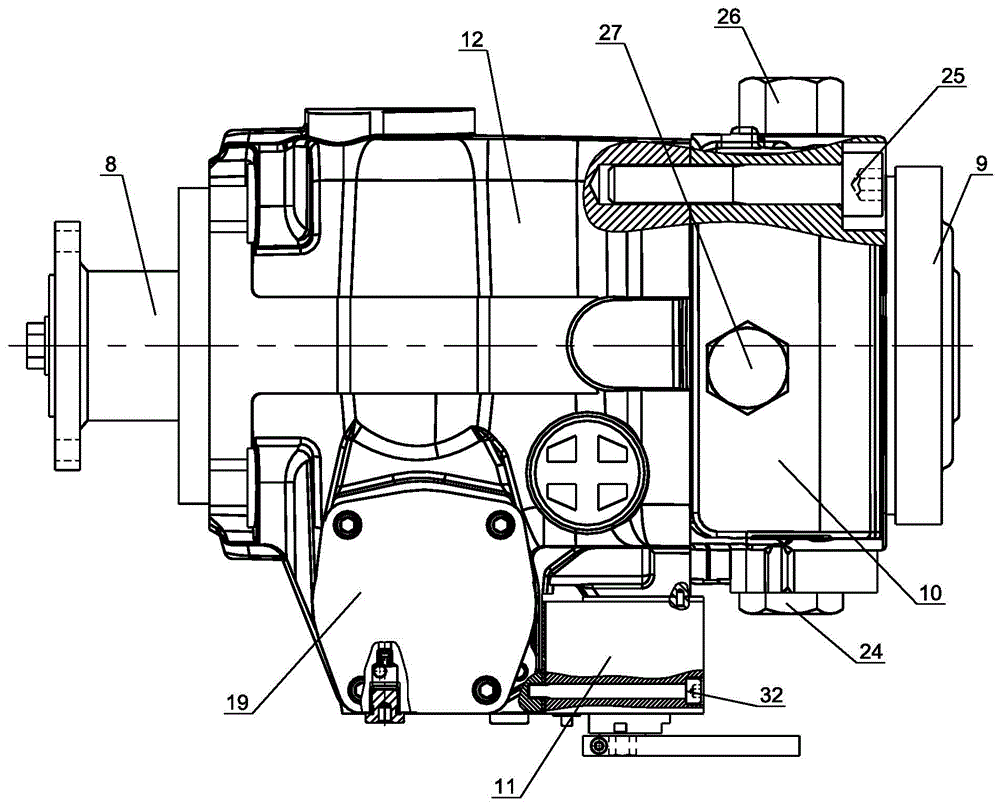

Through-shaft axial piston pump capable of realizing energy recovery

InactiveCN111237155AReduce inputImprove the lubrication effectPositive displacement pump componentsPositive-displacement liquid enginesDrive shaftCylinder block

The invention discloses a through-shaft axial piston pump capable of realizing energy recovery, and relates to the technical field of fluid machinery. The through-shaft axial piston pump comprises a pump body, a transmission shaft, a cylinder body, a swash plate, wherein an axial hole is formed in the cylinder body, and a piston is arranged inside the axial hole; the through-shaft axial piston pump further comprises a piston resetting device; an inner cavity of the cylinder body comprises a rodless cavity located on the side, away from the swash plate, of the right side of the piston as well as a rod cavity located on the left side of the rodless cavity and internally provided with a piston rod, wherein the rod cavity and the rodless cavity communicate with the outside of the cylinder bodythrough channels; and the pump body is further provided with a first fluid discharge channel, a first fluid indraft flow channel, a second fluid indraft channel and a second fluid discharge flow channel. According to the through-shaft axial piston pump capable of realizing energy recovery, input of external force is effectively reduced, recycling of waste energy is achieved, the structure is simple, manufacturing is convenient, lubricating effects of the piston are improved, friction is reduced, good economic benefits are brought, and adaptability is high.

