An Unloading Independent Variable Radial Piston Pump

A plunger pump and radial column technology, which is applied in the field of unloading independent variable radial plunger pumps, can solve the problems of increasing the calorific value of the pump body and reducing the energy conversion efficiency of the hydraulic pump, so as to reduce the volume and improve the energy conversion Efficiency and reliability, the effect of manufacturing process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

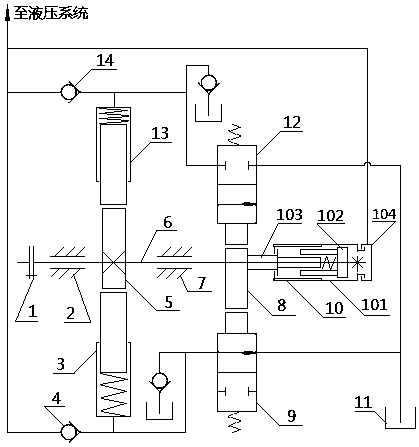

[0018] An unloading independent variable radial plunger pump, comprising a plunger pump, an eccentric wheel 5, a reversing valve cam 8, a reversing valve, a helical swing oil cylinder 10 and an oil storage tank 11, and the plunger pump includes a plunger pump I13 and plunger pump II3, the reversing valve includes reversing valve I12 and reversing valve II9, and the eccentric wheel 5 and the swing cylinder body 101 of the helical swing cylinder 10 are respectively fixed on the same On the pump shaft 6, the reversing valve cam 8 is connected to the swing cylinder shaft 103 of the helical swing cylinder 10, and the eccentric wheel 5 is coaxial with the reversing valve cam 8 and can rotate relatively; the plunger pump I13 and plunger pump II3 Both are driven and connected with the eccentric wheel 5, the reversing valve I12 and the reversing valve II9 are both driven and connected with the reversing valve cam 8, the plunger pump I13 is connected with the oil circuit of the reversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com