Laminated organic thin-film solar cell and preparation method thereof

A technology of solar cells and organic thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as limiting the energy conversion efficiency of tandem cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

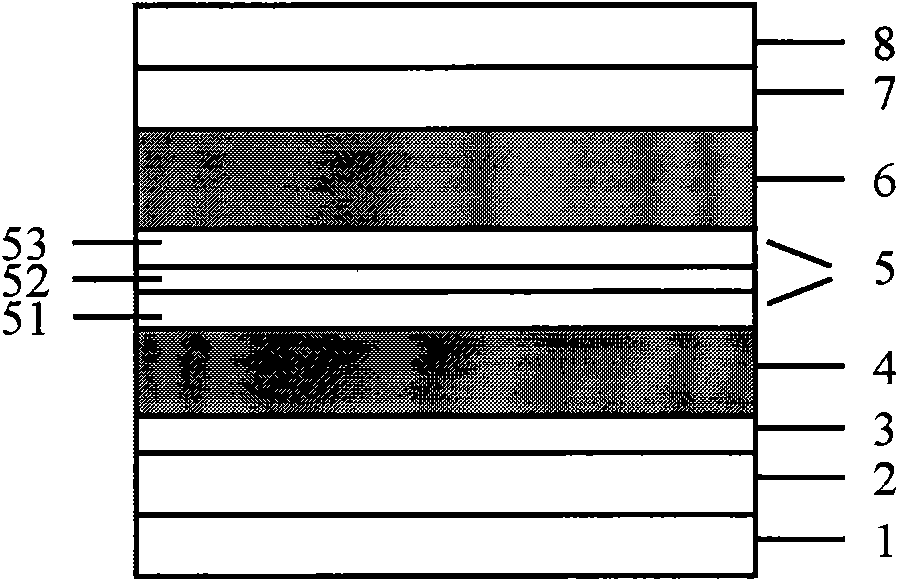

[0052] Such as figure 2 As shown, the connection layer in the device structure includes an anti-reflection film and a hole transport layer, and the material of the anti-reflection film is TiO 2 , the hole transport layer material is MoO 3 , the transparent anode material is ITO, and the anode buffer layer material is MoO 3 , the organic photoelectric conversion layer 1 is SubPc / C 60 Heterojunction, organic photoelectric conversion layer 2 is SubNc / C 60 Heterojunction, the cathode buffer layer material is Bphen.

[0053] Glass substrate / ITO / MoO 3 (5nm) / SubPc(16nm) / C 60 (30nm) / TiO 2 (5nm) / MoO 3 (5nm) / SubNc(10nm) / C60 (30nm) / Bphen(3nm) / Ag(100nm)

[0054] The preparation method is as follows:

[0055] ①Use ethanol solution, acetone solution and deionized water to ultrasonically clean the transparent conductive substrate ITO glass, and dry it with dry nitrogen after cleaning. Wherein the ITO film on the glass substrate is used as the cathode layer of the device, the squar...

Embodiment 2

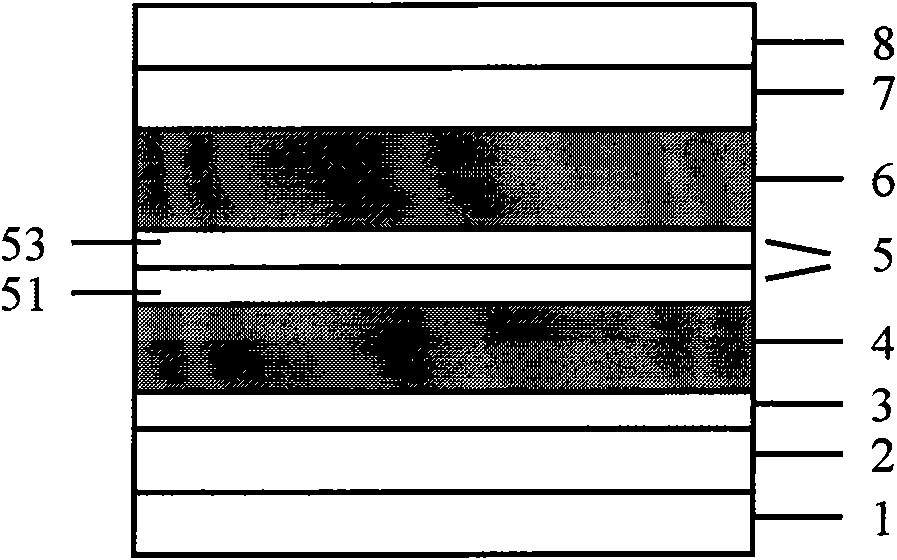

[0070] Such as Image 6 As shown, the connection layer in the device structure includes an anti-reflection film, a thin metal layer and a hole transport layer, and the material of the anti-reflection film is TiO 2 , the thin metal layer is Ag, and the hole transport layer material is MoO 3 , the transparent anode material is ITO, and the anode buffer layer material is MoO 3 , the organic photoelectric conversion layer 1 is SubPc / C 60 Heterojunction, organic photoelectric conversion layer 2 is SubNc / C 60 Heterojunction, cathode buffer layer material is Bphen

[0071] Glass substrate / ITO / MoO 3 (5nm) / SubPc(16nm) / C 60 (30nm) / TiO 2 (5nm) / Ag(0.2nm) / MoO 3 (5nm) / SubNc(10nm) / C 60 (30nm) / Bphen(3nm) / Ag(100nm)

[0072] The preparation method is as follows:

[0073] ①Use ethanol solution, acetone solution and deionized water to ultrasonically clean the transparent conductive substrate ITO glass, and dry it with dry nitrogen after cleaning. Wherein the ITO film on the glass subst...

Embodiment 3

[0079] Such as figure 2 As shown, the connection layer in the device structure includes an anti-reflection film and a hole transport layer, and the material of the anti-reflection film is TiO 2 , the hole transport layer material is MoO 3 , the transparent anode material is ITO, and the anode buffer layer material is MoO 3 , the organic photoelectric conversion layer 1 is a P3HT:PCBM bulk heterojunction, the organic photoelectric conversion layer 2 is a PSBTBT:PCBM bulk heterojunction, and the material of the cathode buffer layer is Bphen

[0080] Glass substrate / ITO / MoO 3 (5nm) / P3HT:PCBM(150nm) / TiO 2 (10nm) / MoO 3 (5nm) / PSBTBT:PCBM(120nm) / Bphen(3nm) / Ag(100nm)

[0081] The preparation method is as follows:

[0082] ①Use ethanol solution, acetone solution and deionized water to ultrasonically clean the transparent conductive substrate ITO glass, and dry it with dry nitrogen after cleaning. Wherein the ITO film on the glass substrate is used as the cathode layer of the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com