Owner:YANSHAN UNIV +1

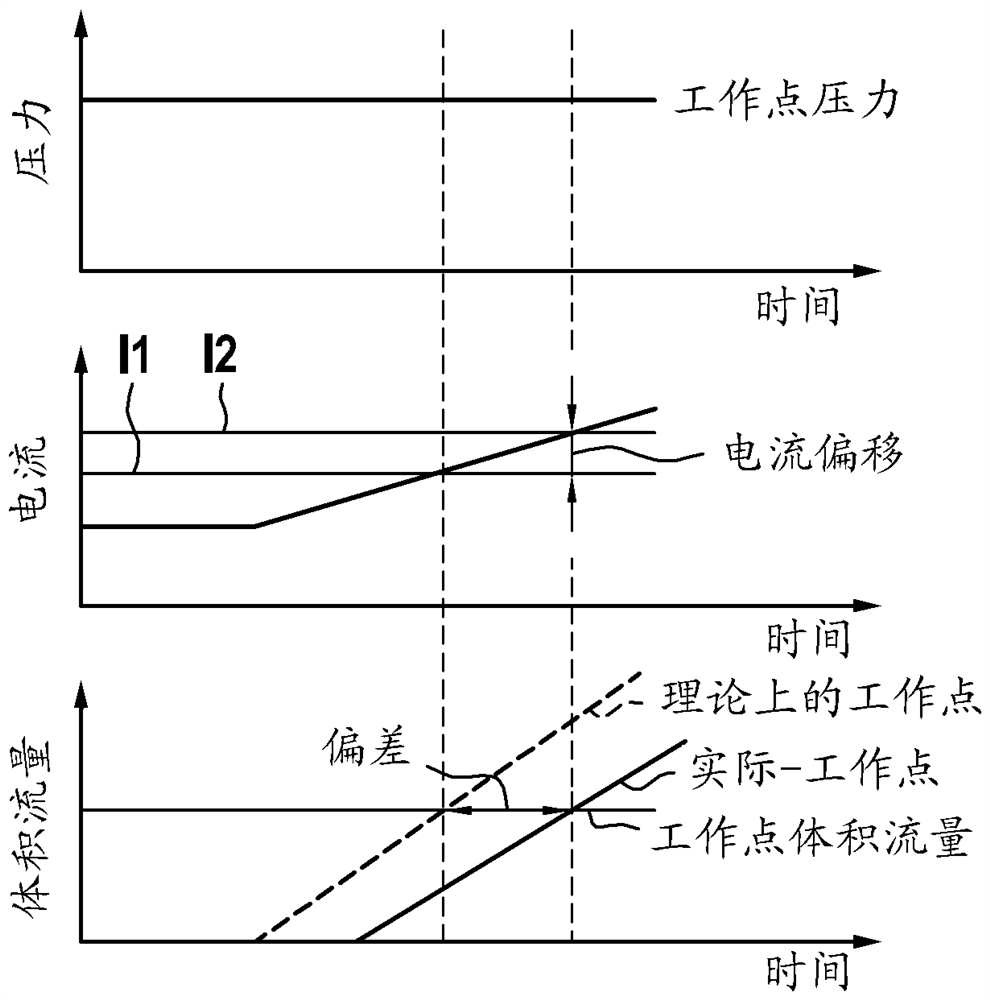

Method for calibrating electrically scalable continuous valve

PendingCN113700692AChange displacementLow pressure fluidFluid-pressure actuator testingServomotor componentsControl signalControl engineering

The invention relates to a method for calibrating a continuous valve which is arranged in a hydraulic system and can be adjusted proportionally with respect to an actuation signal of an electronic control unit. According to the invention, the method comprises the following steps: 1) regulating the pump pressure to a preset pressure when the continuous valve is closed; 2) detecting a value at least for the displacement of the hydraulic pump; 3) changing, in particular raising, the control signal of the continuous valve starting from the initial control signal until a difference between a current pump volume flow rate and a predetermined pump volume flow rate corresponding to a predetermined volume flow rate is detected in the case of a closed flow cross-section of the continuous valve; 4) determining an offset of the control signal by comparing the control signal of the continuous valve detected when the predetermined volume flow is reached with a theoretical control signal.

