Use of a motor-driven speed-variable hydraulic pump as a hydrostatic transmission

A technology of hydraulic pumps and motors, which is applied in the field of application of motor-driven, variable-speed hydraulic pumps as hydrostatic transmissions, and can solve the problems of expensive energy consumption of hydraulic machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] A) a transmission with two different shifting stages (minimum and maximum pump displacement);

[0048] B) As a continuously variable automatic transmission with continuous adjustment of the transmission ratio.

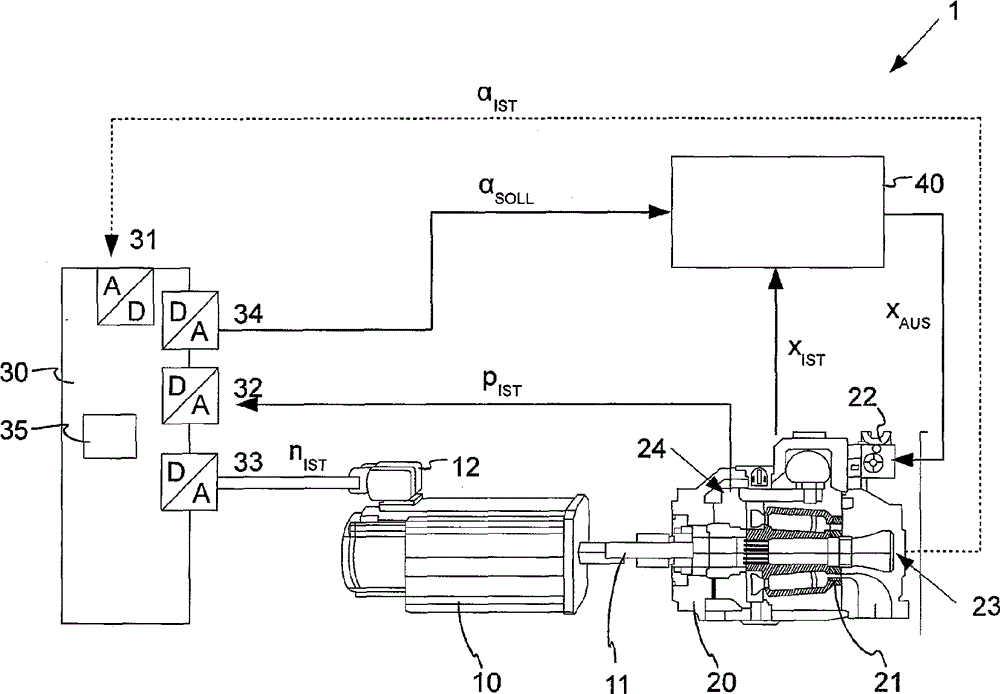

[0049] According to the third embodiment, it can also be arranged like this: if it is not necessary to adjust the actual swing angle α of the swing plate 10 of the hydraulic pump 10 IST Input into the regulating device 30 , the input 34 of the regulating device 30 is then omitted. In this case, the swivel angle sensor 23 can also be omitted. As a result, it is also not necessary to connect the pivot angle sensor 23 to the adjusting device 30 . As a result, adjustment device 30 can also be realized more cost-effectively. In other respects, the second exemplary embodiment is designed identically to the first exemplary embodiment.

[0050] In summary, in the previously described exemplary embodiment, an adjusting device 30 and an adjusting method for adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com