Owner:ROBERT BOSCH GMBH

An Unloading Independent Variable Radial Piston Pump

ActiveCN106640576BImprove energy conversion efficiencyImprove reliabilityPump controlPiston pumpsRadial piston pumpFuel tank

The invention relates to an unloading type independent variable radial plunger pump. The unloading type independent variable radial plunger pump comprises plunger pumps, an eccentric wheel, a reversing valve cam, reversing valves, a spiral swing cylinder and an oil storage tank, wherein both the eccentric wheel and the reversing valve cam are arranged on the same pump shaft which is connected to a motor, both a first plunger pump and a second plunger pump are connected to the eccentric wheel in a driven mode, both a first reversing valve and a second reversing valve are connected to the reversing valve cam in a driven mode, the first plunger pump is connected to the first reversing valve in an oil-way mode, the second plunger pump is connected to the second reversing valve in an oil-way mode, the first plunger pump is connected to a hydraulic system and the spiral swing cylinder in an oil-way mode through a one-way valve, the second plunger pump is connected to the hydraulic system and the spiral swing cylinder in an oil-way mode through the one-way valve, and a swing cylinder rotating shaft in the spiral swing cylinder is connected to the reversing valve cam. According to the unloading type independent variable radial plunger pump, a cam is adopted to control the reversing valve to unload part of displacement of the working operation of the plunger pumps, and effective oil extraction working operation of the plunger pumps and change of displacement of an oil pump are achieved.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

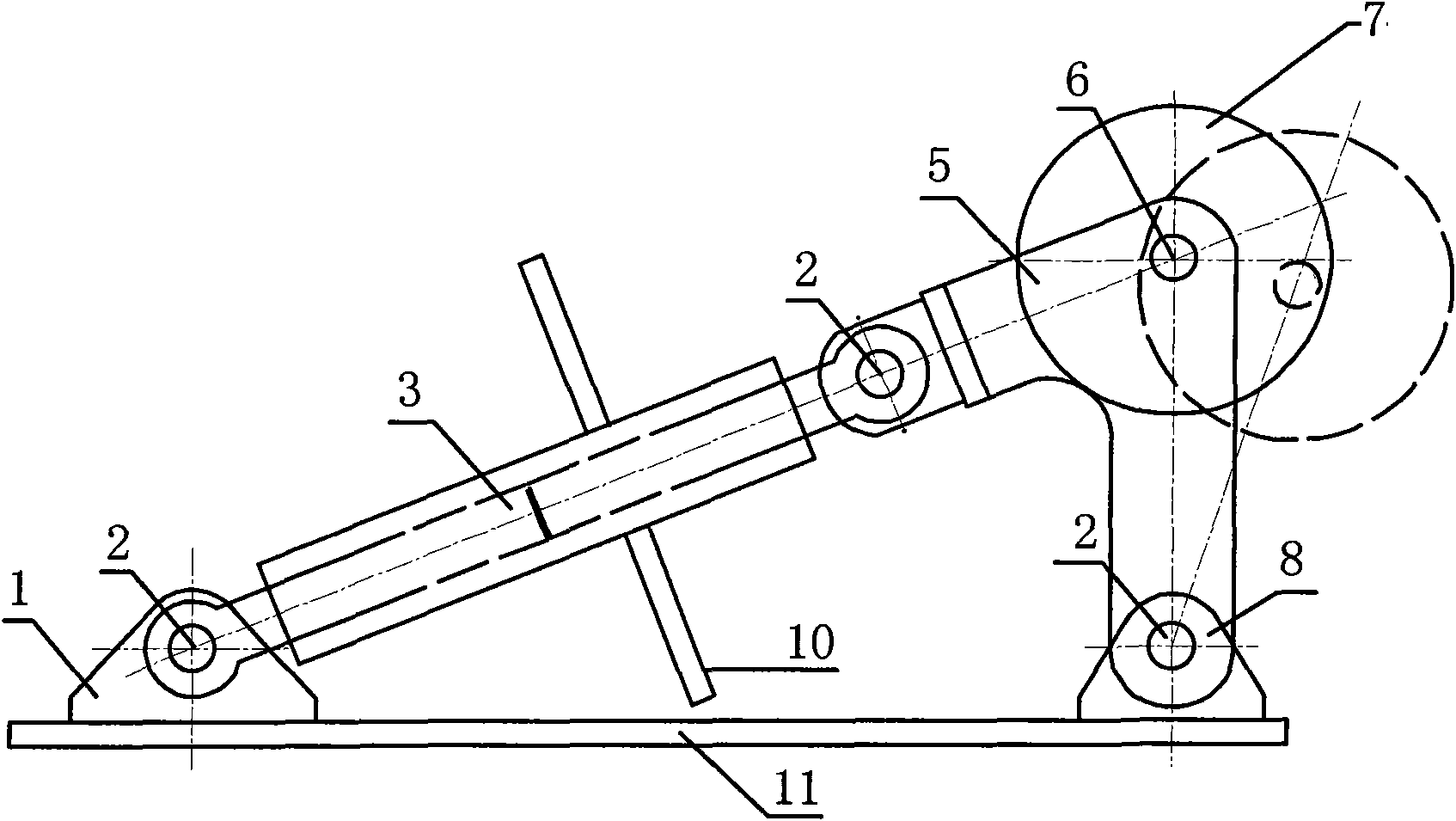

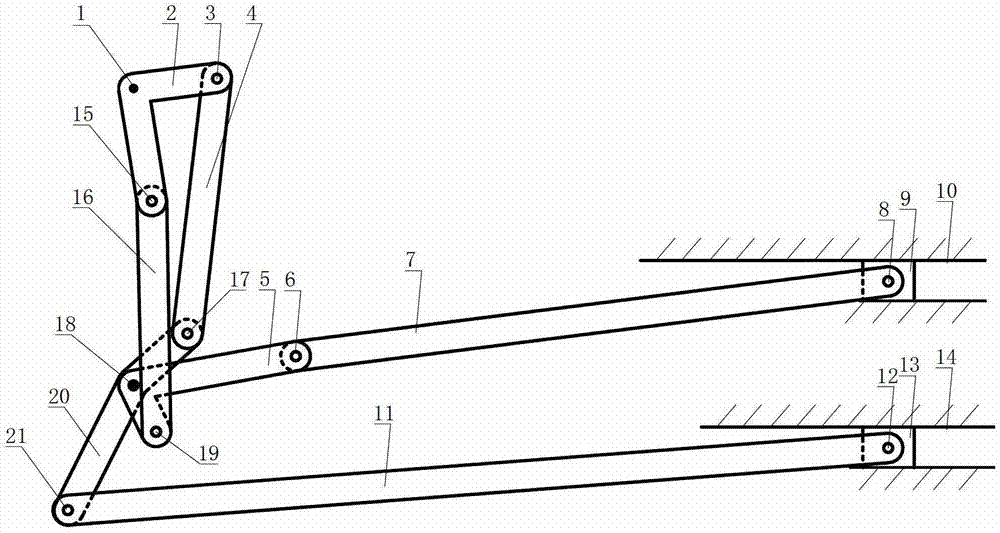

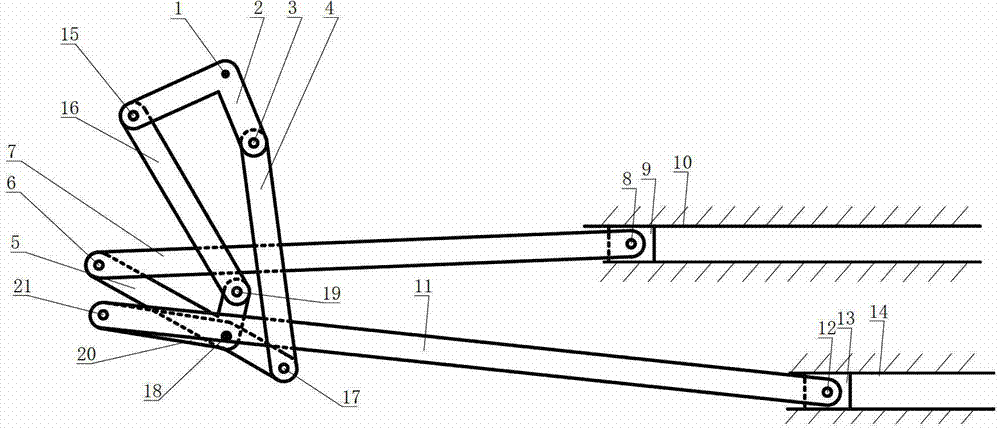

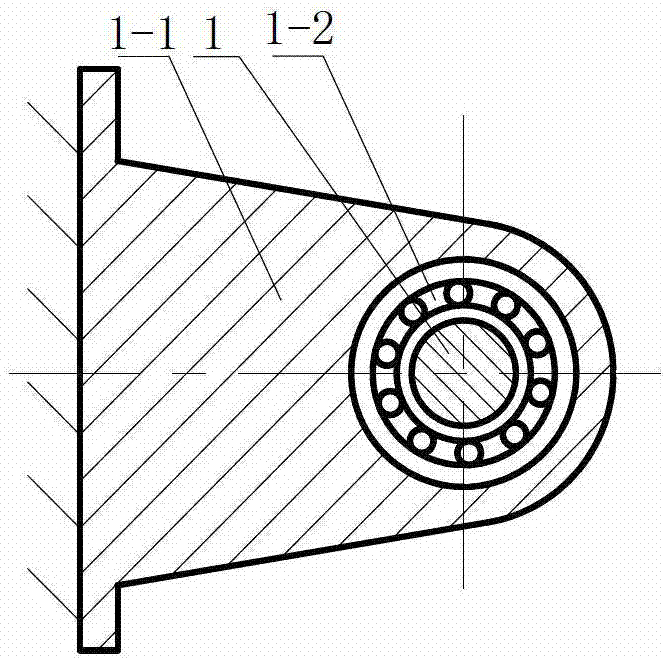

Double glide transmission mechanism

ActiveCN102881477ACompact structureReduce frictionContact driving mechanismsHigh-tension/heavy-dress switchesTime segmentEngineering

The invention provides a double glide transmission mechanism, which comprises a first glide transmission branch mechanism and a second glide transmission branch mechanism, wherein the first glide transmission branch mechanism and the second glide transmission branch mechanism comprise two slideways, two slide blocks, three connecting levers and four connecting rods; a few connecting levers and connecting rods are adopted, so that the double glide transmission mechanism is simple in structure and convenient to manufacture and mount and transmits large kinetic energy, and the double slide of the two slide blocks can be realized through one input; the three connecting levers employ two support shafts, and the structure is compact; small angles are formed between the connecting rods and the slideways, so that the friction between the slide blocks and the slideways is reduced and the slide blocks slide smoothly; and in a time interval in the moving process of the two slide blocks, one slide block decelerates, the other slide blocks accelerates, the decelerating impulse of the decelerating slide block helps accelerate the accelerating slide block, and drive energy is saved.

Owner:CHINA XD ELECTRIC CO LTD +1

Piston assembly, reciprocating compressor and refrigerator

ActiveCN113217343AChange displacementAdapt to the needs of usePositive displacement pump componentsPlungersIceboxEngineering

The invention provides a piston assembly, a reciprocating compressor and a refrigerator. The piston assembly comprises a piston pin assembly used for connecting a piston and a connecting rod. The piston pin assembly comprises a piston pin, the piston pin is arranged in a piston pin hole, and at least two mounting positions are arranged in the piston pin hole so that the piston pin can be located at different positions in the axial direction of the piston. One end of the connecting rod is sleeved on the piston pin. According to the piston assembly, the piston pin is adjusted to be located at different positions in the piston pin hole, the piston assembly can meet the use requirements of pistons of different types and displacements, and therefore the universality is greatly improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com